#roller press

Explore tagged Tumblr posts

Text

This week, I participated in a printmaking workshop. To my surprise, the studio resembled a factory filled with machines. I even recorded a video of myself using a roller press to print images.

5 notes

·

View notes

Text

Common Roller Press Faults and Their Solutions

In cement production, the roller press is a key piece of equipment, and its operational stability directly affects production efficiency and product quality. Below are specific cases and experience sharing regarding fault handling from T Company, J Company, and S Company. If you encounter similar issues during equipment operation, feel free to contact us at Darko. As a professional manufacturer and supplier of cement equipment, we are dedicated to providing you with high-quality equipment and services.

Cement Plant A Abnormal Situation Description

Fault Phenomenon

Cement Plant A uses a vertical feeding pipe between the roller press and the weighing silo. However, this pipe is too short. As a result, the roller press experiences low working pressure and poor extrusion capability. Consequently, the feed material has high screening residue and low fine powder content. This situation leads to low system yield and high grinding energy consumption.

System Configuration

Roller Press: 120-50 roller press (material throughput 165t/h, main motor power 250kW, current 21A×2)

Dispersing and Classifying Machine: 550/120 (processing capacity 140—175t/h, motor power 45kW+30kW)

Tube Mill: Φ3.2×13m three-chamber open circuit tube mill (main motor power 1600kW, grinding media loading 127t)

Dust Collection Fan: Comprises an open circuit combined grinding system

Results

The system produces P.O42.5 grade cement with a finished specific surface area of at least 380±10m²/kg. It achieves a yield of 65t/h while consuming 35kWh/t of energy. However, the R80μm residue of the feed material reaches 78.7%, resulting in only 21.3% of the material being fine powder. This leads to a high content of coarse particles in the finished cement.

Technical Diagnosis Analysis

The vertical feeding pipe height between the roller press and the weighing silo is less than 1.2m, causing low material pressure in the pipe, requiring frequent adjustment of the rod valve. The weighing silo frequently experiences segregation or material collapse, and there is significant dust in the production area. The working pressure of the roller press is only 6.0—6.5MPa, which directly affects the extrusion effect of the material.

Technical Measures and Effects

During the annual overhaul, the height of the elevator and weighing silo was increased, raising the vertical feeding pipe height to 2.5m. The side plates of the roller press were repaired by overlay welding to reduce leakage. Maintaining the weighing silo's material level at 60%—70% eliminated segregation and material collapse. The working pressure of the roller press was adjusted to 7.2—7.5MPa, and the R80μm residue of the feed material was reduced to 49.8% (with the fine powder content reaching 50.2%). The system yield increased to 79t/h, and grinding energy consumption decreased to 26.4kWh/t. Annually, this modification can save 4.8 million kWh of electricity, resulting in an economic benefit of over 2.8 million RMB.

Cement Plant B Abnormal Situation Description

Fault Phenomenon

At Cement Plant B,operators face unstable feeding control to the roller press. This instability results in poor working capability. Consequently, the main motor produces insufficient output. As a result, the feed material contains low fine powder content. Ultimately, this situation leads to low yield and high grinding energy consumption.

Grinding System Configuration

Roller Press: 170-100 roller press (material throughput 620t/h, main motor power 900kW)

Classifier: Vx8820

Tube Mill: φ4.2×13m double-chamber tube mill (main motor power 3550kW)

Dust Collection Fan: Comprises a double closed-circuit combined grinding system

Results

The system produces P.O42.5 grade cement at a yield of 165t/h (finished fineness R45μm residue 9.0±1.0%), with grinding energy consumption reaching 44kWh/t.

Technical Diagnosis Analysis

The unstable feeding to the roller press results in poor extrusion capability and insufficient motor output, with the operating current only at 42%—45%. The specific surface area of the feed material is around 160m²/kg.

Technical Measures and Effects

A patent technology from a technology company, the "Lever-type Dual Feeding Device for Roller Press," was adopted to stabilize feeding control, increasing the main motor output to 72%—78%. Internal structural improvements ensured a higher content of finished material in the output. Ultimately, the system yield for P.O42.5 grade cement reached 210t/h, and grinding energy consumption decreased to 38.1kWh/t, achieving a 13.41% energy saving. After optimizing system power, production efficiency was significantly improved.

Cement Plant C Abnormal Situation Description

Fault Phenomenon

At Cement Plant C, both fly ash and desulfurized gypsum with small particle sizes enter the weighing silo together. The high moisture content of the desulfurized gypsum causes severe material adhesion on the silo walls, impacting the output of the roller press and the overall system yield.

Grinding System Configuration

Roller Press: 120-50 roller press (material throughput 165t/h, main motor power 250kW)

Dispersing and Classifying Machine: 550/120

Tube Mill: Φ3.2×13m three-chamber tube mill (main motor power 1600kW)

Dust Collection Fan: Comprises an open circuit combined grinding system

Results

The system produces P.O42.5 grade cement at a yield of 65t/h (finished specific surface area ≥ 360±10m²/kg), with grinding energy consumption of 33kWh/t. The R80μm residue of the feed material is more than 65% (with <80μm fine powder content around 35%).

Technical Diagnosis Analysis

The powdery materials affect the extrusion capability of the roller press, leading to low operating current. The weighing silo experiences severe material adhesion due to high moisture content, affecting the flow of material in the feeding pipe.

Technical Measures and Effects

Fly ash and desulfurized gypsum were switched to separate metering before direct feeding into the tube mill, and the adhesion on the walls of the weighing silo was cleaned to create stable material pressure. The roller press achieved over-saturated feeding, improving extrusion performance. The R80μm residue of the feed material was reduced to 55% (with <80μm fine powder content reaching 45%). The P.O42.5 cement yield increased to 75t/h, a rise of 15.38%; grinding energy consumption decreased to 30kWh/t, achieving a 9.1% energy saving.

Conclusion

The stable operation of the roller press is crucial for cement production. We can achieve this by monitoring equipment status and optimizing operational processes. Additionally, conducting regular maintenance helps us reduce faults effectively. This, in turn, improves production efficiency and enhances product quality. If you encounter any issues with cement equipment, please contact us. Darko, as a professional manufacturer and supplier of cement equipment, is committed to providing quality equipment and solutions. Together, we can drive progress in the industry.

0 notes

Note

Have you seen this? I head "Michael got excited about being connected through matching bracelets" and immediately thought that you're going to have some thoughts.

https://vm.tiktok.com/ZGeQE7KSk/

Oh my god. No, I hadn't seen this video until now, but thank you SO much for sending it to me! I'll post a clip of the most pertinent part about what Michael said below, but I urge folks to check out the whole thing on Tiktok, as this is the woman who made the bracelets we saw David wearing at the Proud Nerd Con last weekend:

My first immediate reaction after seeing/hearing this was utter disbelief and delight, coupled with a complete lack of surprise because...Michael. If there is anyone who could channel "15-year-old girl during the last week of summer camp" energy, it is Michael. It's also terribly bittersweet and yet somehow fitting knowing that we're nearing the end of Michael's time in London--which I think we can now refer to as Shennant Summer, at least in Australia, though the last six months were technically the winter here.

(My second thought was that I feel like we're a hell of a lot closer than ever before to my imaginings of Michael and David getting complementing tattoos somehow manifesting into reality...)

But...my god. I don't think any of us could picture Michael and David not being connected in some way, even if/when they're not in the same city, and yet the thought of Michael wanting to have some tangible reminder of David with him always is doing things to my heart that may necessitate the use of defibrillators. I feel like this is some kind of reverse Parent Trap situation where Michael is going to "accidentally" pack one of the Tennant kids in his suitcase, which will mean David will have to go to Wales to collect his wayward offspring, and then the next thing you know they're on a yacht drinking Champagne while "I Love You (For Sentimental Reasons)" plays in the background.

I think what is so incredible to me is that we know how soft (in the best way possible) Michael is, but to know that he's specifically gotten that way over David--that he holds David in that deep heart space--is achingly beautiful. I know a lot of folks will say that this is giving all of the "friendship bracelet" and "besties" vibes, but I really don't think it's much of a stretch to think that it could be something more. Everything about this just feels so romantic at this point that, in my opinion, it would seem almost ludicrous to not consider it a possibility. Because right now, neither Michael nor David appear to be holding back, and I'm so here for it.

Thank you again so much for sending this my way. I'd love to hear what everyone else thinks, so please feel free to add your thoughts in the comments. Thanks for writing in! x

#weirdandtired#reply post#michael sheen#welsh seduction machine#david tennant#soft scottish hipster gigolo#proud nerd con 2024#Michael is about as subtle as a drunken llama on roller skates#at this point the subtext might as well be a billboard#i am hard-pressed to think of any other male 'BFFs' who have matching bracelets#i'm just saying#there is no heterosexual explanation for this#high profile friendship#low profile lovers#they are perfect together your honor#ineffable lovers#discourse

107 notes

·

View notes

Text

🐈⬛: I went in smoothly and take care of him (Bison)

🐈: It made him let his guard down. But P’ Kant is cruel. He tricked him (Bison) into falling in love with him

🐈⬛: I’ll raise my hand now, bow 🙇🏻♂️ and apologise in advanced. Kant and First are different people (😅😅😅)

Source: link

TH Headline x THK interview

15/11/2024

#we are in for a roller coaster of emotion people#khaotung thanawat#first kanaphan#firstkhao#kantbison#the press tour#TH Headline x THK interview

25 notes

·

View notes

Text

what louis did to lestat and what louis did to armand are connected and that's important to the story but also. it is simply not the same. nothing louis did excuses armand's behaviour, that's not how anything works, but he did not "cross a line" or "poke at armand," he weaponized armand's history of abuse to belittle and demean him. nothing armand said to louis came close- the equivalent would have been "oooh, i'm such a stupid bitch that my husband can beat me half to death and i'll keep crawling back for more even when it endangers my daughter!" it's retraumatizing and deeply destabilizing to hear that shit from your partner. and in response armand should have been like "well this man sucks when he's high and he's high all the time, so i'm bouncing" but if he'd done that we wouldn't have a story, would we?

edit: i've come back to give armand credit for "claudia didn't love you like we did/do. ps. u used her to distract from your own hurt feelings" that shit does hit in a similar way. however "the ways someone hurt you have left you contemptible and weak. they scrawled 'dirty and annoying' all over your soul in red ink and it's never coming off" is just outstanding work. timeless

#press says iwtv#interview with the vampire#louis is my special little princess i love him forever and i enjoyed that fight so much#probably my favourite part of the episode#and it had a lot of competition#but tbh the discourse feels almost full circle victim blaming#like yeah what he said was that bad. and he still didn't deserve that#but it was very much that bad#also that was blatantly an addict fight#you do this all the time and then apologize#but it never means anything and you always start up again?#plus louis' little aww i was jus having fun... sorry#they have been on this roller coaster louis has been a tremendously shitty boyfriend armand should leave him!#but there's no amount of bad behaviour where you get to do surgery on your husband's memories torture him for days#and self soothe by tormenting his mistress to death!#if you CAN go you go. and armand can go. that's what he has going for him that claudia for example did not#which is why she does get to murder lestat and his mistress#i mean she could anyway#because i love her#but that's the crucial distinction in their behaviour she's trying to get away armand is trying to make louis stay#they're all monsters. this is not about claudia good armand bad. they are both serial killers. but still. these things are not the same#for the record yes louis was also honestly a pretty shitty boyfriend to lestat but y/k.#was he out there being like oooooohhh i'm lestat i have abandonment issues because my rapist killed himself in front of me#because i'm just that pathetic#he was not.#and if he had it would still have been wrong for lestat to beat him up and drop him from the stratosphere.#tw: sa#tw: abuse

33 notes

·

View notes

Note

Disco frog (with roller skates ofc!)

Amphibious Queen of the Skate Rink!! She's so sparkly you can hardly look at her, but so dazzling you can hardly look away!

I hope you (and Emma!) enjoy! :D

#robot art#digital art#frog furry#sfw furry#furry#anthro frog#disco#roller skating#character design#sorry this is so late! my ipad broke <3#pressed-possum

14 notes

·

View notes

Text

i need to be kissed before i do something outrageous. borderline blasphemous. downright reprehensible.

#jules.intothevoid✨#I need to be put into a panini press and crushed.#and I need to be rolled flat under a steam roller.#I need to be tossed into an incinerator.#I'm gonna go lay on my living room floor and tip my bookshelf over to crush me flat#I'm gonna go shove myself into my mailbox and then shove the mailbox into my trashcan. don't ask how.

37 notes

·

View notes

Photo

chapter 3, hajime makes murder investigation much more difficult by not trying to watch the video call to the end

#my point being if hed kept watching for 2 more seconds he would have been able to see#that the person on the stepladder was never going to hang themselves#did he really think he could run from one building to another quicker than a person on a stepladder could walk up two steps anyway#sdr2#super danganronpa 2#hajime hinata#hanging tw#my art#press night tonight!!! super excited#ive had my hair in rollers all night n most of the day and completely forgot that im supposed to have my hair in a tight bun#for the show itself#hopefully my hair will have retained at least a bit of bounce for after where were all glammed up and drinking bubbly and posing for cameras#wish me luck queens#hehehe

144 notes

·

View notes

Text

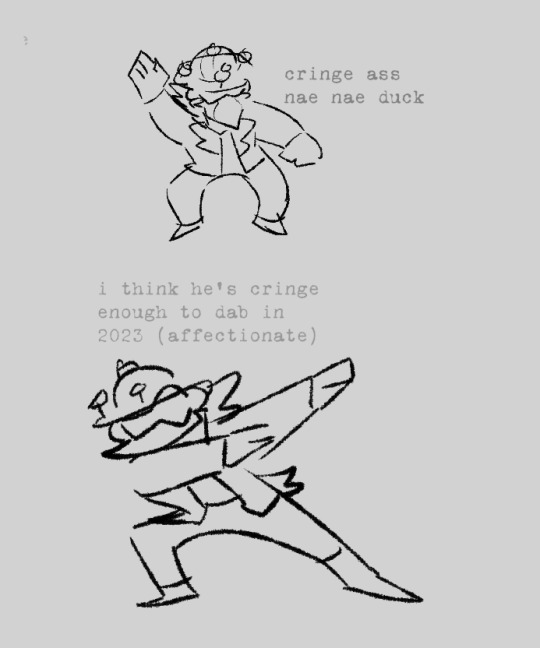

shitpost doodle requests? based on the wonderful thoughts of @weaponsdrawn . robert taken away by a (realistic) bird. i couldnt draw hr hitting the gritty so hes doing that instead. lil oldman exploding

#shitpost#doodle#guz art#lil oldman#high roller#ottoman#chairman#also to quote what i said earlier#i want to fucking pick up robert and soak him in milk and slap him against the wall and put him in the washing machine at full#speed and put him in the mixer and run him over with a steamroller and fire at him with a flamethrower and put him under a hydraulic press#but like affectionately#you get me? catch the drift? ya feel me? yknow?

48 notes

·

View notes

Text

roller coaster fandom is wild. they made the smiler a tumblr sexyman. like. what. that is not your little guy he seriously injured five people In Real Life

#/lh im not too pressed abt it there are worse things online#roller coasters#the smiler#the smiler alton towers#baja’s blasting

7 notes

·

View notes

Photo

Hilton Street, Manchester.

#The number one acid slag#not my words#the words of the rambler#guitarist#bassist#flautist#songwriter#the iris division#doug#bay city roller trousers#withnail#trenchcoat#floral shirt#joker#card#30s press#trilby#eyeliner#guyliner#Manchester#street style#NQ#fashion#etc

88 notes

·

View notes

Text

look @ my pigeons boy!

6 notes

·

View notes

Text

Efficient Roller Press Solutions

What is a roller press used for?

The roller press, also known as a squeeze mill, roller mill, or double roller machine.A roller press is a grinding device used in industrial applications, particularly in cement production. It consists of two counter-rotating rollers that compress and grind the material. This process significantly reduces the particle size of the material, making it an efficient alternative to traditional grinding methods.

The roller press has high grinding efficiency, low energy consumption, and high output, making it widely used in the cement industry. However, during operation, various issues arise due to factors such as design, usage, and external conditions. These problems lead to poor working conditions, inadequate feed control, and hydraulic system failures, all of which negatively affect the performance of the roller press. To address these challenges, we analyze the root causes and implement improvements across multiple aspects, including design and usage. As a result, we optimize the modification process, enhance efficiency, and achieve better operational results.

I.Role of the Roller Press in Cement Plants

In cement plants, operators use the roller press to grind clinker and other raw materials into fine powder. Typically, they employ it alongside other grinding systems, such as ball mills, to enhance overall efficiency and reduce energy consumption. Furthermore, the roller press's capacity to manage high pressure and produce fine products makes it an essential component of modern cement production.

II.Differences Between Roller Press and Ball Mill

The primary difference between a roller press and a ball mill lies in their grinding mechanisms. A roller press compresses the material between two rollers under high pressure, resulting in lower energy consumption and higher efficiency. In contrast, a ball mill relies on the impact and friction of balls to grind the material, which typically consumes more energy. Therefore, roller presses usually perform better in terms of energy efficiency and product fineness.

III.Skew Issues in Roller Presses

Skew refers to the misalignment between the rollers of the roller press and may arise from mechanical wear or improper installation. This misalignment can lead to uneven pressure distribution, which ultimately reduces grinding efficiency. Therefore, regular maintenance and proper alignment are crucial for minimizing skew and ensuring the optimal performance of the roller press.

IV.Analysis of Issues with Roller Presses

1. Fine Powder Content at the Outlet

The fine powder content at the outlet of the roller press, also known as first-pass yield, directly reflects the effectiveness of the pressing process. However, many companies overlook this critical aspect. Testing samples from various enterprises revealed that the German BHS roller press achieved an outlet fineness of 33% on a 0.9mm sieve and 64% on a 0.08mm sieve (with 36% below 0.08mm). In contrast, many of these machines do not reach similar results.

2. Working Pressure

The pressing force is the most fundamental parameter determining the effectiveness of the roller press. To calculate the total force F (in kN) of the roller press, we use the formula:

F=n⋅S⋅Pr

where:

n= number of hydraulic cylinders

S= effective area of the hydraulic cylinder (m²)

Pr = hydraulic system pressure (MPa)

Moreover, the average roller pressure Pcp(in kN/m²) is given by:

Pcp=2F/D⋅B⋅sinα

Here:

D = diameter of the grinding roller (m)

B = effective width of the grinding roller (m)

α = pressure angle, also known as the bite angle (°)

Projected Pressure Calculation

In addition, the projected pressure PT (in kN/m²) is calculated using:

PT=F/B⋅D

Impact of Maximum Roller Pressure on Pressing Efficiency

In practice, the maximum roller pressure significantly affects the pressing effect. Specifically, when the line connecting the centers of the two rollers is set at 0 degrees, the pressure angle starts at 8.3 degrees and ends at -1.6 degrees. Notably, the maximum peak pressure occurs at 1.5 degrees, slightly exceeding twice the average pressure.

Moreover, the hydraulic system of the roller press plays a crucial role, as it provides the dynamic roller pressure necessary to compress the material. This system consists of various components, including the oil station, hydraulic cylinders, nitrogen bags, solenoid valves, overflow valves, pressure gauges, oil lines, and control cabinet. If the configuration lacks damping adjustment valves and stroke adjustment valves, it cannot achieve optimal pressing results. Therefore, in some cases, adding small nitrogen bags may prevent the displayed pressure from accurately reflecting actual pressure changes.

Nitrogen Bag Configuration and Pressure Management

The size of the nitrogen bags and the piping must be calculated based on the size of the hydraulic cylinders. Furthermore, using pipes that are too small will increase resistance. In a parallel setup, when one large and one small nitrogen bag are used, the small bag activates first, followed by the large bag. As a result, this process repeatedly suppresses the opening of the roller gap, which operates in a cycle of retracting, retracting, and advancing, ultimately resulting in low pressing efficiency.

Moreover, the pressures of the nitrogen bags are set at 8, 10, and 12 MPa, meaning that only one nitrogen bag operates within a specific range while the other two become ineffective. Although this theory of differential pressure was initially proposed by German engineers, it failed to achieve the expected results due to significant variations in material properties. Consequently, the Germans did not pursue this approach further.

In general, it is advisable to set the nitrogen bag pressure at 60-80% of the system’s minimum pressure. This approach ensures that when the system operates at its lowest working pressure, a certain level of safety is maintained between the nitrogen bags and the on-off valve. However, the system’s operational state must be monitored on-site to determine its effectiveness. If the oil temperature is too high or too low, it indicates that the system is not in good working condition, which severely impacts pressing efficiency.

3. Roller Speed

The roller speed of the roller press can be expressed in two ways: one is the circumferential linear speed V of the rollers, and the other is the rotational speed of the rollers. The circumferential linear speed is related to output, power consumption, and operational stability. Generally, higher roller speeds lead to increased output; however, excessively high speeds can cause greater relative sliding between the rollers and the material, resulting in poor engagement and increased wear on the roller surfaces, which negatively impacts the output of the roller press.

Currently, the typical roller speed ranges from 1.0 to 1.75 m/s, with some experts suggesting that it should not exceed 1.5 m/s. The linear speed of the rollers usually falls between 1.0 and 1.7 m/s, with most operating around 1.5 to 1.7 m/s, and some even reaching 2.0 to 2.2 m/s. It is crucial to prioritize the squeezing effect when selecting the speed; this effect should be based on actual sampling. If the speed is too high, the pressing time shortens, leading to increased vibrations in the equipment. The significant variations in force become difficult to control, resulting in excessive power consumption without achieving the desired pressing effect.

4. Operating Gap and Material Properties

The operation of the roller gap is influenced by various factors, including the properties of the material (such as hardness, particle size, and moisture content), the form of the roller surface, the speed, the pressure, and the pressure control method. There are two ways to control the hydraulic cylinder pressure: constant pressure control and constant gap control. However, regardless of the method used, both are fundamentally flawed from a hydraulic perspective because pressure and gap continuously fluctuate.

The pressure gauge has a response time of 200 milliseconds, which complicates the control of the oil pump's pressure adjustments. This, in turn, affects the hydraulic cylinder pressure and subsequently the roller gap. As a result, there are two main issues: first, there is a lag in response; second, excessive pressure differentials occur. These factors hinder the stable operation of the roller press and negatively impact pressing efficiency.

5. Feeding Device

Currently, most roller presses use a feeding device that directs material straight from the hopper into the roller gap, pulling the material between the two rollers. This process is commonly referred to as the "pull-in angle" of the roller press. However, controlling the flow from two directions is not feasible, as the adjustment range is limited, making it difficult to achieve precise and stable control. Additionally, the other two directions cannot be adjusted at all. As a result, issues such as material segregation and roller misalignment frequently occur, leading to unmanageable conditions.

V.Roller Press System Modification Plan

1. Replacement of Feeding Device

Replace the roller press feeding device with a new type of four-direction feeding system (patented technology) to control the material feed. This system allows for adjustment and control from two directions, enabling reasonable control of material flow. The other two directions can be adjusted to correct the lateral gap deviation between the rollers, reducing the impact of the material on the roller press and facilitating the formation of a stable material bed. This approach eliminates issues such as material segregation and roller misalignment, and it operates at a low hopper position, making it easier to adjust and control.

2. Upgrading the Hydraulic System

We replaced the hydraulic system of the roller press, including components such as the oil station, overflow valve, pressure gauge, accumulator (nitrogen bag), and valve assembly. Additionally, we incorporated damping adjustment valves and stroke adjustment valves (patented technology) to make the hydraulic system flexible, rigid, and controllable.

During the research and development process, we conducted extensive field tests using a specialized high-precision pressure measurement device (1000 Hz) to collect and analyze data. We employed dedicated simulation software and complex mathematical models to successfully develop a dual-channel adjustable damping anti-vibration regulation mechanism, achieving a reasonable balance of rigidity and flexibility in the hydraulic system.

3. Implementing PLC Control

We replaced the roller press hydraulic PLC and implemented four-directional control of the feeding device, utilizing a constant power control method for easier centralized operation. We configured the system with Siemens SIMATIC S7-1200, integrating Siemens SINAMICS drive products and SIMATIC human-machine interface products. The CPU comes standard with an Ethernet interface that supports various industrial Ethernet communication protocols, including PROFINET, TCP, UDP, and Modbus TCP.

Our company developed this technology through mathematical modeling, gathering extensive field data during the research and development process. We employed specialized simulation software and complex mathematical models, which have been validated through practical application.

VI.Case Studies

1. Chao Lake Hengxin Cement Co., Ltd.

Since the modification in August 2020, production efficiency has increased from 200 tons/hour to 290 tons/hour, with energy consumption controlled at 22 kWh/ton of cement.

2. Hainan Huaren Cement

In June 2022, the roller press was upgraded, increasing hourly output from 150-160 tons to 180-200 tons, with energy consumption reduced to about 23 kWh/ton.

3. Guizhou Southwest

Through the upgrade, output has risen to 180-190 tons/hour, and energy consumption decreased from 32 kWh/ton to 25 kWh/ton.

4. Jiangxi Sanqing Cement Co., Ltd.

After the modification, the output increased to 270-280 tons/hour, with stable operation and nitrogen bag temperatures maintained at 40-60°C.

VII.Benefits of Roller Press Technology Upgrade and Modification

The stability of the roller press has improved, with virtually no side leakage. There are three methods for adjusting roller skew: first, four-directional feed adjustment; second, hydraulic system adjustments; and third, separate pressure adjustments for left and right. Control is stable, with minimal occurrences of material collapse and roller skew.

The hydraulic system of the roller press is flexibly adjustable and controllable. The fluctuation of the roller gap has changed from slow retraction and fast advance to fast retraction and slow advance, increasing pressing efficiency. The fine powder content at the roller press outlet has increased by 3-7%, the specific surface area of the input material has improved, and hourly output has increased by 10-20%.

A constant power control method is used, with operational power maintained at 85±5% of the rated power. The efficiency of the roller press has two requirements: first, high operational power; second, high first-pass yield. By improving the efficiency of the roller press and reducing mill power consumption, the overall energy consumption has been lowered by 2-5 kWh/ton.

If you have needs regarding the modification and upgrading of roller press systems, please feel free to contact us at Darko. We will provide you with professional solutions and support.

0 notes

Note

HAPPY BAPPY MASON!!!!!!! i hope your day is full of treats :D

THANK U !! today me and my partners are going to the theme park i worked at last summer!! i have free entry passes because i worked over a hundred hours last year :o3 im very excited to get to ride the rollercoasters i spent the whole summer operating hehe

#please imagine a dog in the roller coaster control booth pressing a big red button with a skull on it#sending the coaster cars careening off into the distance#that was me last summer#(hyperbole ofc i was very good at my button pushing job no one died lol)

4 notes

·

View notes

Text

youtube

Extrusion Granulator: Efficient and Eco-Friendly Solution for Fertilizer and Feed Production

#rotary drum granulator#disc granulator#organic fertilizer granulator#double roller press granulator#fertilizer granulator price#Youtube

2 notes

·

View notes

Text

anyone ever feel like you need a hug but that’s so tight it feels like being through one of those pasta things? No? Yeahhhh me neather that would be weird right

9 notes

·

View notes