#renewable energy engineering

Explore tagged Tumblr posts

Text

Detailed Engineering in Utility-Scale Solar for Long-Term Reliability

Australia’s expansion of renewable energy continues to accelerate, with large-scale solar installations playing a leading role. However, the long-term success of these projects depends on more than location and funding. It requires precision renewable energy engineering to ensure safe, efficient, and compliant performance throughout the system’s lifespan.

Detailed engineering transforms early-stage concepts into buildable, grid-ready solar infrastructure. This article outlines how detailed design supports each stage of a utility-scale project, from pre-construction planning to solar to long-term operation.

Why Detailed Engineering Matters in Utility-Scale Solar

Detailed engineering serves as the blueprint that bridges concept and construction. It translates design intent into actionable plans, technical specifications, and performance studies that guide solar farm site coordination and ensure reliable long-term operation.

Without this foundation, even the best ideas can result in costly redesigns, inefficient layouts, and non-compliant systems. With it, developers gain clarity, control, and confidence from early design to commissioning.

Site Planning and General Arrangement of the Project

Effective pre-construction planning for solar begins with precise site layout design. Engineers develop general arrangement (GA) plans that detail the positioning of major components, including:

Access roads

Drainage systems

Inverter and transformer stations

Substations

Equipment maintenance zones

These layouts influence everything from construction management for solar farms to long-term access and maintenance efficiency. By analysing terrain, flood zones, soil characteristics, and clearance requirements, engineers help avoid spatial conflicts, construction delays, and rework.

Electrical Design Supports End-to-End Energy Flow

A well-executed electrical design is central to renewable energy engineering. It ensures consistent power flow across the project’s voltage levels and helps demonstrate compliance with Australian standards and utility requirements. Key areas include:

DC (Direct Current) Design – PV string sizing, conductor selection, and voltage drop analysis

LV (Low Voltage) Design – Auxiliary systems including lighting, control circuits, and internal power distribution

HV (High Voltage) Design – Transformer connections, switchgear layouts, and grid export systems

Engineers also conduct power system studies such as load flow analysis, fault level calculations, and thermal performance evaluations. These are critical to grid compliance and system optimisation.

Structural and Civil Engineering Improve Stability and Durability

Structural and civil engineering designs are tailored to site-specific conditions such as wind loads, rainfall patterns, and soil bearing capacity. This includes:

Mounting structure specifications

Foundation design using geotechnical data

Stormwater drainage and erosion control

Access road engineering for heavy equipment

Civil and electrical engineers collaborate closely to coordinate cable trenches, foundation zones, and structure placements, reducing design conflicts and keeping the build on track.

Substation and Building Layouts Align Infrastructure

Substations, control rooms, and inverter stations are central to a solar power plant’s functionality. Their layout affects everything from electrical performance to O&M access.

Electrical consultants assess:

Arc flash boundaries

Equipment spacing and door clearances

Cable trench routing

Earthing integration and conduit runs

Designs should align with grid codes and site constraints to ensure safety and efficiency throughout the asset’s lifecycle.

Earthing Design Increases Safety and Equipment Protection

A properly designed earthing system is an essential component of renewable energy engineering, protecting personnel and equipment by mitigating voltage rise during electrical faults or lightning strikes. Key engineering tasks include:

Step and touch voltage assessments

Soil resistivity testing

Earth grid layout and impedance modelling

Bonding of metal structures and conductive components

All designs are aligned with AS 3000 and AS 1768. In addition to improving safety, earthing helps protection devices operate reliably, contributing to overall system stability.

Protection Coordination for Fault Isolation

In utility-scale solar projects, protection systems should quickly detect and isolate faults while maintaining uptime across the unaffected portions of the plant. An experienced electrical engineering consultant conducts detailed protection coordination studies, which typically include:

Time-current curve analysis

Arc flash assessments

Fault level and relay setting calculations

Protection schemes follow AS/NZS 7000 and IEC 61850 standards to ensure compliance and support reliable grid integration.

Comprehensive Design Packages for Seamless Construction

A full design package streamlines construction management for solar farms by providing all the technical documentation needed for procurement and construction. Typical inclusions are:

Civil, electrical, and structural drawings

Site layout plans and trench details

Equipment schedules and specification sheets

Issued for Construction (IFC) documentation

These packages reduce site queries, limit change orders, and help all stakeholders work from a coordinated plan, resulting in faster, smoother execution.

Build Solar Farms That Last with ElectraGlobe

Utility-scale solar farms should operate safely, deliver consistent performance, and meet grid connection standards for decades. Achieving this depends on detailed engineering that considers every system interaction, layout constraint, and compliance obligation from the outset.

At ElectraGlobe, we deliver complete engineering services tailored to large-scale solar and battery energy storage system (BESS) projects. Our team specialises in technically sound, grid-compliant designs that support your project from concept through construction and commissioning. For expert support in renewable energy engineering, get in touch with us today!

#electraglobe#detailedengineering#electrical engineers#electricalprojects#renewable energy engineering

0 notes

Text

#Engineering Graduate Training#Bachelor of Engineering#Engineering College#Emerging Technologies#AI in Engineering#IoT for Engineers#Renewable Energy Engineering#Robotics and Automation#Blockchain in Engineering#5G Technology#Engineering Career#Engineering Training Programs#TVS Training & Services#Future of Engineering#Industry 4.0

0 notes

Text

🌞 Empowering the Future with Renewable Energy Discover how innovations in renewable energy engineering are shaping a sustainable tomorrow. From harnessing solar power to overcoming challenges, we’re committed to creating a brighter, eco-friendly future. 🌍💡

#Renewable energy engineering#Solar photovoltaic technology#Wind energy advancements#Bioenergy innovations#Energy storage solutions#Renewable energy challenges#Algae-based biofuels

0 notes

Text

wind farm design | solar engineering companies

The Symphony of Sustainability: Harmonizing Renewable Energy Engineering and Wind Farm Design with a Consultant's Touch

Renewable energy engineering is the new vital player in the quest for clean and sustainable energy sources. Wind power is a towering presence among the diverse renewable energy options, with wind farms as the key infrastructure. This article delves into the fascinating intersection of renewable energy engineering and other related items, shedding light on the crucial role of renewable energy consultants in orchestrating sustainable energy solutions.

The Essence of Renewable Energy Engineering

Renewable energy engineering is the bedrock of our transition to clean energy sources. It encapsulates the science and art of harnessing renewable resources, such as wind, solar, and hydroelectric power, and converting them into electricity. Renewable energy engineers are tasked with developing cutting-edge technologies and systems that maximize energy generation while ensuring reliability and sustainability.

The Renaissance of Wind Farms

With their iconic turbines dotting the landscape, wind farms have become emblematic of the renewable energy revolution. However, designing a wind farm goes beyond placing turbines in open spaces. It involves meticulous planning, environmental considerations, and strategic placement of turbines to maximize energy output.

The Role of Renewable Energy Consultant

Renewable energy consultant are the unsung heroes in the realm of sustainable energy solutions. They bridge engineering and design, bringing a unique blend of technical prowess and environmental consciousness to the forefront. The responsibilities of renewable energy consultants are multifaceted:

1. Site Assessment

Renewable energy consultants conduct comprehensive site assessments to ascertain the viability of wind farm projects. This involves an in-depth analysis of wind patterns, environmental impacts, and compliance with local regulations.

2. Optimizing Turbine Placement

Leveraging advanced simulations and modeling, consultants identify optimal locations for wind turbines within a wind farm. This ensures maximum energy output while minimizing interference with local ecosystems.

3. Environmental Impact Mitigation

It is essential to minimize the ecological footprint of wind farm projects. Renewable energy consultants work tirelessly to mitigate the impact on wildlife, habitats, and local communities.

4. Grid Integration

For the energy generated by wind farms to be truly effective, it must seamlessly integrate with existing power grids. Consultants are crucial in ensuring this clean energy's efficient distribution and utilization.

The Art of Wind Farm Design

Wind farm design extends beyond functionality; it embodies a harmonious blend of function and aesthetics. A well-designed wind farm can serve as a captivating testament to the beauty of sustainability.

Innovations in Turbine Technology

In recent years, remarkable innovations in wind turbine technology have revolutionized wind farm design. Taller towers, larger blades, and advanced materials have significantly enhanced efficiency and power generation capacity.

Balancing Energy Production and Environmental Conservation

A critical challenge in wind farm design is striking the right balance between energy production and environmental conservation. Here, renewable energy consultants work hand in hand with engineers to ensure that the chosen design mitigates environmental impacts and preserves local ecosystems.

Community Engagement and Acceptance

Gaining community acceptance is another hurdle in wind farm design. Renewable energy consultants actively engage with local communities, address concerns, and foster support for wind farm projects, emphasizing the broader environmental benefits and economic advantages.

Case Studies in Sustainable Wind Farm Design

The article showcases real-world case studies of wind farms designed with a strong emphasis on sustainability. These success stories underscore the synergy between renewable energy engineering and the consultant's expertise in creating projects that benefit the environment and local communities.

Conclusion: Orchestrating a Sustainable Future

The role of renewable energy consultant in orchestrating this synergy cannot be overstated. With their expertise in site assessment, environmental impact mitigation, and community engagement, renewable energy consultants are conductors in the grand symphony of sustainability. They ensure that every note is perfectly played, creating a harmonious blend of renewable energy, engineering, and design—a clean and sustainable wind energy-powered future.

KW Renewable Engineering (KWRE) is a leading provider of renewable energy solutions. With expertise in land development and strategic project execution, its cross-disciplinary team offers comprehensive services from planning to construction management. They specialize in various renewable energy projects, including solar and wind fields, battery storage, and fuel cells. KWRE's services cover development planning, electrical engineering, civil engineering, land surveying, hydrological engineering, project management, and construction management. They handle critical aspects such as site assessments and navigating interconnection and permitting challenges.

#wind farm design#substation engineering#solar engineering companies#solar engineering#solar energy engineering#renewable energy engineering#renewable energy consultant#electrical engineering renewable energy

1 note

·

View note

Text

447 notes

·

View notes

Text

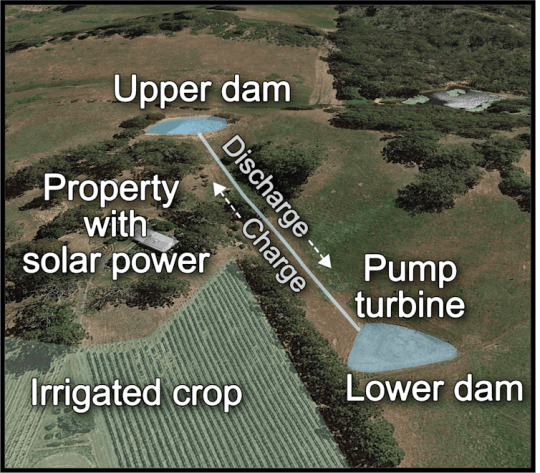

For farmers, there’s now another option: connect one of your dams to a river – or link two dams together – to create a small pumped hydro plant to store electricity from solar to use at night. The water in your dams could offer yet another form of self-reliance.

Our new research has identified over 30,000 rural sites where micro pumped hydro could work. A typical site could produce two kilowatts of power and store 30 kilowatt hours of energy – enough to run a typical home in South Australia for 40 hours.

#solarpunk#solar punk#solarpower#hydropower#renewable energy#self reliant farms#australia#engineering

22 notes

·

View notes

Text

Understanding Zero Energy Buildings: A Sustainable Solution

Key Points Zero energy buildings produce as much energy as they consume using renewables. They use efficient designs and technologies like solar panels and heat pumps. They’re becoming more common to fight climate change and save energy costs. What Are Zero Energy Buildings? Zero energy buildings are structures designed to have no net energy consumption over a year. This means they generate…

#Building Performance#Clean Energy Solutions#climate-change#Eco-Friendly Buildings#energy#Energy Efficiency#Environment#Environmental Engineering#Green Building Design#Renewable Energy#sustainability#Sustainable Architecture#Sustainable Construction#Zero Energy Buildings

2 notes

·

View notes

Text

Aughhh I have work experience on Tuesday and Wednesday

#i think it's gonna be interesting#it's for a renewable energy company#apparently they're interested in how to get more girls and women into the industry#I'm gonna get a tour of the place and stuff apparently#I'll have to prepare some stuff to talk about#how to get women into engineering? uh#advertisements? social media? movies? talking about it in schools?

4 notes

·

View notes

Text

Electricity Grievance: UP Residents Demand Accountability

Grievance Status for registration number : GOVUP/E/2024/0080640Grievance Concerns ToName Of ComplainantYogi M. P. SinghDate of Receipt09/11/2024Received By Ministry/DepartmentUttar PradeshGrievance DescriptionMost respected sir there is a breakdown in the supply of electricity for 5 hours since the morning. Concerned accountable staff are not picking up their close unit group mobile numbers…

#24 hours supply of electricity#Disruption in supply#energy#Executive engineer electricity distribution divisions again#news#renewable-energy#solar-power#Supply of electricity#sustainability

3 notes

·

View notes

Text

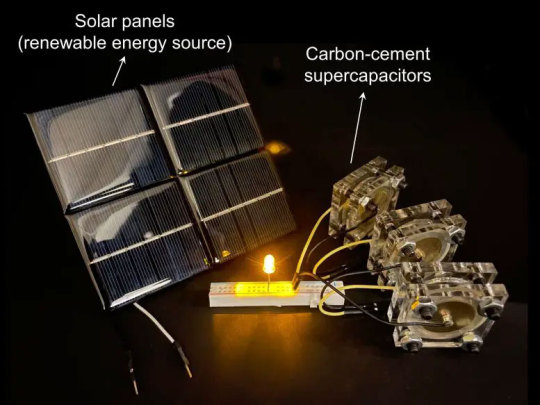

New Breakthrough in Energy Storage – MIT Engineers Create Supercapacitor out of Ancient Materials

MIT engineers have created a “supercapacitor” made of ancient, abundant materials, that can store large amounts of energy. Made of just cement, water, and carbon black (which resembles powdered charcoal), the device could form the basis for inexpensive systems that store intermittently renewable energy, such as solar or wind energy. Credit: Image courtesy of Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

Constructed from cement, carbon black, and water, the device holds the potential to offer affordable and scalable energy storage for renewable energy sources.

Two of humanity’s most ubiquitous historical materials, cement and carbon black (which resembles very fine charcoal), may form the basis for a novel, low-cost energy storage system, according to a new study. The technology could facilitate the use of renewable energy sources such as solar, wind, and tidal power by allowing energy networks to remain stable despite fluctuations in renewable energy supply.

The two materials, the researchers found, can be combined with water to make a supercapacitor — an alternative to batteries — that could provide storage of electrical energy. As an example, the MIT researchers who developed the system say that their supercapacitor could eventually be incorporated into the concrete foundation of a house, where it could store a full day’s worth of energy while adding little (or no) to the cost of the foundation and still providing the needed structural strength. The researchers also envision a concrete roadway that could provide contactless recharging for electric cars as they travel over that road.

The simple but innovative technology is described in a recent paper published in the journal PNAS, in a paper by MIT professors Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn, and four others at MIT and at the Wyss Institute.

Capacitors are in principle very simple devices, consisting of two electrically conductive plates immersed in an electrolyte and separated by a membrane. When a voltage is applied across the capacitor, positively charged ions from the electrolyte accumulate on the negatively charged plate, while the positively charged plate accumulates negatively charged ions. Since the membrane in between the plates blocks charged ions from migrating across, this separation of charges creates an electric field between the plates, and the capacitor becomes charged. The two plates can maintain this pair of charges for a long time and then deliver them very quickly when needed. Supercapacitors are simply capacitors that can store exceptionally large charges.

The amount of power a capacitor can store depends on the total surface area of its conductive plates. The key to the new supercapacitors developed by this team comes from a method of producing a cement-based material with an extremely high internal surface area due to a dense, interconnected network of conductive material within its bulk volume. The researchers achieved this by introducing carbon black — which is highly conductive — into a concrete mixture along with cement powder and water, and letting it cure. The water naturally forms a branching network of openings within the structure as it reacts with cement, and the carbon migrates into these spaces to make wire-like structures within the hardened cement.

These structures have a fractal-like structure, with larger branches sprouting smaller branches, and those sprouting even smaller branchlets, and so on, ending up with an extremely large surface area within the confines of a relatively small volume. The material is then soaked in a standard electrolyte material, such as potassium chloride, a kind of salt, which provides the charged particles that accumulate on the carbon structures. Two electrodes made of this material, separated by a thin space or an insulating layer, form a very powerful supercapacitor, the researchers found.

Since the new “supercapacitor” concrete would retain its strength, a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills, and allow it to be used whenever it’s needed. Credit: Image courtesy of Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

The two plates of the capacitor function just like the two poles of a rechargeable battery of equivalent voltage: When connected to a source of electricity, as with a battery, energy gets stored in the plates, and then when connected to a load, the electrical current flows back out to provide power.

“The material is fascinating,” Masic says, “because you have the most-used manmade material in the world, cement, that is combined with carbon black, that is a well-known historical material — the Dead Sea Scrolls were written with it. You have these at least two-millennia-old materials that when you combine them in a specific manner you come up with a conductive nanocomposite, and that’s when things get really interesting.”

As the mixture sets and cures, he says, “The water is systematically consumed through cement hydration reactions, and this hydration fundamentally affects nanoparticles of carbon because they are hydrophobic (water repelling).” As the mixture evolves, “the carbon black is self-assembling into a connected conductive wire,” he says. The process is easily reproducible, with materials that are inexpensive and readily available anywhere in the world. And the amount of carbon needed is very small — as little as 3 percent by volume of the mix — to achieve a percolated carbon network, Masic says.

Supercapacitors made of this material have great potential to aid in the world’s transition to renewable energy, Ulm says. The principal sources of emissions-free energy, wind, solar, and tidal power, all produce their output at variable times that often do not correspond to the peaks in electricity usage, so ways of storing that power are essential. “There is a huge need for big energy storage,” he says, and existing batteries are too expensive and mostly rely on materials such as lithium, whose supply is limited, so cheaper alternatives are badly needed. “That’s where our technology is extremely promising, because cement is ubiquitous,” Ulm says.

The team calculated that a block of nanocarbon-black-doped concrete that is 45 cubic meters (or yards) in size — equivalent to a cube about 3.5 meters across — would have enough capacity to store about 10 kilowatt-hours of energy, which is considered the average daily electricity usage for a household. Since the concrete would retain its strength, a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills and allow it to be used whenever it’s needed. And, supercapacitors can be charged and discharged much more rapidly than batteries.

After a series of tests used to determine the most effective ratios of cement, carbon black, and water, the team demonstrated the process by making small supercapacitors, about the size of some button-cell batteries, about 1 centimeter across and 1 millimeter thick, that could each be charged to 1 volt, comparable to a 1-volt battery. They then connected three of these to demonstrate their ability to light up a 3-volt light-emitting diode (LED). Having proved the principle, they now plan to build a series of larger versions, starting with ones about the size of a typical 12-volt car battery, then working up to a 45-cubic-meter version to demonstrate its ability to store a house-worth of power.

There is a tradeoff between the storage capacity of the material and its structural strength, they found. By adding more carbon black, the resulting supercapacitor can store more energy, but the concrete is slightly weaker, and this could be useful for applications where the concrete is not playing a structural role or where the full strength-potential of concrete is not required. For applications such as a foundation, or structural elements of the base of a wind turbine, the “sweet spot” is around 10 percent carbon black in the mix, they found.

Another potential application for carbon-cement supercapacitors is for building concrete roadways that could store energy produced by solar panels alongside the road and then deliver that energy to electric vehicles traveling along the road using the same kind of technology used for wirelessly rechargeable phones. A related type of car-recharging system is already being developed by companies in Germany and the Netherlands, but using standard batteries for storage.

Initial uses of the technology might be for isolated homes or buildings or shelters far from grid power, which could be powered by solar panels attached to the cement supercapacitors, the researchers say.

Ulm says that the system is very scalable, as the energy-storage capacity is a direct function of the volume of the electrodes. “You can go from 1-millimeter-thick electrodes to 1-meter-thick electrodes, and by doing so basically you can scale the energy storage capacity from lighting an LED for a few seconds, to powering a whole house,” he says.

Depending on the properties desired for a given application, the system could be tuned by adjusting the mixture. For a vehicle-charging road, very fast charging and discharging rates would be needed, while for powering a home “you have the whole day to charge it up,” so slower-charging material could be used, Ulm says.

“So, it’s really a multifunctional material,” he adds. Besides its ability to store energy in the form of supercapacitors, the same kind of concrete mixture can be used as a heating system, by simply applying electricity to the carbon-laced concrete.

Ulm sees this as “a new way of looking toward the future of concrete as part of the energy transition.”

Reference: “Carbon–cement supercapacitors as a scalable bulk energy storage solution” by Nicolas Chanut, Damian Stefaniuk, James C. Weaver, Yunguang Zhu, Yang Shao-Horn, Admir Masic and Franz-Josef Ulm, 31 July 2023, Proceedings of the National Academy of Sciences. DOI: 10.1073/pnas.2304318120

The research team also included postdocs Nicolas Chanut and Damian Stefaniuk at MIT’s Department of Civil and Environmental Engineering, James Weaver at the Wyss Institute for Biologically Inspired Engineering, and Yunguang Zhu in MIT’s Department of Mechanical Engineering. The work was supported by the MIT Concrete Sustainability Hub, with sponsorship by the Concrete Advancement Foundation.

Source: scitechdaily.com

#Carbon Emissions#Civil Engineering#Engineering#MIT#Renewable Energy#Energy Storage#Ancient Materials#Tech News#good news

12 notes

·

View notes

Text

MIT design would harness 40 percent of the sun’s heat to produce clean hydrogen fuel

Conventional systems for producing hydrogen depend on fossil fuels, but the new system uses only solar energy.

Jennifer Chu | MIT News

MIT engineers aim to produce totally green, carbon-free hydrogen fuel with a new, train-like system of reactors that is driven solely by the sun.

In a study appearing today in Solar Energy Journal, the engineers lay out the conceptual design for a system that can efficiently produce “solar thermochemical hydrogen.” The system harnesses the sun’s heat to directly split water and generate hydrogen — a clean fuel that can power long-distance trucks, ships, and planes, while in the process emitting no greenhouse gas emissions.

Today, hydrogen is largely produced through processes that involve natural gas and other fossil fuels, making the otherwise green fuel more of a “grey” energy source when considered from the start of its production to its end use. In contrast, solar thermochemical hydrogen, or STCH, offers a totally emissions-free alternative, as it relies entirely on renewable solar energy to drive hydrogen production. But so far, existing STCH designs have limited efficiency: Only about 7 percent of incoming sunlight is used to make hydrogen. The results so far have been low-yield and high-cost.

In a big step toward realizing solar-made fuels, the MIT team estimates its new design could harness up to 40 percent of the sun’s heat to generate that much more hydrogen. The increase in efficiency could drive down the system’s overall cost, making STCH a potentially scalable, affordable option to help decarbonize the transportation industry.

“We’re thinking of hydrogen as the fuel of the future, and there’s a need to generate it cheaply and at scale,” says the study’s lead author, Ahmed Ghoniem, the Ronald C. Crane Professor of Mechanical Engineering at MIT. “We’re trying to achieve the Department of Energy’s goal, which is to make green hydrogen by 2030, at $1 per kilogram. To improve the economics, we have to improve the efficiency and make sure most of the solar energy we collect is used in the production of hydrogen.”

Keep reading.

Make sure to follow us on Tumblr!

#renewableenergy#solar#renewable power#climate change#sustainability#energy#carbon emissions#environment#mechanical engineering

5 notes

·

View notes

Text

A significant amount of solar energy that reaches Earth remains unutilized owing to the scarcity of photosensitive materials capable of responding to light in the near infrared (NIR) region. However, this challenge has been addressed by a recent breakthrough from researchers at Tokyo Institute of Technology and National Yang Ming Chiao Tung University. They have developed an innovative Au@Cu7S4 yolk@shell photocatalyst, which is responsive to both visible and NIR wavelengths. This photocatalyst has demonstrated remarkable efficiency in solar hydrogen production, achieving an excellent quantum yield under illumination by both visible and NIR light.

1 note

·

View note

Text

what if 🤔 i told you 🫵🏻 your girl is thinking abt changing her major again 🫣

#NOT smth as drastic as english to biomedical engineering. but still. ruminations are happening#personal#the engineering chronicles#im thinking i might want to go for a renewable energy track instead. from what i can tell it’s not too late for that bc the foundation#courses seem to be the same w one exception which is v inconvenient (since i’d have to squeeze it in either next semester alongside my#already plotted 15 credits or take it alongside my internship over the summer when i don’t know yet what city my internship will be in) but#it should be doable#idk if i will though. but i have to decide soon bc the internship i choose this semester and it’s supposed to mesh well w my major#renewable energy feels much more in my lane and i did in fact deeply consider majoring in environmental studies freshman year. and i think#it’s smth i could genuinely grow to love and be excited abt. but im not sure processing electrical signals from the brain still sounds so#cool 😭 in theory at least. idkidk

3 notes

·

View notes

Text

Corporate Visa Strategies for Renewable Energy Professionals – 2025 Guide

As the world accelerates toward a carbon-neutral future, renewable energy is no longer a niche, it's a global priority. Projects in wind, solar, hydropower, and green hydrogen are breaking ground everywhere from Texas to Tamil Nadu. But building the infrastructure for tomorrow's energy demands more than panels and turbines. It needs people and the freedom for those people to move across borders legally and efficiently.

In 2025, securing the right corporate visas is a make-or-break factor for renewable energy companies looking to deploy engineers, project managers, technicians, and sustainability experts across international projects.

This guide outlines how energy companies and mobility teams can navigate visa systems strategically to build and move a borderless green workforce.

Why Visas Matter in Renewable Energy

Unlike traditional industries, renewable energy projects are:

Location-dependent (e.g., solar farms in deserts, wind farms offshore)

Time-sensitive, driven by government deadlines and incentives

Heavily collaborative, involving engineers from multiple countries

That means:

Experts need to be deployed quickly across jurisdictions

Delays in visa processing = project delays = lost investment or penalties

Non-compliance with immigration laws can risk licenses and contracts

A sound visa mobility strategy ensures talent flows as seamlessly as electricity through a smart grid.

Common Visa Types for Renewable Energy Professionals

1. Intra-Company Transfer (ICT) Visas

Best for:

Moving employees from HQ to foreign branch

Project engineers, technical directors, energy consultants

Deployment on mid- to long-term construction and commissioning phases

Examples:

L-1 (USA)

UK Global Business Mobility – Senior or Specialist Worker

EU ICT Permit

Canada Global Talent Stream (employer-sponsored)

Why it works:

Fast-track routes for skilled staff

Supports renewable energy MNCs with global offices

Spouse/dependent inclusion possible

Limitations:

Usually requires 12+ months of prior employment

Position must match specific seniority or salary bands

2. Work Permits for Project-Based Hiring

Best for:

Hiring local or foreign talent directly for a country-specific renewable project

EPC contractors, turbine installers, solar PV experts, HSE officers

Examples:

Germany Blue Card (for engineers and IT professionals)

Australia Subclass 482 Temporary Skill Shortage Visa

South Africa Critical Skills Visa (includes green energy jobs)

UAE Work Permit under Free Zone or Ministry of Energy

Why it works:

Allows new hires on a contract or permanent basis

Often aligned with national green energy targets

Certain countries offer expedited routes for strategic sectors

Limitations:

Requires local entity or sponsor

Some require labor market testing or job advertisement

3. Short-Term Business or Technical Visas

Best for:

Site visits, feasibility assessments, maintenance

Cross-border training and consultations

Renewable energy sales and vendor onboarding

Examples:

USA B-1 Visa

UK Standard Visitor (Business Route)

Schengen Business Visa

Japan Business Manager Visa (for startup setups)

Why it works:

Quick approval for short missions (7–90 days)

Low documentation burden

Great for feasibility and strategy teams

Limitations:

Strict “no hands-on work” policy in most countries

No salary payments from host country permitted

Key Visa Challenges in the Energy Sector

1. Multinational Collaboration

Projects often involve multiple subcontractors and partners. Misalignment in visa responsibilities can cause confusion or non-compliance.

➡ Solution: Have a central mobility team or visa agency coordinate all project-based movements.

2. Remote or Offshore Locations

Wind farms or solar arrays are often built in remote zones with special visa or security rules.

➡ Solution: Apply for area-specific permits early—especially in regions with restricted access (e.g., Arctic zones, coastal waters).

3. Permit Timelines vs. Project Deadlines

Construction timelines are often tight, while visa approvals may take 4–8 weeks.

➡ Solution: Pre-identify visa categories per country, and pre-clear roles via blanket agreements where possible.

What Documentation Is Usually Required

Regardless of country, most renewable energy visa applications require:

Valid passport (6–12 months validity)

Employment contract or intra-company transfer letter

Qualifications (engineering degrees, certifications)

Experience letters or CV

Medical/health clearance

Police/background checks

Proof of project or worksite (especially for technical visas)

Pro tip: Bundle documentation for project teams to process as a unit—faster and more consistent.

Case Study: Solar Deployment in the Middle East

A European solar EPC firm is awarded a 120 MW project in Saudi Arabia. The team includes:

Project managers from Spain

PV engineers from India

Environmental officers from Jordan

Visa Strategy:

Use Saudi business visas for initial site survey teams

Apply for Iqama Work Permits via the local branch for long-term technical staff

Contract a third-party visa agency to manage regulatory submissions and worker medical checks

Result: ✔ All staff deployed on schedule ✔ Zero immigration issues ✔ Project commissioned 3 weeks early

Final Tips for Renewable Energy Mobility Teams

Map visa requirements per project site in advance

Centralize documentation with a shared mobility platform

Use visa categories aligned with energy, engineering, or critical skills

Track expiry dates and renewal cycles especially on long-term builds

Partner with immigration experts familiar with energy regulations

Final Thoughts: Visas That Power the Green Transition

The renewable energy transition depends not just on turbines and technology but on people who can be where the power is needed. Visas aren’t just paperwork, they're the infrastructure behind the workforce powering wind, solar, and hydrogen projects around the world.

To stay competitive, clean energy companies need to be just as agile in their talent deployment as they are in their energy innovation.

#renewable energy visa#corporate visa for engineers#green workforce mobility#solar project visa#wind energy global work permit#energy sector visa strategy#clean energy talent relocation#global energy projects visa

0 notes

Text

Why 24-Hour Electricity in Mirzapur Remains Unfulfilled

Modi Sir, currently there is eight hours supply of electricity in the rural area and in urban area 12 hours supply of electricity and it is mockery of promise made by you to supply 24 hour supply of electricity. Grievance Status for registration number : GOVUP/E/2025/0079337 Grievance Concerns To Name Of Complainant Yogi M. P. Singh Date of Receipt 14/07/2025 Received By…

#24 hours supply of electricity#energy#Executive Engineer#Executive engineer EDD II#narendra modi#renewable-energy#sustainability#yogi adityanath

0 notes

Text

Using a lake as a battery

Energy storage is a major factor in making renewable energy viable. Without storage, power output is only available when the wind is going, it's sunny, or there's enough water in the lake (Sorry Lake Mead). Luckily, there are a ton of really cool and innovative methods for storing energy, from the absurdly primitive to something you'd see in science fiction.

Let's start from the bottom: Pumped water storage! It's like a dam, but in reverse. You build a huge reservoir for water high up, and when you have excess energy output, pump water up there. When you need energy, release it through turbines. It loses a lot of energy through efficiency losses, but it's dead simple. Unless the levy breaks. That happened like once.

Heat is another way to store energy. There are a lot of energy plants that create ice when there's excess power. This ice is stored and then used to cool buildings instead of running air conditioning. It's kind of single-purpose, but great when you expect to need AC most of the time. You can go the opposite direction like a plant in Alberta which pumps heat into the soil under the plant and uses it to warm nearby houses too!

As a side note, this lead me to reading about "virtual batteries" which sound really cool and I have to read more about later.

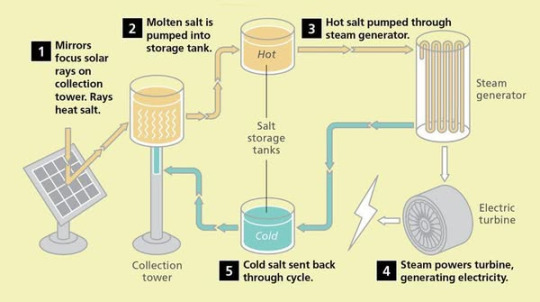

Now we're getting into sci-fi. Molten salt. How cool is molten salt? There's already molten salt energy generation by directing sunlight (and a nuclear explosion that one time), but you can also channel electricity to heat it and extract the energy later.

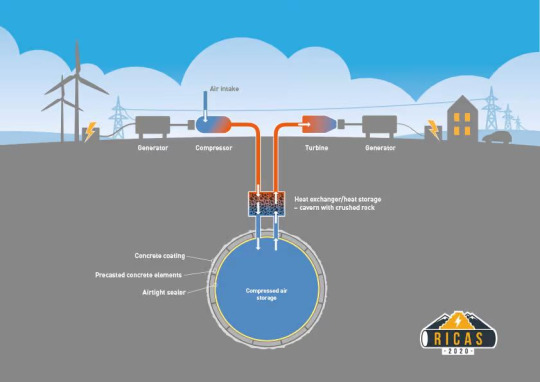

After that is compressed air storage. No, not the little air compressor in your garage (though those can be used as starter motors on a small scale). You can dig out a new cavern or use an abandoned mine, seal off all of the entrances, and build up pressure inside to extract later. One catch: Remember PV = NRT? As you increase pressure, you increase heat, and that heat has to be dealt with. But it lasts a very long time, when kept sealed, unlike salt, which stays hot less than a day.

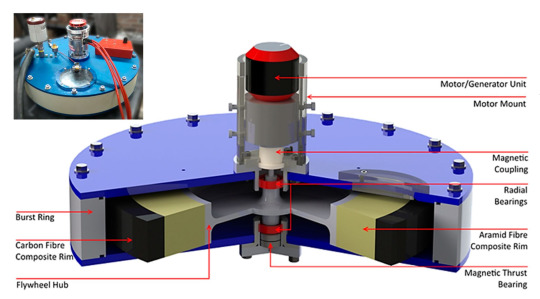

Last one because it sounds the coolest: Flywheel energy storage. A massive metal wheel with magnetic bearings is spun up with excess energy. Reduce the rotational energy to extract power with a generator. They're highly efficient, especially in a vacuum! And then can be spun up and down very quickly compared to all of the other methods here. I don't really understand high temperature superconductors yet, but apparently they'll be critical to making these viable on a wide scale.

One more fun note that I've bookmarked for later is that there are small-scale applications for all of these, especially for transportation. Compressed air cars are being researched. In the 1950s Switzerland had the "Gyrobus", a bus powered by flywheel energy storage. No news on someone powering a car with molten salt. Yet.

0 notes