#refrigerated air dryer Manufacturers

Explore tagged Tumblr posts

Text

Understanding the Different Types of Refrigeration Air Dryers: A Manufacturer's Guide

As industries evolve and technological advancements reshape manufacturing landscapes, the demand for efficient, reliable, and cost-effective air drying solutions has never been higher. Air dryers are critical in ensuring the smooth operation of pneumatic systems, preventing moisture-related issues that can cause equipment failures and production downtimes. Among the various types of air dryers available, refrigeration air dryers stand out for their effectiveness and energy efficiency.

In this comprehensive guide, we'll explore the different types of refrigeration air dryers, their working principles, and the benefits they offer. We'll also introduce you to Trident Pneumatics, one of the leading refrigeration air dryer manufacturers, and explain why our products are considered the best in the industry.

What Are Refrigeration Air Dryers?

Refrigeration air dryers remove moisture from compressed air by cooling it to a temperature where the water vapour condenses into liquid droplets. These droplets are then separated and removed from the system, leaving behind dry air suitable for various industrial applications. The process involves two main stages: cooling the air and separating the condensed moisture.

Types of Refrigeration Air Dryers

Several refrigeration air dryers are designed to meet specific needs and operational requirements. Here, we categorize them based on their design and cooling methods:

Cycling Refrigeration Air Dryers

Cycling refrigeration air dryers are energy-efficient systems that adjust their cooling capacity based on the demand for compressed air. They use thermal mass or digital scroll compressors to regulate the refrigeration cycle, ensuring optimal performance while minimizing energy consumption. These dryers are ideal for applications with varying air flow demands.

Advantages:

Energy savings due to demand-based operation

Consistent dew point performance

Reduced operational costs

Applications:

Maufacturing facilities with fluctuating air demand

Plants seeking energy-efficient solutions

Non-Cycling Refrigeration Air Dryers

Non-cycling refrigeration air dryers operate continuously, maintaining a steady cooling capacity regardless of the airflow demand. They use hot gas bypass valves to control the refrigerant flow and maintain a consistent dew point. These dryers are known for their reliability and simplicity, making them suitable for applications where constant airflow is required.

Advantages:

Simple design with fewer components

Reliable and consistent dew point control

Lower initial cost compared to cycling dryers

Applications:

Facilities with constant air flow requirements

Industries need a reliable and straightforward drying solution

Modular Refrigeration Air Dryers

Modular refrigeration air dryers are designed for scalability and ease of maintenance. Multiple independent modules can be added or removed based on the required air drying capacity. This modularity allows for flexibility in installation and maintenance, as individual modules can be serviced without shutting down the entire system.

Advantages:

Scalable to meet changing air drying needs

Easy maintenance with minimal downtime

High reliability and redundancy

Applications:

Large industrial plants with varying production demands

Facilities requiring high reliability and easy maintenance

Compact Refrigeration Air Dryers

Compact refrigeration air dryers are designed for installations where space is limited. These dryers offer the same performance as their larger counterparts but with a smaller footprint. They are perfect for small workshops, laboratories, and other settings where space constraints are a primary concern.

Conclusion

Refrigeration air dryers are essential for maintaining the efficiency and reliability of pneumatic systems across various industries. Understanding the different types of refrigeration air dryers and their applications can help you choose the right solution for your specific needs.

Trident Pneumatics is committed to providing the best refrigeration air dryers in the market. Our focus on quality, innovation, energy efficiency, and customer support sets us apart from other manufacturers. Whether you need a compact dryer for a small workspace or a modular system for a large industrial facility, we have the expertise and experience to deliver the perfect solution.

0 notes

Text

refrigerated air dryer Manufacturers

A refrigerated air dryer manufacturer is a type of compressed air dryer that uses a refrigeration cycle to remove moisture from compressed air. Compressed air often contains water vapor, which can condense and cause damage to pneumatic tools, machinery, and instruments. Refrigerated air dryers work by cooling the compressed air, causing the moisture to condense and then collecting and removing it from the system.

0 notes

Text

youtube

Established in the year 2016, Airomach Engineers is one of the leading Manufacturer and Wholesaler of Air Dryer, Air Heater, Water Chiller and much more. In their development process, we assure that only top notch basic material is used by our professionals along with modern tools. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Working under the mentorship of Mr. Sanehit Bhardwaj (Proprietor), we have acquired a reputed stature in the industry.

#heat exchanger manufacturer in delhi#Air Compressor Tank Price in India#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Refrigerated Air Dryer Supplier in Delhi#Water Chiller Supplier in Delhi#Air Dryer System in Delhi#Air Compressor Tank Price in delhi#Water Cooled condenser manufacturers in delhi#water chiller manufacturers in delhi#Youtube

1 note

·

View note

Text

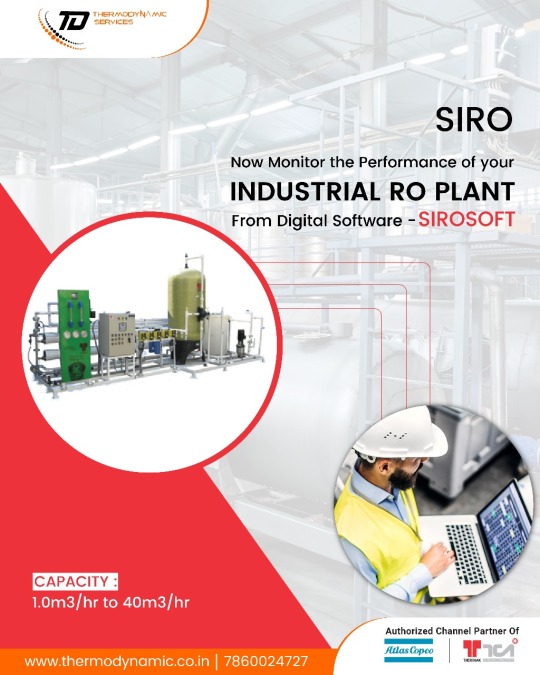

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

The Importance of Air Dryer Compressors: A Comprehensive Guide

Air dryer compressors are vital in a wide range of industrial and commercial applications, delivering dry, clean, and efficient compressed air for optimal performance. By removing moisture and subtle impurities from the air, they help create a healthier and safer work environment. In humid conditions, compressed air dryers play an essential role in maintaining uninterrupted operations and preventing costly downtime. In this article, we will explore the importance of air dryer compressors, and their various types, highlight their applications, and offer practical tips for selecting the ideal system to meet specific needs.

What is an air dryer compressor?

An air dryer supplier is a specialised device or system designed to remove moisture from the air, ensuring the efficient process of compressed air systems. These systems are essential for facilities utilising compressed air, as compression significantly increases the relative humidity in a given space, potentially leading to operational challenges. Air dryer compressors serve using various methods, depending on the type of system in place. Regardless of the mechanism, their primary goal is to extract moisture from the air to prevent vapor condensation, allowing the system to work at peak efficiency. Common techniques employed by compressed air dryer manufacturers include adsorption, filtration, absorption, refrigeration, and diffusion, all of which work to eliminate excess moisture and maintain optimal performance.

Why is an air dryer supplier important?

Air dryer supplier is essential for well-functioning air compressor systems. Moisture is unavoidable with air compression — it’s a natural byproduct of the system, and without removal, your facility will soon have a moisture problem. Here are some of the advantages you can expect when you add air dryer compressors to the compression system:

Prevents freezing: If vapor condenses into water, the water can freeze in the face of low temperatures. Freezing can lead to jams in moving parts. It can also stash on process lines and interfere with process or product fluid movement.

Removes contamination: Contamination is a danger for industries using high-purity compressed air. Places like plasma generation, food and pharmaceutical products manufacturing, laser cutting and welding, painting, coating, and shot blasting all require pure compressed air to work. If water builds up, efficiency decreases, productivity slows or products get damaged.

Halts water buildup: Water will build up in small pockets within downstream equipment without moisture removal. Too much buildup can cause sensitive equipment to perform inaccurately, harming production quality and output.

Reduces microbial growth: The pharmaceutical and food and beverage industries use compressed air to mix and convey products. Water is prone to bacteria growth, and any water in the condensed air system can quickly lead to food and beverage spoilage or contamination. Additionally, small amounts of microbes in pharmaceutical plant products can result in entire batches being thrown out to avoid health risks.

Improves efficiency: If your facility uses air-powered equipment and tools powered by energy from compressed air systems, water will reduce its efficiency. It can damage internal parts and reduce the power delivered, impacting production.

Inhibits corrosion: Water is excellent at corroding steel. Components like pipes, drums, vessels, and tanks are commonly made from steel and will begin to break down when moisture buildup turns to water and corrosion. When corrosion conditions, process, and product streams can quickly become contaminated.

How does the air dryer supplier work?

At the most basic level, air dryer compressors separate moisture from industrial process air. Moisture is inherent to compressed air, so the air dryer must take that air and remove the excess moisture from it. This is done through diffusion, absorption, filtration, or refrigeration. Each method sends compressed air through the system, drawing out the water so that the system can work efficiently and without damage.

The action of an air dryer supplier and the way it protects compressed air from excess moisture will vary depending on the type of air dryer supplier used. The standard types of air dryer compressors include:

Refrigerated dryers: The most common type of air dryer compressors will see in an industrial compressed air system is the refrigerated dryers. These work by a simple mechanism of using one or more heat exchangers to cool down the hot compressed air, condense out the bulk of the water, and remove the water through a separator equipped with an automatic drain. If you are looking for a reasonably-priced dryer and do not need unusually high drying capabilities, these are often the best and most economical choices.

Desiccant dryers: If you are in a harsh situation where air is subject to very low temperatures or your products or environment cannot handle any moisture at all, a desiccant dryer may better serve you. These dryers use a material such as activated alumina to absorb water from the compressed air.

Specialty gas and liquid dryers: Water is not the only moisture-related contaminant that could impact on a facility. Many industries work with gases or liquids that might interfere with production. If your company works with exotic or dangerous gases or liquids that need drying, such as benzene, butane, hydrogen, or landfill gas, there are specialty dryers designed to safely remove moisture from these products. They work similarly to air dryers but focus on their specific gas or liquid removal instead of just water.

Membrane dryers: Membrane dryers are very efficient dryers that dehumidify and depress the dew point as the air comes into the system. These dryers have an absorbent membrane that allows water vapor to pass through. The membrane catches the water vapor, lowering the dew point temperature so condensation cannot occur. They are becoming increasingly popular as they require no electricity, have a low installation cost, are easy to maintain, and perform quietly.

Deliquescent dryers: Deliquescent dryers are another brand of electricity-free, economical air dryer compressors. They work using a pressure vessel containing dissolving salt tablets that absorb water vapor. Compressed air runs through the dryer, and the salt pulls all the water out. The salt dissolves with the water, turning into a brine that collects in a special tank. Meanwhile, the air passes out through the system moisture-free.

How to choose the right air dryer compressor

Understand your requirements

Evaluate the desired dew point for your application.

Identify the airflow rate (CFM) needed for your operations.

Consider the environment

Evaluate the ambient temperature and humidity levels of your workspace.

Choose an air dryer supplier that can handle these conditions effectively.

Energy efficiency

Opt for energy-efficient models to save operational costs.

Look for features like automatic drain valves to reduce wastage.

Space constraints

Consider the size of the equipment, especially for smaller facilities.

Compact options like membrane air dryers may be ideal.

Budget and maintenance

Balance initial costs with long-term savings from reduced maintenance and energy consumption.

Check for easy access to replacement parts and reliable service support.

Maintenance tips for air dryers recommended by compressed air dryer manufacturers

Regular filter replacement: Prevent clogging by replacing air filters frequently.

Monitor dew point: Ensure the system is delivering the required air quality.

Inspect drains: Keep drain valves clean and operational to avoid water build-up.

Scheduled servicing: Conduct routine maintenance checks to identify and address potential issues.

Wrapping up:

Air dryer compressors are vital in ensuring the efficiency, reliability, and longevity of industrial processes. Investing in the right type and maintaining it properly, can protect the equipment, improve product quality, and achieve cost savings. Whether you’re in manufacturing, healthcare, or construction, choosing the right air dryer supplier tailored to your needs is key to optimizing your operations. By partnering with reliable compressed air dryer manufacturers, can ensure that your systems remain efficient and the operations run smoothly.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer Kuber Industries Present You Appliance covers in Different type of color and design that looks very attractive and elegant plus made of washable fabric which help you maintain cleanliness and hygiene in your home. We Present you Appliance covers for Maintaining the Tools, you use Daily at home, especially in the kitchen area, These Covers protect your tool from Grease, dust, and other external sources which tend to spoil the look of the toasters, Cylinder, Ac, microwaves, washing machines, refrigerators, etc. VIBRANT COLOR & DESIGN Covering your appliances does not have to be unappealing, as there are plenty of slipcovers available that are printed with aesthetic designs in vibrant & solid colors. Dressing up your appliances and tools can make your home feel more organized and intentional. Our list of products offers slipcovers that toe the line between and style and are also affordable. UNIVERSAL SIZE Our Covers comes in all size fit option, which is suitable for any kind of brand’s and fits every type of fridge, ac, washing machine, oven and etc. It is regarded as a practical and household daily necessity. QUALITY MATERIAL Home appliances, from refrigerators to microwaves need routine upkeep and protection. Since all these appliances are used several times during the day and by multiple members, it is essential that they are covered with strong quality covers. Our covers is made out of high quality material. It Comes with waterproofing quality which keeps liquids and stains stay out and ensures the product lasts longer and offers maximum protection. EASY TO CARE Wash your appliance covers by hand to avoid damage and prevent your covers from losing their shape. Simply use water and a mild dishwashing soap to wash and dry with a towel. Do not use bleach or other harsh chemicals. You can also put it in the dishwasher on a gentle cycle. However, do not put it in the dryer, let it air dry instead. Kuber Industries Founded in the year 1995 in Jaipur (Rajasthan, India), We "Kuber Industries” are engaged in manufacturing of a highly-quality range of Home & Storage Organizer Like Saree Covers, Laundry Organizer, Jewellery Kits, Table Covers, Make Up Kit, Bangle Boxes, Baby Bags, Blouse Covers, etc. Due to our client-centric approach and ethical business policies, we have established an affluent position for ourselves in this domain.

Ensuring a positive customer experience, making available goods and services that are of top-notch quality is given prime importance. We cater to the diverse requirements of the customers by offering a premium grade and excellent product range.The extensive product range we offer is highly appreciated among the customers, owing to the excellent quality, durable products. So, whether it’s antique or stylish, it is your choice. Color: Maroon, Size Name: Standard Package Contents: Polyester 1 Pieces Fridge Top Cover (Maroon) Size: 94x54x1 CM Package Content: 1 Piece Fridge Top Cover.Dimension: 55x98x1 CM, Material: Polyster, Color: Maroon. Design- Floral The Product Dimension in LxW: Inches(37x21) :: in cms(93.98x53.34). It Comes with 6 utility pockets. on each side to increase its worthiness The color combination & design of the cover is praiseworthy and looks very attractive & elegant and will enhance the beauty of your kitchen/room It is resistant to rough handling and is easy to wipe and clean, and will protect your precious kitchen companion surface from everyday scratches, wear and tear, stain, dust and other particles [ad_2]

0 notes

Video

youtube

R5 High Speed Hair Dryer Factory Wholesale High Quality LCD High Speed H...

R5 High Speed Hair Dryer: The Ultimate Hair Styling Revolution

Introducing the R5 High Speed Hair Dryer, meticulously crafted to give you salon-quality results at home. Designed for those who demand excellence, the R5 combines power, efficiency, and intelligent technology for all your hair drying and styling needs.

Powerful Specifications

Rated Power: 1600W Wind Speed: 25m/s Motor Speed: 110,000 RPM Effortlessly dry your hair quickly and efficiently without sacrificing hair health! Quiet Yet Powerful

Noise Level: Just 60dB Enjoy a serene drying experience while still achieving high performance—perfect for any time of day. Advanced Hair Care Features

Negative Ions: Generates 200 million negative ions, reducing frizz and enhancing shine for a sleek finish. Constant Temperature: Maintains a safe and effective drying temperature of 100°C to prevent heat damage, ensuring your hair remains healthy. User-Centric Design

LED Display: The full-color digital screen features an inner ring with a three-color light indicator, making it easy to monitor settings at a glance. Dual Magnetic Suction: Comes with a magnetic suction nozzle and magnetic air intake net, providing versatility and ease of use. Specifications

Cable Length: 1.8 meters with a single air nozzle Color Options: Available in White and Silver Grey, with customized colors upon request. Smart Functions for Perfect Styling

9 Speed Wind Temperature Adjustments: Tailor your drying experience with precise temperature control. One-Key Refrigeration: Instantly cool your hair after drying for a sleek finish. Large Air Volume, Low Noise: Experience powerful drying action without the disturbance. Perfect for both professional salons and home use, the R5 features a stable quality and comes equipped with three air nozzles to cater to all your styling preferences.

Elevate your hair care routine with the R5 High Speed Hair Dryer! Ready to transform your styling game? Click the link to purchase R5 High Speed Hair Dryer : https://www.teejoiniot.com/product/hair-dryer-with-led-screen-and-magnetic-nozzle

Unleash the beauty of your hair with the R5 Hair Dryer today!

#hairdryer #hairstyler #hairstylingtools #highspeedhairdryer #factory #hairtools #hairdrying #haircareproducts #hairdryerandstyler #ahairdryer #ahairdryerwillwork #hairdryerbrush #hairdryerbraun #Newhairdryer #r5 #hairdryercurles #hairdryercurles #hairdryereffect #hairdryerengine #hairdryergmax #lhairdryer #HairDryerOem #HairDryerODM #hairstyle #hairbeauty #hairdryers #S5HairDryer #HairDryerS5 #hairdryerfactory #manufacturer #manufacturerprice #chinafactory #futuretech #highSpeedHairDryerwithLCD

0 notes

Text

Contact and Convective Dryers Market 2024 Size, Share, Growth Report 2032

Contact and Convective Dryers Market Size & Growth 2024

Latest Updated Report 2024, The Global Contact and Convective Dryers Market to Growing A CAGR of % during forecast period of 2024-2031. The Market is segmented by Global Contact and Convective Dryers Market Breakdown by Application (Pharmaceuticals, Metallurgy, Food & Beverages, Chemicals, Other) by Type (Horizontal, Vertical) and by Geography (North America, South America, Europe, Asia Pacific, MEA).

The Contact and Convective Dryers Market 2024 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the global Contact and Convective Dryers market. This report explores all the key factors affecting the growth of the global Contact and Convective Dryers market, including demand-supply scenario, pricing structure, profit margins, production, and value chain analysis.

Discover Who You Really Compete Against In The Marketplace, Get PDF Sample Report Now! @ https://www.prudentmarkets.com/sample-request/153769/

The report concludes with the profiles of major players in the Contact and Convective Dryers market are:

Kilburn Engineering, Andritz Gouda, GEA Group, FLSmidth, ThyssenKrupp AG, HEINKEL, Uzelac Industries, Orion Air Conditioning & Refrigeration, AVA GmbH

Contact and Convective Dryers Market 2024 Overview:

The dryer can effectively and timely eliminate moisture content, improve the treatment characteristics and stability of moisture sensitive materials, reduce the adverse impact of moisture on the quality of products, and improve industrial processing efficiency.Intermittent drying equipment, with high energy efficiency, can save energy and avoid cross contamination during an energy-consuming and time-consuming drying process.

Prudent Markets latest report provides a deep insight into the global Contact and Convective Dryers market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, Porters five forces analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Contact and Convective Dryers Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Contact and Convective Dryers market in any manner.

Global Contact and Convective Dryers Market: Market Segmentation Analysis

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Market Segmentation Are:

Type Segmentation:

Horizontal, Vertical

Industry Segmentation:

Pharmaceuticals, Metallurgy, Food & Beverages, Chemicals, Other

Speak To Our Analyst For A Discussion On The Above Findings, And Ask For A Discount On The Report @ https://www.prudentmarkets.com/discount-request/153769/

Prudent Markets provides attractive discounts that fit your needs. Customization of the reports as per your requirement is also offered. Get in touch with our sales team, who will guarantee you a report that suits your needs.

The report covers the competitive analysis of the market. As the demand is driven by a buyer’s paying capacity and the rate of item development, the report shows the important regions that will direct growth. This section exclusively shares insight into the budget reports of big-league members of the market helping key players and new entrants understand the potential of investments in the Global Contact and Convective Dryers Market. It can be better employed by both traditional and new players in the industry for complete know-how of the market.

Strategic Points Covered in Table of Content of Global Contact and Convective Dryers Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Contact and Convective Dryers market

Chapter 2: Exclusive Summary – the basic information of the Contact and Convective Dryers Market.

Chapter 3: Displaying the Market Dynamics- Drivers, Trends and Challenges & Opportunities of the Contact and Convective Dryers

Chapter 4: Presenting the Contact and Convective Dryers Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country

Chapter 6: Evaluating the leading manufacturers of the Contact and Convective Dryers market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Any Questions? Feel Free To Enquire Here. We Will put you on the Right Path @ https://www.prudentmarkets.com/enquiry-request/153769/

Free Customization on the basis of client requirements on Immediate purchase:

Free country-level breakdown of any 5 countries of your interest.

Competitive breakdown of segment revenue by market players.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +91 83560 50278 || USA/Canada(Toll Free): 1800-601-6071 to share your research requirements.

Get ready to Recognize the pros and cons of the regulatory framework, local reforms, and its effect on the Industry. Understand how the Leaders in Intelligent Network are keeping themselves one stage forward with our most up-to-date survey analysis.

For In-Depth Competitive Analysis – Purchase this Report now at a Complete Table of Contents (Single User License) @ https://www.prudentmarkets.com/checkout/?id=153769&license_type=su

In conclusion, the Contact and Convective Dryers Market report is a genuine source for accessing the research data which is projected to exponentially grow your business. The report provides information such as economic scenarios, benefits, limits, trends, market growth rates, and figures. SWOT analysis and PESTLE analysis is also incorporated in the report.

About Us:

We are leaders in market analytics, business research, and consulting services for Fortune 500 companies, start-ups, financial & government institutions. Since we understand the criticality of data and insights, we have associated with the top publishers and research firms all specialized in specific domains, ensuring you will receive the most reliable and up to date research data available. To be at our client’s disposal whenever they need help on market research and consulting services. We also aim to be their business partners when it comes to making critical business decisions around new market entry, M&A, competitive Intelligence and strategy.

0 notes

Text

Choosing the Right Air Dryer for Your Industry: Key Considerations

In many industries, compressed air plays a crucial role in powering equipment, tools, and processes. However, one aspect that often gets overlooked is the moisture content in compressed air, which can cause significant issues if not managed correctly. This is where air dryers come into play. Choosing the right air dryer for your industry is essential for ensuring the longevity of equipment, maintaining product quality, and minimizing maintenance costs. In this blog, we'll explore key considerations to help you select the best air dryer for your specific industrial needs.

1. Understand the Different Types of Air Dryers

Before you can choose the right air dryer, it’s important to understand the various types available. Each has its advantages and is suited to different applications.

a. Refrigerated Air Dryers

Refrigerated air dryers are the most common and economical type of air dryer. They cool the compressed air, condensing moisture into water, which is then removed from the system. These dryers are ideal for general-purpose applications and industries that don’t require ultra-dry air.

Advantages:

Low maintenance

Cost-effective

Simple to operate

b. Desiccant Air Dryers

Desiccant air dryers use materials that absorb moisture from the compressed air. These dryers are suitable for industries that require extremely dry air, such as electronics manufacturing or pharmaceutical production.

Advantages:

Provides very dry air

Suitable for extreme conditions

c. Membrane Air Dryers

Membrane air dryers are compact and use a selective membrane to allow moisture to pass through while retaining dry air. These dryers are ideal for applications that require small volumes of dry air, such as laboratories or sensitive instruments.

Advantages:

Energy-efficient

Compact and portable

d. Heatless Regenerative Air Dryers

These dryers regenerate desiccant without the use of external heat. They are highly effective at drying air to very low dew points, making them suitable for critical applications in industries like petrochemical and aerospace.

Advantages:

Ideal for very low dew point requirements

No external heat needed for regeneration

2. Evaluate Your Industry’s Specific Needs

The next step is to assess your industry’s specific air quality requirements. The right air dryer will depend on factors such as the environment, air quality standards, and the application of the compressed air.

a. Moisture Sensitivity

Some industries, such as electronics or pharmaceuticals, have strict moisture control requirements. Even a small amount of moisture can damage sensitive equipment or products. For these industries, desiccant or membrane air dryers are often the best choices due to their ability to provide extremely dry air.

b. Operating Environment

The environment in which the air dryer will operate is also critical. For instance, in extremely cold or humid environments, you’ll need a dryer that can handle such conditions. Desiccant dryers are particularly useful in cold climates as they can prevent freezing.

c. Required Air Pressure and Flow

Consider the air pressure and flow rate needed for your application. Larger industrial operations may require high-pressure air dryers that can handle significant volumes of air, whereas smaller operations may be well-suited for more compact, lower-flow options.

3. Consider Energy Efficiency and Operational Costs

The operational costs of air dryers can vary significantly depending on the type and the energy requirements. Since compressed air systems already consume a substantial amount of energy, choosing an energy-efficient air dryer can reduce overall costs.

a. Energy Consumption

Energy-efficient models, such as membrane dryers or refrigerated dryers with variable-speed drives, are ideal for industries looking to minimize operational expenses. While the initial investment may be higher, the energy savings over time can be substantial.

b. Maintenance Requirements

Different air dryers have different maintenance needs. Refrigerated air dryers, for example, tend to have lower maintenance requirements compared to desiccant dryers, which may need regular desiccant replacement. If downtime is critical in your industry, opt for a dryer with minimal maintenance needs to ensure smooth operations.

4. Consider Your Industry’s Budget Constraints

When choosing the right air dryer, your industry’s budget will be a deciding factor. Fortunately, there are various air dryers available at different price points to meet the needs of small to large businesses.

a. Initial Investment vs. Long-term Costs

While refrigerated air dryers are often the most budget-friendly initially, desiccant and membrane dryers may offer better long-term savings due to lower energy consumption and maintenance needs. It’s important to evaluate both the upfront costs and the total cost of ownership over the lifespan of the dryer.

b. Financing and Leasing Options

Some manufacturers offer financing or leasing options for high-end air dryers. If your budget is limited but your air quality requirements are strict, it might be worth exploring these options to obtain the best possible dryer for your needs.

5. Explore Additional Features and Technologies

Modern air dryers come with various advanced features that can enhance performance, reduce energy consumption, and improve ease of use. Consider the following features when selecting an air dryer:

a. Automatic Drain Systems

Some air dryers are equipped with automatic drain systems that remove accumulated moisture from the system without the need for manual intervention. This feature reduces maintenance time and ensures the air system remains dry.

b. Digital Monitoring and Control

Air dryers with digital displays and monitoring capabilities can provide real-time data on dew point, air pressure, and dryer performance. These features can be crucial for industries where consistent air quality is essential.

c. Heat Recovery Systems

In some air dryers, waste heat generated during the drying process can be recovered and reused elsewhere in the system, further reducing energy costs.

6. Check Manufacturer Reputation and Support

Finally, it’s essential to choose an air dryer from a reputable manufacturer that offers excellent customer support. In industries where air quality is critical, downtime caused by faulty equipment can be costly. Look for manufacturers that provide:

a. Warranties and Service Contracts

Ensure the manufacturer offers a solid warranty and, if possible, a service contract for routine maintenance and repairs. This can save you significant time and costs in the long run.

b. Technical Support

Choosing a manufacturer with reliable customer and technical support ensures that you can quickly resolve any issues that may arise during operation.

Conclusion

Choosing the right air dryer for your industry involves careful consideration of your specific needs, the type of dryer, energy efficiency, and budget. By evaluating these factors, you can select a dryer that not only meets your compressed air quality requirements but also provides long-term savings and reliability. Whether your industry demands ultra-dry air or you need a cost-effective solution, there is an air dryer out there that’s perfect for your application.

0 notes

Text

Design Considerations When Opting for Compressed Pipework Reticulation Installation

A good compressed air system denotes a method of transferring pressurised atmosphere (“air”) from the plant to your workshop. An air compressor generates that compressed air and a good system of pipework assures the flow of the air properly without causing any pressure drop or pressure leakage.

Designing an effective compressed air reticulation installation system is essential for ensuring reliable and efficient operation in any workshop or industrial facility. The key to achieving this lies in making informed decisions about several design considerations. Take a look at them in detail from this blog

Pipe Quality

The base of any compressed pipework reticulation installation depends on the quality of the pipes, fittings, and tubes. These components must ensure a firm, leak-free connection to minimise pressure drops and prevent costly air leaks. Using high-quality materials is crucial, as it directly impacts the overall performance and longevity of the system.

Also getting help from professional air pipe installers is important. Their expertise ensures that the system is set up correctly, leveraging best practices to optimize performance. This is particularly important for workshop reticulation installation services, where precision and reliability are non-negotiable.

Air Treatment

The quality of the air at the point of use is vital, especially for delicate machinery that relies on specific air quality standards. Condensate management plays a significant role in maintaining this quality. Depending on your needs, you may choose between a “wet receiver” and a “dry receiver,” both of which serve to manage moisture within the system.

Additional techniques like inclining pipes, incorporating drain points, and using filtration and dryers further enhance condensate management, ensuring that moisture does not compromise the system's integrity.

System Design

The design of the air system itself, whether it be a ring main or a fishbone layout, significantly impacts airflow and pressure stability. Each design has its own set of advantages, especially when multiple users depend on the compressed air simultaneously.

Optimising the layout to minimise bends, sudden changes in direction, and any restriction points is essential to avoid unnecessary pressure drops. A well-thought-out layout also makes the system more adaptable for future expansions, which can be crucial for growing operations.

Sizing of the air system

Sizing the air system is equally important when you opt for the compressed pipework reticulation installation. Proper sizing helps the system to accommodate the current needs while being flexible enough for future expansions. Generally, it’s advisable to size the system as large as your budget and physical constraints allow.

This approach provides a buffer for increased demand without sacrificing performance. For instance, refrigerated air dryers often need to be oversized by up to 30% compared to the manufacturer's recommendations to account for the specific conditions in Australia. On the other hand, cyclonic water separators should be sized exactly to match the airflow at the point of use, ensuring effective moisture removal and maintaining system efficiency.

In summary, designing and installing a compressed air pipework service in South Australia requires careful consideration. By focusing on these key factors, you can ensure that your compressed air reticulation installation not only meets your current operational needs but also remains adaptable for future demands.

Final Words

For over 30 years, Airequip and Pipetool have been leading experts in compressed air pipework services in South Australia. With years of relevant industry knowledge, they provide reliable, efficient, and customised solutions for all your workshop reticulation installation service needs. Whether you're setting up a new system or upgrading an existing one, Airequip and Pipetool are trusted professionals who can deliver excellence in compressed air solutions.

#compressed air pipework service in south Australia#compressed air reticulation installation#workshop reticulation installation service#Compressed pipework reticulation installation#Air pipe installer South Australia

1 note

·

View note

Text

Refrigerated Air Dryer Manufacturers

Air Care Equipments is one of the trusted and reliable Refrigerated Air Dryer Manufacturers and Suppliers in India. Our Refrigerated Air Dryers are available in various sizes, allowing you to choose according to your requirements. Our quality experts ensure the high quality of our products. If you are interested, please visit our website.

Add : Khewat No. 197/202, Khasra No. 13/11, Village Garauli Khurd, Gurgaon- 122001

Ph : +91-9599293541, +91-9871793228

Email : [email protected]

Visit : https://www.aircareequipment.co.in/screw-air-compressor-noida/

0 notes

Text

Energy-Efficient Refrigeration Air Dryers: What Manufacturers Are Doing

In the ever-evolving landscape of industrial equipment, energy efficiency has become a focal point for manufacturers, especially for refrigeration air dryers. As industries continue to seek sustainable solutions, refrigeration air dryer manufacturers are stepping up to the challenge, developing innovative technologies that meet the demand for efficient air drying and contribute to environmental conservation. In this blog post, we’ll explore the latest trends and advancements in energy-efficient refrigeration air dryers and shed light on what manufacturers are doing to address these crucial requirements.

Refrigeration air dryers play a pivotal role in maintaining compressed air quality by removing moisture, preventing corrosion, and ensuring the longevity of downstream equipment. Traditionally, these systems were notorious for their energy-intensive operation. However, with growing awareness about energy consumption and environmental impact, manufacturers have been spurred into action to enhance the efficiency of these vital components.

Variable Speed Drive (VSD) Technology:

One of the notable advancements in energy-efficient refrigeration air dryers is the integration of variable speed drive (VSD) technology. Manufacturers have recognized the importance of adjusting the compressor speed based on air demand, leading to significant energy savings compared to fixed-speed alternatives. This adaptive approach reduces energy consumption and prolongs the lifespan of the equipment.

Heat Exchanger Optimization:

Efficient heat exchange is critical for the proper functioning of refrigeration air dryers. Manufacturers are investing in advanced heat exchanger designs that maximize heat transfer efficiency, enabling the system to achieve the desired dew point while minimizing energy consumption. Enhanced thermal performance contributes to a more sustainable and cost-effective operation.

Smart Control Systems:

The advent of smart control systems has revolutionized the way refrigeration air dryers are managed. Manufacturers are incorporating intelligent control algorithms that continuously monitor and adjust the system parameters in real-time. This level of automation ensures optimal performance under varying operating conditions, resulting in energy savings and reduced environmental impact.

Environmentally Friendly Refrigerants:

To align with global efforts to reduce greenhouse gas emissions, manufacturers are exploring and adopting environmentally friendly refrigerants. The transition to refrigerants with low Global Warming Potential (GWP) not only complies with environmental regulations but also contributes to the more sustainable operation of refrigeration air dryers.

Industry Best Practices:

Refrigeration air dryer manufacturers are embracing industry best practices to enhance the energy efficiency of their products further. Regular maintenance, proper sizing, and system audits are integral aspects that contribute to optimal performance. Manufacturers are fostering a culture of sustainability within the industrial sector by educating end-users about these best practices.

The Role of Trident Pneumatics:

As a leader in industrial air solutions, Trident Pneumatics has been at the forefront of the energy-efficient refrigeration air dryer movement. Our commitment to innovation and sustainability is reflected in the technologies we integrate into our products. The Trident Pneumatics refrigeration air dryers leverage cutting-edge variable speed drive (VSD) technology, ensuring precise control and optimal energy consumption.

Our heat exchanger designs are meticulously optimized for efficiency, and our smart control systems guarantee seamless and adaptive operation. By prioritizing environmentally friendly refrigerants, we contribute to a greener future while maintaining the high-performance standards our customers expect.

Conclusion:

The dynamic landscape of refrigerated air dryer Manufacturers has been transformed by emphasizing energy efficiency. Manufacturers actively incorporate innovative technologies such as VSD, optimized heat exchangers, smart control systems, and environmentally friendly refrigerants. Trident Pneumatics, a trusted name in the industry, continues to lead the way with its commitment to sustainability and cutting-edge solutions. By choosing Trident Pneumatics, customers invest in top-tier industrial air solutions and contribute to a more energy-efficient and environmentally responsible future.

#Refrigerated air dryer systems#Refrigeration air dryer Manufacturers#refrigerated air dryer Manufacturers

0 notes

Text

refrigerated air dryer Manufacturers

A refrigerated air dryer manufacturer is a type of compressed air dryer that uses a refrigeration cycle to remove moisture from compressed air. Compressed air often contains water vapor, which can condense and cause damage to pneumatic tools, machinery, and instruments. Refrigerated air dryers work by cooling the compressed air, causing the moisture to condense and then collecting and removing it from the system.

0 notes

Text

Established in the year 2016, Airomach Engineers is one of the leading Manufacturer and Wholesaler of Air Dryer, Air Heater, Water Chiller and much more. In their development process, we assure that only top notch basic material is used by our professionals along with modern tools. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Working under the mentorship of Mr. Sanehit Bhardwaj (Proprietor), we have acquired a reputed stature in the industry.

#heat exchanger manufacturer in delhi#Air Compressor Tank Price in India#Air Compressor Dryer System in Delhi#Air Compressor dryer system in india#Refrigerated Air Dryer Manufacturer in Delhi#Water Chiller Manufacturer in Delhi#Refrigerated Air Dryer Supplier in Delhi#Water Chiller Supplier in Delhi#Air Dryer System in Delhi#Air Compressor Tank Price in delhi#Water Cooled condenser manufacturers in delhi#water chiller manufacturers in delhi

0 notes

Text

Industry Outlook of North America Small Kitchen Appliances Market 2024 Trends to 2030

North America Small Kitchen Appliances Industry Overview

The North America small kitchen appliances market size was estimated at USD 10.66 billion in 2023 and is projected to grow at a CAGR of 3.7% from 2024 to 2030. Consumers are increasingly opting for appliances that can save time and effort in meal preparation, leading to a surge in the popularity of multi-functional and automated appliances in the region. Moreover, the growing number of single-person households and smaller living spaces are also contributing to the demand for compact and space-efficient appliances that can fit into limited kitchen areas.

The preference for home-cooked meals among Americans has experienced a notable surge, marking a significant lifestyle shift following lockdown periods. This change in behavior has spurred considerable market growth for small kitchen appliances. With more individuals opting to cook at home, there is an increased demand for appliances that facilitate convenient and efficient meal preparation. From air fryers to slow cookers, these small kitchen appliances have become essential tools for individuals looking to create homemade meals that are both convenient and nutritious.

Gather more insights about the market drivers, restrains and growth of the North America Small Kitchen Appliances Market

A survey conducted by the National Frozen and Refrigerated Foods Association (NFRA) in 2023 revealed significant shifts in Americans' grocery shopping habits, particularly in their cooking behaviors. While there has been a slight decrease since its peak in 2020 and 2021, a substantial 81% of consumers are still cooking more than half of their meals at home. This trend is largely driven by the desire to save money and maintain control over their budgets, with 64% of Americans citing these reasons.

Many individuals have gained confidence in their cooking skills during lockdowns and are now seeking inspiration to prepare healthier meals at home. To aid in this endeavor, more people are turning to online grocery shopping and social media platforms for recipe ideas and ingredient usage tips. In addition, the survey found that 45% of consumers rely on air fryers, while 43% utilize slow cookers for cooking and meal preparation.

Browse through Grand View Research's Electronic & Electrical Industry Research Reports.

The global hair dryer market sizewas estimated at USD 8.72 billion in 2023 and is expected to grow at a CAGR of 5.6% from 2024 to 2030.

The global portable bluetooth speaker market sizewas estimated at USD 12.90 billion in 2023 and is expected to grow at a CAGR of 11.7% from 2024 to 2030.

Key North America Small Kitchen Appliances Company Insights

The North America small kitchen appliances industry is fragmented in nature, attributed to the presence of many small, regional companies that are introducing smart multi-functional appliances with attractive product designs and specifications to cater to diverse consumer preferences.

Key manufacturers are working toward increasing the availability of small kitchen appliances in retail and online stores. Moreover, these manufacturers are constantly striving to develop new and improved products that offer enhanced functionality, energy efficiency, and ease of use. This has led to the emergence of smart appliances, which can be controlled and monitored through smartphones or other connected devices, providing users with greater control and convenience.

Ninja (SharkNinja, LLC) and GE Appliances (Haier Company) are the dominant players operating in the North America dishwasher market.

Ninja (SharkNinja, LLC) sells its products through a variety of trade channels, with a significant portion dependent upon retail partnerships through both traditional brick-and-mortar retail channels and e-commerce channels. As of December 2023, the company partnered with 42 retailers across the United States and over 140 retailers globally. Their largest retailers include Walmart, Amazon, and Costco, each of which accounted for more than 10% of their net sales and together made up around 45% of their net sales for the year 2023.

GE Appliances (Haier Company) has a significant presence both domestically in the U.S. and internationally. The company's workforce operates in nine manufacturing plants spanning five states, manufacturing a wide range of small kitchen appliances that find their way into half of all households across the U.S.

Key North America Small Kitchen Appliances Companies:

Ninja (SharkNinja, LLC)

Hamilton Beach

GE Appliances (a Haier Company)

Panasonic Corporation

Cuisinart

SMEG USA, Inc

Tefal S.A.S. (T-fal)

Bella Housewares (Gather)

Russell Hobbs (Spectrum brands)

Kenmore (Transform Holdco LLC)

Recent Developments

In March 2024, KitchenAid unveiled its latest appliance, the automatic grain and rice cooker, which introduces a convenient solution for cooking grains and beans. With 21 presets available, users can prepare a variety of grains effortlessly, eliminating the need for constant measuring or supervision. The appliance accurately dispenses the required amount of water based on the grains added, streamlining the cooking process.

In March 2024, HUROM introduced its latest innovation: the H320 Slow Juicer. Designed to meet the discerning needs of juicing enthusiasts worldwide, the H320 Slow Juicer embodies meticulous engineering to deliver ultra-low pulp juice. Despite its advanced features, loading and preparation remain exceptionally convenient, ensuring a seamless juicing experience for users.

In January 2024, Bosch Home Appliances, a renowned home appliances brand, introduced its latest innovation, a line of countertop Fully Automatic Espresso Machines. Recognized as a CES 2024 Innovation Award Honoree in the smart home category, these machines promise premium-quality coffee and a diverse array of beverage options, all easily accessible with a simple touch on the intuitive Active Select Display.

Order a free sample PDF of the North America Small Kitchen Appliances Market Intelligence Study, published by Grand View Research.

0 notes

Text

Troubleshooting Common Issues with Air Dryer Compressors

Air dryer compressors are essential components in compressed air systems, designed to remove moisture and ensure that the air remains dry and clean. However, like any machinery, they can experience issues that affect their performance and efficiency. Experiencing issues with your air dryer compressor can be frustrating, especially if it’s your first time dealing with such problems. It’s essential to repair promptly to keep moisture out and protect your pipes, tools, and equipment. Start by checking the cooler on your air compressors. If the inlet air temperature going into the air dryer compressor is too high, the dryer will be overworked and may not reach the required dew point.

Ensuring the inlet air temperature is within the recommended range is necessary for optimal performance. Before troubleshooting or repairing, always prioritise safety by disconnecting the power from the air dryer supplier. This precaution is essential to avoid accidents and prevent further damage to the equipment. Once you’ve ensured safety, inspect the dryer for visible signs of damage or wear. Addressing these issues can help prevent more significant problems in the future. Here’s a complete guide to diagnosing and resolving common issues with air dryer compressors.

Some common problems, causes and solutions of air dryer compressors:

Insufficient drying:

Problem: When your air dryer compressor fails to remove moisture sufficiently, it results in wet compressed air, leading to problems like rust and corrosion in your system.

Possible causes:

Blocked or dirty filters: Filters are essential in removing particulates and water. Over time, they can become clogged, reducing airflow and drying efficiency.

Incorrect settings: If the air dryer compressor’s settings are incorrect to your system’s requirements, it may not perform optimally.

Faulty refrigerant: Refrigerant issues, such as low levels or leaks, can impair the cooling process, affecting moisture removal.

Solutions:

Inspect and replace filters: Regularly check air and condensate filters. Replace them if they seem dirty or blocked. Routine maintenance is necessary to maintain performance.

Adjust dryer settings: Ensure that the air dryer compressor is according to the manufacturer’s recommendations and the specific needs of your system. Check settings like temperature and pressure to match working conditions.

Check refrigerant levels: Inspect refrigerant levels and look for leaks. If necessary, renew the refrigerant or address leaks to restore proper function.

High pressure drop:

Problem: A noticeable drop in pressure across the air dryer supplier can reduce system efficiency and performance.

Possible causes:

Blocked air intake: Dust and waste can block the air intake, reducing the volume of air processed and causing a pressure drop.

Dirty heat exchangers: Hoarding dirt and grime in heat exchangers can restrict heat transfer and airflow, resulting in pressure issues.

Faulty pressure regulator: A malfunctioning pressure regulator can lead to inaccurate pressure readings and affect system performance.

Solutions:

Clean air intake: Regularly clean the air intake to ensure precise airflow. Remove any waste or blocks.

Maintain heat exchangers: Clean heat exchangers to remove collected dirt. This will help maintain optimal heat transfer and airflow.

Check and replace pressure regulator: Inspect the pressure regulator for proper function. Replace it if it’s not delivering proper pressure readings.

Excessive noise:

Problem: Unusual or excessive noise from the air dryer compressors can show underlying issues and affect the overall process of your system.

Possible causes:

Loose parts: Vibrations from loose parts can cause noise. This is often due to poor assembly or wear and tear.

Worn bearings: Bearings that are worn out or damaged can produce grinding or rattling noises.

Improper support: Incorrect support of parts can lead to vibrations and noise during the process.

Solutions:

Tighten loose parts: Check and tighten all loose parts and connections. Ensure that all parts are securely fastened.

Inspect bearings: Examine the bearings for signs of wear or damage. Replace worn bearings to stop grinding noises.

Ensure proper support: Ensure all parts are scaled correctly and securely to prevent vibrations and noise.

Frequent cycling:

Problem: If the air dryer supplier is on and off too repeatedly, it can lead to inefficient function and unstable drying.

Possible causes:

Overloaded system: An overloaded system can cause the air dryer to supply more continually as it struggles to keep up with demand.

Short cycling: Short cycling by incorrect settings or rapid changes in temperature or pressure.

Faulty thermostat: A malfunctioning thermostat can lead to erratic cycling and impact the dryer’s efficiency.

Solutions:

Check system load: Ensure the system is beyond the dryer’s capacity. Adjust the load.

Adjust settings: Check and resolve air dryer compressor settings to avoid short cycling. Ensure that air compressors work within their scheduled parameters for temperature and pressure.

Test and repair thermostat: Inspect the thermostat for proper functioning. If faulty, repair or replace it to stabilise cycling and maintain efficient operation.

Water in the compressed air:

Problem: Finding water in the compressed air despite using an air dryer shows that air dryer compressors are not effectively removing moisture.

Possible causes:

Undersized dryer: If the air dryer compressor is too small for the system’s needs, it may not handle the moisture load effectively.

Malfunctioning drain valve: A faulty or blocked drain valve can prevent proper condensate removal, leading to water in the air stream.

High ambient temperatures: Excessively high temperatures can reduce the dryer’s efficiency, allowing moisture to pass through.

Solutions:

Verify dryer capacity: Confirm that the air dryer compressor is perfect for your system. If necessary, consider upgrading to a larger unit.

Inspect and maintain the drain valve: Regularly check the drain valve for proper operation. Clean or replace it as needed to ensure effective condensate removal.

Monitor and manage ambient temperature: Check the air dryer supplier’s temperature. Consider more cooling solutions or a more robust dryer if high temperatures are an issue.

Increased energy consumption:

Problem: Increasing energy consumption can lead to higher operating costs and show inefficiencies in the performance of air dryer compressors.

Possible causes:

Dirty parts: Collection of dirt on filters and heat exchangers can force the air compressors to work harder, consuming more energy.

Inefficient process: Incorrect settings or maintenance issues can lead to inefficient operation and higher energy use.

Older equipment: Outdated air dryer compressors may be less energy-efficient than newer models with advanced technology.

Solutions:

Clean and maintain: Regularly clean filters and heat exchangers for optimal performance. Schedule routine maintenance to address any inefficiencies.

Optimise settings: Review and adjust the air dryer compressor settings to ensure efficient operation. Avoid unnecessary energy consumption by fine-tuning parameters like pressure and temperature.

Upgrade equipment: Consider replacing outdated equipment with newer, more energy-efficient models. Modern air dryer compressors often come with advanced features that improve energy efficiency.

Leaking Condensate:

Problem: Leaks in the condensate system can lead to water damage and reduced performance in the air compressors.

Possible causes:

Faulty condensate drain: A malfunctioning or blocked drain can cause leaks and prevent proper water removal.

Loose or damaged connections: Leaks can occur due to loose connections or damage in the condensate lines or tanks.

Cracked or worn parts: Cracks or wear in the condensate system parts can lead to leaks and reduced efficiency.

Solutions:

Inspect and repair drain: Check the condensate drain for blockages or malfunctions. Clean or repair the drain as needed to ensure proper operation.

Tighten connections: Ensure connections in the condensate system are secure. Tighten any loose fittings and replace damaged parts.

Replace damaged parts: Examine the condensate lines and tanks for cracks or wear. Replace any damaged parts to prevent leaks and maintain system goodness.

Wrapping up:

Troubleshooting common issues with air dryer compressors includes understanding the probable problems and executing practical solutions. You can maintain the efficiency and reliability of your compressed air system by addressing issues such as insufficient drying, high-pressure drops, excessive noise, frequent cycling, water in the compressed air, increased energy consumption, and leaking condensate. Regular maintenance and prompt attention to any signs of trouble will help ensure that your air dryer compressor works smoothly and effectively, providing clean, dry, compressed air for your needs.

0 notes