#rapid prototyping china

Explore tagged Tumblr posts

Text

Know About the Post-Processing in Rapid Prototyping

Rapid Prototyping China is a ray of efficiency and inventiveness in the field of product development and innovation. By offering quick iterations and concrete concept representations, it transforms conventional methodologies. However, inside this miracle of contemporary engineering, there is a critical—often disregarded but unquestionably necessary—step called post-processing. It's the period of transformation that unlocks the actual potential of a rough prototype and turns it into a polished masterpiece.

Enhancement of Visual Appeal

Even in the world of prototypes, first impressions count. Post-processing makes it possible to improve the visual appeal of a prototype by removing flaws and rounding off edges. Simple models may be transformed into visually beautiful representations by using techniques like painting, polishing, or sanding, which can improve the model's aesthetic appeal and professionalism.

The perception of a product is greatly influenced by its aesthetics, which also affects consumer acceptability and engagement. Consequently, spending money on post-processing guarantees that prototypes not only work effectively but also grab attention due to their striking appearance.

Improvement of Material

Chinese Rapid Prototyping Services relies heavily on material selection, which affects characteristics like strength, flexibility, and durability. Nevertheless, the intrinsic qualities of raw materials could not meet the required standards. A solution is provided by post-processing, which enhances material qualities to satisfy demands. One can achieve desired characteristics like heat resistance, conductivity, or waterproofing by applying coatings, surface treatments, or chemical procedures. Post-processing broadens the possibilities by improving material qualities, making prototypes more resilient to real-world use and more environment-adaptable.

Individualization and Tailoring

Each product is different from the others and meets the demands of different users. Post-processing makes it easier to customize and personalize prototypes to suit these unique tastes. Prototypes may be given individuality and flare by post-processing, which includes adding textures, engravings, and detailed detailing. It also makes it possible to incorporate branding components, which promote brand loyalty and awareness.

Iterative Enhancement

Iteration is the lifeblood of Rapid Prototype; each cycle improves and refines the idea. Post-processing provides insightful input for iteration cycles, acting as a stimulus for iterative progress. Designers can identify areas for improvement and identify strengths and shortcomings by evaluating post-processed prototypes. Prototypes are refined through iterative development, which encourages ongoing learning and innovation.

#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

In the ever-changing world of product development and production, accuracy and speed are critical. Innovation and market response are hampered by the long lead times and high costs associated with traditional prototype and tooling procedures. But now that rapid prototyping China services are available, companies can shorten the time it takes to develop new products while still upholding high standards of quality. We explore the many advantages of using rapid prototyping China services, especially in relation to molding and tooling procedures.

0 notes

Text

Unlocking Innovation : Aluminum Prototype And Sheet Metal Prototyping

In the dynamic world of manufacturing and design, prototyping stands as a crucial step in the development process. Among the various materials and techniques used, aluminum prototypes and sheet metal prototyping have gained significant attention for their versatility, durability, and cost-effectiveness. This blog explores the advantages, applications, and innovations in aluminum and sheet metal prototyping.

0 notes

Text

CNC Car Parts: Revolutionizing Automotive Manufacturing with Precision and Efficiency

Introduction In the ever-evolving world of automotive manufacturing, the demand for high-quality, precise, and efficient production processes has become paramount. The advent of advanced technologies, such as online machining, SLA rapid prototyping, aluminum casting in China, CNC prototypes, and small metal parts fabrication, has brought about a paradigm shift in the production of car parts. This article explores the significance of CNC (Computer Numerical Control) in the automotive industry and how it has revolutionized the manufacturing of car parts.

Online Machining: Streamlining Production Processes Online machining, also known as CNC machining, has emerged as a game-changer in car part manufacturing. With online machining, manufacturers can create intricate and complex car parts with exceptional precision and speed. By utilizing computer-aided design (CAD) software, engineers can develop 3D models that are then translated into machine instructions for CNC machines.

The CNC machines, equipped with high-speed rotating tools, cut, drill, and shape raw materials, such as aluminum, steel, and alloys, into precise car parts. The automated nature of online machining not only enhances accuracy but also reduces the risk of human errors, resulting in improved quality control.

SLA Rapid Prototyping: Accelerating Innovation SLA (Stereolithography) rapid prototyping is another technology that has significantly impacted the automotive industry. It enables the creation of quick and cost-effective prototypes for car parts. Using SLA, manufacturers can transform digital designs into physical models by using a specialized machine that cures liquid resin layer by layer, producing a solid object.

The application of SLA rapid prototyping allows automotive designers and engineers to iterate and test their designs more efficiently. This iterative approach helps identify and rectify flaws or design issues at an early stage, saving both time and resources. By accelerating the prototyping process, SLA technology fosters innovation and drives the development of cutting-edge car parts.

Aluminum Casting China: Cost-Effective and Versatile Aluminum casting in China has gained prominence as a cost-effective and versatile method for producing car parts. Aluminum, with its lightweight properties and excellent thermal conductivity, is an ideal material for automotive applications. China, with its well-established manufacturing infrastructure, offers competitive advantages in terms of cost, quality, and production capacity.

By utilizing aluminum casting techniques, manufacturers can create complex shapes and structures that would be challenging to achieve with traditional methods. The process involves pouring molten aluminum into pre-designed molds, allowing for the production of intricate car parts with high dimensional accuracy. Furthermore, aluminum casting provides excellent surface finishes and is highly resistant to corrosion, making it suitable for various automotive components.

CNC Prototypes: Transforming Design Concepts into Reality CNC prototypes play a pivotal role in the development of car parts. Before moving into full-scale production, manufacturers often create prototypes to validate the design, functionality, and performance of the intended car parts. CNC machines excel in producing accurate prototypes that closely resemble the final product.

By using CNC prototypes, automotive engineers can evaluate the form, fit, and function of car parts, ensuring they meet the desired specifications. Any necessary modifications or improvements can be identified and implemented at this stage, minimizing the risk of costly errors during mass production.

Small Metal Parts Fabrication: Precision at Scale The production of small metal parts is a critical aspect of automotive manufacturing. These components, although small in size, play a vital role in the overall performance and functionality of a vehicle. CNC machining enables the precise fabrication of small metal parts, ensuring that they meet the stringent requirements of the automotive industry.

Whether it's engine components, brackets, connectors, or fasteners, CNC machining can accurately produce small metal parts with high repeatability. The ability to manufacture these parts at scale while maintaining consistent quality is a significant advantage of CNC technology.

Conclusion The use of CNC technology has had a significant impact on the overall cost of manufacturing CNC car parts. The integration of online machining, SLA rapid prototyping, aluminum casting in China, CNC prototypes, and small metal parts fabrication has revolutionized the manufacturing of car parts. These advanced technologies offer enhanced precision, efficiency, and cost-effectiveness in the production process. As the automotive industry continues to evolve, the utilization of CNC in car part manufacturing will be instrumental in meeting the demands for innovation, quality, and performance in vehicles worldwide.

#online machining#SLA rapid prototyping#aluminum casting china#CNC prototypes#CNC car parts#small metal parts fabrication

0 notes

Text

A group of leading Chinese chip design firms have formed a patent protection alliance for RISC-V, as the country bets on the open-source architecture to help achieve its long-sought goal of semiconductor self-sufficiency.

Members of the alliance will share patents with each other and license them to third parties in the name of the alliance, according to Dai Weimin, chairman of VeriSilicon and head of the China RISC-V Industry Alliance, formed in 2018. The new alliance aims to contribute to a “healthy” open-source chip ecosystem and promote the rapid development of RISC-V technologies. At a RISC-V industry forum held in Shanghai’s Lingang New Area on Monday, nine chip companies – including Alibaba Group Holding’s chip unit T-Head and Shanghai-listed VeriSilicon Holdings – agreed to form the alliance that includes a condition for members to not sue each other over patent infringement, according to local media The Paper, under the state-run Shanghai United Media Group. Alibaba owns the South China Morning Post.

RISC-V is an open-standard instruction set architecture that gives chip developers the ability to configure and customise their designs. First published in 2010, it is the fifth generation of cooperative projects from researchers at the University of California, Berkeley. It has gained popularity in China amid hopes that the technology can help it break what is largely a duopoly controlled by US-based Intel and UK-based Arm, bringing the country closer to its strategic goal of technological self-sufficiency.[...]

China’s enthusiasm for RISC-V stems from its numerous benefits as an open standard. As the cost of innovation in chip design is high, a chip start-up has to raise around US$20 million to deliver a working prototype, compared with US$3 million for an internet start-up, according to the RISC-V Foundation, which manages the standard.

As an open source chip ecosystem, RISC-V can offer faster time to market with lower costs, lowering barriers to entry for the industry, the foundation said in an article published earlier this month.

29 Aug 23

34 notes

·

View notes

Text

Unprecedented U.S. Hypersonic Weapons Test From Guam Has Occurred

Joseph TrevithickPUBLISHED Mar 19, 2024 7:02 PM EDT

The Air Force has conducted an unprecedented test launch of a live AGM-183A ARRW hypersonic missile in the Western Pacific, sending signals to China and elsewhere in the region amid uncertainty about this particular program's future.

Lockheed Martin

The U.S. Air Force has confirmed that it conducted its final planned end-to-end test launch of a live AGM-183A Air-Launched Rapid Response Weapon hypersonic missile, or ARRW, earlier this week. A B-52H bomber flying from the highly strategic U.S. Pacific island territory of Guam fired the missile. The War Zone was the first to predict this test was coming after the Air Force curiously released pictures of a live AGM-183A at a show-and-tell training event at Guam's Andersen Air Force Base in late February.

This is the first time an ARRW missile, or any other known American hypersonic weapon, has been test launched in this region. As such, the test sends signals across the Pacific, especially toward China. At the same time, this comes as ARRW's future continues to be murky with signs pointing to a potential follow-on program, which may already be in progress.

A live AGM-183A ARRW hypersonic missile seen under the wing of a B-52H bomber at Andersen Air Force Base on Guam on February 27, 2024. USAF

“A B-52H Stratofortress conducted a test of the All-Up-Round AGM-183A Air-launched Rapid Response Weapon," an Air Force spokesperson told The War Zone in a statement. "This test launched a full prototype operational hypersonic missile and focused on the ARRW’s end-to-end performance The test took place at the Reagan Test Site with the B-52 taking off from Andersen Air Force Base, Guam on March 17, 2024 local time."

The Reagan Test Site consists of various facilities spread across multiple islands at Kwajalein Atoll in the Republic of the Marshall Islands. The site is one of the U.S. military's premier missile test ranges and is regularly used to support the testing of very long-range munitions, including hypersonic weapons like ARRW.

Andersen Air Force Base on Guam is a key U.S. military hub in the Western Pacific and the Air Force's main base for staging long-range bomber operations in the region. It would play a central role in any future major conflict in the region, including one against China. U.S. hypersonic weapons, which are expected to be very expensive and acquired in relatively limited numbers, would be particularly valuable in a high-end fight for conducting conventional strikes against very high-value and heavily defended targets. These could include major air defense and other command and control nodes.

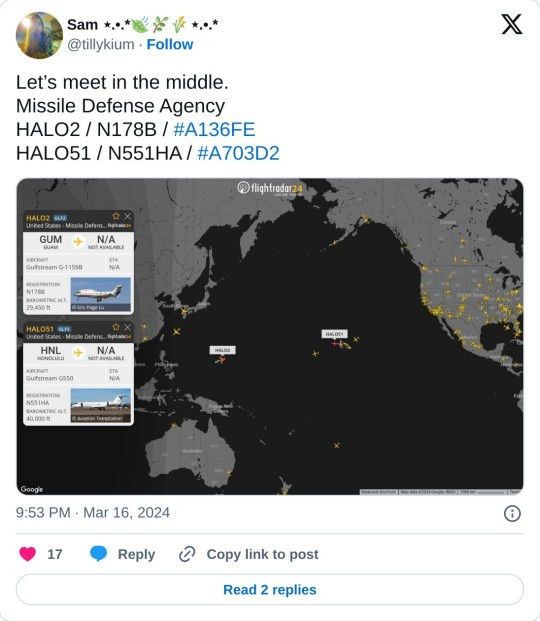

There had already been evidence that the ARRW test had occurred on or about March 17 based on the appearance and then cancellation of various warning notices. Online flight tracking data also showed signs the test was finally about to happen, including specially modified High Altitude Observatory (HALO) Gulfstream business jets operating in relevant areas. The HALO aircraft have supported past ARRW flight tests.

ARRW Update: New round scheduled tonight between 00:09 and 04:30 UTC.

So I guess launch did not happened last night despite 49th T&E Squadron's B-52H spotted by @FMilcoms.

The Air Force has only provided limited information so far about the test's outcome and has not explicitly said whether or not it was successful.

"The Air Force gained valuable insights into the capabilities of this new, cutting-edge technology. While we won’t discuss specific test objectives, this test acquired valuable, unique data and was intended to further a range of hypersonic programs," the Air Force spokesperson said in their statement to The War Zone. "We also validated and improved our test and evaluation capabilities for continued development of advanced hypersonic systems.”

The Air Force has used roughly similar language in statements about the previous three end-to-end tests of live ARRW missiles, which occurred in March, August, and October 2023. The March 2023 test ended in failure. Information about the August and October 2023 launches remains scant. The service also conducted another end-to-end ARRW test in December 2022, but this appears to have not involved a live all-up-round missile.

An AGM-183A missile seen during an earlier test launch in 2021 that did not involve a full end-to-end demonstration of the weapon. USAF

Whatever the exact outcome of the March 17 test was, ARRW's future is uncertain, as The War Zone has previously reported in depth.

"Currently, right now, we do not have the ARRW in the [Fiscal Year] 25 budget," Air Force Lt. Gen. Dale White, the Military Deputy at the Office of the Assistant Secretary of the Air Force for Acquisition, Technology, and Logistics, told members of the House Armed Services Committee at a hearing last week. "However, we are continuing to analyze the test data that we have from that capability."

"With ARRW ... we are undergoing the final test of the all-up-round [AUR] with a planned test program completion by the end of [the] second quarter [of] Fiscal Year 2024," White added. "Future ARRW decisions are pending final analysis of all flight test data."

Following years of at best mixed test results, the Air Force announced in March 2023 that it planned to end the ARRW program and shift resources to work on a different type of hypersonic weapon, the Hypersonic Attack Cruise Missile (HACM). You can read more about the differences between ARRW, which has an unpowered hypersonic boost-glide vehicle payload, and air-breathing hypersonic cruise missiles like HACM here.

A rendering of a notional air-breathing hypersonic cruise missile from Raytheon, the prime contractor for the Air Force's HACM program. Raytheon

The Air Force has subsequently appeared on multiple occasions to be backtracking on its ARRW decision, despite the program still being officially set to come to an end this year. There are now signs that the service could be looking at a follow-on air-launched hypersonic boost-glide vehicle program, if it isn't already in the works.

Whatever the case, the Air Force has now completed its final planned end-to-end test of an ARRW missile, which it has said will inform its future hypersonic weapon plans.

Contact the author: [email protected]

9 notes

·

View notes

Text

PTS-Rapid Prototyping & On-demand Production Services https://www.ptsindu.com/

PTS Industrial Ltd was founded in 2002, located in Dong Guan and Shenzhen, China. PTS starts from precision plastic injection molds making, and step into plastic injection molding services, cnc machining services, After 20 years of development, now we have 4 subsidiaries. Since 2002, PTS has been proudly providing high-quality CNC machining parts, injection molding services, and plastic injection molds to a diverse range of industries, Serving well-known companies such as HUA WEI, BMW, EPSON, etc.

plastic injection molding services, cnc machining services, cnc milling services, cnc turning services, plastic injection molds maker

9 notes

·

View notes

Text

Vacuum Forming Is a Game Changer in Manufacturing

Innovation in the manufacturing sector is what propels cost-effectiveness, adaptability, and efficiency. Vacuum forming is one such cutting-edge method that has completely changed the way goods are created and manufactured. Due to its many benefits, vacuum forming technique has become more and more common in a variety of sectors.

Production at a Low Cost

The affordability of vacuum forming is one of its main benefits. Vacuum forming uses less expensive machinery and tools than conventional production techniques like die casting or injection molding. Because of this, vacuum forming is a desirable alternative for small- to medium-sized production runs, allowing companies to save costs without sacrificing quality.

Quick Prototyping

Rapid prototyping is made possible by Vacuum Forming China, which enables engineers and designers to test and iterate product concepts fast. It is possible to build several prototypes at a reasonable cost because to the short lead times and inexpensive tooling costs. This quickens the process of developing new products, allowing companies to launch new concepts more quickly and adapt quickly to the needs of their customers.

Flexibility in the Choice of Materials

A large variety of thermoplastic materials may be used with vacuum forming, giving producers the freedom to select the material that is best suited for their particular purpose. Because of their versatility, goods with different levels of flexibility, transparency, and durability may be made. Vacuum forming is a flexible solution for a multiplicity of sectors, accommodating a wide range of material needs from durable automotive components to thin-gauge packaging.

Smooth Customization of the Design

Vacuum forming makes it simple to easily customize complex designs. It is possible to accomplish intricate textures, undercuts, and forms without the requirement for costly tool adjustments. Vacuum forming is a great option for creating aesthetically pleasing and useful items in a variety of sectors, including consumer electronics, car interiors, and signs, because of its adaptability in design customization.

Lightweight Goods

Because vacuum-formed materials by vacuum forming manufacturer are lightweight by nature, they are appropriate for uses where weight is a crucial consideration. This benefit is especially pertinent to the aerospace and automobile sectors, where weight reduction may improve overall performance and fuel economy. Additionally, vacuum-formed items' lightweight design makes handling, shipping, and installation simpler.

Next: Investment Casting Offers Both Versatility and Precision

#Vacuum Forming#Vacuum Forming Process#vacuum forming manufacturer China#vacuum forming manufacturer#Vacuum Forming Companies#Custom Vacuum Forming

2 notes

·

View notes

Text

7 Facts You Must Know Regarding Startups In 2023

You are saying that you have a burning inkling that you think could transform the world in any way? Oh, you are desiring about earning millions or even billions of dollars by launching a business around this boiling idea? Then you could probably be the father of a Startup.

Industry professional, Ashish Aggarwal, CEO of Acube Ventures insinuates that Startups are prominent business prototype that steers invention and economic promotion across the world. An exotic set of products and services are established by startups each year. They are the articulation of imaginative and ambitious entrepreneurs who have remarkable ideas.

India has evolved to be the third-largest startup ecological community in the world after the US and China. The first Unicorn was seen in India in 2011, and almost after a decade in 2022, India crossed the mark of 100 Unicorns. The bragging of 100 Unicorns is not an ordinary affair, and that is why the startup ecosystem is flinging in joy and bulging with dignity.

"Startups in India have grown remarkably over the last six years.

The number of newly recognised startups around the world has heightened to over 14,000 in 2021-22 from only 733 in 2016-17, a survey said.

When someone says the word “startup”, we usually instantly think of diverse triumph stories and exponential business expansion. However, in actuality, not all startups are prosperous. We usually only hear about the winners, and that is one-sided information that doesn’t tell the entire story. Everyone wants to listen to favourable achievement anecdotes, but you need to know all of the details if you want your startup to prosper.

Mr Ashish Aggarwal, an Industry Expert and Consultant has laid out 7 most crucial details about startups, including statistics, facts, and trends that will help you give a decent awareness of the universal startup landscape:

1. Dispersion of startups worldwide as per industry - 7.2% of the startups in the world function in the Fintech industry which is followed by the healthcare sector with 6.9%, Artificial intelligence with 4.9%, Gaming industry with 4.7%, Adtech commerce with 3.2%, and Edtech sector with 2.9%. Even though there isn’t entirely accurate data about enterprise dispersion, it’s clear that contemporary startups gravitate more towards the online network, cyberspace, the internet and digital technologies. With this information, we can also discern which industry is adequate for startups at the moment.

2. The valuation of E-Commerce revenues globally is approximately $3.5 trillion - E-Commerce is one out of the most prominent industries for young startups with rapid growth expected in the future. The next enterprise in line is “FinTech” i.e. Financial technology. Another huge focus of new startups is cybersecurity. These companies realize how crucial online security will be in the future. FoodTech combines food and technology and is another famous enterprise for startups. With over $16 billion of investments in 2018, EdTech is coming to be another outstanding startup industry that provides educational technology remedies to people worldwide.

3. Over 68% of startup businesses started as home businesses - The idea has to commence somewhere and form posture. Even though maximum startups don’t have the integral allocation at the onslaught to insulate office expenses, they can launch their operations from home.

4. The ‘sharing economy market' is expected to cross a total revenue of $335 billion by 2025 - In just a matter of a few years, sharing economy startups namely, Airbnb and Uber have grown exponentially and solidified a global existence. At the moment, Airbnb is valued at $24 billion, and Uber is worth $50 billion. In 2014, the total revenue of market sales was $17 billion, which means that in just eight years, the projected earnings of this market grew more than 20 times.

5. AI is presently the most profitable innovation technology -Over 63℅ of entrepreneurs agree that AI, not just presently but for at least the next 10 years is the most prominent technology. The tracts of this technology with the highest potential are autonomous transportation and huge data. Even though these two sectors are already making strides, it’s anticipated that they will flourish substantially in the close future.

6. ByteDance is valued at over $350 billion - The most profitable unicorn company in the world, ByteDance (China) is a tech company that owns Tiktok. There are presently 1000+ Unicorn companies around the world. However, the maximum of them is tracked down in China or the United States.

7. 95% of entrepreneurs that establish startups have at least a bachelor’s degree - Many people claim that education isn’t significant. They talk about Mark Zuckerberg and Elon Musk as instances. However, the majority of the people who birthed the world’s most triumphant startups have a higher education.

Ashish Aggarwal aspires to watch numerous Indian Startup Parents succeed in their entrepreneurial endeavours, which is why he shares his invaluable insights about startups. According to him, The startup industry will persist to be the driving component for global innovation and business development for many years. Nonetheless, companies must learn how to adapt to trends while being endurable and productive so that more startups can withstand the dynamic business environment.

#ashish aggarwal#ashish aggarwal indo innovation#ashish aggarwal acube venture#ashish aggarwal space mnatra

2 notes

·

View notes

Text

Understanding the Key Drivers of Printed Electronics Market and Future Prospects

The global printed electronics market was valued at USD 8.66 billion in 2021 and is projected to grow at a robust compound annual growth rate (CAGR) of 22.3% during the forecast period. This impressive growth can be attributed to the increasing adoption of printed electronic products across various industries, driven by their ability to be integrated into a wide array of dynamic and innovative applications. Notably, sectors such as the Internet of Things (IoT) and consumer electronics are seeing rapid expansion, which has significantly contributed to the demand for printed electronics.

One of the primary factors fueling this growth is the rising penetration of IoT devices. As IoT becomes more ubiquitous, it opens up numerous opportunities for the deployment of printed electronics in a variety of IoT devices, including smart sensors, wearable electronics, and connected products. This broadens the scope of printed electronics, providing a wider range of applications within IoT ecosystems. Furthermore, printed electronics are increasingly being used in consumer electronics, offering unique advantages such as low production costs, higher efficiency, and low power consumption—all of which are essential for the next generation of smart devices.

Another key trend driving the adoption of printed electronics is the growing demand for advanced display technologies, such as Organic Light Emitting Diode (OLED) displays. OLEDs, known for their superior performance and energy efficiency, are increasingly being incorporated into products like smartphones, televisions, and wearable devices. Printed electronics play a crucial role in reducing the production costs of OLED displays, which makes this technology more accessible to manufacturers and ultimately lowers the cost of end products for consumers. Similarly, printed RFID (Radio Frequency Identification) devices are gaining traction due to their affordability, small form factor, and efficient performance, further expanding the applications for printed electronics.

Gather more insights about the market drivers, restrains and growth of the Printed Electronics Market

Regional Insights

The growth of the inkjet printing segment can be largely attributed to the unique advantages of inkjet technology, which includes its compact design, flexibility in printing, and low material consumption. Inkjet technology is characterized by its ability to directly direct ink onto a substrate, ensuring minimal wastage and low initial setup costs. This technology is highly versatile, making it suitable for a variety of applications ranging from prototyping to large-scale industrial production. Since inkjet printing uses minimal ink and produces less material waste, it is a cost-effective solution for many industries, especially in terms of energy efficiency and resource optimization. Additionally, inkjet technology is adaptable, allowing for flexible integration into different stages of the production process, further enhancing its value for manufacturers.

Asia Pacific Market Insights

The Asia Pacific (APAC) region led the global market in 2021, accounting for over 45.00% of the total revenue share. This dominant market share is primarily due to the growing adoption of printed electronics technology in consumer electronics applications. The APAC region is home to some of the largest electronics manufacturing hubs, such as China, South Korea, and Japan, which contribute significantly to the market's expansion. In particular, China plays a key role in the production of consumer electronics, solidifying its position as a major driver of the market. The increasing demand for smart devices, IoT products, and wearable electronics in the region has created a high demand for printed electronics, which are essential for the production of flexible, lightweight, and energy-efficient devices.

Looking forward, the Asia Pacific market is expected to retain its dominant position and grow at the fastest CAGR during the forecast period. This is driven by the rapid development of the electronics manufacturing sector in the region, as well as the continuous technological innovations within the printed electronics space. The region's robust infrastructure and high-tech manufacturing capabilities provide a solid foundation for the adoption of printed electronics across industries such as consumer electronics, automotive, and healthcare. Additionally, the region's proactive approach to research and development (R&D) further contributes to its market leadership.

North America and Europe Market Insights

While Asia Pacific dominates the global printed electronics market, North America and Europe are also expected to see steady growth in the coming years. The growth in these regions is mainly driven by increasing investments in R&D, as well as the growing adoption of printed electronics in diverse industrial applications, such as photovoltaic cells, lighting, and RFID devices.

• In North America, the demand for printed electronics is expanding due to the region's focus on technological advancements and the adoption of innovative solutions. The rise of smart building technologies, solar power applications, and wearable electronics in the U.S. and Canada is significantly driving the demand for printed electronics in these countries.

• In Europe, the market is benefiting from the increasing adoption of eco-friendly technologies, sustainability initiatives, and the growing popularity of consumer electronics. Europe is home to a strong base of technology-driven companies that are keen to adopt cutting-edge solutions like printed electronics. Furthermore, the region's high investments in smart manufacturing and industrial automation are expected to contribute to the steady growth of printed electronics in the coming years.

Browse through Grand View Research's Electronic Devices Industry Research Reports.

• The global broadcast switchers market size was valued at USD 2.39 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2024 to 2030.

• The global inspection camera system market size was valued at USD 390.0 million in 2024 and is expected to grow at a CAGR of 11.2% from 2025 to 2030.

Key Companies & Market Share Insights

Key companies operating in the printed electronics market are focused on expanding their presence across various regions to meet the growing demand from consumers. Many of these companies are targeting emerging markets to broaden their customer base, often through strategic partnerships, acquisitions, and market expansions. To stay competitive in this rapidly evolving market, companies are investing heavily in research and development (R&D), aiming to create innovative products and enhanced printing capabilities. This focus on continuous innovation allows them to maintain a competitive edge in the market.

An example of such a strategic move is E Ink Holdings Inc., which, in April 2021, entered into an agreement with DATA MODUL, a company specializing in touch, display, and embedded monitor solutions. Through this partnership, E Ink Holdings expanded its reach in the U.S. and European markets, particularly focusing on the increasing demand for e-paper and electronic display technologies. Such collaborations highlight the trend of companies leveraging strategic agreements to enhance their market positioning and gain a competitive advantage in the growing printed electronics space.

Some of the prominent players operating in the global printed electronics market are:

• BASF SE

• DuPont

• Molex, Inc.

• PARC, a Xerox company

• E-Ink Holdings, Inc.

• Thin Film Electronics ASA

Order a free sample PDF of the Printed Electronics Market Intelligence Study, published by Grand View Research.

#Printed Electronics Market#Printed Electronics Market Analysis#Printed Electronics Market Report#Printed Electronics Market Regional Insights

0 notes

Text

Manufacturability Design in Rapid Prototyping

Quickly producing physical models or prototypes with additive manufacturing technologies like 3D printing, CNC machining, or other sophisticated fabrication techniques is known as Rapid Prototyping China. With this method, designers may test their ideas, evaluate functionality, and spot problems in their designs early on, which cuts down on development expenses and time-to-market.

Manufacturability-focused design (DFM)

DFM is a collection of best practices and standards for improving a product's design so that it can be manufactured more easily. DFM concepts are as important at the rapid prototyping stage, even though they are typically linked with mass production. Engineers may minimize problems and streamline the prototype process by taking manufacturing restrictions into account early in the design phase.

Essential DFM Takeaways for Quick Prototyping

Material Choice

Select materials that work well with the quick prototyping method you've chosen.

Depending on the planned use, take into account the material's strength, flexibility, and heat resistance.

Complexity of Geometry

Simplify designs to save money and time during manufacture.

Reduce overhangs and complex features, which might be difficult to create using some fast prototyping techniques.

Accuracy and Tolerance

Recognize the dimensional accuracy constraints of the fast Rapid Prototype technique that you have selected.

To guarantee the required precision in the finished prototype, design with the proper tolerances.

Assisting Frameworks

To avoid deformations during fabrication, especially in 3D printing, take into account the essential support structures in the design.

Reduce post-processing work and material waste by optimizing support structures.

Assembly Considerations

Create components that are simple to test and dismantle for adjustments.

When it's feasible, reduce the amount of components to expedite the prototype process.

Time Efficiency Gains from Using DFM in Rapid Prototyping

Designers may expedite the whole prototype phase by avoiding several revisions and delays by addressing manufacturability problems early on.

Lowering of Expenses

During the fast prototype stage, optimal design decisions result in cost savings through effective material consumption and less waste.

Better Cycles of Iterations

Faster design iterations are made possible by the prompt discovery and resolution of manufacturability difficulties, which enable more extensive testing and refinement.

Improved Prototyping Caliber

By keeping DFM principles in mind, you may minimize unforeseen difficulties during testing and validation by ensuring that the final Rapid prototyping manufacturer closely resembles the planned design.

#Rapid prototyping manufacturer#Rapid Prototype#Rapid Prototyping Services#Metal Rapid Prototyping Services#Rapid prototyping Supplier#Rapid Prototyping China#Chinese Rapid Prototyping Services

2 notes

·

View notes

Text

Fast, accurate, and efficient product development is necessary in the fast-paced production environment. This is where plastic injection molding China and rapid prototyping China are useful. These two technologies have completely changed the production process and can greatly improve the design and development of new products when combined.

0 notes

Text

Innovations in China’s Rapid Prototype and Rapid Manufacturing Industries

China has established itself as a global leader in the fields of rapid prototyping and rapid manufacturing, revolutionizing industries with its cutting-edge technologies and efficient processes. These advancements are reshaping product development cycles, reducing time-to-market, and enabling innovative designs across various sectors.

0 notes

Text

Precision in Every Pixel: Exploring the Power of 3D CAD Software

The global 3D CAD software market report provides an in-depth analysis of market segments and sub-segments across multiple regions, covering the period from 2015 to 2023. This comprehensive report evaluates the market trends, growth factors, and projections for the global and regional markets. According to updated forecasts, the global 3D CAD software market is anticipated to grow at a compound annual growth rate (CAGR) of 7.1% during the forecast period from 2023 to 2030, with the market size expected to reach approximately USD 12.4 billion by 2030, up from USD 7.5 billion in 2023.

What is 3D CAD Software?

3D CAD (Computer-Aided Design) software enables engineers, designers, and architects to create, visualize, and modify digital models of physical objects. This software is widely used across various industries—including automotive, aerospace, construction, and consumer goods—for tasks such as product design, prototyping, and structural analysis. The ability to create precise 3D models facilitates enhanced design accuracy, reduces manufacturing errors, and supports efficient product development cycles.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/809

Market Drivers and Growth Factors

Several factors are driving the expansion of the 3D CAD software market:

Increasing Demand in Product Design and Manufacturing: The need for precision in product design and the push towards digital transformation in manufacturing processes have heightened the demand for 3D CAD software. Industries like automotive and aerospace rely on 3D CAD for prototyping, testing, and customization.

Technological Advancements in CAD Tools: Modern CAD tools offer features like cloud integration, augmented reality (AR) support, and artificial intelligence (AI) enhancements, making them more accessible, scalable, and useful in diverse applications.

Rising Adoption in Architecture and Construction: 3D CAD software plays a critical role in building design, structural analysis, and project planning in architecture and construction, supporting intricate designs and efficient planning.

Digital Twin Technology: As industries adopt digital twins for real-time simulations and predictive analytics, demand for advanced 3D CAD software for creating digital replicas of physical assets has increased.

Regional Analysis

North America: North America is a leading market for 3D CAD software due to the high adoption rate in sectors like automotive, aerospace, and construction, with the U.S. playing a dominant role in driving growth.

Europe: Europe holds a significant share in the global market, supported by industries like automotive and industrial machinery. Germany, the UK, and France are notable contributors to this region’s growth.

Asia-Pacific: Asia-Pacific is projected to experience the highest growth rate, driven by rapid industrialization in countries like China, Japan, and India. Increasing adoption in manufacturing and rising demand for automotive and construction applications fuel market expansion.

Rest of the World: Gradual adoption of 3D CAD software in Latin America, the Middle East, and Africa is observed as these regions increase their focus on industrial and architectural development.

Competitive Landscape

The 3D CAD software market is competitive, with major players concentrating on technology innovations, product development, and strategic partnerships:

Autodesk, Inc.: Known for its wide range of CAD solutions, Autodesk offers user-friendly software tools suitable for multiple industries.

Dassault Systèmes: Dassault’s SOLIDWORKS and CATIA platforms are widely used across various industries for high-precision 3D modeling and design.

PTC Inc.: PTC’s CREO platform supports high-performance 3D CAD and offers advanced simulation and augmented reality capabilities.

Siemens PLM Software: Siemens provides NX and Solid Edge software, known for their efficiency in complex design tasks and industrial applications.

Bentley Systems: Bentley specializes in software for infrastructure, catering to construction, transportation, and energy sectors.

Report Overview : https://www.infiniumglobalresearch.com/reports/3d-cad-software-market

Challenges and Opportunities

Challenges: Despite the growth prospects, the 3D CAD software market faces some challenges. High initial costs and ongoing licensing fees can be prohibitive for small and mid-sized enterprises, limiting adoption rates. Additionally, the complexity of some advanced CAD tools often necessitates specialized training, which can increase operational costs and create a learning curve barrier. Compatibility issues among various CAD platforms may also hinder seamless collaboration across projects that involve multiple software systems.

Opportunities: The 3D CAD software market has substantial opportunities for growth through the integration of emerging technologies. For example, the incorporation of AI and machine learning enables CAD tools to suggest design improvements and automate certain processes, enhancing productivity. Cloud-based CAD solutions also present new opportunities by making sophisticated software accessible to remote teams and reducing infrastructure costs.

Conclusion

The global 3D CAD software market is set for steady growth, driven by increasing industrial applications, technological advancements, and expanding adoption in sectors like automotive, aerospace, and construction. The market outlook remains strong with significant growth expected in Asia-Pacific, backed by rapid industrialization and demand for digital solutions across various industries.

0 notes