#racking system for warehouse

Explore tagged Tumblr posts

Text

Enhance Safety and Organization with a Custom Warehouse fit-out

Maximizing Space with a Custom Warehouse Design A well-planned warehouse fit-out can transform your space to make it more efficient and functional. Working with experts like Complete Warehouse Solutions can get a custom design that suits your needs. This includes using high-quality materials and professional installation services to enhance your space and business operations.

Creating Safer and More Comfortable Workspaces A warehouse fit-out can improve worker safety and comfort. You can choose between open-plan offices for a modern look or traditional enclosed offices that offer more privacy. In noisy environments with machines and forklifts, these enclosed offices can be soundproofed to reduce distractions.

Better Supervision with Clear Views By using perimeter partitions with double-glazed windows, managers can have a clear view of the warehouse while keeping noise to a minimum. This setup allows supervisors to easily monitor daily operations without leaving their office.

Designing the Perfect Office for Your Warehouse The offices in your warehouse can be fully customized. You can select from various floor coverings like carpet tiles, vinyl, or timber laminate. For the ceiling, you can choose either plasterboard or drop-in tiles, with thermal insulation added if new air conditioning is being installed.

Furnishing the New Office Spaces To complete the office fit-out, you can include workstations, storage cupboards, meeting tables, shelving systems, and even office seating. For meeting and collaboration purposes, whiteboards and pinboards can also be installed.

Installing Essential Services A fit-out wouldn’t be complete without essential services like air conditioning, fire protection systems, plumbing, and electrical installations. These features ensure that your warehouse is fully equipped to handle day-to-day operations smoothly.

Improving Functionality with Specific Areas A warehouse fit-out can also help you divide your space into specific areas for different tasks. These could include:

Dedicated office spaces

Separate areas for machinery

Restrooms for staff

Control rooms for managing operations

A reception area for visitors

Employee break rooms to relax and recharge

On-site cafeteria or eateries

Conclusion: Enhancing Your Warehouse with a Fit-Out

A well-planned warehouse fit out can greatly improve your business operations efficiency and safety while creating a more comfortable environment for your employees. Complete Warehouse Solutions, serving Lake Illawarra, NSW, is here to help you design and build the perfect fit-out for your warehouse.

#warehouse fit outs#racking system for warehouse#pallet storage warehouse near me#warehouse storage equipment#warehouse fitouts#warehouse fit out costs#property refurbishment#make good services#property refurb#property refurbishments#business

1 note

·

View note

Text

#pallet rack warehouse & supply#pallet rack warehouse#pallet shuttle system#carton flow racking systems#industrial warehouse racking cincinnati ohio

1 note

·

View note

Text

From Floor to Function: Choosing the Right Shelving System in the UAE

Storage isn’t just about putting things away. It’s about how quickly you can find them again. How safely they’re kept. And how well your space works when you’re trying to get orders out the door. Across warehouses and storage facilities in the UAE, one thing is clear: shelves aren’t just background furniture—they’re part of the workflow. Choosing the right shelving system in UAE can change how your business moves, stores, and grows.

1. Understand Your Space Before You Fill It : Before buying racks or adding levels, take a close look at your current layout. How much of your wall height is being used? How much floor space is eaten up by pallets and boxes that could be stacked better? Many businesses in Dubai and Sharjah have tall warehouses but only use the lower half. This means paying rent for air. A good shelving system fixes that. By storing vertically, you get more capacity out of the same space, without needing a bigger building or a new lease.

2. Plan for Movement, Not Just Storage : It’s one thing to store your stock. It’s another to keep your team moving through it without slowing down. The right shelving system helps staff move faster, pick items without confusion, and avoid backtracking. You can organize products by order volume, zone by department, or set up fast-access lanes for popular items. If your shelves cause bottlenecks or block equipment like forklifts, you don’t need more space—you need better layout.

3. Match the Shelving to the Job: Light items, bulky cartons, heavy-duty pallets—they don’t belong on the same type of rack. For general picking and storage, long-span shelving or boltless racks work well. For heavier loads or pallets, go for structured pallet racking. And if you need storage above head height, a rack supported platform in Dubai might be the best fit. Using the wrong system leads to damage, delays, and safety issues. The right system keeps your goods safe—and your team safer.

4. Make Inventory Easier to Handle: Misplaced stock, missed reorders, and expired goods often start with poor shelf setup. Shelves that are clearly marked and logically arranged help staff count faster, rotate smarter, and reduce waste. You don’t need a fancy tracking system—just good visibility, clean labeling, and a structure that makes sense. For companies dealing with food, medicine, or high turnover products, this makes a huge difference.

5. Think Long-Term: Can Your Shelving Grow? : A business that starts with 100 products can grow to 1,000 quickly. If your shelving system can’t grow with you, it holds your business back. That’s why modular systems are smart. You can raise shelf levels, add more racks, or switch sections over to pallet racking in Dubai when heavy loads are involved. It’s flexible, fast, and much cheaper than tearing everything down to rebuild.

Final Thought

Often, when warehouse space feels tight or disorganized, shelving is the first place to look. Fix that, and suddenly things move quicker, errors drop, and your team works with fewer roadblocks. Choosing the right shelving system in UAE is less about buying metal racks and more about building a smarter workflow. ABR Dubai specializes in smart, durable, and scalable shelving solutions. From basic storage racks to custom pallet racking and rack supported platforms, we help businesses across the UAE make the most of their space.

Source: https://www.abrdubai.com/pallet-racking-in-dubai

#Racking System Dubai#Shelving System Dubai#Storage System UAE#Shelving System UAE#Rack Supported Platform Dubai#Pallet Racking Dubai#Storage Racking System UAE#Warehouse Racking Dubai#Warehouse Racking System UAE#Warehouse Shelving Dubai

0 notes

Text

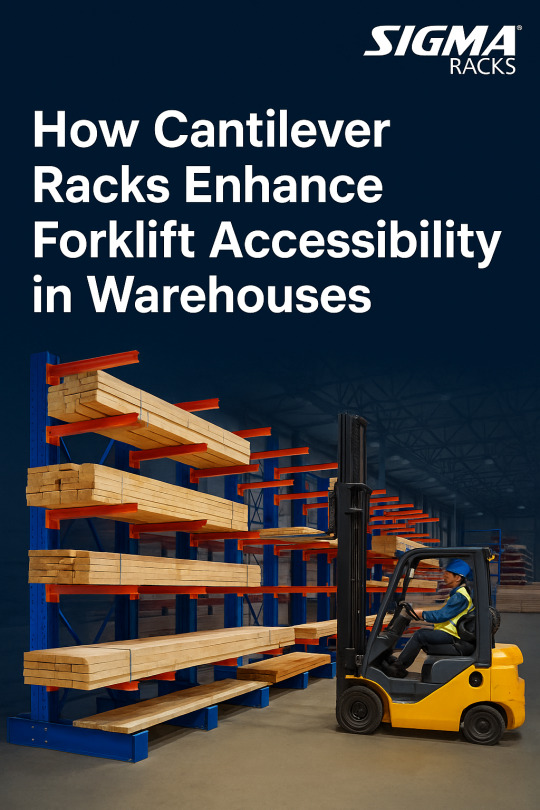

How Cantilever Racks Enhance Forklift Accessibility in Warehouses?

In any warehouse handling long, bulky, or heavy inventory like pipes, wooden panels, metal bars, or construction beams — the storage system must not only be strong but also allow safe and smooth forklift access. That’s where Cantilever Racks prove their true worth.

Unlike traditional pallet racks, cantilever systems are designed with arms extended from vertical columns, leaving the front completely open. This open-front structure provides a clear, obstruction-free path for forklifts to approach, lift, and place inventory without navigating around vertical frames or support beams.

🚜 Faster Loading and Unloading

Time is money in a warehouse — and forklift operators need to move fast and precisely. Cantilever racks eliminate the tight gaps and awkward corners that standard racks often have. Forklift drivers can easily approach from the front, lift long items, and place them directly onto the arms with minimal adjustments. This reduces material handling time, increases turnaround speed, and ensures smoother operations.

🛠️ Safe Handling of Bulky Items

Trying to squeeze long or uneven materials into conventional racks often leads to unsafe stacking and potential product damage. Cantilever racks solve this by offering adjustable arms and wide-open faces, which perfectly accommodate irregular or oversized inventory. This not only prevents damage but also reduces the risk of forklift collisions — one of the leading causes of warehouse accidents.

📦 Better Aisle Planning

Since cantilever racks don’t require deep structures, they can be placed against walls or back-to-back with wide aisles in between. This helps in planning efficient forklift movement paths, reducing travel time and ensuring easy access to inventory without the need for U-turns or complex maneuvers. Your warehouse becomes more organized and navigable — even with high forklift activity.

🧱 Customizable Rack Arms for Forklift Fit

Depending on the type and size of forklifts used in the facility, cantilever racking systems can be designed with custom-length arms and spacing to match specific aisle widths and turning radiuses. This kind of adaptability allows warehouses to optimize their layout for both storage and movement, especially in operations where high volumes and heavy items are moved frequently.

🧠 Less Manual Handling = More Efficiency

In warehouses where forklifts are used properly with the right racking system, manual labor is significantly reduced. Cantilever racks support mechanized movement by allowing forklifts to access every level directly, without needing extra handling or shifting of inventory. This boosts speed and reduces physical strain on staff.

🔧 Built for Real-World Use

Cantilever racks are typically built using powder-coated or galvanized steel with robust base plates — ensuring they stay stable even during repeated forklift use. When installed professionally and planned well, they last for years with minimal maintenance, making them a reliable long-term investment for forklift-heavy warehouses.

✅ Final Thoughts

If your warehouse regularly uses forklifts to store or retrieve long, heavy, or irregular goods — cantilever racks can dramatically improve your speed, safety, and storage efficiency. Their open structure, flexibility, and custom-fit options make them one of the smartest storage solutions for high-volume industrial environments.

#cantilever racks#cantilever racks near me#cantilever racking systems#cantilever racking#industrial storage rack manufacturer#warehousestorage#warehouse storage systems#industrial racking#heavy duty racks

1 note

·

View note

Text

Efficient storage is the backbone of any thriving distribution center, and choosing the right warehouse racking system is the first step toward streamlined operations. From selective pallet racks to high-density flow racks, each solution offers unique advantages depending on inventory turnover, space constraints, and handling equipment. Understanding the differences can help facility managers optimize floor space, improve safety, and boost throughput.

Learn more - https://overheadproductions.net/types-of-warehouse-racking-system-differences-benefits/

0 notes

Text

Pallet Racking Installation: What You Must Know First

Pallet racking installation is a method of arranging sturdy shelves to store heavy goods in a warehouse. A well-planned pallet racking installation will help you store more products. Let’s explore everything about pallet racking installation before you start it.

#Pallet racking#industrial racking systems#warehouse management system#pallet racking system#blog post

0 notes

Text

Why Do You Think Businesses Invest In Top-Quality Storage Racks In Brisbane?

Are you searching for an innovative and efficient storage solution for your business in Brisbane? If so, then storage racks Brisbane offer the right solution for industrial, retail, and warehouse sectors. They are well structured and robustly designed to keep items cohesive and safe in a space-efficient place. The pointers below outline why investing in storage racks Brisbane is smart.

Keeping the available space fully maximised

In Brisbane, you will see industrial centres and retail facilities often face problems with storage, as space is very limited. That is why heavy-duty storage racks are crafted to make the ultimate use of the vertical area. Thus helping businesses to have more open space on the floor. And that will keep the workflow in order. These storage shelves make the best use of space by keeping items upwards instead of storing them outward.

Reliable and designed to handle heavy-duty items

The storage racks Brisbane are designed to handle huge weights, making them ideal for stacking bulk raw items, construction goods, or inventories. Whether you are operating a manufacturing unit or a warehouse, these racks ensure the security of the items, preventing damage and minimizing the chance of goods collapsing.

Ensuring the safety in the workplace remains high

Safety is the ultimate concern of any business, especially when dealing with heavy-duty loads. So, investing in robust storage racks with less chance of workplace casualties is wise. These racks are brilliantly designed, helping to keep items in an orderly manner. Besides, it keeps the walkways ultimately clear. Thus promoting a safer ambiance.

Built to last for a long in different weather conditions

Brisbane is known for its humid climate. Therefore, industries must put their money on top-quality storage racks to keep items safe. Well-built storage racks can bear the wear and tear, thus offering the best performance for a longer duration.

Conclusion

By strategically Including Shelving Racks Brisbane or Archive Shelving, you can ensure long-term value, safety, and productivity. Storage racks' customization, adaptability, and robustness make them indispensable for companies looking to expand sustainably.

#Storage Racks Brisbane#Shelving Racks Brisbane#Pallet Racks Brisbane#Pallet Racking Brisbane#Pallet Racking Shelving#Pallet Racking Systems#Warehouse Racking#Vehicle Racking

0 notes

Text

How Expert Space Planners and Innovative Shop Systems Optimise Inventory Shelving

If there’s one thing retailers dread more than empty shelves, it’s shelves so disorganised they look like a tornado passed through. Luckily, there’s a breed of professionals who have taken it upon themselves to solve this crisis: space planners. Yes, the people who make inventory shelving systems look like they’re curated by an interior designer with an OCD streak. They’re here to ensure that your shop systems aren’t just practical but almost Instagram-worthy—if that’s your thing.

Space Planners: The Unsung Heroes of Retail Spaces

Who are these mysterious space planners, and why should you care? Think of them as the architects of organisation. While you were busy worrying about footfall and profit margins, workspace planners were obsessing over the exact width of your aisles and how to optimise shelf heights to ensure that your customers can reach that last jar of artisanal honey without pulling a muscle.

These experts specialise in marrying functionality with aesthetics. Sure, you could slap a few shelves together and hope for the best. But a professional space planner will consider your inventory type, customer behaviour, and overall layout to make sure your shop not only runs smoothly but also invites customers to linger (and spend more).

Because let’s face it, you’re not just selling products; you’re selling an experience. And if your shelves scream chaos, your customers might scream their way out the door.

The Magic of Shop Systems

Now, let’s talk about shop systems —the backbone of any well-organised retail space. A good shop system does more than hold items; it orchestrates them. From modular shelves to digital inventory trackers, store systems are the unsung multitaskers of retail.

Gone are the days when shelving was just about stacking items vertically. Today’s store systems incorporate innovative features like adjustable racks, integrated lighting, and even IoT-enabled trackers that can alert you when stock runs low. (Because who wants to run out of that one item everyone suddenly decided they couldn’t live without?)

With the right shop system, you can transform your retail space from a cluttered maze to a shopper’s paradise. And guess who can help you choose the perfect system? That’s right—our good friends, the workspace planners.

Why All This Matters

Still not convinced that expert workspace planners, store systems, and inventory shelving solutions deserve your attention? Let’s spell it out:

Efficiency: A well-organised store allows for faster stocking and easier navigation, saving both time and money.

Customer Experience: Shoppers love a store that’s easy to browse. Messy shelves? Not so much.

Sales Boost: Strategic product placement can significantly impact purchasing behaviour.

Brand Perception: Like it or not, your shelves are a reflection of your brand. Sloppy displays suggest a sloppy business.

The Inevitable Truth

You could try to go it alone, improvising your layout and hoping for the best. But do you really want to take that gamble when workspace planners are available to bring order to the chaos?

These professionals understand that inventory shelving solutionsaren’t just about storage; they’re about strategy. They know how to optimise store systems to create an environment that encourages customers to browse, buy, and maybe even come back for more.

Inventory Shelving Systems: The Glue Holding It All Together

If store systems are the backbone, then inventory shelving systems are the glue that holds your retail ecosystem together. A great shelving system isn’t just about where you put things; it’s about how you display them.

Modern inventory shelving solutions are designed to maximise space and accessibility while keeping your products looking their best. Whether it’s gondola shelving for supermarkets or sleek, minimalist racks for high-end boutiques, there’s a shelving system tailored to your needs.

And don’t underestimate the psychological impact of good shelving. Studies have shown that customers are more likely to purchase items that are displayed at eye level or in neatly organised rows. In other words, a well-thought-out shelving system can do half your selling for you.

Wrapping It Up (Neatly, Of Course)

In a world where first impressions can make or break a business, having a well-organised retail space is no longer optional—it’s essential. Expert workspace planners and innovative store systems are your secret weapons in this battle. They help you create a store that not only functions seamlessly but also looks the part.

So, the next time you’re staring at a pile of products and wondering how to make sense of it all, remember this: there’s a better way. And it starts with letting the experts—and their cutting-edge inventory shelving solutions—take the reins.

After all, why settle for good enough when you can have a retail space that’s nothing short of spectacular? Imagine shelves so well-organised that they practically whisper buy me to every passer-by. Picture a store layout so intuitive that customers can navigate it blindfolded (though we don’t recommend testing that). A seamless, efficient, and visually appealing retail space isn’t just a dream; it’s entirely achievable with the right expertise and systems in place.

#shop systems#inventory shelving systems#shopfitting solutions#shelve management systems#shop fitting equipment#shopfitting suppliers#custom fitting solutions#inventory shelving solutions#display shelving solutions#shelving systems#shopfitting warehouse shelves#display shelving systems#inventory systems#inventory rack system#shelving management systems#shop fitting shelving#Inventory shopfitting online#retail shelving display

0 notes

Text

0 notes

Text

Carton Flow Rack Warehouse Equipment

Maximizing Efficiency with Carton Flow Rack Warehouse Equipment

In the fast-paced world of warehousing and distribution, efficiency and organization are key to maximizing productivity. One of the most effective solutions to streamline order picking and inventory management is the use of Carton Flow Rack Warehouse Equipment. These specialized racks are designed to optimize storage and improve picking speed in high-volume, high-turnover environments.

What Are Carton Flow Racks?

Carton flow racks are gravity-fed shelving systems that use roller or wheel tracks to allow cartons and boxes to move smoothly from the loading side to the picking side. The system is slightly inclined, so when a product is picked from the front, the next item automatically flows forward into place. This design supports the First-In, First-Out (FIFO) inventory method, ensuring that older stock is always picked first, reducing product waste and maintaining product integrity.

Benefits of Carton Flow Rack Systems

One of the main advantages of using carton flow racks is their ability to increase order-picking efficiency. By keeping items organized and always within reach, workers spend less time walking, searching, or restocking. This results in faster fulfillment times and improved accuracy.

Carton flow systems also help maximize space utilization. Unlike static shelving, these racks use every inch of vertical and horizontal space, allowing businesses to store more products in the same footprint. This is particularly valuable in warehouses with limited space or those looking to scale operations without expanding their physical footprint.

Applications and Flexibility

These systems are ideal for warehouses, distribution centers, retail backrooms, and manufacturing environments where picking efficiency and organization are crucial. They can be customized to handle a wide variety of box sizes, weights, and product types. Modular designs allow for easy reconfiguration as business needs evolve.

Conclusion

Investing in Carton Flow Rack Warehouse Equipment is a smart move for businesses aiming to boost productivity, improve inventory control, and optimize warehouse operations. With their space-saving design and streamlined picking process, these systems are an essential component of any efficient warehouse.

0 notes

Text

#warehouses#industrial storage racks in noida#industrial racks for warehouses#metalstorage#drive-in racking system#business#slotted angle racks manufacturers#modular mezzanine floor in pune#mezzanine floor structure manufacturers#driveinracking

0 notes

Text

Live from IWS 2025: Sigma Racks Showcases the Future of Warehouse Storage

IWS 2025: Explore Sigma Racks’ Storage Solutions

As the India Warehousing Show 2025 kicks off in full swing at the India International Convention & Expo Centre (IICC), Dwarka, New Delhi — the energy is high, the innovation is everywhere, and Sigma Racks is right at the heart of it all.

As an industry leader in warehouse storage racks, logistics planning, and supply chain solutions, Booth C77 has become the go-to destination for warehouse professionals, logistics planners, and supply chain experts. Sigma Racks is setting a new standard for modern warehousing, with visitors pouring in from FMCG, e-commerce, pharmaceutical, cold storage, and manufacturing fields.

What’s Happening at Sigma Racks — Booth C77

Visit our booth to see how our racking systems solve real-world warehousing problems. From limited space to growing inventory volumes, visitors can see how we combine strength, efficiency, and design precision into every product.

Here’s what you’ll find on display:

Heavy-Duty Pallet Racks: Built for maximum load-bearing with high vertical utilization.

Cantilever Racks: Perfect for long and bulky goods like timber, pipes, and metal bars.

Mezzanine Floors: Demonstrating how you can double usable floor space without expanding the warehouse.

Slotted Angle Racks: Fully adjustable racks for retail, inventory rooms, and lightweight warehousing.

Automated Rack Configurations: CNC-processed components ensuring accuracy, finish, and long service life.

Each system is paired with real warehouse layout plans to help visitors visualize how these solutions will perform in their own spaces.

Real Conversations, Real Needs

From Day 1, we’ve been engaging with operations heads, supply chain managers, architects, and even startup founders — all facing similar challenges: limited space, inconsistent storage, and rising fulfillment pressure.

And guess what? They’re not just browsing — they’re asking the right questions:

“Can these racks be customized to my SKU size?”

“How much load can a mezzanine floor hold?”

“Can I automate storage in a 1000 sq. ft. space?”

In these interactions, Sigma Racks has demonstrated the importance of exhibitions such as IWS. They bring decision-makers face-to-face with problem-solvers, and Sigma Racks provides solution-driven clarity, innovation, and truthfulness.

Designed for India, Built to Last

Our products are proudly manufactured in India using automated machinery that assures uniform strength, alignment, and finish. With factory-direct pricing and in-house engineers, visitors are surprised to discover that “premium quality” does not always mean “premium pricing.”

Our systems are specifically built to handle the real-life challenges of Indian warehousing:

Humidity-prone zones

Irregular flooring

High-density inventory

Quick restocking cycles

Whether you’re storing pharma stock in Hyderabad, grocery inventory in Mumbai, or auto parts in Gurugram — our racks are built to perform.

The Future Is Vertical (and Modular)

As industry trends shift towards vertical expansion and space-efficient storage, multi-tier racking systems, mezzanine floors, and modular racks are becoming the talk of the show. Visitors are impressed by how Sigma Racks integrates these formats into customized warehouse layouts — without disrupting existing operations.

They’re realizing that the future of warehousing isn’t just automation — it’s smart space design backed by precision-built infrastructure.

Why Warehouse Owners Are Stopping at Booth C77

Aside from the engineering brilliance, what’s drawing people in is:

1-on-1 consultations with technical experts

Live demos on racking strength and modularity

Ready-to-go layout options for various industries

Transparent talk on pricing and timelines

On-the-spot lead generation and follow-ups

If you’re visiting IWS 2025, this is where you get ideas — and real solutions.

Don’t Miss Your Window

IWS 2025 runs till June 28, and Sigma Racks is just getting started. Whether you’re redesigning your storage facility, upgrading to automation, or planning a new warehouse altogether — now’s the time to experience what reliable, future-ready storage looks like.

Visit Booth C77 at India International Convention and Expo Centre (IICC), Dwarka, New Delhi

Dates: June 26–28, 2025

Explore more: www.sigmastorage.com

Sigma Racks isn’t just showcasing racks — we’re building the backbone of India’s warehousing revolution. See it live. Talk to the team. And reimagine your storage, the smart way.

#pallet racking systems#industrial racking#mezzanine floor systems#cantilever racks#slotted angle racks#modular warehouse design#warehouse layout solutions#warehouse space optimization#warehouse racking solutions#automated racking systems

0 notes

Text

How to Choose Industrial Pallet Racking That Is Best for Your Needs

Product weight, warehouse design, cost, and scalability must all be considered when choosing industrial pallet racking. Effective planning helps firms maximize storage and simplify processes for future expansion by ensuring efficiency, safety, and long-term cost-effectiveness.

#industrial pallet racking#industrial racking for sale#industrial racking systems#industrial warehouse racking

0 notes

Text

An efficient warehouse is critical to ensuring smooth operations and meeting business objectives. A properly designed warehouse racking system serves as a key component in maximizing productivity while utilizing space effectively. Upgrading these systems can drastically improve storage capacity, enhance accessibility, and streamline workflow. With warehouses facing demands like increased inventory and faster order fulfillment, investing in professional upgrades becomes a smart choice for long-term success. By tailoring the racking system to suit evolving business needs, companies can create an optimized storage solution that drives both efficiency and profitability.

Learn more - https://fondsectorb.com/how-warehouse-racking-system-upgrades-boost-productivity/

0 notes

Text

Does Your Business Require Industrial Racking? Discover Now!

Industrial racking is a greater category of heavy-duty storage equipment that is applied in warehouses, factories, and other industrial settings. Learn how industrial racking can maximize space, enhance organization. Find out if your business requires it and how to select the correct system.

0 notes

Text

Why Do You Need To Install The Adjustable Warehouse Racking System?

Discover why installing an adjustable warehouse racking system is essential for efficient storage. Maximize space, improve organization, and enhance accessibility with flexible racking solutions. Easily adapt to changing inventory needs, boost productivity, and streamline operations. Upgrade your warehouse with adjustable racking for smarter, safer, and more efficient storage management.

0 notes