#drive-in racking system

Explore tagged Tumblr posts

Text

#warehouses#industrial storage racks in noida#industrial racks for warehouses#metalstorage#drive-in racking system#business#slotted angle racks manufacturers#modular mezzanine floor in pune#mezzanine floor structure manufacturers#driveinracking

0 notes

Text

How to Choose the Right Mezzanine Floor Installers for Your Warehouse

Choosing the right mezzanine floor installers for a warehouse is a critical decision that can significantly influence the efficiency and functionality of the space. A mezzanine can maximize storage capacity, create additional office space, or facilitate better workflow. However, the success of these benefits hinges on the quality of the installation. Thus, understanding the key factors that contribute to selecting the right professionals for the job is essential for warehouse managers and business owners alike.

Understanding Your Warehouse Needs

Before diving into the selection process, it is important to assess the specific needs of the warehouse. Each facility has unique characteristics that must be considered. For instance, the height of the existing structure, the weight capacity required, and the purpose of the mezzanine all play crucial roles in determining the best type of installation. Warehouse managers should conduct a thorough analysis of the space, taking measurements and identifying potential obstacles that could hinder installation.

After identifying these needs, it becomes essential to look for mezzanine floor installers who have experience in handling similar projects. A contractor with a proven track record in the specific type of mezzanine required will be better equipped to navigate challenges that may arise during the installation process. This is where research comes into play. Reading reviews, asking for references, and checking the installers’ previous work can provide insight into their reliability and quality of service.

Evaluating Installer Qualifications and Experience

When it comes to hiring mezzanine floor installers, qualifications and experience should be at the forefront of the selection criteria. It is advisable to look for installers who are certified and adhere to industry standards. This not only ensures compliance with safety regulations but also reflects a commitment to quality workmanship. Experienced installers will bring a wealth of knowledge to the project, capable of anticipating challenges and offering solutions that a less experienced contractor might overlook.

Moreover, the installation process should be handled by professionals familiar with the specific materials and technologies involved in mezzanine construction. An installer with a diversified portfolio that includes various types of mezzanine systems will likely have the expertise necessary to address the unique demands of each project. This breadth of experience can be the difference between a successful installation and one that leads to costly mistakes.

Importance of Customization and Design

One of the key advantages of mezzanine flooring is the ability to customize the design to fit the specific needs of the warehouse. This means that the mezzanine floor installers should not only be skilled in construction but also in design. They should work collaboratively with the warehouse management team to create a structure that maximizes space efficiency while aligning with operational workflows.

A good installer will offer a range of design options and be willing to adapt to changes in layout or function as required. They should also understand the importance of integrating the mezzanine with existing systems, such as lighting, HVAC, and fire safety measures. This holistic approach to design ensures that the new mezzanine floor not only fits within the warehouse but enhances its overall functionality.

Safety and Compliance Considerations

Safety is paramount in any construction project, especially in a busy warehouse environment. The chosen mezzanine floor installers must prioritize safety measures throughout the installation process. This includes ensuring that all materials used are up to code and suitable for the intended use of the mezzanine. Additionally, the installation team should follow strict safety protocols to protect both their workers and the warehouse staff during construction.

Moreover, compliance with local building codes and regulations cannot be overlooked. A reputable installer will be familiar with the necessary permits and inspections required to complete the installation legally. This not only helps avoid fines and project delays but also ensures that the newly installed mezzanine will pass all safety inspections, providing peace of mind for warehouse operators.

Post-Installation Support and Maintenance

The relationship with the mezzanine floor installers should not end once the project is completed. A reliable contractor will offer post-installation support and maintenance services to ensure the longevity of the mezzanine structure. Regular inspections and maintenance checks can help identify any potential issues before they escalate into costly repairs.

Furthermore, some installers may provide warranties on their work, which can be an essential factor in the decision-making process. This warranty serves as a safeguard against defects or problems that may arise after the installation. A commitment to ongoing support can significantly enhance the overall value of the investment in the mezzanine floor.

Conclusion

Selecting the right mezzanine floor installers for a warehouse is a multifaceted process that requires careful consideration of various factors, including the specific needs of the facility, the qualifications and experience of the installers, customization options, safety compliance, and post-installation support. By taking the time to evaluate these elements, warehouse managers can ensure they choose a contractor who will deliver a high-quality, functional mezzanine that enhances their operational efficiency.

For businesses looking for expert guidance and top-notch installation services, partnering with a reputable company like Dalvie Systems can provide the assurance needed for a successful mezzanine project. Their commitment to quality and customer satisfaction makes them an ideal choice for any warehouse needing mezzanine floor installation.

0 notes

Text

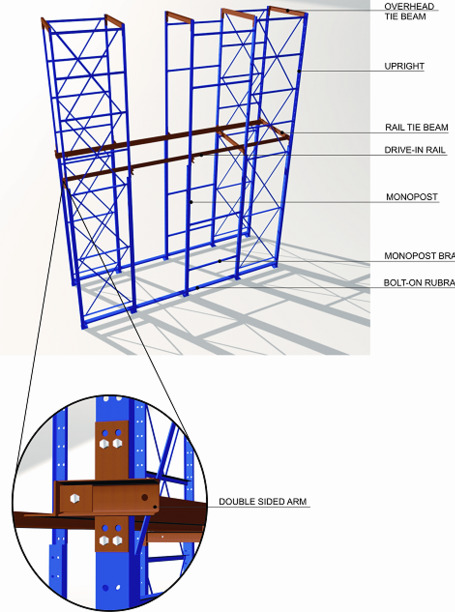

#Drive-In Pallet Racking is installed in warehouses and distribution centers that need a cost effective#high density storage solution for their products.Drive-in systems can be designed to store 2 to 10 pallets deep per lane. Because of its de#drive-in pallet rack is a first in#last out (FILO) storage system.

0 notes

Text

The Drive-In Racking system is an excellent solution for maximizing warehouse storage in high-density environments. Designed for storing large quantities of similar products, this system allows forklifts to drive directly into the rack structure, enabling deep storage of pallets in lanes. With no need for individual access aisles for each pallet, Drive-In Racking optimizes space by allowing more goods to be stored in a smaller area. It’s ideal for industries with high-volume, low-rotation products, such as cold storage and food processing. Eurorack’s Drive-In Racking is built to handle heavy loads while ensuring stability and safety.

#drive in racking system#pallet racking system#drive in racks#drive thru racking system#storage racking system#heavy duty racks#eurorack#warehouse racking system#eurorack drive in racks

1 note

·

View note

Text

Optimizing Storage Solutions with Drive-In Racking in UAE - A Focus on Storewell Shelves UAE

Introduction: In the dynamic landscape of warehousing and storage solutions, the UAE has witnessed a significant surge in demand for efficient and space-saving storage systems. One such innovative solution gaining prominence is Drive-In Racking. In this blog post, we will explore the benefits of Drive-In Racking in the UAE context, with a special focus on the offerings by Storewell Shelves UAE.

Understanding Drive-In Racking:

Drive-In Racking in UAE is a specialized storage system designed to maximize warehouse space by eliminating aisles. Instead of traditional rack configurations, this system allows forklifts to enter the storage lanes, providing direct access to pallets stored on both sides. This unique design ensures high-density storage, making it an ideal choice for businesses dealing with large quantities of homogeneous products.

Benefits of Drive-In Racking in the UAE:

Space Optimization: Given the premium on real estate in the UAE, Drive-In Racking offers an efficient solution by maximizing the use of available space. The elimination of aisles means more pallets can be stored in the same footprint.

Cost-Effective: With the ability to store more products in a smaller space, businesses can benefit from reduced operational costs. The cost per pallet position is significantly lower compared to traditional racking systems.

Ideal for Bulk Storage: Drive-In Racking is particularly suitable for businesses dealing with bulk quantities of similar products. It is commonly used in industries such as food and beverage, manufacturing, and cold storage.

Increased Throughput: The direct access provided by Drive-In Racking enhances the efficiency of inventory management. Forklifts can easily maneuver within the storage lanes, leading to quicker loading and unloading times.

Storewell Shelves UAE: Tailoring Storage Solutions to Your Needs Amid the growing demand for innovative storage solutions in the UAE, Storewell Shelves UAE has emerged as a reliable provider of Drive-In Racking systems. With a commitment to delivering high-quality storage solutions, Storewell Shelves UAE stands out in the competitive market.

Customization: Storewell Shelves UAE understands that every business has unique storage requirements. Their Drive-In Racking systems can be customized to accommodate specific pallet sizes, weight capacities, and storage configurations.

Quality Assurance: Ensuring the durability and reliability of their products, Storewell Shelves UAE adheres to international quality standards. Their Drive-In Racking systems are built to withstand the rigors of heavy-duty storage operations.

Expert Consultation: The team at Storewell Shelves UAE comprises storage experts who can provide valuable insights into optimizing warehouse layouts and selecting the most suitable storage solutions for your business.

Conclusion: As businesses in the UAE strive to enhance their storage capacities while minimizing operational costs, Drive-In Racking emerges as a compelling solution. Storewell Shelves UAE, with its commitment to quality and customization, proves to be a trusted partner in meeting the evolving storage needs of businesses across various industries in the UAE. Investing in Drive-In Racking in UAE from Storewell Shelves could be the key to unlocking a more efficient and space-conscious storage strategy for your business.

Contact Us:

Mobile Number (+971) 56 3848680 (+971) 56 8576009 Tel : (+971) 6 5643021

Office Address Industrial Area Jurf-Ajman-U.A.E

0 notes

Text

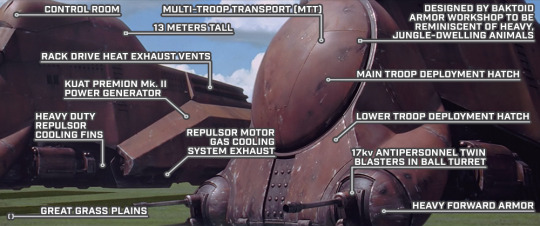

Multi-Troop Transports

STAR WARS EPISODE I: The Phantom Menace 01:48:40

#Star Wars#Episode I#The Phantom Menace#Naboo#Great Grass Plains#Battle of Naboo#Battle of the Great Grass Plains#control room#Multi-Troop Transport#MTT#rack drive heat exhaust vent#Kuat Drive Yards#Premion Mk. II power generator#heavy duty repulsor cooling fin#repuslor motor gas cooling system exhaust#Baktoid Armor Workshop#main troop deployment hatch#lower troop deployment hatch#17kv antipersonnel twin blasters#heavy forward armor

1 note

·

View note

Text

Revolutionizing Storage: The Advantages of Push Back Racking Systems

Push Back Racking Systems have transformed the landscape of storage and inventory management, offering an unparalleled efficiency in maximizing warehouse space. Unlike traditional racks, Push Back Racks can store up to six pallets deep, boosting storage capacity by 25-30% more than selective racking systems. This leap in efficiency is achieved through an innovative design: pallets rest on wheeled carts that glide along inclined rails, enabling deep storage without necessitating multiple aisles.

See More: https://camaraindustries.com/revolutionizing-storage-the-advantages-of-push-back-racking-systems/

0 notes

Text

Compactor Storage Systems Manufacturer In Pune – Max Space

Max Space Racking Systems is a leading compactor storage systems manufacturer in Pune. Explore our space-saving solutions for efficient storage. In a world where efficient storage solutions are paramount, Max Space Racking Systems emerges as a trusted compactor storage systems manufacturer in Pune, India. Compactor storage systems are a vital component of modern storage solutions. They offer a space-saving and highly organized way to store a wide range of items, from documents and files to goods in warehouses and distribution centers.

#Compactor Storage Systems Manufacturer in Pune#Design & Manufacturing Of Racking System in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer#Cantilever#Racks Manufacturer#Racks for Bobbin / Rolls Manufacturer

0 notes

Text

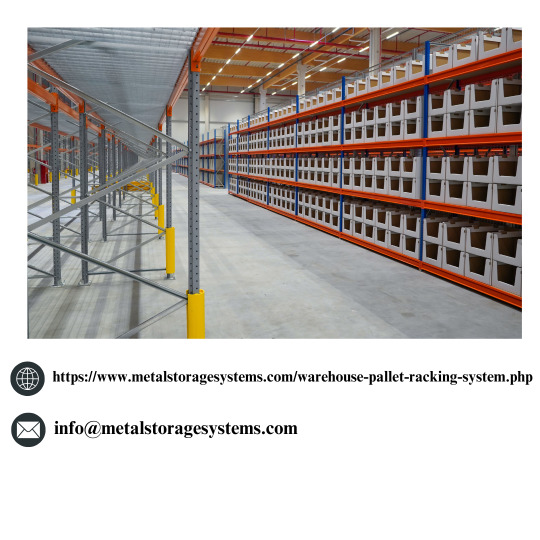

Visit us: https://www.metalstoragesystems.com/warehouse-pallet-racking-system.php

Phone: +91 9845103088

Mail: [email protected]

#warehouses#industrial racks for warehouses#mezzanine floor structure manufacturers#business#metalstorage#industrial storage racks in noida#drive-in racking system#slotted angle racks manufacturers#modular mezzanine floor in pune

0 notes

Text

MEX Storage Systems Pvt. Ltd., based in Noida, is a highly reputable manufacturer of top-quality Heavy Duty Storage Rack. Our range of products includes Heavy Duty Panel Racks, Storage Systems, Slotted Angle Racks, MS Pallet Racks, Drive In Racking Systems, Pallet Racking Systems, and more. Our dedicated team is committed to providing you with exceptional products that meet and exceed your expectations. With a focus on delivering real-time quality, we strive to be your trusted partner for all your storage needs.

#Heavy Duty Storage Rack#Heavy Duty Panel Racks#Storage Systems#Slotted Angle Racks#MS Pallet Racks#Drive In Racking Systems#Pallet Racking Systems

0 notes

Text

Maximize your warehouse space with pallet racks. Pallet Racking offers efficient, economical use of floor space and unused over head space.

#pallet racking#pallet shuttle system#pallet rack warehouse & supply#pallet rack warehouse#rack and pinion drive system

0 notes

Text

(alpha sae x omega reader // hurt/comfort // WC: ~1.9k // minors dni)

sae wakes up alone.

it's late, early morning, probably. he doesn't bother checking his phone, the relative silence of the cityscape outside tells him enough. your bedroom nearly pitch black. aside from faint light slipping in from under the door of the en suite bathroom, the room is still and the corners shadowy.

sae doesn't enjoy waking up alone.

it feels wrong, these days. like he's missing a limb. the other side of your bed is empty and almost cold. the duvet and sheets are pushed down to the foot of the bed in a rumpled pile. your scent is all over the apartment, this room, and especially this bed, but it's still too faint. without you in this bed, it's too faint. it's unnatural for it to be so faint, this later at night— early in the morning, when you should be tucked into his side as you belong.

sae peels himself out of bed enough to sit up, rubbing at his cheeks. he thumbs over the (oh so controversial) claim bite on the base of his throat. the etch of your teeth laid into him forever. it's a romantic gesture, at least you think so. your thinking has rubbed off on him— at least a little.

sae already knows where you are. he's known since the moment he realized you weren't beside him where you'd be.

his nose guides through the dark, padding lightly and carefully across the hard flooring. he pauses in front of the door to the ensuite. your scent, distressed and louder than it should be in sleep, curls out from the room in waves.

the door to the ensuite opens almost silently.

the only light in the room pours off from a little nightlight, plugged in near the sink. it's some round cat-like character you think is very cute but sae thinks is kind of stupid looking, but sae loves you, and would do anything for you, so he loves the nightlight just as much as you do. it's nights like tonight where is very grateful for its slowly morphing rainbow of colors, pouring out over the space, just enough that sae can see you across the room.

'maladaptive omegan behaviors' weren't something sae was very familiar with, prior to seeing you (accidentally), courting you (intentionally) and mating you (very intentionally). he'd maybe heard the term tossed around in passing and on social media, but he never dug further into it. he didn't see himself taking a mate, so it didn't seem worth knowing about, especially since most of his peers were alphas just like him.

when you started letting sae into your nest, he had to learn quickly.

omegas with rough upbringings, whose mothers had difficult or traumatic pregnancies, and those with chronic physical illness often developed these behaviors. dysregulated systems, desperately trying to regulate themselves in the way that were taught— which is to say they were often taught incorrectly or not taught at all. it spawned into lists of behaviors associated with diagnosable criteria that sae could, if asked, probably recite from memory.

low scent production and a lack of scenting instinct. bite risk. inflamed scent glands outside of heat cycles. isolation drive and the subsequent isolation sickness.

the dysregulated trait you struggled the most with, though, was the maladaptive nesting behavior.

you lay in the large bathtub, curled up tightly into a ball, your forehead near your knees. thrown over you are an assortment of unused blankets from the nearby linen closet and towels dragged down from the nearby warming rack. sae knows that some are still probably damp, given you shared a shower before bed. your head is only supported on your folded hands. you look very sad and very small.

sae hates to see you like this.

he knows you can't help it. you've explained to him before, that sometimes— this just happens. you wake up in a cold sweat, panicked, and— you just can't be where you are in that moment. you struggle to describe the specific feeling, what drives you. it frustrates sae, because he needs to understand to help. but he never holds it against you (how could he?) even with what you are able to give him, sae gleans a little more each time you choose to confide in him.

slowly and gently, he reaches out to run a few fingers over your temples. you barely flinch, probably half-awake.

"baby," he says softly. his own voice surprises him on these nights. he never knew it could become so soft and entirely yours.

you're quiet for a moment, before turning into your damp nest. "... hi."

"not feeling so good?"

"'s fine now." your words slur with exhaustion. you've had a big week, you both have, between games, travel, and the media circus you somehow put up with. "go back to bed, sae."

"you know the rules." he scratches along your hairline. "not without you."

there's room in that bathtub for the both of you, if you refuse to leave. otherwise sae will sleep on the bathmat. he doesn't care.

something about the size of the bathroom and the depth of the bathtub makes you less scared. that's hard to emulate on a king-sized bed, no matter how well you make your nest and how long you fuss over it.

you glare at him, a little wet in the eyes, before hiding back in your makeshift nest.

he could, theoretically, reach over the lip of the bathtub and extract you himself. and he could probably hold you tightly enough and long enough that you feel safe, even in your nest that doesn't. he's your alpha, that's his job, one he likes—

but that's also not what he wants to do.

sae does lean over the edge of the bath and press his lips to your hairline before leaving you there.

see, you do this often. often enough that sae has poured through articles and reddit posts between rewatching his own matches to look for ways to help. to ease. it's not— in his nature, this type of helping. if not having you near is like missing a limb, learning to help you with your maladaptive behaviors is like exercising a underused one.

sae found a particular reddit post that seemed promising. a product recommendation that was out of budget for most folks, but sae has too much fucking money, and if his money isn't good for this, then what is it good for?

he knees down beside the bed and pulls out a parcel.

it takes him a moment, two, ten, to wrangle it out of the package. it's a frame of sorts, made of a metal-like, lightweight material. it comes with a set of straps too. the metal pieces come dissembled, and once assembled, become two poles and connecting between them. he deftly secures one pole to each of the posts of your bedframe with the straps, pulling them tight and taut so the poles are flush. the connecting bit spans between the bed posts, high, taller than sae if he were kneeling on the mattress. the frame itself rises over the top half of the bed, and slopes with another set of support poles to the bottom.

over it, sae hangs a sheet, one he's been scenting himself in secret, knowing that this exact event would occur. it drapes down over all sides of the bed, making enclosure, yet airy space. there's a string of LED, no heat lights that came with the frame that he strings along the outside, dappling the inside of the space in warm light.

sae is an alpha, so he doesn't have the same sense for nestmaking as an omega would. he does try, because he loves you, and fluffs up pillows and rearranges things to look more inviting. he only goes to get you when he is certain things are as good as he can get them.

you're sleepier when he fetches you from the bathtub, easier to coax out with the promise of a glass of water and skinship. you don't fight him, even on night's when the need to hide here is more violent and panic-inducing for you. the trust you give sae is implicit and seemingly endless. it is important that he covets it.

presenting you the frame, draped sheet, and cute lights, you blink at the structure.

"... a fort?"

"it's called a nest hide."

"who calls it that?"

"reddit."

you snort and press your nose into his bicep. you're all wrapped around of of his arms, clinging to him. he thinks, if you asked him a few years ago if he would like this kind of thing, he would've said no. deadpanned because he couldn't imagine ever enjoying this much contact with anyone casually. now, however? he craves it with you so much, that he hasn't gone to a single away game alone for god knows how long. his teammates tease sae about how you have him wrapped around you finger, and he doesn't fight them on it. it's true; he is.

you both clamor into bed, your nest, you first and him second, after allowing you to adjust the nest accordingly. it doesn't take you as long as it did earlier in the evening. you lean over the edge of the bed and pick up a forgotten friend, a plush of the same pudgy character as the nightlight. you set it next to fluffed pillows and preen.

your scent has bloomed, stronger than it was, more content. he can tell you're still tired, so tired, and your scent reveals your exhaustion easily.

"c'mere?" you tell him, once you're done, extending a hand to him.

sae takes your hand, he always will.

it's easy then, to settle together under your mutual favorite blanket, a soft knit thing sae's grandmother made for you after sae's claim became public knowledge. she thanked you for 'finally making that boy settle down some' which sae didn't agree with at the time, but now he does. you've domesticated him a bit, and he wouldn't trade that for much at all.

you lay, facing each other, as sae stretches to shut the string lights off. in an instant, you're completely wrapped around each other. your forehead it cushioned against his chest, his arms around your waist, legs tangled. it's so good. far better than a bathtub.

"... thank you, sae," you say, softly. half-spoken into the his bare chest, and half into the still of your shared.

"there's nothing to thank me for." he huffs a little, just enough that you laugh lightly. "i like making sure you're comfortable."

it's as simple as that. it's always been that simple with you, and you make things easy to be simple. it's a privilege, he has come to realize.

"well, you're very comfy." you hum, voice wavering with sleep. "still."

as a final act, before you fall properly and fully asleep until sae deigns to wake you the next morning, you lay a kiss over his claim bite scar. your scents mingle, mix, and roll over the space. you're— so very good at drawing such a fragrance out of him. sun-warm, earthy, all him. it tangles with your own.

he thumbs over your own scar, once he watches you fall asleep, peaceful and as hale as you can be, and safe, and thinks that he'd do far more than built some little safe haven for you, if he could. if he needed to, he'd move the world.

sae lays a kiss on your forehead, nuzzling there, with only quiet night song of the city to witness his most vulnerable affections.

#lore writes#drabbles#sae itoshi x reader#wrote this in a cold sweat#this idea has been on my brain all day#sae would be a very good alpha 🙂↕️ he's just gonna be doing some learning along with u#tw omegaverse

200 notes

·

View notes

Text

Back a Ways Part Two

Part One | Part Three

Notes: I lied it's going to be three parts but part three is also getting posted tonight so y'all don't have to wait

Pairing: Dr. Jack Abbott x Surgeon!Reader

Length: 3.7K

Rating: M

Warnings: Fluff; angst; yearning; cursing; slow burn

Summary: "Why would Jack disapprove? Matter of fact—” Everett folds his arms on the table, “Why would Jack care?”

What the hell can you tell Everett? That it’s just a feeling, a hunch? That the way Jack eyed you when you were talking to Dana had been nearly as intimidating as the only time you went against his direct orders when you were a resident?

u can come over

It’s as close as your brother gets to issuing invitations these days. From what you can gather, Everett only sees people a couple of times a week—your parents, and Jack, and a few of the friends he made at the academy. He’s never been the most outgoing guy, but he’d grown more and more reclusive since he’d been honorably discharged. The traumatic brain injury that he’d sustained while serving had only made the scope of who he dealt with on a daily basis even more narrow.

Everett has never tried to explain to you what had happened while he was on active duty. Jack has only made you privy to a thing or two, but you know that he doesn’t want to betray your brother’s confidences.

Pulling up to Everett’s house and seeing Jack’s car in the driveway almost makes you drive away. You haven’t seen him since Dana ratted you out about Wilkins in the ER; haven’t spoken to or texted him since then, either. You consider it as the car idles, your hands twisting on the steering wheel. It’s possible that neither of the guys know you’re out there. Everett likes to have visitors out on his back patio when they come over—having too many people in his house makes him feel ‘penned in.’

But, this is the first time in months that Everett has given you the green light to see him.

You grudgingly pull your car into the parking space in front of his house. You use the spare key to get into the house, kicking your shoes off as you look around. The living room is neat as a pin—mail is stacked on the living room table, sorted into two piles; the couch looks like it hasn’t been sat on for weeks; there’s not a speck of dust in sight.

You look down at your shoes, considering putting them properly on the rack with the others…And then leave them on the floor by the door. It’s a minor show of protest in the face of Everett’s near-compulsive need for order. He’d always been an oddly neat kid, and his time in the military had cemented a hatred for any hint of mess. You reach out, pushing one of the pillows over on the couch before you head into the kitchen.

The coffee pot is nearly empty, and looking into his cabinet, you see two of his mugs missing. You begin to brew a fresh pot before you turn, walking down the hall to the back patio. You peer through the window, catching sight of the back of your brother’s head, and Jack sitting across from him.

You know that the movement has caught his attention when Jack’s focus flickers to you. His gaze doesn’t hold for long as he meets Everett’s eye again, reaching for his mug. You consider going out, but hell—you’ve had a long night, and you don’t think you can face your brother without coffee in your system…Maybe something stronger. If you remember rightly, Everett tends to keep whiskey in the cabinet.

--

“You gonna hide in here all morning?”

You roll your eyes at the question, not bothering to turn as Jack sidles up to you at the counter.

“It’s been five minutes—and I was making more coffee.”

Jack grunts, bracing his hands on the cool formica. You let your eyes sweep over his hands, savoring the heat of him next to you.

“...He doing okay?”

“The same.”

“Mm,” You nod.

“A little better, maybe.”

“Oh?”

“Sure.” Jack turns, tucking his hands into his pockets as he props his hips against the counter. “You know he’s dating someone?”

It surprises the hell out of you, and you don’t bother to hide it.

“Really?”

“Mhm. Something else the two of you seem to have in common these days.”

It’s a fact, but it feels like an accusation. A hundred answers sit on your tongue—David is a nice guy, someone who understands what you do (but so is Jack); you haven’t been out with anyone for a while, you’re just shaking the dust off (when was the last time Jack went on a date?); you can’t just twiddle your thumbs and wait for a man that will never see you that way���

“Jeez, Queenie—The hell did you do?”

His tired question snaps you out of your spiral, and before you can ask what he’s talking about, he’s stepping out of the kitchen and neatening the nudged pillow. You watch, amused, as he reaches down, putting your shoes away properly.

“Everett needs some mess in his life," You insist. "It’d be good for him.”

Jack grunts as he straightens. “Last thing I need is the two of you at each other’s throats all morning.”

“All morning is a stretch. I’m probably not staying long.”

“No?” His hands tuck back into his pockets as he joins you again. You eye the counter as he faces away from it, picturing his hands pressed there just a moment ago. You’ve thought of those hands a lot of other places—on your hips, sliding under your shirt—

“Night shift getting to you?” He plies.

He doesn’t realize he’s offered you an easy out. You nod, raising a hand and scrubbing it across your eyes for emphasis. Jack grunts in sympathy.

“How’s it been?”

“You know how it is.”

“...Yeah.” Jack nods, shifts beside you again. “You ever regret it?”

“Regret what?”

“Switching to surgery.”

Your brow furrows, a frown pulling at your lips. It’s the first time Jack has spoken to you about your decision, years since you’d sat him down and told him that you’d be switching to a surgical residency and needed his support.

“No. Not once. I…” You trail off, trying to nail your thoughts down as you turn to lean back against the counter. “Being in the ER isn’t for me, Jack. I never got my footing.”

“You kidding me?”

“No, I’m not, and I wasn’t—”

“Queenie—”

“No, Jack. I don’t want you to bullshit me. Not about this.”

Jack is quiet for a moment. You can see the steady waggle of his head as he shakes it, hear him draw in a deep breath.

“I liked it better when you were down where I could keep an eye on you.”

Your heart stutters in your chest, and you can’t stop your rush to get a better look at him. Jack’s head is bowed slightly, lips pursed into a thin line. He doesn’t look at you as he adds:

“When you came to the Pitt, I promised your brother I’d look out for you.”

You just manage to stifle a deprecating, humorless laugh, staring blankly at the cabinet across from you. Of course.

“You’ve made too many promises to that man, Jack. Hell, he’s my brother, I don't even heed him like that.”

“....It’s different.”

And you can’t argue with that. You have a love-hate relationship with your brother, give the man shit, but he and Jack went through hell together. The worst that you had to face with Everett was a united front when he’d broken one of your mother’s favorite vases, and you’d recognized the abject terror on his face (you’d been able to convince her that it had been the dog; Everett had bought your silence with three months’ worth of his allowance money).

“Yeah,” You nod, “It is.” You nudge his arm with yours. “If you’re really that worried, you could come up and see how I’m doing sometime.”

“Right, with the mountain of free time I have.”

“You take bathroom breaks occasionally, right? Come take one upstairs. They can do without you for a couple of minutes.”

“Maybe you come back down, see how you do.”

“What’d I just say about the ER?”

“That was before. You were a resident back then, Queenie. Your instincts are different now, your knowledge is stronger, your reflexes are faster.”

Your mouth works wordlessly for a moment before you shake your head, pushing out a disbelieving laugh.

“Why won’t you let this go?”

“Because it drives me nuts that you don’t see what I see.”

“And what’s that.”

“A brilliant, capable doctor—and a badass.”

His gaze sears yours and you freeze, caught in the intensity that he watches you with. You don’t blink; you’re not entirely sure that you’re even breathing. Jack shifts, and your heart thuds as he turns to face you more fully. He takes one step, and then another, until he’s so close that you can feel the heat radiating off of his body, smell the crisp scent of his body wash.

“You’ve always had it, Queenie,” He murmurs, “But you never gave yourself any goddamn grace.”

Your mouth works wordlessly as you flounder for a reply, stunned heat creeping up your neck and sweeping across your face. Jack’s eyes seem to flicker in focus between your eyes and your mouth, and in the split-second that you’re certain you’ve caught him looking, the world goes still, and quiet.

And then you hear the click of Everett’s back door closing, snapping you out of your fantasy and spurring you to whirl away. You take the coffee pot up with an imperceptibly shaking hand, curling the other tightly around your mug. You laser-focus on it as you pour, forcing yourself to hone in on it—not on your brother’s footsteps, or in the way that Jack is still watching you.

“Thought I heard your voice,” Everett comments. You hum, non-committal, and lift the coffee pot.

“Figured I’d make a fresh pot before coming to say hello. Want some?”

Everett nods, setting his mug down beside yours. He waits patiently as you fill it, stands still as a stone, and huffs a curse when a dribble of coffee lands on the counter as you lift the pot back up a little too quickly. You take a step back, biting back a bratty chuckle as he rips a paper towel off of the roll to swipe it up.

You glance toward Jack, expecting to find a gentle, chastising smile—but Jack’s expression is closed off, jaw set as he watches Everett clean up. He can’t be mad at you for that, can he? It was barely three drops worth—Everett will be over it by the time he swipes it up.

“C’mon,” Everett urges. “Let’s go outside. Less for you to mess up out there.”

You push off of the counter, grumbling, “Don’t bet on it,” As you stride out ahead of them.

--

As visits with Everett go, this one is far more stilted than usual. Typically, if both you and Jack are there, it’s an easy enough go around—smooth slides between talking about the Pitt, Everett complaining about his neighbors, Jack ribbing him about some op that went well when they served together—round and round you go.

But this time, neither you nor Jack are making much of an effort to engage with one another. Everett is left to act as the conversational conduit, and for a man with a penchant for keeping his mouth shut, the morning crawls by at a snail’s pace. Jack heads out before you do—stands and shakes Everett’s hand, promises to see him next week, to call sooner.

When his gaze flickers to you, you force yourself to study the bottom of your coffee cup, turning it from side to side and eyeing the few drops left.

“…See you at the Pitt.”

“Yeah.” It’s all you can muster. You can’t even bring yourself to meet his eye and give him a small smile as you say it. Jack’s footsteps retreat; the door opens, closes behind him. And after a few minutes of silence, Everett lets out the weariest fucking sigh you’ve ever heard.

“Alright, what’d he say.”

You look up then, frowning at the question. Everett’s brows tip up as he waits for your answer. You flounder, shaking your head.

“What do you mean?”

“I haven’t seen you so closed off around the guy since you decided to change your residency—and even that wasn’t as bad as whatever the hell this was.”

You slouch down in your seat, setting the coffee cup back down.

“Jack didn’t say anything.” Except rattle the hell out of you and trick you into thinking he was staring at your mouth. “I’m just in my head about something. Sorry, Ev.”

He grunts, leans back in his seat. “...Wanna talk about it?”

It’s your turn for your brows to lift in surprise.

“Wow, I didn’t realize I was that off.”

“Yes or no,” Everett presses. You consider for a moment before you shake your head.

“It’s not…I have a date with a surgeon that I work with.”

“Okay,” He shifts in his seat as his brow furrows. “What’s that got to do with Jack?”

“Just got the sense that he doesn’t approve.”

“That bothers you?” Disbelief is rife in Everett’s tone, and you can’t blame him. You haven’t put so much stock in his opinion—but it’s not the same. “What’s the guy like?”

“David? He’s—” You flounder. “Nice, I guess. Smart, quick…He’s got really nice eyes—”

“I don’t need that level of detail.”

“He’s a good guy.”

“Then why would Jack disapprove? Matter of fact—” Everett folds his arms on the table, “Why would Jack care?”

You let your eyes lower to the table, your hands wringing in your lap. What the hell can you tell Everett? That it’s just a feeling, a hunch? That the way he eyed you when you were talking to Dana had been nearly as intimidating as the only time you went against his direct orders when you were a resident?

“He probably doesn’t. Guess I’m just reading into things.”

“Well whatever it is, talk to him—and soon. Two’a you will put me off having visitors over again.”

“Except for your new girlfriend?”

It’s Everett’s turn to go quiet, and your smile widens. It’s so rare that you’ve been able to catch him out.

“You gonna tell me about her?” You prod.

“...Next time,” He musters, adding, “It’s early,” Before you can argue. You purse your lips, considering.

“Don’t wanna jinx it?”

“Something like that.”

“I respect that.”

“Good. Now get the hell outta my house before you spill any more coffee on my countertop.”

--

It’s in the spirit of air-clearing. In a quiet moment at the top of your fifth night shift, you grab a Twix from a vending machine and head down to the ER. You expect a quick word, a drop off, maybe a smile to send you on your way with reassurance.

You don’t expect to get roped into two cases in a row—an arm fractured in a car accident, and a stab wound. Any hope of ducking out after the first case is dashed when Jack just nudges your arm and directs, “Let’s go.”

You don’t even have to think. Following him is automatic. And as the two of you run through routine questions, diagnoses, criteria, you realize that you forgot how good this feels—not the rush of the ER, but Jack’s steadiness; his closeness; his encouragement.

As you peel off your gloves and leave Shen to stitch up the patient, you find Jack giving you an approving nod.

“Well handled, Queenie.”

“Thank you.”

“You come down here just to prove my point?”

You can’t help your eye roll as the two of you pump hand sanitizer into your palms and work it in.

“No,” You lean on the denial as you follow him to his desk. “I came to give you this.” You fish into your pocket for the Twix, holding it out. Jack’s lips quirk with a smile.

“You tryin’ to butter me up for somethin’?”

You were trying to cover off for the foul mood you managed to put Jack in while you were both at Everett’s, but the cloud that had hung over his head during that visit seems to have dissipated.

“Nope,” You pop the ‘p’, “Just figured I’d take a minute to pop down and annoy you.”

“Well,” He rips the packet open, drawing one of the Twixes out, “You only managed half.”

“Excuse me?”

“You came down, but you haven’t managed to annoy me. The opposite, actually.”

“Really.”

“Really.” Jack holds up one of the Twix in range of you, and waits, his eyes steady on yours. You can’t help the wicked little thrill that runs through you as you lean in, taking a bite of it. His smile widens as you chew, and as he raises the Twix to take a bite for himself.

“Hey, there you are!”

The sound of David’s voice makes you straighten u, turning to spot him just a few feet away.

“Oh, hey,” You greet, swiping a bit of missed caramel off of your lower lip. “What are you doing down here?”

“I’m heading out, but Princess said she saw you heading down here.”

“And…Here I am.”

“Yeah.” David’s gaze darts to Jack before he met your eye again. “We still on for tomorrow morning?”

“Mhm,” You nod.

“Sweet. I’ll be here at 7:30.”

“Cool.”

David nods again, seeming to meet Jack’s eye and give him a small wave before leaving. You turn back to face Jack, folding your arms on the desk as you try to meet his eye—but Jack seems laser-focused on the computer in front of him. The Twix is gone—shoved to the side, behind his keyboard.

“I should head back up,” You manage after a moment, straightening up. “Try not to have too much fun down here without me.”

Jack gives a soft hum, a nod, a murmur of, “Will do.”

You let yourself linger for just a second longer before heading to the elevator, stomach twisting with the feeling that you had somehow managed to annoy him after all.

--

Going back down near the end of your shift feels like kicking the hornet’s nest, but whatever it is that annoyed him, Jack’s surely had a chance to sufficiently cool off, right?

You duck into the restroom once you’ve changed out of your scrubs, giving yourself a quick once-over. You’d promised to meet David downstairs for your breakfast date, but truth be told, you're beginning to regret agreeing to seeing him that morning. Not because of the way Jack had acted (at least, not completely), but you are tired as hell. You should’ve held off until you had a day off.

You glance back at the sound of the door opening, offering Dana a weak smile.

“Clocking in?”

“Mhm,” She hums. “Clocking out?”

“Yep.” You take up your bag, patting her shoulder. “Have a good shift, lady.”

“Go get some rest. You look like hell.”

You chuckle softly, teasing, “Always the charmer.”

The ER is bustling as busily as ever as you step out onto the floor, looking around for Jack. You spot him coming out of North Two, and damn yourself for hesitating when he catches sight of you in his sweeping gaze. You meet him in the middle, tucking your hands into your pockets as you fight the urge to reach out and pick a piece of lint off of his shirt.

“Doing alright?”

He nods, casting his gaze over your shoulder. You turn your head, following his gaze, and see David waiting for you by one of the exits. You swallow thickly, turning back to face Jack.

“I have to go.”

"Have to?" There's a sharp lean to the way he asks, a resolute tension tightening his handsome features. It's harsh; new to you in a way that's rattling. The judgement in his tone catches you off-guard, and your hands curl into fists in your pockets.

“I’m going to.”

“Well, that’s something different, isn’t it.”

Your mouth works wordlessly as your mind races. You raise a hand to signal David to give you another minute when he calls out to you, unable to draw yourself away from Jack when he looks so goddamn disappointed in you.

“What has crawled up your ass lately?” You hiss.

“Excuse me?”

“You’ve been so—” You wave a hand toward him, “You keep shutting me out—”

“You shouldn’t keep Wilkins waiting.”

Your head jerks back like the man’s just slapped you, and Jack’s jaw tightens as he averts his gaze. You push out a stunned, affronted laugh, shaking your head as you step back.

“Wow—”

“Queenie—”

“No. No, you’re right.” You turn away from Jack without another word, forcing a smile onto your face when you make eye contact with David.

“Sorry about that.”

“Nah, s’okay. You, uh—” His eyes dart over your shoulder to where you left Abbott. “You ready to go?”

“Yep!” You chirp. You refuse to turn around, to see if Jack is still standing there. For once, you don’t try to shut the rest out, to check if he’s watching. You just move forward. And when David’s hand settles on your lower back to guide you outside, you resolve yourself to have a good time.

--

You have never been on a more awkward date in your life.

The conversation just doesn’t flow. When you and David are working together, there’s banter, there’s ease, but when you’re alone and there’s no one between you on a table, it’s like there’s this…block.

You chalk it up to the fact that you’re so tired you could cry, that your sleep schedule is all out of whack. And sure, that’s a factor, but you just can’t get Jack out of your fucking mind. You know that the stilted nature of your conversation with David isn’t helped by the few times that you’d checked your phone. But Jack has hardly texted in months, so why should today be any different?

The date ends with knowing smiles, teasing, “See you at work”s before you get into your cars. You buckle in, wave at David as he drives off, and then just sink back in your seat, staring at your steering wheel.

When the tears prickle your eyes, you tell yourself that you’re just overtired—that you need a nap, and some good coffee (because the coffee from the bad cart was watery and flavorless). You push the tears back, shaking your head. Nothing about the date was worth crying over. You’re still in the parking lot at work for christ’s sake.

Just get yourself home. You can have a nice cry in a hot shower.

Last Part

Tag list:

@missredherring ; @fantasticcopeaglepasta ; @massivecolorspygiant ; @amneris21 ;

@ew-erin ; @youngkenobilove ; @moonlightburned ; @milf-trinity ;

@millllenniawrites ; @videogamesandpoorlifechoices ; @missswriter ;

@thembosapphicclown ; @brandyllyn ; @wildmoonflower ; @realwhoreforfictionalmen; @mad-girl-without-a-box ;

@winchestershiresauce ; @lorecraft ; @kmc1989 ; @cannonindeez ; @gabsgabsvaz

@rhaelintoo ;

#Dr Jack Abbott x Reader#Dr Jack Abbott x You#Dr Jack Abbott/Reader#Dr Jack Abbott /You#Jack Abbott x Reader#Jack Abbott x You#Jack Abbott/Reader#Jack Abbott/You#Back a Ways

151 notes

·

View notes

Text

Tesla has made Autopilot a standard feature in its cars, and more recently, rolled out a more ambitious “Full Self-Driving” (FSD) systems to hundreds of thousands of its vehicles. Now we learn from an analysis of National Highway Traffic Safety Administration (NHTSA) data conducted by The Washington Post that those systems, particularly FSD, are associated with dramatically more crashes than previously thought. Thanks to a 2021 regulation, automakers must disclose data about crashes involving self-driving or driver assistance technology. Since that time, Tesla has racked up at least 736 such crashes, causing 17 fatalities. This technology never should have been allowed on the road, and regulators should be taking a much harder look at driver assistance features in general, requiring manufacturers to prove that they actually improve safety, rather than trusting the word of a duplicitous oligarch. The primary defense of FSD is the tech utopian assumption that whatever its problems, it cannot possibly be worse than human drivers. Tesla has claimed that the FSD crash rate is one-fifth that of human drivers, and Musk has argued that it’s therefore morally obligatory to use it: “At the point of which you believe that adding autonomy reduces injury and death, I think you have a moral obligation to deploy it even though you’re going to get sued and blamed by a lot of people.” Yet if Musk’s own data about the usage of FSD are at all accurate, this cannot possibly be true. Back in April, he claimed that there have been 150 million miles driven with FSD on an investor call, a reasonable figure given that would be just 375 miles for each of the 400,000 cars with the technology. Assuming that all these crashes involved FSD—a plausible guess given that FSD has been dramatically expanded over the last year, and two-thirds of the crashes in the data have happened during that time—that implies a fatal accident rate of 11.3 deaths per 100 million miles traveled. The overall fatal accident rate for auto travel, according to NHTSA, was 1.35 deaths per 100 million miles traveled in 2022. In other words, Tesla’s FSD system is likely on the order of ten times more dangerous at driving than humans.

3K notes

·

View notes

Text

Drive-In Racking System | Drive-Through Racking System I Camara Industries, Inc

Drive-In Rack and Drive-Through Rack Systems are Ideal for high-volume, low-SKU applications . Lane depth can reach over 10 pallets deep and are a practical way to redeem pallet efficiency by using this high density storage system method. Contact Camara Industries, Inc to learn about our cost-effective drive in racking systems and start improving your storage capacity!

#Rack Drive#Drive In Racking System#Drive-Thru Pallet Rack Systems#Drive-In Rack#Drive-In Pallet Rack Systems#Drive-Thru Rack#Cold Warehouse Storage#Structural Drive-In Rack#Structural Drive-Through Rack

0 notes

Text

Design & Manufacturing of Racking System in Pune | Max Space Rack

At Max Space Racking System, our expertise lies in designing and manufacturing high-quality racking systems in Pune. We are dedicated to optimizing your space and streamlining your operations for maximum efficiency.

#Design & Manufacturing Of Racking System in Pune#Compactor Storage Systems Manufacturer in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer

0 notes