#Drive-In Pallet Rack Systems

Explore tagged Tumblr posts

Text

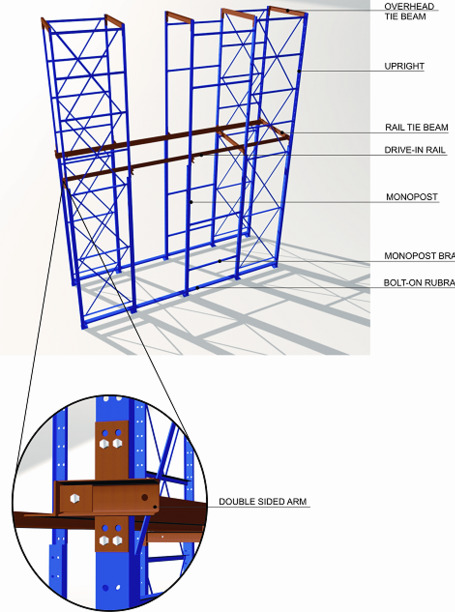

Drive-In Racking System | Drive-Through Racking System I Camara Industries, Inc

Drive-In Rack and Drive-Through Rack Systems are Ideal for high-volume, low-SKU applications . Lane depth can reach over 10 pallets deep and are a practical way to redeem pallet efficiency by using this high density storage system method. Contact Camara Industries, Inc to learn about our cost-effective drive in racking systems and start improving your storage capacity!

#Rack Drive#Drive In Racking System#Drive-Thru Pallet Rack Systems#Drive-In Rack#Drive-In Pallet Rack Systems#Drive-Thru Rack#Cold Warehouse Storage#Structural Drive-In Rack#Structural Drive-Through Rack

0 notes

Text

Mobile Pallet Racking System: Maximizing Storage Efficiency

In the field of modern warehousing optimizing space is paramount. A Mobile Pallet Racking System provides a dynamic solution. It combines high-density storage and easy accessibility. This innovative system amplifies warehouse operations. It uses mobile bases to move pallet racks along tracks. This creates flexible aisles only when necessary.

What is a Mobile Pallet Racking System?

It is a storage solution where pallet racks are mounted on mobile bases. These bases come with wheels or tracks. They can be moved electronically or manually. This allows access to a specific Pathway, while the rest of the system remains compacted.

Key Features of Mobile Pallet Racking Systems :

Storage with High Density

Make use of all available space by decreasing the number of aisles. It is an ideal solution for facilities with storage capacity constraints.

Ease of Access

Mobile mechanisms allow the opening of aisles when you want. They make sure the stock retrieval is efficient.

Handling Heavier Loads

These systems are intended to manage pallets of a heavy-duty nature. They are ideal for industrial applications.

Advanced controls

Systems are equipped with electronic controls. Additionally, they have safety features such as motion detectors to avoid accidents or collisions.

Configurations that Can Be Customized

Systems are available in designs that are single or double-depth. These are to meet specific storage requirements.

Benefits of Utilizing a Mobile Pallet Racking System:

Space Optimization: Utilize up to 80% of warehouse space. Improved Inventory Management: Accessing specific pallets is easy. Ensures streamlined inventory handling.

Cost Savings: The need for extra warehouse space is reduced. This is accomplished by maximizing the existing capacity.

Enhanced Security: Locking mechanisms limit access. Those features protect goods of high value.

Applications of Mobile Pallet Racking Systems :

1. Cold storage facilities.

2. Manufacturing plants.

3. Distribution centers.

4. Warehouses with space limitations.

Conclusion :

Mobile Pallet Racking System is an innovative storage solution. It is designed to enhance efficiency in warehouses. Productivity is also enhanced. This system is a compact design. Combined with flexible access it makes it an excellent choice. Businesses can use it to optimize storage space. Functionality is not compromised. Invest in a mobile pallet racking system. The system can transform your warehouse operations. It also meets the demands of a modern high-density storage environment.

#warehouses#drive-in racking system#mezzanine floor structure manufacturers#business#metalstorage#industrial storage racks in noida#industrial racks for warehouses#slotted angle racks manufacturers#modular mezzanine floor in pune#mobile pallet racking system

0 notes

Text

#Drive-In Pallet Racking is installed in warehouses and distribution centers that need a cost effective#high density storage solution for their products.Drive-in systems can be designed to store 2 to 10 pallets deep per lane. Because of its de#drive-in pallet rack is a first in#last out (FILO) storage system.

0 notes

Text

The Drive-In Racking system is an excellent solution for maximizing warehouse storage in high-density environments. Designed for storing large quantities of similar products, this system allows forklifts to drive directly into the rack structure, enabling deep storage of pallets in lanes. With no need for individual access aisles for each pallet, Drive-In Racking optimizes space by allowing more goods to be stored in a smaller area. It’s ideal for industries with high-volume, low-rotation products, such as cold storage and food processing. Eurorack’s Drive-In Racking is built to handle heavy loads while ensuring stability and safety.

#drive in racking system#pallet racking system#drive in racks#drive thru racking system#storage racking system#heavy duty racks#eurorack#warehouse racking system#eurorack drive in racks

1 note

·

View note

Text

Compactor Storage Systems Manufacturer In Pune – Max Space

Max Space Racking Systems is a leading compactor storage systems manufacturer in Pune. Explore our space-saving solutions for efficient storage. In a world where efficient storage solutions are paramount, Max Space Racking Systems emerges as a trusted compactor storage systems manufacturer in Pune, India. Compactor storage systems are a vital component of modern storage solutions. They offer a space-saving and highly organized way to store a wide range of items, from documents and files to goods in warehouses and distribution centers.

#Compactor Storage Systems Manufacturer in Pune#Design & Manufacturing Of Racking System in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer#Cantilever#Racks Manufacturer#Racks for Bobbin / Rolls Manufacturer

0 notes

Text

MEX Storage Systems Pvt. Ltd., based in Noida, is a highly reputable manufacturer of top-quality Heavy Duty Storage Rack. Our range of products includes Heavy Duty Panel Racks, Storage Systems, Slotted Angle Racks, MS Pallet Racks, Drive In Racking Systems, Pallet Racking Systems, and more. Our dedicated team is committed to providing you with exceptional products that meet and exceed your expectations. With a focus on delivering real-time quality, we strive to be your trusted partner for all your storage needs.

#Heavy Duty Storage Rack#Heavy Duty Panel Racks#Storage Systems#Slotted Angle Racks#MS Pallet Racks#Drive In Racking Systems#Pallet Racking Systems

0 notes

Text

Montclair Warehouse Space for Rent- Flexible, Affordable, and Strategically Located

Are you searching for reliable and well-maintained Montclair Warehouse Space For Lease? Whether you're a growing e-commerce brand, a logistics company, or a local business looking to expand operations, Montclair offers a variety of warehouse rental options to meet your specific needs. With a strategic location, easy transportation access, and competitive rental rates, Montclair is quickly becoming a sought-after destination for warehouse and industrial space.

Why Choose Montclair for Your Warehouse Needs?

Montclair is ideally positioned in New Jersey, close to major highways, ports, and rail networks, making it a prime location for storage and distribution. Its proximity to New York City, Newark, and other major urban centers means your goods can be moved quickly and efficiently, helping you streamline operations and reduce shipping costs.

Montclair’s business-friendly environment also offers the advantage of lower property costs compared to other nearby cities. It’s a great place for startups and established businesses alike to scale operations without overspending on overhead.

Features of Available Warehouse Spaces

Montclair offers a variety of warehouse spaces, from small units suited for boutique operations to large-scale facilities for distribution and manufacturing. Common features you can expect include:

High Ceilings and Wide Access Bays – Ideal for accommodating forklifts, pallet racks, and oversized equipment.

Loading Docks and Drive-In Doors – Streamline your shipping and receiving processes with ease.

Climate-Controlled Units – Perfect for temperature-sensitive goods, from food products to electronics.

24/7 Access and Security – Many spaces offer around-the-clock access with security systems in place to protect your inventory.

Flexible Leasing Options – Choose from short-term or long-term leases depending on your business’s evolving needs.

Ideal for a Range of Industries

Whether you're in retail, wholesale, food distribution, manufacturing, or even creative production, Montclair’s warehouse spaces are adaptable to a wide range of uses. The area’s strong infrastructure and diverse business community make it easy to find services and suppliers to support your operations.

Cost-Effective and Scalable Solutions

Renting warehouse space in Montclair is more affordable than in densely populated urban centers, yet still offers the connectivity your business needs. With scalable options, you can rent just the space you need now, and expand as your operations grow. Many landlords are open to customizing the space to better fit your layout, workflow, or storage systems.

Start Your Search Today

Finding the right Montclair Warehouse Space For Lease is easy when you know what you’re looking for. Whether you need 1,000 or 20,000+ square feet, there are listings that fit various budgets and requirements. Partner with a local commercial real estate agent or search verified listings online to explore available properties.

Conclusion

Montclair is more than just a vibrant residential and cultural hub—it’s also an excellent place to grow your business. With a range of available warehouse spaces for rent, competitive pricing, and excellent transport access, Montclair offers the right conditions for business success. Don’t miss your opportunity to secure the ideal warehouse space in this thriving New Jersey community.

0 notes

Text

Why Modern Businesses Can’t Ignore the Power of Efficient Storage Racks

In today’s fast-paced industrial environment, efficient space management is not just an operational advantage—it’s a business necessity. From manufacturing units and warehouses to retail stores and logistics hubs, organizations across sectors face a common challenge: storing more in less space while keeping everything accessible, secure, and organized.

That’s where modern, industrial-grade storage racks come into play.

Whether setting up a new facility or upgrading your current infrastructure, understanding the role of storage systems can significantly impact your productivity and cost efficiency. If you’re looking for trusted Storage Rack Manufacturers in Delhi, Storage Rack Manufacturers in Gurgaon, or Storage Rack Manufacturers in Punjab, read on—this blog is designed to help you make an informed choice.

The Role of Storage Racks in Business Efficiency

Today’s storage systems are not just shelves—they’re engineered solutions designed to support workflow efficiency, safety, and scalability. Here’s how:

Maximize Vertical Space: Rather than expanding floor area, smart businesses are building upwards with multi-tier racks and mezzanine systems—maximizing storage without increasing real estate.

Better Inventory Organization: Load-bearing shelves with structured compartments allow teams to categorize, locate, and retrieve goods with minimal effort.

Time and Cost Savings: A well-organized storage setup means fewer errors, faster order fulfillment, and reduced labor costs—directly improving your bottom line.

Storage Rack Trends in 2025

With India’s industrial and commercial sectors growing rapidly, here are the key racking trends shaping business strategies this year:

Customization Over Standardization: Modern businesses want storage systems that align precisely with their operational flow, inventory weight, and spatial layout.

Mobile Racking Systems: Movable racks are rising in demand, especially in offices, record rooms, and compact storage environments.

High-Density Warehouse Racks: With e-commerce driving faster turnover, businesses are investing in high-capacity pallet racking systems to streamline inventory management.

Safety and Durability First: Structural integrity, high-grade steel, powder coatings, and compliance with industry standards are non-negotiables today.

Most In-Demand Types of Storage Racks

Understanding the various racking systems available helps businesses choose the right fit:

Pallet Racks: Ideal for logistics, cold storage, and distribution centers.

Heavy-Duty Racks: Engineered for bulky, industrial inventory like machinery components.

Slotted Angle Racks: A modular, economical choice for light-to-medium inventory loads.

Cantilever Racks: Designed to store lengthy items such as pipes, wood planks, and rods.

Mobile Compactors: Space-saving, movable solutions ideal for archives, libraries, and documentation centers.

High-Demand Regions in India

Some of the fastest-growing markets for storage solutions include:

Delhi & NCR – Driven by exponential e-commerce, warehousing, and retail expansion.

Gurgaon – A rising industrial and IT hub where advanced storage infrastructure is key.

Punjab – With its robust manufacturing and logistics base, the need for durable storage is constantly growing.

These evolving demands have pushed businesses to seek reliable Storage Rack Suppliers in Punjab and Storage Rack Suppliers in India who can provide both standardized and custom-designed solutions.

What to Look for in a Storage Rack Supplier

Choosing the right partner is critical for long-term storage efficiency. Here’s what matters:

Industry Experience: Look for manufacturers with a proven track record across diverse industries.

Customization Capabilities: Can the supplier tailor systems to your floor plan, load capacity, and handling requirements?

Material Quality: Are the racks made of premium-grade steel with corrosion-resistant finishes?

Installation and Support: Ensure the vendor offers full-service support from design to after-sales maintenance.

Client Portfolio: A strong client list reflects trust, product quality, and delivery reliability.

One trusted name known for meeting these benchmarks is Spanco Storage Systems, a leading choice among businesses seeking dependable Storage Rack Manufacturers in Delhi, Gurgaon, and Punjab.

Closing Insights

Smart storage isn't just about stacking products—it’s about enabling speed, safety, and scalability across your operations. As industries in India continue to digitize, scale, and evolve, investing in high-performance racking systems is no longer optional—it’s essential.

Whether you're launching a new facility, expanding storage capacity, or improving operational flow, don’t overlook the impact of engineered storage systems. Start by evaluating top-tier Storage Rack Suppliers in India who offer durable, customizable, and scalable solutions built for today’s dynamic business needs.

#StorageRackManufacturersInDelhi#StorageRackManufacturersInGurgaon#StorageRackManufacturersInPunjab#StorageRacks#HeavyDutyRacks#PalletRacks#SlottedAngleRacks#CantileverRacks

1 note

·

View note

Text

Revolutionizing Storage: The Advantages of Push Back Racking Systems

Push Back Racking Systems have transformed the landscape of storage and inventory management, offering an unparalleled efficiency in maximizing warehouse space. Unlike traditional racks, Push Back Racks can store up to six pallets deep, boosting storage capacity by 25-30% more than selective racking systems. This leap in efficiency is achieved through an innovative design: pallets rest on wheeled carts that glide along inclined rails, enabling deep storage without necessitating multiple aisles.

See More: https://camaraindustries.com/revolutionizing-storage-the-advantages-of-push-back-racking-systems/

0 notes

Text

Get Best Pallet Racking Solutions In Los Angeles

Discover top pallet racking solutions in Los Angeles with ATB Material Handling. Offering custom selective, drive-in, and pallet flow systems, ATB optimizes warehouse efficiency. With over 29 years of experience, their expert team ensures precise installation and durable racks. Contact ATB Material Handling for tailored storage solutions that maximize space and boost productivity in your Los Angeles warehouse.

0 notes

Text

Types of Storage Warehousing Every Business Should Know

Storage warehousing is the unsung hero of the supply chain world. It’s where products wait patiently before heading to store shelves, fulfillment centers, or your doorstep. But not all warehouses are created equal—different goods, industries, and business goals demand different storage solutions. Whether you’re storing perishable foods, industrial machinery, or e-commerce inventory, choosing the right types of storage warehousing can make or break your operational efficiency. Let’s break down the options, explore key considerations, and share actionable tips to optimize your setup—no forklift license required.

What Is Storage Warehousing (And Why Should You Care)?

At its core, storage warehousing is the practice of storing goods in a way that balances safety, accessibility, and cost-effectiveness. Think of it as a strategic pause button in the supply chain: products stay put until they’re needed for production, distribution, or sale. But it’s not just about stacking boxes in a giant room. Modern warehousing involves smart layouts, advanced technology, and systems tailored to the unique needs of the items being stored.

Why does this matter? For starters, efficient warehousing:

Reduces costs: Proper storage minimizes damage, loss, and wasted space.

Speeds up order fulfillment: Organized systems mean products are easier to find and ship.

Supports scalability: A flexible warehouse adapts as your business grows.

Enhances inventory control: Track stock levels accurately to avoid overstocking or shortages.

For example, an e-commerce company might use storage warehousing to keep best-selling items closer to shipping zones, while a manufacturer could store raw materials near production lines. Even industries like pharmaceuticals rely on specialized climate-controlled warehouses to protect sensitive vaccines. The goal is always the same: keep goods secure, accessible, and ready to move when needed.

Common Types of Storage Warehousing Systems

Not sure which storage system fits your business? Let’s explore five popular types, their pros, and their best uses.

1. Pallet Racking

Pallet racking is the go-to for storing large, heavy, or bulk items like appliances, construction materials, and palletized goods. It maximizes vertical space and works well with forklifts. Selective racking allows easy pallet access, while drive-in racking offers high-density storage. Ideal for high-volume inventory with uniform sizes, it’s essential to avoid overloading racks, as collapses can be hazardous.

2. Shelving Systems

Shelving systems suit smaller items like electronics and tools. Static shelves stay fixed, while mobile shelves slide to save space. Bookstores use static shelving for browsing, while hospitals prefer mobile units for compact storage. Labeled bins help speed up picking and reduce errors, making shelving a flexible choice.

3. Multi-Tier Racking

Multi-tier racking is perfect for warehouses with limited floor space, allowing storage to expand vertically. These systems create multiple levels connected by stairs, ladders, or conveyors, making them ideal for lightweight, high-turnover products like cosmetics or small electronics. By doubling or tripling storage capacity without expanding the footprint, they make efficient use of high ceilings while keeping inventory accessible.

4. Mezzanine Flooring

Mezzanine flooring introduces an additional storage level by installing a raised platform, making the most of vertical space. It’s commonly used by retailers for seasonal stock or packing stations, providing an affordable alternative to relocation. However, proper engineering checks are necessary to ensure load capacity and safety. This system works well for businesses needing extra storage without major structural changes.

5. Automated Storage and Retrieval Systems (ASRS)

Automated storage and retrieval systems (ASRS) use robots or conveyors to store and retrieve items with minimal labor. Common in e-commerce and automotive warehouses, they offer long-term efficiency despite high initial costs. Regular IT maintenance is essential to keep operations smooth.

Choosing the Right System: 6 Factors to Consider

Picking a storage system isn’t one-size-fits-all. Ask these questions to narrow your options:

What’s your inventory like?

Size, weight, and fragility matter. Delicate glassware needs different storage than tractor parts.

Temperature-sensitive goods (like chocolate or vaccines) may require climate-controlled areas.

How often do you access items?

High-turnover products should be easily accessible (near shipping zones or ground level).

Seasonal stock? Tuck it away in dense storage areas like drive-in racking.

What’s your space like?

Low ceilings? Skip multi-tier systems and focus on horizontal solutions like mobile shelving.

Limited floor space? Mezzanines or vertical carousels maximize vertical real estate.

What’s your budget?

Pallet racking is cost-effective for startups; ASRS suits deep-pocketed enterprises.

Factor in long-term costs like maintenance (e.g., automated systems need tech upgrades).

Are you planning to grow?

Choose scalable systems. Modular shelving beats fixed structures if you anticipate expansion.

Lease agreements should allow flexibility for future layout changes.

Any regulatory or safety needs?

Pharmaceuticals require FDA-compliant storage with strict temperature logs.

Hazardous materials need fire-resistant systems, proper ventilation, and spill containment.

Optimizing Your Storage Warehouse: Efficiency Hacks

Once you’ve chosen a system, boost productivity with these strategies:

Design a workflow-friendly layout: Place high-demand items near packing stations. Use a “ABC analysis” to categorize inventory by turnover rates (A = fast-moving, C = slow-moving). For example, Amazon’s warehouses strategically position top-selling products closest to packing zones.

Embrace technology: Warehouse management systems (WMS) track inventory in real time. Pair them with barcode scanners or RFID tags for error-free picking. Some systems even predict demand to optimize stock placement.

Go semi-automated: Not ready for robots? Try hybrid solutions like carton-flow racks (which use gravity to move items forward as they’re picked) or vertical lift modules for small parts.

Train (and retain) your team: Well-trained staff prevent accidents and bottlenecks. Regular drills keep everyone sharp—think fire safety training or equipment handling workshops.

Audit and adjust: Conduct quarterly reviews to identify slow-moving stock or layout inefficiencies. Rotate inventory based on seasonal trends (e.g., holiday decorations in November).

Think green: Install energy-efficient LED lighting or solar panels to cut costs. Recycle packaging materials and optimize delivery routes to reduce your carbon footprint.

Wrapping Up: The Future of Storage Warehousing

Storage warehousing isn’t just about stashing boxes—it’s a strategic tool that impacts your bottom line. By matching your needs to the right system and continuously refining operations, you’ll save time, money, and headaches. As technology evolves, trends like AI-driven inventory forecasting and drone-assisted picking are reshaping the industry. Staying adaptable ensures your warehouse remains competitive.

#StorageWarehousing#TypesofStorageWarehousing#CrossCountryFreightTracking#CommonModesofCrossCountryFreight#LogisticsCompany#HowtoChoosetheRightLogisticsCompany#WhattoLookforinaCarShippingCompany#WhyShipYourCarInsteadofDrivingIt

1 note

·

View note

Text

Maximize your warehouse space with pallet racks. Pallet Racking offers efficient, economical use of floor space and unused over head space.

#pallet racking#pallet shuttle system#pallet rack warehouse & supply#pallet rack warehouse#rack and pinion drive system

0 notes

Text

The Ultimate Guide to Choosing the Right Pallet Truck for Your Business

Introduction

Pallet trucks, also known as pallet jacks, are essential tools for businesses that require efficient material handling. Whether you operate a warehouse, retail store, or manufacturing unit, choosing the right pallet truck can increase productivity, reduce manual labor, and enhance workplace safety. However, with various types and features available, selecting the right pallet truck can be challenging.

This ultimate guide will walk you through the types, key features, and factors to consider before purchasing a pallet truck for your business.

1. Understanding Different Types of Pallet Trucks

Before selecting a pallet truck, it’s important to understand the different types available in the market.

A. Manual Pallet Trucks

Operated by hand-pumping the hydraulic system to lift loads.

Ideal for small warehouses and short-distance transport.

Cost-effective and easy to maintain.

Best for businesses handling light to medium loads (up to 2500 kg).

B. Electric Pallet Trucks

Powered by a battery-operated motor.

Reduces manual effort and speeds up operations.

Suitable for medium to large warehouses handling frequent material movement.

Can handle heavier loads, typically up to 3000 kg.

C. Semi-Electric Pallet Trucks

Combines manual lifting with an electric drive system.

More affordable than fully electric models.

Great for businesses transitioning from manual to powered equipment.

D. High-Lift Pallet Trucks

Designed to lift pallets to a higher height.

Useful for loading/unloading trucks and stacking.

Prevents strain on workers by reducing excessive bending.

E. Weighing Scale Pallet Trucks

Equipped with a built-in scale to weigh loads instantly.

Useful in warehouses, shipping, and production units.

F. Rough Terrain Pallet Trucks

Designed for outdoor and uneven surfaces.

Features large, durable wheels for stability.

Ideal for construction sites and agricultural businesses.

2. Key Factors to Consider Before Choosing a Pallet Truck

Once you understand the types, consider the following factors to select the best pallet truck for your business needs:

A. Load Capacity

Choose a pallet truck with a capacity that matches or exceeds your typical load weight.

Standard pallet trucks support 1500–3000 kg.

Overloading can cause wear and tear and reduce the truck’s lifespan.

B. Fork Length & Width

Standard fork length: 1150mm (suitable for standard pallets).

Short forks: Ideal for small pallets and confined spaces.

Wide forks: Better for handling large or custom-sized pallets.

C. Lift Height

Standard pallet trucks lift up to 200mm.

High-lift pallet trucks can reach 800mm or more.

Consider lift height based on your racking and storage requirements.

D. Material & Build Quality

Opt for high-quality steel construction for durability.

Galvanized or stainless-steel models are ideal for corrosive environments (e.g., food & chemical industries).

E. Wheels & Manoeuvrability

Polyurethane wheels: Quiet, smooth rolling, and floor-friendly.

Nylon wheels: Ideal for rough surfaces and wet environments.

Rubber wheels: Provide better grip and shock absorption.

Consider 360-degree swivel wheels for enhanced maneuverability in tight spaces.

F. Ease of Use & Ergonomics

Look for ergonomic handles to reduce strain on workers.

Electric models with easy-to-use control panels improve efficiency.

Low-resistance pumps and smooth-rolling wheels make manual handling easier.

G. Battery Life (For Electric Pallet Trucks)

Ensure long-lasting battery performance for uninterrupted operations.

Lithium-ion batteries offer faster charging and longer life.

Check for easy battery replacement and charging options.

3. Benefits of Choosing the Right Pallet Truck

Investing in the correct pallet truck can benefit your business in several ways:

✅ Increases efficiency – Faster material handling reduces downtime. ✅ Enhances worker safety – Reduces the risk of injuries from manual lifting. ✅ Saves operational costs – Reduces labor costs and increases productivity. ✅ Improves space utilization – Enables better storage management. ✅ Extends equipment lifespan – Choosing the right model reduces wear and maintenance costs.

4. Best Practices for Maintaining Your Pallet Truck

To maximize your pallet truck’s lifespan, follow these maintenance tips:

🔹 Regularly inspect wheels for wear and tear. 🔹 Check hydraulic fluid levels and top up when necessary.

🔹 Lubricate moving parts to ensure smooth operation.

🔹 Keep the forks clean and free from debris.

🔹 Store electric pallet trucks properly and charge batteries as required.

5. Where to Buy the Best Pallet Trucks Online?

If you are looking to buy a pallet truck online, consider the following tips:

🔸 Choose a trusted supplier with positive customer reviews. 🔸 Compare features, warranties, and after-sales support. 🔸 Check if the seller offers fast shipping and easy returns. 🔸 Look for discounts and bulk purchase deals.

Conclusion

Selecting the right pallet truck for your business involves understanding your operational needs, load capacity, terrain, and budget. Whether you need a high-lift, electric, or manual hand pallet truck, choosing the correct model will boost efficiency, enhance safety, and save costs in the long run.

Take your time to assess your requirements and invest in a high-quality pallet truck to improve material handling operations.

Looking to buy the best pallet truck online? Explore top-rated models from leading suppliers and make an informed decision today!

0 notes

Text

Design & Manufacturing of Racking System in Pune | Max Space Rack

At Max Space Racking System, our expertise lies in designing and manufacturing high-quality racking systems in Pune. We are dedicated to optimizing your space and streamlining your operations for maximum efficiency.

#Design & Manufacturing Of Racking System in Pune#Compactor Storage Systems Manufacturer in Pune#Vertical Carousels Manufacturer in Pune#vertically stacked trays or shelves in Pune#Pallet Shuttle Systems Manufacturer in Pune#Selective Pallet Racks Manufacturer in Pune#Drive-in Racks Manufacturer in Pune#Multi Tier Racks Manufacturer in Pune#Shelving Racks Manufacturer#FIFO Racks Manufacturer

0 notes

Text

Maximizing Storage Efficiency: Choosing the Right Racking System

Efficient storage is the backbone of any warehouse or industrial facility. Without a proper racking system in Dubai, businesses may face disorganization, reduced productivity, and safety hazards. Choosing the right racking solution can significantly enhance storage capacity, streamline operations, and ensure optimal space utilization.

Understanding Racking Systems

A racking system UAE is a structural framework designed to store goods in an organized manner. These systems are commonly used in warehouses, logistics centers, and retail storage units. Racking solutions help businesses optimize vertical and horizontal space, making inventory management more efficient and accessible.

Types of Racking Systems

Selecting the right racking system depends on various factors, such as available space, product type, and operational needs. Below are some common racking systems:

1. Selective Racking

This is the most commonly used racking system, providing direct access to every pallet. It is ideal for warehouses that store various SKUs and require frequent inventory rotation.

2. Drive-In Racking

A high-density storage system designed for large quantities of the same product. This system minimizes aisle space, allowing forklifts to enter the racks to load and unload goods.

3. Cantilever Racking

Perfect for storing long, bulky items such as pipes, steel bars, and lumber. This system features arms extending from columns, providing easy access and flexibility.

4. Pallet Flow Racking

A dynamic storage solution that uses gravity rollers to move pallets from one end to the other. This system is ideal for FIFO (First In, First Out) inventory management.

5. Mezzanine Racking

This system utilizes vertical space by adding an additional level of storage above existing racks. It is an excellent choice for warehouses with high ceilings and limited floor space.

Factors to Consider When Choosing a Racking System

When selecting a racking system in Dubai, businesses should consider the following factors:

1. Load Capacity

Different racking systems are designed to support varying weight capacities. It is essential to determine the maximum load each rack will hold to ensure safety and durability.

2. Space Utilization

Maximizing storage efficiency involves utilizing both vertical and horizontal space. High-density racking systems like drive-in racking can help increase storage capacity.

3. Accessibility and Inventory Rotation

The type of products stored determines whether a FIFO or LIFO (Last In, First Out) system is more suitable. For instance, perishable goods require a FIFO system, whereas non-perishable items can be stored in LIFO systems.

4. Warehouse Layout

The available floor space and ceiling height play a crucial role in determining the most effective racking solution. Proper planning ensures seamless warehouse operations.

5. Safety Regulations

Ensuring compliance with safety standards is essential when installing racking systems. Businesses must adhere to load-bearing capacities, seismic considerations, and fire safety regulations.

The Role of Racking Companies in Dubai

With growing demand for efficient storage solutions, businesses turn to expert racking companies in Dubai to find the right system for their needs. These companies provide customized solutions, ensuring businesses maximize storage efficiency while maintaining safety standards.

Benefits of a Well-Designed Racking System

1. Increased Storage Capacity

A well-planned racking system allows businesses to store more products in a limited space, improving overall efficiency.

2. Enhanced Organization

Proper racking solutions enable easy access to products, reducing time spent searching for inventory and improving workflow.

3. Cost Savings

Investing in a high-quality racking system reduces damage to products, minimizes operational delays, and lowers labor costs.

4. Improved Workplace Safety

Properly installed racks prevent accidents, ensuring a safer work environment for employees.

5. Scalability

Racking systems can be modified or expanded based on business growth, making them a long-term storage solution.

Why Choose Professional Racking System Suppliers in UAE?

Selecting reliable racking system suppliers in UAE ensures businesses receive high-quality, durable, and customized storage solutions. Professional suppliers offer expert consultation, installation, and maintenance, helping businesses optimize their storage spaces effectively.

Final Thoughts

Investing in the right racking system is crucial for businesses looking to enhance storage efficiency, improve productivity, and ensure workplace safety. Whether you need selective racking for easy access or high-density drive-in racking for bulk storage, choosing the right system can transform your warehouse operations.

For the best storage solutions tailored to your business needs, Cosmictech provides top-tier racking systems designed for efficiency and durability. Partnering with experts ensures you maximize your warehouse space while maintaining safety and operational excellence.

0 notes

Text

Boosting Retail Success with Cutting-Edge Inventory Shelving Systems with Expert Shop Fitting Solutions

Retail businesses depend on operational efficiency to drive profitability and ensure customer satisfaction. Factors like store layout and inventory organisation play pivotal roles in this process. A key contributor to this efficiency is the use of advanced inventory shelving systems, coupled with the craftsmanship of top shop fitting manufacturers. These elements not only ensure smooth operations but also enhance the shopping experience, encouraging customers to spend more time browsing and increasing the likelihood of purchases.

Importance of Inventory Shelving Systems in Retail:

Inventory shelving systems form the backbone of retail operations, providing the necessary infrastructure for storing, displaying, and managing products. Beyond mere storage, the right shelving can boost sales by organising products in a way that makes them more accessible and appealing to customers. Additionally, these systems can improve staff productivity by making restocking and inventory management more efficient.

An organised shelving system plays a crucial role in product placement, allowing retailers to categorise products logically, guiding customers effortlessly through the store. This not only enhances the customer journey but also reduces the chances of misplaced items, resulting in a more pleasant shopping experience and better inventory control.

Furthermore, advanced shelving solutions help optimise store space—an invaluable resource in retail. Modular and adaptable shelving systems can fit various store layouts, allowing retailers to display a broader range of products without cluttering the space. This leads to improved product visibility, better visual merchandising, and a more inviting store environment.

Varieties of Inventory Shelving:

Retailers can choose from a wide range of shelving systems to suit their specific needs. Each type has its benefits and is ideal for different retail environments:

Gondola Shelving: A favourite among retailers due to its flexibility and sturdiness, gondola shelving can be configured to display products on both sides, making it ideal for creating aisles in supermarkets and convenience stores.

Wire Shelving: Lightweight and versatile, wire shelving is excellent for product visibility and air circulation. It’s commonly used in backrooms or for displaying products that don’t require prime positioning.

Slatwall Shelving: Offering great flexibility, slatwall systems use wall-mounted slats for adjustable shelving and display fixtures, making them perfect for stores that frequently change their product displays, such as fashion boutiques or electronics retailers.

Pallet Racking: Common in warehouses and large retail spaces, pallet racking is built for heavy-duty storage and helps maximise vertical space, making it a smart solution for backroom stock storage.

Cantilever Shelving: Designed for bulky, oversized items, cantilever shelving features arms that support long products like pipes or furniture, making it a favourite in hardware and home improvement stores.

Modern Shelving Systems for Today’s Retailers:

In the current retail landscape, shelving systems have evolved beyond simple storage solutions. Advanced systems now integrate technology to improve operational efficiency and streamline processes. Smart shelving systems, which use sensors and software to monitor inventory levels in real time, are becoming more prevalent. These systems can notify staff when stock is low, helping to prevent out-of-stock situations.

Additionally, smart shelving systems provide valuable insights into customer behaviour by tracking product interactions. This data can inform better merchandising decisions, help optimise product placement, and guide promotional strategies, allowing retailers to operate in a more data-driven and responsive manner.

The Role of Shop fitting makers in Retail Efficiency:

Leading shop fitting manufacturers play a key role in optimising retail efficiency and aesthetics. They offer tailored solutions that maximise space utilisation and align with the store's branding. By crafting custom shelving systems, these manufacturers ensure that retail spaces are both functional and visually appealing, helping stores stand out while improving operational flow.

Durability is a key advantage of working with top manufacturers. High-quality materials ensure that fixtures last longer, reducing the need for replacements and leading to cost savings over time. Many manufacturers are also shifting towards sustainable practices, using eco-friendly materials that appeal to both retailers and environmentally conscious customers.

Benefits of Partnering with Shop fitting makers:

Working with top shop fitting manufacturers offers several advantages, including:

Custom Solutions: Shelving systems designed to fit the specific needs and layout of each store.

Innovative Designs: Modern shelving options that improve product visibility and ease of access.

Sustainability: Eco-conscious materials and practices that align with retailers’ sustainability goals.

Durability: Long-lasting materials that ensure shelves can withstand the wear and tear of a busy retail environment.

Brand Enhancement: Thoughtfully designed fixtures that reinforce the store’s brand identity and create an inviting shopping experience.

Conclusion:

In conclusion, retail efficiency is significantly boosted by the use of advanced inventory shelving and the expertise of top shop fitting makers. These systems not only help in managing inventory effectively but also enhance the overall customer experience through better organisation, optimised space, and aesthetically pleasing displays. Partnering with experienced shop fitting manufacturers ensures that retailers benefit from durable, sustainable, and custom solutions that improve operations and drive sales. For retailers aiming to improve profitability and customer satisfaction, investing in advanced shelving systems and collaborating with skilled manufacturers is essential.

#inventory shelving systems#shop fitting manufacturers#shop display equipment#inventory rack system#shop fitting equipment#inventorymanagement#inventory management systems#inventory management#warehouse inventory management#custom fitting solutions#shopfitting solutions#shop fitting shelving#display shelving solutions#shopfitting suppliers#Shelve management systems#Inventory shelving solutions#retail shelving system#retail activation#retail display shelving#shelving systems

0 notes