#qualitymanagement

Explore tagged Tumblr posts

Text

youtube

📢 Did you know? Most API audit issues start with poor document control

How do organizations keep critical documents in check?

It all starts with the Control of Documents procedure — a key requirement in API Q1 & Q2.

✅ Internal docs: Must be approved, reviewed & updated.

✅ External docs: Controlled & integrated into your processes.

🎥 Watch this reel to learn how API-compliant companies manage documentation effectively.

#apistandards#apiconsultant#apispecq2#apispecq1certification#Documentation#auditready#Youtube#vegasconsulting#oilandgasindustry#riskmanagement#qms#qualitymanagement

0 notes

Text

Your Trusted ISO Certification Partner – Quality Solutions

💼 Ready to Elevate Your Business Standards?

At Quality Solutions, we are your dream ISO consultants, dedicated to helping you achieve certification with ease and excellence. ✅

🎯 Our Services: 🔹 ISO 9001:2015 - Quality Management 🔹 ISO 14001:2015 - Environmental Management (EMS) 🔹 ISO 45001:2018 - Occupational Health & Safety … and many more!

📞 Get 30% Off on ISO certification consulting – limited time offer!

📩 Contact us today: 📱 +91-9873335231 📧 [email protected]

#ISOCertification#QualityManagement#ConsultingExperts#QualitySolutions#BusinessCompliance#ISO9001#ISO14001#ISO45001#StartupIndia#CertificationExperts#BusinessGrowth

0 notes

Text

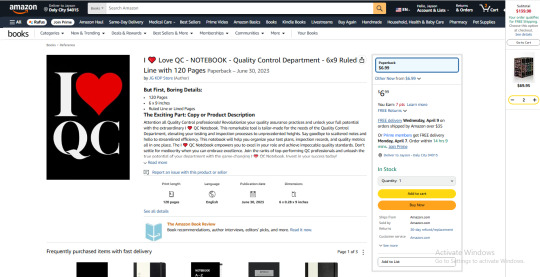

Quality Control Professionals! This is the perfect Notebook for YOU.

I ❤️ Love QC Quality Control NOTEBOOK on Amazon!

#QualityControl#QC#QualityAssurance#QAQC#QualityManagement#QMS#Inspection#Compliance#StandardOperatingProcedures#ContinuousImprovement

0 notes

Text

ISO 22000 CERTIFICATIONS SERVICES

#ISO22000#ISO22000Certification#CertificationsServices#FoodSafety#QualityManagement#FoodSafetyStandards#GlobalFoodSafety#HACCP#ISOStandards#FoodIndustry#CertificationProcess#Compliance#BusinessGrowth#ISOExperts#SafetyProtocols#RiskManagement#Manufacturers#FoodQuality#HygieneStandards#CertifiedBusiness

0 notes

Text

Hey all,

I recently found a Quality Assurance & Control Training Course that covers key QA/QC principles and thought I’d share it here for anyone looking to level up their skills.

This course dives into:

Core QA/QC concepts: Understand the difference between QA and QC.

Tools & Methodologies: Learn techniques for managing quality and improving processes.

Continuous Improvement: Methods like Kaizen for ongoing quality enhancement.

It’s practical and applicable to anyone in QA/QC roles or looking to get into it. Anyone here taken a similar course or have insights on QA/QC best practices?

Check it out if you're interested: Effective Quality Assurance & Control Training.

Looking forward to hearing your thoughts!

#QualityAssurance #QualityControl #QAQC #ContinuousImprovement #Kaizen #ProcessImprovement #QualityManagement #ISOStandards #QualityTraining #LeanManufacturing #SixSigma #QualityTools #ProfessionalDevelopment #QAQCTraining #ProcessOptimization #QualityManagementSystems

#QualityAssurance#QualityControl#QAQC#ContinuousImprovement#Kaizen#ProcessImprovement#QualityManagement#ISOStandards#QualityTraining#LeanManufacturing#SixSigma#QualityTools#ProfessionalDevelopment#QAQCTraining#ProcessOptimization#QualityManagementSystems

0 notes

Text

ISO 13485 vs. MDSAP: What’s the Difference? 🤔

If you're in the medical device industry, you know compliance is everything. But do you need ISO 13485 or MDSAP—or both?

✨ ISO 13485 = The global gold standard for a quality management system (QMS). It ensures medical devices are safe, effective, and meet regulatory expectations worldwide. 🌍

🚀 MDSAP = A single audit that covers USA, Canada, Japan, Brazil, and Australia. Instead of multiple regulatory audits, one MDSAP audit satisfies them all. Talk about efficiency! ✅

ISO 13485 helps you build a strong QMS, while MDSAP makes global compliance smoother. If you're planning to sell in multiple markets, having both might be the key to success.

Are you working on certification? What’s been the biggest hurdle? Let’s chat! ⬇️

0 notes

Text

Our current ISO 9001-certificate is available!

In February we have been recertified by the SGS and now have received a current certificate. It can be accessed in our download section.

Great news! 🎊 Our company has successfully achieved ISO 9001 certification – the globally recognized standard for quality management! 💪 What does this mean for you? ✔ Highest quality standards in all our processes ✔ Optimized workflows for even better service ✔ Customer satisfaction is our top priority ✔ Continuous improvement – for you and with you! We offer quality that matters! ✅ This certification confirms our commitment to excellence, reliability, and innovation. A huge thank you to our team and customers who have supported us on this journey! ❤️ Let’s continue striving for the highest level of quality together! 🚀

#ISO9001#Quality#Certification#WeAreCertified#Excellence#CustomerSatisfaction#SupplierEvaluation#QualityManagement#Innovation#Success#Trust#CWH

0 notes

Text

Steel Industry ERP: Streamlining Operations & Ensuring Quality

Looking for ways to enhance efficiency in the steel industry? ⚙️ ERP solutions integrate production planning, inventory management, supply chain coordination, and quality control to optimize operations and ensure compliance. 🚀 By automating workflows, tracking real-time data, and reducing waste, ERP helps businesses improve decision-making and drive continuous growth.

Stay updated on the latest ERP trends, best practices, and implementation strategies to maximize efficiency and cost savings. Join the discussion and bookmark this for future reference!

https://www.lighthouseindia.com/erp-for-steel.html

0 notes

Text

Why Every Manufacturer Needs ERP: 10 Must-Know Benefits

In the current fast-paced manufacturing industry, companies are confronted with greater challenges in production planning, supply chain cost management, and managing inventory. In order to remain competitive, manufacturers require a solid solution that makes processes easier, increases efficiency, and guarantees profitability. This is where ERP software for manufacturing Business enters the picture.

An ERP system for manufacturing industry consolidates all the major manufacturing processes in one platform and provides real-time data analysis as well as automation to streamline business operations. Listed below are 10 must-learn advantages of ERP for manufacturing and why business growth requires ERP.

Why ERP is Crucial for Modern Manufacturing

ERP (Enterprise Resource Planning) software assists manufacturers in managing and integrating core business processes. ERP facilitates smooth coordination among departments, enhances workflow efficiency, and achieves a data-driven decision-making process.

Better Production Planning & Scheduling : Effective manufacturing production planning software is important for fulfilling customer demand without incurring delays. Manufacturing industry-specific ERP software assists manufacturers in producing reliable production schedules, efficiently assigning resources, and avoiding bottlenecks in the production process.

Better Cost Control & Budgeting : Cost management is an essential element in the success of manufacturing. Manufacturing cost control solutions with ERP allow companies to monitor financials in real-time, include budgeting and cost analysis tools, and maintain control over expenses to maximize profitability.

Simplified Supply Chain Management : An effective supply chain ERP system for manufacturing guarantees on-time delivery of finished products and raw materials. Cloud-based supply chain management ERP facilitates enhanced collaboration between suppliers, streamlines procurement processes, and enhances logistics to provide increased overall efficiency for the supply chain.

Improved Inventory Management : ERP inventory management software for manufacturers eradicates problems such as overstocking and stock outs by offering real-time monitoring of inventory and forecasting demand. This keeps the manufacturers at optimal stock levels, saving them from wastage and enhancing cash flow.

Improved Quality Management : Product quality needs to be kept in check to ensure customer satisfaction. An ERP solution for quality control in manufacturing has quality control modules that monitor defects, comply with industry standards, and enhance product consistency.

Increased Productivity & Efficiency : Manual processes are automated with a contemporary ERP system for manufacturing automation, which eliminates human errors and improves workforce efficiency. Workers are able to dedicate time to high-value tasks instead of repetitive administrative tasks.

Real-Time Data & Business Intelligence : Real-time manufacturing analytics ERP software gives manufacturers the ability to make fast, well-informed decisions. Business intelligence with cloud ERP delivers dashboards and reports that provide insights into production performance, sales trends, and operational efficiency.

Regulatory Compliance & Risk Management : Manufacturers are required to comply with industry standards and regulations. Regulatory compliance ERP software for manufacturing maintains compliance by keeping accurate records, auditing trails, and automating compliance processes to minimize risks.

Seamless Integration & Scalability : As companies expand, they require agile systems that adapt to growth. A strong scalable ERP for expanding manufacturing companies integrates perfectly with current business solutions such as CRM, financial management, and HR software, accommodating expansion without interruptions.

Enhanced Customer Satisfaction : An optimized manufacturing ERP solution for customer care streamlines order accuracy, minimizes lead times, and maximizes overall service delivery. This results in enhanced customer satisfaction and long-term partnerships.

Challenges in Implementing ERP in Manufacturing

Although ERP systems provide many advantages, their implementation may be challenging in terms of high upfront costs, training, and integration issues. To avoid these challenges, manufacturers must:

Select an ERP solution that meets their industry requirements.

Offer adequate training to employees for easy adoption.

Engage seasoned ERP consultants to facilitate smooth implementation.

Final Thoughts on ERP for Manufacturing

Implementing ERP software for manufacturing is no longer optional—it's a requirement for companies that want to remain competitive. From controlling costs and planning production to managing inventory and optimizing supply chains, an integrated ERP system optimizes operations and efficiency. With real-time data analytics, manufacturers can make data-driven decisions, minimize waste, and maximize overall productivity.

Selecting the correct ERP software for manufacturing success hinges on scalability, customization, and industry requirements. With cloud-based and AI-enabled ERP solutions, manufacturers can future-proof their businesses and respond to market needs, ensuring long-term business growth and sustainability.

#ERPSoftware#ManufacturingERP#ERPForManufacturing#SupplyChainManagement#ProductionPlanning#CostControl#InventoryManagement#BusinessGrowth#ManufacturingAutomation#CloudERP#QualityManagement#RealTimeData#SmartManufacturing#EnterpriseResourcePlanning

0 notes

Text

You don't have to reinvent the wheel.

Enhance operational efficiency and boost business performance with ISO certifications.

Streamline processes, ensure compliance, and drive growth effortlessly.

If you don’t know why you need risk in your management systems, you need us.

Visit us @ www.isoinadash.com

#iso#isostandards#isotraining#training#businessmanagementsystems#consulting#iso certification#isoinadash#iso27001#iso9001#isocompliance#isoaudits#iso 9001#qualitymanagement#isocertification#compliance#iso22000#isms#bms#infosec

0 notes

Text

#ISO9001#QualityManagement#ISO9001Certification#QMS#QualityAssurance#ISOTraining#CertifiedQuality#KeralaBusiness#TamilNaduBusiness#InternationalCertification#ISOCompliance#QualityFirst#CertificationServices

0 notes

Text

🚀 Accelerate Your Career with an MBA in Quality Management! 🚀

Are you ready to elevate your career in quality management? Our MBA in Quality Management course offers the knowledge and skills you need to lead quality initiatives and drive improvement strategies across organizations.

Why Attend? ✅ Master leadership, communication, and strategic skills essential for quality management ✅ Learn the most effective quality management tools like Six Sigma, Lean, and FMEA ✅ Develop the expertise to implement quality systems and drive continuous improvement ✅ Prepare for leadership roles with an in-depth understanding of quality philosophies and ethical practices ✅ Gain global perspectives to position yourself as a leader in quality management

Course Highlights:

📚 In-depth understanding of quality philosophies and tools (Deming, Juran, Crosby, etc.) 📈 Practical skills in Six Sigma, Lean, and failure analysis tools 🌍 Strategic planning for quality improvement and organizational growth 📊 Key performance indicators (KPIs) for measuring success in quality management

🔗 Join the course now and shape the future of quality management in your organization!

#MBAinQualityManagement #QualityManagement #SixSigma #LeanManagement #Leadership #CareerGrowth #ProjectManagement #ContinuousImprovement #BusinessExcellence #HigherEducation #QualityLeadership

#MBAinQualityManagement#QualityManagement#SixSigma#LeanManagement#Leadership#CareerGrowth#ProjectManagement#ContinuousImprovement#BusinessExcellence#HigherEducation#QualityLeadership

0 notes

Text

Dass Steel Service Centre – ISO 9001:2015 Certified | 370 New Enterprise Way, Vaughan, ON L4H 0S8 |+19054504303

#CutToLength#MetalProcessing#DassSteelServiceCentre#ISO9001#QualityManagement#ExcellenceInService#CustomerFirst#SteelIndustry#SteelServices#SteelDelivery#LogisticsSolutions#OnTimeService

0 notes

Text

🌟 Reduce Risk, Not Freshness! 🌟

Our cold storage management software, , ensures your products maintain peak quality from entry to exit. ❄️📦 Discover more at Omex Cold Storage Management System!

#ColdStorage#QualityManagement#OmexCSMS#FoodSafety#SupplyChain#Freshness#Logistics#ProductQuality#SoftwareSolutions

1 note

·

View note

Text

youtube

Struggling with messy quality documentation? Confused about what goes where? 🤯 Don’t worry—we’ve got you covered! In this video, we simplify the 6 essential levels of quality documentation to help you streamline your Quality Management System (QMS) and ensure efficiency, compliance, and success!

You'll discover the importance of Quality Manuals, Policies & Procedures, Work Instructions, Templates, and Records. No matter your industry—manufacturing, oil & gas, or API certification—structured quality documentation is essential for staying audit-ready and compliant!

💬 Drop a reply in the comments if you found this helpful! LIKE, SHARE for more expert insights!

#QualityManagement#QualityDocumentation#Compliance#QMS#APIStandards#BusinessSuccess#AuditReady#QualityControl#ISO9001#ProcessImprovement#Youtube

0 notes

Text

Understanding The Importance of ISO Certification in Tender Bidding

A company must follow strict rules about quality, safety, and how it runs if it wants to work with the government or other large companies. This is often one of the most important things you need to do before you bid on something. Why do you need ISO to bid on a work? In this work market, what does this mean for businesses? What does it mean for a business to be ISO-approved? How does that help them get more bids? This blog post talks about these things in great depth.

What is ISO Certification? The International Organization for Standardization (ISO) is not run by the government. They make sure the rules are safe, well-thought-out, and simple to understand. A company needs to follow the rules of other countries in order to get ISO approval. You can trust it more and it works better.

Common ISO certifications relevant to tender bidding include:

ISO 9001: Quality Management System (QMS)

ISO 14001: Environmental Management System (EMS)

ISO 27001: Information Security Management System (ISMS)

ISO 45001: Occupational Health and Safety Management System (OHSMS)

ISO 22000: Food Safety Management System

Why is ISO Certification Important in Tender Bidding?

1. Following the bid's rules many business and government bids make it clear that you need to be ISO-certified before they will work with you. If someone or a business doesn't have the right ISO license, they might not be able to bid. If these things are true, you can bid. The deal is more likely to go through. 2. Demonstration of Quality and Reliability A company that has ISO approval is known all over the world to follow quality management rules. Clients understand that the business has a plan for quality, risks, and making sure clients are pleased. 3. Enhanced Credibility and Trust When people buy from a company that has ISO approval, they know that it runs its business in the best way possible. Because it shows they can do good work, this makes it more likely that they will get the work. 4. Competitive Advantage A business is not the same as another type of business just because it has ISO. People and the government are more likely to buy from a company that cares about the area when they need to. 5. Staying safe and following the rules set by the government Following ISO rules is one way to deal with risks. These make sure that people follow the rules and the law. This is important for many things, like building, food safety, IT, healthcare, and more. 6. Things that are faster and work better The workers at the company care about them and make sure they are safe at work. That makes everything work better, lose less, and do better all around.

Key ISO Certifications for Tender Bidding

1. ISO 9001: Quality Management System (QMS) you can always feel safe when you buy something or do business somewhere that has ISO 9001. This is the title that most people who want to bid on work want. It's true at work, in business, and when you make things. 2. ISO 14001: Environmental Management System (EMS) Deals are being judged more and more by how green they are. A company that has ISO 14001 knows it needs to take care of the earth. 3. ISO 27001: Information Security Management System (ISMS) Getting ISO 27001 approval is very important for bids that have to do with IT, data security, or hacking. People will attack and hack a company less often if it takes care of its stuff. 4. ISO 45001: Occupational Health and Safety Management System (OHSMS) Before you move, make, or build something, ISO 45001 shows you what you can do. The company follows all health and safety rules because they care a lot about the safety of their workers. 5. ISO 22000: Food Safety Management System A food business must follow HACCP rules after getting ISO 22000 approval. These are the best ways to make sure that food is safe. The government and more people now trust you.

How ISO Certification Improves Success Rates in Tender Bidding

1. Higher Scoring in Tender Evaluations You can get help with money, school, and the government if you offer. You might be able to handle the rules and technology better if you get ISO approval. You'll get more work this way. 2. Strengthening Proposal Documents In their cover letter, people who want to bid and have an ISO license can say so. They care because they want to stay safe and get things done fast and well. When something costs more, people who need it will buy it more often. 3. Meeting Industry-Specific Regulations Things that have the ISO mark on them have been checked to make sure they follow the rules in that area. This is very important. You can be fired from IT, medicine, IT, health care, or IT if you break the rules. 4. Facilitating International Tender Participation Before a company can do business in another country, it has to agree to the ISO. Anywhere, someone from another country can work for a business. Steps to Obtain ISO Certification for Tender Bidding 1. Pick the right ISO number. Find out what kind of license your business needs and how much an ISO license costs. How much should it cost? Get prices or talk to people who live or work in the area. 2. Check out the holes. To find out what's wrong, read what ISO says about how to run a business. Things are going to get better. 3. Do what you need to do. When you do something, follow the rules that ISO gives you. To do this, you need to be willing to take chances and follow the rules about safety or the world. 4. Get your company a badge. Make sure the licensing group can have your work before you send it to them. 5. Look over your own work and show other people how to do things. Before the last certification check, teach your team about ISO standards and how to follow them. Make sure they're done. 6. Get a pass and follow the directions. Remember to always follow the rules once you have your license. Do things differently and check them often.

Q&A on Understanding the Importance of ISO Certification in Tender Bidding

Q.1 Why is getting ISO approval important for getting a work?

If a company gets ISO approval, it means it meets the requirements for its field. The company has a better chance of getting business and government contracts since it meets more bid standards and seems more reliable.

Q.2 Can a business do work that hasn't been checked by ISO?

These days, no one will hire you unless you pass ISO first. You have an advantage if you have ISO approval, even if the bid doesn't ask for it. This is for your own safety and to show that you understand the rules.

Q.3 Does ISO 27001 have to be used in bids for IT and security?

It is very important for both IT and military projects to follow ISO 27001 to keep information safe. In this way, threats and leaks of private information online are kept at bay.

Q.4 How does having ISO 14001 help a business get work from the government?

Making sure the plans will last is a big part of many government projects that are green and follow environmental rules. A company that has ISO 14001 shows that they care about this a lot.

Conclusion

To get a deal, you need to know a lot about ISO. Things will go faster and look better if you pay attention to the rules. A company in the same area that has the ISO mark stands out from the rest. More people will bid on the job if they show they care about the goods, the environment, and safety. In the business world, where contracts are very important, getting ISO approval is no longer a nice-to-have; it's a must. A business can grow, get new customers, and stand out in the market if it has the right ISO license. For more details visit : https://bidhelp.co/

#urban development department jharkhand tender#industries and mines department#horticultural tender#technical education department up tender#metro tenders#central railway tenders#WinningTenders#GlobalStandards tender#ISO9001#ISO14001#ISO27001#GovernmentTenders#ProcurementSolutions#ContractBidding#PublicProcurement#BusinessStandards#ISOCertification#QualityManagement#BusinessGrowth

0 notes