#quality control testing for cement

Explore tagged Tumblr posts

Text

Ensuring the quality and durability of cement is crucial for any construction project. Performing an effective test on cement involves several cement testing methods to assess its properties and compliance with standards. This guide outlines the effective cement testing procedures and highlights key aspects of quality control testing for cement.

#test on cement#cement testing methods#effective cement testing procedures#quality control testing for cement#soundness test#laboratory equipment for cement testing

0 notes

Note

Hi. How are you? Can you please write a fic, Zoro x Fem Reader, where Zoro loves reader but doesn’t know/get that he’s in love. He’d do anything for her but he wonders if it’s love or what? Thank you so much. You’re amazing 💕

Hello! I'm hanging in there and hope you're doing well, too. Thank you for sending in a request. I hope you like it, lovely 💜💜

You were his friend, nothing more. He gave you a helping hand every now and then just like he did with the others. Giving you advice for combat was something he would give any of his friends. So what was it about you that got his heart racing and his palm sweaty? Brushing it off wasn’t doing any good, further piquing his curiosity.

CW: SFW, fem!reader, fluff, slow burn, mention of combat training, confession

The kind of love that sneaks up on you (Zoro)

In a world where only the strongest seemed to thrive, you were left no choice but to learn how to properly defend yourself. You were finding yourself in sticky situations more and more often, and despite Zoro always being there to save you, deep down the fear that one day he wouldn’t be able to grew. Guilt festered as you felt more like a burden. Even though no one made you feel like you were, you were clearly weaker than the rest. However, that was something you were determined to change.

One-on-one sessions with Zoro were spent working on your reflexes and general combat skills. It wasn’t necessary for you to become the strongest; merely keeping your head afloat and learning to use your enemies' advantages against them were skills you had set out to exercise.

“You gotta keep your eyes on me. Don’t look away.” The next swing he delivered was swift yet controlled, testing how good your intuition was.

Each move from him was countered with more confidence than the last. You nodded at his advice, keeping your head held high and not allowing yourself to stay cowering in the shadows anymore.

Zoro’s expression was stern, serious, and each push he gave you was carried out from a place of care, for letting you off “easy” would be an insult to your abilities. He believed in you, and your progress never went unnoticed.

Panting from exertion, you had reached your limit. The subtle shift in his demeanor was followed by him retracting his next move. He sighed, “Let’s stop here for today.”

“What? Why? I can keep going!”

“It’s not weak to know your limits.” Wisdom was a quality of his that was often overlooked. Swallowing the tough pill, you knew arguing would be useless.

Watching your inner conflict was something that felt all too familiar. There was a tightness keeping his heart from beating freely as you stood there looking defeated. His mouth went dry and his gulps felt like wet cement caught in his throat.

There’s no point in sulking was what he wanted to say, but he hesitated. It was true, so why couldn’t he form the words? They’d hurt you, perhaps deep down he knew that. However, you were sensible enough not to take it personally… weren’t you? The thought of bringing you to tears kept him locked in place. This uncertainty of how to approach you would settle on his chest every now and then, unexplainable and popping up at the oddest times.

“You should get cleaned up.” When your eyes met his once more, his breaths grew uneven. “You look a bit sweaty and would probably be more comfortable if you changed.” The subtle touch to your hair as you averted your gaze caused his cheeks to burn red.

Should I have mentioned she looks sweaty? He mulled over the awkwardness now dispersing through the air when you left the room. The room felt hot all of the sudden. His brow furrowed and he crossed his arms in irritation. Images of you were there in his mind’s eye: your eagerness to improve, the devotion and passion that were evident when you fought, and that refusal to be forced into a box just because you were a woman.

Such traits were admirable and honorable, parts of you which sent his heart racing in an uncontrollable state that not even meditation could calm sometimes. When you weren’t with him, he went looking for you, and when you were, he didn’t want you to leave.

Did you feel the same? He wondered. Such a question made him antsy with anticipation. Uncertainty never deterred him from pushing forward in the past, but you were different. The reason why wasn’t clear, you just were.

A long slightly agitated sigh left him. Irritation not tied to you specifically but to the emotional state he found himself in. Pulling, tugging, grasping: he could feel the discomfort clawing away at him. His fingers dug into his biceps while he fought off the meddlesome thoughts to confront you in vain. Shaking slightly, he couldn’t take it.

Without a plan, his feet carried him to you, which left him at loss for words when you turned towards him. The face that kept him in a chokehold was washed with concern given he appeared to be hyperventilating.

“Are you alright?” Gentle, caring, selfless: you had no idea how much your tone affected him.

“Yeah, I just came here to say…” A fear he never thought would trouble his life reared its ugly head time and time again. “That I hope our last training session wasn’t too much for you.”

“Is that really all you wanted to tell me?”

The pounding in his chest was nearly agonizing, but what was he to do? Ignoring the way he felt about you was only making this pain worse, taking the plunge into the unknown seemed like the only option to lift this weight off his shoulders.

“No, but I’m not sure how to articulate this exactly.” He gestured to the state of him—riddled with nerves that were beyond his understanding. There was no explanation needed, though.

“I know how you feel.” Your smile gave away your own struggle with trying to comprehend how he affected you. “It’s kind of scary,” you added with a chuckle.

“It’s… yeah, scary,” he breathed. A flush of red spread across his face when you stepped closer. Your eyes held such a depth of emotion towards him. His heart began racing again, but this time was different. Instead of uncertainty, elation pounded against his chest. When you wrapped your arms around him, the hesitation from him wasn’t out of figuring out what he should do, but instead disbelief.

Fear had never left him shaken before. Knowing that you not only understood but also returned his feelings made that unease deep within fade, and the longer you held onto each other, the more he distanced himself from it.

#one piece#x reader#one piece x reader#one piece imagine#one piece x you#op#op x reader#one piece fluff#roronoa zoro#zoro x reader#zoro x you#op x you#zoro roronoa

109 notes

·

View notes

Note

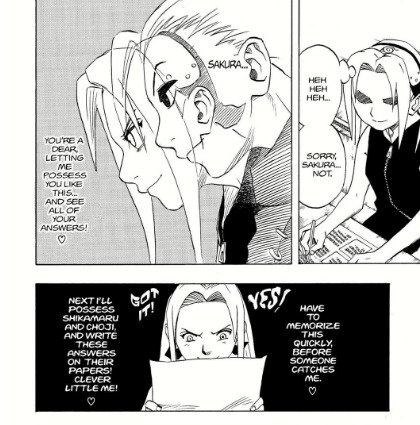

I think canon did the Yamanaka, and thus Ino, dirty by necessity tbh. I don't like it, but also the show is mostly focused on front line combat and training for it. Which is the opposite of Yamanaka strengths, as a clan focused on spying, interrogation, conversion, and (in more gritty/dark fanon) seduction and subtle poison. If a Yamanaka is in a position where their skill is compared to a front line assault ninja, they've already failed, yknow? Their targets shouldn't even comprehend they're near a ninja. And I get why the show didn't focus on that, it was NARUTO Shippuden not INO Shippuden. But on that basis alone it's an unfair and futile comparison to set Ino up as Sakura's long term rival. If anyone it should've been Shizune, or more realistically Kabuto (and she ISNT Kabuto's equal, imo)

Hi there, I’m not at the moment replying asks and this might be unfair to some people that send me questions that I haven’t replied before (apologies), but I wanted to tackle this specific subject (Ino), as I don’t get that many asks about her.

I think canon did the Yamanaka, and thus Ino, dirty by necessity tbh. I don't like it, but also the show is mostly focused on front line combat and training for it. Which is the opposite of Yamanaka strengths, as a clan focused on spying, interrogation, conversion, and (in more gritty/dark fanon) seduction and subtle poison.

I apologize, but I have to disagree with you, not on the fact that two-thirds of Team 7 focuses on frontal attacks (Naruto and Sakura -Sasuke, as Uchiha and a prodigy who also knows kenjutsu, can tackle pretty much any range of attack), and as the team with the most panel time they get pretty much highlighted throw out the series. Still, this manner of attack isn’t the story's primary focus.

The story in itself is about political warfare and the overall cruelties of the system, Sasuke -as an antagonist, it’s the main plot driver of the show (as are Obito, Nagato, and Orochimaru), and the main character that the narrative establishes as “the good ones” are reactors rather than causers.

Once this is established, I do agree that the show focuses mostly on front-line attacks as those are the ones the main duo (and some other fan favorites) possess, however, this manner of combat isn’t as relevant in the overall structure: Itachi and Nagato, for instance, rely on either genjutsu or upon their rinnegan and vast amount of chakra to control other people and perform their binding. Deidara fought against Sasuke while putting distance between them through his secret technique, and so on.

The relevance of such a style of combat is well established during the Chünin Exams: this type of approach is the most “spectacle-friendly” as it allows viewers to witness true carnage and visible consequences, cementing before the audience the overall military power of a village or a character –which is similar, if not equal, of how a shönen works for its audience.

However, it’s constantly highlighted, albeit secretly (as this portion of the tests isn’t shown to the rest of the civilian population as it lacks the “thrill” that combats possess and I’ll say some readers skipped it as they, too, liked to see displayed raw physical power, as that’s how most mainstream heroes are depicted, not having to think around their power shall it be more complicated than a powerful punch); the relevance of Information gathering skills, having an entire test dedicated to it: such exam, Sakura failed, as she never realized what the test was actually for. Ino-Shika-Chö passes it because Ino was the only one out of the three of them shown to have understood it and has the perfect technique for it, here.

There are, however, other mentions of such specialty relevance during the second stage as well, here and here –of course, this specific portion of the “information gathering” skills are to be more rudimentary as they’re more focused upon the shinobi’s survival rather than sharpening their spy qualities, but they are necessary to guarantee the success of a mission.

Obito specifically targeted the Intelligence Division where Inoichi and Shukaku were to guarantee his success as they worked quickly with the information they received of the battlefield to send specific teams to different locations to warrant the enemy’s defeat (like when they sent Team 10 to support Kumo and fight the Gold and Silver Brothers, or how they also asked them to defeat Asuma); Hashirama specifically asked for a Yamanaka to spread amongst the shinobi forces the information he had and Shikamaru’s strategy.

Sasuke and Naruto (or even Hashirama and Madara), are people whose strength isn’t the usual norm, as they’re particularly strong even amongst those considered “the strongest” in the military population (Kages), so them not having to rely on prior information to win a battle (despite them coming up with strategies all the time upon seeing how their enemies work –something Sakura isn’t shown doing, as she either relies on other people (Chiyo) or fails, as she did against Dosu) it’s an off the norm occurrence, only to be applied to them.

People's preference around which techniques are best or more "spectacle-friendly" -something necessary for a manga that relies on visual story-telling, doesn't dispute the overall value of Yamanaka clan's techniques inside the plot and structure Kishimoto established (they, after the UCM, became the clan with the most information-gathering relevance, as they were the only non-Sharingan users that could control their target and read their mind, and while the Saiko Denshin it's a T&I jutsu and not a Yamanaka one, it's clear by Ino's recollection of it that it's at least taught at its most basic form).

If a Yamanaka is in a position where their skill is compared to a front line assault ninja, they've already failed, yknow? Their targets shouldn't even comprehend they're near a ninja. And I get why the show didn't focus on that, it was NARUTO Shippuden not INO Shippuden.

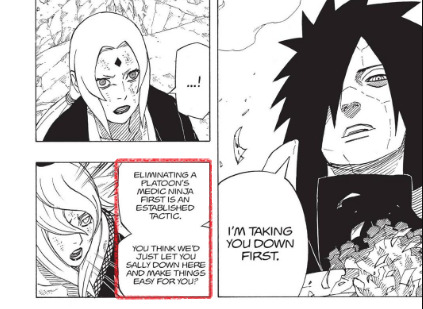

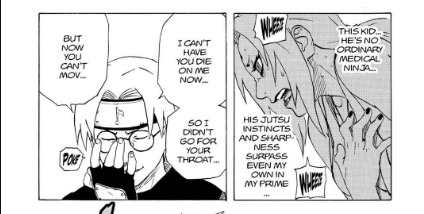

I agree that Ino isn’t a specialized combater, although she did fight Asuma while controlling two Zetsu (I speak a little about the possibility of it being a technique she came up with here), so her taijutsu is -at least, better than Shikamaru’s who stood back as support; her family’s technique and her medical training taught her to stay out of conflict (as she did when vs. Hidan and Kakuzu) in order to be able to attend those wounded (the only ones able to fight are those that mastered Mitrocondrial Regeneration, as they are able to heal without using signs and have more chakra to spare since they stored it, x and x), as medics are also main targets during combats (x).

[If you are more interested in Medical skills, here’s a little post about it: x]

However, I’ll say that, as a secondary character, she got more panel time and development than many other characters who were pushed aside shortly after their introduction (Hinata, Kiba, Shino, Kurenai -to name some of Konoha’s). She was able to help discern, albeit with her father and an ANBU, Nagato’s location when sharing information about her mind-body switch control, she also realized one of the Paths used a similar technique to Inoichi’s (Saiko Denshin) and was given a few very powerful moments during the war, which is more than other fandoms were given.

But on that basis alone it's an unfair and futile comparison to set Ino up as Sakura's long term rival. If anyone it should've been Shizune, or more realistically Kabuto (and she ISNT Kabuto's equal, imo)

Do you mean, unfair for Ino to be Sakura's rival or the other way around? Kabuto is a far better medic than any of them, and Sakura, while impressive, didn’t surpass Tsunade at this stage –as she improved not Tsunade’s techniques, being solely able to master them prior in age to her mentor as Tsunade created them and had to experiment with her own body in order to use it and teach it afterward. Kabuto invented his own version of Mitochondrial Regeneration (x), which is the reason why Orochimaru chose him. He’s the only one who Tsunade considers surpassed her during her prime (x, x).

Sakura and Ino’s rivalry has less to do with their overall techniques and more to do with their attraction to Sasuke, which is the main focus Sakura puts upon their rivalry. Asuma claimed during his last speech to Ino that she mustn't lose either Ninjutsu or love, but the bars they both have about their techniques are completely different –Sakura, medical-wise, possesses a natural advantage that Ino doesn’t, which is natural delicate chakra control, something inherently necessary to learn the Yin Seal; while Ino’s medical skills (likely taught to her through Shizune), are rudimentary at best in order to do something else for her team while on a mission that doesn’t require her technique, in order to guarantee her safety.

Now, you might wonder, why does she have to be safe? Canonically speaking, besides collecting information, the team must guarantee at least one survivor who can pass on the knowledge (or, at least, a way to communicate the information). No other team is expected to ensure such a thing (x).

In that sense, Team 7, Team 8, and Team Gai are mostly viewed as expendable** (I am aware that all of the soldiers are viewed in such light, I’m specifically referring to such an idea when already inside that “disposable spectrum”). Only those front-lines combateurs that have techniques with enough power to defy even shinobi standards (Naruto, Hashirama, Tobirama, and some others –and I’m not putting Uchiha there as they are able to cover multiple ranges), are highlighted and rewarded with the Hokage title, the rest are sent to die or to distract the enemy in order to open space for teams more specialized in gathering the enemy’s secrets or strategies.

[Minato, also considered amongst the best, relied on other front-liners to plant his special kunais upon his targets and to take care of a big portion of the enemies, as he killed the rest. Saving the small group of survivors.]

Being rivals has nothing to do with having similar techniques, but either opposed goals (Sasuke vs. Naruto) or the same goal (Sasuke’s love reciprocation when it comes to Sakura and Ino).

Inside the manga itself, the notion of rivalry is shown to be deeply intertwined with shinobi culture, as they encourage such a mindset so shinobi would push each other to new highs of their respective techniques in order to win their competitions as long as they don’t put Konoha’s stability in jeopardy: Madara/Hashirama, Danzo/Hiruzen, Kakashi/Obito, Naruto/Sasuke, Sakura/Ino.

[**Sakura, as a front-line fighter, is expendable, as a medic-nin, slightly less, as she is expected to die, if doing so, last of all. Not to return alive, as Team 10].

In case you’re interested, I have some other post regarding kunoichi:

The infinite “who’s strongest Kunoichi” debate and the sexist erasure/degradation of female characters and an addition

Yamanaka clan techniques

Posts of my Naruto re-read

#naruto#ino yamanaka#yamanaka ino#yamanaka#yamanaka clan#sakura haruno#sakura#team 10#inoshikacho#choji#shikamaru#sakura vs. ino#sakuravsino#kunoichi#kabuto#tsunade#tsunade senju#medical ninjutsu

69 notes

·

View notes

Text

Understanding Muffle Furnace 1400 Degree: Applications, Features, and Benefits

A muffle furnace is a vital tool in laboratories and industries for conducting high-temperature applications. Designed to reach extremely high temperatures, muffle furnaces are used for tasks like material testing, ashing, calcination, and heat treatment. The Muffle Furnace 1400 degree model, in particular, is engineered to withstand temperatures up to 1400°C, making it ideal for a range of specialized applications.

What is a Muffle Furnace?

A muffle furnace is an enclosed chamber furnace with heating elements embedded within insulating materials, typically ceramic or mineral fiber. The insulation creates a “muffling” effect, reducing the loss of heat and preventing direct exposure to heating elements. This design enables the furnace to achieve uniform heat distribution across the chamber, making it highly effective for controlled high-temperature applications.

The Muffle Furnace 1400 degree version is specifically made to handle temperatures up to 1400°C. This level of heat is essential in industries requiring precise thermal conditions, including metallurgy, ceramics, pharmaceuticals, and materials science. Due to its high-temperature capability, this furnace model provides a safe and efficient environment for processes like sintering, annealing, and heat treatment of metals and other materials.

Key Features of Muffle Furnace 1400 Degree

High-Temperature Capacity: As the name suggests, the Muffle Furnace 1400 degree can reach up to 1400°C, allowing it to handle demanding applications that require intense heat. This capacity is crucial in processes where lower temperature furnaces may not be sufficient.

Advanced Insulation Materials: High-quality ceramic fiber insulation is used to retain heat, ensuring efficient energy use while preventing heat loss. This advanced insulation also improves safety by minimizing the external temperature of the furnace housing.

Temperature Control Precision: Most modern muffle furnaces come with digital temperature control systems. These systems allow precise temperature settings and program control, maintaining consistent heat for extended periods. This feature is beneficial in laboratories and production environments where accuracy and repeatability are crucial.

Durable Construction: The Muffle Furnace 1400 degree is constructed with durable materials that can withstand the strain of high temperatures over time. The heating elements, often made from materials like silicon carbide or molybdenum disilicide, are designed to sustain prolonged exposure to extreme heat without degradation.

Safety Mechanisms: Safety is essential when working with high-temperature equipment. Muffle furnaces generally come with safety features like over-temperature protection, automatic shut-off mechanisms, and alarm systems, ensuring a safe operating environment.

Applications of Muffle Furnace 1400 Degree

A Muffle Furnace 1400 degree model is versatile and finds applications across various sectors. Here are some common uses:

Material Testing: Muffle furnaces are widely used in materials testing to assess properties of metals, ceramics, and other materials. The high temperature enables the testing of material behavior, structure, and strength under intense heat.

Ashing: In industries such as pharmaceuticals, food, and environmental analysis, muffle furnaces are used for ashing. This process involves burning off organic substances to leave behind inorganic material for analysis.

Calcination: Calcination involves heating materials to remove volatile substances or moisture, creating a more stable form of the material. The high temperature of a 1400-degree muffle furnace makes it suitable for calcination in chemical and cement industries.

Heat Treatment of Metals: Muffle furnaces are frequently used to alter the physical and sometimes chemical properties of metals. Processes like annealing, hardening, and tempering benefit from the furnace's high and consistent temperatures.

Sintering of Ceramics: Ceramics require high temperatures for sintering, a process that compacts powdered materials into a solid structure. The 1400-degree capability is ideal for this, as it ensures the material is uniformly sintered for optimal quality.

Benefits of Using Muffle Furnace 1400 Degree

Enhanced Efficiency: With the capacity to reach 1400°C, this furnace reduces the time needed to complete high-temperature processes. It also allows for batch processing, improving operational efficiency in industrial applications.

Uniform Heating: The muffle design ensures even heat distribution across the entire chamber, crucial for applications where temperature consistency is necessary to achieve accurate results.

Energy Saving: Advanced insulation materials reduce energy consumption by retaining heat. This makes the furnace more economical to operate, especially when it is used continuously in an industrial setting.

Reliable Performance: Designed for durability, muffle furnaces can sustain high temperatures without compromising on performance. Their construction and robust heating elements ensure that the furnace remains reliable over long-term use.

Versatility in Application: With the ability to handle diverse materials and processes, the Muffle Furnace 1400 degree model is suitable for various industries, from laboratories to large-scale manufacturing environments.

Conclusion

In conclusion, the Muffle Furnace 1400 degree is essential for high-temperature applications across various industries. With its capability to reach 1400°C, advanced insulation, precise temperature controls, and durable construction, it supports efficient, safe, and consistent results in materials testing, metal treatment, and more. When considering a reliable high-temperature furnace, Bionics Scientific provides a range of high-quality muffle furnaces designed to meet these demanding requirements, making it an ideal choice for laboratories and industrial settings alike.

1 note

·

View note

Text

Vasantha Advanced Systems: A Leading EMS Company in India

Vasantha Advanced Systems, a trusted and leading EMS company in India, has been a pioneer in the electronic manufacturing landscape since its inception in 1995. Based in Coimbatore, Tamil Nadu, Vasantha Advanced Systems has made significant strides in providing advanced, reliable, and customized electronic manufacturing services (EMS) to both national and international clients. With decades of experience and a commitment to quality, we bring a unique approach to the EMS industry, ensuring that our services meet and exceed industry standards.

Certified Excellence in Electronic Manufacturing Services

Vasantha Advanced Systems is an ISO 9001:2015 and IATF 16949:2016 certified EMS company in India, showcasing our commitment to high-quality standards and operational excellence. These certifications underscore our dedication to providing superior EMS solutions, backed by stringent quality controls and thorough process management. By adhering to these global standards, Vasantha Advanced Systems has cemented its reputation as a reliable EMS provider capable of meeting the most rigorous quality requirements.

Our Mission: Innovating Electronic Manufacturing in India

Our mission at Vasantha Advanced Systems is to be at the forefront of innovation in electronic manufacturing services. We aim to revolutionize the EMS sector by streamlining our design processes and integrating advanced technology with real-world applications. As a result, we offer clients cutting-edge solutions that not only meet but also anticipate the dynamic needs of the electronic manufacturing industry.

As a leading EMS company in India, Vasantha Advanced Systems is committed to redefining the standards of efficiency, quality, and innovation in electronic manufacturing. Our team of skilled professionals continuously pushes the boundaries to create solutions that align with the fast-evolving technological landscape.

Customized EMS Solutions for National and International Clients

Vasantha Advanced Systems understands that each client’s needs are unique. As an adaptable and highly capable EMS company in India, we provide tailored solutions to fit specific requirements, regardless of the scale or location. Our experience with both national and international clients has equipped us with the expertise to meet a diverse range of demands in electronic manufacturing.

Whether you require PCB assembly, testing, or complex system integrations, Vasantha Advanced Systems has the knowledge, technology, and commitment to deliver superior quality. We take pride in being an EMS company in India that national and international businesses trust to bring their visions to life through our innovative approach to EMS.

The Vasantha Advantage: Experienced Technocrats and a Dedicated Team

At Vasantha Advanced Systems, we believe that our people are our greatest strength. Our team consists of highly skilled technocrats and trendsetters dedicated to maintaining the highest standards in EMS. Each team member is committed to professional ethics and operational excellence, ensuring that Vasantha Advanced Systems remains a leading EMS company in India. Our employees’ expertise, combined with our advanced infrastructure, allows us to deliver unparalleled solutions that drive value for our clients.

Why Choose Vasantha Advanced Systems for Your EMS Needs?

Choosing Vasantha Advanced Systems means choosing an EMS company in India that prioritizes quality, efficiency, and customer satisfaction. Our certifications, innovative approach, and client-centric focus make us the ideal partner for businesses seeking dependable electronic manufacturing services. With our extensive experience, cutting-edge technology, and a team of dedicated professionals, we consistently deliver solutions that help our clients succeed.

Conclusion

If you’re looking for a trustworthy EMS company in India that combines experience with innovation, Vasantha Advanced Systems is your ideal partner. Our commitment to quality, customized solutions, and client satisfaction has made us a top choice for electronic manufacturing services in India and beyond. Contact Vasantha Advanced Systems today to learn how we can help bring your electronic manufacturing projects to life with precision, efficiency, and unparalleled expertise.

1 note

·

View note

Text

Soda Feldspar Powder Manufacturers

Soda Feldspar Powder Manufacturers

Quartz Silica powder is a versatile material used across various industries for its unique properties In the glass industry, it serves a key ingredient, providing clarity and strength. In metal casting, quartz sand is combined with other substances to create durable molds. Additionally, it plays a crucial role in ceramics, abrasives, fillers, water filtration, and even in some personal care products, showcasing its wide-ranging applications.

Iota Metaflux is manufacturing and exporting Quartz powder in different grades for various Industrial uses. Iota metaflux is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced.

Iota Metaflux is also manufacturing Grade B and Grade Super Quartz powder for industries like paint Industry, Cement Industry, ceremic industry, coating Industry etc. We specilize in manufacturing quartz powder as per the clients specifications. Our Quartz powder is widely used in cement Industries for concrete slab manufacturing.

Welcome to Iota Metaflux, a thriving mineral manufacturing and supplying company established in 2010. Nestled in the heart of the Rajasthan-North region in India, our mines and processing plants yield an abundant supply of high-grade materials, specializing in feldspar, quartz, rice husk ash powders, and more. Soda Potash Feldspar

Our roots trace back to a founding team of IIT/NIT alumni with over two decades of industry experience. Comprising experts in Metallurgy and Material Science, Chemistry, Ceramic Engineering, and Chemical and Process Engineering, our professionals bring a wealth of knowledge to the table. At Iota Metaflux, we pride ourselves on our unique approach to understanding the science behind minerals, fostering high-level customer interaction to meet specific industrial needs. Click for more information Soda Feldspar Powder

We are committed to offering our clients top-notch, competitively priced raw materials with consistent and timely supplies. Our goal is to emerge as an industry leader, leveraging our unparalleled knowledge and expertise. From our in-house processing technology to the dedicated efforts of our R&D teams, we prioritize precision and maintain stringent quality standards. Click now for more update Potash Feldspar Powder

At Iota Metaflux, we operate under three core principles:

Top Quality: Our commitment to delivering products of the highest caliber sets us apart. We adhere to rigorous quality control measures to ensure our materials meet the most demanding industry standards.

Customer-Friendly: We understand the unique requirements of our clients and engage in meaningful interactions to tailor our offerings accordingly. Your satisfaction is our priority, and we strive to foster long-lasting partnerships.

Reduced Environmental Impact: We are dedicated to sustainability. By adopting eco-friendly practices and minimizing our environmental footprint, we contribute to a greener future. Click now Soda Feldspar Powder Manufacturers

As technology evolves, so do we. By staying at the forefront of industry advancements, we guarantee that our clients receive the best products available. Explore our site to discover how Iota Metaflux can provide you with quality, innovation, and reliability.

0 notes

Text

The Growing Role of Capsule Manufacturers in India’s Pharmaceutical Industry

India has established itself as one of the world's most significant pharmaceutical manufacturing hubs, producing high-quality drugs for domestic and international markets. Capsule manufacturers are critical in supplying dependable and efficient medication delivery systems in this thriving industry. Capsules provide an effective method of administering drugs in controlled doses, crucial for patient compliance and treatment efficacy. With technological breakthroughs and a greater emphasis on quality, Indian capsule producers are meeting rising demand and setting new benchmarks in the global pharmaceutical industry.

Why Capsules Are Integral to Modern Pharmaceuticals

Capsules are a popular alternative for drug formulation because of their diversity, convenience of administration, and ability to protect active components. They can include both solid and liquid drugs, allowing for a diverse range of compositions. Furthermore, capsules are perfect for controlled and prolonged release, which improves dosing accuracy and patient comfort. This versatility makes them an intriguing option for pharmaceutical businesses developing unique solutions across multiple therapeutic categories.

Trends Driving the Growth of Capsule Manufacturing in India

Several reasons contribute to the increasing need for capsule manufacturers in India. These trends show India's growing reliance on high-quality, efficient, and compliant pharmaceutical producers, helping it maintain its position as a worldwide drug production leader.

Expansion in Therapeutic Areas

The Indian pharmaceutical sector has diversified into several therapeutic areas, including cardiology, neurology, cancer, and infectious illnesses. Capsules provide a versatile and effective solution to many health concerns by allowing for formulation and dosage customisation. Indian producers are meeting expanding demand by developing various capsule forms, including immediate-release and modified-release capsules. This has allowed manufacturers to meet a more excellent range of health demands while remaining flexible in medicine administration.

2. Technological advances in manufacturing

As technology advances, capsule manufacturers across India implement advanced procedures to improve manufacturing efficiency, lower prices, and maintain tight quality control. Manufacturers may now exceed international requirements while lowering the risk of contamination or human error thanks to innovations such as automated encapsulation machines and enhanced quality testing methodologies.

3. Compliance with Global Quality Standards

Capsule producers in India follow high-quality standards to ensure compliance with worldwide regulatory regulations, including those set by the US FDA, WHO, and the European Medicines Agency. Compliance with these criteria has enabled Indian producers to export their products to diverse markets, cementing India's reputation as a reliable source of pharmaceutical items. Quality assurance has thus become a pillar for capsule makers seeking to supply safe and effective medicines to patients globally.

4. Emphasis on sustainable and ethical practices

With a rising emphasis on sustainability, capsule manufacturers are implementing environmentally friendly methods into their manufacturing processes. This involves utilising sustainable raw materials, energy-efficient manufacturing, and waste-reduction programs. Furthermore, Indian producers are becoming more devoted to ethical procedures, including openness, fair pricing, and a focus on public health.

To summarise, India's capsule manufacturing sector is integral to the pharmaceutical industry, promoting growth and innovation in drug formulation and delivery. With prominent enterprises like Prakruti Life Sciences setting quality and efficiency standards, the country remains a trusted partner in global healthcare.

0 notes

Text

Comprehensive Solutions for Dental and Medical Supplies in Muscat

In the bustling city of Muscat, where healthcare needs are ever-growing, Al Farsi Dental & Medical Supplies stands out as a trusted partner for dental and medical practitioners. Our commitment to providing high-quality products tailored to the unique demands of healthcare professionals makes us the leading supplier in the region. Whether you're looking for dental supplies, medical supplies, or specialized equipment, we offer a diverse range of products to meet your needs. This article delves into the various categories of supplies we offer, the significance of quality in healthcare, and how Al Farsi can support your practice.

The Importance of Reliable Dental Supplies in Muscat

Dental health is a crucial aspect of overall wellness, and having access to reliable dental supplies in Muscat is essential for practitioners. At Al Farsi, we understand that dental professionals require high-quality tools and materials to provide the best care to their patients. Our extensive inventory includes everything from basic dental instruments to advanced diagnostic equipment.

Essential Dental Instruments

Every dental clinic needs a reliable set of instruments to perform various procedures. We supply a wide array of dental instruments, including:

Examination Tools: Mirrors, probes, and explorers for thorough assessments.

Extraction Instruments: Forceps and elevators designed for effective tooth removal.

Restorative Materials: High-quality dental composites, amalgams, and cements to restore tooth function and aesthetics.

Dental Chair Supplies in Muscat

A comfortable and functional dental chair is vital for both patient comfort and efficient practice. Al Farsi provides an assortment of dental chair supplies, including:

Cushioning Materials: High-density foam and covers that ensure comfort during procedures.

Replacement Parts: Components such as armrests, headrests, and upholstery to maintain chair functionality.

Operational Accessories: Foot pedals, control systems, and lighting solutions that enhance the overall experience in the dental office.

Medical Supplies in Muscat: Meeting Diverse Healthcare Needs

In addition to dental supplies, Al Farsi Dental & Medical Supplies is your go-to source for medical supplies in Muscat. We cater to various healthcare settings, from hospitals to private practices, ensuring that every professional has access to essential medical products.

Comprehensive Medical Equipment

Our selection of medical supplies encompasses a broad spectrum of products, including:

Diagnostic Tools: Stethoscopes, sphygmomanometers, and otoscopes that enable accurate patient assessments.

Consumables: Gloves, syringes, and bandages that are necessary for day-to-day medical practices.

Emergency Supplies: Defibrillators, oxygen masks, and first aid kits to handle critical situations efficiently.

Laboratory Supplies in Muscat

The quality of laboratory supplies is fundamental to achieving accurate test results and ensuring patient safety. At Al Farsi, we offer a comprehensive range of laboratory supplies in Muscat that cater to various fields, including:

Testing Kits: Essential for various medical tests, ensuring accurate and timely results.

Glassware: Beakers, flasks, and petri dishes made from high-quality materials to facilitate laboratory experiments.

Safety Equipment: Personal protective equipment (PPE) to protect laboratory personnel during procedures.

Hygiene Products Supplies in Muscat

In today's healthcare landscape, hygiene has become more critical than ever. At Al Farsi, we emphasize the importance of hygiene products in maintaining a safe and sterile environment for both patients and healthcare providers.

Infection Control Supplies

We provide a wide variety of hygiene products supplies in Muscat, focusing on infection control, such as:

Sanitizers: Hand sanitizers and disinfectants that help minimize the risk of infection.

Personal Protective Equipment (PPE): Masks, gowns, and face shields that ensure the safety of both healthcare providers and patients.

Waste Management Solutions: Biohazard disposal bags and containers to safely manage medical waste.

Ensuring Quality and Compliance

At Al Farsi Dental & Medical Supplies, we prioritize quality in all our products. We understand that healthcare professionals need supplies that not only perform well but also meet regulatory standards. Our team is dedicated to sourcing products from reputable manufacturers who adhere to international quality standards. This commitment ensures that our clients receive products that are safe, effective, and reliable.

Why Choose Al Farsi Dental & Medical Supplies?

Choosing the right supplier can significantly impact the quality of care you provide. Here are a few reasons why Al Farsi stands out as the preferred choice for dental and medical supplies in Muscat:

Extensive Product Range: We offer a wide variety of dental, medical, and laboratory supplies to meet diverse needs.

Quality Assurance: All our products are sourced from trusted manufacturers, ensuring compliance with safety and quality standards.

Competitive Pricing: We believe that high-quality supplies should be accessible. Our pricing structure is designed to be competitive while maintaining the highest quality.

Customer Support: Our knowledgeable team is always available to assist you with product selection and provide support for your specific needs.

#Dental Supplies in Muscat#Medical Supplies in Muscat#Laboratory Supplies in Muscat#Dental Clinic Supplies in Muscat

0 notes

Text

Top Chips Manufacturers in India – Quality & Variety

The snack enterprise in India has seen superb boom over time, and most of the maximum popular objects is chips. With the call for for chips producers in India continually growing, finding the right producer acknowledged for exceptional, taste, and reliability is vital. Shyam-G Snacks stands out as one of the first-rate chips producers in India, with a popularity for handing over fine snacks national. This article explores why Shyam-G Snacks is the desired preference for chips and the way it compares to different chips producers in India.

What Makes Shyam-G Snacks the Best Chips Manufacturer in India

When it comes to chips manufacturers in India, Shyam-G Snacks has set high requirements. Here’s why it leads the industry:

Commitment to Quality

Shyam-G Snacks is thought for the usage of simplest top rate-high-quality ingredients in each chip they produce. Unlike many different chips producers in India, Shyam-G guarantees that every product keeps high standards.

Variety of Flavors

In addition to traditional salted chips, Shyam-G Snacks gives a wide kind of flavors, from highly spiced masala to tangy tomato, making it a flexible preference among chips manufacturers in India.

Advanced Manufacturing Facilities

Shyam-G operates from modern production units positioned in Kanpur and Hisar, ensuring exquisite output with every batch. These facilities permit Shyam-G to remain aggressive amongst chips producers in India.

Quality Control and Safety Standards

Shyam-G Snacks follows rigorous exceptional control measures. All merchandise are tested to satisfy enterprise standards, which similarly cements Shyam-G’s recognition as a top preference among chips manufacturers in India.

Types of Chips Shyam-G Snacks Offers Shyam-G offers a wide range of merchandise, from traditional potato chips to particular variants. Here are some popular alternatives:

Classic Salted Chips

Classic salted chips are a undying favourite, and Shyam-G’s version has a perfect stability of crunch and saltiness, making them a top pick out amongst chips producers in India.

Why Choose Shyam-G Over Other Chips Manufacturers in India?

When it comes to chips manufacturers in India, numerous factors set Shyam-G Snacks apart:

Nationwide Distribution

Shyam-G Snacks has a well-hooked up distribution network that guarantees clean availability of its merchandise national. This is a widespread advantage over many different chips manufacturers in India.

Innovative Packaging

Shyam-G emphasizes green, innovative packaging to preserve products fresh even as minimizing environmental impact. This considerate approach differentiates it from different chips producers in India.

Affordable Pricing

Despite being a premium product, Shyam-G Snacks offersaggressive pricing. Compared to different chips manufacturers in India, it offers excellent snacks at an lower priced rate.

Excellent Customer Feedback

Shyam-G Snacks has acquired rave critiques from clients across India. Positive remarks on exceptional, flavor, and freshness makes it a frontrunner among chips manufacturers in India.

The Journey of Shyam-G as a Top Chips Manufacturer in India

Shyam-G’s fulfillment as one of the pinnacle chips manufacturers in India is attributed to its determination to exceptional and innovation. From a single unit to becoming a pacesetter in the Indian snack enterprise, Shyam-G's journey is inspiring.

Expansion Across India: Shyam-G began in Kanpur and has increased to numerous cities, making sure its position as a outstanding player amongst chips producers in India.

Innovations in Flavors and Ingredients: To cater to converting choices, Shyam-G frequently introduces new flavors and merchandise, keeping them in advance of other chips manufacturers in India.

Sustainability Initiatives: Shyam-G is devoted to sustainability through making an investment in green production strategies, setting an example for other chips producers in India.

How Shyam-G Supports Indian Farmers

Shyam-G Snacks sources a lot of its raw materials directly from neighborhood farmers, which not only ensures the quality of elements but additionally supports the local economic system. This approach enhances the agency’s role among chips producers in India who're known for ethical sourcing.

Comparing Shyam-G with Other Leading Chips Manufacturers in India

While different chips manufacturers in India produce lots of merchandise, Shyam-G Snacks makes a speciality of great, innovation, and customer satisfaction.

Feature Shyam-G Snacks Other Chips Manufacturers in India

Quality Control Consistent and thorough Varies

Product Variety Extensive range Moderate

Pricing Affordable and competitive Ranges

Distribution Nationwide Limited in a few instances

Conclusion

When selecting the right chips producers in India, Shyam-G Snacks is a top choice that gives fantastic, low-cost, and delicious snacks. Their focus on best ingredients, fitness-aware merchandise, and client pleasure makes them a desired call inside the industry. If you are seeking out the best in chips producers in India, Shyam-G Snacks is a preference you can rely on.

0 notes

Text

Training Staff on Compliance Management Software ISO 17025: Best Training Practices

In the modern laboratory practice scenario, adherence to international standards such as ISO 17025 is crucial to the credibility and correctness of test results. Compliance management software ISO 17025 is considered a basic tool that will help laboratories attain these standards efficiently. This article outlines some great ways to train personnel on the use of ISO 17025 compliance software so that your team can maintain very high-quality standards.

Set Clear Learning Objectives

Define the learning objectives for the compliance software implementation process. These objectives can focus on anything from documentation processes and audit management to quality control and corrective action management within the software environment. By defining these objectives, you can tailor the training approach to be more specific and practical for a comprehensive understanding and clearly defining roles among the employees.

Select Appropriate Training Methods

The strategy adopted for the training program can also be one factor that helps staff members learn the software more quickly and get used to it. A mixed strategy where workshops and practical activities are interposed with digital learning experiences can help with different types of preferences. In the case of ISO 17025 software, for instance, interactive simulations of potential real-world experiences enable the learner to be part of an experiential learning process. Here, a pragmatic understanding is developed rather than theoretical learning.

Ongoing Assessment for Improved Competence

The provision of regular assessment during the training process is necessary for the cementing of prior learning and for determining if there is any need for further learning. Ongoing assessment can be carried out through examinations, software practice exercises, and peer reviews. This means all the employees are brought to the same level of understanding of what is required to operate the compliance management software ISO 17025.

Leveraging the Expertise of Trained Professionals

Incorporation of expertise by some users or specialists can really boost the value of learning that can be acquired. These experts can bring practical insights, tips, and real-life case studies of managing ISO compliance through the software. Their experience in the software can help new learners grasp the applicability of the software and understand the subject with which the standards are implemented.

Develop a Culture of Everlasting Learning

However, considering that ISO 17025 standards and compliance mandates have changed, training on compliance software should be set as an ongoing process. In creating a culture of general education and understanding changes in software and ISO standards, there is a better aspect to this initiative. A central resource center where all staff have access to ongoing education materials, updates, and means of resolving issues clearly allows for upholding this high standard of compliance.

Conclusion

Any laboratory that is devoted to meeting the international standards of quality must have strong impartation on the use of compliance management software ISO 17025. Using your team with more defined learning objectives, variable instructional techniques, ongoing assessments, subject matter experts' guidance, and the environment of continuous learning, you can drive the software. This way, compliance, and quality control are enhanced, making laboratory results even more reliable and your institute more reputable in the scientific world.

0 notes

Text

Top Calcite Powder Manufacturers in India - Jyoti Mineral Industries

Introduction

Calcite powder is widely used in various industries, from construction to plastic production, due to its versatile properties. Jyoti Mineral Industries stands out as one of the top calcite powder manufacturers in India, providing high-quality products with exceptional customer service. In this article, we will explore calcite powder, its applications, and why Jyoti Mineral Industries is a leader in the industry.

Understanding Calcite Powder and Its Applications

Calcite powder, derived from natural calcium carbonate, is known for its high purity and consistency. It finds applications in a broad spectrum of industries, such as:

Plastic manufacturing: Used as a filler to enhance strength and finish.

Paint industry: Adds brightness and consistency to paints.

Construction: Integral in cement, mortar, and concrete production.

Pharmaceuticals: An essential ingredient in producing calcium supplements.

Paper industry: Improves paper quality by adding smoothness and brightness.

Jyoti Mineral Industries: A Leading Manufacturer

Among the many calcite powder manufacturers in India, this company is recognized for its exceptional quality. With over a decade of experience, they have remained committed to producing high-grade calcite powder. Their extensive industry expertise enables them to cater to various sectors, providing tailored solutions to meet specific industry needs. Production Excellence The company emphasizes high-quality production processes to ensure the calcite powder they provide meets industry standards. Their advanced manufacturing techniques guarantee the production of high-purity powder, which is vital for a range of critical applications. This focus on excellence ensures the consistent delivery of superior products tailored to meet the specific needs of various industries.

Advanced Manufacturing Technology

The company uses advanced technology to extract, process, and grind high-quality calcite. Precision tools help them control the particle size, ensuring consistency in their products. The calcite powder goes through strict testing at various stages of production to guarantee purity and the right level of fineness. Their processing methods reduce impurities, resulting in high-quality products that meet the needs of different industries.

Product Range and Specifications

The company offers a wide range of products to meet the needs of different industries. From micronized calcite powder to larger particle sizes, their products are tailored for various uses. The powder is available in several grades, including:

Fine powder for plastic and rubber industries

Coarse powder for cement and construction

Specialized calcite for pharmaceutical and paint industries

These options ensure their products meet industry standards while offering high performance and durability.

Why Choose Indian Calcite Powder Manufacturers?

India is home to many reputable calcite powder manufacturers, and there are several reasons why choosing one from India is beneficial:

Cost-effective production: Indian manufacturers provide high-quality products at competitive prices due to access to local resources and affordable labor.

Strict quality standards: Indian manufacturers follow international quality guidelines, ensuring reliable products.

Sustainable practices: Many Indian manufacturers are adopting eco-friendly practices to minimize their environmental impact.

Competitive Advantages

They have several advantages that make them a top manufacturer of calcite powder in India:

Customized solutions: They offer tailored calcite powder solutions to meet different industry needs.

Timely delivery: With a strong supply chain, they ensure prompt deliveries, prioritizing customer satisfaction.

Excellent customer service: Their dedicated team handles all inquiries efficiently, ensuring smooth business operations.

Future of Calcite Powder Manufacturing in India

As industries develop, the demand for calcite powder is expected to grow, especially in fields like construction, pharmaceuticals, and plastic manufacturing. Indian producers are well-positioned to meet this increasing demand by advancing their technology and expanding their production capabilities.Jyoti Mineral Industries is a trusted leader among calcite powder manufacturers in India, known for their commitment to quality, innovation, and customer satisfaction. With a broad product range and advanced production methods, they cater to diverse industries across the country and beyond. As the demand for calcite powder continues to grow, it remains at the forefront, providing dependable solutions to meet industry needs.

#calcite powder manufacturers#calciumcarbonatemanufacturerinindia#high brightness talc powder manufacturers#soapstone powder / talc powder

0 notes

Text

Durable & Cost-Effective Interlocking Tiles Making Machine for Your Business

Transform your construction business with BTM Product's state-of-the-art interlocking tiles making machine that combines precision engineering with outstanding durability. Our machines are designed to meet the growing demands of the construction industry while ensuring maximum efficiency and profitability for your business.

Advanced Technology Meets Industrial Excellence

At BTM Product, we understand that investing in an interlocking tiles making machine is a crucial decision for your business growth. Our machines incorporate the latest technological advancements to deliver superior quality products consistently. The robust construction and innovative design ensure minimal maintenance and maximum output, making it an ideal choice for both small-scale and large-scale operations.

Versatility in Production

Our paver block making machine offers unmatched versatility in production capabilities. Whether you need to manufacture traditional rectangular blocks or intricate designer patterns, our equipment can handle it all. The flexible mold system allows you to:

- Create various shapes and sizes of pavers - Produce different thickness options - Switch between designs quickly - Maintain consistent quality across batches

Superior Quality Output

When you choose BTM Product's best fly ash brick making machine, you're investing in quality that speaks for itself. Our machines are engineered to produce blocks with:

- Precise dimensions and smooth finish - High compressive strength - Excellent durability - Uniform color distribution - Perfect interlocking capabilities

Cost-Effective Production Solutions

We understand the importance of operational costs in your business. Our paver block making machine is designed to optimize resource utilization and minimize waste, resulting in:

- Reduced power consumption - Minimal raw material wastage - Lower labor requirements - Increased production speed - Better return on investment

Technical Specifications and Capacity

The interlocking tiles making machine from BTM Product comes with impressive specifications:

- Production capacity: Up to 1000 blocks per hour - Power consumption: Energy-efficient motor system - Hydraulic pressure: Adjustable for different products - Vibration system: Advanced technology for proper compaction - Control panel: User-friendly interface with automatic features

Raw Material Flexibility

Our best fly ash brick making machine is compatible with various raw materials, including:

- Cement - Fly ash - Crushed sand - Stone dust - Industrial waste materials - Color pigments

After-Sales Support

BTM Product believes in building long-term relationships with our clients. We offer:

- Comprehensive installation support - Operator training programs - Regular maintenance services - 24/7 technical assistance - Spare parts availability - Warranty coverage

Quality Assurance

Each paver block making machine undergoes rigorous quality testing before delivery. Our quality control measures ensure:

- Structural integrity - Component durability - Performance consistency - Safety compliance - Production efficiency

Environmental Responsibility

At BTM Product, we're committed to environmental sustainability. Our interlocking tiles making machine incorporates eco-friendly features:

- Reduced carbon footprint - Energy-efficient operations - Waste material utilization - Water conservation systems - Noise reduction technology

Investment Benefits

Investing in BTM Product's machinery offers numerous advantages:

1. Quick Return on Investment - High production capacity - Low operational costs - Minimal maintenance requirements - Extended equipment life

2. Market Competitiveness - Superior product quality - Diverse product range - Consistent output - Cost-effective production

3. Business Growth - Scalable production - Market expansion opportunities - Enhanced reputation - Increased profitability

Installation and Setup

We ensure a smooth transition from purchase to production:

- Site preparation guidance - Professional installation - Initial testing and calibration - Operator training - Production optimization support

Customization Options

Understanding diverse business needs, we offer customization in:

- Production capacity - Mold designs - Automation levels - Control systems - Safety features

Conclusion

Choose BTM Product's machinery for a reliable, efficient, and profitable manufacturing solution. Our commitment to quality, innovation, and customer satisfaction makes us the preferred choice in the construction equipment industry. With our best fly ash brick making machine and comprehensive support system, your business is positioned for success in the competitive construction market.

Experience the difference with BTM Product's superior manufacturing solutions. Contact our team today to discuss your specific requirements and discover how our machines can transform your business operations. Let us be your partner in building a successful and sustainable construction materials manufacturing enterprise.

0 notes

Text

Understanding the Importance of Ready-Mix Concrete Plant for Construction Projects

Regarding modern construction, efficiency, quality, and precision are critical for success. One of the essential innovations in this field is the ready-mix concrete plant. This plant provides pre-mixed concrete made to precise specifications, ensuring consistency and reducing the time required for on-site preparation. This blog will explore the benefits, process, and significance of ready-mix concrete plants, focusing on Kamdhenu Cement, India's leading cement manufacturer and supplier.

What is a Ready-Mix Concrete Plant?

A ready-mix concrete plant is a facility where concrete is produced in large quantities. The concrete is mixed to exact specifications and delivered to construction sites in specialized vehicles. This eliminates the need for on-site mixing, making the process faster and more efficient. The plant combines various materials such as cement, water, sand, gravel, and other additives to create a high-quality mix for building foundations, roadways, and other construction projects.

The Process of Ready-Mix Concrete Production

The process of creating ready-mix concrete is meticulously planned and executed. It begins with a careful selection of raw materials, primarily high-quality cement. Kamdhenu Cement, the No.1 cement manufacturer in India, plays a crucial role in ensuring the quality of ready-mix concrete. Their cement is lab-tested and made from the finest raw materials, offering durability and strength to construction projects.

At the plant, the raw materials are measured accurately to ensure the right balance. The cement is mixed with water, aggregates, and sometimes additional materials like fly ash or silica fume. The result is a precise blend that is mixed uniformly to ensure consistency. The concrete is transported in specialized trucks, maintaining its quality until it reaches the construction site.

Benefits of Using Ready-Mix Concrete

Consistency and Quality Assurance: One of the most significant advantages of ready-mix concrete is its quality assurance. Because the concrete is mixed under controlled conditions at the plant, there is less room for error, resulting in consistent strength and durability. Kamdhenu Cement ensures that all batches are of the highest quality, providing reliable products for large-scale projects.

Time Efficiency: Time is a critical factor in construction. Using ready-mix concrete significantly reduces the time spent preparing the mix on-site. Construction teams can focus on their primary tasks with the concrete delivered ready for use. This efficiency leads to faster project completion times, which is especially important in large infrastructure projects.

Cost-Effectiveness: Although ready-mix concrete might seem more expensive initially, it is more cost-effective in the long run. On-site concrete mixing involves hiring extra labor, purchasing and maintaining machinery, and dealing with potential wastage. Ready-mix concrete, on the other hand, minimizes wastage and reduces labor costs, ultimately saving money.

Environmentally Friendly: Ready-mix concrete plants are designed to reduce environmental impact. By producing concrete in a controlled environment, emissions and waste are reduced. Kamdhenu Cement, committed to sustainability, ensures that its production methods are eco-friendly, contributing to reducing carbon footprints in construction projects.

Customized Concrete Mixes: Ready-mix concrete plants offer the advantage of creating specific mixes tailored to the needs of a project. Whether for a high-rise building, a bridge, or a road, the concrete mix can be adjusted for different strengths, durability, and setting times. Kamdhenu Cement's expertise in cement manufacturing allows them to cater to these specific needs, ensuring that the best mix is used for every project.

Why Choose Kamdhenu Cement for Ready-Mix Concrete?

Kamdhenu Cement has established itself as India’s No. 1 cement manufacturer due to its commitment to quality and innovation. Offering a wide range of cement products, Kamdhenu provides the foundation for some of the most critical construction projects across the country. The company’s products are lab-tested, ensuring only the highest quality materials are used.

Kamdhenu Cement is known for its state-of-the-art production facilities, which are equipped with advanced technology. This allows the company to produce cement that meets international standards, making it ideal for use in ready-mix concrete plants. Additionally, Kamdhenu Cement is committed to offering the best prices and ensuring that clients receive high-quality products without excessive costs.

Ready-Mix Concrete in Infrastructure Development

India’s infrastructure development is booming, and ready-mix concrete supports this growth. Whether it's the construction of highways, bridges, or high-rise buildings, ready-mix concrete plants provide the necessary material to complete projects efficiently and on time. Kamdhenu Cement’s superior products have become a trusted choice for contractors and builders looking to ensure the success of their projects.

The reliability and efficiency of ready-mix concrete make it an ideal solution for modern construction. With the support of Kamdhenu Cement, known for its excellence in cement production, the quality of ready-mix concrete can be further enhanced, providing unmatched strength and durability to every project.

Conclusion

Ready-mix concrete plants have revolutionized the construction industry by providing high-quality, consistent, and efficient solutions. The benefits of ready-mix concrete, including time and cost savings, environmental friendliness, and customizability, make it an invaluable asset for construction projects.

Kamdhenu Cement, India’s best cement manufacturer and supplier, offers the perfect partner for any ready-mix concrete plant. Their commitment to quality, innovation, and sustainability ensures that every project can be completed with the best possible materials at competitive prices. When you choose Kamdhenu Cement, you select the best foundation for your construction success.

0 notes

Text

Ensuring Quality: The Importance of Ready-Mix Concrete in Pakistan's Construction Industry

Ready Mix Concrete In Pakistan construction industry. As infrastructure development rapidly expands across the country, from highways to residential complexes, the demand for high-quality building materials has grown. Ready-mix concrete offers builders a reliable, efficient, and durable solution for large-scale and small-scale construction projects.

In this article, we will explore why ready-mix concrete is essential to the construction industry in Pakistan, highlighting its advantages, the need for quality assurance, and how it contributes to sustainable building practices.

What is Ready-Mix Concrete?

Ready-mix concrete is a pre-engineered mixture of cement, water, aggregates (such as sand, gravel, or crushed stone), and additives that is produced in a batching plant and delivered to the construction site. Unlike traditional on-site concrete mixing, ready-mix concrete is prepared under controlled conditions, ensuring that each batch meets specific requirements.

Using ready-mix concrete in Pakistan’s construction industry offers a range of benefits, including:

Time and Labor Savings: Since RMC is delivered ready for use, it eliminates the need for on-site concrete mixing.

Consistent Quality: Produced under standardized conditions, RMC ensures uniformity and higher quality.

Customizable Properties: Different mixes can be tailored to meet the specific requirements of each project.

The Role of Ready-Mix Concrete in Pakistan's Construction Industry

The construction industry in Pakistan is booming, driven by government infrastructure projects, private real estate developments, and industrial expansion. Ready-mix concrete is now the preferred choice for construction professionals across the country, and for good reason.

1. Meeting the Demands of Large-Scale Infrastructure Projects

Pakistan is undergoing massive infrastructure development, including the construction of roads, bridges, dams, and energy projects. Such large-scale initiatives require materials that are both durable and reliable. Ready-mix concrete is ideal for these projects as it offers consistent strength and quality across large volumes, which is crucial for the long-term stability and durability of structures.

The efficiency of ready-mix concrete production also helps to meet tight deadlines, making it a critical factor in the successful completion of major infrastructure projects across Pakistan.

2. Ensuring Consistent Quality in Residential and Commercial Projects

For residential and commercial building projects, the consistency and reliability of materials are key to ensuring the structural integrity of the finished product. Ready-mix concrete in Pakistan offers this consistency because it is manufactured under strict quality control measures. This minimizes the chances of errors that can occur with on-site mixing, such as inaccurate ratios or poor handling.

In housing and commercial construction, where aesthetic appeal and durability are equally important, using high-quality ready-mix concrete guarantees that the project not only looks great but also stands the test of time.

3. Reducing Waste and Enhancing Sustainability

In today’s construction landscape, sustainability is becoming increasingly important. Ready-mix concrete has significant environmental benefits because it reduces waste associated with on-site mixing and overproduction. Since the exact amount of concrete required is delivered to the site, it minimizes leftover materials that would otherwise go to waste.

Moreover, batching plants can recycle water and aggregates, further contributing to the sustainability of ready-mix concrete in Pakistan. By using ready-mix concrete, construction companies can lower their environmental footprint while still delivering high-quality projects.

Advantages of Ready-Mix Concrete in Pakistan

There are numerous advantages to using ready-mix concrete in Pakistan, especially in comparison to site-mixed concrete. Some of the key benefits include:

1. Time Efficiency

One of the major advantages of ready-mix concrete is its time efficiency. Traditional concrete mixing requires significant labor, equipment, and time for accurate batching. Ready-mix concrete, on the other hand, is prepared and delivered to the site, ready for immediate use. This saves valuable time and allows construction crews to focus on other critical aspects of the project.

For fast-paced construction environments like those in Pakistan, time savings can directly translate to cost savings and faster project completion.

2. Consistent Quality and Strength

Quality control is essential in any construction project, and ready-mix concrete guarantees uniform quality across every batch. Since it is produced in a controlled environment, each mix is consistent, ensuring that the final product meets the strength, durability, and performance criteria required by the project.

This consistency is especially important for complex structures like high-rise buildings and bridges, where uneven quality could compromise the safety and longevity of the construction.

3. Versatility and Customization

Ready-mix concrete can be customized to meet the specific needs of different projects. Whether it’s high-strength concrete for load-bearing structures or lightweight concrete for non-structural elements, ready-mix concrete can be adapted to any type of construction.

Additives such as accelerators, retarders, and plasticizers can also be used to alter the properties of the concrete, allowing it to perform optimally under different conditions, such as extreme weather or unique architectural designs.

4. Minimizing Material Wastage

One of the biggest challenges in on-site concrete mixing is material wastage. When concrete is mixed on-site, it’s difficult to estimate the exact amount needed, leading to excess production and wastage. Ready-mix concrete is delivered in the precise quantity required for each project, helping to minimize waste and lower costs.

This also helps reduce the environmental impact of construction projects, as less material goes to landfills, and fewer resources are consumed overall.

Quality Control in Ready-Mix Concrete Production

One of the primary reasons ready-mix concrete is preferred in Pakistan’s construction industry is the strict quality control that comes with it. Quality control in ready-mix concrete production is ensured through several measures:

1. Stringent Batching Processes

Each batch of ready-mix concrete is created according to specific design parameters, including the mix of cement, aggregates, and additives. Batching plants use advanced machinery and software to ensure accurate mixing ratios, which are crucial for the strength and durability of the concrete. This level of precision is difficult to achieve with on-site mixing.

2. Testing and Monitoring

Throughout the production process, various tests are conducted to ensure that the ready-mix concrete meets the required standards. These tests include checking the concrete’s strength, slump (workability), and durability. Monitoring during production ensures that the final product is consistent in quality, meeting the demands of the construction project.

3. Adherence to International Standards

Many ready-mix concrete producers in Pakistan, such as Allied Materials, follow international standards for concrete production. This ensures that the concrete used in both public and private projects is of the highest quality, capable of withstanding Pakistan’s diverse weather conditions and heavy loads.

By adhering to these stringent standards, ready-mix concrete contributes to the safety and longevity of infrastructure, residential buildings, and commercial spaces in Pakistan.

Choosing a Reliable Supplier for Ready-Mix Concrete in Pakistan

Selecting the right ready-mix concrete supplier is critical for ensuring the success of any construction project. When looking for a supplier, consider the following factors:

Reputation: Choose a supplier with a strong reputation for quality and reliability. Ask for recommendations from other contractors or industry professionals.

Quality Control Measures: Ensure that the supplier follows strict quality control measures and adheres to international standards.

Delivery and Logistics: A reliable supplier should have a well-organized delivery system to ensure that the concrete arrives on time and in optimal condition.

Customization Options: Look for a supplier that can customize the mix to suit the specific needs of your project.

Allied Materials, a leading ready-mix concrete supplier in Pakistan, has a proven track record of providing high-quality materials for various construction projects. They offer customized concrete solutions to meet the unique demands of residential, commercial, and infrastructure developments.

Conclusion

Ready Mix Concrete In Pakistan growing construction industry by offering time efficiency, consistent quality, and environmental benefits. With the rising demand for durable, sustainable materials in large-scale infrastructure projects and residential developments, ready-mix concrete has become the material of choice for construction professionals.

Ensuring quality through stringent production processes and adhering to international standards, ready-mix concrete suppliers like Allied Materials are transforming the construction landscape in Pakistan. By opting for ready-mix concrete, builders can achieve cost-effective, high-quality results that stand the test of time.

0 notes

Text

Trusted Concrete Construction in Adelaide – Platinum Concrete

When it comes to concrete construction in Adelaide, Platinum Concrete is a name synonymous with quality, durability, and expertise. Whether you're working on a residential project or a large commercial development, we provide comprehensive concrete solutions tailored to your specific needs. With years of experience in the industry, our team is committed to delivering exceptional craftsmanship and results that stand the test of time.

Why Choose Platinum Concrete for Your Project?

At Platinum Concrete, we believe that successful concrete construction is more than just pouring cement—it’s about precision, planning, and quality control. Here are some key reasons why we are a preferred choice for concrete construction in Adelaide:

Experienced Team: Our team of skilled contractors brings years of experience to every project. From laying foundations to decorative finishes, we’ve done it all. We take pride in delivering projects that meet the highest industry standards.