#print prototype

Explore tagged Tumblr posts

Text

Maximizing Efficiency with CNC Milling Service and Sheet Metal Fabrication

CNC milling service and sheet metal fabrication are two indispensable processes in modern manufacturing. They offer unparalleled precision and efficiency, making them essential for a wide range of industries. In this blog post, we will explore the benefits of these services and how they can help businesses optimize their production processes.

CNC milling service is a computer-controlled machining process that utilizes rotary cutters to remove material from a workpiece. This highly precise method allows for the creation of complex shapes and designs with minimal error. By leveraging the power of machining online, businesses can tap into a vast network of CNC milling service providers, ensuring access to a diverse range of capabilities and expertise.

Sheet metal fabrication, on the other hand, involves the manipulation of thin metal sheets to create various products and components. It encompasses cutting, bending, and assembling processes to achieve the desired end result. With advancements in technology, such as the availability of aluminum die casting molds, sheet metal fabrication has become even more versatile and efficient.

One of the key advantages of CNC milling service and sheet metal fabrication is their ability to streamline production processes. By utilizing these services, businesses can reduce manual labor, minimize errors, and expedite production timelines. Furthermore, the availability of print prototypes enables manufacturers to test and validate designs before committing to full-scale production, saving both time and resources.

However, it's essential to consider the cost aspect when implementing these services. While metal CNC machine costs can vary depending on factors such as machine size and capabilities, the long-term benefits usually outweigh the initial investment. The precision, speed, and repeatability offered by CNC milling and sheet metal fabrication services often result in improved product quality and overall customer satisfaction.

In conclusion, CNC milling service and sheet metal fabrication are pivotal in maximizing manufacturing efficiency. By leveraging machining online, businesses can access a wide range of capabilities and expertise. The availability of aluminum die casting molds and print prototypes further enhances the precision and efficiency of these processes. Though metal CNC machine costs may vary, the long-term benefits often justify the investment. Embracing these services can help businesses stay competitive in today's fast-paced manufacturing landscape.

#CNC Milling Service#Sheet Metal Fabrication#machining online#aluminum die casting mold#print prototype#metal cnc machine cost

0 notes

Text

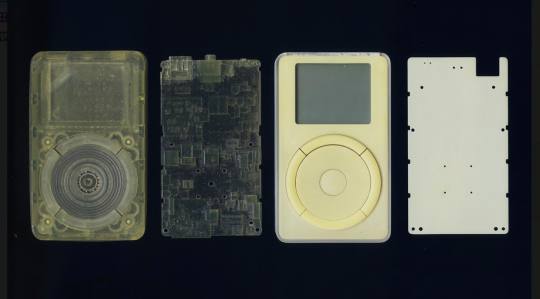

3D printed & machined prototypes of the first gen iPod

2K notes

·

View notes

Text

Holy shit things costs money? Why did nobody tell me this.

#guys im so sorry#i finished up the prototypes with the laser shop! thry liik fantastic#but each one costs 3.50 in printing alone. which means a set has to be $50#who is going to pay for that??#thats so much money it boggles thr mind#no profits for me either#ceetainly not enough to cover my labor#guysssss what do i do?#ornaments

90 notes

·

View notes

Text

3D Printing Rio's Death Crown - Attempt #1 FDM Print

#scaled it about 8% larger than the size it came in but still feels a bit too small#but it also fits very very nicely on one's head#le sigh as one of the front pointy ends snapped off a bit during support removal#which was an experience#felt like i was at risk of stabbing myself in the eye#anyhoo shall treat this as a prototype#playing with this to give myself motivation to do a SLA print#and maybe get stronger resin for this#so it doesn't snap so easily#it IS an extremely cool design

34 notes

·

View notes

Text

ups is just fucking with me at this point i think

#the eternal prototype print was supposed to be here five days ago. every day i have waited for my package#and every day at 7 pm when it has not arrived i open the ups package tracker and watch the delivery date go up by 1 in real time#girl WHERE IS IT. GIVE ME MY FUCKING PACKAGE#personal

70 notes

·

View notes

Text

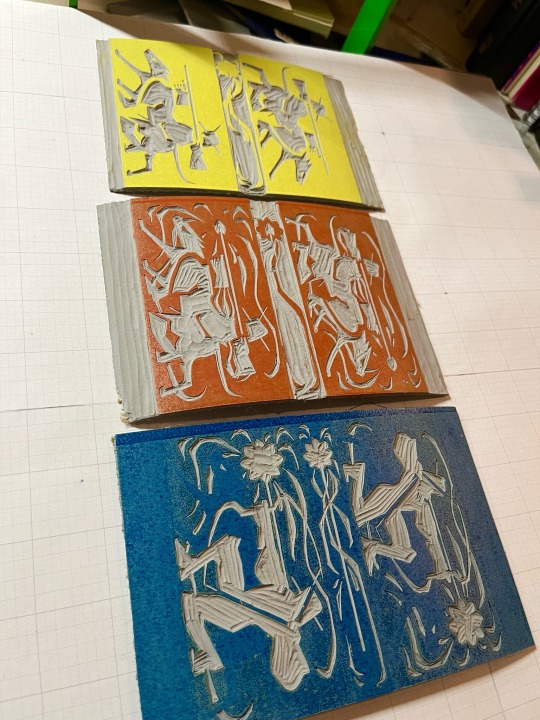

I’m hard at work making Christmas presents for my family aka I’m forcing some artwork upon them this year yet again :)

#original art#artists on tumblr#printmaking#linocut#relief printing#printmakers on tumblr#WIP#this isn’t even its final form I still have a trey to make but bc im on a deadline they will all get an updated trey later#right now.. they will just have to live with it being in prototype stage one

41 notes

·

View notes

Text

I finally finished and printed my 4th iteration of the connector. It features now a thicker shell and some sort of infill grid that stablizes it more. I am quite happy with the result, very excited to built the 1:1 Model now!

#architecture#design#industrial design#3d print#3d druck#3d printing#connector#art exhibition#modular#modular architecture#prototype#prototyping

10 notes

·

View notes

Text

Bahaha, so here's the other surprise package from my friend, Rae. It's a busted Namihu BJD Creatures Astarion she purchased from them during that charity drive for the dog that ended up dying anyway and HOOOBOY.

Apparently Rae hadn't even opened this package when it arrived since she was busy getting last minute stuff ready for Resin Rose so we have no idea how busted it was prior to her deciding to give it to me, but uh...dayum. Even his little dagger didn't make it in one piece (that I can glue back together though, most likely).

Honestly, even if it didn't arrived broken, this is still such a janky fucking doll. I cannot believe someone would charge people money for this garbage. I've been in the hobby for 15+ years and have owned and handled probably 80+ dolls from various makers and this is by far the worst body I've ever come across. This thing makes Resinsoul bodies seem like a dream in comparison. Absolutely unacceptable level of quality for the amount of cash Namihu charges. Genuinely embarrassing.

On top of the poor joint design, there are tons of cracks everywhere from the printing process. If this is the norm for 3D printed dolls, it's no wonder some faceup and modding artists don't accept commissions for them.

ALSO ALSO, learn how to properly wrap a fucking doll for shipping, Namihu. The taped up monstrosity I opened up was atrocious.

Counting my blessings I didn't bother commissioning Namihu for my CP2077 character's doll head, and it straight up was because the headback looked funky to me in what few pictures they have posted of it. It seemed like it'd have very limited head movement and I was absolutely correct. On top of that, because of how it was designed, it leaves scratches on the front of the neck lmao.

#namihu bjd creatures#bjd#legit bjd#3d printed bjd#ball jointed doll#my camspam#my doll: jankstarion#i am so pissed for my friend even if she never handled this doll bahaha#like...jeeeeesus chriiiiist#like bruh did the creator do absolutely no prototyping before posting this shit for sell?#pieces straight up don't even fit together properly

7 notes

·

View notes

Text

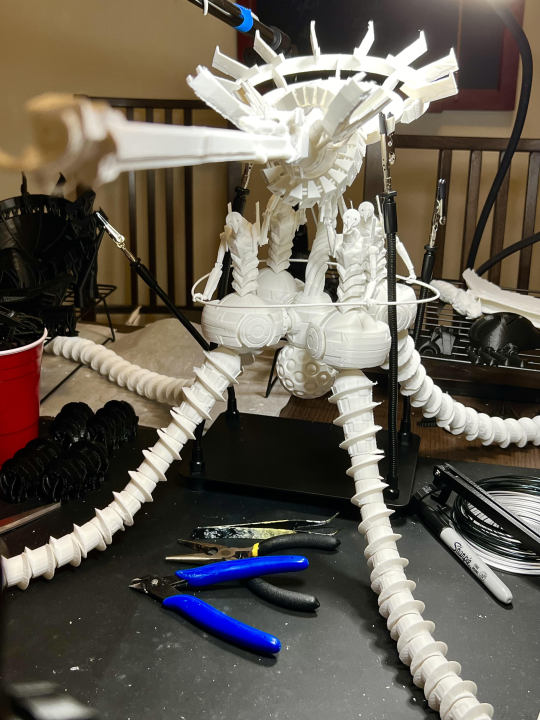

Finished with the prototype of Evangelion Mark.4444c. Managed to complete this figure in a couple of weeks with life happening, including travel to a wedding. Gonna do a final print and color later.

Also wanted to thank my friends for helping with the critiques and suggestions <3

#art#3d print#articulated#prototype#3d model#evangelion 3.0+1.0#evangelion#mark 4444c#mark#4444#4444c#c#eva#neon genesis evangelion#3d#3d modeling#3d figure#3d art#tentacle#tentacles#positron#cannon#positron cannon#figure

42 notes

·

View notes

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Text

Have you seen them? Now you have!

If you've ever wanted to grab prints of my art, there's a lot of options on my inprnt <3

#saints art#inprnt#dnd#dnd5e#my prints#prints#art print#my art#ttrpg#league of legends#art of legends#prototype 2009#dnd oc#dnd ocs#dungeons and dragons#dnd oc art#oc art

33 notes

·

View notes

Text

Prototype for my mom's Christmas present printed today 🙌🏽

Definitely needs a lot of fixing 😭

8 notes

·

View notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

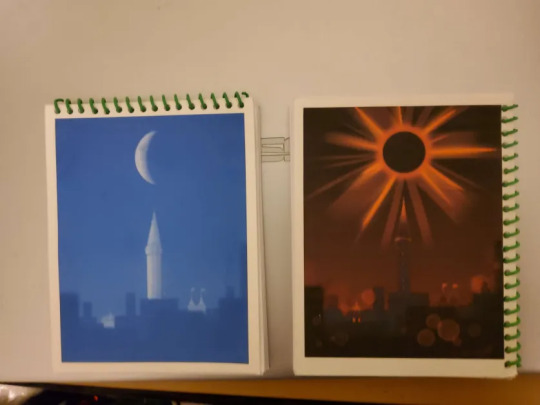

Covers courtesy of @katebluebird

The matte cardstock took a bit of the luster away from the art but they still turned out amazing. They've already sent me two more pieces that I plan on making into notebooks.

Kate keeps saying it's just something simple she threw together. Everyone go tell her how fucking amazing they are!

I did these with a singular hole punch. My hand is going to be so strong after making these notebooks lol

#wardenspeaks#notebook prototypes#katebluebird#I cant wait to get a decent print setup so i can see these in their full glory

4 notes

·

View notes

Text

just ordered the loz comics zine prototype 😁😁

#its 62 pages altogether & includes 5 comics!! very excited to see them printed#trying to figure out pricing and sales options rn. i have no concept of how much shipping costs fr#im thinking theyre gonna be about $10 sans shipping for physical zines and i may do a pay-what-you-want-above-$1 for the pdf#bc it does include 5 new title page illustrations as well as the new cover illustration and 2 spot illustrations!#<<this is all assuming my $35 prototype comes in as planned btw. making products is soooo hard#personal

279 notes

·

View notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes