#precision machining cnc

Explore tagged Tumblr posts

Text

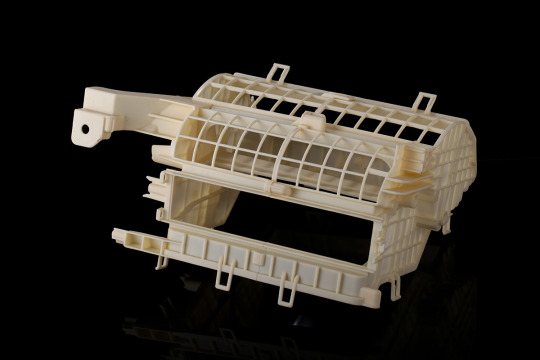

High precision multi-axis CNC machining

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc precision machining#high precision#cnc metal fabrication#cnc metal process#cnc metal machining#cnc metal processing#cnc metal parts#metal machining#metal cnc#5 axis cnc machining#5axismachining

4 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Note

Bro just straight up pouring molten bronze like it's not the coolest thing in the world wtf

Right now I work in a wood & metals fabrication shop and As a man of many hats if I see a piece of machinery I make it my life goal to get my dirty little hands on operating it at least once (when i was on the pour team i did most jobs but pouring from the big crucible of metal was my favorite and i was pretty good at it. never did the crane bc i have a bad sense of direction and you have to be pretty quick when pouring molten metal)

My next target is this thing:

#5 axis cnc i will get you.#i currently specialize in the 3 axis but i havent been able to learn to toolpath this thing bc its significantly more complicated#and also our shop's is kind of .broken#but i toured a shop that had 7 axis cncs in enclosed cabinets and shit literally the most insane precision machining#idk if i would be able to work in a shop like that but a man can dream#m#answers

5 notes

·

View notes

Text

Materialism is not at the base of humans' nature as a species, objects and property were not always at the centerpoint of our culture either. but i got disorders that make me extremely materialistic, becuse i tend to think a lot about which materials are objects made from. It is also really important for me to know which properties define them.

individualism and solitude is not natural to human living but sadly i have mental conditions that predispose me to being a hermit

#boy autism#i have a fixation on parallels#they are just super precisely made blocks of shiny metal#but my brain goes full clepto mode when i see them at the cnc machining place

3K notes

·

View notes

Text

Heavy Duty Panel Saw Machine | Automatic Panel Saw Machine | Manufacturers

Heavy Duty Panel Saw Machine With features like Double Layer Heavy Duty Sliding Aluminium System along with Made in India machine, Heavy Duty Panel Saw Machine is a reliable Panel cutting machine for any factory. 45 years of experience in machine and machine part making, Electricals and Motors of Crompton or similar International Brand only and with customisable panel saw machine makes it a user friendly and maintenance free partners for wood working companies.

Heavy Duty Panel Saw Machine, Automatic Panel Saw Machine, Industrial Panel Saw, Wood Cutting Saw Machine, CNC Panel Saw, High Capacity Panel Saw, Precision Panel Cutting Tool, Industrial Heavy Duty Panel Saw Machine, Heavy Duty Woodworking Equipment, Sliding Table Saw, Best Sliding Panel Saw Machine in India, Heavy Duty Panel Saw Machine Price in India, Table Saw Wood Cutting Machine, Saw Cutting Machine, Woodworking Machinery.

#Heavy Duty Panel Saw Machine#Automatic Panel Saw Machine#Industrial Panel Saw#Wood Cutting Saw Machine#CNC Panel Saw#High Capacity Panel Saw#Precision Panel Cutting Tool#Industrial Heavy Duty Panel Saw Machine#Heavy Duty Woodworking Equipment#Sliding Table Saw#Best Sliding Panel Saw Machine in India#Heavy Duty Panel Saw Machine Price in India#Table Saw Wood Cutting Machine#Saw Cutting Machine#Woodworking Machinery.

0 notes

Text

Enhancing Precision Cutting with Oxy-Fuel Cutting Machines

Oxy-fuel cutting machine Manufacturers, also known as oxy-acetylene cutting, is a process that uses a combination of oxygen and fuel gases (typically acetylene) to cut through metal. The process works by heating the metal to its ignition temperature and then directing a high-pressure stream of oxygen onto the heated area. The reaction of the oxygen with the metal causes it to oxidize and burn away, leaving behind a clean cut.

While oxy-fuel cutting was once overshadowed by plasma and laser cutting technologies, it remains one of the most reliable and cost-effective methods for precision cutting, particularly when dealing with thick or heavily oxidized materials.

The Benefits of Oxy-Fuel Cutting Machines

Cost-Effectiveness One of the standout advantages of oxy-fuel cutting is its affordability. Oxy-fuel machines are generally less expensive than their plasma or laser counterparts. The process also requires relatively low maintenance, making it a cost-effective choice for businesses that need precision without breaking the bank.

Versatility Oxy-fuel cutting machines are highly versatile and can be used to cut a wide variety of metals, including carbon steel, stainless steel, and aluminium. Additionally, they are perfect for cutting thick materials, something that other cutting methods like plasma may struggle with.

Precision and Control Modern oxy-fuel cutting machines are equipped with advanced controls that allow for highly precise cuts. With adjustable torch settings and the ability to fine-tune the oxygen flow, operators can achieve cleaner cuts with minimal distortion. This level of control is particularly important for industries that require intricate cuts, such as aerospace and automotive manufacturing.

Ability to Cut Thick Materials Oxy-fuel cutting machines excel when it comes to cutting thick sections of metal, especially those thicker than 1 inch. The ability to cut through heavy materials, such as steel plates used in shipbuilding or construction, makes oxy-fuel machines invaluable in industries that deal with large, heavy components.

Portability Oxy-fuel cutting equipment is relatively portable, especially compared to other cutting technologies like laser cutters. This portability is a huge advantage in industries like construction or shipbuilding, where cutting needs may arise in remote locations or on-site.

Applications of Oxy-Fuel Cutting

Oxy-fuel cutting machines are used across a broad range of industries, thanks to their precision and versatility. Here are some of the sectors that benefit from this technology:

Construction: Oxy-fuel cutting machines are commonly used to cut through steel beams, plates, and other construction materials.

Shipbuilding: The ability to cut thick metal sheets makes oxy-fuel machines a key tool in shipbuilding.

Automotive: For the manufacturing of automotive parts, precision cutting is crucial, and oxy-fuel machines are well-suited to cut through both thick and thin metal components.

Heavy Machinery: Oxy-fuel cutting is ideal for creating precise cuts in large parts used in industrial equipment and machinery.

Aerospace: Aerospace industries require precise cuts for various components, and oxy-fuel cutting ensures a high degree of accuracy.

Stay Connected

Want to see our machines in action? Follow us on https://www.instagram.com/winarc_cutting_system/ for live demonstrations, industry news, and behind-the-scenes content.

Contact Us

Got a question? Need support? Our expert team is here for you.

Call us: +91 9902555693

Email us: [email protected]

#CNC laser cutting#metal laser cutting#sheet metal cutting machine#fiber laser technology#automated laser cutting#best laser cutting machines#precision cutting technology#fabrication cutting machines#steel cutting equipment#plasma cutting machines#oxy-fuel cutting

0 notes

Text

Ultimate Guide to Precision CNC Machining: From Design to Delivery

Precision CNC machining services are essential for creating high-accuracy components used in industries like aerospace, automotive, and medical. This process involves designing parts using CAD software, selecting the right materials, and utilizing advanced CNC machines to achieve tight tolerances. Quality control and post-processing ensure durability and functionality, while timely delivery completes the cycle. Companies like Pangea Technologies excel in providing end-to-end precision CNC machining services, combining cutting-edge technology, skilled engineering, and rigorous quality checks. Whether for prototypes or large-scale production, Pangea Technologies delivers reliable, high-quality solutions, making them a trusted partner in precision manufacturing.

Understanding Precision CNC Machining Services

Precision CNC machining services involve the use of computer-controlled machines to manufacture parts with exceptional accuracy and consistency. These services are essential for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can lead to significant issues. CNC machining ensures tight tolerances, high repeatability, and the ability to work with a variety of materials, including metals, plastics, and composites. Companies like Pangea Technologies specialize in providing state-of-the-art precision CNC machining services, leveraging advanced technology and skilled engineers to meet the most demanding requirements.

The Design Phase: Turning Ideas into Reality

The first step in precision CNC machining is the design phase. Engineers and designers use CAD (Computer-Aided Design) software to create detailed 3D models of the component. This phase is critical because it determines the feasibility, functionality, and manufacturability of the part. Pangea Technologies collaborates closely with clients during this phase, offering design-for-manufacturability (DFM) feedback to optimize the design for CNC machining. This ensures that the final product is not only functional but also cost-effective to produce.

Material Selection: The Foundation of Quality

Choosing the right material is crucial for the success of any precision CNC machining project. Factors such as strength, durability, thermal resistance, and machinability must be considered. Common materials used in CNC machining include aluminum, stainless steel, titanium, brass, and engineering plastics. Pangea Technologies provides expert guidance on material selection, helping clients choose the best option for their specific application. Their extensive material inventory ensures that clients have access to high-quality raw materials for their projects.

Machining Process: Precision at Its Finest

Once the design and material are finalized, the machining process begins. CNC machines, such as mills, lathes, and multi-axis machining centers, are programmed to follow the CAD model’s specifications. These machines use cutting tools to remove material from the workpiece, shaping it into the desired form. Precision CNC machining services offered by Pangea Technologies utilize advanced equipment, such as 5-axis CNC machines, to produce complex geometries with unparalleled accuracy. Their commitment to quality ensures that every part meets the highest standards.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of precision CNC machining. Each part undergoes rigorous inspection using tools like coordinate measuring machines (CMMs), optical comparators, and surface finish testers. This ensures that the final product adheres to the specified tolerances and quality standards. Pangea Technologies employs a comprehensive quality control process, combining advanced inspection techniques with skilled technicians to guarantee the accuracy and reliability of every component.

Post-Processing: Adding the Finishing Touches

After machining, parts often require post-processing to enhance their appearance, functionality, or durability. Common post-processing techniques include anodizing, powder coating, polishing, heat treatment, and plating. These processes not only improve the part’s performance but also protect it from environmental factors like corrosion and wear. Pangea Technologies offers a wide range of post-processing services, ensuring that every component meets the client’s exact requirements. Their expertise in finishing techniques adds value to the precision CNC machining process.

Delivery: Bringing Your Vision to Life

The final step in the precision CNC machining journey is delivery. Once the parts have passed all quality checks and post-processing, they are carefully packaged and shipped to the client. Timely delivery is essential to ensure that the client’s production schedule remains on track. Pangea Technologies prides itself on its efficient logistics and reliable delivery services. Their commitment to customer satisfaction ensures that every project is completed on time and to the highest standards.

Conclusion

Precision CNC machining services are at the heart of modern manufacturing, enabling the production of high-quality, complex components with unmatched accuracy. From design to delivery, every step in the process requires expertise, advanced technology, and a commitment to quality. Companies like Pangea Technologies exemplify the best in precision CNC machining services, offering end-to-end solutions that meet the needs of diverse industries. By combining cutting-edge technology, skilled engineers, and a customer-centric approach, Pangea Technologies ensures that every project is a success. Whether you’re developing a prototype or scaling up production, partnering with a trusted provider like Pangea Technologies can help you achieve your goals with precision and efficiency. Embrace the future of manufacturing with precision CNC machining services that deliver results you can count on.

0 notes

Text

What Is The Role Of CNC Machining In Manufacturing?

Considering the advantages of CNC machining, it won’t be an exaggeration to call this technology a revolution in the manufacturing industry. It is simply the best because it manufacturers according to product specifications.

#CNC machining#cnc machining solutions in vietnam#cnc machining manufacturer#precision turning#ams machining vietnam

0 notes

Text

5 Key Industries That Rely on Precision CNC Machining Services

Precision CNC machining services play a crucial role in various industries, ensuring high accuracy, efficiency, and quality in manufacturing. The aerospace industry depends on CNC machining for complex components like turbine blades and aircraft parts. In the automotive sector, CNC machining helps produce engine components, transmission parts, and custom prototypes. The medical industry relies on CNC machining for surgical instruments, implants, and medical devices requiring extreme precision. The electronics industry benefits from CNC machining in manufacturing circuit boards, connectors, and enclosures. Lastly, the defense and military sector uses CNC machining for weapon systems, armor, and specialized equipment. These industries trust CNC technology for its reliability, repeatability, and ability to create intricate parts with tight tolerances.

Aerospace Industry: High-Tolerance Manufacturing

The aerospace industry demands extreme precision, reliability, and high-performance materials. Precision CNC machining services are essential for producing complex aircraft components such as turbine blades, engine housings, and landing gear parts. Advanced CNC milling and turning processes ensure tight tolerances, superior surface finishes, and compliance with stringent FAA and aerospace standards. The ability to machine lightweight materials like titanium and aluminum makes CNC machining a cornerstone of aerospace manufacturing.

Automotive Industry: Enhancing Efficiency and Performance

The automotive sector relies on CNC machining for manufacturing critical engine components, transmission systems, and brake parts. CNC lathes, milling machines, and multi-axis machining centers produce high-precision parts that enhance vehicle performance, fuel efficiency, and durability. The rapid prototyping capabilities of CNC machining also allow for the development of innovative automotive technologies, such as electric vehicle (EV) components and advanced driver-assistance systems (ADAS).

Medical Industry: Precision and Compliance in Healthcare

In the medical field, precision cnc machining services plays a vital role in producing surgical instruments, prosthetics, and complex implants. Medical-grade materials such as stainless steel, titanium, and PEEK require high-precision machining to meet FDA and ISO standards. Multi-axis CNC milling and micromachining ensure accuracy in producing intricate components like orthopedic screws, dental implants, and diagnostic equipment. CNC machining’s ability to maintain biocompatibility and sterility makes it indispensable in medical device manufacturing.

Electronics Industry: Micro-Machining for High-Tech Devices

The electronics industry benefits from CNC machining’s ability to manufacture precision components for circuit boards, connectors, and semiconductor equipment. Miniature parts require tight tolerances and ultra-fine machining to ensure optimal performance. CNC micro-machining processes enable the production of heat sinks, enclosures, and housings for consumer electronics, telecommunications, and industrial automation systems. The demand for miniaturization and advanced materials like copper and aluminum alloys makes CNC machining crucial in the electronics sector.

Defense and Military Industry: Durable and High-Performance Parts

The defense industry depends on precision cnc machining services for producing robust components used in firearms, armored vehicles, missile systems, and aerospace defense applications. CNC machining ensures high-strength materials like titanium, Inconel, and hardened steels meet the stringent requirements of military-grade equipment. Multi-axis CNC machining and EDM processes enhance precision and durability, ensuring mission-critical parts withstand extreme conditions and heavy operational loads.

Energy Sector: Precision in Renewable and Traditional Power Systems

From wind turbines to oil and gas extraction equipment, the energy sector requires high-precision CNC-machined parts. CNC machining supports the production of turbine blades, drilling components, and heat exchangers that must endure high pressures, extreme temperatures, and corrosive environments. Advanced CNC processes, such as 5-axis milling and CNC turning, allow for the fabrication of intricate components for renewable energy solutions, including solar panel frames and hydroelectric turbines.

Industrial Equipment Manufacturing: Custom Machined Components

Industrial machinery and automation systems rely on CNC machining for custom parts, gears, and bearings. CNC-machined components improve the efficiency and longevity of manufacturing equipment, robotics, and conveyor systems. With CNC milling, turning, and grinding, manufacturers can create durable and precise machine parts for diverse industrial applications. CNC machining’s adaptability ensures compatibility with materials like stainless steel, brass, and engineered plastics, meeting the high demands of industrial production.

Conclusion

Precision CNC machining services are the backbone of numerous industries, ensuring the production of high-quality, reliable, and complex components. Whether in aerospace, automotive, medical, electronics, defense, energy, or industrial manufacturing, CNC machining delivers accuracy, efficiency, and consistency. As technology advances, CNC machining continues to evolve, driving innovation and meeting the growing demands of modern industry. The combination of automation, multi-axis capabilities, and high-tolerance machining ensures CNC machining remains a critical force in global manufacturing.

0 notes

Text

CNC precision machining service

#business#design#autos#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#machining parts#cnc machining service#cnc services#cnc precision machining#5 axis cnc machining#5 axis precision machining#5 axis cnc#cnc machining parts

4 notes

·

View notes

Text

Top CNC Precision Machining Company | High-Quality Components

As a leading CNC precision machining company, we specialize in custom manufacturing, precision parts, and advanced CNC solutions.

#cnc manufacturing companies#top cnc machine manufacturers#best cnc machine company#cnc precision machining company

0 notes

Text

The Potential of High-Tech Rapid Prototyping

High-tech Rapid Prototyping has become a game-changer in the rapidly changing fields of innovation and technology, altering the way things are planned, developed, and introduced to the market. This dynamic process, which promotes creativity, shortens time-to-market, and ultimately drives unmatched innovation, has emerged as a key component for companies looking to maintain their leadership positions in their respective fields.

The Innovation-Promoting Technologies

The 3D Printing Process

3D printing is a key component of the fast prototyping revolution because it allows digital models to be layered into actual items. This technology has made it easier to produce intricate, personalized prototypes and greatly reduced design cycles.

Machining using computer numerical control (CNC)

Prototypes made of different materials may be accurately cut, shaped, and assembled with the help of computer-controlled gear thanks to CNC machining from CNC Machining Manufacturer. This adaptable technique works especially well for creating prototypes with intricate geometries and great accuracy.

Using Injection Molding

Rapid prototyping is greatly aided by injection molding, a process that is frequently employed in mass manufacturing. The appearance, feel, and functioning of the final product are accurately represented by injection-molded prototypes.

Benefits of Rapid High-Tech Prototyping

Quicker Iterations in Design

Design revisions may be completed quickly and affordably using rapid prototyping. Instead of weeks or months, designers may test several iterations of a product, improve functionality, and fix bugs in a matter of days.

Economy of Cost

High-tech fast prototyping decreases the upfront expenses associated with traditional manufacturing methods by eliminating the need for expensive equipment and molds. This makes it possible for companies to test concepts more affordably before committing to large-scale manufacturing.

Improved Cooperation

Improved cross-functional team communication is facilitated by prototyping. A prototype may be physically interacted with by stakeholders, who can offer insightful input and encourage cooperation between end users, engineers, and designers.

Sensitivity to the Market

Being able to react swiftly to customer input and industry developments is critical in businesses that move quickly. Businesses may maintain their agility, adjust to shifting customer needs, and obtain a competitive advantage in the market by using high-tech fast prototyping and Precision CNC Machining.

Follow our Facebook and Twitter for more information about our product.

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company#Precision CNC Machining Manufacturer Company

2 notes

·

View notes

Text

#long roller drilling tufting machine#tufting machine manufacturer#roller drilling tufting machine#industrial tufting machine#automated tufting machine#brush tufting machine#cnc tufting machine#high-speed tufting machine#custom tufting machine#tufting equipment supplier#brush making machine#drilling and tufting machine#precision tufting machine#industrial brush machine#tufting technology manufacturer.

0 notes

Text

CNC Precision Machining: Unlocking Accuracy and Efficiency in Manufacturing

CNC (Computer Numerical Control) precision machining has revolutionized the manufacturing industry by offering unparalleled accuracy, efficiency, and versatility. This advanced technology has become a critical component in producing high-quality, intricate parts used in a wide range of industries, from aerospace to automotive. But what exactly is CNC precision machining, and why is it so essential in today’s manufacturing world? Let's explore the details.

What is CNC Precision Machining?

CNC precision machining involves using computer-controlled machines to manufacture parts with high precision. Unlike traditional machining methods, where manual input is required, CNC machines are fully automated and guided by pre-programmed computer software. This allows manufacturers to produce parts that are incredibly accurate and repeatable, meeting the strictest tolerances required by industries such as aerospace, medical, and automotive.

The term "precision" refers to the tight tolerances these machines can achieve. A tolerance is the allowable deviation from the intended dimensions of a part. In CNC precision machining, tolerances can be as tight as ±0.001 inches, which is crucial for parts that need to fit perfectly within larger assemblies.

The CNC Machining Process

The CNC machining process is an intricate series of steps, each contributing to the final product's precision. Here's an overview of the typical stages involved:

Design & Programming: The process begins with the design of the part, usually created using CAD (Computer-Aided Design) software. The design is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program dictates the movements of the machine to shape the raw material into the desired part.

Material Selection: CNC machining works with various materials, including metals like aluminum, steel, and titanium, as well as plastics and composites. The material selection depends on the specific requirements of the part, such as strength, weight, or heat resistance.

Machining Operations: The CNC machine uses tools like mills, lathes, and drills to perform a variety of operations, including cutting, grinding, and shaping the material. This process is highly automated, ensuring the part is produced with minimal human intervention.

Inspection & Quality Control: Once the part is machined, it undergoes thorough inspection to ensure it meets the required specifications. High-precision instruments such as coordinate measuring machines (CMM) are often used to check the part’s dimensions and tolerances.

Benefits of CNC Precision Machining

High Accuracy: One of the main advantages of CNC precision machining is its ability to produce parts with extreme accuracy. This ensures that the final product fits perfectly within the specified dimensions, which is critical in high-performance industries like aerospace or medical device manufacturing.

Consistency & Repeatability: CNC machines can produce thousands of identical parts with consistent quality. This repeatability is vital for industries that rely on mass production, where each part must meet the same high standards.

Complex Geometries: CNC machines can handle complex geometries that would be difficult or impossible to achieve using traditional machining methods. This makes them ideal for creating intricate designs and parts with multiple features.

Reduced Human Error: Since CNC machines are computer-controlled, the risk of human error is significantly reduced. This not only enhances the overall quality of the parts but also reduces the amount of rework and scrap produced during manufacturing.

Efficiency & Speed: CNC machining is highly efficient and can produce parts faster than traditional methods. Automated setups and minimal operator intervention contribute to faster production times, making it an excellent option for industries with tight deadlines.

Industries That Benefit from CNC Precision Machining

CNC precision machining is a versatile technology used across numerous industries. Some key sectors that benefit from it include:

Aerospace: CNC machining is critical in the aerospace industry, where high-precision parts are needed for aircraft and spacecraft. Components such as engine parts, brackets, and fittings must meet strict tolerances for safety and performance.

Medical Devices: In the medical field, CNC machining is used to create intricate parts for medical devices, including surgical instruments, implants, and diagnostic equipment. The precision required for these parts is essential for patient safety and device functionality.

Automotive: CNC machining plays a key role in the automotive industry, where precision is necessary for manufacturing engine components, transmission parts, and safety features. The technology ensures that each part performs optimally and fits correctly within the vehicle assembly.

Conclusion

CNC precision machining is a game-changer in modern manufacturing, offering unmatched accuracy, speed, and versatility. Whether you're in the aerospace, automotive, or medical industry, CNC machining ensures that you can produce high-quality, precise parts that meet the highest standards. As technology continues to evolve, CNC machining will undoubtedly remain at the forefront of innovation in manufacturing.

If you’re looking for CNC precision machining services, choosing a reliable and experienced provider is crucial to ensuring your parts are crafted to perfection. With the right equipment, expertise, and technology, CNC machining can help bring your designs to life with unparalleled precision and efficiency.

0 notes