#pp yarn manufacturers in india

Explore tagged Tumblr posts

Text

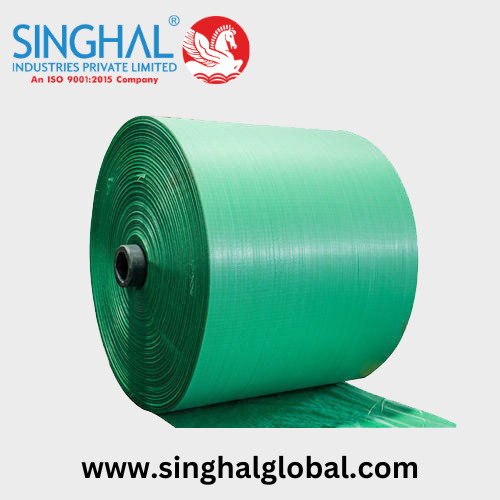

PP Yarn: A Comprehensive Overview

Polypropylene (PP) yarn has emerged as a critical component in various industries due to its versatility, durability, and cost-effectiveness. As one of the leading synthetic fibers, PP yarn finds applications in textiles, packaging, automotive, and agriculture.

This article explores the landscape of PP Yarn Manufacturer in India, highlighting their significance and contributions to the industry.

0 notes

Text

A Comprehensive Guide to PP Yarn:

PP yarn, a crucial material in various industries, offers exceptional strength, durability, and versatility. This guide explores the key aspects of PP yarn manufacturers in India, PP yarn suppliers in Gujarat, and polypropylene yarn exporters in Ahmedabad.

What is PP Yarn?

PP yarn is made from polypropylene, a synthetic polymer renowned for its robustness. This yarn is used in a range of applications, from textiles to industrial products, due to its strength and resistance to wear and tear.

Advantages of PP Yarn

Strength: Known for its high tensile strength, PP yarn can handle heavy loads and strenuous conditions.

Durability: It resists abrasion and degradation, extending the lifespan of products made from it.

Lightweight: The yarn is lightweight, making it easy to handle and reducing transportation costs.

Chemical Resistance: PP yarn is resistant to chemicals, including acids and bases, which enhances its versatility.

Versatility: It is used in diverse applications such as ropes, sacks, textiles, and industrial fabrics.

Key Industry Players

PP Yarn Manufacturers in India: These manufacturers specialize in producing high-quality polypropylene yarns. They cater to various sectors, ensuring consistent quality and supply.

PP Yarn Supplier in Gujarat: Suppliers in Gujarat offer a range of PP yarns, making them accessible to different regions and industries. They play a vital role in ensuring the availability of yarns for local and regional needs.

Polypropylene Yarn Exporter in Ahmedabad: Exporters in Ahmedabad focus on distributing polypropylene yarns to international markets, providing global access to high-quality products.

Choosing the Right PP Yarn

When selecting PP yarn, consider the following factors:

Strength and Durability: Ensure the yarn meets the specific strength and durability requirements for your application.

Type of Yarn: Different types of PP yarns, such as multifilament and monofilament, cater to various needs. Choose based on your specific requirements.

Reputable Suppliers and Manufacturers: Evaluate PP yarn manufacturers in India, PP yarn suppliers in Gujarat, and polypropylene yarn exporters in Ahmedabad based on their reputation and reliability.

Pricing and Availability

The price of PP yarn can vary depending on factors such as type, quality, and supplier. Typically, prices range from ₹200 to ₹400 per kilogram. For the best value, compare quotes from various suppliers and manufacturers.

Conclusion

PP yarn is a versatile and cost-effective material used across many industries due to its strength, durability, and chemical resistance. By understanding the roles of PP yarn manufacturers in India, PP yarn suppliers in Gujarat, and polypropylene yarn exporters in Ahmedabad, you can make informed decisions and find the best yarn for your needs.

FAQs

What is PP yarn made of? PP yarn is made from polypropylene, a synthetic polymer known for its strength and durability.

What are the common applications of PP yarn? It is used in textiles, packaging materials, ropes, and industrial fabrics.

How can I find PP yarn manufacturers in India? Look for specialized PP yarn manufacturers in India who produce high-quality polypropylene yarns.

What should I consider when choosing a PP yarn supplier in Gujarat? Consider product quality, reliability, and the supplier’s ability to meet your specific needs.

What is the role of polypropylene yarn exporters in Ahmedabad?Polypropylene yarn exporters in Ahmedabad help distribute polypropylene yarns to international markets, making them available globally.

#pp yarn manufacturers in india#pp yarn Supplier in Gujarat#polypropylene yarn Exporter in Ahmedabad

0 notes

Text

Understanding the Different Grades of PP Multifilament Yarn

Polypropylene (PP) multifilament yarn is a versatile and widely used material across various industries, including textiles, packaging, and agricultural applications. As a synthetic fiber derived from the polymerization of propylene, PP yarn is known for its durability, lightweight properties, and resistance to moisture and chemicals. Understanding the different grades of PP multifilament yarn is crucial for manufacturers, suppliers, and end-users to make informed choices that suit their specific requirements.

The Basics of PP Multifilament Yarn

PP filament yarn consists of numerous filaments twisted together to form a single strand. The multifilament structure enhances the yarn's strength and elasticity while maintaining its flexibility. These yarns are available in a range of grades, each tailored for specific applications and industries. The quality and characteristics of PP multifilament yarn can vary significantly based on the production process, raw materials used, and intended end use.

Common Applications of PP Multifilament Yarn

PP multifilament yarns find applications in various fields due to their unique properties:

Textiles: In the textile industry, Multifilament yarns in India are used to produce fabrics for garments, upholstery, and industrial textiles. Their resistance to moisture makes them ideal for outdoor fabrics and sportswear.

Ropes and Twines: The strength and durability of PP multifilament yarns make them suitable for manufacturing ropes and twines used in fishing, agriculture, and construction.

Geotextiles: These yarns are used in geotextiles for soil stabilization, erosion control, and drainage applications, helping to improve the longevity and stability of structures.

Packaging: In the packaging industry, PP multifilament yarns are utilized to create strong and lightweight bags, nets, and containers, enhancing the protection of products during transportation and storage.

Grades of PP Multifilament Yarn

PP multifilament yarns can be categorized into different grades based on several factors, including denier, tensile strength, elongation, and specific applications. Understanding these grades helps manufacturers and end-users select the most appropriate yarn for their needs.

1. Low-Denier vs. High-Denier

Denier is a unit of measurement that expresses the thickness of the yarn. Low-denier yarns (typically below 300 denier) are finer and more suitable for lightweight applications, such as textiles and delicate fabrics. They offer a softer feel and better drape, making them ideal for clothing and interior fabrics.

High-denier yarns (above 300 denier) are thicker and more robust, making them suitable for heavy-duty applications. These yarns are commonly used in manufacturing ropes, tarpaulins, and industrial fabrics that require enhanced strength and durability.

2. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand without breaking. Different grades of PP multifilament yarns exhibit varying tensile strengths based on their production processes and raw material quality.

High tensile strength yarns are essential for applications requiring durability and resistance to wear and tear, such as in the production of ropes and nets. PP multifilament yarn manufacturer often specify tensile strength in their product descriptions, allowing users to select the appropriate grade for their specific applications.

3. Elongation at Break

Elongation at break measures how much a yarn can stretch before breaking. This property is vital for applications where flexibility and stretchability are essential. Different grades of PP multifilament yarns have varying elongation characteristics, with some being designed for high elasticity while others prioritize strength over stretch.

In industries like textiles, where garments need to accommodate movement, a higher elongation at break is desirable. Conversely, applications like ropes may benefit from lower elongation, ensuring the material retains its shape and does not stretch excessively under load.

Factors Influencing the Selection of PP Multifilament Yarn

When selecting the right grade of PP multifilament yarn, several factors come into play. Here are some essential considerations:

End Use: Understanding the intended application is crucial. For example, if the yarn is intended for clothing, a low-denier, softer yarn with good draping qualities would be ideal. In contrast, heavy-duty applications require high-denier, high-strength yarns.

Environmental Conditions: The environment in which the yarn will be used can also influence the choice of grade. For instance, if the yarn will be exposed to harsh chemicals or UV radiation, selecting a grade with enhanced resistance to these conditions is critical.

Cost Considerations: While high-quality yarns may come at a premium, it’s essential to balance cost with performance. Identifying the most suitable grade that meets performance requirements without overspending is a key consideration for manufacturers and buyers.

The Role of Manufacturers of PP Multifilament Yarn

In India, the demand for PP multifilament yarn is on the rise, driven by the growing textile and packaging industries. Various PP multifilament yarn manufacturers in India are working to meet this demand by offering a wide range of grades and specifications. These manufacturers often invest in advanced technologies and quality control processes to ensure their products meet international standards.

Working closely with manufacturers allows businesses to customize yarns according to specific needs. For instance, a manufacturer may produce specialized yarn grades that cater to unique requirements in industrial textiles or custom rope production. Additionally, reputable manufacturers often provide technical support and guidance to help clients select the best grade for their applications.

Conclusion

Understanding the different grades of PP multifilament yarn is essential for anyone involved in industries that utilize this versatile material. By grasping the significance of denier, tensile strength, elongation, and specific applications, manufacturers and end-users can make informed decisions when selecting the appropriate yarn for their needs.

As the demand for PP filament yarn continues to grow, particularly in India, it is crucial to partner with reliable PP multifilament yarn manufacturers who can provide high-quality products tailored to specific applications. With the right knowledge and resources, businesses can harness the unique properties of PP multifilament yarn to enhance their products and meet the demands of an ever-evolving market. Frequently Asked Questions (FAQs)

How is the quality of PP multifilament yarn determined? The quality of PP multifilament yarn is determined by factors such as tensile strength, elongation, denier, and resistance to environmental factors like UV light and moisture. Manufacturers often conduct tests to ensure the yarn meets industry standards.

Is PP multifilament yarn suitable for outdoor use? Yes, many grades of PP multifilament yarn are suitable for outdoor use, especially those treated for UV resistance. These yarns are commonly used in products like tarpaulins, outdoor furniture, and awnings.

What are the common applications of PP multifilament yarn? Common applications include textiles for clothing and upholstery, industrial fabrics, ropes, nets, and agricultural products. Its versatility allows it to be used in a wide range of products across various industries.

0 notes

Text

PP webbing generally refers to webbing made from polypropylene (PP) material. Polypropylene is a thermoplastic polymer commonly used in a variety of applications due to its lightweight, durability, and resistance to moisture and chemicals.

PP webbing manufacturer India can provide you with access to expertise, resources, and production capabilities that are essential for creating high-quality products that require durable and versatile webbing materials.

0 notes

Text

CIRCULAR FIBC

Alpine FIBCPVT LTD is a best manufacturer, exporters and suppliers of high quality Circular (Tubular) FIBC Bags in India, USA, Germany, France, UK, Italy, Canada, Spain, Netherlands, Portugal, Greece, Sweden, Argentina, Chile, Poland. Circular bulk bags (FIBC) have a circular/tubular body that is a seamless, with only a top and bottom panel sewn into the bag. Circular style bags are ideal for fine and hydroscopic materials. ALPINE FIBC PVT.LTD. is one of the leading manufacturer and exporter of a wide range of FIBC/Big Bags and Food Grade FIBC like Builder bags, 4 Panel bags, U Panel bags, Circular bags, Baffle bags, UN Certified bags, On-Two Loop bags, Ventilated bags, Container Liner bags, BOPP Baffle bags, Gambo bags, Tie Baffle & Net Baffle bags, Asbestos bags, Garden bags, Fall Arrest bags, Reel bags, (Roll packing), Ez Opening bags, Perforated Liner bags, Sling bags, Helicopter bags, Stretch Hood and PP Woven Sack, Spiral Tubing, Multifilament Yarn, Tarpaulins, Ground Covers, PP Woven Fabrics.

#circular bags#CIRCULAR FIBC BAGS#Circular (Tubular) FIBC Bags#Circular (Tubular) FIBC Bags in India

2 notes

·

View notes

Link

0 notes

Text

Turkish textile industry will meet at the textile machinery fair GTM2025 in Gaziantep

The GTM 2025 Textile Machinery Fair, which brings together the leading figures in the textile industry with the region where 75 percent of Turkish textile production is carried out, will be the prevalent textile event both in Turkey and around the world. The Gaziantep Textile Machinery Fair GTM 2025 will set out a vision for world textiles, and will bring a mobility to the industry valued at millions of dollars. Gaziantep, the meeting spot of Turkish textiles where the production of Turkish textile and garment products are mainly carried out around neighboring cities such as Adana, Adıyaman, Kayseri, Kahramanmaraş, Malatya, Niğde, Osmaniye and Şanlıurfa, is an important center for the organization of a such event. The Textile Machinery Fair, which will be held in a 30,000 square meter closed area at the Gaziantep Middle East Fair Center between October 15-17, 2025, will bring together domestic and foreign machinery manufacturers with the textile industry.

GTM 2025 Fair

Will be held under the auspices of Gaziantep Metropolitan Municipality With the support of textile and raw material exporter associations With the cooperation of Gaziantep Chamber of Industry, Gaziantep Chamber of Commerce, Gaziantep Organized Industrial Zone Directorate.

Business Networking Opportunities Worth of Million Dollars

According to statistical data, the Turkish textile machinery market has a volume of 3 billion 4 million dollars. According to 2023 TÜİK data, 1 billion 950 million dollars of textile machinery imports were realized, while 1 billion 450 million dollars of the Turkish domestic market's capacity was met by domestic textile machinery manufacturers. In the same period, exports of Turkish textile machinery manufacturers recorded as 840 million dollars. Turkey is the world's largest machinery buyer, right after China and India. It is the most important market for both domestic and foreign machinery manufacturers. At Gaziantep Textile and Apparel Machinery Fair GTM2025, which will bring the textile industry together under one roof, technology manufacturer brands will showcase their newest applications and will have the opportunity to exhibit their innovative products. Companies wishing to take advantage around domestic and foreign markets will have the opportunity to establish new business connections and to form new partnerships. The fair, which will increase the innovative capacity of the textile industry, will bring a mobility to the industry valued at millions of dollars.

What will be showcased at the Fair?

Textile machinery manufacturer companies participating in the fair will have the opportunity to directly reach the market with the hosting of Gaziantep, which holds a prominent importance in textiles, ready-made clothing, home textiles, carpet, nonwoven, fabric and yarn production. Gaziantep, which is amongst the provinces that have made significant progress in the textile sector, has been the leader in many product groups with its Textile Production Capacities. In addition to the textile production carried out by Gaziantep, the city positioned as the center of Turkish textile production with the textile industry which is clustered around the neighboring cities. Gaziantep, is the leading producer in Turkey, producing 91% of the machine-made carpet production in Turkey, 91% of the Polipropilen İplik / Polypropylene Yarn production produced in Turkey, 82% of Dokusuz kumaş / Nonwoven fabric production, 77% of (Akrilik İplik) Acrylic Yarn production, 48% of Gipe İplikler / Gipe Yarns production, 40% of the production of Çuval, torba / Bags and Sacks from PE/PP Band from PE or PP strip, 36% of Pamuk İpliği / Cotton Yarn alone.

The following Product Groups constitute the Participant Concept of the Fair;

Yarn Preparation Machines

Yarn and Fabric, Dyeing & Finishing Machines

Cotton and Fiber Preparation Machines

Transferring, Twisting, Texturing Machines

Nonwoven Machines

Weaving Preparation Machines

Weaving Machines

Tufting and Carpet Weaving Machines

Narrow Weaving Machines

Warp Knitting Preparation Machines

Flat and Circular Knitting Machines

Washing, Bleaching, Drying Machines

Wrapping and Folding Machines

Cord and Rope Machines

Socks Machines

Embroidery Machines

Quilting Machines

Textile Printing Machines

Digital Textile Printing Machines

Textile Printing Dyes and Chemicals

Textile Chemicals, Laboratory Equipment and Quality Control Systems

CAD-CAM-CIM Applications and Automation Systems

Auxiliary Machines, Spare Parts and Accessories

Garment machines and accessories

0 notes

Text

Monofilament Extrusion Plant Manufacturers | Aawadkrupa Plastomech

Monofilament Extrusion Plant Manufacturers | Akiropes

At Aawadkrupa Plastomech Pvt. Ltd., we're a top manufacturer of monofilament extrusion plants in India. Our machines are top-notch and go all around the world. They work really well and save time and energy because we use the latest technology. We can even customise our machines to fit exactly what you need. Plus, we're always here to help you with setup and maintenance. We've been doing this for a long time, and we're always trying to make our machines even better for you. Key Features

Extra strength & shining to yarn.

Longer life of screw & barrel.

AC inverter & motor which synchronises the entire extruder.

PP, HDPE & LD can be processed due to its special screw design.

Latest technology used to force the melt into the die very effectively.

Less noisy pollution.

Less power consumption.

More power saving in heater due to self-calibration Technology.

Use a friendly touch screen display with a separate desk.

All parameters and reading will be shown on display.

Timer based Auto-startup and shutdown heating system.

Reverse heating interlocking system to avoid damage to the machine.

Emergency full length foot switches parallel to the godded length for both godded.

Available Models

1 APPL / MF – 55 AC

2 APPL / MF – 65 AC

3 APPL / MF – 75 AC

4 APPL / MF – 90 AC

5 APPL / MF – 100AC

6 APPL / MF – 80 GF

7 APPL / MF – 110AC

8 APPL / MF – 120AC

9 APPL / MF – 75 AC

10 APPL / MF – 90 AC

11 APPL / MF – 110 AC

Unrivalled Quality and Precision

Akiropes' monofilament extrusion plants are engineered to deliver unrivalled quality and precision in every strand. With a keen focus on innovation and meticulous attention to detail, these plants are designed to produce monofilaments of exceptional consistency and durability. Whether you're extruding nylon, polyethylene, or any other material, Akiropes' machinery ensures superior performance and reliability.

Global Reach, Local Support

With a strong presence in over 65 countries, Akiropes understands the diverse needs of customers worldwide. Whether you're located in Asia, Africa, Europe, or the Americas, Akiropes provides localised support and service to ensure seamless integration of their monofilament extrusion plants into your production process. Their team of experts is available 24/7 to address any queries or concerns, ensuring a hassle-free experience from start to finish.

On-Time Delivery

In today's fast-paced business environment, timely delivery is essential. Akiropes recognizes the importance of meeting deadlines and strives to ensure that orders are processed and dispatched promptly. Their streamlined manufacturing processes and efficient logistics management guarantee on-time delivery, allowing you to stay ahead of schedule and meet your production targets with confidence.

Comprehensive Solutions

Akiropes offers a comprehensive range of monofilament extrusion plants to cater to a variety of applications and requirements. Whether you're in need of a standard model or a customised solution tailored to your specific needs, Akiropes has the expertise and capability to deliver. Their experienced engineers work closely with customers to understand their unique challenges and provide optimal solutions that maximise efficiency and productivity.

Conclusion

In conclusion, Akiropes is your trusted partner for high-quality monofilament extrusion plants. With a commitment to excellence, global reach, 24/7 support, and on-time delivery, they offer a comprehensive solution for businesses worldwide. Whether you're looking to expand your production capabilities or upgrade your existing machinery, Akiropes has the expertise and resources to meet your needs. Get in touch with them today to request a quote and experience the Akiropes difference firsthand!

For More Information:

"Aawadkrupa" survey no-131-A,Navagam Bhavnagar-Rajkot highway Bhavnagar, Gujarat 364060

9510186014,9879615963

#monofilament extrusion#monofilament extrusion plant#monofilament extrusion machine#monofilament extrusion plant for sale#monofilament extrusion plant price#monofilament extrusion plant manufacturer#monofilament extrusion plant exporter#monofilament extrusion plant in india#monofilament extrusion machine in india

0 notes

Text

PP Spunbond Nonwoven Fabric: Versatile, Durable, Eco-Friendly Solutions

In the world of modern manufacturing and packaging, materials that offer versatility, durability, and environmental sustainability are highly valued. PP (Polypropylene) Spunbond Nonwoven Fabric stands out as a key player in meeting these criteria, serving a wide range of applications across various industries. At Singhal Industries, we specialize in manufacturing high-quality PP Spunbond Nonwoven Fabric that meets stringent standards of performance and eco-friendliness.

What is PP Spunbond Nonwoven Fabric?

PP Spunbond Nonwoven Fabric is a type of nonwoven material made from thermoplastic polymer polypropylene. Unlike traditional woven fabrics, which are created by weaving or knitting yarns together, nonwoven fabrics are manufactured by bonding fibers together through various processes. PP Spunbond Exporter in Ahmedabad is produced by spinning and bonding polypropylene fibers together to form a strong and durable web.

Key Characteristics of PP Spunbond Nonwoven Fabric

1. Versatility:

PP Spunbond Nonwoven Fabric is incredibly versatile and finds applications in diverse industries such as agriculture, medical, automotive, construction, and packaging.

It can be engineered to have different properties like water resistance, breathability, and strength, making it suitable for a wide range of end uses.

2. Durability:

Known for its strength and durability, PP Spunbond Nonwoven Fabric offers excellent tear and tensile strength, making it ideal for applications where robust performance is essential.

It withstands harsh environmental conditions, including exposure to chemicals and UV radiation, without compromising its integrity.

3. Eco-Friendliness:

As environmental sustainability becomes increasingly important, PP Spunbond Nonwoven Fabric stands out for its eco-friendly characteristics.

It is recyclable and can be manufactured using recycled polypropylene materials, reducing overall environmental impact.

The production process of Spunbond non woven fabric manufacturer consumes less energy and water compared to traditional woven fabrics, making it a greener choice.

Applications of PP Spunbond Nonwoven Fabric

PP Spunbond Nonwoven Fabric's versatility makes it indispensable in various industries:

1. Agriculture:

Used in crop protection, greenhouse coverings, and as ground covers due to its permeability to air and water.

2. Medical and Hygiene:

Widely used in surgical gowns, face masks, and medical wipes due to its softness, breathability, and bacteria resistance.

3. Packaging:

Ideal for packaging applications such as tote bags, shopping bags, and promotional bags due to its strength, lightweight nature, and printability.

4. Automotive:

Used in car upholstery, interior trim, and insulation due to its durability, noise reduction properties, and resistance to mold and mildew.

5. Construction:

Used as geotextiles, roofing membranes, and house wrap due to its strength, moisture resistance, and ability to provide thermal insulation.

Why Choose Singhal Industries for PP Spunbond Nonwoven Fabric?

Singhal Industries is a leading manufacturer of PP Spunbond Nonwoven Fabric, offering:

High-Quality Products: We adhere to strict quality control measures to ensure our PP Spunbond Nonwoven Fabric meets international standards.

Customization: We offer customization options in terms of colors, weights, and specifications to meet specific customer requirements.

Sustainability: Our manufacturing processes emphasize sustainability, with a focus on reducing environmental impact through responsible practices.

Reliability: With years of industry experience and a commitment to customer satisfaction, Singhal Industries is a trusted partner for all your nonwoven fabric needs.

Conclusion

PP Spunbond nonwoven Supplier India continues to revolutionize industries with its versatility, durability, and eco-friendly properties. Whether you're looking for packaging solutions, medical textiles, agricultural covers, or automotive components, PP Spunbond Nonwoven Fabric from Singhal Industries offers a reliable and sustainable choice. Contact us today to explore how our innovative nonwoven fabric solutions can benefit your business.

FAQS

What is PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric is a type of material made from polypropylene fibers that are spun and bonded together. It is known for its strength, durability, and versatility in various applications.

What are the key benefits of PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric offers versatility across industries, durability against wear and tear, and eco-friendly properties as it is recyclable and can be made from recycled materials.

In which industries is PP Spunbond Nonwoven Fabric commonly used? It is used in agriculture for crop protection and ground cover, in medical applications for surgical masks and gowns, in packaging for bags and wraps, in automotive for upholstery and insulation, and in construction for geotextiles and roofing membranes.

How environmentally friendly is PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric is considered eco-friendly due to its recyclability and the potential to use recycled materials in its production. Its manufacturing process also consumes less energy and water compared to traditional fabrics.

Why choose PP Spunbond Nonwoven Fabric from Singhal Industries? Singhal Industries offers high-quality PP Spunbond Nonwoven Fabric with customization options, stringent quality control measures, and a commitment to sustainability. Our products meet international standards and are tailored to meet specific customer needs.

0 notes

Text

Unveiling the Versatility of PP Multifilament Yarn: A Comprehensive Exploration

Unveiling the Versatility of PP Multifilament Yarn: A Comprehensive Exploration

Polypropylene (PP) multifilament yarn stands as a cornerstone in the textile industry, offering a myriad of applications and benefits. In this in-depth exploration, we delve into the characteristics, uses, manufacturing process, and innovative advancements of PP multifilament yarn, shedding light on its pivotal role in various sectors.

Understanding PP Multifilament Yarn: Characteristics and Composition

PP multifilament yarn is composed of multiple continuous filaments of polypropylene, intricately spun together to form a durable and flexible thread. Known for its high tensile strength, abrasion resistance, and low moisture absorption properties, PP multifilament yarn exhibits excellent performance in diverse applications. With a range of deniers and filament counts available, manufacturers can tailor the yarn to meet specific requirements and preferences.

Exploring the Applications of PP Multifilament Yarn

PP multifilament yarn finds extensive use across various industries:

Textiles: Used in the production of fabrics, ropes, cords, and webbings for apparel, home furnishings, and technical textiles.

Geotextiles: Employed in geotextile applications such as erosion control, soil stabilization, and drainage systems for civil engineering projects.

Packaging: Utilized for manufacturing flexible packaging materials, industrial bags, and woven sacks for the packaging and transportation of goods.

Automotive: Integrated into automotive components such as seat belts, airbags, and upholstery for enhanced safety and durability.

Sports and Outdoor Equipment: Incorporated into sports equipment, camping gear, and outdoor apparel for its lightweight and resilient properties.

The Manufacturing Process of PP Multifilament Yarn

The production of PP multifilament yarn involves several key stages:

Polymer Extrusion: Polypropylene polymer pellets are melted and extruded through spinnerets to form continuous filaments.

Quenching: The extruded filaments are rapidly cooled to solidify them and prevent sticking together.

Drawing: The filaments are stretched to align the polymer molecules and improve strength and uniformity.

Annealing: The stretched filaments are heated to relieve internal stresses and enhance dimensional stability.

Winding: The treated filaments are wound onto bobbins or spools to create the final yarn product.

Leveraging Innovations in PP Multifilament Yarn

Recent advancements in polymer technology and yarn spinning techniques have led to innovations in PP multifilament yarn production. These innovations include:

Enhanced Strength and Durability: Improved polymer formulations and spinning processes result in yarn with higher tensile strength and abrasion resistance.

Specialized Finishes and Treatments: Surface treatments and coatings are applied to the yarn to impart specific properties such as UV resistance, antistatic properties, and flame retardancy.

Recyclability: Developments in recycling technology enable the production of eco-friendly PP multifilament yarn from recycled polypropylene materials, contributing to sustainability efforts in the textile industry.

Leading the Industry: Multifilament Yarn Suppliers in India

India boasts a thriving textile industry, supported by a network of multifilament yarn suppliers catering to diverse market demands. These suppliers offer a wide range of multifilament yarn options, including polypropylene (PP) multifilament yarn, to meet the needs of various sectors such as textiles, packaging, and industrial applications. With a focus on quality, reliability, and customer satisfaction, Multifilament Yarn Suppliers in India play a pivotal role in driving the growth and innovation of the textile industry nationwide.

Exporting Excellence: Polypropylene Multifilament Yarn Exporters in Ahmedabad

Ahmedabad, a prominent industrial city in Gujarat, serves as a hub for polypropylene multifilament yarn exporters, leveraging its strategic location and robust infrastructure to meet global market demands. These exporters specialize in supplying high-quality PP multifilament yarn to customers worldwide, offering a diverse range of yarn options tailored to specific applications and requirements. With a commitment to excellence in product quality, packaging, and timely delivery, Polypropylene Multifilament Yarn Exporters in Ahmedabad contribute significantly to the international textile trade and Gujarat's reputation as a textile manufacturing hub.

Innovating Excellence: PP Multifilament Yarn Manufacturer in Gujarat

Gujarat, known for its entrepreneurial spirit and manufacturing prowess, hosts several leading PP multifilament yarn manufacturers driving innovation and excellence in the industry. These manufacturers utilize advanced technology, state-of-the-art machinery, and quality assurance processes to produce PP multifilament yarn of superior quality and consistency. With a focus on research and development, PP Multifilament Yarn Manufacturer in Gujarat continuously strive to enhance product performance, expand product offerings, and meet the evolving needs of customers in domestic and international markets.

Conclusion: Harnessing the Power of PP Multifilament Yarn

In conclusion, PP multifilament yarn stands as a versatile and indispensable material in the textile and manufacturing sectors. With its exceptional properties, diverse applications, and continuous innovations, PP multifilament yarn continues to play a vital role in enhancing product performance, efficiency, and sustainability across industries. As technology advances and demand grows, PP multifilament yarn remains poised to shape the future of textiles and beyond.

Frequently Asked Questions About PP Multifilament Yarn

What are the key advantages of PP multifilament yarn compared to other textile materials? PP multifilament yarn offers several advantages, including high tensile strength, abrasion resistance, low moisture absorption, and affordability. These properties make it suitable for a wide range of applications across industries.

Can PP multifilament yarn be dyed or colored? Yes, PP multifilament yarn can be dyed or colored using various dyeing techniques and pigments. However, it is essential to consider the specific properties of PP and the desired colorfastness requirements for the intended application.

Is PP multifilament yarn suitable for outdoor applications? Yes, PP multifilament yarn is commonly used in outdoor applications due to its resistance to UV radiation, moisture, and chemicals. It is frequently employed in products such as outdoor furniture, camping gear, and marine ropes.

How does the denier of PP multifilament yarn affect its performance? The denier of PP multifilament yarn refers to the thickness or diameter of the individual filaments composing the yarn. Higher denier yarns typically offer increased strength and durability, making them suitable for heavy-duty applications such as industrial ropes and geotextiles.

Are there any environmental considerations associated with PP multifilament yarn? PP multifilament yarn is recyclable and can be reused or repurposed into new products after its lifecycle. Additionally, advancements in recycling technology enable the production of eco-friendly PP multifilament yarn from recycled materials, contributing to sustainability efforts in the textile industry.

0 notes

Text

PP Yarn: A Comprehensive Overview

This article delves into the world of PP Yarn Manufacturers in India, exploring the features of Polypropylene Yarn in India, and providing insights into the leading PP Yarn Manufacturers.

0 notes

Text

The Versatility and Benefits of PP Woven Fabric

PP woven fabric, crafted from polypropylene, has emerged as a versatile and indispensable material across numerous industries. Renowned for its durability, strength, and cost-effectiveness, it's a preferred choice for manufacturers seeking reliable and sustainable solutions. Let's delve into the advantages of this exceptional fabric and explore the expertise of leading PP woven fabric manufacturers in India.

Understanding PP Woven Fabric

PP woven fabric manufacture is produced by interlacing polypropylene yarns to create a robust and flexible material. Its unique properties make it suitable for a wide range of applications.

Benefits of PP Woven Fabric

Exceptional Strength and Durability: PP woven fabric is renowned for its high tensile strength, making it capable of withstanding heavy loads without tearing or breaking. This durability ensures the protection of products during transportation and storage.

Water Resistance: The fabric exhibits excellent water resistance, safeguarding contents from moisture damage. This property is crucial for packaging products like fertilizers, chemicals, and food grains.

Lightweight and Flexible: Despite its strength, PP woven fabric is lightweight and flexible, making it easy to handle and transport. This characteristic enhances efficiency in various industries.

Cost-Effective: Compared to other packaging materials, PP woven fabric offers excellent value for money without compromising quality.

Versatility: The fabric's versatility shines through in its diverse applications, including packaging, agriculture, construction, and industrial use.

Eco-Friendly: Being recyclable and biodegradable, PP woven fabric aligns with environmental sustainability goals.

Leading PP Woven Fabric Manufacturers in India boasts a thriving textile industry, with numerous PP woven fabric manufacturers contributing to the country's economic growth. These manufacturers offer a wide range of products tailored to meet diverse industry requirements.

FAQs about PP Woven Fabric

Is PP woven fabric resistant to chemicals?

Yes, PP woven fabric is resistant to most chemicals, making it ideal for packaging chemicals and fertilizers.

Can PP woven fabric be recycled?

Absolutely, PP woven fabric is recyclable, promoting environmental sustainability.

What are the common applications of PP woven fabric?

Common applications include packaging bags, sacks, geotextiles, and agricultural coverings.

Is PP woven fabric suitable for outdoor use?

Yes, its water resistance and UV resistance make it suitable for outdoor applications.

Can PP woven fabric be customized?

Many manufacturers offer customization options in terms of size, weight, and color to meet specific requirements.

PP woven fabric has solidified its position as a preferred material across industries due to its exceptional properties and cost-effectiveness. By partnering with reputable PP woven fabric manufacturers in India, businesses can access high-quality products tailored to their specific needs.

0 notes

Text

Best Practices for Working with PP Multifilament Yarn

Polypropylene (PP) multifilament yarn is widely recognized for its durability, versatility, and lightweight characteristics. These properties make it a popular choice in various applications, from textiles to industrial materials. As industries increasingly adopt PP filament yarn for their production processes, understanding best practices for working with this material becomes crucial. This article outlines essential practices to ensure optimal performance when utilizing PP multifilament yarn, with a focus on quality, handling, and application techniques.

Understanding PP Filament Yarn

PP filament yarn is made from long, continuous strands of polypropylene, resulting in a yarn that is both strong and flexible. Its high tensile strength makes it ideal for applications where durability is critical, such as in ropes, nets, and upholstery. The manufacturing process of PP multifilament yarn involves melting polypropylene granules, extruding them through spinnerets, and then cooling and stretching the filaments to enhance their properties. Familiarity with the characteristics of PP filament yarn is the first step in effectively utilizing it in any project.

Selecting the Right Supplier

When sourcing PP multifilament yarn, selecting a reputable manufacturer is crucial. Quality can vary significantly among different suppliers, impacting the final product's performance and durability. Look for a PP multifilament yarn manufacturer that adheres to international quality standards and has a proven track record in the industry. Reading reviews and seeking recommendations can also help in making informed decisions. A reliable supplier not only ensures high-quality yarn but also provides essential documentation and support for proper usage.

Storage and Handling

Proper storage and handling of PP multifilament yarn are essential to maintain its integrity and performance. Store the yarn in a cool, dry place away from direct sunlight to prevent degradation. Prolonged exposure to UV rays can weaken the fibers, leading to reduced strength and lifespan. Additionally, avoid storing the yarn near chemicals or solvents that might compromise its quality. Handling the yarn with care during transportation and processing is equally important. Preventing kinks, knots, or excessive tension during handling can significantly enhance its usability.

Preparing for Production

Before beginning any project with PP multifilament yarn, proper preparation is key. Ensure that all machinery and tools are clean and well-maintained. Dirt, debris, or rust can cause damage to the yarn during the manufacturing process. It’s also important to check the tension settings on your machinery. Adjusting the tension according to the specifications of the yarn will help in achieving consistent quality.

Utilizing the Right Techniques

When working with Multifilament yarns in India, adopting the correct techniques during weaving, knitting, or sewing is vital for achieving the desired results. For weaving applications, consider using specialized looms designed for multifilament yarns to ensure even tension and prevent breakage. In knitting, use needles that can accommodate the finer strands of the yarn, as using inappropriate sizes can lead to snags or uneven stitches. When sewing with PP multifilament yarn, select a needle that is suitable for heavy-duty fabrics, ensuring that it can pierce through the yarn without causing damage.

Testing and Quality Control

Implementing testing protocols during production can significantly enhance the quality of products made with PP multifilament yarn. Conduct tensile strength tests to assess the yarn's durability and ensure it meets specific requirements. Regular quality checks can help identify any inconsistencies in the yarn, such as variations in thickness or color, that might affect the final product's performance. Documenting these tests and maintaining a record can provide valuable insights into the yarn's quality over time, allowing manufacturers to make necessary adjustments.

Compatibility with Other Materials

When incorporating PP multifilament yarn into a project, consider its compatibility with other materials. For instance, when blending it with other fibers or materials, understand how the characteristics of PP yarn interact with those substances. Testing various blends can help determine the optimal combination for specific applications, such as achieving desired aesthetics, strength, or flexibility. Properly selecting compatible materials can enhance the overall quality and performance of the finished product.

Maintenance of Final Products

Products made from PP multifilament yarn require proper maintenance to ensure longevity. Educating end-users about the care requirements for items like ropes, nets, or upholstery can help in preserving their performance. Recommend washing with mild detergents and avoiding harsh chemicals that might degrade the fibers. Additionally, advise users to store items properly when not in use, particularly avoiding prolonged exposure to sunlight or extreme temperatures. Providing maintenance guidelines can significantly enhance customer satisfaction and extend the life of the products.

Environmental Considerations

As industries move towards sustainable practices, understanding the environmental impact of using PP multifilament yarn is becoming increasingly important. While polypropylene is recyclable, not all products made from this material are designed with recycling in mind. Encourage manufacturers to adopt eco-friendly practices, such as using recycled materials in their processes or developing strategies for responsible disposal. Educating consumers about the recyclability of PP products can also foster a culture of sustainability within the industry.

Innovation and Continuous Improvement

The textile and manufacturing industries are constantly evolving, and so are the technologies and methods used to work with PP multifilament yarn. Staying updated on the latest advancements in yarn production, processing technologies, and application techniques is essential for manufacturers aiming to maintain a competitive edge. Attending industry conferences, participating in workshops, and engaging with peers can provide valuable insights into emerging trends and best practices. Continuous improvement in processes and products not only enhances quality but also contributes to overall efficiency and customer satisfaction.

Conclusion

Working with PP multifilament yarn offers numerous advantages, but achieving the best results requires a commitment to best practices. By understanding the characteristics of PP filament yarn, selecting the right suppliers, maintaining proper storage and handling, and adopting effective production techniques, manufacturers can enhance the quality of their products significantly. Testing, compatibility with other materials, and attention to maintenance further contribute to successful outcomes. As the industry evolves, embracing innovation and sustainability will ensure that the use of PP multifilament yarn remains effective and responsible. By following these guidelines, businesses can maximize the potential of PP Multifilament yarn manufacturer and around the globe, leading to improved performance and customer satisfaction. Frequently Asked Questions (FAQs)

How should I store PP multifilament yarn? Store the yarn in a cool, dry place away from direct sunlight. Avoid dragging it across rough surfaces to prevent fraying, and arrange multiple spools neatly to avoid tangling. What should I do if my PP multifilament yarn is fraying or breaking? Ensure your equipment is set up correctly for the specific yarn you are using. Check for rough edges on machines that may be causing fraying, and perform regular maintenance to prevent these issues.

How can I ensure the quality of PP multifilament yarn? Conduct thorough testing of the yarn for consistency in thickness, strength, and color before starting any project. Work with a reputable PP multifilament yarn manufacturer to ensure stringent quality control during production.

0 notes

Text

PP Woven Fabric: The Sustainable and Versatile Workhorse of Textiles

Introduction: In the vast landscape of textiles, one material stands out for its versatility, durability, and sustainability: PP (Polypropylene) woven fabric. Used across a myriad of industries, from agriculture to packaging, construction to geotextiles, PP woven fabric has become the workhorse of modern textiles. In this article, we delve into the characteristics, applications, and sustainability aspects of PP woven fabric, while also exploring the landscape of suppliers and manufacturers, particularly focusing on Ahmedabad, Gujarat, and India as a whole.

Understanding PP Woven Fabric: PP woven fabric is a type of synthetic fabric made from polypropylene polymer. Its construction involves weaving polypropylene tapes or flat yarns together to create a strong and durable fabric. This weaving process imparts exceptional tensile strength and tear resistance to the fabric, making it suitable for a wide range of applications.

Key Characteristics:

Strength and Durability: PP woven fabric is renowned for its high strength-to-weight ratio, making it ideal for applications requiring robustness and resilience. It can withstand heavy loads, punctures, and abrasion, ensuring long-lasting performance.

Lightweight: Regardless of its solidarity, PP woven texture is lightweight, which makes it simple to deal with and transport. This trademark is especially favorable in applications like bundling and transportation.

Water Resistance: PP woven fabric exhibits inherent water resistance, making it suitable for outdoor applications where exposure to moisture is a concern. It can be further enhanced with laminations or coatings for increased impermeability.

UV Stability: UV stability is another notable feature of PP woven fabric, allowing it to withstand prolonged exposure to sunlight without significant degradation. This makes it suitable for outdoor applications such as agricultural covers and geotextiles.

Applications of PP Woven Fabric: The versatility of PP woven fabric lends itself to a wide array of applications across various industries. Some of the key applications include:

Packaging: PP woven fabric is extensively used in packaging materials such as sacks, bags, and FIBCs (Flexible Intermediate Bulk Containers). Its strength and durability make it an ideal choice for transporting bulk goods such as grains, seeds, fertilizers, and cement.

Agriculture: In agriculture, PP woven fabric finds applications in crop protection, ground coverings, shade nets, and greenhouse films. Its UV stability and water resistance make it well-suited for protecting crops from adverse weather conditions and pests.

Construction: PP woven fabric is used in construction for purposes such as scaffolding nets, tarpaulins, and temporary enclosures. Its strength and durability make it an indispensable material for ensuring safety and protection on construction sites.

Geotextiles: In civil engineering and landscaping projects, PP woven fabric is employed as geotextiles for erosion control, soil stabilization, and drainage applications. Its permeability and strength contribute to the longevity and effectiveness of such infrastructure projects.

Sustainability Aspects: In addition to its functional attributes, PP woven fabric also offers significant sustainability benefits:

Recyclability: Polypropylene is a recyclable thermoplastic polymer, which means that PP woven fabric can be recycled and reused in various applications, reducing the demand for virgin materials and minimizing waste.

Energy Efficiency: The manufacturing process of PP woven fabric consumes relatively less energy compared to other materials such as paper or traditional textiles, contributing to lower carbon emissions and environmental impact.

Longevity: The durability of PP woven fabric ensures a longer lifespan compared to alternative materials, reducing the frequency of replacements and the associated resource consumption.

Resource Efficiency: PP woven fabric is produced using minimal water and natural resources, making it a more sustainable choice compared to materials that require extensive water and land resources for cultivation or extraction.

Suppliers and Manufacturers: Ahmedabad, Gujarat, and India as a whole boast a robust network of suppliers and manufacturers catering to the demand for PP woven fabric:

PP laminated woven fabric suppliers in Ahmedabad offer a diverse range of products tailored to specific applications, with options for customization and lamination to meet customer requirements.

PP woven fabric manufacturers in Gujarat leverage the state's industrial infrastructure and expertise in textile manufacturing to produce high-quality PP woven fabric at competitive prices.

PP woven fabric roll manufacturers in India cater to both domestic and international markets, supplying a wide range of industries with standard and customized fabric rolls to suit diverse applications.

Conclusion: PP woven fabric emerges as a sustainable and versatile solution for a multitude of applications, owing to its inherent strength, durability, and eco-friendly attributes. As industries continue to prioritize sustainability and efficiency, the demand for PP woven fabric is expected to rise, further driving innovation and advancements in its production and applications. With a strong network of suppliers and manufacturers in Ahmedabad, Gujarat, and across India, the future of PP woven fabric looks promising as it continues to establish itself as the workhorse of modern textiles.

Frequently Asked Questions about PP Woven Fabric

Is PP woven fabric eco-friendly? PP woven fabric's recyclability and durability contribute to its eco-friendly nature. However, the environmental impact depends on factors like production practices and end-of-life management.

Is PP woven fabric breathable? In its natural state, PP woven fabric exhibits limited breathability. However, breathable variations are available for specific applications.

How strong is PP woven fabric? PP woven fabric offers surprising strength and tear resistance, making it suitable for heavy-duty applications.

Can PP woven fabric be dyed? While dyeing PP woven fabric directly is challenging, it can be produced in various colors during manufacturing.

What are the limitations of PP woven fabric? PP woven fabric might not be the best choice for applications requiring high breathability or heat resistance.

#pp laminated woven fabric suppliers in Ahmedabad#pp woven fabric manufacturer in Gujarat#pp woven fabric roll manufacturers in india

0 notes

Text

ALPINE FIBC PVT.LTD.

Alpine FIBC PVT LTD is a leading FIBC/Jumbo Bags Manufacturer, Exporters & Suppliers in India, USA, Germany, France, UK, Italy, Canada, Spain, Netherlands, Portugal, Greece, Sweden, Argentina, Chile, Poland. We Provide high quality Jumbo Bags, Big Bags, Bulk Bags and Ton Bag at affordable rates. ALPINE FIBC PVT.LTD. is one of the leading manufacturer and exporter of a wide range of FIBC/Big Bags and Food Grade FIBC like Builder bags, 4 Panel bags, U Panel bags, Circular bags, Baffle bags, UN Certified bags, On-Two Loop bags, Ventilated bags, Container Liner bags, BOPP Baffle bags, Gambo bags, Tie Baffle & Net Baffle bags, Asbestos bags, Garden bags, Fall Arrest bags, Reel bags, (Roll packing), Ez Opening bags, Perforated Liner bags, Sling bags, Helicopter bags, Stretch Hood and PP Woven Sack, Spiral Tubing, Multifilament Yarn, Tarpaulins, Ground Covers, PP Woven Fabrics. We also supply customize bags. Our Design and Development team is regularly working on designing and developing of FIBC’s according to the customer requirements.

#FIBC/Jumbo Bags#circular bags#fibc/big bags and food grade fibc#u panel bags#builder bags#4 panel bags#baffle bags#un certified bags

2 notes

·

View notes

Text

What Are the Benefits of Using Non-Woven Fabric?

The non-woven fabrics are materials that are produced by thermal, mechanical and chemical processes. These are engineered fabrics that are used in various industrial and consumer products, by itself or with other materials. It is hygroscopic, UV resistant and flame retardant.

The non-woven fabrics have various benefits, including minimising solid wastes, and landfills and releasing no pollutants in the air and soil. In this blog, we will look into the various benefits of using non-woven fabrics that make them more practical and versatile than other traditional fabrics.

What is Non Woven Fabrics?

The non woven fabric is an engineered material manufactured from different fibers. These materials need not be converted to fibres into yarn, as the fibre yarns are bonded together due to inherent friction from one fibre to another.

Benefits of Using Non Woven Fabrics

Light Weight: The pp non-woven fabrics are the primary raw material for production. Its specific gravity is only 0.09, which is ⅗ of cotton. It is super-soft and pleasant to touch.

Softness: Its softness makes it ideal for non woven fabric bags. The bags are soft and comfy.

Eco-friendly: The reason why geotextile fabric manufacturers in Gujarat are in demand for its non-woven fabrics is its eco-friendly nature. This makes it applicable in different industries. With the rising concerns over environmental consciousness and sustainability, woven materials have gained immense popularity.

Air-Permeable: The non woven bags are made of fiber that exhibits excellent air permeability. This makes it easy to clean and maintain.

Non-Toxic and Non-irritant: The non woven bag material is non-toxic, non-irritant, odourless and stable. The manufacturers use food-grade materials, which makes it ideal for industries like pharmaceutical, personal care, cosmetics and other products.

Water Resistant: The non woven fabric manufacturer in India caters to different industries that need water-repellent materials. The non woven materials are made of polypropylene chips and are non-absorbent and water resistant properties. This makes the end-product exhibit excellent breathabilty and porous.

Excellent Physical Properties: As the material is made of PP spinning directly into the mesh and thermally bonded, it gives the products exceptional strength than other fibre materials.

Uses of Non Woven Fabric

The Non Woven Fabric is Used in a Variety of Applications, Such as:

Medical: The non-woven fabrics have gained a lot of popularity, especially during the pandemic. It is widely used in the manufacturing of various medical products like gloves, masks, surgical drapes, plastic, medical packaging, cleanroom wipes, disposal face masks and more.

Health & Hygiene: The spunboud non woven material has brought an evolution in the hygiene industry. It is used in producing various hygiene products like sanitary pads, diapers, make-up wipes, nail wipes, facial pads, and other products.

Geotextile and Construction: The PP cover manufacturers provide non-woven geotextiles that are used in various applications in the construction and engineering industry. It is primarily used for drainage systems, separation, canal construction, filtration, landfill lining and others.

Household: We are surrounded by non woven geotextiles. It is a part of everyday lives, ranging from water and air filters, household wipes, floor wipes, coffee filter material and much more. Shankar Packaging Ltd. is a prominent filtration fabric manufacturer. We offer a range of filtration materials in 100% multifilament, monofilament spun and other combinations.

Conclusion

Woven fabrics are used in different industrial sectors and play a pivotal role in the technical industry globally. Its soil stability, tear and puncture resistance, UV resistance, breathability, excellent weather ability and tensile strength make it a versatile material. Shankar Packaging Ltd. is a leading geotextile manufacturer and supplier in India.

We offer a comprehensive range of technical textiles, indu-tech, geo-tech, agro-tech and pack-tech products to clients across the globe. Our geotextile is also ideal for geo tubes and geo bags. At SPL, we provide technical textiles in 3 different yarns viz PES multifilament, PP tape yarns and PPMF. To know more about geotextiles and other products, contact us.

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes