#polypropylene sheet

Explore tagged Tumblr posts

Text

5 Reasons Why Polypropylene Sheet Is The Best Material For Your Project

Polypropylene sheet is an incredibly versatile material that can be used in a variety of projects. It is an ideal choice for a variety of projects, from simple craft projects to complex engineering applications. Read this blog to know 5 reasons why polypropylene sheet is the best material for your project

0 notes

Text

High-Density Polyethylene Sheet

High-Density Polyethylene (HDPE) Sheets are known for their remarkable strength and chemical resistance. They are made from a flexible, long-lasting plastic resin. These sheets are used in many different industries, such as packaging, construction, agriculture manufacturing, outdoor furniture, playground equipment and more. Discover the lightweight nature of HDPE sheets that doesn't compromise on durability, making them an ideal choice for various projects. With a smooth surface and excellent impact resistance, HDPE sheets offer a reliable solution for both indoor and outdoor applications.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#hdpesheet#hdpesheetmanufacturer#hdpesheetsupplier#pp#polypropylene#plasticsheet#plastic#polyethylene#sheets#sheetmanufacturer#ecommerce#marketing#artwork#ppbag#branding#sales#commercial

1 note

·

View note

Text

What Factors Affect The Properties of a Polymer?

What factors affect the properties of a polymer?

Polymers are a versatile class of materials with a wide range of applications. They’re often used in products that need to be strong but also lightweights, such as sports gear and vehicle parts. In this blog post, we will explore some factors that affect the properties of polymers. Understanding these factors allows you to better design polymers for specific applications and achieve the desired properties.

What is a polymer?

Polymers are materials that consist of many repeating units, or monomers. These monomers can be small molecules, like ethylene glycol, or large molecules, like styrene. Polymers can have many properties due to how the monomers are linked together. Some important factors that affect the properties of a polymer include: 1) The type of monomer: Different monomers will give polymers different properties. For example, ethylene glycol is a functional group molecule with two reactive groups on it (one at each end). This means it can join with other molecules easily to create long-chain reactions.

Styrene is a simple molecule with no functional groups, which means it's less likely to link up with other molecules and form long chains. 2) The degree of polymerization: The more monomers there are in a polymer, the more complex the structure will be and the harder it will be to break down into its individual monomers. Higher degrees of polymerization also make polymers stronger and more resistant to breaking down. 3) The type of bonds between the monomer molecules: Monomer molecules need to have specific types of bonds for them to link up together into polymers.

Several different types of bonds can occur between monomer molecules: covalent bonds (where two atoms share an electron), ionic bonds (where an atom gains or loses an electron), and hydrophobic (water-avoiding) bonds. 4) The degree of orientation: Polymers can be oriented in two main ways: random or crystalline. Crystalline polymers comprise long chains of identical molecules tightly packed together. This makes them strong and resistant to breaking down, making them difficult to process.

Random polymers are made up of shorter chains that are more spread out. They're less dense and more flexible, which makes them easier to process and shape.

Properties of Polymers

Polymers are a type of synthetic inorganic or organic compound. The molecules that makeup polymers are connected together through covalent bonds, which means that the individual molecules are permanently linked.

This makes polymers strong and flexible and resistant to heat, water, and many other elements. Polymers can also be formed into various shapes, including films and fibers. The properties of a polymer depend on several factors, including the size and shape of the molecules that make it up, the number of atoms in each molecule, and the way those atoms are linked together.

Some of these factors can be controlled by the polymer's chemist, while others are determined by the polymer's natural environment.

Factors that Affect Polymer Properties

The properties of a polymer are determined by the chemical composition and the manner in which the molecules are linked together. Some important factors that affect the properties of a polymer include: -The type of monomer used to make the polymer. -The degree of branching in the molecule. -The way in which the monomers are joined together. Each of these factors can have a significant impact on the way a polymer behaves, conducts electricity, and reacts with other substances.

For example, polyesters are made from carbon-carbon double bonds, while polyamides are composed of alternating nitrogen and carbon atoms.

Multiple bonds make polyesters strong and resistant to heat and sunlight, while polyamides tend to be more flexible and have better electrical properties. Another factor that can influence a polymer's properties is the manner in which the monomers are joined together. Polymers that are highly branched will tend to be less stiff than those that aren't as branched because they're able to move more freely through the material.

On the other hand, rigid polymers are often made from chain molecules that don't branch easily, so they exhibit high resistance to compression and don't stretch much when under stress.

Conclusion

Polymers are a type of molecule that consists of many repeat units. Polymers can be made from many substances, and their properties depend on the monomers that make them up.

Some factors that affect polymer properties include the composition of the monomers, the temperature at which they are mixed, and the amount of cross-linking that occurs. We can better control their behavior in various applications by understanding how these factors influence polymer properties.

For more information visit us at - https://polestarpolymers.com/ Contact us at - +91 9168514741

6 notes

·

View notes

Text

https://synkretic.mn.co/posts/68954859?utm_source=manual

0 notes

Text

Easy Steps to Cut and Shape PP Sheets for Your Projects

Polypropylene sheets, widely known for their versatility and durability, are increasingly popular in various industries. Whether you’re a DIY enthusiast or a professional looking to create custom shapes and designs, understanding how to cut and shape polypropylene sheets can be beneficial for your projects. This guide will provide easy steps to effectively work with polypropylene sheets while also discussing their applications, particularly in manufacturing cable drums, and addressing the current PP price in India.

Understanding Polypropylene Sheets

Polypropylene sheets, or PP sheets, are thermoplastic polymers that exhibit high resistance to chemicals, moisture, and impact. These properties make them ideal for various applications, from packaging to construction. In India, the demand for polypropylene sheets is growing, especially in sectors like automotive, electronics, and packaging. Their lightweight nature and rigidity contribute to their popularity in making products like cable drums, which require durable and reliable materials.

Tools Required for Cutting PP Sheets

Before diving into the cutting process, it’s essential to gather the necessary tools. The following items will help you achieve precise cuts on polypropylene sheets:

Utility Knife: A sharp utility knife is one of the most effective tools for making clean cuts in thinner sheets.

Circular Saw or Jigsaw: For thicker sheets, using a circular saw or jigsaw with a fine-toothed blade will yield better results.

Straight Edge: A ruler or straight edge is crucial for ensuring straight cuts.

Cutting Mat: Placing the sheet on a cutting mat protects your work surface and prevents the blade from dulling.

Safety Gear: Always wear safety glasses and gloves to protect yourself while cutting.

Preparing the Polypropylene Sheet for Cutting

The first step in the cutting process is to prepare the polypropylene sheet. Begin by measuring the dimensions you need for your project. Use a measuring tape to ensure accuracy, and mark your measurements clearly on the sheet with a marker or pencil.

Using a Straight Edge for Guidance

Once you have marked the dimensions, place a straight edge along the line you intend to cut. This will serve as a guide for your utility knife or saw. Ensure that the straight edge is firmly positioned, as this will help you achieve a cleaner cut.

Cutting the Polypropylene Sheets

With your tools ready and the sheet prepared, it’s time to cut.

Cutting Thin PP Sheets

If you are working with thinner polypropylene sheets, such as those typically used for crafts or packaging, a utility knife is sufficient. Here’s how to proceed:

Score the Surface: Align your utility knife with the straight edge and score the surface of the sheet along the marked line. Apply moderate pressure but do not cut all the way through; a single pass is usually enough to create a groove.

Repeat the Scoring: Make several passes along the scored line until you reach the desired depth. This technique prevents the sheet from cracking or splitting.

Snap the Sheet: Once the groove is deep enough, hold the sheet firmly on both sides of the score line and gently bend it until it snaps along the line.

Cutting Thick PP Sheets

For thicker polypropylene sheets, follow these steps:

Using a Circular Saw or Jigsaw: Set up your circular saw or jigsaw with a fine-toothed blade, as this will produce a smoother cut. Adjust the saw to the appropriate cutting depth.

Cut Along the Marked Line: With the saw running, slowly guide it along the marked line. Allow the blade to do the work; do not force it through the material.

Finish the Edges: After cutting, you may notice rough edges. Use a fine-grit sandpaper or a file to smooth out the edges for a more polished finish.

Shaping the Polypropylene Sheets

Once you have cut the sheets to the desired size, you may want to shape them for specific applications. Shaping polypropylene sheets can be accomplished through several techniques:

Heating and Bending

Polypropylene sheets can be easily bent when heated. To shape your sheets:

Preheat the Area: Use a heat gun or a hairdryer to apply heat to the area you want to bend. Keep the heat source moving to avoid melting the sheet.

Bend Slowly: As the material warms, it will become more pliable. Gently bend the sheet to your desired angle.

Cool the Shape: Hold the shape in place until it cools down. The polypropylene will retain its new form once cooled.

Drilling Holes

If your project requires holes, follow these steps:

Mark the Drill Points: Use a marker to indicate where you want to drill.

Use a Drill with a Plastic Bit: Set the drill to a low speed and use a drill bit designed for plastic. This minimizes the risk of cracking the sheet.

Drill Carefully: Apply gentle pressure while drilling, and ensure the sheet is securely clamped to prevent movement.

Applications of PP Sheets in India

Polypropylene sheets are extensively used in various industries. One of the notable applications is in manufacturing PP sheet for cable drum. Cable drums require durable materials that can withstand the weight and tension of cables during transport and storage. The lightweight nature of polypropylene makes it an ideal choice, allowing for easier handling and transportation.

Additionally, the versatility of PP sheets extends to other applications such as packaging, automotive parts, and even agricultural products. As industries evolve, the demand for high-quality polypropylene sheets continues to rise, which impacts the PP price in India.

Current Market Trends and Pricing

When considering polypropylene sheets for your projects, it’s essential to stay informed about the current market trends and prices. As of now, the PP price in India fluctuates based on various factors, including demand, production costs, and raw material availability. Keeping an eye on these trends can help you make informed purchasing decisions and potentially save on costs.

You can find polypropylene sheets from various suppliers across India, often with competitive pricing based on bulk orders. Whether you're a business looking for industrial-grade sheets or an individual tackling a DIY project, understanding the pricing landscape will assist in your budgeting.

Conclusion

Cutting and shaping polypropylene sheets does not have to be a daunting task. With the right tools and techniques, you can easily create custom shapes for your projects. By utilizing these easy steps, you can enhance your skills and expand your creativity with polypropylene sheets. Whether you are using Polypropylene sheets in India for crafting, packaging, or manufacturing applications like cable drums, mastering these techniques will allow you to bring your ideas to life while navigating the market for the best prices on PP sheets. Embrace the versatility of polypropylene sheets and let your creativity soar!

Frequently Asked Questions (FAQs)

What thickness of PP sheet is suitable for my project? The thickness you need will depend on the application. For lightweight tasks, thinner sheets (up to 3mm) are sufficient, while heavier applications may require thicker sheets (3mm to 10mm). Can I paint polypropylene sheets? Yes, you can paint polypropylene sheets, but it's advisable to use paints specifically designed for plastics for better adhesion.

How should I store polypropylene sheets? Store polypropylene sheets in a cool, dry place away from direct sunlight to prevent warping or fading.

0 notes

Text

Durable and Versatile Corrugated Plastic Sheets by Corpac

Corpac is your go-to provider for high-quality corrugated plastic sheets, offering durable and versatile solutions for a range of industries. Whether you need them for packaging, signage, or construction purposes, Corpac’s corrugated plastic sheets are engineered to deliver excellent strength, flexibility, and resistance to harsh weather conditions.

These corrugated plastic sheets are ideal for businesses seeking reliable and long-lasting materials. They are water-resistant, chemical-proof, and UV-stable, making them perfect for both indoor and outdoor applications. At Corpac, we ensure that our sheets are manufactured to meet the highest quality standards, offering optimal performance for your needs.

In addition to being durable, Corpac’s corrugated plastic sheets are eco-friendly, as they are 100% recyclable. With a variety of sizes and thicknesses, Corpac offers customizable solutions that suit your specific requirements, making them a go-to choice for industries looking for cost-effective yet robust materials.

Conclusion: For strength, reliability, and sustainability, Corpac’s corrugated plastic sheets provide the ideal solution. Whether you need them for industrial, commercial, or creative projects, Corpac is committed to delivering top-quality products designed to meet diverse business needs. Choose Corpac for the best in corrugated plastic sheet innovation.

0 notes

Text

Optimizing Space with Partition Sheets by Nilkamal Bubbleguard

For businesses and homeowners alike, maximizing space utilization is an ongoing quest. Here's where partition sheets come into play. Offered by Nilkamal Bubbleguard, these innovative panels provide a lightweight yet robust method for creating temporary or permanent divisions within a room.

Partition sheets boast a unique honeycomb structure that imbues them with exceptional strength and rigidity. This translates to effective compartmentalization without sacrificing valuable floor space. Unlike traditional walls, partition sheets can be easily installed, dismantled, and reconfigured, fostering a dynamic and adaptable environment.

Nilkamal Bubbleguard's partition sheets are crafted from high-quality polypropylene, a material renowned for its waterproof and tear-resistant properties. This ensures the longevity of the sheets and their ability to withstand everyday wear and tear. Additionally, the polypropylene construction makes them remarkably lightweight, simplifying installation and transportation.

Partition sheets offer a plethora of applications. In commercial settings, they can be used to create designated work areas, private meeting spaces, or storage sections. Residential environments can benefit from partition sheets to establish play areas for children, separate laundry zones from living spaces, or even construct temporary home offices.

The inherent versatility of partition sheets extends beyond their functionality. Nilkamal Bubbleguard offers customization options, allowing for the incorporation of branding elements or a desired color scheme. This empowers businesses to leverage partition sheets for visual impact, subtly reinforcing their brand identity within the workspace.

In conclusion, partition sheets by Nilkamal Bubbleguard present a compelling solution for optimizing space division. Their lightweight design, exceptional durability, and adaptability make them a valuable asset for both commercial and residential settings.

0 notes

Text

Customized PP Sheet Manufacturers - Brothers Packaging

Brothers Packaging is a well-known manufacturer and supplier of customized polypropylene (PP) sheets in Ahmedabad. Whether you're an industry professional looking for high-quality packaging solutions or a creative thinker with a one-of-a-kind idea, Brothers Packaging specializes in producing PP sheets to your specific requirements, with a wide variety of sizes, colors, and sizes to meet your demands.

In addition to customization, Brothers Packaging prioritizes durability and utility. Our PP sheets are renowned for their strength, resistance to chemicals and temperature changes, and tear resistance. This guarantees that your items or works are well-protected during transportation, storage, and daily usage. Brothers Packaging's commitment to client satisfaction makes them the best manufacturers and suppliers of customized PP sheets in Ahmedabad. Visit our site: https://www.brotherspackaging.in/customizedppsheetinahmedabad.php or Contact us today at +918446036105

#PP Sheet#Customized PP Sheet#PP Sheet Price#Cost of polypropylene Sheet#Customized PP Sheet Suppliers#PP Sheet in Ahmedabad#Customized PP Sheet Manufacturers#polypropylene Sheet in ahmedabad#Customized PP Sheet Manufacturers in ahmedabad

0 notes

Text

Unleash Creativity and Durability with Fluted Polypropylene Sheets from Everplast Industrial

Discover the perfect blend of creativity and durability with Fluted Polypropylene Sheets at Everplast Industrial. Our fluted polypropylene sheets are meticulously crafted to provide a lightweight yet robust solution for a wide range of applications. From eye-catching signage to protective packaging, these sheets offer excellent printability, impact resistance, and weatherproof performance. Whether you're creating attention-grabbing displays or seeking a reliable material for outdoor use, Everplast Industrial's fluted polypropylene sheets offer versatility and longevity. Elevate your projects with a material that combines strength and aesthetics. Explore the possibilities in our collection at Everplast Industrial.

0 notes

Text

CPP Film Manufacturer

Welcome to our blog, where we delve into the world of CPP films. As a leading manufacturer in the industry, we specialize in producing high-quality CPP films for diverse applications. In this blog, we will explore the manufacturing process, unique characteristics, and wide-ranging applications of CPP films. Join us as we uncover the excellence of CPP films and their contribution to various industries.

Understanding CPP Films: Cast Polypropylene (CPP) films are versatile packaging materials known for their exceptional transparency, flexibility, and heat sealability. CPP films are produced by melting polypropylene resin and extruding it through a flat die onto a chill roll, resulting in a thin, continuous film. These films offer a combination of advantageous properties, making them suitable for a wide range of applications.

Manufacturing Process: The CPP Film Manufacturer involves several crucial steps to ensure optimal quality and performance:

a) Extrusion: Polypropylene resin is melted and extruded through a flat die to form a continuous film.

b) Chill Roll Cooling: The extruded film is rapidly cooled by contact with a chill roll, solidifying the molten resin into a thin, uniform film.

c) Orientation: The solidified film is then biaxially stretched to improve its mechanical properties, such as tensile strength and clarity.

d) Heat Setting: The stretched film is heated and then rapidly cooled again to set the molecular structure and finalize the film's properties.

Key Characteristics and Benefits: CPP films offer a host of advantageous features that make them popular in the packaging industry: a) Excellent Transparency: CPP films exhibit exceptional transparency, allowing for enhanced product visibility and presentation.

b) Flexibility and Formability: CPP films are highly flexible, making them suitable for packaging products of various shapes and sizes. They can be easily folded, twisted, or wrapped around objects.

c) Heat Sealability: CPP films possess excellent heat sealability, enabling secure and tamper-evident packaging solutions. They can be sealed using heat-sealing equipment, ensuring product freshness and protection.

d) Moisture and Gas Barrier: CPP films provide good moisture and gas barrier properties, protecting packaged products from external elements and extending their shelf life.

e) Superior Printing Surface: CPP films offer a smooth and printable surface, allowing for vibrant and high-quality graphics, branding, and product information.

Diverse Applications: CPP films find extensive applications across various industries, including: a) Food Packaging: CPP films are widely used in food packaging for items such as snacks, confectionery, frozen foods, and more. They offer excellent moisture barrier properties, ensuring product freshness and quality.

b) Lamination: CPP films are often used as a component in laminated structures, providing strength, barrier properties, and printability. They are used in applications such as flexible packaging, labels, and pouches.

c) Stationery and Cards: CPP films serve as protective covers for notebooks, folders, and cards, offering durability, water resistance, and an enhanced visual appeal.

d) Textiles and Apparel: CPP films are utilized in the textile industry for applications like garment bags, packaging for clothing items, and protective film for fabrics during transportation.

Innovation and Future Trends: The CPP film industry is continuously evolving, driven by innovation and emerging technologies. Manufacturers are exploring advanced formulations and processing techniques to enhance film properties, such as improved barrier performance, biodegradability, and recyclability. These developments aim to meet the evolving needs of sustainability and environmental consciousness.

#Keyword#cpp film technical data sheet#cpp film full form#cpp film vs bopp film#cast polypropylene manufacturing process#cpp film raw material#cpp film density#metalized cpp film#rahil cpp films pvt ltd zauba

0 notes

Link

Polypropylene is a versatile material that can be used in a variety of ways. Your industry may already make heavy use of polypropylene sheet, but what do you know about its material properties? Read this blog to know about 5 best material properties of polypropylene sheet

0 notes

Text

I've been watching some of the G1 MH movies I never watched back in the day and I was surprised how much I liked Boo York Boo York. Of course I felt like we were robbed for not having a Seth Ptolemy doll made so naturally it spurned me to make my own.

I mostly put him on a BTS/g2 body because it's all I had honestly but I think it suits the animation. The outfit was excruciatingly hard for me to do as I hand painted his bandage print shirt, harem pants and custom neck piece.

His pants are actually based more on the graphical version seen in the concept art @garrettsander posted awhile ago where instead of just geometrical shapes it had blue added to the colour scheme and had a more graphical/graffiti style look to it, which I thought was much more interesting than the dorito print he had in the film.

His neckpiece is actually a sheet of polypropylene I heat shaped and cut out then spray painted it gold and hand painted the details onto it. I honestly had no idea what or how this would have been constructed for the mass production doll, but I wanted him to suit the mainline BYBY dolls who had a chromed sculpted element to their outfits.

I'm really happy I attempted this doll as I love BYBY as a movie and am sad we never got Seth as a doll for g1.

247 notes

·

View notes

Text

Doll and Pony Repair Tools

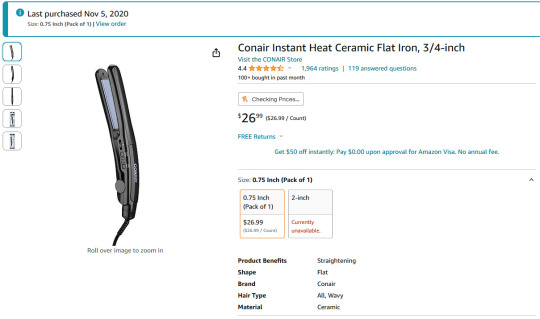

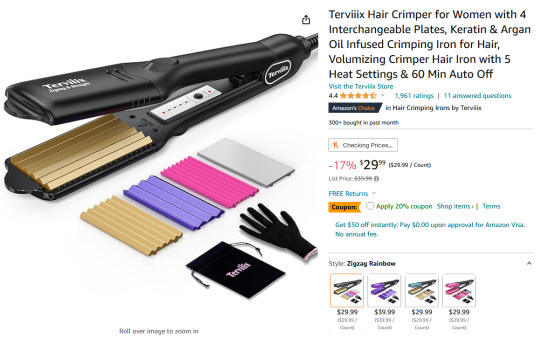

For a while, there, I was using this Conair flat iron (you can see when I bought it):

It’s here: https://amzn.to/3tL8Qtt

This one has 30 heat settings, though it doesn’t tell you what they are, exactly. They’re just labeled 1-30.

Kanekalon - 1

Nylon - 10 through about 15

Polypropylene - 10 through about 15

Foil and plastic tinsel - 1 to 10, choose whichever matches the hair fiber

Saran - 5 - 10

Brushed acrylic yarn - I know I have used this to flatten brushed acrylic but I don’t remember what setting it was on. You’d have to start at 1 and work your way up to figure it out, but it’s doable with this iron.

It was ok, but I found it difficult to get close to the scalp on a lot of dolls and ponies with my flea comb, which gives the smoothest flattening. The Conair also had a problem where the plates only really touched each other at the very tip, and that’s not very useful, honestly. It’s difficult to get a good flattening unless you’re committed to doing 1/4th inch sections at a time.

I started seeing really narrow flat irons on Instagram, and went looking for one to try.

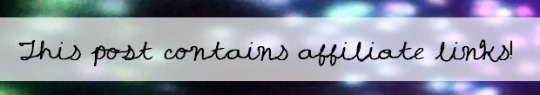

I found this one:

Now this one, which is here: https://amzn.to/3S7jLqA

I am so impressed!!!!!

It tells you the actual temp (in Fahrenheit; important to know), but not only does it show you the temp you’ve set it to, it shows the temp it actually is! You can watch it count up as it heats up! That’s super handy and makes it easier to know if it’s malfunctioning.

it also beeps at you when it’s ready.

It’s lowest temp is 120F which is far too cool to even do anything to Kanekalon, meaning this flat iron works for many 80′s and 90′s Barbies that are otherwise difficult to smooth out without melting their hair. I haven’t tested, yet, whether it’ll work on Creata hair without melting it.

I found 200 is right around when I could feel the hair starting to stick to the plates, so for Kanekalon I recommend 190 and no higher than 200.

For nylon, 250 is where it started to feel a little sticky, so 240 to 300 is about as high as you’d want to go. Nylon is pretty hardy and may tolerate a slightly higher temp. Go higher at your own risk.

Polypropylene needs a temp right about where Nylon is but I didn’t test it to find out the exact right setting.

Regardless of which flat iron you’re using, remember to wash and condition the hair first, to get the best results.

Ironing damp hair works best, but you don’t want it dripping wet. Dripping wet hair can result in boiling hot drops in your lap, or water getting into the flat iron and causing an electrical short. Towel the hair off, first.

To get the smoothest hair with the flat iron, I use a handled, metal flea comb to lead the iron.

https://amzn.to/3S5ICv6

You do want metal tines. They aren’t going to snag on or tear the individual hair fibers the way plastic tines can. Though avoid any metal combs that are punched from a sheet rather than made of individual wires. Those will destroy everything with their sharp edges

This comb having a handle lets me keep my hands away from the heating elements on the flat iron without needing to wear heat-resistant gloves.

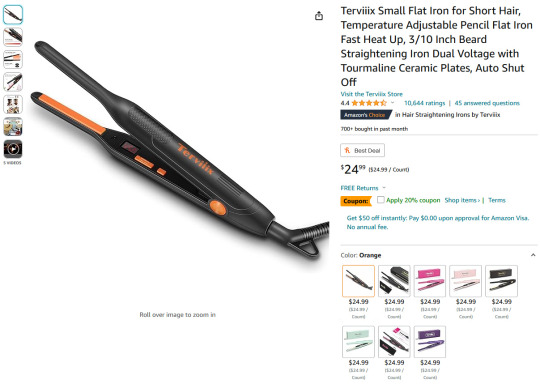

These dog combs are excellent for detangling prior to making your final passes with the flea comb.

https://amzn.to/41UpX8U

The wire tines are smooth and gentle with hair, but it is also unyeilding so you do have to be cautious that you’re not ripping or tearing through tangles.

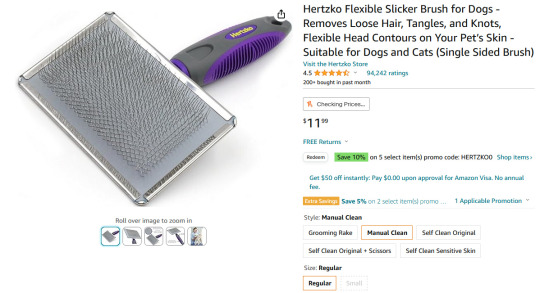

If you have a lot of knots that are difficult to remove, try a cat slicker brush.

https://amzn.to/47mw4DT

Again, the wires are metal and won’t shred your hair fiber. Using a cat slicker over tangled hair will make an awful noise, but that noise isn’t the hair tearing like it would be with the metal combs above, it’s the sound of the wires being pulled back and then springing up again.

A slicker brush yields to the tangles a bit and doesn’t pull.

You do have to be careful with a slicker, though, because the wire bristles are very fine and will stab you.

I do work with older Barbies sometimes, and sometimes they have Kanekalon hair that’s supposed to be crimped. Kanekalon can’t take much heat and melts easily, so again, you need a variable temp tool.

This multi tool works: https://amzn.to/3S5aT4W

I haven’t tried using it to flat iron because it’s rather wide, but I have successfully recrimped Kanekalon on the lowest heat setting, and nylon on the second or third setting.

You can see that this crimper combo tool is the same brand as the new flat iron mentioned above, but I think this one is in Celsius. I’m not 100% on that.

I’ve been using Army Painter paints lately, and like them a lot: https://amzn.to/3Yd42dl

I also use Mungyo soft pastels https://amzn.to/3zzaS2i which are decent but I only use these because they’re much more affordable than Pan Pastel.

Pan Pastel https://amzn.to/3Wh06a4 are AMAZING and work so very well on dolls.

I do NOT gate-keep tools or supplies so if you have any questions, let me know.

191 notes

·

View notes

Text

0 notes

Note

They just restocked the stickers. So if anyone hasn't gotten them yet, go for it! They just had to remake more lol

OOOOH THANK YOU FOR THE UPDATE!!!

if anyone wants to get them now:

11 notes

·

View notes

Text

Geotextile Manufacturers in Bangladesh | 100% Polypropylene Geo Sheets

Geotextile Fabric প্রোডাক্ট মূলত পলিস্টার, পলিপ্রপিলিন, পলিঅ্যামাইড দিয়ে তৈরি করা হয়। Geotextile sheet এর সবচেয়ে বেশি ব্যবহার হয় সিভিল এবং কনস্ট্রাকশনের কাজে। এতে মাটির বৈশিষ্ট্য পরিবর্তন করে দূর্বল ও অকার্যকর জায়গায় ভবন নির্মাণ এর উপযোগি করে তুলে। Geotextile Bags সাধারনত সমুদ্র, নদী ও পুকুরের পাড় ভাঙ্গন রোধ করতে ব্যবহৃত হয়ে থাকে, সেটিও এই Geotextile sheet থেকেই তৈরি হয়। GSM এর উপর ভিত্তি করে এর দাম নির্ধারণ হয়ে থাকে। আধুনিক সিভিল এবং কনস্ট্রাকশন ইঞ্জিনিয়ারিং এ বহুল ব্যবহৃত হচ্ছে এই Geo sheet।

অর্ডার পদ্ধতিঃ ওয়েবসাইট থেকে অর্ডার করতে পারবেন। সরাসরি হোয়াটসঅ্যাপ, মেসেঞ্জার বা ফোন করে অর্ডার করতে পারবেন।

হোয়াটসঅ্যাপে অর্ডার করতে কিক্ল করুন

মেসেঞ্জারে অর্ডার করতে কিক্ল করুন

কল করুন ০৯৬১৩৮২৪২৪১

পেমেন্ট পদ্ধতিঃ অর্ডার করার সময় “সম্প��র্ণ পেমেন্ট” করে দিতে হবে। বড় রোল গুলো কন্ডিশনে বুকিং দেওয়া হয় না। কন্ডিশনে শুধু মাত্র ছোট রোল গুলো দেওয়া হয়। ছোট রোল নিতে- Best Geotextile in Bangladesh

ডেলিভারি পদ্ধতিঃ পেমেন্ট করার ২ থেকে ৩ দিনের মধ্যে কুরিয়ার করা হয়। (তবে প্রোডাক্টের পরিমাণ বেশি হলে কিছুটা সময় লাগতে পারে ) কুরিয়ারের মাধ্যমে জেলা সদর পর্যন্ত নিতে পারবেন। কুরিয়ার চার্জ দিয়ে প্রোডাক্টটি কুরিয়ার অফিস থেকে নিতে হবে। যদি বেশি প্রোডাক্ট হয় সে ক্ষেত্রে ট্রাকে করে নিতে পারবেন। ট্রাক গুলো আমরাই ঠিক করে দেয়। প্রোডাক্ট সাইটে পৌছাড় পর ট্রাক ভাড়া পরিষোধ করতে পারবেন।

আরো জানতে ভিজিট করুন - Sirajtech

2 notes

·

View notes