#cast polypropylene manufacturing process

Explore tagged Tumblr posts

Text

CPP Film Manufacturer

Welcome to our blog, where we delve into the world of CPP films. As a leading manufacturer in the industry, we specialize in producing high-quality CPP films for diverse applications. In this blog, we will explore the manufacturing process, unique characteristics, and wide-ranging applications of CPP films. Join us as we uncover the excellence of CPP films and their contribution to various industries.

Understanding CPP Films: Cast Polypropylene (CPP) films are versatile packaging materials known for their exceptional transparency, flexibility, and heat sealability. CPP films are produced by melting polypropylene resin and extruding it through a flat die onto a chill roll, resulting in a thin, continuous film. These films offer a combination of advantageous properties, making them suitable for a wide range of applications.

Manufacturing Process: The CPP Film Manufacturer involves several crucial steps to ensure optimal quality and performance:

a) Extrusion: Polypropylene resin is melted and extruded through a flat die to form a continuous film.

b) Chill Roll Cooling: The extruded film is rapidly cooled by contact with a chill roll, solidifying the molten resin into a thin, uniform film.

c) Orientation: The solidified film is then biaxially stretched to improve its mechanical properties, such as tensile strength and clarity.

d) Heat Setting: The stretched film is heated and then rapidly cooled again to set the molecular structure and finalize the film's properties.

Key Characteristics and Benefits: CPP films offer a host of advantageous features that make them popular in the packaging industry: a) Excellent Transparency: CPP films exhibit exceptional transparency, allowing for enhanced product visibility and presentation.

b) Flexibility and Formability: CPP films are highly flexible, making them suitable for packaging products of various shapes and sizes. They can be easily folded, twisted, or wrapped around objects.

c) Heat Sealability: CPP films possess excellent heat sealability, enabling secure and tamper-evident packaging solutions. They can be sealed using heat-sealing equipment, ensuring product freshness and protection.

d) Moisture and Gas Barrier: CPP films provide good moisture and gas barrier properties, protecting packaged products from external elements and extending their shelf life.

e) Superior Printing Surface: CPP films offer a smooth and printable surface, allowing for vibrant and high-quality graphics, branding, and product information.

Diverse Applications: CPP films find extensive applications across various industries, including: a) Food Packaging: CPP films are widely used in food packaging for items such as snacks, confectionery, frozen foods, and more. They offer excellent moisture barrier properties, ensuring product freshness and quality.

b) Lamination: CPP films are often used as a component in laminated structures, providing strength, barrier properties, and printability. They are used in applications such as flexible packaging, labels, and pouches.

c) Stationery and Cards: CPP films serve as protective covers for notebooks, folders, and cards, offering durability, water resistance, and an enhanced visual appeal.

d) Textiles and Apparel: CPP films are utilized in the textile industry for applications like garment bags, packaging for clothing items, and protective film for fabrics during transportation.

Innovation and Future Trends: The CPP film industry is continuously evolving, driven by innovation and emerging technologies. Manufacturers are exploring advanced formulations and processing techniques to enhance film properties, such as improved barrier performance, biodegradability, and recyclability. These developments aim to meet the evolving needs of sustainability and environmental consciousness.

#Keyword#cpp film technical data sheet#cpp film full form#cpp film vs bopp film#cast polypropylene manufacturing process#cpp film raw material#cpp film density#metalized cpp film#rahil cpp films pvt ltd zauba

0 notes

Text

Fluoropolymer Processing Aid Market Industry Leaders Outlook & New Revenue Pockets

The market size of f fluoropolymer processing aid market size is estimated as USD 1.5 Billion in 2023 and is projected to reach USD 1.7 Billion in 2028 at a CAGR of 2.9%.The increasing demand for production of blown and cast films and the need to produce cost effective and efficient products drive the market for fluoropolymer processing aid.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=94932274

Based on polymer type, the fluoropolymer processing aid market has been segmented into polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and other thermoplastic polymers. Polyethylene is further grouped into LDPE, LLDPE, HDPE, and other PE. Polypropylene accounted for the largest market share among the other polymer types, in terms of value in the year 2022. Since polypropylene is lighter than other plastics, desire for lightweight vehicles is the key driver of the segment growth.

Blown film & cast film, wires & cables, pipes & tubes, fibers & raffia, and others were found as significant applications for fluoropolymer processing aid market. In 2022, blown film & cast film accounted for the major market share, in terms of value in this market followed by pipes & tubes, and fibers & raffia. Blown film technology is the most used process for manufacturing plastic film, especially in the packaging industry. It is used for food packaging, pharmaceutical and medical packaging, and industrial packaging.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=94932274

Based on region, the market for fluoropolymer processing aid is segmented into Europe, North America, Asia Pacific, Middle East & Africa, and South America. At present, Asia Pacific accounts for the major share in the market. The fluoropolymer processing aid market in the Asia Pacific region is projected to have the highest CAGR of 3.51% and is anticipated to dominate the market.

#Fluoropolymer Processing Aid Market#Fluoropolymer Processing Aid#Fluoropolymer Processing#Fluoropolymer#Fluoropolymers

0 notes

Text

Why CPP Films Are Essential for Flexible and Lightweight Packaging

In the world of packaging, innovation continues to push boundaries, with businesses constantly seeking materials that are versatile, durable, and environmentally friendly. One material gaining popularity in flexible packaging solutions is Cast Polypropylene (CPP) film. Known for its strength, clarity, and versatility, CPP films are being adopted in a range of industries, from food to pharmaceuticals.

A unique variant, anti fog films, offers even more specialized benefits, helping to maintain product clarity in humid or variable temperature conditions. This article explores why CPP films are essential for flexible and lightweight packaging and the unique benefits they bring to modern packaging needs.

What Are CPP Films?

CPP films are created through a cast extrusion process, resulting in a material that has an exceptional balance of transparency, tensile strength, and flexibility. These films are typically soft, making them ideal for a variety of applications that require lightweight yet durable packaging. The primary types of CPP films include:

General-Purpose CPP: Widely used in food packaging for items like baked goods, textiles, and stationery.

Metallized CPP: Offers high barrier protection, commonly used in snack packaging and other applications where increased shelf life is essential.

Anti Fog Films: This variant includes special additives that prevent fogging, especially useful in food packaging for perishable goods where visibility is crucial.

Among these, anti fog films stand out due to their ability to resist condensation and maintain clarity, making them an ideal choice for products stored in refrigerated conditions.

Key Benefits of CPP Films in Packaging

Lightweight and Flexible

One of the most significant benefits of CPP films is their lightweight nature. Traditional packaging materials, such as glass or rigid plastics, tend to be heavy, which can increase transportation costs and contribute to a larger carbon footprint. In contrast, CPP films offer a lightweight solution that is still robust enough to protect products effectively. This flexibility makes them ideal for use in various industries, including food, pharmaceuticals, and cosmetics.

Additionally, their flexibility allows for easy customization. CPP films can be molded, sealed, and printed upon, allowing manufacturers to create packaging that suits specific product shapes and branding requirements. This adaptability reduces the need for excessive materials, helping to reduce waste and lower packaging costs.

Transparency and Gloss

Consumers are increasingly drawn to products with visually appealing packaging that allows them to see the contents before purchasing. CPP films offer excellent transparency and gloss, making products look attractive on store shelves. This feature is especially valuable in food packaging, where product visibility is crucial for quality assurance and consumer appeal.

For instance, anti fog films help preserve product clarity even in high-humidity environments, such as refrigerators or freezers, by preventing moisture build-up inside the packaging. This means that even under conditions that would typically cause fogging, products remain clearly visible, enhancing consumer confidence in the product's freshness and quality.

Durability and Resistance

While being lightweight, CPP films are also highly durable. They possess strong tensile strength and puncture resistance, protecting the product from external factors such as moisture, dust, and contaminants. This durability is essential for products with longer shelf lives or those exposed to handling and transportation stresses.

Moreover, CPP films offer excellent tear resistance. In industries where packaging integrity is crucial—such as pharmaceuticals or medical supplies—using CPP films reduces the risk of contamination by keeping the product secure throughout its journey from the manufacturer to the consumer.

Barrier Properties for Extended Shelf Life

CPP films have excellent barrier properties, especially when combined with other materials. Metallized CPP, for example, provides additional protection against light, oxygen, and moisture, extending the shelf life of perishable products. This makes CPP an ideal choice for the food industry, where freshness and longevity are essential.

Anti fog films enhance this benefit further by maintaining transparency in refrigerated conditions, which is particularly useful for packaging fresh produce and other food items. With these films, consumers can see the product clearly without any clouding caused by condensation, which reinforces the idea of freshness and high quality.

Cost-Effective Solution

Compared to other packaging options, CPP films are cost-effective without compromising on quality. They require fewer raw materials, reducing production costs and making them a viable choice for businesses looking to optimize their packaging budgets. Additionally, their lightweight nature reduces shipping costs, an added advantage in logistics and supply chain management.

Because they can be customized to suit various applications, from snack packaging to pharmaceuticals, CPP films offer value to businesses across multiple sectors, allowing them to streamline their packaging without sacrificing functionality or aesthetic appeal.

Environmental Impact and Sustainability

Sustainability is increasingly important to both consumers and businesses, and CPP films are contributing positively in this regard. They require less material to achieve effective packaging solutions, resulting in less waste compared to heavier or more rigid options. Additionally, CPP films are recyclable, making them a more environmentally responsible choice for packaging.

The anti fog films variant is particularly valuable in sustainable packaging because it reduces the need for secondary packaging to protect against condensation, thus decreasing overall material use.

Why Choose Anti Fog Films in Flexible Packaging?

Anti fog films have become essential in certain segments of the food industry where clarity is key, such as for fresh produce, meats, and ready-to-eat meals. In these settings, packaging that maintains visibility enhances consumer trust and product appeal. Anti fog films in CPP are engineered with additives that minimize fogging, ensuring that condensation does not obscure the view of the contents.

Additionally, anti fog films are beneficial in extending the shelf life of products stored in fluctuating temperature environments. By keeping moisture away from the product and preventing condensation build-up, these films contribute to a clean, clear presentation even in demanding conditions. For businesses looking to combine functionality with consumer appeal, anti fog CPP films offer the best of both worlds.

CPP films, with their lightweight, flexible, and durable properties, have become indispensable in the realm of flexible packaging. Their versatility, combined with transparency, strength, and adaptability, makes them ideal for applications across industries.

Anti fog films in particular offer specialized benefits for food packaging, allowing products to retain visibility and freshness, even in humid conditions. As the demand for sustainable and cost-effective packaging solutions grows, CPP films continue to set the standard for quality and performance in flexible packaging.

By embracing CPP and its variants like anti fog films, businesses can not only improve product protection and shelf appeal but also move toward more sustainable and efficient packaging practices.

0 notes

Text

Polypropylene Film: A Versatile Material for Modern Applications

Polypropylene film, a durable and flexible plastic material, has become an integral part of various industries worldwide. Its versatility, cost-effectiveness, and superior performance characteristics make it an ideal solution for a wide range of applications, from packaging to industrial uses. At San-East, we specialize in providing high-quality polypropylene films tailored to meet diverse industry needs, ensuring that our customers get the most out of this multifaceted material.

In this blog, we’ll explore the different types of polypropylene films, their properties, applications, and why they are essential in today’s modern manufacturing landscape.

Understanding Polypropylene Film

Polypropylene (PP) is a thermoplastic polymer that is widely used in the production of films, fibers, and molded products. Polypropylene film, derived from this polymer, is created through a process known as extrusion. During extrusion, the polypropylene material is melted and stretched into thin sheets or films, which can then be further treated to achieve the desired properties. The result is a material that is not only lightweight but also boasts excellent mechanical strength, chemical resistance, and moisture barrier properties.

There are two primary types of polypropylene film: cast polypropylene (CPP) and biaxially oriented polypropylene (BOPP). While they share common characteristics, each has unique features that make them suitable for different applications.

1. Cast Polypropylene (CPP) Film

Cast polypropylene film is made by casting the melted polymer onto a chilled roller, resulting in a film with excellent clarity, softness, and flexibility. CPP film is typically used for food packaging, textile packaging, and stationary due to its ability to maintain its form even at lower temperatures. This type of film also offers excellent heat-sealing capabilities, making it a popular choice in industries where packaging integrity is critical.

Some notable advantages of CPP film include:

High transparency: The clear nature of CPP film makes it an excellent choice for packaging where product visibility is important.

Good moisture barrier: CPP films provide a reliable barrier against moisture, helping to preserve the quality of the packaged products.

Flexibility and tear resistance: It can easily conform to different shapes without tearing, making it suitable for wrapping items of varying sizes.

Low-cost production: Compared to other types of films, CPP offers an economical solution without compromising on quality.

2. Biaxially Oriented Polypropylene (BOPP) Film

Biaxially oriented polypropylene film, commonly referred to as BOPP, is created by stretching polypropylene film in both the machine direction and the transverse direction. This process aligns the molecules in two directions, which significantly improves the film’s tensile strength, clarity, and resistance to wear and tear. BOPP films are widely used in the food packaging industry, label production, and in the manufacture of adhesive tapes.

Key characteristics of BOPP film include:

Exceptional strength: Due to its biaxial orientation, BOPP film is far stronger and more durable than other plastic films.

Excellent clarity and gloss: The film’s high clarity and gloss provide an attractive appearance for consumer goods packaging.

Superior barrier properties: BOPP films offer excellent protection against moisture, grease, and various gases, helping to preserve the freshness of food products.

Recyclability: BOPP film is environmentally friendly and can be recycled, making it a sustainable option for companies looking to reduce their environmental impact.

The Properties That Make Polypropylene Film Stand Out

Polypropylene film’s wide acceptance across industries is due to a combination of its physical, chemical, and mechanical properties. Here’s a closer look at what makes polypropylene film so special:

1. Lightweight and Durable

Polypropylene film is incredibly lightweight, making it easy to handle and transport. Despite its light weight, it offers impressive strength and durability, allowing it to withstand harsh conditions without breaking or tearing.

2. Chemical Resistance

Polypropylene film has excellent resistance to a variety of chemicals, including acids, bases, and solvents. This makes it ideal for packaging products that may come into contact with such substances, especially in industrial or laboratory settings.

3. Heat Resistance

Polypropylene films can withstand high temperatures without melting or losing their structural integrity. This property is particularly important for food packaging, where materials often need to endure various processing conditions such as sterilization or cooking.

4. Moisture Barrier

Polypropylene films provide an effective barrier against moisture, which is crucial for applications like food packaging where maintaining freshness and preventing spoilage is a priority.

5. Flexibility and Transparency

Polypropylene films can be produced in various thicknesses, offering flexibility for different uses. Their high transparency also makes them ideal for clear packaging that showcases the product inside.

Common Applications of Polypropylene Film

Thanks to its versatility, polypropylene film is used in numerous industries. Let’s take a look at some of its most common applications:

1. Packaging Industry

One of the largest consumers of polypropylene film is the packaging industry. Both CPP and BOPP films are widely used in food packaging, offering excellent moisture and oxygen barrier properties. Polypropylene film is also favored for its clarity, which allows for attractive packaging designs that enhance product visibility on store shelves.

In addition to food packaging, polypropylene film is commonly used for wrapping textiles, cosmetics, and electronics due to its ability to protect products from environmental factors such as moisture, dust, and dirt.

2. Labels and Tapes

BOPP films, in particular, are a popular choice for the production of self-adhesive labels and tapes. Their high clarity and gloss make them perfect for creating visually appealing labels for consumer goods. Additionally, the strength of BOPP film ensures that labels and tapes remain intact even under harsh conditions, making them ideal for shipping and logistics.

3. Stationary and Graphic Arts

Polypropylene films are also widely used in the stationary industry for products like document covers, folders, and binding sheets. The film’s durability, resistance to water, and attractive appearance make it an excellent material for items that require both functionality and aesthetics.

4. Medical and Pharmaceutical Applications

Polypropylene films are often utilized in the medical and pharmaceutical industries for packaging sterile equipment and medicines. The film’s ability to resist moisture and contaminants helps ensure that medical supplies remain sterile and uncontaminated until they are needed.

5. Industrial Uses

In addition to packaging and consumer goods, polypropylene films have various industrial applications. They are often used as insulation materials in cables and capacitors, thanks to their electrical insulating properties. Polypropylene film is also used for protective overlays, laminates, and surface protection in industries such as automotive and construction.

Why Choose San-East for Polypropylene Film?

At San-East, we understand the importance of quality and reliability in the materials you choose for your business. Our polypropylene films are manufactured to the highest standards, ensuring that they meet the specific needs of your industry. Whether you’re looking for film solutions for packaging, labeling, or industrial uses, we’ve got you covered.

We offer both CPP and BOPP films, customized to your specifications. With a focus on sustainability, we are committed to providing recyclable polypropylene films that help reduce the environmental impact of plastic waste.

Conclusion

Polypropylene film is an essential material in modern manufacturing and packaging, offering unmatched versatility and performance across various industries. Its lightweight, durable, and environmentally friendly properties make it the material of choice for companies around the globe.

At San-East, we pride ourselves on delivering high-quality polypropylene films that meet your business needs. Contact us today to learn more about our products and how we can help you improve your operations with our top-notch polypropylene films.

0 notes

Text

Cast Polypropylene Manufacturing Plant Project Report 2024: Setup and Cost

Introduction

The production of cast polypropylene (CPP) is a key component in the packaging industry, offering a versatile and high-performance material used in various applications such as food packaging, medical supplies, and industrial uses. A Cast Polypropylene Manufacturing Plant Project Report serves as a comprehensive guide for establishing a facility dedicated to the production of CPP. This report provides an in-depth look at the necessary steps for setting up a CPP manufacturing plant, including market analysis, plant design, production processes, and financial considerations. Whether you're an entrepreneur looking to enter the industry or an investor evaluating a potential opportunity, this guide will equip you with the insights needed to navigate the complexities of launching a CPP manufacturing business.

Project Overview

Objectives

The primary objectives of setting up a cast polypropylene (CPP) manufacturing plant include:

To produce high-quality CPP film that meets industry standards and customer specifications.

To establish a cost-effective and efficient production process.

To create a strong market presence and drive growth in the packaging and related industries.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/cast-polypropylene-cpp-manufacturing-plant-project-report/requestsample

Market Research

Conducting thorough market research is crucial for understanding the potential and demands of the CPP industry. Key aspects to focus on include:

Market Demand: Evaluate the current and projected demand for CPP in various sectors such as food packaging, medical, and industrial applications.

Competitor Analysis: Study existing CPP manufacturers to understand their market position, product offerings, and competitive advantages.

Consumer Preferences: Research what features and qualities customers value in CPP products, such as thickness, clarity, and barrier properties.

Plant Setup

Location

Choosing the right location for your manufacturing plant is essential. Consider the following factors:

Proximity to Raw Materials: Being close to suppliers of polypropylene resin can reduce transportation costs and improve supply chain efficiency.

Access to Markets: Select a location with good logistics to effectively reach your target customers.

Regulatory Environment: Ensure the location complies with local regulations and offers favorable conditions for manufacturing operations.

Facility Design

Designing the facility involves planning several key components:

Production Areas: Allocate space for extrusion, cooling, winding, and quality control processes.

Storage: Plan for separate storage areas for raw materials and finished products.

Utilities: Ensure adequate provisions for electricity, water, and waste management.

Safety: Implement safety measures to protect workers and comply with health and safety regulations.

Equipment

Invest in high-quality equipment to ensure efficient production:

Extrusion Lines: For melting and forming polypropylene resin into film.

Cooling Systems: To rapidly cool the extruded film and maintain its quality.

Winding Units: For winding the CPP film into rolls.

Quality Control Instruments: To test the physical and chemical properties of the film, such as thickness, strength, and clarity.

Production Process

Raw Material Sourcing

Secure reliable sources for raw materials, including:

Polypropylene Resin: The primary raw material used in the production of CPP film.

Additives: Such as stabilizers and colorants, to enhance the properties of the film.

Manufacturing Steps

Extrusion: Melt the polypropylene resin and extrude it into a thin film.

Casting: Use a casting process to cool and solidify the film onto a rolling surface.

Winding: Wind the cooled film into rolls for further processing and packaging.

Quality Control: Conduct tests to ensure the film meets quality and performance standards.

Packaging: Package the finished CPP film rolls for distribution.

Compliance and Certification

Ensure compliance with relevant regulations and standards:

ISO Certification: For quality management systems.

Food Safety Regulations: If producing CPP for food packaging, adhere to relevant safety standards.

Environmental Regulations: For waste management and emissions control.

Marketing and Distribution

Branding

Develop a strong brand identity to stand out in the market:

Brand Name and Logo: Create a memorable and relevant brand name and logo.

Product Design: Focus on features such as film clarity, strength, and barrier properties that appeal to your target market.

Marketing Strategy: Utilize digital marketing, trade shows, and industry publications to promote your products.

Distribution Channels

Establish effective distribution channels:

Direct Sales: Engage directly with large customers such as packaging companies and industrial users.

Distributors: Partner with distributors to expand your market reach.

Online Platforms: Consider e-commerce options to reach a broader audience.

Financial Considerations

Budgeting

Develop a comprehensive budget that covers:

Initial Investment: Costs for facility construction, equipment, and raw materials.

Operational Expenses: Ongoing costs such as labor, utilities, maintenance, and raw materials.

Marketing and Distribution: Budget for promotional activities and logistics.

Funding

Explore various funding options:

Bank Loans: Secure loans from financial institutions.

Investors: Attract venture capital or angel investors interested in manufacturing and packaging innovations.

Grants and Incentives: Look for government grants or subsidies for manufacturing projects.

FAQs

What are the main applications of cast polypropylene film?

Cast polypropylene film is used in various applications, including food packaging, medical supplies, and industrial uses. Its properties make it suitable for use in flexible packaging, labels, and protective coverings.

How long does it take to set up a CPP manufacturing plant?

The setup time for a CPP manufacturing plant typically ranges from 12 to 24 months. This includes time for facility construction, equipment installation, and obtaining necessary certifications and approvals.

What are the primary challenges in establishing a CPP manufacturing plant?

Key challenges include securing reliable raw material suppliers, managing production costs, ensuring compliance with industry standards, and establishing an effective marketing and distribution network.

What certifications are required for CPP manufacturing?

Essential certifications include ISO for quality management systems, compliance with food safety regulations (if applicable), and adherence to environmental regulations for waste and emissions control.

How can I ensure the quality of the CPP film produced at the plant?

Ensure quality through rigorous testing during production, adherence to industry standards, and regular audits. Invest in quality control equipment and employ skilled personnel to maintain high manufacturing standards.

Media Contact:

Company Name: Claight Corporation Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A. Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com Aus Site: https://www.expertmarketresearch.com.au/

0 notes

Text

Innovations in Shrink Film and Stretch Film for Sustainable Packaging

In today's fast-paced world, sustainability is more than just a buzzword—it's a necessity. For industries that rely heavily on packaging, such as food and beverage manufacturers, consumer goods companies, and retailers, finding eco-friendly packaging solutions is crucial. Innovations in shrink film and stretch film are leading the way in sustainable packaging, offering not only environmental benefits but also improved functionality and cost savings.

Understanding Shrink Film and Its Types

Shrink film, commonly known as shrink wrap, is a versatile polymer material used for packaging various products. When heat is applied, the film shrinks tightly around the item, creating a transparent, durable protective barrier. This makes shrink film ideal for securing products during transportation and storage.

Polyvinyl Chloride (PVC) Shrink Film

Polyvinyl Chloride (PVC) is a robust and durable plastic film material. It is created by combining vinyl chloride monomers with other additives, resulting in a heat-shrinkable product. PVC shrink film is widely used for packaging electronics, food, toys, automotive parts, and furniture. Its strength and durability make it a go-to choice for many applications.

Polyolefin (POF) Shrink Film

Polyolefin shrink film is formed from a blend of polypropylene and high-density polyethylene (HDPE). This blend provides excellent tear strength and heat resistance, making it suitable for high-temperature applications. POF shrink film is also resistant to oil, grease, and moisture, making it ideal for packaging food products and other items requiring protection from environmental elements.

Polyethylene (PE) Shrink Film

Polyethylene (PE) is the most common type of plastic film, available in low-density to high-density variants. PE shrink film offers excellent clarity and tensile strength, making it ideal for various packaging applications. Its versatility and reliability make it a popular choice in the packaging industry.

Benefits of Shrink Film

Shrink film offers numerous benefits for packaging, including:

Protection: Shrink film provides a secure and durable barrier around products, protecting them from dust, dirt, and moisture.

Versatility: It can be used for packaging various products, from electronics to food items.

Cost-Effectiveness: Shrink film is relatively inexpensive, making it a cost-effective packaging solution for businesses of all sizes.

Exploring Stretch Film and Its Advantages

Stretch film is a polyethylene-based material that stretches when pulled, making it easy to apply by hand or with wrapping machines. It offers excellent product protection and tamper resistance, with superior strength and tear resistance compared to other films.

Cast Stretch Film

Cast stretch film is known for its high clarity, which is ideal for products requiring visibility. It is produced through a casting process that results in a smooth, clear film. Cast stretch film is easy to unwind and offers consistent stretchability, making it a popular choice for many packaging applications.

Blown Stretch Film

Blown stretch film offers greater puncture resistance, making it suitable for wrapping irregularly shaped or heavy products. It is produced through a blowing process that results in a more resilient film. Although blown stretch film may cloud the product's appearance, its strength and durability make it a reliable option for challenging packaging tasks.

Types of Stretch Wrap

Stretch wrap comes in two primary types: hand stretch film and machine stretch film.

Hand Stretch Film

Hand stretch film is designed for manual application and is available in clear and colored varieties. It is lightweight yet strong enough to securely package products. Hand stretch film offers excellent tear resistance, making it ideal for wrapping heavier items requiring additional protection.

Machine Stretch Film

Machine stretch film provides superior strength and puncture resistance compared to hand stretch film. It comes in various sizes, thicknesses, and colors to suit any packaging need. Machine stretch film is designed to work with wrapping machines, reducing labor costs and increasing productivity.

Benefits of Stretch Wrap

Stretch wrap offers several advantages, including:

Product Protection: It helps protect products from dust, dirt, and moisture, ensuring they remain in optimal condition during transportation and storage.

Tamper Resistance: Stretch wrap provides tamper-resistant seals, enhancing the security of packaged products.

Cost Savings: Stretch wrap reduces labor costs as it can be applied quickly with wrapping machines or by hand. Its superior strength and tear resistance also minimize product damage, leading to cost savings.

Recyclability: Stretch wrap is easy to recycle and can be reused multiple times before disposal, contributing to sustainability efforts.

Innovations Driving Sustainable Packaging

The packaging industry is continually evolving, with innovations in shrink film and stretch film leading the charge toward more sustainable solutions. Here are some recent advancements:

Biodegradable Shrink Film

Biodegradable shrink film is made from renewable resources, such as plant-based materials, and decomposes naturally over time. This reduces waste and environmental impact, making it an eco-friendly alternative to traditional plastic films.

Recyclable Stretch Film

Recyclable stretch film is designed to be easily recovered and processed into new products. This innovation reduces the demand for virgin materials and minimizes waste, supporting the circular economy.

Lightweight Films

Lightweight shrink and stretch films use less material while maintaining strength and durability. This reduces the overall environmental footprint of packaging and lowers transportation costs.

Smart Packaging

Smart packaging incorporates technology, such as sensors or QR codes, into shrink and stretch films. This enables real-time tracking, monitoring, and communication, enhancing supply chain efficiency and product safety.

1 note

·

View note

Text

Polypropylene Film for Capacitors, The Top 18 Largest Companies in World Ranked by Revenue in 2023 (2023)

Polypropylene Film for Capacitors Market Summary

Polypropylene film is the core material of the capacitor, which is made of polypropylene resin by casting, blow molding or biaxial stretching. Polypropylene film has good physical stability, mechanical strength, air tightness, high transparency and gloss, and is tough and wear-resistant. It is currently the most widely used capacitor film.

Polypropylene Film Production Process:

Thick film production: resin is melted and extruded at 170-210 ° C, and flows out from the circular rotating head through the filter to the inner cooling jacket, and is cooled to obtain a thick tube film.

Vertical and horizontal stretching: the tube film is preheated to the stretching temperature by infrared rays, and under the action of compressed air and clamping wheels with different speeds before and after, the tube film is stretched in both vertical and horizontal directions at the same time.

Trimming and winding: After cooling, the cylinder is divided into two layers of membranes, and then rewound after heat treatment.

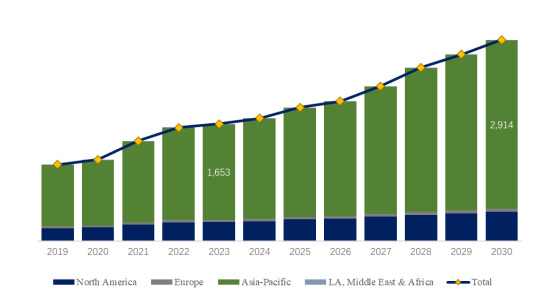

According to the new market research report "Global Polypropylene Film for Capacitors Market Report 2024-2030", published by QYResearch, the global Polypropylene Film for Capacitors market size is projected to grow from USD 2026 million in 2023 to USD 3478 million by 2030, at a CAGR of 8.6% during the forecast period.

Figure. Global Polypropylene Film for Capacitors Market Size (US$ Million), 2019-2030

Figure. Global Polypropylene Film for Capacitors Top 18 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Polypropylene Film for Capacitors include Toray Industries, Hebei Haiwei Group, Jindal Films, Zhejiang Great Southeast, Quanzhou Jiadeli Electronic, Anhui Tongfeng Electronics, Hubei Longchen Technical, Oji F-Tex, Aerospace CH UAV, Foshan Plastics Group, etc. In 2023, the global top 10 players had a share approximately 79.0% in terms of revenue.

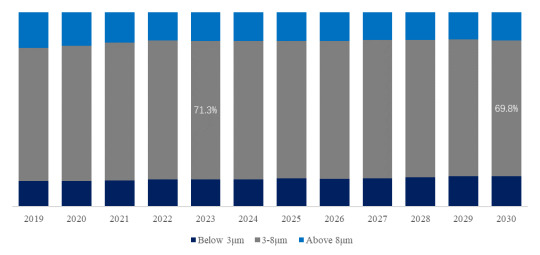

Figure. Polypropylene Film for Capacitors, Global Market Size, Split by Product Segment

In terms of product type, 3-8μm Film is the largest segment, hold a share of 71%. Films in this range are mainly used in PV & Wind Power, home appliances, medical equipment, industrial equipment, LED lights and other consumer electronics. ≤5μm is also available for NEV.

Figure. Polypropylene Film for Capacitors, Global Market Size, Split by Application Segment

In terms of product application, Automotive is the largest application, hold a share of 38% in 2023. The main applications of film capacitors in the field of new energy vehicles are: new energy vehicle electric drives, OBCs and charging piles. The drive inverter is one of the most important components in the electric vehicle power system. Power modules, sensors, and film capacitors are the most critical equipment. The growth of new energy vehicles will drive up the demand for film capacitors/raw material films.

Figure. Polypropylene Film for Capacitors, Global Market Size, Split by Region

Market Drivers:

1. Support from national policies: For example, in China, Benefit from China’s emphasis on new energy, the market has grown rapidly. And considering the long-term impact of "peak carbon dioxide emissions" and "carbon neutrality" policies, the business cycle of the capacitor film industry will be extended, and it is expected to show a slow upward trend in the future.

2. Downstream market demand: The development and growth of the capacitor film market is driven by many driving factors, especially in the fields of new energy vehicles, electronics, energy storage systems and 5G.

Restraint:

1. Market competition intensifies:

The polyester film industry is highly competitive, with continued growth in market capacity and an increasing number of large-scale production companies. As the production scale of polyester film companies continues to expand, market competition in the global polyester film industry has further intensified. In this competitive environment, the gross profit margin of some companies' products may decline.

2. High technical barriers in high-end industries:

Among the companies capable of producing BOPP ultra-thin capacitor films, due to factors such as high technical thresholds, large R&D investment, and multiple product functions, there are relatively few companies that can produce ultra-thin films. But on the contrary, it has a strong competitive advantage in market segments.

Trend:

1. Improved product performance: mainly reflected in film thickness (ultra-thin), corrosion resistance, high temperature resistance, and high-pressure resistance. And it can meet the mechanical and electrical performance requirements of different application scenarios.

Ultra-thin Film: In the field of new energy vehicles, ultra-thin capacitor films can accommodate more energy storage materials, increase the energy density of batteries or capacitors, increase vehicle cruising range, and meet users' needs for long-distance driving. And ultra-thin films can also reduce capacitor weight and control costs.

High temperature resistance: New energy vehicle batteries will generate heat during operation. The high temperature resistant film can cycle stably in this environment, avoiding performance degradation in high temperature environments and maintaining long-term use. High-temperature resistant film capacitors are the key to ensuring the stable, safe and long-term operation of NEV batteries under complex working conditions and promoting the reliability and popularity of electric vehicles.

2. Market size and downstream demand growth: The rapid development of downstream new energy vehicles, photovoltaics, UHV and other fields will further drive demand in the electronic components/electronic component materials industry. For example, the "New Energy Vehicle Industry Development Plan (2021-2035)" issued by the Chinese government proposes that by 2025, China's new energy vehicle sales will account for more than 20% of new automobile sales, and by 2035, new energy vehicle sales will account for more than 20% of new automobile sales. New car sales are mainstream. In the future, the market capacity of PP films for new energy vehicle capacitors is expected to exceed 10 times, and the film thickness is mainly concentrated at 2.0-2.9 microns.

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Non Metallic Pumps vs. Metallic Pumps: A Comparison

Overview Of Non Metallic Pumps & Metallic Pumps

It is however very important that care be taken to select appropriate material for the pump in industrial applications to enhance efficiency, durability and mitigating against frequent breakdowns. As compared to the non-metallic pumps, the metallic pumps also have their own merits and demerits and can act effectively in different areas and conditions. In this article the writer goes further and focus on the differences between non-metallic and metallic pumps while also defining the functions of both Non Metallic Pump Manufacturers and Slurry Pump Manufacturers in providing reliable and efficient products for the varied purposes of industries. VND Plastico Pumps Pvt. Ltd. is a leading name among Non Metallic Pump Manufacturers, providing durable, corrosion-resistant pumps for diverse industries. Trust us for innovative, high-quality, and efficient pumping solutions.

Understanding Pump Types

Metallic Pumps

Metallic pumps are made of metal centric materials like stainless steel, cast iron and aluminum etc. Due to their characteristics, metallic pumps are perfect for hostile surroundings due to the high resistance and sturdiness of these materials.

Non-Metallic Pumps

Non-metallic pumps refer to those pumps that are manufactured using such materials as polypropylene, PVC/UPVC, polyvinylidene fluoride, polytetrafluoroethylene and other forms of plastic. These pumps offer the best corrosion protection, and they are normally lighter compared to material-handling pumps.

Key Differences Between Non-Metallic and Metallic Pumps

1. Material Properties

Metallic Pumps:

Durability and Strength: Metallic will always be a preferred material due to its durability in handling very hard pressure within pump systems. They can easily handle pressure systems and overall mechanical stress that a system can subject it to.

Temperature Tolerance: Angular contact ball bearings that are used in these pumps offer high temperature stability and that is why these pumps are ideal for use in processes involving hot fluid such as stainless steel.

Chemical Resistance: There is another type of pumps known as metallic pumps which provide the best chemical undoubtedly since they also resist most of the chemicals but they are vulnerable to corrosion by certain types of chemicals.

Non-Metallic Pumps:

Corrosion Resistance: Non-metallic types are particularly good when it comes to different types of corrosion including both the acidic as well as the caustic kinds. Because of this, they are well suited for managing of ruthless chemicals.

Lightweight: With these pumps, there is often considerable weight reduction and this can be essential in certain instances especially where the race or the mounting of the pump is a major concern.

Temperature Limitations: It is also found that non-metallic pumps may have lower tolerance to heat compared to metallic pumps hence they can only be used in specific high-temperature environment.

2. Application Suitability

Metallic Pumps:

Industrial Manufacturing: Sturdy enough to sit well with abrasive surfaces and pressure fluids as well.

Chemical Processing: This type of valve is suitable for use where the environment is a little harsher than the above, and where solvents or corrosive substances are used but where the chemicals are not strongly attacking the metals.

Oil and Gas: As they are normally used in refineries and extraction processes because of features like high strength and pressure tolerance.

Slurry Handling: Slurry pumps being used in industries today are primarily metallic pumps, particularly those devised by Slurry Pump Manufacturers, due to their ability to withstand wear and tear when handling slurries and other abrasive materials.

Non-Metallic Pumps:

Water Treatment: Beneficial to accommodate chemical solutions which are utilized in the water and wastewaters treatment due to their anticorrosive nature.

Food and Beverage: Not corrosive or charting, which makes them appropriate for use in handling foods that may require the containers to come into contact with the foodstuffs or drinks.

Pharmaceuticals: Applied in pharma industries where cleanings and chemical endurance is highly significant.

General Chemical Handling: Frequently used to pump aggressive as well as corrosive materials that would affect metallic pumps and their performance.

3. Cost Considerations

Metallic Pumps:

Usually costlier thus the cost of raw materials and the process of manufacturing the products.

Requires more initial capital investment but may last considerably longer in appropriate applications.

Non-Metallic Pumps:

Generally cheaper, particularly for uses where the toughness of metals is not needed.

Lower initial cost and maintenance cost as the material is corrosion resistant.

4. Maintenance and Longevity

Metallic Pumps:

It is recommended that they should be regularly overhauled to avoid corrosion and wearing especially in unfavourable conditions.

Durable in uses where chemical intrusion and rubbing action are reasonably moderate.

Non-Metallic Pumps:

Lower maintenance requirements because of enhanced corrosion resistance.

Possibly reduced service life in high temperature or highly abrasive conditions.

Choosing the Right Pump

Selecting between metallic and non-metallic pumps depends on several factors:

Fluid Characteristics: Look at the chemical make-up, temperature and the degree of abrasive nature of the fluid handling.

Operating Environment: Evaluate the potential exposure to extremes in temperature as well as exposure to chemicals.

Application Requirements: Consider the pressure, flow, and durability requirements for the specific application you are going to use it in.

Budget Constraints: Pay attention to implementation costs, ongoing expenses, and total ownership costs.

Role of Manufacturers

Non-metallic Pump Manufacturers

Manufacturers of non-metallic pumps are very important in providing advanced solutions for industries which need light weight and corrosion resistant pumps. They emphasize their work on innovation and materials science to improve performance as well as durability of nonmetallic pumps. These manufacturers serve several sectors such as water treatment, food and beverages, pharmaceuticals and also general handling chemicals.

Slurry Pump Manufacturers

These companies specialize in making pumps that are used for moving viscous fluids like slurries through them, which are often abrasive. Typically, the materials used to make these pumps are strong metals that can resist wear and tear caused by moving a slurry. Their expertise ensures that the most rugged, dependable and capable pump is created for use in the most demanding industrial settings.

Conclusion

VND Plastico Pumps Pvt. Ltd. stands out among Non Metallic Pump Manufacturers and Slurry Pump Manufacturers, offering durable, high-performance pumps for handling abrasive and viscous fluids. Trust us for reliable and efficient slurry pumping solutions., Both metallic and non-metallic types of pumps offer unique benefits thereby suiting different applications. Non-metallic versions have excellent resistance to corrosion, are lightweight structures, cost effective for handling aggressive chemicals or sanitary applications. Conversely, metallic types demonstrate higher durability along with strength plus greater temperature tolerances thus they would be appropriate for high pressure but also harsh environments.

0 notes

Text

Endless Possibilities of Polypropylene: Manufacturing Details to Practical Applications

In this blog, we explore one of the most common plastics in use today in industries all over the world. Polypropylene or PP is a highly popular plastic thanks to its unique production process and versatility. This polymer is produced through the polymerization of propylene gas and is a thermoplastic polymer with high chemical and thermal resistance as well as durability.

Welcome to our world of Polypropylene manufacturing where the magic of science and technology turns raw materials into the products that we use in our everyday lives. This article will explore the manufacturing of PP to its latest production technologies and processes. However, our investigation doesn’t stop here. We will also explore the extensive uses of Polypropylene from packaging to textile to automotive and medical devices.

From a regular customer to the aspiring engineer to the experienced professional – our Polypropylene story will inform and engage you. So, let’s get started and see what Polypropylene has to offer!

Introduction

Polypropylene (PP), a polyolefin with a chemical formula of (C3H6)n, stands out as a versatile thermoplastic polymer slightly tougher than Polyethylene. Its low density coupled with remarkable heat resistance makes it indispensable across various industries. From packaging food, beverages, and consumer goods to manufacturing automotive components like bumpers and interior trim, PP demonstrates its reliability. It's also a trusted material in the medical field for its sterilization compatibility, non-reactive nature, and in consumer goods for its strength. Moreover, in specialized applications such as cast films, Polypropylene's moldability and extrudability enable intricate designs, further solidifying its status as a cornerstone material in modern manufacturing.

Some of the interesting properties includes:

Melting Point: PP melts at different temperatures depending on its type (homopolymer or copolymer).

Lightweight: PP is one of the lightest plastics, making it ideal for applications where weight reduction matters.

Chemical Resistance: PP handles a wide range of chemicals well, but is not suitable for strong solvents or oxidizing agents.

Heat and Water Performance: PP maintains its properties even in hot, humid, or wet environments.

Stress Cracking: PP resists cracking under pressure from the environment.

Microbial Resistance: While good for some sterilization methods, PP can be susceptible to mold and bacteria growth.

Manufacturing Process

Polypropylene is derived from propene, which is abundantly produced from gas oil, naphtha, ethane, and propane. Concurrently, various methods are under development to generate bio-based Polypropylene, also known as bio-based Polypropylene, utilizing bio-based propene.

(a) Using a Ziegler-Natta catalyst

In the polymerization process, Ziegler-Natta catalysts play a crucial role, formed through the interaction between Titanium(IV) Chloride and an Aluminum Alkyl like Triethyl Aluminum. While the slurry method is occasionally employed, the primary methods for polymer production utilizing these catalysts are two.

(i) The bulk process

Polymerization occurs within liquid propene, conducted without a solvent at temperatures ranging from 340 to 360 Kelvin and pressures between 30 to 40 atmospheres to maintain propene in its liquid state. Following polymerization, solid polymer particles are isolated from the liquid propene, which is subsequently recycled. Utilizing liquid propene as a solvent during polymer formation eliminates the necessity for hydrocarbons like C4-C8 alkanes, commonly employed in the concurrent production of polyethylene.

(ii) The gas phase process

Propene and hydrogen blend is directed over a bed housing the Ziegler-Natta catalyst at temperatures ranging from 320 to 360 Kelvin and pressures varying between 8 to 35 atmospheres.

The polymer is isolated from the gaseous propene and hydrogen through cyclones, while the unused gas is reclaimed for reuse. Both processes can be conducted continuously and employ 'stereospecific' Ziegler-Natta catalysts to catalyze polymerization. These catalysts persist in the product and must be deactivated using water or alcohols before the polymer is transformed into pellets.

Bulk and gas phase techniques have substantially reduced gaseous and aqueous byproducts by utilizing highly active catalysts, leading to minimal residues in the final polymer.

(b) Using a metallocene as catalyst

Metallocenes, originally defined as molecules with a transition metal atom sandwiched between two parallel cyclopentadienyl ligands, with ferrocene being a notable example, now encompass a broader range of ligands related to cyclopentadienyl. Among these, zirconium-based metallocenes stand out as the sole commercial method for producing syndiotactic poly(propene). Similar to Ziegler-Natta catalysts, metallocenes facilitate polymerization through bulk or gas phase methods, as described earlier, or through the slurry process.

Poly(propenes) manufactured using metallocenes, known as mPP, find specific applications in producing non-woven fibers and heat-seal films. Additionally, metallocenes catalyze the production of copolymers comprising propene and ethene.

Technologies used by Major Polypropylene Manufacturers

Process Name : Spheripol process

LyondellBasell has been at the forefront of innovation with the introduction of the Spheripol Polypropylene process. Through the development of a third-generation high-yield, high-selectivity catalyst, LyondellBasell has streamlined the Spheripol process, simplifying its steps and enhancing product quality to a remarkable extent. The Spheripol process consists of three main units:

Catalyst feeding

Polymerization

Finishing section

At the core of all polymerization facilities lies the bulk polymerization segment, which is responsible for generating homo and random copolymers.

This method entails tubular loop reactors filled with liquid propylene, continuously supplied with catalyst and hydrogen to regulate molecular weight.

For random copolymers, an additional comonomer like ethylene is introduced. The resulting polymer is consistently discharged from the reactor, with any unreacted propylene recycled back into the loop reactor.

To manufacture impact copolymers, a vital gas phase reactor comes into play. Polymer from the loop reactor is transferred to this reactor, where an elastomer, derived from the polymerization of ethylene and propylene, interacts with the homopolymer matrix produced in the initial reactor.

Applications of Polypropylene

Packaging

Polypropylene's impressive combination of strength, good looks, and affordability makes it a dominant player in the packaging industry. This versatile material can be shaped into both rigid and flexible forms, catering to a wide range of product protection needs. In the realm of flexible packaging, PP's crystal-clear clarity and ability to effectively block moisture vapor make it ideal for food packaging, personal care products, and various other applications. It's a familiar sight in shrink wrap that keeps products bundled together, and its thin, flexible films find uses in the electronics industry, graphic arts, and even the closures on disposable diapers. Shifting to rigid applications, Polypropylene excels in blow molding, a technique that transforms it into sturdy crates, bottles, and containers. From housing delicate medical equipment to holding your favorite yogurt, PP's diverse capabilities make it a packaging material you'll likely encounter on a daily basis.

2. Consumer Goods & Items

Polypropylene isn't just for packaging! This versatile plastic pops up all around your house in a variety of applications. From see-through containers to sturdy furniture, housewares, appliances, luggage, and even toys, PP's durability and lightweight properties make it a popular choice for many consumer goods.

3. Automotive

Polypropylene (PP) emerges as a preferred choice for automotive parts owing to its trifecta of affordability, exceptional mechanical attributes, and moldability. Its extensive use spans across battery cases, trays, bumpers, fender liners, interior trim, instrumental panels, and door trims, reflecting its versatility in various applications within the automotive sector. Noteworthy characteristics such as a low coefficient of linear thermal expansion and specific gravity, alongside high chemical resistance and excellent weatherability, further elevate PP's appeal. Its superior processability and a finely tuned balance between impact resistance and stiffness add to its allure, making Polypropylene a stalwart material in the automotive industry, meeting stringent performance requirements while offering cost-effective solutions.

4. Fibre

Polypropylene fibers find their way into a variety of applications, including ropes, straps, and different fabric types. These fibers are especially strong and handle moisture well, making them ideal for uses in marine environments like ropes and twines.

Market Outlook

The packaging industry remains the dominant consumer of Polypropylene (PP) , particularly within food applications. However, the automotive sector is expected to be also contribute to the PP market growth in the coming years. Polypropylene's cost-effectiveness and robust mechanical properties make it ideal for automotive components like bumpers, dashboards, and door trims, contributing to over half of its total plastic usage. The burgeoning demand for electric and hybrid electric vehicles (EV/HEVs) further bolsters Polypropylene's appeal, promising to significantly augment market expansion. Additionally, the building & construction and electrical & electronics industries are projected to accelerate Polypropylene market growth due to its exceptional insulating properties. This surge in demand across diverse sectors suggests a robust future for the Polypropylene market.

Polypropylene Major Global Producers

Major companies in the Global Polypropylene market are Braskem, Reliance Industries Limited, ExxonMobil Chemical, LyondellBasell, Borouge, Shenhua Ningxia Coal Industry, Total Petrochemicals, Prime Polymer Co., Ltd., Indian Oil Corporation Limited, SABIC Europe, Zhejiang Petrochemical, Sinopec KPC PC JV, INEOS, Japan Polypropylene Corporation, Saudi Polyolefins, and Petrochina Dushanzi Petrochemical, and Others.

Conclusion:

Polypropylene (PP) is one of the most important plastic materials in modern industry because of its unique properties and wide range of applications. PP has been able to gain popularity in the world of polymers due to its cost-effectiveness, superior mechanical properties, and ease of molding. It is used in all automotive parts like battery cases and interior trims and ropes and twines for marine uses to prove its versatility. Polypropylene is likely to continue to be used in everyday items and various advances in the future of technology and industry because of its ability to contribute to our society in significant ways.

#Polypropylene#Polypropyleneprices#Polypropylenemarket#Polypropylenenews#Polypropylenepricetrend#Polypropylenepriceforecast#Polypropylenemarketprice#priceofPolypropylene

1 note

·

View note

Text

Threaded Equal Tee Exporters in India

INTRODUCTION:- Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications. The most popular kind of pipe fitting that can be used to combine or divide liquid streams is a threaded tee fitting. The ASTM A182 SS Threaded Tees can be accessed via a female-threaded side outlet and female thread sockets, solvent-weld sockets, or solvent-weld sockets.

Threaded Equal Tees can be used to divert a pipe run, connect pipes of different diameters, or do both. A stock list of forged threaded tees made in various materials, sizes, and wraps is available at Shasan Piping Solution. Additionally, the screwed tee made of alloy steel can also be used to transfer two liquid combinations. Based on their three connections, tees can be classified as equal or unequal in size, with equal tees being the most often produced kind.

DESCRIPTION:- These threaded tee fittings have undergone additional treatments, one of which includes surface treatments, to improve their outer layer. The threaded tee ASME B16.11 is available in several completions. Typical finishes for the outer layer of the threaded tee include electroplating, nickel plating, white coating, dark cast, gold plating, excited finish, and so forth. While these treatments provide an external advantage to the ASME B16.11 threaded tee features, there should occasionally be an opportunity to further enhance its mechanical qualities, such as by boosting its resistance to and tensile strength of erosion.

Most commonly, cast metal or bronze, forged alloy and carbon steel, or cast dark or flexible iron could be used to make threaded screwed tee fittings. Alternatively, alternative materials such as stainless steel, aluminum, nickel, cast iron, bronze, plastic, elastic, copper, metal, polypropylene, etc. might also be used to make the ASTM A182 SS Threaded Tees. There are three tension ratings available for the ASME B16.11 threaded tee fitting aspects: Class 2000, Class 3000, and Class 6000.

Presumably, the earliest technique for connecting pipe systems is represented by the threaded tee fitting characteristics of ASME B16.11. The ASME B16.11 threaded tee fittings, often called little drag pipework, are mostly used for small pipe diameters, much as socket weld fittings. Little drag pipe is typically defined as piping with an apparent diameter of NPS 2 or less.

SPECIFICATIONS:- 1. Specifications- Forged Threaded equal tee 2. Dimension Specification- ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 3. Threaded equal tee Forged Fittings Thread- NPT, BSPT, BSPP 4. Threaded equal tee FittingsType- DN15-DN1200 5. End- Threaded, Welding, JIC 6. Threaded equal tee Fittings Pressure Rating- Threaded end-2000lb/ 3000lb/ 6000lbs Threaded equal tee, Connection, Welding 7. Bending Radius- R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom 8. Threaded equal tee 8. Size Range- 1/8" NB TO 4" NB 9. Manufacturing process- Push, Press, Forge, Cast, etc. 10. Threaded equal tee Test Certificates- EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc 11. Origin & Mills - Japanese, Indian, USA, Korean, European, Ukraine, Russian 12. Key markets and industries for Threaded equal tee Fittings- Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals and acids. 13. Application - Threaded equal tee To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc.

BENEFITS:- High-Quality Products: Threaded equal tee exporters provide products that meet international standards such as ASME 16.11, MSS SP-79, and BS 3799. This ensures that the tees are of superior quality and suitable for various industrial applications.

Wide Range of Options: Exporters offer a diverse range of threaded equal tees, including different sizes, pressure ratings, and materials. This variety allows customers to find the perfect fit for their specific requirements, enhancing flexibility and compatibility with existing systems.

Ease of Installation: Threaded connections offer ease of installation, allowing for quick and hassle-free assembly of piping systems. Threaded equal tees provide a secure and reliable connection without the need for specialized tools or welding, saving time and labor costs during installation.

Versatility: Threaded equal tees are versatile components that can be used in a wide range of industries and applications, including petroleum, chemical, construction, and shipbuilding. Their ability to connect three pipes of equal diameter at right angles makes them essential for branching and distributing fluid flow in piping systems.

Customization Options: Exporters often offer customization options for threaded equal tees, allowing customers to tailor the fittings to their specific needs. Whether it's a particular size, material, or threading requirement, exporters can accommodate various customization requests to meet customer specifications.

Reliable Supply Chain: Exporters ensure a reliable supply chain, ensuring timely delivery of threaded equal tees to customers worldwide. With a robust manufacturing infrastructure and efficient logistics network, exporters can fulfill orders promptly, minimizing downtime and maximizing operational efficiency for businesses.

CONCLUSION:- In conclusion, threaded equal tee exporters play a crucial role in providing high-quality fittings for industrial piping systems. By offering a wide range of options, ease of installation, versatility, customization capabilities, and a reliable supply chain, exporters empower businesses to optimize their piping systems for enhanced efficiency and performance. Threaded equal tees serve as integral components in various industries, facilitating the distribution and control of fluid flow in piping networks. With a commitment to quality, reliability, and customer satisfaction, threaded equal tee exporters contribute to the success and competitiveness of industries worldwide.

CONTACT US:- Phone :+91-88797-09191 Phone :+91-22-6651 8642 E-mail : [email protected]

#Threaded Equal Tee Manufacturers#Threaded Equal Tee Suppliers#Threaded Equal Tee Stockists#Threaded Equal Tee Exporters#Threaded Equal Tee Manufacturers in India#Threaded Equal Tee Suppliers in India#Threaded Equal Tee Stockists in India

0 notes

Text

Unveiling the Excellence of Polypropylene Corrugated Sheet Manufacturers in India

Polypropylene (PP) corrugated sheets are a type of lightweight, durable, and versatile material commonly used in a wide range of applications across various industries. These sheets are made from polypropylene resin, which is processed using a corrugated extrusion technique, resulting in a structure with alternating ridges and valleys.

Uses and Applications of PP Corrugated Sheets:

1. Packaging: PP corrugated sheets are widely employed in packaging applications due to their excellent strength-to-weight ratio, durability, and impact resistance. They are used for creating boxes, trays, dividers, and protective packaging for transporting fragile or sensitive items.

2. Signage and Display: PP corrugated sheets are popular choices for signage and display applications. They provide a smooth surface for printing high-quality graphics, making them ideal for advertising boards, promotional displays, signage panels, and exhibition booths.

3. Construction: In the construction industry, PP corrugated sheets find applications as temporary protection for floors, walls, and surfaces during renovation or construction projects. They also serve as formwork for concrete casting and as insulation panels for roofing.

4. Agriculture: PP corrugated sheets are used in agriculture for various purposes such as greenhouse roofing, crop protection, and as partitions in agricultural crates and containers. Their lightweight nature makes them easy to handle and transport in farm settings.

5. Automotive: PP corrugated sheets are utilized in the automotive industry for manufacturing automotive interior components, such as door panels, trunk liners, and parcel shelves, due to their lightweight, impact-resistant, and moisture-resistant properties.

6. Stationery and Crafts: Due to their versatility and ease of cutting and shaping, PP corrugated sheets are popular materials for stationery items like folders, binders, and document organizers. They are also used in arts and crafts projects for creating 3D models, costumes, and decorative items.

7. Medical and Healthcare: PP corrugated sheets are used in the medical and healthcare industry for creating sterile packaging for medical devices, instruments, and pharmaceutical products. They provide protection against contamination and are easy to sterilize.

8. Environmental Protection: PP corrugated sheets are environmentally friendly and recyclable, making them a preferred choice for sustainable packaging solutions. They can be reused or recycled after their initial use, reducing waste and environmental impact.

Overall, PP corrugated sheets offer a versatile, cost-effective, and environmentally friendly solution for a wide range of applications across diverse industries, making them indispensable materials in modern manufacturing and packaging processes.

In today's fast-paced industrial landscape, finding reliable and efficient materials for packaging and signage solutions is paramount. Among the multitude of options available, polypropylene corrugated sheets Manufacture in india have emerged as a versatile and cost-effective choice. As demand surges, the spotlight shines on manufacturers who excel in crafting high-quality PP corrugated board manufacture in india. In India, one name stands out: Singhal Global.

Leading the Way in PP Corrugated Sheet Manufacturing

Singhal Global PP corrugated board manufacture in india, a pioneering force in the realm of packaging solutions, takes pride in its advanced manufacturing capabilities and unwavering commitment to quality. As one of the premier PP corrugated sheet manufacturers in India, Singhal Global has earned a stellar reputation for delivering products that meet the highest standards of durability, versatility, and performance.

Unraveling the Advantages of PP Corrugated Sheets

PP corrugated sheets offer a myriad of advantages that make them indispensable across various industries:

1. Durability: With exceptional strength and resilience, PP corrugated sheets ensure long-lasting performance even in challenging environments.

2. Versatility: From packaging solutions to signage applications, PP corrugated sheets can be tailored to meet diverse needs, offering endless possibilities for customization.

3. Weather Resistance: Whether exposed to harsh sunlight or extreme temperatures, PP corrugated sheets maintain their structural integrity, making them ideal for outdoor use.

4. Lightweight: Despite their robustness, PP corrugated sheets are remarkably lightweight, facilitating easy handling and transportation.

Redefining Excellence in Gujarat's PP Corrugated Plastic Sheet Manufacturing

Situated in the heart of Gujarat, Singhal Global's state-of-the-art manufacturing facility exemplifies innovation and precision in PP corrugated plastic sheet manufacture in Gujrat production. Leveraging cutting-edge technology and industry expertise, Singhal Global ensures that every product adheres to stringent quality standards, surpassing customer expectations with each delivery.

Conclusion

In the dynamic landscape of packaging and signage solutions, the role of PP corrugated sheet manufacturers cannot be overstated. Singhal Global's unwavering commitment to excellence, coupled with its advanced manufacturing capabilities, positions it as a frontrunner in India's industrial scene. As businesses continue to seek reliable and efficient materials, Singhal Global emerges as the trusted partner of choice, offering unparalleled quality and performance.

FAQ

Q: Are PP corrugated sheets recyclable? A: Yes, PP corrugated sheets are highly recyclable, making them an environmentally sustainable choice for packaging and signage solutions.

Q: Can PP corrugated sheets withstand extreme weather conditions? A: Absolutely. PP corrugated sheets are engineered to withstand harsh sunlight, moisture, and temperature fluctuations, making them suitable for both indoor and outdoor applications.

Q: What customization options are available for PP corrugated sheets? A: Singhal Global offers a wide range of customization options, including various colors, thicknesses, and sizes, allowing businesses to tailor PP corrugated sheets to their specific requirements.

0 notes

Text

Plastics Market Trends, Share, industry Growth 2024-2032