#pom plastic sheets

Explore tagged Tumblr posts

Text

Nylon Rods Manufacturer: Providing Versatile Solutions for Multiple Industries

Nylon rods are known for their versatility, strength, and ability to withstand extreme environmental conditions. Nylon rods manufacturers have catered to various industries by delivering durable and high-performance materials that meet diverse industrial needs.

Features of Nylon Rods

High Tensile Strength: Nylon rods can handle heavy loads, making them an essential material in manufacturing and heavy industries.

Abrasion and Wear Resistance: Nylon rods manufacturers produce rods that are perfect for high-friction applications.

Excellent Chemical Resistance: Nylon rods resist exposure to oils, solvents, and chemicals, increasing their longevity in harsh industrial environments.

Industries Benefiting from Nylon Rods

Construction Industry: Nylon rods manufacturers provide durable materials for construction components, such as bushings, rollers, and gears.

Automotive Industry: The automotive sector relies on nylon rods for lightweight and robust components that improve vehicle efficiency.

Electrical Industry: Due to their insulation properties, nylon rods are extensively used in electrical applications to prevent shocks and short circuits.

Conclusion

Nylon rods manufacturers continue to innovate and provide high-performance solutions across multiple industries. Their versatility makes nylon rods an indispensable component in industrial manufacturing and design.

0 notes

Text

🍁 Fall-Themed Activities 🍂

These hands-on activities are ones I actually use as an educator! They can be a ton of fun, great for age regression, and can apply to different age groups! Some may require some adult help, others could be done by yourself. Some of these are super simple, some require a bit more effort, but this list should provide different options!

🍁 Googly Eye Sensory Bag - Sensory bags can be fun, interesting, and easy to cleanup and reuse! For this one, fill a plastic ziplock bag with green slime and googly eyes! With this, you can push the googly eyes around, squish the slime, whatever feels right.

🍂 Fall-Themed Sensory Bins - Like the sensory bags, this is all about doing what feels right and playing on sensory. For bins, you can buy a box at the dollar store and just use that. For fall themed, you can fill bins with colored rice, plastic spiders, tiny plastic pumpkins, fake leaves, small plastic bones - go with the flow. You can then play with these bins using small shovels, buckets, tweezers, or just your hands!

🍁 Washing My Pumpkin - This is really easy! If you have a pumpkin, you can put it in the sink or bathtub and give your pumpkin its own bath! Pumpkins need to be washed, too :3

🍂 Pumpkin Painting - Buy yourself a small (or big!) pumpkin and paint anything you want on it! You can also buy plastic pumpkins!

🍁 Nature Art - You just need a paper plate or piece of paper and some glue! Go outside, collect leaves, sticks, pinecones, acorns, and glue them down to make art from nature!

🍂 Pinecone Bird Feeder - This is great if you have big pinecones where you live! You only need a pinecone, some peanut butter, and bird seed. Cover the pinecone in peanut butter and roll it in the bird seed! You can tie yarn around it to hang it up or just set it outside somewhere - watch out! This is messy!!

🍁 Corn Shakers - For a fun and noisy activity you can do, take an empty plastic bottle, can be big or small, and fill it with dry corn OR popcorn kernels. Close the top and shake! shake! shake! You now have a little musical instrument you can shake around for fun! And the best part, if you use popcorn kernels, you can always take them out and make them into popcorn (just ask for help :3)!

🍂 Shaving Cream Art - You will want a tray, maybe a baking sheet, just something big enough to cover a piece of paper, shaving cream, and paint. Pour the shaving cream onto the tray, then take your paints, could be red, yellow, orange, black, fall themed colors, and drizzle them over the shaving cream however you would like. Next, take the paper and gently press it ontop. When you lift the paper up, your colors and designs will be on the other side! You could also do this with something that is already printed on the paper.

🍁 Make a Treat Bag - All you need is a paper bag and anything you want to decorate it with! This can include paint, markers, crayons, googly eyes, glitter, pom poms, feathers, glue, and more. Make a pretty bag for holding some of your candy for Halloween!

🍂 Paper Plate Crafts - You can do so much with paper plates, like paint them into pumpkins, add tons of eyes and pipe cleaners and make them into spooky spiders, or give them pieces of cut paper to make into a scarecrow, there are many possibilities.

20 notes

·

View notes

Note

Found your work through desperate searches for sylvanian family customisation or recolour resources and WOW your art/characters/worldbuilding are also astoundingly good... gonna be scrolling here a while. Out of curiosity do you do custom/commissioned sylvanian figures or do you have a tutorial/materials list someplace? Thanks for reading!!

Aw gosh, thank you, Anon!

I did one custom commission as an experiment (which I'm sure you've seen if you looked through the tag) and it was pretty fun, but man are these things a time suck! I tried to do too many dolls in too short of a time, got kind of burned out on them, and haven't touched them in months... I'm currently trying to work up motivation to get back into it and finish the projects I have materials for. If I do, I'll take pictures this time and put together a proper tutorial.

Unfortunately I can't take any commissions right now, but I'd be happy to share a materials list! It's under the cut:

The paint used is basic acrylic paint, like the kind you can get from Walmart or craft stores for under two bucks. There's a bit of a trick to painting them without making the fur clumpy, I described the painting process here!

For the hair, you'll want doll hair ("My Little Pony" size is way more than sufficient), a hair rooting tool/kit, and either a heat gun or blow dryer. I wrote some notes on hair rooting Sylvanian Family dolls here.

For the clothes, you can use a number of different fabrics, but you want it to be very, very thin. That super cheap, thin cotton fabric you can find at Joann Fabrics is pretty perfect and comes in a wide variety of colors and patterns, though some stuff like doll-sized flannel you might have to look online for (or DIY--you can use acrylic paint on fabric, it just makes it stiffer). I use ribbon for trim. Other accessories like jewelry, buttons, chains, crystals, and belts can be sourced from craft stores, too... I usually just bring my WIP doll with me in my pocket and hold it up next to anything I'm interested in buying to check if the sizing is right (the lady at the fabric cutting station was incredibly charmed by them, hah). For more specialty items, like tiny hats and replica firearms, you will probably need to look online.

If you can't find a specific accessory, or need to sculpt something like armor, you can try making it out of epoxy clay and painting it with the same acrylic paint you used for the figure. Mod Podge will help seal it and give it a nice glossy finish. (Do not use Mod Podge on Sculpey--it makes it sticky!)

Tails are generally pipe cleaners or occasionally pom poms. Cut the original tail off with wire cutters, digging out as much of it as you can, and super glue the new tail in the hole.

Horns are done with epoxy clay. For big horns on the head, I use wire cutters to cut the pointy part off a pin, embed that in the clay horn, and then stick the end of the pin into the plastic head to more securely anchor it.

Bat and dragon wings are done with leather sheets you can buy from a craft store.

Other essentials: Super glue, sewing kit, Dritz fray check. Super glue is essential for both tails/horns/etc and clothing (it's often better for ultra-fine detail than sewing). Sewing kit is needed for clothing. You will not have much success with clothing without Dritz fray check. It keeps the edges of the fabric from disintegrating, which is a major concern when working on such a tiny scale.

Also this isn't a material so much as a tip: I often use the pointy end of a pin to do fine detail painting. It's also useful for sculpting miniatures.

Hope that helps! Good luck on your customization ventures, and feel free to ask if you have any more questions!

#sylvanian families#calico critters#doll custom#doll customization#anon#ask#not an art post#ALSO THANK YOU FOR THE KIND WORDS ON MY WORLDBUILDING AND CHARACTER STUFF... it is what I live for

21 notes

·

View notes

Text

🔧✨ Witness the precision of our CNC machines transforming POM engineering plastics into custom components. Elevate your OEM projects with our tailored solutions. Discover more:

#cncmachining#oem#pom#custommanufacturing#engineering#precisionengineering#industrial design#manufacturing#innovation#tech

0 notes

Text

Compare and contrast Copolymer Acetal and Dupont Delrin Homopolymer in Sheet or Plate and Round Rod

Delrin is the best plastic for turning on a lathe lathe. It is simple to turn, but it does require slow speeds. I use this material to make Scottish small pipes chanters. I have purchased many items from Industrial Plastic. Smaller pieces always ship quickly and everything has been well packed. I’ve never had an issue with an order.Between the Delrin and POM-C rods, both materials are very…

youtube

View On WordPress

0 notes

Text

What’s the Difference Between Thermoforming and Injection Molding

Often, customers in their own hands of the product in the thermoforming process or injection molding process can not tell the difference, or their own design in the end should be used in the injection molding process or thermoforming process?

In the market, the most common plastic parts in the market are thermoforming products or injection molded product. and thermoforming and injection molding are popular manufacturing processes. In fact, for many products, both can vacuum form and also can be plastic injection molding,. That specifically. In which way, do different users have different choices, exactly how is good? Cost, efficiency, and quality are often the most important considerations.

Of course, they are not opposites but complementary. In this blog, we will introduce the Difference Between Thermoforming and Injection Molding in detail.

Different Manufacturing Process

Thermoforming processing

The principle of thermoforming technology is also called the vacuum forming molding process. It is a thermoforming processing method, the use of the thermoplastic sheet, the manufacture of open plastic shell products the method, is the plastic sheet is cut to a certain size after heating and softening, with the help of the heated plastic sheet on both sides of the difference in air pressure and mechanical pressure, so that the deformation of a specific mold profile, after cooling and shaping, and cutting and trimming to complete the thermoforming products process!

Injection molding process

Injection molding is a process in which thermoplastic plastic pellets are heated and molten liquid polymers are, and then the molten plastic is injected into the injection molds through the injection molding machine with high pressure, after a certain cooling time, the plastic is solidified and shaped in the injection molding tooling.

Different materials used

The most significant difference between thermoforming and injection molding is the different materials used. The commonly used materials are PP, PE, ABS, PVC, PET, PS, and other thermoplastic pellets and sheets, while injection molding uses more thermosetting plastics, such as PP, PA, PC, ABS, POM, PE, and other granular raw materials.

Thermoforming uses plates and sheets, so the raw materials will be more expensive compared to injection molding granular materials.

Different design structure of products

Injection molded products are more accurate and can produce complex shapes and structures, while thermoforming products generally produce simpler shapes.

The shape obtained by injection molding is often the final product, and no further processing is required before it is installed or used as a final product. Many details, such as projections, ribs, and threads, can be molded in a single step in injection molding.

Thermoforming products can be produced in simple shapes, with smooth surfaces, are easy to process and assemble, and require post-processing to make holes and remove excess material after the product has been molded. The products mainly include packaging boxes, handicrafts, cards, and so on. Thermoforming products are also widely used in electronics, home appliances, medical and toys.

Different product usage

Due to the different materials and processes, there are some differences between the products made of thermoforming and injection molding. Thermoforming products usually have strong flexibility, impact resistance, and wear resistance, especially suitable for the production of curved and arched products, such as blister packaging boxes, three-dimensional billboards, and so on.

While injection molding products usually have the characteristics of high precision, high strength, good dimensional stability, etc., they are suitable for the production of electronic product shells, automobile parts, industrial equipment, and so on.

Different equipment and tools

Injection molding requires injection molding machines, molds, and other equipment and tools; injection molding machines are mainly divided into vertical injection molding machines, horizontal injection molding machines, two-colour injection molding machines, single-colour injection molding machines, high-speed injection molding machines and so on.

Thermoforming products require equipment and tools such as thermoforming machines and thermal processing devices. According to the different types of pressurization of thermoforming, the mainstream thermoforming equipment is mainly divided into the following three categories:

(1) Vacuum negative pressure forming machine, mainly through the negative pressure vacuum method, so that the plastic sheet is affixed to the mold;

(2) Positive pressure vacuum machine, through the air compressor on the front of the plastic sheet with atmospheric pressure, so that the softened plastic sheet is affixed to the mold;

(3) Positive and negative pressure vacuum molding machines, which form a strong pressure difference between the two sides of the plastic sheet by means of pressurization and vacuum, so that the softened plastic sheet is molded. These three kinds of equipment, each has its own advantages and disadvantages, need to be based on the characteristics of the product to choose the machine.

The parameters of temperature, pressure, and flow rate of injection molding equipment in the process of product processing can be precisely adjusted through the control system, which ensures the precision of product making. At the same time, injection molding equipment consumes less raw materials when processing high-precision products, which also reduces product costs.

In contrast, blister molding equipment is limited in the means of controlling parameters such as temperature, pressure, and flow rate, which is a limitation to the production of products requiring high precision.

Different production efficiency

Injection molding is a kind of high volume production runs plastic processing method. The general production efficiency of injection molding equipment can reach a production capacity of hundreds to thousands of pieces per hour.

At the same time, the degree of automation of injection molding equipment is also very high, and it can quickly complete the processing of products and improve production efficiency. In contrast, the production speed of thermoforming is slower compared to injection molding, and the processing time of the products usually takes several minutes to tens of minutes.

Different costs

A. Tooling Costs

Injection mold according to the complexity of the product, different precision, and mold material at different prices. The commonly used mold materials are S50C, P20, H13, 718H, NAK80, S136, etc., due to the complexity of the product is different, and involves a lot of complexity of the mold processing process than the thermoforming mold, the cost of the relative thermoforming molds are also higher than 5 to 10 times.

The molds used for thermoforming: The molds commonly used for blistering are gypsum molds, aluminum molds, copper molds, wood molds, and steel molds.

The materials used in plastic injection molds are relatively low, and the product structure is simple, so the molds are relatively simple, the materials are cheap, and there are lower tooling costs.

Gypsum mold: the material is gypsum powder, simple to manufacture and amend, usually a single piece of mold only needs 1~3 days, because it is brittle and difficult to dissipate heat, gypsum molds are usually used for the case of having samples handmade samples, not for production.

Aluminum mold: it is made of aluminum through machining and grinding. The aluminum mold has high precision, a smooth surface and is hard and durable, but the price is very expensive, generally used under strict requirements of the product, and ordinary molds can't achieve the precision effect of the use of such molds.

Copper mold: Copper mold should be made with plaster mold first, then take the sample to copper plating, and then fill with gypsum inside.

The copper mold has a better appearance and finish, strength can also reach the usual production requirements, and it is one of the widely used thermoforming molds.

Substitute wood mold: the material is substitute wood, the material cost is higher, needs CNC processing, the manufacturing cycle is short, usually a few hours, easy to sand and punch. The material is also brittle, suitable for sampling in the scene with 3D drawing files, not for production.

Steel mold: generally S45C, S50C, and P20 materials; generally thermoforming, use this type of steel mould.

B. Product costs

The cost of thermoforming vs injection molding is not the same. As the production process of injection molding is relatively simple, the cost advantage of injection molding is obvious when producing large quantities and high-cost products; while thermoforming molding is suitable for smaller production quantities, short production cycles, complex shape products, etc., which is relatively more economical.

The initial cost of injection molds is higher, but the cost per piece is lower when producing large quantities, and the start-up cost of thermoforming is lower, but the cost rises with the increase in production.

In injection molding equipment in the production process, recycling raw material loss will be much less than the vacuum forming molding equipment, especially in the production of larger batches of products, injection molding equipment in the cost savings have obvious advantages.

In addition, injection molding equipment has a higher degree of automation, which does not require much manual operation and also reduces production costs, it's more cost effective for high volume production.

Overall, injection molding is more efficient than blister molding is proven, although the investment in injection molding equipment is larger, in the long run, its production efficiency and production cost advantage will bring more profits and competitive advantage for enterprises.

Conclusion

To sum up, although both thermoforming and injection molding belong to the plastic molding process, there are obvious differences in their materials, production processes, uses, production precision, and product characteristics.

When choosing the molding process, you need to select the most suitable process according to the requirements and characteristics of the specific product. In the actual production and use need to choose the right type of product according to the specific needs.

0 notes

Text

0 notes

Text

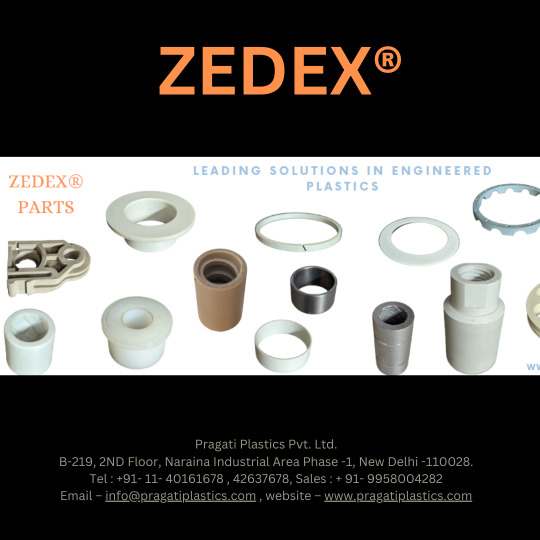

ZEDEX® composite polymer materials are robust and ultimate in performance for bushing, sliding, thrust and extreme pressure sealing applications, when all other polymers have failed or give less than expected life. ZEDEX® grades are supplied as rods, sheets, hollows, machined parts, granular for injection molding and filaments for 3-D printing. ZEDEX® materials replace and outperform phos-bronze, brass, St. steel, PTFE/ filled PTFE, POM, Nylon, PEEK and others. Outstanding features of ZEDEX® are:

Extremely low wear and creep.

Very low coefficient of friction starting 0.07.

High Compressive Strength from 70 MPa upward.

Cryogenic grades down to -200 deg. C.

High edge strength.

Perfectly machinable down to tight tolerances.

Thoroughly tested both in labs and application conditions.

Hundreds of proven applications worldwide in equipment.

For More Info :

Pragati Plastics Pvt. Ltd.

B-219 , 2ND Floor , Naraina Industrial Area Phase -1 ,New Delhi -110028.

Tel : +91- 11- 40161678 , 42637678, Sales : + 91- 9958004282

Email – [email protected] , website – www.pragatiplastics.com

0 notes

Text

PEEK/PPS/PPSU/PEI/POM/PA Cold Push Bar and Sheet Production Line

PPS plastic (polyphenylene sulfide) is a kind of thermoplastic special engineering plastic with excellent comprehensive performance.The main use of PPS is in the field of electronic appliances, such as making transformer skeletons, high-frequency coil bobbins, plugs, sockets, wiring frames, contactor drum drums and various precision parts. PEI has good flame retardancy, chemical reaction resistance and electrical insulation characteristics. Pei also has low shrinkage and good isotropic mechanical properties. Adding glass fiber, carbon fiber or other fillers can achieve the purpose of reinforcement and modification; It can also form heat-resistant polymer alloy with other engineering plastics, and can be used for a long time at the working temperature of - 160 ~ 180 ℃. Application: because PEI has excellent comprehensive balance performance, it is generally used in industrial departments such as electronics, motor and aviation, and as a metal substitute for traditional products and cultural and daily necessities. Using PEI instead of metal to manufacture optical fiber connector can optimize the component structure, simplify its manufacturing and assembly steps, and maintain more accurate dimensions. It is used in the automotive field, such as manufacturing high-temperature connectors, high-power lamps and indicator lamps, sensors for controlling the external temperature of automobile compartments (air conditioning temperature sensors) and sensors for controlling the temperature of air and fuel mixtures (effective combustion temperature sensors). It can also be used as vacuum pump impeller resistant to high temperature lubricating oil erosion, ground glass joint (socket) of distiller operated at 180 ℃, and reflector of non illuminated anti fog lamp. POM plate and bar (1) POM is a crystalline plastic with good rigidity, commonly known as saigang. (2) It has excellent properties such as fatigue resistance, creep resistance, wear resistance, heat resistance and impact resistance. (3) POM is not easy to absorb moisture and has good dimensional stability in humid environment. It is difficult to control the size during injection molding. The thermal deformation temperature is 172 ℃, and there are two kinds of polyoxymethylene with different properties (polyoxymethylene has better temperature resistance). Main technical specification Model SJZ45/25, SJZ65/28 Material PEEK/PPS/PPSU/PEI/POM/PA Main engine rate of revolution 10-49r/min Main motor power 11KW Capacity 20kg/h Note: The specifications are subject to change without prior notice. Plant equipment diagram Read the full article

#PEEKBarextrusionLine#PEEKColdPushBarandSheetextrusionLine#PEEKplateProductionLine#PEEKSheetextrusionLine#PEEKSheetProductionLine#POMBarandplateextrusionmachine#PPSBarandSheetProductionLine#PPSPlateExtrusionline#PPSUColdPushBarextrusionLine#PPSUSheetProductionLine

0 notes

Text

FIC: Kurt Birthday Drabbles

Earlier this week @elledelajoie left a comment on something I wrote all the way back in 2014. I had genuinely forgotten I ever started it, but the original idea was to write 21 Kurt Hummel birthday drabbles. I had written just 7 of them, but after we chatted about it, I decided to go ahead and finish.

If you’re not familiar, a drabble is a scene of exactly 100 words, not counting title headers. Since Chris Colfer and Kurt Hummel’s co-birthday (May 27) is coming up this Thursday, here they are. This goes definite AU at Birthday #19. Because you know I would never sentence my beloved Kurt to a life of being a doormat to people who did not appreciate and value him.

Never underestimate the power of feedback!

~*~*~*~*~

Birthday #1

Kurt’s blue eyes went wide as a frosted cupcake was set upon his high-chair tray, a single candle ablaze on its surface.

When Mommy, Daddy, Uncle Andy, Grandpa Curtis and Grandma Eileen started singing to him, he smiled and clapped both hands hard around the tempting pile of frosting.

Kurt laughed when the sugary topping went flying and a big splatter of white abruptly decorated Daddy’s surprised face.

Everyone else started laughed too, including the startled father, who retaliated by giving his birthday boy a sticky peck on the cheek and then helped him to blow out a new candle.

Birthday #2

Kurt looked between his presents, confused.

Mommy had given him the pretty dolly he had begged for at the store. Daddy had given him a truck, not big enough to ride but too big to live with the little cars Daddy gave him at Christmas.

His parents seemed to be mad at each other.

Kurt looked at the doll, then at the truck. He smiled and placed Dolly inside the truck and began to drive her around the carpet.

Mommy and Daddy seemed surprised by his actions, but then they laughed, and Kurt knew he had figured out the puzzle.

Birthday #3

His shoes were black and shiny, buckles on the sides and 1-inch heels on the base. He clomped over the hardwood floors, listening to the click-tap-click-tap in delight. They went perfectly with his dove gray coveralls with “Kurt” sewn on the pocket in black sequins. Mommy had made the outfit for him.

Spotting Daddy watching him, Kurt threw himself into waiting arms. Daddy’s smile looked like he had an owie but was trying to be a big boy and not cry.

Kurt hugged him. “It’s okay, Daddy.”

Burt looked surprised but hugged him back. “Yeah, buddy. I think it is.”

Birthday #4

Ballet girls were nice. When they heard it was his birthday today, they threw him a party. Kurt puffed up with pleasure when presented with cookies, a sparkly wand and a tiara that read ‘Happy Birthday’ in shiny letters. He was not as fond of the kisses they gave, but four was very grown up, so he screwed up his face and allowed it. The teacher even let him wear the special puffy pink tutu over his little black leotard!

He saw Mommy and Daddy up in the gallery taking pictures, so he waved.

Kurt hoped today would last forever.

Birthday #5

“Can I have cupcakes?”

Kurt’s mother looked up from her book. “I don’t think we have any, sweetheart.”

“Can we have some Thursday? My birthday is the last day of preschool.”

“It is?” she said, looking surprised. “Is it your birthday already?”

He nodded seriously. “Don’t you remember, Mommy? You were there.”

She laughed. “Well, you have me there. What kind of cupcakes would you like, sweetie? And don’t say cheesecake. Those are two completely different kinds of dessert.”

Kurt’s hopeful expression fell. “Oh,” he said, clearly disappointed. Then his face brightened again. “Chocolate?”

She nodded. “That we can do.”

Birthday #6

“Daddy!”

Burt sat up just in time to catch the little body that launched at him. “What’s wrong, slugger?”

“It’s my birthday!”

Grinning despite the way his heart was hammering at the abrupt awakening, Burt asked, “Yeah? I like birthdays. Do I get a present?”

“No,” the boy scoffed. “I get presents!”

Burt squinted at the clock. 3:15am. “Not until morning, you don’t.”

Kurt pouted and tried, “It’s almost morning.”

“Not close enough, kid. C’mere,” Burt pulled him into the warm bed between himself and his wife.

Kurt snuggled down and went right back to sleep.

Burt was less lucky.

Birthday #7

Kids had started treating him funny this year. He was too fancy, too girly, holding hands was weird.

Nobody was coming.

“I’m sorry, sweetie.”

“Am I too late?”

They jumped as a little black girl with pom-pom hair popped out of nowhere.

“I’m Mercedes,” she greeted. “We just moved here. Mom said you would have invited me if you’d known.”

“I’m Kurt.” He smiled. “Do you like tea parties?”

“Is there cake?”

Mrs. Hummel beamed. “Cake, ice cream, and Kool-Aid.”

Kurt shrugged. “Nobody else came.”

She grabbed his hand like she’d known him forever. “More for us! Happy Birthday, Kurt.”

Birthday #8

Kurt took a deep breath, thought for a moment, and carefully blew out the candles. All but the extra one that his parents always put on his cake.

“Aren’t you gonna finish, bud?”

He looked from Daddy over to his mother, home again, but so frail he was sometimes afraid to hug her, worried she might pop like a fragile soap bubble. He offered her the candle. “Here, Mommy. Blow it out. Maybe you’ll get another year to grow on.”

The eyes of the two adults met, then Mommy nodded. The three of them blew out the final candle together.

Birthday #9

Barely daring to hope, Kurt came down the stairs. Birthday cakes and presents had been Mommy’s specialty. Daddy had forgotten his own birthday and had nearly forgotten Christmas.

Kurt gasped when he saw it, waiting, shining and spectacular against the front door.

“A bike!”

Bright green, sissy bars with foil streamers, and a banana seat. Perfect!

Burt smiled. He had scoffed a such a “girly” bike when Kurt spotted it at the toy store. But now, looking at the all-too-rare joy in his son’s eyes and feeling the approving smile his wife would have given, he nodded. It was perfect.

Birthday #10

Buying gifts was tough when your kid always clammed up on you. A dad had to be observant.

Ten years old. A landmark like that needed something special, but the only thing Kurt seemed into was clothes. He had enough of those for ten kids.

He’d probably like a Barbie he could change in and out of different outfits, but Burt cringed at the thought.

He did doodle pretty good though. Sure, it was mostly pictures of clothes, but that was a start.

A fancy sketchpad with a case and a hundred different colored pencils. Yeah, that was the ticket.

Birthday #11

“Dad, where are we going?”

“You’ll see.”

Kurt sighed with exaggerated impatience. He had come home from school to find Dad waiting at the truck, ordering him to get in, then not saying another word. The suspense was killing him.

“Ta-Dahhhh!”

They had pulled up in front of a nondescript brick building. “Columbus Culinary Arts?”

“You like to cook right? Well, we’re gonna fix your birthday dinner this year with the help of a real chef. Lessons are once a week for the next couple months.”

Gourmet cooking lessons!

“Oh wow. Dad, this is amazing!”

Burt grinned. “Happy Birthday, kid.”

Birthday #12

Last year’s surprise had gone so well that Burt had decided on a repeat. But when he saw the excitement on Kurt’s face at finding a pair of tickets inside his birthday card turn to disappointment and horror, quickly masked with a fake smile, he knew he’d goofed.

“I know baseball isn’t your thing,” he said, almost pleading. “But you’ve never seen a live game before. It’s a whole different experience. It’s a home game. We can yell and scream, and cheer our team on with thousands of other fans.”

The stiff not-smile never wavered. “Sounds . . . fun.”

Birthday #13

Dad had bought out one of the partners at the garage this spring and now owned a majority share of the renamed “Hummel Tires & Lube”. Kurt wanted to snicker at that name, but he was proud too.

His birthday this year coincided with Friday Night Dinner. Dad had invited all the mechanics over for a potluck. They’d had Mary’s special fried chicken, Cassius’s homemade cornbread, and Davy’s mac’n’cheese. Now Dad brought out the cake.

Kurt laughed. A sheet-cake with a tow-truck and two little plastic mechanics for decoration.

“You and me kid. Partners.”

The mechanics cheered and everybody dug in.

Birthday #14

Kurt froze when he saw tickets peeping out of his card. Not again. Noise, sunburn, unhealthy food, tacky uniforms, and Dad trying so hard to make a boring sport seem like fun.

He sighed and pasted on a smile, which quickly transformed into shock.

“Wicked?” he squeaked, staring hard at the little papers as if the printing might change if he dared to look away.

“Embassy Theater is giving regional business owners a discount this year,” Burt said apologetically. “It’s just a traveling production, not real Broadway, but I …”

His apology was cut off by a joyful teenaged hug.

Birthday #15

“Don’t worry, son, you got this. Just remember everything I taught you. You got a whole year to get ready for the practical test.”

“I know.”

“And it’s okay if you don’t get it right the first time. Not everybody does.”

“I’m fine, Dad.”

“I’ll be right here waiting for you when you’re through.”

“I know that, Dad. I’ll be okay, really.”

At that moment, Kurt’s name was called and he sprang from his hard green plastic chair. His dad’s repeated reassurances were making him jumpy.

Twenty minutes later, a brightly grinning Kurt was waving his freshly minted driver’s permit.

Birthday #16

Burt patted the giant blue bow the dealership had provided over the hood of the shining black Lincoln Navigator.

Kurt was gonna flip! He’d passed his DMV test with flying colors and was no doubt showing off his shiny new license to all his friends at school.

He paused. Did Kurt have any friends to share this accomplishment with? He always seemed so alone.

Maybe that’s why he had decided to spoil his son with a huge birthday gift.

It wasn’t right for such a good kid to be all alone. Maybe having his own ride would help change that.

Birthday #17

A dozen teens gathered in Kurt’s basement to celebrate the end-of-school, non-disbanding of Glee, and Kurt’s birthday, all in one.

“Not like ten years ago,” Mercedes said to Kurt, as they watched Mike and Brittany dance.

“Ten years?”

“Your seventh? It was just you, me, your mom, and lots of chocolate cake.”

Kurt was astounded. “That was you?”

“You forgot?”

“I remember a little girl who showed up and invited herself to my party.”

“And I remember a little boy who needed a friend as much as I did.”

He squeezed her hand. “Thanks for coming.”

She squeezed back. “Always.”

Birthday #18

Kurt stared at his birthday cake, unable to think of anything to wish for.

He was 18-years-old today, a legal adult. He had new family in Carole and Finn, his dad was on the mend, he would be back at McKinley for senior year, he had made his first visit to New York City, and he had a boyfriend! One who had just told Kurt that he loved him for the very first time.

‘I wish for next year to be as good as this,” he thought, taking a deep breath and blowing.

The flames flickered out, all except one.

Birthday #19

Senior year had been a disaster, and now he had not gotten into NYADA, despite his well-praised audition.

“Blaine wants me to spend another year here,” he whispered. “I just can’t.”

Burt’s callused hand squeezed his neck. “Then don’t. You’re 19 now, a man. You got talents galore, work experience from the garage, enough drive for ten kids, and your mom’s life insurance money to give you a start.”

“But…”

“No buts,” Burt said firmly. “You go on to New York and grab life by the balls.”

Kurt felt his optimism rise. “Help me look for apartments?”

“You got it.”

Birthday #20

What a difference a year made.

He’d dumped Blaine after being cheated on less than a month after leaving Lima. He was enrolled at FIT and sharing a shoebox apartment with a fellow design student and a Broadway hopeful, but both were young gay men from small towns, and they had a lot in common.

“Happy Birthday!” Elliott shouted, tossing a handful of glittery sequins at him.

Adam came in playing the birthday song on a kazoo he had gotten from who-knows-where. “Ready for Callbacks? $20 on who gets the first hot guy’s number!”

“I already have yours. I win!”

Birthday #21

“I have the honor of presenting your first official grown-up drink,” Adam said, smiling lovingly at his grinning boyfriend of nearly a year. He set down a martini glass with a cherry floating on top. “A Manhattan seemed appropriate.”

Kurt beamed and gave him a kiss, then took an experimental sip. “I’ve had alcohol before,” he admitted. “Mostly wine, though. Mm, this is good!”

“I thought you’d like it. Happy Birthday, my love. May the future bring every good thing you wish for, and never more heartache than you can handle.”

Kurt could not have asked for a better sentiment.

THE END

34 notes

·

View notes

Text

Dive into the world of high-performance plastics and their diverse applications. Discover top Nylon sheet suppliers and how Polestar Polymers leads the market with quality and reliability.

0 notes

Text

Heartbreaker

Pairing: Modern Ivar x Female character/ reader (She)

Word Count: 3057

Warnings: Language mostly, implied sexual relations and angst.

Beautiful moodboard made by the amazing @peterquillzsblog Thank you again 💙

This was written for the lovely @youbloodymadgenius 400 Followers Writing Challenge. I'm super late, but thank you so much for letting me participate 💙 I had fun writing this and I hope you like it.

I used prompts #12 and #28. They are highlighted in bold.

I tagged those who might be interested.

...

“I told you not to fall in love with me.”

The words hit her like a fucking truck. They tumbled so easily from his lips with that dreaded nonchalant tone she'd only ever heard him use on others whenever he spoke over the phone. It was never aimed at her.

He had his arms crossed over his naked chest with brows raised, sitting comfortably up against the large fancy black headboard of his equally large and fancy bed, the very bed he had her in only nights before. His long hair was messy, shooting out in all directions from being tugged at mercilessly. A pretty blonde had snaked her way from under his black satin sheets, her naked body in full view. She makes a show for him, pulling her denim jeans over her sad excuse of a behind slowly, obviously interested in hearing the rest of their exchange.

Ivar licks his lips, his blue eyes following the soft lines of that broads basic body before shifting them back to her. “You’d only get hurt in the end.” He finally says.

What a low blow.

She swallows the lump forming in her throat, knowing the tears would be forcing their way out of her glossy eyes soon. How fucking stupid was she? She stood there, hands balled into fists as her eyes flipped between him and the smirking blonde. Her lower lip trembled like a goddamn child, standing awkwardly in front of the pair. From the looks of it, this dalliance with the blonde had been going on for a while. The girl seemed far too comfortable.

Ivar was right. He did warn her not to fall in love with him. It was just supposed to be a fling, nothing more. They had met at a mutuals party, Ubbe’s friends cousin or some shit. They couldn’t remember the details now if you asked them, but they both knew the guy, and when they met, it was instant physical attraction. And that was when their “friends with benefits” relationship began. She had been a phenomenal plaything for him, and she seemed to know exactly what Ivar needed. She was pretty, had an amazing body, shiny hair, long fluttering lashes. She looked perfect on his arm and he liked her enough to keep her around, but he didn’t love her. How could he? He wasn’t meant for that shit. He was Ivar the heartbreaker, a hot young bachelor born into the old money of the Ragnarsson family. He could have any woman he wanted. And he did.

She was so fucking stupid, but Ivar was fucking stupid too. He’d given her a key to his flat, allowing her freedom to come and go as she pleased as if they were a fucking couple. And she was stupid enough to believe that was the relationship they were forming, that somehow they had silently crossed this bridge of uncertainty that went from nothing to something. They had been “together” for months, almost an entire year. Ivar wasn’t a bad person, he was just bad at relationships. He couldn’t settle with one girl, so he played with many. She wondered how many others he played with when she wasn’t around.

Not much regret could be detected in his eyes, his blue orbs shimmering with the words she could read so clearly: Get out. So that's exactly what she did. Turning swiftly on her booted heels, she walks back into his fancy kitchen, slamming his key with this cute pastel blue pom pom keychain she bought onto the marble island counter. Digging into one of the totes full of groceries that she intended to use to cook the fucker dinner, she pulls out a small tub of Häagen-Daz strawberry ice cream, shoving it in her bag. She'd need it later. With a shaky breath she looks around the modern sleek flat one last time before slamming the door behind her.

She could hear that bitch giggling as she left.

…

“Did you see the look on her face?” Freydis giggles, slipping on her low cut cropped top before pouncing onto the bed beside Ivar, “Poor thing. You really had her hung up.” Ivar did see the look on her face, and although he’d seen it many times before on countless other women, it hit him a little differently this time. Dammit.

She looked heartbroken, eyes wet like that day her cat had gotten sick and she begged Ivar to rush them over to the vet that was an hour away. He didn’t really care much for the cat, it had sharp claws and was always hissing at him, but he did it for her. Her cat was saved from whatever the fuck was wrong with him, and she was happy. She’d given him the sweetest smile he’d ever seen.

That night had been a great fuck.

Ivar releases a breath from his nostrils, ignoring Freydis babbling on and on about god knows what. The blonde was a fool if she thought she would be next to take her place. Fucking bimbo. Was only good for a measly fuck. And she was terrible at it. He pushes away the satin sheets, completely nude, before turning to peer at her from over his sculpted shoulder with a look of indifference.

“Get out.”

“Ivar?” She looks up at him through her lashes, her lips forming into a frown at his sudden disdain.

“I didn’t stutter,” He states calmly, but a stern tone laced his words that had her sitting up at attention,” I said get the fuck out.” Freydis rolls her eyes, pushing herself off the bed and grabbing her purse she meticulously hung in his closet.

“Douchebag,” She mutters, but she offers him a sickly sweet smile, pushing a lock of her blonde hair behind her ear, “You know I’m always available. I’ll be waiting for your call.” She winks at him, blowing him a kiss before slinking out of his room. Once Ivar heard his front door slam close he sighs, shuffling over to his bathroom for a much needed bath.

For some reason, he felt dirty.

…

It had started raining as soon as she left Ivar’s flat. She had forgotten her umbrella at home and she was soaked to the bone from the heavy droplets by the time she stepped foot into her own flat.

It was cute and cozy, with fairy lights and tapestries that were the complete opposite of Ivar’s stupid modern sleek bachelor pad. Ivar preferred simplistic Scandinavian living, while she gravitated towards that boho atmospheric vibe with scented candles that she had in practically every room. He joked about it whenever he slept over, which wasn’t very often. It looked childish to him. The scented candles made him sneeze and the cat was a bitch, but he’d settle under her warm quilted covers just fine, gazing up at her ceiling that reflected a projection of a star lit sky. That was actually kinda cute. She was always a romantic, but that was the problem.

She kicks off her tall boots, tossing her keys atop the little ceramic dish by the door. Moving over to her tiny kitchen, she puts away the ice cream in the freezer and makes a b-line towards her bedroom. She hangs up her bag on the very corner of the door to her closet, shedding her jacket and the rest of her clothes on the floor without a care before heading to her bathroom. She immediately lights all her candles, setting up a relaxing bubble bath with a lavender scented bath bomb. Lastly, she grabs her phone, searching for the right playlist before sinking into the warmth of the bubbly water.

As soon as her eyes fall shut, her mind goes back to Ivar.

Fuck him. And the blonde.

She didn’t want to berate herself anymore than she already did while taking that miserable walk home, but she couldn’t help feel like her heart was burning a hole right through her chest. It beat faster the more she thought of him, and her eyes pricked with the sensation of tears, until finally, she let them fall. The fat drops roll down her cheeks as she cries into her hands to muffle her sobbing.

This would be the only night she’d shed tears for him, she promised herself. Tomorrow was a new day.

Benji, her fat calico cat, slinks his way into the bathroom, curling up in a corner to enjoy the warmth of the bath for himself. She brings her teary eyes to him, the calm state of the feline having her wish she could feel such peace. Sometimes she wished she were a cat herself, only having to worry about sleeping, eating, shitting, and doing it all over again day after day.

Sinking deeper into the water she forces herself to relax, listening to the soothing sounds of Moonlight Sonata, a dreary tune for a dreary day off. When her eyes fluttered with sleep, the classical playlist was interrupted by the obnoxious sound of her phone's vibration over the plastic toilet seat. With a scowl she reaches over to snatch her phone, biting her lip as Ivar’s name flashed on the bright screen. Without hesitation, she taps her finger to end the call, sending him straight to voicemail. She had nothing to say to him.

Fuck him.

After 30 seconds, her phone vibrated again. Ivar was fucking persistent.

Again, she ignored the call, and after the 4th call, she angrily slams her finger on the green button, bringing the phone to her ear.

“What do you want?” She spits, shivering now that the water had significantly dropped in temperature. She runs a hand down her gooseflesh covered leg as she awaits his answer, but so far he was silent, only a frustrated breath could be heard on his end, “I detect guilt.” Her words were dripping in pure venom, something he honestly found rather attractive. But now was not the time for that.

“Are you okay?” He asks softly, so unlike him, and somehow, so fucking irritating.

“Peachy,” She replies sarcastically, sinking into the water once again. The bubbles had long disappeared and she was getting cold, “Why do you care?”

“I don’t.” Was the weak scoff. There was an awkward silence after that, which was strange considering she felt she could talk to Ivar endlessly about anything really. That’s the sort of pair they were, or maybe it was her doing all the talking and soul baring while Ivar patiently listened and...kept his own secrets. She sighs, just about ready to hang up until she hears him mutter something.

“I can’t hear you.” She counters, annoyed.

“I didn’t want you to see this,” He clears his throat, “I didn’t want you to see us. Me and Freydis.”

“You did a great fucking job hiding it.”

“Is this really a good time for your sarcasm?”

“Fuck you, Ivar.”

“I’m being serious,” He hisses in frustration, “That was nothing for you to see. I had no idea you were off today.” He sounded irritated, as if it were somehow her fault he got caught. It shouldn’t have mattered if they weren’t anything to begin with. “I don’t even know why I’m explaining myself to you!” He ended his little childish rant with a sigh, the kind of sigh where he needed to run a hand down his face to keep his shit together.

“So then why the fuck did you call me?” She hissed back, and in her annoyance she splashed water from out the tub, the cold droplets sprinkling over Benji. It had the cat screeching for his life before running out of there.

“I don’t even fucking know myself.” She hears him take in another frustrated breath, grumbling something about the complications of women. Asshole. He was the complicated one.

The splashing of water was heard on his end. He must have been having a bath of his own. That was their thing, after a particularly rough day at work, or whenever the actions of their lovemaking called for a bath, they didn’t hesitate to slip in together and enjoy each other again. It was clear she valued those moments more than he did. It all meant nothing to him.

Her traitorous mind conjured up images of how his body must have looked, water droplets running down his glistening chest and chestnut colored hair plastered on his face. Fuck.

“I’m fucking stupid.” She groans, already feeling another wave of tears surging through her. She sniffles, bringing her knees to her naked chest as she stares at the flickering candles surrounding the tub.

“You’re crying,” Ivar says stupidly, his tone unreadable, “Please, don’t cry. I hate it when you cry,” He was speaking gently, as if that would be enough to soothe her, “I told you not to fall in love with me.” He repeats the phrase softly, almost sadly, like the corny lead of some fucking corny romantic comedy that did trash in the cinema.

“Yeah…” She says, fighting to hold back the sob she wanted so badly to release, “Yeah, I know.” And with that, she hung up, tossing her phone aside and sinking deeper into the now freezing water.

Maybe if she stayed in there long enough she’d feel numb.

…

She had stared at her ceiling, the star lit sky projection twinkling down at her, much like they always did when she was a little girl back in her hometown. They always did serve to calm her, making her feel safe and helped her sleep a lot better. They didn't help much this time around.

She stared all night, even after the stars disappeared with the sunrise, thinking about him. She was getting too old for this, crying like a fucking teenage girl.

She barely slept and was desperate for a cup of coffee the moment she rolled out of her cocoon-like bed. Dragging her feet over to the kitchen, she brews a pot of the caffeinated liquid before preparing Benji’s breakfast. The cat slithered between her legs, meowing uncontrollably as he awaited his food.

“Shut up, Benji.” She mutters to him tiredly, placing down his food bowl and giving him a quick pat. She leans against the counter, her eyes following the slow drip of the coffee into the glass pot, wondering how the fuck she’d gotten to this point. Her eyes hurt, swollen from all the crying she did last night, and everything felt hazy and slow.

After last night’s conversation with Ivar, she decided to block him, erasing whatever memories she had of him. Ivar was always a generous man with her, sometimes buying her little things that caught her eye, probably just things to appease her with she realized. She gathered all the items up in a cardboard box she had laying around, leaving it by the door to throw away once she left for work.

Finally, the coffee was done. She poured herself a much needed cup, adding a few drops of her favorite vanilla creamer. Taking a small sip of the hot beverage, she groans in delight as it coats her taste buds, ignoring the burning caused by her impatience.The fusion of bitter and sweet was helping her recharge for the day. She’d need at least 2 more cups if she was going to do these guided tours at the museum today.

There was a knock on her door as soon as she moved to get ready. In her confusion she pauses her morning playlist, turning to look toward her door as if something were about to burst through and devour her whole. It was 7:30 in the morning, an unusual hour to knock on anyone’s door. Her first thought was Ivar, but why would he even bother showing up to her door? He was never awake this early as he got to show up to his office whenever he wanted. Ruling him out, she finally makes her way to the door, peeking through the peephole. No one was there.

She unlocks the door, turning to look towards the left and right of the hall before looking down. She blinks, stunned.

Flowers. A huge bouquet of flowers. Her favorites actually, Gerbera Daisies, all in a soft powdery pink color with bright yellow centers. They were placed in a monstrosity of a vase of white porcelain, painted with stunning blue designs like fine china. Beside it was a small bag with a generic looking orange tabby cat on the front with its paw up. Those were Benji’s favorite treats.

Taking one last look around the hallway she bends down, carefully picking up the vase of flowers and the cat treats, all while pushing Benji back in before he tried to make a run for it. She tosses the treats aside, staring long and hard at the pretty flowers with a scowl. There was a white card clipped within the stems, wet from the vase water. Snatching it, she runs her finger over the parchment-like surface before opening it to see a familiar scrawl in the blackest ink. The water spreads the ink, staining the white card in black streaks like tears. She read the simple message:

I know these are your favorites. You deserve pretty flowers. I’m sorry you felt the need to fall in love.

-Ivar.

Her brows arch and a frown tugs at her lips. She felt her heart drop instantly as her brain finally processed the simple words he’d written. Reading it was enough for her to sense the emptiness of the message. She knew him well enough to know he slept just fine last night. Probably next to that other chick. How could he possibly think that flowers would make it all better?

She quickly rips the card into little pieces, tossing them into her trash can. She lifts the bouquet of daisies from their stems, removing them from the vase and throwing them harshly into the trash with a snarl. She squeezes her eyes shut, the tears already coating her lashes, rolling down her cheeks and onto those stupid flowers. She already broke her promise of no more tears and it wasn’t even 8 am. She bites her lips, glaring down at the daisies as if they were the root of the problem.

“Fuck you, Ivar.”

...

Part 2

...

@heavenly1927 @didiintheblog @leilabeaux @inforapound @a-mess-of-fandoms @shannygoatgruff @syrenak

#vikingsfanfiction#vikings fanfic#vikings ivar#modern ivar#ivar the boneless#alex hogh andersen#ivar imagine#ivar x reader

213 notes

·

View notes

Text

Comparing Dupont Delrin and Acetal Copolymer in Round rods or sheets and plate

Comparing Dupont Delrin and Acetal Copolymer in Round rods or sheets and plate

Delrin is a great plastic for turning on a lathe lathe. It is very easy to turn, however it does require reduced speeds. I’ve used this plastic to make Scottish small pipes chanters. I have purchased numerous items from iPlastic. Small parts usually ship quickly and everything is always well packed. I have never had a problem with an order.Between the Delrin and POM-C rods, both materials are…

youtube

View On WordPress

2 notes

·

View notes

Note

“I’m going to pogo stick my way out of here”

Ahhh I’m sorry it took me so long to write this!!! I set it in the Theatre AU, so I hope that’s okay, and I hope you enjoy it!

Prompt from this list

Word count: 1,075

“Ugh,” Elaine groaned, heaving a misshapen plastic bin stuffed full of fabric up onto the cutting room table. “This is my least favorite thing.”

“I thought you said you liked inventory,” Sarah laughed, already marking off a new section on the sheet of scrap paper in front of her. “What’s this one?”

“Uh… Polar fleece, bin two of three.”

“Two of three?”

“Yeah, but… Where are the other two?”

On the floor on the other side of the room, Crutchie laughed. He was surrounded by piles of jewelry that he was sorting, reorganizing, and inventorying for the updated costume storage binder that the three of them were working on. They had quickly discovered that very little of the organizational “system” in the cutting room—or costume storage in general, which was also spread over the sewing and receiving rooms on the third floor, as well as most of the basement two floors down—made any sense, and was horribly out of date, as things had been thrown out and added to storage without being logged in the inventory lists. Fabric storage was possibly the worst off, and Elaine and Sarah had been slogging through the wall full of storage bins for almost the entire week, pulling out, measuring, logging, and refolding fabric cuts, swatches, and scraps, while Crutchie sorted through endless drawers, smaller bins, and other storage containers full of things like pocket squares, jewelry, socks, undershirts, and much more.

In the rest of the theatre, the boys on the crew were doing similar work. Jack and Albert had been pulled by Weisel for props organizing, and were up to their elbows in dust and dirt in the storage hole above stage left. Jack pulled a plastic bin off of a shelf and began to sputter and cough as a cascade of dust and a handful of dead bugs poured off down onto his head. “Gross,” he groaned, trying to brush it off, onto the floor instead of the other props around him.

“Yeah, tell me about it,” Albert made a face as he ran a finger across the top of a toy drum, leaving a streak in the layer of dirt there.

“Why do we keep some of this stuff?” Jack asked, opening the offending bin to reveal that it was stuffed full of cheerleader’s pom-poms.

“Christmas stuff needs to be saved because shows are recycled, and you never know what you might need for them when they get redesigned anyways,” Albert droned, repeating the line that they heard regularly from Weisel and the other authority figures around them when similar questions were posed. “And other stuff is really the same thing: you never know when you might need it again.”

“How often do we really need cheerleading pom-poms?” Jack asked, holding one up and shaking it, the plastic rustling.

“Well, we did just use some for Ovation, last summer,” Albert mused. “None of those, obviously.” Both boys laughed, Jack shoved the pom back into the bin, and placed it on their pile of “things to ask Weisel if we can please throw away”.

.*.*.*.*.*.

That afternoon, as the crew was wandering out of the theatre into the brisk winter air—not cold enough to need anything more than a light jacket, and a few of the boys weren’t even wearing those—they were chattering cheerfully amongst themselves, happy to be out in the bright sun and fresh air.

“Hey, Laine, Crutchie,” Jack grinned, appearing between his roommates and slinging his arms around their shoulders as they headed for the front of the building to walk home. “You guys find anything cool today?”

“Check it out!” Elaine said, holding up a misshapen white tophat, the tags still attached. “Brand new. They couldn’t use it for the show they bought it for, ‘cause it was so messed up, so Weisel said I could keep it. It was going to get thrown out otherwise, because of the way the brim is warped and stuff. Perfectly good—well, not good, but useable—and brand new.”

“What are you going to do with it?” Jack asked.

“I dunno,” Elaine shrugged. “But it’s cool.”

Jack laughed.

“What about you?” Crutchie asked. “You guys find anything cool or weird or whatever?”

“Oh, yeah; check it out.” Jack pointed across the parking lot, towards Finch, Elmer, JoJo, Albert, and Race clustered together near their cars, laughing about something. As they watched, Albert’s head popped up over everyone else’s, bobbed up and down a few times, and then Race and JoJo lunged to catch him as he fell.

“What is that?” Elaine laughed.

“Come on,” Jack grinned, steering the other two towards the group.

As they got closer, the object Albert was holding became visible: a pogo stick.

“Where did you find that?” Crutchie asked as Albert started to climb back up onto the device, JoJo hovering worriedly behind him in case he fell again.

“Props hole, over stage left,” Albert grunted as he took a test hop forward. When he didn’t immediately fall over, he kept going, making it almost a full six feet before losing his balance and starting to fall.

“Albert,” Elaine groaned. “You’re going to kill yourself.”

“Or at least break something,” Finch grumbled.

“No, I’m not,” Albert grunted as he untangled himself from the pogo stick. “I’m going to pogo stick my way out of here.”

“Pogo stick your way to death, more like,” Race laughed.

“Oh, ye of little faith!” Albert retorted.

“I’m literally watching you right now. I have the appropriate amount of faith.” ”I’m getting better,” Albert protested.

“That’s what everyone says,” said Finch, “right before they fall and break their face.”

“I feel doubted,” said Albert.

“Oh, one hundred percent,” said Finch. “The only thing I don’t doubt right now is that you’re going to get hurt.”

Albert stuck his tongue out and started to climb back up onto the pogo stick, only to immediately start to fall towards the asphalt, a look of horror frozen on his face. JoJo scrambled to try and catch him, the others lunging uselessly forward with no way to cross the distance in time to help, but he managed to get a foot down to partially catch himself to avoid slamming into the pavement.

“You okay?” JoJo asked, helping Albert once again untangle himself from the pogo stick.

“Yeah,” Albert laughed sheepishly. “Maybe you guys are onto something. There’s a slight possibility I should get some pads before I try and master this thing.”

#asked and answered#prompt#request#newsies#newsies fic#newsies au#newsies modern au#newsies theatre au#the theatre au#finch cortez#finch (newsies)#albert dasilva#albert (newsies)#race higgins#race (newsies)#sarah jacobs (newsies)#sarah jacobs#elaine o’dell (newsies oc)#crutchie morris (newsies)#crutchie morris#jojo de la guerra#jojo (newsies)#elmer (newsies)#jack kelly#jack kelly (newsies)#prettyinlimegreenboots

10 notes

·

View notes

Text

The most popular plastic beads today.

Inabata Vietnam Firm, which started off as synthetic resins (PP, PMMA, HIPS and ABS ...), may be used, making numerous items including each day devices, development materials. , Inabata Vietnam focuses on handling all sorts of supplies: man-made resin (PP, HIPS and ABS PMMA ...) design plastic materials (POM, PC, PA, LCP and PBT Personal computer / Abdominal muscles ...) Plastic beads. The very important material in the making of plastic products is plastic resins, or polypropylene granules. The resin is odorless, tasteless, and low-toxic. Plastic beads are transparent in color, so throughout the producing method, they are usually mixed with tinted beads to give the merchandise whole shade. Furthermore, the hard plastic material, much less smooth as PE, is just not stretched so the resin is additionally manufactured into fibers. Technology plastics. Technological plastic is really a product or service of various plastic materials used in industry for specialized handling work. Specialized plastic has many different forms, a few of which are preferred by means of bedding, fibers, bars, trees and rolls videos. Practical plastic materials in Vietnam are being used in nearly every discipline of industrial production and are most frequently known as: Bakelite plastic sheet, PTFE resin, HDPE plastic, Pom plastic, teflon plastic ...

Primary plastic. Major plastic is a plastic item manufactured from petroleum, has not been employed and it is not adulterated, without any chemicals. You may realize that this really is a "real" plastic, having a high wholesomeness like 4 amount 9 rare metal. Unused virgin plastic is normally organic white-colored colored. When getting put into the application form, men and women frequently include coloration granules to obtain distinct colors such as green,purple and red, yellow-colored ... At the moment in the world you can find well-liked primary resins such as: PE, PP, ABS, PP, POM, PVC, PET, PC ... The most common plastic beads these days. The PP resin includes a feature white colored coloration that is certainly translucent, includes a high technological energy, is fairly difficult, not adaptable. PP plastic resins have great oiliness, toughness, and extremely good work surface smoothness. ABS resin is normal white colored or opaque white-colored, difficult however, not fragile. What exactly are plastic beads used for? Design plastic materials could be used to: Make molds in garment production facilities. It really is used for an electric powered insulation machine in the market. Software to create great-technical electronic digital circuit board or as anti--static and waterproof partition. There are excellent software that help with advertising, construction, interior and construction. Raw resins are used differently according to the components of the resin. Software rich in-end products which demand security like carparts and aircraft, health-related gear ... For additional information about nhua nguyen sinh visit this resource.

1 note

·

View note

Text

What’s the Difference Between Thermoforming and Injection Molding

Often, customers in their own hands of the product in the thermoforming process or injection molding process can not tell the difference, or their own design in the end should be used in the injection molding process or thermoforming process?

In the market, the most common plastic parts in the market are thermoforming products or injection molded product. and thermoforming and injection molding are popular manufacturing processes. In fact, for many products, both can vacuum form and also can be plastic injection molding,. That specifically. In which way, do different users have different choices, exactly how is good? Cost, efficiency, and quality are often the most important considerations.

Of course, they are not opposites but complementary. In this blog, we will introduce the Difference Between Thermoforming and Injection Molding in detail.

Different Manufacturing Process

Thermoforming processing

The principle of thermoforming technology is also called the vacuum forming molding process. It is a thermoforming processing method, the use of the thermoplastic sheet, the manufacture of open plastic shell products the method, is the plastic sheet is cut to a certain size after heating and softening, with the help of the heated plastic sheet on both sides of the difference in air pressure and mechanical pressure, so that the deformation of a specific mold profile, after cooling and shaping, and cutting and trimming to complete the thermoforming products process!

Injection molding process

Injection molding is a process in which thermoplastic plastic pellets are heated and molten liquid polymers are, and then the molten plastic is injected into the injection molds through the injection molding machine with high pressure, after a certain cooling time, the plastic is solidified and shaped in the injection molding tooling.

Different materials used

The most significant difference between thermoforming and injection molding is the different materials used. The commonly used materials are PP, PE, ABS, PVC, PET, PS, and other thermoplastic pellets and sheets, while injection molding uses more thermosetting plastics, such as PP, PA, PC, ABS, POM, PE, and other granular raw materials.

Thermoforming uses plates and sheets, so the raw materials will be more expensive compared to injection molding granular materials.

Different design structure of products

Injection molded products are more accurate and can produce complex shapes and structures, while thermoforming products generally produce simpler shapes.

The shape obtained by injection molding is often the final product, and no further processing is required before it is installed or used as a final product. Many details, such as projections, ribs, and threads, can be molded in a single step in injection molding.

Thermoforming products can be produced in simple shapes, with smooth surfaces, are easy to process and assemble, and require post-processing to make holes and remove excess material after the product has been molded. The products mainly include packaging boxes, handicrafts, cards, and so on. Thermoforming products are also widely used in electronics, home appliances, medical and toys.

Different product usage

Due to the different materials and processes, there are some differences between the products made of thermoforming and injection molding. Thermoforming products usually have strong flexibility, impact resistance, and wear resistance, especially suitable for the production of curved and arched products, such as blister packaging boxes, three-dimensional billboards, and so on.

While injection molding products usually have the characteristics of high precision, high strength, good dimensional stability, etc., they are suitable for the production of electronic product shells, automobile parts, industrial equipment, and so on.

Different equipment and tools

Injection molding requires injection molding machines, molds, and other equipment and tools; injection molding machines are mainly divided into vertical injection molding machines, horizontal injection molding machines, two-colour injection molding machines, single-colour injection molding machines, high-speed injection molding machines and so on.

Thermoforming products require equipment and tools such as thermoforming machines and thermal processing devices. According to the different types of pressurization of thermoforming, the mainstream thermoforming equipment is mainly divided into the following three categories:

(1) Vacuum negative pressure forming machine, mainly through the negative pressure vacuum method, so that the plastic sheet is affixed to the mold;

(2) Positive pressure vacuum machine, through the air compressor on the front of the plastic sheet with atmospheric pressure, so that the softened plastic sheet is affixed to the mold;

(3) Positive and negative pressure vacuum molding machines, which form a strong pressure difference between the two sides of the plastic sheet by means of pressurization and vacuum, so that the softened plastic sheet is molded. These three kinds of equipment, each has its own advantages and disadvantages, need to be based on the characteristics of the product to choose the machine.

The parameters of temperature, pressure, and flow rate of injection molding equipment in the process of product processing can be precisely adjusted through the control system, which ensures the precision of product making. At the same time, injection molding equipment consumes less raw materials when processing high-precision products, which also reduces product costs.

In contrast, blister molding equipment is limited in the means of controlling parameters such as temperature, pressure, and flow rate, which is a limitation to the production of products requiring high precision.

Different production efficiency

Injection molding is a kind of high volume production runs plastic processing method. The general production efficiency of injection molding equipment can reach a production capacity of hundreds to thousands of pieces per hour.

At the same time, the degree of automation of injection molding equipment is also very high, and it can quickly complete the processing of products and improve production efficiency. In contrast, the production speed of thermoforming is slower compared to injection molding, and the processing time of the products usually takes several minutes to tens of minutes.

Different costs

A. Tooling Costs

Injection mold according to the complexity of the product, different precision, and mold material at different prices. The commonly used mold materials are S50C, P20, H13, 718H, NAK80, S136, etc., due to the complexity of the product is different, and involves a lot of complexity of the mold processing process than the thermoforming mold, the cost of the relative thermoforming molds are also higher than 5 to 10 times.

The molds used for thermoforming: The molds commonly used for blistering are gypsum molds, aluminum molds, copper molds, wood molds, and steel molds.

The materials used in plastic injection molds are relatively low, and the product structure is simple, so the molds are relatively simple, the materials are cheap, and there are lower tooling costs.

Gypsum mold: the material is gypsum powder, simple to manufacture and amend, usually a single piece of mold only needs 1~3 days, because it is brittle and difficult to dissipate heat, gypsum molds are usually used for the case of having samples handmade samples, not for production.

Aluminum mold: it is made of aluminum through machining and grinding. The aluminum mold has high precision, a smooth surface and is hard and durable, but the price is very expensive, generally used under strict requirements of the product, and ordinary molds can't achieve the precision effect of the use of such molds.

Copper mold: Copper mold should be made with plaster mold first, then take the sample to copper plating, and then fill with gypsum inside.

The copper mold has a better appearance and finish, strength can also reach the usual production requirements, and it is one of the widely used thermoforming molds.

Substitute wood mold: the material is substitute wood, the material cost is higher, needs CNC processing, the manufacturing cycle is short, usually a few hours, easy to sand and punch. The material is also brittle, suitable for sampling in the scene with 3D drawing files, not for production.

Steel mold: generally S45C, S50C, and P20 materials; generally thermoforming, use this type of steel mould.

B. Product costs

The cost of thermoforming vs injection molding is not the same. As the production process of injection molding is relatively simple, the cost advantage of injection molding is obvious when producing large quantities and high-cost products; while thermoforming molding is suitable for smaller production quantities, short production cycles, complex shape products, etc., which is relatively more economical.

The initial cost of injection molds is higher, but the cost per piece is lower when producing large quantities, and the start-up cost of thermoforming is lower, but the cost rises with the increase in production.

In injection molding equipment in the production process, recycling raw material loss will be much less than the vacuum forming molding equipment, especially in the production of larger batches of products, injection molding equipment in the cost savings have obvious advantages.

In addition, injection molding equipment has a higher degree of automation, which does not require much manual operation and also reduces production costs, it's more cost effective for high volume production.

Overall, injection molding is more efficient than blister molding is proven, although the investment in injection molding equipment is larger, in the long run, its production efficiency and production cost advantage will bring more profits and competitive advantage for enterprises.

Conclusion

To sum up, although both thermoforming and injection molding belong to the plastic molding process, there are obvious differences in their materials, production processes, uses, production precision, and product characteristics.

When choosing the molding process, you need to select the most suitable process according to the requirements and characteristics of the specific product. In the actual production and use need to choose the right type of product according to the specific needs.

1 note

·

View note