#polymeric spunbond

Text

Polyolefin Resins: A Look at Their Wide Range of Uses

Polyolefins are a class of polymers formed from the polymerization of olefins such as ethylene and propylene. These polymers include polyethylene, polypropylene, and other polymers made from alkenes. Polyolefins exhibit many useful properties that have enabled their widespread use in a variety of industries and applications.

Chemical Structure and Properties

Polyolefins are hydrocarbon polymers, meaning they are composed purely of hydrogen and carbon atoms in long molecular chains. The main difference between polyolefin types is the structure of these repeating molecular units - polyethylene contains an ethane repeating unit (–CH2–CH2–) while polypropylene contains a propene repeating unit (–CH2–CH(CH3)–).

The carbon backbone structure gives Polyolefin Resins their main mechanical properties. The strong covalent carbon-carbon bonds make polyolefins rigid yet flexible and resistant to chemicals and corrosion. The lack of polar chemical groups also means polyolefins are generally non-polar and hydrophobic – this property enables uses where water or moisture resistance is important. Polyolefins also have low densities, ranging from 0.89–0.97 g/cm3 for LDPE and 0.90–0.92 g/cm3 for polypropylene.

Polyethylene

Polyethylene (PE) is produced in various forms depending on process variables used during Polyolefin Resins. Low-density polyethylene (LDPE) resin is lightly branched with densities around 0.915-0.940 g/cm3. LDPE products have good clarity and flexibility ideal for food packaging films, shrink wrap, and trash bags.

Linear low-density polyethylene (LLDPE) has a linear polymer chain structure with short branches, lowering densities to 0.910-0.940 g/cm3. LLDPE resins can be processed at higher rates than LDPE and offer good impact resistance suitable for industrial films and lamination applications.

High-density polyethylene (HDPE) has fewer and shorter branches, making it essentially linear. HDPE has densities in the range of 0.941-0.970 g/cm3, imparting high strength and stiffness properties useful for pipes, bottles, containers, and durable household goods.

Polypropylene

Polypropylene (PP) differs from PE in having a pendant methyl group on every third carbon in its polymer chain. Isotactic polypropylene, the most common type, has these methyl groups oriented on the same side of the polymer backbone. This gives isotactic PP higher melting points than LDPE or HDPE, ranging from 160-171°C depending on composition.

Isotactic PP has a balance of properties making it suitable for a huge diversity of applications. It is rigid yet tough, with high heat distortion temperatures up to 120°C. Common uses include caps and closures, textiles, rope and cord, automotive components, pipes, living hinges, and medical devices and components. Atactic or syndiotactic PP varieties offer varying property profiles.

Uses and Applications

As the most widely produced plastics globally, Polyolefin Resins are highly versatile materials that bring value to many markets:

Packaging - PE and PP resins dominate the packaging industry with their moisture and chemical resistance. They are used extensively for food packaging, shrink and stretch films, bags, bottles, containers and more.

Consumer and Industrial Products - Durables like tools, pails, detergent bottles, cable jacketing, automotive components, car interiors and more capitalize on polyolefin toughness, durability and design freedom. Outdoor furniture, pipe systems, and construction products also use polyolefins extensively.

Medical Devices - The biocompatibility and processing characteristics of medical grade polyolefins support use in devices, components, tubing, gowns, drapes and other single-use applications.

Textiles - Spunbond PE and PP nonwovens are major materials for geotextiles, diapers, wipes and hygiene products, filtration media, and other textile applications. Fiber and filament grades also see use in carpet and apparel fibers.

Polyolefin Resins are amongst humanity's most significant material inventions. The unmatched versatility and balanced mechanical properties of PE and PP, coupled with facile production methods, have enabled polyolefins to permeate nearly every industry and market segment. With global annual production now exceeding 100 million tons, polyolefins will assuredly continue to play an outsized role supporting modern society and economies into the foreseeable future.

Get more insights on Polyolefin Resins

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#PolyolefinResins#Polyethylene#Polypropylene#Thermoplastics#PolymerIndustry#PackagingMaterials#AutomotiveComponents

0 notes

Text

Barrier Innovation: Revolutionizing Medical Implant Packaging

Materials and Processes for Medical Implant Packaging

The materials used for medical implant sterile packaging must meet strict biocompatibility and sterilization requirements. The primary materials used are polymeric films, paper, nonwoven composites and tyvek. Polymeric films such as PVC, PET and polyolefin films offer high strength, sealability and barrier properties. However, polymeric films may leach extractables which is a concern for medical applications. Tyvek is a spunbonded polyethylene fabric that is strong, tear resistant and breathable. It is commonly used as a sterile barrier in packaging. Paper provides printability and is more economical but needs to be properly coated or laminated to prevent wetting issues during sterilization. Nonwoven composites offer textile-like handle and moisture resistance. The materials undergo extensive testing to ensure they do not interact or leach harmful substances to packaged medical implants.

The various processes used in manufacturing medical implant sterile packaging include forming, sealing, sterilization and validation. Thermal and ultrasonic sealing technologies are commonly used to seal the packaging laminates. Etching and inkjet printing provide product information directly onto the packaging materials. Sterilization is a crucial step to kill all microorganisms and spores. Common sterilization methods are gamma irradiation, E-beam and steam sterilization. Automated packaging lines with aseptic isolation zones and strict control over materials and processes ensure product and personnel protection during packaging operations. Final product testing and validation ensure the packaged products maintain predefined shelf life and performance standards under normal distribution and storage conditions.

Design of Medical Implant Packages

The design of medical implant packages focuses on protecting the sterility and functional integrity of the packaged product from point of sterilization to surgery. Different packaging configurations are used based on the nature of implant - for eg. folded peel pouches for sheets/meshes and rigid trays or thermoformed clamshells for orthopedic implants. Peel pouches made of laminated nonwoven-film provide easy access while maintaining sterility. Rigid trays have wells or cavities to hold prosthetics securely in place. Lid stock made of paper or plastic seals the tray. Blister packs using PVC or Tyvek backing incorporated with lidding film are used for small medical devices and implants.

Tamper evident seals and security seals ensure package integrity from manufacture to use. Perforation or score lines in lidding film allow for easy but controlled peeling open. Complex contours and narrow flanges in thermoformed packaging facilitate proper placement of irregularly shaped implants. Special features like tethers prevent loss of small components during opening. Process challenge devices inside final packages validate the sterilization process. Printed indicators reveal if package was subject to deleterious conditions during shelf life or transportation. Detailed protocols are established for package design testing, design validation and review.

Sterilization and Shelf Life

Gamma irradiation from radioactive cobalt-60 isotope is the most widely used method for sterilizing loaded medical implant sterile packaging as it penetrates deep and guarantees sterilization. E-beam irradiation uses high energy electron beam for better penetration compared to gamma but requires special shielding. Steam sterilization at elevated temperature and pressure destroys bacteria and spores on package surfaces. The packaging materials and seal integrity are tested to withstand defined sterilization protocols without deterioration.

Sterilized packages are assigned expiration dating based on extensive real time and accelerated aging studies under controlled warehouse conditions. This established shelf life could be 2-3 years under recommended storage of 15-30°C and <60% relative humidity as per AAMI/ISO 11607 standards. Periodic shelf life extension programs involve further testing packages pulled from distribution to validate if shelf life can be safely extended based on package condition. Proper distribution and warehousing under standardized conditions are key to maintain product safety and efficacy till expiry date.

Quality and Regulatory Compliance

Medical implant sterile packaging operations are conducted under strictly controlled environments with ISO classified clean rooms. Robust quality systems adhering to ISO 13485 and applicable medical device directives ensure consistent production. Automated packaging lines with in-built monitoring and sensors help achieve reproducible results. Periodic preventive maintenance and calibration exercises maintain equipment quality.

Comprehensive design controls and review processes validate package functionality as per design inputs. Sterilization validation involves biological indicators to prove sterilizing dose and cycle. Shelf life studies statistically establish expiration periods. Package testing includes barrier properties, strength, extractable and particulate contamination testing. Sterilization and packaging processes are periodically re-qualified. Distribution simulation involves package testing after transit shock and vibration. Strict document controls ensure batch traceability. Regular audits and regulatory inspections help maintain high quality and compliance standards. This focus on quality ultimately ensures patient safety with effective and reliable medical implant sterile packaging.

Conclusion

With increasing sophistication of medical implant technology, sterile packaging plays a more crucial role in maintaining the efficacy and shelf life of these lifesaving products. Package designs must address complex implant geometries while guaranteeing sterility. Choosing right materials becomes even more important with new generation of biocompat

0 notes

Text

Applications of Hot Melt Technology

Hot melt technology is widely used in different industrial and manufacturing procedures. It can provide extreme adhesive power in assembling parts and sealing packages. Here are the different applications of hot melt technology:

1. Packaging - In packaging, the adhesive should not be that strong because it will be removed upon getting the product out of the package. You do not want to have the product sealed forever inside the box (or whatever container is used). However, the adhesive should be strong enough to keep the product inside the package in a perfectly safe and dry condition (especially if it is food).

There are specially designed industrial hot melt equipment for packaging. These equipments can be used for carton sealing, bag sealing, case sealing, tamper-proof closures, box making, tray making, etc.

2. Nonwovens - The use of nonwoven fabrics in clothing and other furnishings are widely embraced because of their strength and resilience. The hot melt technology has a part in achieving those properties of nonwoven fabrics.

Nonwovens are fabrics that are not knitted or woven. The fibers used in nonwoven fabrics are bonded with the application of heat and pressure. There are special resins, called binders, which are used in holding the fibers together.

The most common fibers used in making nonwovens are cotton, rayon, polyester, wool, acetate and acrylic.

Some binders used in Two component nonwoven fabric are acrylic, vinyl acrylic, vinyl acetate and styrenated acrylics.

3. Appliance assembly - Hot melt technology is starting to get the attention of appliance manufacturers because of its low cost without the strength getting compromised.

Specialized industrial equipment dispenses molten thermoplastic resins that are used as adhesives in assembling an appliance. The strength of the adhesive will be achieved upon the cooling of the pliable resin. This is a great time saver for manufacturers because it reduces the clamping time.

4. School projects, arts and crafts - This is the most basic application of this technology is the traditional consumer glue gun. It is the simplest adhesive dispenser that is readily available in households and schools.

The traditional adhesive used is the glue stick which may be cleared or colored. There are also novelty glue sticks like glittered sticks and glow-in-the-dark that are made specifically for artworks.

If it is the most basic, why do we have to mention it? For all we know, advanced technology always originates from the traditional practice. The traditional adhesive used (aside from glue stick, there are other thermoplastic resins that are traditionally used) are subjected to limitations. They tend to melt at high temperature and become brittle in low temperature; thus, losing the strength of the bond.

To address the temperature sensitivity of traditional adhesives, advanced adhesives are developed. Companies like Nordson also built high performance hot melt equipment for a better application of these adhesives.

see more: https://hkamber.com/

1 note

·

View note

Text

What Is The Material Of Disposable Surgical Gown ?

https://www.disposablesgowns.com/disposables-gowns-surgical-isolation.htmlDisposable surgical gowns are used by medical staff for invasive treatment of patients in specialized operating rooms and require strict sterilization. For contaminated blood, body fluids and other infectious substances, wearing disposable surgical gowns can serve as two-way isolation between medical staff and patients.

SMS non-woven fabric

The material of disposable surgical gown is SMS non-woven fabric, the common colors are blue and green, and the material weight is generally between 30gsm and 60gsm. SMS non-woven fabric is different from ordinary spunbond non-woven fabric. It is a composite non-woven fabric, which is a composite of Spunbond + Meltblown + Spunbond Nonwovens. Because the middle meltblown layer has the properties of bacteria barrier and liquid penetration resistance, SMS non-woven fabric has the advantages of high strength, good filtering performance, no adhesive, non-toxic, and breathable. Through special treatment of equipment, SMS non-woven fabric The cloth can also achieve the properties of three antibodies (antistatic, anti-alcohol, anti-plasma), water repellency, etc., and is widely used to make medical disposable surgical gowns, protective clothing, surgical drapes, medical wraps, and medical bed sheets.

In order to strengthen the bacterial barrier effect, SMS can also be upgraded to SMMS or SMS. The double-layer or triple-layer meltblown composite non-woven fabric greatly improves the material’s bacterial filtration and liquid barrier properties and is often used to make high-level protection requirements, like three resistance surgical gowns.

Is SMMMS better than SMS?

Some products in the market are described as having multiple layers of melt-blown layers between the spunbond materials. Though this sounds good, it is not possible to differentiate between the different meltblown layers in the finished product as they end up combining together.

What is more important to consider is the thickness of the melt-blown layers. A gown with 5 layers of 0.2 grams of meltblown will have the same effectiveness when compared with another gown with a single 1 gram melt-blown layer. It is, therefore, best to judge the gown’s integrity and quality by the weight of its fabric.

Polyethylene

Polyethylene is a very useful plastic and is used as a fiber to make such items as medical gowns. Polyethylene is a lightweight, durable thermoplastic with a variable crystalline structure (Omnexus, 2021). and is made from the polymerization of ethylene (or ethene) monomer. Low-Density Polyethylene (LDPE) is a very flexible material with unique flow properties that makes it particularly suitable for gowns and other plastic film applications. LDPE has high ductility but low tensile strength, which is evident in the real world by its propensity to stretch when strained.

If you want to know more about the material of disposable medical gowns, you can contact us at SIGNO, we are a professional manufacturer of disposable medical gowns and are committed to producing high-quality disposable medical gowns for our customers. Feel free to take the initiative to contact us.

0 notes

Text

Wide Range of Woven Products for Different Industrial Applications

The advanced machinery and state of the art manufacturing facilities available at Mayur Wovens, enables us to manufacture and supply a variety of products catering to a plethora of industries.

The products are:

Flexible Intermediate Bulk Containers: The Flexible Intermediate Bulk Containers, also known as FIBC or Bulk Bags, are designed to reduce the overall costs incurred while shipping, maximize the storage space, eliminate spillage and improve flow control. FIBC have a very low packaging weight making it safe to use and are available in various forms. We also provide custom bulk bags by taking into consideration a couple of factors such as- filling and discharging conditions, the hydroscopic properties and the density of the product being packaged. The big bags have a capacity of up to 3 cubic meters and capable of supporting several tons in weight.

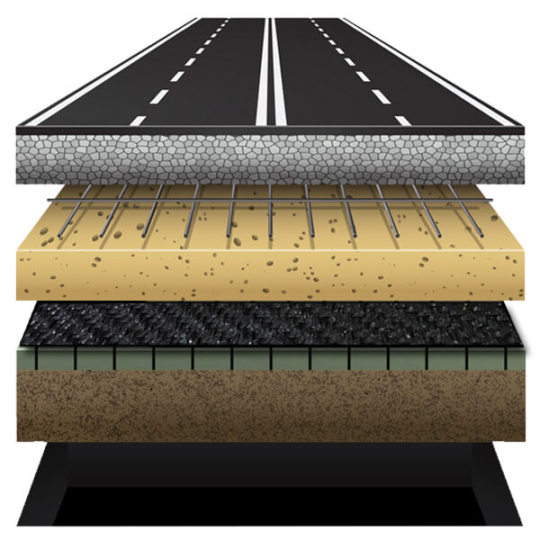

Geotextile l Ground Covers: Geotextile or ground covers are produced using high-quality polypropylene fibers, supplied in our manufacturing facilities, ensuring the dimensional stability of the strong fibers and making it resistant to damage. We manufacture a wide array of geotextile fibers using varied polymers making them useful for numerous civil construction applications. They are widely used for filtration and separation in road constructions, to prevent migration and mingling of materials, yet allowing free movement of water. Our Geotextile fabrics are porous in nature and hence when used in association with soil, possess the ability to separate, filter, reinforce, protect, or drain.

Synthetic Roof Underlayment: Our Synthetic Roof Underlayment is designed keeping in mind with the technological advancements which are lightweight & designed as an alternative to asphalt saturated felt. It has a single underlayment sheet which features a woven polymeric scrim for increased strength and reduced slippage between the underlayment and roof sheathing. The Synthetic underlayment provides a secondary weather barrier to help fortify roofs from wind-driven rain or simple exposure to the elements.

Tarps & Covers l Lumber Covers: We offer tarps & covers to safeguard the valuable machinery, goods and buildings. Custom Tarps are also supplied, required to fit boxes, cubes or cylinders. The grommets and webbing to the can also be applied to the tarpaulins for trucking, pallets or other industrial applications. They are also used for various other applications such as shelter from the elements, i.e., wind, rain, or sunlight, protect brickwork and masonry from weather damage. We also supply tarps of various different materials, colors, and size for diverge applications allowing consumers to make a wide selection.

Sewing Yarns & Threads: Sewing Yarns are produced by twisting together relatively short fibers or fine continuous filaments. It is very important to have a thorough knowledge of yarn and thread as even the smallest of the failure can result in losses on investments in material, equipment, engineering, and labor. Our sewing threads are intricately designed and then designed making sure that it passes through a sewing machine rapidly and forms efficient stitches without breaking or becoming distorted during the useful life of the product.

Apart from these products, we also manufacture and supply customized products for specific applications such as- VCI-Volatile Corrosion Inhibitor, Zero Shrink, Aluminum Coating, Adhesive Tapes, Insulation Backing, Leno Weave Fabrics, and Spunbond Fabric. With over 47 years of industrial experience, Mayur Wovens are considered as one of the leading companies when it comes to Woven PP/PE Manufacturers and we intend to continue to do so by providing quality products and services fulfilling every little requirement which is expected from us.

0 notes

Text

Disposable Surgical Dressing Kits Market Evolving Technology, Trends and Industry Analysis 2025

11 January 2019 - Global Disposable Surgical Dressing Kits Market is expected to grow at a higher CAGR in the forecast period. Healthcare workers engaged in treating and caring for injured patients as well as sick patients can be exposed to biological aerosols that transmit contagious diseases. These diseases may cause a variety of microorganisms that can pose a significant risk to patient’s life. Surgical dressingkits are thus used to offer heal and care by healthcare professionals and nurses to reduce the contamination level in the operation room. Also, the surgical dressing kits encompass various items such as dressing packs, ice packs, dressing tray, dressing forceps, waterproof dressing towel etc are used.

Surgical kits are produced by using fabric forming technology and the typical material being polypropylene made using spunbond technology. Commercially, there is an increase in the demand for polymeric nanofibers used for various applications that include tissue engineering, filtration, sensors and protective clothing. Nanofibers have a large surface area to volume ratio that makes them suitable to manufacture filtration products and particularly for medical textile products. The high degree of filtration efficiency of surgical face masks depends on the manufacturing methods, shape of the fibre and change. Disposable surgical dressing kits market is driven by factors such as rise in medical infrastructure need for hygienefor patients and medical professionals.

View Full Report with TOC @ https://www.millioninsights.com/industry-reports/disposable-surgical-dressing-kits-market

Geographically, the disposable surgical dressing kits market spans North America, Latin America, Europe, Middle-East and Africa. North America dominates the global market in the predicted period owing to rise in medical infrastructure and growth in medical tourism. Also, the rise in number of patients suffering from various disease is likely to add to the market growth.The global key players in the disposable surgical dressing kits market include 3M, Johnson & Johnson, Medtronic, Dynarex, Smith & Nephew, BDF, Hartmann, Kawamoto, Medline, Chengdu Weicai, Derma Sciences, Shifeng, HuaBang, Kaiwei, Beijing Sunny Medical and Kangyu.

Market Segment:

Geographically, this report is segmented into several key Regions, with production, consumption, revenue (million USD), market share and growth rate of Disposable Surgical Dressing Kits in these regions, from 2013 to 2025 (forecast), covering

• North America

• Europe

• China

• Japan

• Southeast Asia

• India

Global Disposable Surgical Dressing Kits market competition by top manufacturers, with production, price, revenue (value) and market share for each manufacturer; the top players including

• Johnson & Johnson

• 3M

• Medtronic

• Dynarex

• Smith & Nephew

• BDF

• Hartmann

• Kawamoto

• Medline

• Derma Sciences

• Chengdu Weicai

Request Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/disposable-surgical-dressing-kits-market/request-sample

#Disposable Surgical Dressing Kits Market Report#Disposable Surgical Dressing Kits Market Share#Disposable Surgical Dressing Kits Market Growth#Disposable Surgical Dressing Kits Industry

0 notes

Text

Polypropylene (PP) Absorbent Hygiene Market - ‘Safe’ly Surging Ahead

If someone asks us about the characteristics and usages of polypropylene in daily lives, we would be stumped; and would find ourselves googling the term and usages, later. However, I can bet that what we find on Google will be more shocking to us. It is one of the essential materials which are used for self hygiene and safety by us, but we still know so less about it.

Polypropylene, Its Properties & Market Nuances

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefin and is partially crystalline and non-polar.

In short, it is a very useful type of plastic with numerous commercial, industrial, and fashion applications. Due to its properties, it has gained demand from hygiene and healthcare sector, along with several others, so much so that, the Global Polypropylene Market was valued over USD 9.00 billion in 2014.

Some of its properties which make it highly useful are -

· It is very resilient to wear, tear, and fatigue: this makes it perfect for items that endure high levels of physical stress.

· It is resilient to mold, rot, bacteria, and more - which means we can use it for extended periods in indoor and outdoor environments without risking damage.

· It is lightweight and flexible - meaning we can tailor it upon our wishes and needs

· It comes with the smallest environmental impact among all plastic types; we can recycle polypropylene items and parts into many applications (cases, cans, home storage, flowerpots, pallets, crates, composite lumber etc.); it produces less solid waste by weight and less CO2 equivalents by weight than PET, PS or PVC.

These properties of polypropylene make it very apt to be used in the hygiene products. Polypropylene as a hygiene and safety product is used in baby diapers, female hygiene products and adult incontinence products.

In the above diagram, baby diapers accounted for 36.1% of the global polypropylene absorbent hygiene market in 2014 followed by female hygiene products. Owing to less cost, softness and recent technological breakthrough, these products are expected to contribute increased market revenue for the manufacturers present in the industry.

In-depth report on global polypropylene (PP) absorbent hygiene market by Grand View Research:

https://www.grandviewresearch.com/industry-analysis/polypropylene-pp-absorbent-hygiene-market

Regional Insights

Asia Pacific region is leading the growth of the market with market share above 35%. Countries like India, Malaysia, Indonesia and Pakistan among others is experiencing increasing birth rates along with a predominant shift in lifestyle towards modern one. These factors along with growing per capita income is boosting the demand for hygiene products, leading to spurt in the demand for Polypropylene absorbents in the market.

Europe region has also looking at the surge in the demands due to ageing population needing adult care, which revolves around the adult incontinence and wipes products. Along with this female hygiene products are also experiencing a shot in the arm due to increasing preference for female sanitization in the general public. Female sanitization products are expected to grow at a significant pace in Europe, at a CAGR of 6.9%, till 2022.

Aggressive Competition

Handful of industry participants are dominating the global market which is intensely competed. The companies are Jofo, Polymers Group Inc., Global Nonwovens, Gulsan Holding, CNC International Co., Ltd, Mada, Pegas Nonwovens, Fibertex, Mitsui, Kimberly-Clark, SAAFś, Shandong Kangjie Nonwovens and Freudenberg.

Although the international players are strongly established in the regions, they face strong competition from the local, unorganized and regional players for the larger market share.

To request Research report sample copy with TOC please visit @: https://www.grandviewresearch.com/industry-analysis/polypropylene-pp-absorbent-hygiene-market/request/rs1

Recent Developments

· Sabic, a Dutch firm, have developed a new, ultra-high, melt flow polypropylene for lightweight breathable nonwoven fabrics for personal hygiene applications. Named as PP 514M12, this new product can serve a wide range of potential end-uses in personal hygiene applications. It is the first grade of a new family of high-flow resin compounds.

· R2G, a family office based in Prague, Czech Republic which owns majority interest in PEGAS NONWOVENS A.S., and First Quality Enterprises, Inc., announced that the two companies have entered into a definitive agreement under which R2G will acquire 100% of First Quality’s nonwovens operations in the United States and China. This is bound to increase the global reach of the R2G group in the world.

· Fitesa has acquired 51% of spunbond nonwovens maker CNC International. The Rayong, Thailand-based Company largely serves the Southeast Asian markets. It will have its name changed to FitesaCNC. The joint-venture will focus on the hygiene market - in line with the rest of the Fitesa business.

This post was originally published @: https://www.grandviewresearch.com/blog/polypropylene-pp-absorbent-hygiene-market-size-share

0 notes

Text

Polypropylene (PP) Nonwoven Fabrics Market - Brief Approach to Research 2017-2025

Global Polypropylene (PP) Nonwoven Fabrics Market: Overview

There are a host of technologies involved in the processing of polypropylene (PP), viz. meltdown, spunbond, composite, and staple, as a key feedstock. It is after the polymerization of propylene that the basic petrochemical polypropylene is derived. Owing to their faster speed belts bearing a low cost, impressive durability, and soft nature, spunbonded PP nonwoven fabrics are prognosticated to register a higher selling rate. The worldwide PP nonwoven fabrics market is expected to grow stronger with greater advantages such as decreased wastage, distribution, and overall costs, achieved by spunbonded stacks.

Global Polypropylene (PP) Nonwoven Fabrics Market: Key Trends

Appropriate for the delicate skin of infants, PP nonwoven fabrics used for the manufacture of baby diapers flaunt critical performance metrics, which are envisaged to shoot up their application scope. Besides this, the material is projected to win an inflating significance and acceptance with regard to its superior quality and other commanding properties. The size of the world PP nonwoven fabrics market could be boosted further due to a wide application scope also in adult incontinence diapers.

Request Sample Copy of the Report @

https://www.tmrresearch.com/sample/sample?flag=B&rep_id=1568

The durable applications of PP nonwoven fabrics in the automotive and agricultural sectors are envisioned to fuel the demand with an optimistic outlook. The increase in life expectancy and rising healthcare concerns involving the Crohn’s disease and inflammatory bowel are predicted to increase the number of applications in the global PP nonwoven fabrics market.

Global Polypropylene (PP) Nonwoven Fabrics Market: Market Potential

It has already been researched that PP nonwoven fabrics could gain a magisterial traction over similar products having a wide range of applications in the medical instruments sector. However, the efficient usage of PP nonwoven fabrics as a recyclable healthcare material is still under wraps. In a business relation between Goodwill Southern California and Kaiser Permanente, the recyclability of PP nonwoven plastic, called as ‘blue wrap,’ used for swathing surgical apparatus for the purpose of sterilization has prominently come to notice.

Request TOC of the Report @

https://www.tmrresearch.com/sample/sample?flag=T&rep_id=1568

As part of its zero waste approach toward the management of non-hazardous waste materials, Kaiser founded Goodwill as just the right partner for reprocessing its 20 tons per year of blue wrap material generated. The recycling of blue wrap can make available pellets which find usage in carpets, plastic lumber, flowerpots, lawn furniture, wash buckets, and various other products.

Global Polypropylene (PP) Nonwoven Fabrics Market: Regional Outlook

The hygiene product classification is expected to bring in a good business for the Europe PP nonwoven fabrics market, considering the high expansion of capacity, during the forecast period. In terms of the consumption rate recorded in Europe, Germany is foretold to outshine other nations by 2024. The growth in Europe could further escalate on the back of technology upgradation witnessed in full swing in order to comply with regulatory directives.

The regional industry growth in China is anticipated to gain impetus as the country rides on the swelling disposable income of consumers and rich purchase of baby diapers, sanitary pads, and other hygiene products. As the forecast period concludes, China is foreseen to rake in a handsome revenue. Companies such as Hubei Gold (AVGOL), Toray Nantong, and PGI Suzhou have already planned to invest in business expansion in China.

Read Comprehensive Overview of Report @

https://www.tmrresearch.com/polypropylene-nonwoven-fabrics-market.html

However, the pick of the regional markets for PP nonwoven fabrics is the U.S. The country is predicted to strengthen its demand with a rising number of enduring applications such as automotive, geotextiles, and construction. Other factors including the elevating manufacture of hygiene products and increasing base of geriatric population are projected to raise the bar for growth in the U.S.

Global Polypropylene (PP) Nonwoven Fabrics Market: Competitive Landscape

PEGAS, ExxonMobil, Fitesa, SABIC, Mitsui, Toray, Fibetex, AVGOI, Kimberly Clark, and First Quality are some of the popular names in the world PP nonwoven fabrics market. Although the top four companies are prophesied to account for a decent aggregate share, the global market is anticipated to stay moderately fragmented. Howbeit, the trend of acquiring other players for expanding regional presence and product portfolio could make the market consolidated.

About TMR Research

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research,

3739 Balboa St # 1097,

San Francisco, CA 94121

United States

Tel: +1-415-520-1050

Email: [email protected]

0 notes

Text

Polypropylene (PP) Nonwoven Fabrics Market - Competition & Challenges Assessment 2025

Global Polypropylene (PP) Nonwoven Fabrics Market: Overview

There are a host of technologies involved in the processing of polypropylene (PP), viz. meltdown, spunbond, composite, and staple, as a key feedstock. It is after the polymerization of propylene that the basic petrochemical polypropylene is derived. Owing to their faster speed belts bearing a low cost, impressive durability, and soft nature, spunbonded PP nonwoven fabrics are prognosticated to register a higher selling rate. The worldwide PP nonwoven fabrics market is expected to grow stronger with greater advantages such as decreased wastage, distribution, and overall costs, achieved by spunbonded stacks.

Request Sample Copy of the Report @

https://www.tmrresearch.com/sample/sample?flag=B&rep_id=1568

Global Polypropylene (PP) Nonwoven Fabrics Market: Key Trends

Appropriate for the delicate skin of infants, PP nonwoven fabrics used for the manufacture of baby diapers flaunt critical performance metrics, which are envisaged to shoot up their application scope. Besides this, the material is projected to win an inflating significance and acceptance with regard to its superior quality and other commanding properties. The size of the world PP nonwoven fabrics market could be boosted further due to a wide application scope also in adult incontinence diapers.

The durable applications of PP nonwoven fabrics in the automotive and agricultural sectors are envisioned to fuel the demand with an optimistic outlook. The increase in life expectancy and rising healthcare concerns involving the Crohn’s disease and inflammatory bowel are predicted to increase the number of applications in the global PP nonwoven fabrics market.

Global Polypropylene (PP) Nonwoven Fabrics Market: Market Potential

It has already been researched that PP nonwoven fabrics could gain a magisterial traction over similar products having a wide range of applications in the medical instruments sector. However, the efficient usage of PP nonwoven fabrics as a recyclable healthcare material is still under wraps. In a business relation between Goodwill Southern California and Kaiser Permanente, the recyclability of PP nonwoven plastic, called as ‘blue wrap,’ used for swathing surgical apparatus for the purpose of sterilization has prominently come to notice.

Request TOC of the Report @

https://www.tmrresearch.com/sample/sample?flag=T&rep_id=1568

As part of its zero waste approach toward the management of non-hazardous waste materials, Kaiser founded Goodwill as just the right partner for reprocessing its 20 tons per year of blue wrap material generated. The recycling of blue wrap can make available pellets which find usage in carpets, plastic lumber, flowerpots, lawn furniture, wash buckets, and various other products.

Global Polypropylene (PP) Nonwoven Fabrics Market: Regional Outlook

The hygiene product classification is expected to bring in a good business for the Europe PP nonwoven fabrics market, considering the high expansion of capacity, during the forecast period. In terms of the consumption rate recorded in Europe, Germany is foretold to outshine other nations by 2024. The growth in Europe could further escalate on the back of technology upgradation witnessed in full swing in order to comply with regulatory directives.

The regional industry growth in China is anticipated to gain impetus as the country rides on the swelling disposable income of consumers and rich purchase of baby diapers, sanitary pads, and other hygiene products. As the forecast period concludes, China is foreseen to rake in a handsome revenue. Companies such as Hubei Gold (AVGOL), Toray Nantong, and PGI Suzhou have already planned to invest in business expansion in China.

However, the pick of the regional markets for PP nonwoven fabrics is the U.S. The country is predicted to strengthen its demand with a rising number of enduring applications such as automotive, geotextiles, and construction. Other factors including the elevating manufacture of hygiene products and increasing base of geriatric population are projected to raise the bar for growth in the U.S.

Read Comprehensive Overview of Report @

https://www.tmrresearch.com/polypropylene-nonwoven-fabrics-market.html

Global Polypropylene (PP) Nonwoven Fabrics Market: Competitive Landscape

PEGAS, ExxonMobil, Fitesa, SABIC, Mitsui, Toray, Fibetex, AVGOI, Kimberly Clark, and First Quality are some of the popular names in the world PP nonwoven fabrics market. Although the top four companies are prophesied to account for a decent aggregate share, the global market is anticipated to stay moderately fragmented. Howbeit, the trend of acquiring other players for expanding regional presence and product portfolio could make the market consolidated.

About TMR Research

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research,

3739 Balboa St # 1097,

San Francisco, CA 94121

United States

Tel: +1-415-520-1050

Email: [email protected]

0 notes