#Polyethylene

Explore tagged Tumblr posts

Text

A fungus living in the sea can break down the plastic polyethylene, provided it has first been exposed to UV radiation from sunlight. Researchers from, among others, NIOZ published their results in the scientific journal Science of the Total Environment. They expect that many more plastic degrading fungi are living in deeper parts of the ocean. The fungus Parengyodontium album lives together with other marine microbes in thin layers on plastic litter in the ocean. Marine microbiologists from the Royal Netherlands Institute for Sea Research (NIOZ) discovered that the fungus is capable of breaking down particles of the plastic polyethylene (PE), the most abundant of all plastics that have ended up in the ocean. The NIOZ researchers cooperated with colleagues from Utrecht University, the Ocean Cleanup Foundation and research institutes in Paris, Copenhagen and St Gallen, Switzerland. The finding allows the fungus to join a very short list of plastic-degrading marine fungi: only four species have been found to date. A larger number of bacteria was already known to be able to degrade plastic.

Read more.

39 notes

·

View notes

Text

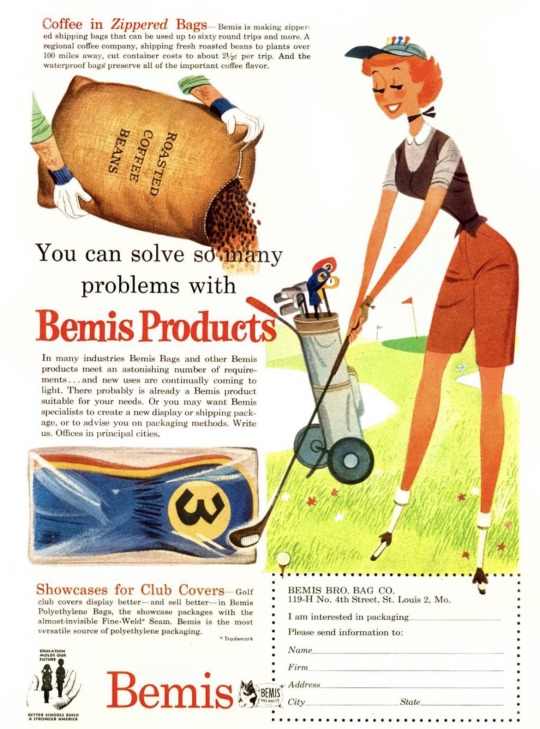

1955 Bemis Bags and Products

#1955#bemis#poly#bag#golf#sales#polyethylene#plastic#vintage illustration#vintageadsmakemehappy#vintage magazine#vintage advertising#magazine#advertising#1950s#50s

65 notes

·

View notes

Text

Plastic degradation by marine bacteria

“Plastic waste pollution on Singapore beach.” - via Wikimedia Commons

#this is what i’m studying for my undergraduate capstone so it’s very much on the brain for me rn#microbiology#plastic remediation#bioremediation#wikipedia#wikipedia pictures#nature#plastic pollution#pollution#environmentalism#environmental science#wikimedia commons#bacteriology#bacteria#marine bacteria#marine pollution#ocean pollution#ocean plastic#science#polyethylene#polypropylene#polyethylene terephthalate#pe#pp#pet#biofilm

17 notes

·

View notes

Text

It’s Saran for smart outdoor furniture. Ad for Dow Chemical Company’s plastics - 1956.

#vintage advertising#chemistry#plastic#plastics#dow chemical company#dow chemical#dow#saran#polyethylene#vintage illustration

5 notes

·

View notes

Text

Goodnight, I'm heading back to my 𝖕𝖔𝖑𝖞𝖊𝖙𝖍𝖞𝖑𝖊𝖓𝖊 𝖌𝖗𝖎𝖊𝖋 𝖈𝖆𝖛𝖊

Get this on a sticker and more on redbubble

2 notes

·

View notes

Text

High-Density Polyethylene Sheet

High-Density Polyethylene (HDPE) Sheets are known for their remarkable strength and chemical resistance. They are made from a flexible, long-lasting plastic resin. These sheets are used in many different industries, such as packaging, construction, agriculture manufacturing, outdoor furniture, playground equipment and more. Discover the lightweight nature of HDPE sheets that doesn't compromise on durability, making them an ideal choice for various projects. With a smooth surface and excellent impact resistance, HDPE sheets offer a reliable solution for both indoor and outdoor applications.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#hdpesheet#hdpesheetmanufacturer#hdpesheetsupplier#pp#polypropylene#plasticsheet#plastic#polyethylene#sheets#sheetmanufacturer#ecommerce#marketing#artwork#ppbag#branding#sales#commercial

1 note

·

View note

Text

Ultra-High Molecular Weight Polyethylene (UHMWPE) Market: Riding the Wave of Durability and Performance

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a remarkable engineering plastic renowned for its exceptional properties, including outstanding abrasion and wear resistance, high impact strength, low coefficient of friction, and excellent chemical resistance. These attributes have propelled UHMWPE into a diverse range of applications across various industries, establishing a robust and growing global market. This blog delves into the current state of the UHMWPE market, highlighting key trends, driving factors, challenges, and future outlook.

Market Size and Growth Dynamics:

The Ultra-High Molecular Weight Polyethylene Market is expected to register a CAGR of 10.2% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

Key Driving Factors:

Several factors are contributing to the expansion of the UHMWPE market:

Growing Demand in Material Handling: The material handling industry is a significant consumer of UHMWPE. Its low coefficient of friction and excellent abrasion resistance make it ideal for conveyor belts, chain guides, and wear strips, enhancing efficiency and reducing downtime in various industrial processes, including manufacturing, logistics, and mining.

Rising Adoption in Healthcare: UHMWPE plays a crucial role in the healthcare sector, particularly in orthopedic implants such as hip and knee replacements. Its biocompatibility, wear resistance, and ability to withstand high loads make it a preferred material for these critical applications, driven by an aging global population and increasing demand for joint replacement surgeries.

Expansion in the Automotive Industry: UHMWPE is finding increasing applications in the automotive sector due to its lightweight nature, impact resistance, and noise dampening properties. It is used in components such as skid plates, bushings, and wear pads, contributing to improved vehicle performance and durability.

Increasing Use in Recreational Activities: The unique properties of UHMWPE make it suitable for various recreational applications, including skis, snowboards, and boat hulls. Its durability and low friction enhance performance and longevity in these demanding environments.

Stringent Environmental Regulations: UHMWPE's long lifespan and recyclability align with growing environmental concerns and stricter regulations, making it an attractive alternative to materials with shorter lifecycles and higher environmental impact.

Segments Covered

By Product Type

Sheet

Rods and Tubes

Fiber

Film

By End-Use Industry

Building and Construction

Automotive

Marine

Oil and Gas

Mining

Food and Beverage

Healthcare

Market leaders and key company profiles

Asahi Kasei Corporation

Braskem S.A.

Celanese Corporation

E. I. Du Pont De Nemours and Company

Honeywell International Inc.

Koninklijke DSM N.V.

Lyondellbasell Industries N.V.

Mitsui Chemicals, Inc.

Saudi Basic Industries Corporation

Challenges and Opportunities:

Despite the positive outlook, the UHMWPE market faces certain challenges:

High Raw Material Costs: Fluctuations in the prices of raw materials, primarily ethylene, can impact the production cost of UHMWPE and potentially affect market growth.

Processing Difficulties: UHMWPE's high viscosity and melt flow index make it challenging to process using conventional techniques, requiring specialized equipment and expertise.

However, the market also presents significant opportunities:

Development of New Applications: Ongoing research and development efforts are focused on exploring new applications for UHMWPE in emerging sectors, such as renewable energy and marine engineering.

Increasing Demand for High-Performance Materials: The growing demand for materials with superior performance characteristics across various industries will continue to drive the adoption of UHMWPE.

Focus on Sustainable Solutions: UHMWPE's durability and potential for recycling align with the increasing global focus on sustainability, creating opportunities for its wider adoption as an environmentally friendly alternative.

Future Outlook:

The future of the UHMWPE market looks promising. Driven by its exceptional properties and expanding applications across diverse industries, the market is poised for continued growth. Technological advancements in processing techniques and the development of new UHMWPE grades with enhanced properties will further fuel market expansion. The increasing focus on sustainability and the demand for high-performance materials will solidify UHMWPE's position as a crucial engineering plastic in the years to come. As industries continue to seek durable, low-friction, and high-performance solutions, the UHMWPE market is expected to thrive, offering significant opportunities for stakeholders across the value chain.

0 notes

Text

https://mahashaktitarpaulins.com/hdpe-tarpaulins/826591276

HDPE Tarpaulin Manufacturer in Guwahati | Industrial Tarpaulin Manufacturer in Eastern India- MAHASHAKTI

Looking for a reliable Industrial Tarpaulin Manufacturer in Eastern India? Mahashakti Narayani Polytex LLP specializes in premium HDPE Tarpaulin Manufacturer in Guwahati, Bihar, and HDPE tarpaulin supplier in Odisha, offering top-quality products at competitive prices.

#HDPETarpaulinManufacturerinIndia#IndustrialTarpaulinManufacturerinEasternIndia#WovenpolythyleneTarpaulinManufacturer#HDPETarpaulinManufacturerinOdisha#HDPETarpaulinsupplierinBihar#HDPEtarpaulinsupplierinOdisha#HDPE Tarpaulin Manufacturer in India#Industrial Tarpaulin Manufacturer in Eastern India#Woven polythylene Tarpaulin Manufacturer#HDPE Tarpaulin Manufacturer in Odisha#HDPE Tarpaulin supplier in Bihar#HDPE tarpaulin supplier in Odisha#HDPE#Tarpaulin#Manufacturer#inIndia#Industrial#Manufacturer inEasternIndia#Woven#polyethylene#inOdisha#supplier#inBihar#tarpaulin#WovenpolyethyleneTarpaulinManufacturer

0 notes

Link

1 note

·

View note

Text

Polyethylene Recycling

Polyethylene - either in the form of high density polyethylene (HDPE), low density polyethylene (LDPE), or another - is considered to be the mostly widely used plastic in the world. It is used to make plastic bags, food containers, cutting boards, etc. However, rates of plastic recycling as a whole are considered relatively low compared to other materials like paper or some metals and polyethylene is no exception to this. This is partially because most plastics, polyethylene included, cannot be infinitely recycled in the way of most metals. Recycling of polyethylene typically results in a decrease in strength of the resulting product, especially after repeated recycling.

Sources/Further Reading: (Image source - 2023 article) (AZO) (Beyond Plastics) (Wikipedia)

27 notes

·

View notes

Text

Michelmersh, Elite Plastics and Braskem I'm green bio-based partner to reduce Carbon Footprint in the construction industry

Michelmersh, UK’s premium producer of clay bricks, is an industry leader in sustainability and innovation, renowned for quality clay products and bespoke services is proud to announce a groundbreaking partnership with Braskem I’m greenTM bio-based, a global pioneer in sustainable bio-based renewable materials. This collaboration was enabled by Elite Plastics, the UK’s leading manufacturer of…

View On WordPress

#Braskem#construction industry#Elite Plastics#I’m Green Bio-based#Michelmersh#polyethylene#renewable materials

0 notes

Text

Polyolefin Resins: A Look at Their Wide Range of Uses

Polyolefins are a class of polymers formed from the polymerization of olefins such as ethylene and propylene. These polymers include polyethylene, polypropylene, and other polymers made from alkenes. Polyolefins exhibit many useful properties that have enabled their widespread use in a variety of industries and applications.

Chemical Structure and Properties

Polyolefins are hydrocarbon polymers, meaning they are composed purely of hydrogen and carbon atoms in long molecular chains. The main difference between polyolefin types is the structure of these repeating molecular units - polyethylene contains an ethane repeating unit (–CH2–CH2–) while polypropylene contains a propene repeating unit (–CH2–CH(CH3)–).

The carbon backbone structure gives Polyolefin Resins their main mechanical properties. The strong covalent carbon-carbon bonds make polyolefins rigid yet flexible and resistant to chemicals and corrosion. The lack of polar chemical groups also means polyolefins are generally non-polar and hydrophobic – this property enables uses where water or moisture resistance is important. Polyolefins also have low densities, ranging from 0.89–0.97 g/cm3 for LDPE and 0.90–0.92 g/cm3 for polypropylene.

Polyethylene

Polyethylene (PE) is produced in various forms depending on process variables used during Polyolefin Resins. Low-density polyethylene (LDPE) resin is lightly branched with densities around 0.915-0.940 g/cm3. LDPE products have good clarity and flexibility ideal for food packaging films, shrink wrap, and trash bags.

Linear low-density polyethylene (LLDPE) has a linear polymer chain structure with short branches, lowering densities to 0.910-0.940 g/cm3. LLDPE resins can be processed at higher rates than LDPE and offer good impact resistance suitable for industrial films and lamination applications.

High-density polyethylene (HDPE) has fewer and shorter branches, making it essentially linear. HDPE has densities in the range of 0.941-0.970 g/cm3, imparting high strength and stiffness properties useful for pipes, bottles, containers, and durable household goods.

Polypropylene

Polypropylene (PP) differs from PE in having a pendant methyl group on every third carbon in its polymer chain. Isotactic polypropylene, the most common type, has these methyl groups oriented on the same side of the polymer backbone. This gives isotactic PP higher melting points than LDPE or HDPE, ranging from 160-171°C depending on composition.

Isotactic PP has a balance of properties making it suitable for a huge diversity of applications. It is rigid yet tough, with high heat distortion temperatures up to 120��C. Common uses include caps and closures, textiles, rope and cord, automotive components, pipes, living hinges, and medical devices and components. Atactic or syndiotactic PP varieties offer varying property profiles.

Uses and Applications

As the most widely produced plastics globally, Polyolefin Resins are highly versatile materials that bring value to many markets:

Packaging - PE and PP resins dominate the packaging industry with their moisture and chemical resistance. They are used extensively for food packaging, shrink and stretch films, bags, bottles, containers and more.

Consumer and Industrial Products - Durables like tools, pails, detergent bottles, cable jacketing, automotive components, car interiors and more capitalize on polyolefin toughness, durability and design freedom. Outdoor furniture, pipe systems, and construction products also use polyolefins extensively.

Medical Devices - The biocompatibility and processing characteristics of medical grade polyolefins support use in devices, components, tubing, gowns, drapes and other single-use applications.

Textiles - Spunbond PE and PP nonwovens are major materials for geotextiles, diapers, wipes and hygiene products, filtration media, and other textile applications. Fiber and filament grades also see use in carpet and apparel fibers.

Polyolefin Resins are amongst humanity's most significant material inventions. The unmatched versatility and balanced mechanical properties of PE and PP, coupled with facile production methods, have enabled polyolefins to permeate nearly every industry and market segment. With global annual production now exceeding 100 million tons, polyolefins will assuredly continue to play an outsized role supporting modern society and economies into the foreseeable future.

Get more insights on Polyolefin Resins

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#PolyolefinResins#Polyethylene#Polypropylene#Thermoplastics#PolymerIndustry#PackagingMaterials#AutomotiveComponents

0 notes

Text

#HDPE#Nonwovens#Tyvek#Polyethylene#PlasticsIndustry#Packaging#ConstructionMaterials#MedicalTextiles#SustainableMaterials#IndustrialFabrics#InnovationInMaterials#EnvironmentalProtection#Manufacturing#TechnicalTextiles#SafetyProducts

0 notes

Text

Poly Tarp | Tarp Supply Inc.® | For All Your Tarp Needs

🔹 Ready to cover, protect, and preserve? Check out Tarp Supply Inc.®'s Poly Tarps! Ideal for construction sites, landscaping, and outdoor adventures. Durable, waterproof, and ready for any challenge. Explore our selection today and find the perfect tarp for your needs! 🔹

📞 Call us at 630-953-4700

#PolyTarps#TarpSupply#ProtectionPerfected#Polyethylene#Poly Tarp#Tarp#Tarps#Tarpaulin#Custom Tarp#Tarp For Sale#Tarp Near Me

0 notes