#polymer resin floor

Explore tagged Tumblr posts

Text

them: star wars: visions is not canon me: u say that about so many things. i do not thing it means what you think it means.

aka: the idea of feudal jedi kingdoms fits perfectly in with the whole jedi lords part of the new sith wars so i'm taking bits of visions and putting them in that part of the timeline. like the ninth jedi (i already threw dekien into chapter 8).

“What’s this one?” I hold up the celadon-hued hilt. Whatever material it’s made from, it doesn’t absorb the heat from my hands like metal does, and I don’t think the protective polymer on the undersides of my hands in place of gloves would stop that process. While our kyber gives our ’sabers a weight that even the least Force-sensitive person can feel, that isn’t the cause here. If the lightsaber was recovered whole, then the crystal that once sat inside it should be floors above the museum, part of the glittering Kyber Arch. “Ahh, yes,” says Huyang. If he breathed, it would be a sigh of delight at what I hold in my hands. “That is one of the Lah family lightsabers.” I turn it over. The lines of gold form an intricate web throughout the cool outer shell of the hilt, creating the effect of lacquerware repaired with gold joinery. “An inherited one?” “The Lah family were famous during the previous millennium for being sabersmiths. The Order has weapon masters and master smiths, but the construction of a Jedi’s lightsaber is an individual task, as you well know.” Huyang tilts his head at me and I fight to keep from ducking my head at the acknowledgement of my own attempt at that task. At my hip, my lightsaber still feels like it’s missing something. “To be able to divine enough of the Force’s intent to know what the housing of a kyber crystal should be, when neither will belong to the maker, is an infinitesimally rare ability. There hasn't been another one since the last centuries of the New Sith Wars, and I doubt we will ever see another. “I believe this one was made by the second of the line, Lah Kara. An exquisite example of her later works, when she began to experiment with unusual materials. She developed several resins for different woods so they could be used as hilts, you know,” he finishes, tapping the side of his head. “I have all her recipes up here.”

2 notes

·

View notes

Text

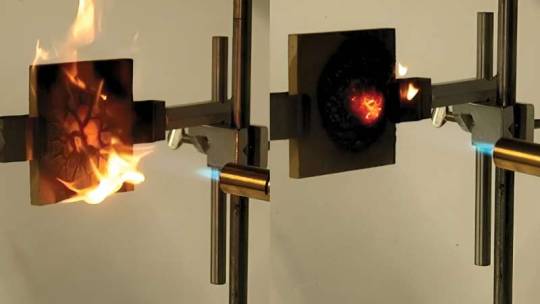

Recycling the non-recyclable: New epoxy resin resists flames and reduces waste

Empa researchers have developed an epoxy resin that can be repaired and recycled, in addition to being flame-retardant and mechanically strong. Potential applications range from coating for wooden flooring to composites in aerospace and railways. Epoxy resins are tough and versatile polymers. In combination with glass or carbon fibers, they are used, for example, to manufacture components for aircraft, cars, trains, ships and wind turbines. Such epoxy-based fiber-reinforced polymers have excellent mechanical and thermal properties and are much lighter than metal. Their weakness: They are not recyclable—at least not yet. Now Empa researchers led by Sabyasachi Gaan at Empa's Advanced Fibers laboratory have developed an epoxy resin-based plastic that is fully recyclable, repairable and also flame retardant—all while retaining the favorable thermomechanical properties of epoxy resins. They have published their findings in the Chemical Engineering Journal.

Read more.

#Materials Science#Science#Recycling#Epoxy#Resins#Flames#Waste#Flame retardants#Polymers#Thermosets#Vitrimers

11 notes

·

View notes

Text

Application of bitumen in building

Bitumen has numerous applications in the construction industry, primarily serving as an adhesive and waterproofing material. Its versatile properties make it indispensable in various building-related functions. Here are some key applications of bitumen in construction:

1. Roofing and Waterproofing:

Bitumen 60/70 is extensively used in roofing systems to provide waterproof membranes for flat roofs. Traditional bitumen roofing membranes consist of layers of bitumen sprayed with aggregate, with a carrier fabric made of polyester or glass in between. Polymer-modified bitumen sheets have become the standard for flat roof waterproofing. Bituminous roofing membranes can also be recycled easily, enhancing their sustainability.

2. Wall Sealing:

Bitumen 60/70 plays a crucial role in sealing walls, providing protection against water and moisture intrusion. It is applied to substrates such as bathrooms and toilets, which are constantly exposed to moisture, to prevent water penetration and safeguard the underlying structures.

3. Floor and Wall Insulation:

Bitumen 80/100 insulation is widely employed for building waterproofing, both horizontally and vertically. It effectively prevents water penetration into floorboards and walls, offering reliable protection. Bitumen's chemical and physical properties make it easy to work with and highly durable.

4. Sound Insulation:

Bitumen's sound-absorbing properties find applications beyond construction. It helps reduce noise transmission, such as the sound of footsteps under floor coverings. Special tar mats in cars and elevators utilize Bitumen 80/100 for sound insulation.

5. Electrical Cable Insulation:

Bitumen's low electrical conductivity makes it suitable for use as an insulating material for electrical cables. It helps protect the cables and prevent electrical hazards.

6. Other Uses:

Bitumen 80/100 & bitumen 60/70 finds application in various other areas, such as the paper industry and the manufacturing of paints and varnishes. Its thermal insulation properties are beneficial in different contexts.

From an ecological standpoint, bitumen is highly regarded for its long lifespan. It remains a popular construction material, with significant demand both domestically and in international markets. The producer of bitumen in Iran exports a large percentage of its production to other countries such as Singapore, Dubai, Panama.

In residential construction, plastic-modified bitumen (KMB) coatings are commonly used for insulation. They compete with bitumen-free FPD (Flexible Polymer Disc) seals, which are easier to apply and offer faster repair options.

Overall, the applications of bitumen in the construction industry are extensive, ranging from roofing and waterproofing to sound insulation and electrical cable insulation. Its versatility and durability make it a valuable material in various building-related functions.

Important Considerations Before Using Bitumen:

1. Surface Preparation:

Before applying bitumen, it is crucial to ensure that the surface is clean, dry, and free from any contaminants. Even the presence of dust, dirt, or grease can hinder the adhesion of the bitumen coating and compromise the effectiveness of the seal. Additionally, the surface should be free from frost. If there are old incompatible coatings, they must be removed. In the case of older buildings, previous applications of bituminous paints may not provide a suitable surface for polymer-modified bitumen (PMB) coatings.

2. Repairing Cracks and Unevenness:

Prior to applying bitumen, any cracks or unevenness on the surface should be repaired using appropriate materials like repair mortar or leveling compounds. This ensures a smooth and uniform surface, promoting better adhesion and a more effective seal.

3. Additional Preparatory Measures:

In some cases, additional preparatory measures may be necessary. One option is to use a layer of synthetic resin on the coarse-pored bed or to apply a sealing slurry. A sealing slurry is a waterproof mixture of cement and plastic that allows water vapor to pass through. The advantage of using a sealing slurry is that it can adhere well to old bituminous coatings, providing an ideal substrate for applying a thick new bituminous coating.

By following these steps and ensuring proper surface preparation, you can optimize the adhesion and effectiveness of bitumen coatings in various applications.

What are the suitable means for repairing cracks and unevenness on the surface before applying bitumen?

There are several suitable means for repairing cracks and unevenness on the surface before applying bitumen. The choice of repair method depends on the severity of the damage and the specific requirements of the project. Here are some common methods for repairing cracks and unevenness:

1. Crack Fillers and Sealants:

For smaller cracks, crack fillers or sealants can be used. These materials, such as asphalt-based crack fillers or specialized concrete crack sealants, are designed to fill and seal cracks, preventing water infiltration and further damage. They are typically applied using a caulk gun or trowel.

2. Repair Mortar:

Repair mortars are suitable for filling larger cracks, holes, or areas of unevenness. These mortars are made from a blend of cement, sand, and additives to enhance adhesion and strength. They can be mixed with water to create a workable paste and then applied to the damaged areas using a trowel or other appropriate tools. Repair mortars are commonly used for repairing concrete surfaces.

3. Leveling Compounds:

Leveling compounds, also known as self-leveling underlayments or floor levelers, are used to create a smooth and level surface. These compounds are typically made from a blend of cement, fine aggregates, and additives. They have a fluid consistency that allows them to flow and self-level over uneven areas. Leveling compounds are commonly used to repair uneven concrete or subfloor surfaces before applying flooring materials.

4. Patching Mixtures:

Patching mixtures, such as asphalt patching compounds or repair mixes, are specifically designed for repairing asphalt surfaces. They typically contain a combination of asphalt binder, aggregates, and additives. These mixtures can be applied to fill potholes, repair damaged areas, or smooth out unevenness in asphalt surfaces.

5. Resurfacing:

In cases where the damage or unevenness is more extensive, resurfacing the entire surface may be necessary. This involves applying a new layer of bitumen or asphalt mixture over the existing surface to create a smooth and uniform finish. Resurfacing can help address multiple issues, including cracks, potholes, and unevenness.

It's important to follow the manufacturer's instructions and best practices when using any repair materials. Additionally, proper surface preparation, including cleaning and removing loose debris, is essential before applying any repair method.

ATDM CO is a manufacturer and exporter of Bitumen 60/70, offering three different quality grades available in drums, bags, and bulk quantities. Our products are classified into premium, second, and third types, each with varying production costs and facilities. We provide a wide range of options to accommodate different customer needs and volume requirements.

#bitumen#bitumen 60/70#bitumen 80/100#bitumen 60/70 specs#bitumen penetration grade 60/70#bitumen 60/70 specification#bitumen 60 70#atdm co llc.

2 notes

·

View notes

Photo

Top, screen capture from Life-death, directed by Katharina Sieverding, 1969/2004. The project consists of 42 one by one meter C-prints in steel frames accompanied by video with the the soundtrack Kraftwerk improvised for it in early 1972. Via. Bottom, installation view and performance, Continental Breakfast by Anna Uddenberg, Premium Economy I & Premium Economy II, 2023, polylactic acid, thermoset polymer resin, electropolished stainless steel, foam boat flooring,leather, chalk paint. Each 64 x 36 x 43 inches. Photograph by Dario Lasagni. On view at Meredith Rosen Gallery, March 18th - April 29, 2023. Via.

--

The subject moves from object to object in order to avoid confronting the fact that it misses the same lost object again and again. The perpetual movement of desire obscures its rootedness in missing the object rather than obtaining it. The subject fails to see that the object is satisfying as an object and not as a possible possession. When the subject invests itself in the fantasy of obtaining the object, it avoids the monotony of the subject’s form of satisfaction. One has dissatisfaction, but one also has a variety of objects that one desires with the promise of a future satisfaction. This future satisfaction never comes, and obtaining objects brings with it an inevitable disappointment. One thought that one was obtaining the impossible lost object, but one ends up with just an ordinary empirical object that pales in comparison. I believed that the piece of chocolate cake that I just ate embodied the lost object itself before I ate it, but after having done so I realize its underwhelming ordinariness.

Todd McGowan, from Capitalism and Desire: The Psychic Cost of Free Markets, 2016. Via.

10 notes

·

View notes

Text

Leading Epoxy Resin Manufacturers in India

MB Enterprises, the leading epoxy resin manufacturers in India, generating high-quality Epoxy Resin at a reasonable price.

Mb Enterprises are epoxy resin manufacturers also one of the most well-known brands in the market, and we provide epoxy resin to our valued customers. We are the Resin Manufacturer in India, which is used in the production of polymers, fibre, paints, coatings, primers and sealers, flooring, and other building and construction goods and equipment.

0 notes

Text

Industrial Flooring Market is valued at approximately USD 9,515.5 million and is projected to grow at a compound annual growth rate (CAGR) of 5.20% over the forecast period, reaching around USD 14,274.38 million by 2032. The industrial flooring market has emerged as a vital component in various industries, offering durable, safe, and performance-driven flooring solutions. Industrial flooring plays a critical role in environments such as manufacturing plants, warehouses, pharmaceutical facilities, and food processing units, where flooring must withstand heavy machinery, chemicals, and rigorous wear and tear. The global industrial flooring market is experiencing robust growth, driven by industrialization, urbanization, and a heightened focus on workplace safety and efficiency.

Browse the full report at https://www.credenceresearch.com/report/industrial-flooring-market

Market Size and Growth

The global industrial flooring market was valued at approximately USD 7 billion in 2024 and is projected to reach USD 12 billion by 2032, growing at a compound annual growth rate (CAGR) of around 6.5% during the forecast period. This growth is attributed to increasing demand from end-use industries, particularly in emerging economies undergoing rapid industrial expansion. The need for flooring solutions that meet stringent regulatory standards and offer high resistance to chemicals, abrasion, and impact is fueling market growth.

Key Market Drivers

One of the primary drivers of the industrial flooring market is the rapid expansion of the construction and manufacturing sectors. With industries seeking to modernize their facilities to improve operational efficiency, the demand for specialized flooring solutions that enhance durability and safety is on the rise. Additionally, the growth of e-commerce and logistics has increased the number of warehouses and distribution centers, further driving demand for industrial flooring.

Technological advancements in flooring materials, including epoxy, polyurethane, and vinyl, have also contributed significantly to market growth. These materials offer superior resistance to chemicals and abrasion, longer lifespans, and easy maintenance, making them ideal for industrial applications. Furthermore, the growing emphasis on sustainability has spurred the development of eco-friendly and recyclable flooring materials, aligning with global environmental goals.

Market Challenges

Despite its promising growth trajectory, the industrial flooring market faces certain challenges. High installation costs and the complexity of flooring systems can act as barriers, particularly for small and medium-sized enterprises (SMEs). Additionally, variations in raw material prices, including epoxy resins and polyurethanes, can affect market dynamics. The need for skilled labor for installation and maintenance also poses a challenge, especially in developing regions.

Future Trends and Opportunities

The industrial flooring market is set to witness several trends that will shape its future. The adoption of smart flooring technologies that integrate sensors to monitor temperature, load, and wear conditions is expected to grow, offering enhanced functionality. The demand for anti-slip and antimicrobial flooring solutions will also rise, particularly in sectors like food processing and healthcare.

Sustainability will remain a critical focus, with manufacturers investing in recyclable and low-emission materials. Innovations in self-healing and energy-efficient flooring systems are also expected to gain traction, aligning with the evolving needs of modern industries.

Key Player Analysis:

BASF SE

Sika AG

RPM International Inc.

Mapei U.K. Ltd.

Fosroc

Don Construction Products Ltd.

Cipy Polyurethanes Pvt Ltd.

Viacor Polymer GmBH

Twintec, Acrylicon

Cornerstone Flooring

Applied Flooring

AVCON Technics Pvt. Ltd.

4m Europe

East Coast Flooring Ltd

Segmentation:

Based on Product Type:

Epoxy Flooring

Polyurethane Flooring

Vinyl Flooring

Concrete Flooring

Rubber Flooring

Other Specialty Flooring

Based on Technology:

Traditional Flooring Solutions

Advanced Flooring Solutions

Smart Flooring Technologies

Self-Leveling Compounds

Modular Flooring Systems

Based on End-User:

Manufacturing

Logistics and Warehousing

Food and Beverage

Healthcare

Retail

Other Industrial Sectors

Based on Region:

North America

United States

Canada

Mexico

Europe

United Kingdom

Germany

France

Italy

Spain

Asia-Pacific

China

India

Japan

Australia

South Korea

Latin America

Brazil

Argentina

Chile

Middle East and Africa

United Arab Emirates

South Africa

Saudi Arabia

Egypt

Browse the full report at https://www.credenceresearch.com/report/industrial-flooring-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Jute Premium ECO Fitness, pilates, Yoga Mat + Foot Massager - 6.5 cm X 16 cm

Size: 24x72x5 mm thick A Natural Fibre Jute Premium Yoga Mat made of natural Jute Fibers & PER Polymer Environmental Resin, is durable, light-weight & has textured surface for Superior Grip. Made of 100% raw materials, it has antimicrobial properties for extra-sweaty practices. The mat can also be used for Pilates and floor exercises. Key Features Eco-friendly Jute Fibres: Jute is a natural…

0 notes

Text

Masterbatch Prices: Trends, Factors, and Future Projections

Masterbatch, a concentrated mixture of pigments and additives encapsulated during a heat process into a carrier resin, plays a pivotal role in the plastics industry. Used for coloring or imparting various properties to polymers, masterbatch is an indispensable material for manufacturers worldwide. However, like many raw materials, its price is subject to various factors, including supply-demand dynamics, raw material costs, and global economic conditions.

Recent Trends in Masterbatch Prices

In recent years, the masterbatch market has seen significant price fluctuations driven by the global economic environment. For instance, the COVID-19 pandemic caused disruptions in supply chains, leading to increased costs of raw materials such as polymers and pigments. As economies recovered, there was a surge in demand for plastics in packaging, automotive, and construction, further influencing masterbatch prices.

In 2024, the masterbatch market witnessed a mixed trend. While the prices of color masterbatches remained stable due to steady demand from the consumer goods sector, additive masterbatches saw an uptick in costs. This increase was attributed to growing requirements for advanced properties like UV resistance, flame retardancy, and antimicrobial functionalities in packaging and healthcare applications.

Get Real time Prices for Masterbatch: https://www.chemanalyst.com/Pricing-data/masterbatch-1117

Factors Influencing Masterbatch Prices

Raw Material Costs: The primary component of masterbatch, polymers, is derived from crude oil or natural gas. Fluctuations in crude oil prices directly impact polymer costs and, consequently, masterbatch prices. Additionally, pigments and additives used in masterbatch production are subject to market dynamics and availability, influencing overall costs.

Energy Costs: The production of masterbatch involves energy-intensive processes. Rising energy prices, especially in regions dependent on non-renewable energy sources, have pushed production costs higher.

Supply Chain Disruptions: Global events such as geopolitical tensions, trade restrictions, or natural disasters can disrupt the supply chain, causing shortages of raw materials and escalating prices.

Environmental Regulations: Increasing emphasis on sustainability has led to higher costs for eco-friendly additives and pigments. Manufacturers adhering to stringent environmental standards often face elevated production expenses, which reflect in the end-product price.

Market Demand: The demand for masterbatch varies across sectors like automotive, construction, and packaging. A surge in demand in any of these industries can drive prices upward, while a downturn can have the opposite effect.

Regional Variations

Masterbatch prices can differ significantly across regions. For instance, Asia-Pacific, being a hub for polymer production and manufacturing, often benefits from competitive pricing. On the other hand, regions like Europe and North America, with higher energy costs and stricter environmental regulations, may experience elevated prices.

Future Projections

To mitigate price volatility, many manufacturers are investing in research and development to create sustainable and cost-effective masterbatch solutions. Additionally, recycling and reusing masterbatch materials are gaining traction, offering potential cost benefits and environmental advantages.

Conclusion

Masterbatch prices are shaped by a complex interplay of factors ranging from raw material costs to market demand. While challenges such as supply chain disruptions and rising energy costs persist, innovations and sustainability efforts promise to reshape the market dynamics. For manufacturers and buyers, staying informed about these trends is crucial for strategic decision-making in this evolving landscape.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Masterbatch#Masterbatch Price#Masterbatch Prices#Masterbatch Pricing#Masterbatch News#Masterbatch Price Monitor#Masterbatch Database#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

The Complete Guide to Glass Epoxy: Creating Sturdy and Elegant Tiles and Flooring

Glass epoxy is a ground-breaking method for improving the toughness and aesthetic appeal of surfaces. Because of its strength and adaptability, glass epoxy has gained popularity for a variety of uses, especially in flooring and tiles. We will discuss the definition of glass epoxy, its advantages, and its applications for flooring, tiles, and other materials in this blog.

What is Glass Epoxy?

A kind of polymer resin bonded with glass fibers or particles is called glass epoxy. In addition to being strong, this combination makes the material resistant to heat, chemicals, and mechanical wear. Because of its superior adhesive qualities and visual attractiveness, glass epoxy is frequently employed in commercial, residential, and industrial contexts.

Glass Epoxy's advantages

Durability: Glass epoxy is perfect for high-traffic areas because of its remarkable resilience to wear and tear.

Chemical Resistance: It ensures longevity by fending off deterioration from chemicals and solvents.

Aesthetic Appeal: Surfaces look better thanks to glass epoxy's glossy sheen.

Moisture Protection: By forming a waterproof layer, it guards against stains and water damage.

Easy Maintenance: Glass epoxy-coated surfaces are simple to keep clean.

Glass Epoxy for Tiles

Despite being a mainstay of contemporary interior design, tiles are susceptible to deterioration and discoloration over time. Glass epoxy for tiles is revolutionary because it adds a protective coating that increases their luster and durability. Glass epoxy guarantees that tiles remain bright and unbroken for many years, whether they are used for decorative flooring, bathroom walls, or kitchen backsplashes.

Epoxy Joint Filler for Tiles

Epoxy tile joint filler is a better option than traditional grout, which over time can break and discolor. It offers a smooth, durable surface in between tiles, guaranteeing a waterproof seal that stops the spread of mold and mildew. By using glass epoxy as a tile joint filler, you may strengthen your tiled surfaces and give them a sleek, glossy appearance.

Epoxy for Tiles on Floors

Impacts, spills, and high foot activity all affect floor tiles. Epoxy improves the longevity and visual appeal of floor tiles. For homes, workplaces, and commercial areas, glass epoxy coatings offer a non-slip, scratch-resistant surface that is ideal. Additionally, the glossy surface gives any space a sense of refinement.

Epoxy for Glass Bond

Glass bond epoxy is the best adhesive for joining glass surfaces together. It is perfect for installing or repairing decorative panels, glass fixtures, and more because of its powerful bonding qualities. This kind of epoxy preserves the glass's transparency and aesthetic appeal while guaranteeing a strong, long-lasting bond.

Durofill Glass Epoxy's salient features include:

High resilience to chemicals and durability

superior strength of bonding

Beautiful, glossy finishes

Simple upkeep and application

Decorate Your Area Using Glass Epoxy

Glass epoxy is a solution that improves your space's usability and appearance in addition to providing protection. Durofill provides a variety of solutions, such as epoxy floor tiles and epoxy tile joint filler, to help you get beautiful, long-lasting results.

Are you prepared to improve your surfaces? Get in touch with Durofill right now to find out how glass epoxy may change your flooring and tiles.

Conclusion

Glass epoxy is a high-performance, multipurpose surface enhancement and protection solution. Durofill's glass epoxy products produce outstanding results whether you're replacing existing tiles, enhancing the durability of your floor, or creating seamless finishes. Glass epoxy is the ideal option for both residential and commercial applications because of its many advantages, which include long-term durability and aesthetic appeal. Make the confident transformation of your rooms by selecting Durofill today.

#epoxy tile joint filler#glass bond epoxy#glass epoxy#benefits of glass epoxy#epoxy for floor tiles#glass epoxy for tiles#what is glass epoxy

0 notes

Text

The Science Behind the Durability of Epoxy Flooring Services

Epoxy flooring is a highly sought-after solution for both residential and commercial spaces due to its impressive durability, resistance to wear and tear, and overall strength. The science behind epoxy flooring's durability lies in its chemical composition, bonding capabilities, and the way it interacts with various surfaces. This article delves into the key factors that contribute to the extraordinary durability of epoxy flooring services, highlighting the unique properties that make it a long-lasting and reliable epoxy flooring contractor choice for a variety of applications.

What Is Epoxy Flooring?

Epoxy flooring consists of a mixture of resin and hardener that, when combined, form a solid, durable surface. The resin is typically derived from petroleum-based compounds, while the hardener is a type of curing agent. When these two components are mixed, a chemical reaction occurs, causing the mixture to harden into a strong, smooth, and resistant coating. This chemical reaction is crucial in creating a floor that can withstand heavy foot traffic, impacts, chemical exposure, and even high temperatures. Epoxy flooring can be applied to various surfaces, including concrete, wood, and metal, making it an adaptable and versatile flooring option.

Chemical Bonding and Cross-Linking

One of the key factors behind the durability of epoxy flooring is its ability to form strong chemical bonds with the substrate it is applied to. The chemical reaction between the resin and hardener creates a cross-linked structure, which gives the floor its strength and rigidity. Cross-linking refers to the process where the polymer chains in the epoxy resin bond together in a three-dimensional network, making the material much stronger than conventional coatings. This interconnected network of molecules provides epoxy floors with their remarkable resistance to scratches, dents, and other forms of physical damage. The denser and more tightly packed the molecular structure, the more resistant the floor is to abrasion and wear.

Impact and Pressure Resistance

Epoxy floors are highly resistant to impacts and heavy loads, which makes them suitable for environments with high traffic or heavy machinery. The scientific explanation behind this is the hardness and flexibility of the epoxy resin. Unlike other materials that may crack or break under pressure, epoxy flooring can absorb and distribute force evenly across the surface. This ability to withstand impacts without showing significant signs of damage makes epoxy flooring ideal for industrial settings, garages, warehouses, and areas where equipment is frequently moved. Additionally, the material’s flexibility allows it to handle slight shifts in the substrate without cracking or buckling, further enhancing its durability.

Chemical Resistance

Another standout property of epoxy flooring is its exceptional resistance to chemicals, which is vital in environments such as laboratories, hospitals, and industrial settings. The chemical composition of epoxy resin makes it highly resistant to a wide range of substances, including oils, solvents, acids, and alkalis. This is due to the inert nature of the epoxy material once it has cured. When epoxy flooring is exposed to harsh chemicals, the surface remains intact without reacting or deteriorating. This chemical resistance is a significant factor in the long-term durability of epoxy flooring, particularly in environments where spills and leaks are common. As a result, businesses in sectors such as automotive, manufacturing, and food processing can rely on epoxy flooring to maintain its integrity even in challenging conditions.

Moisture Resistance

Epoxy flooring’s ability to resist moisture is another critical factor contributing to its durability. The epoxy coating creates a seamless, impermeable surface that prevents water from penetrating the substrate. In areas prone to high humidity, such as basements, kitchens, or bathrooms, this moisture resistance is crucial in preventing issues like mold, mildew, or corrosion. The impermeable surface of epoxy flooring also makes it easier to clean and maintain, as water or cleaning solutions are unable to seep into the floor’s surface, ensuring that the floor remains hygienic and intact over time. Additionally, epoxy flooring helps to protect the underlying substrate, such as concrete, from damage caused by moisture infiltration.

UV Resistance and Longevity

Epoxy floors are typically resistant to ultraviolet (UV) light, meaning they can withstand prolonged exposure to sunlight without degrading. Over time, exposure to UV rays can cause some floor coatings to discolor or degrade, but epoxy flooring maintains its integrity and appearance much longer. However, it’s important to note that standard epoxy coatings may yellow over time when exposed to direct sunlight. To combat this, UV-resistant topcoats can be applied to enhance the floor’s ability to withstand sun exposure without losing its shine or clarity. This makes epoxy flooring an excellent choice for spaces with large windows or areas that receive significant sunlight, as it maintains its appearance and durability for years.

Conclusion

The durability of epoxy flooring is the result of its unique chemical composition, strong molecular structure, and its ability to resist a wide range of physical and environmental stresses. From its cross-linked polymer chains to its resistance to impacts, chemicals, moisture, and UV rays, epoxy flooring offers an unparalleled combination of strength, flexibility, and longevity. These properties make it a perfect choice for high-traffic areas, industrial environments, and spaces exposed to harsh conditions. Whether you are looking for a floor that can handle heavy loads, resist spills, or endure UV exposure, epoxy flooring provides an ideal solution. Understanding the science behind epoxy’s durability can help property owners appreciate its value and choose it with confidence for their flooring needs.

0 notes

Text

PVC Additives Market-Industry Forecast, 2024–2030

PVC Additives Market overview

Request Sample Report :

Report Coverage

The report: “PVC Additives Market- Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the PVC Additives Industry.

By Type: Stabilizers, Impact Modifiers, Processing Aids, Lubricants, Plasticizers, Fillers, Others.

By Form: Granules, Powder, and Liquid.

By Fabrication Process: Extrusion, Injection Molding, Blow Molding and Others.

By Application: Pipes, Packaging, Furniture’s, Door and Windows, Cables, Medical Devices, Flooring, and Others.

By End Use: Building and Construction, Automotive industry, Textile Industry, Electrical and Electronics, Medical Industry, Food and Beverages, and Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

Asia Pacific dominates the PVC Additives market owing to rapid increase in building and construction sector.

Certain applications require higher impact strength than PVC would demonstrate normally.

The market drivers and restraints have been assessed to understand their impact over the forecast period.

The report further identifies the key opportunities for growth while also detailing the key challenges and possible threats.

The other key areas of focus include the various applications and end use industry in PVC Additives market and their specific segmented revenue.

Inquiry Before Buying:

PVC Additives Market Segment Analysis — By Type

Stabilizers held the largest share in the PVC Additives market in 2019. This growth is mainly attributed to the increasing demand for stabilizers in varied applications such as pipes & fittings, rigid & semi-rigid films, and others. Due to their superior properties, such as UV resistance, weathering and heat-aging, stabilizers are increasingly favored over other types of additives. To avoid premature degradation, many polymers are vulnerable to environmental degradation and require the addition of a stabilizer such as an antioxidant or UV absorbent. Hampered phenols and obstructed amine light stabilizers (HALS) deactivate emerging radicals, like air-oxidated peroxy compounds. UV absorbers dissipate UV radiation through the material by a method that is non-destructive. Monomers are added to free radical inhibitors as stabilizers to prevent premature polymerization.

PVC Additives Market Segment Analysis — By Forms

Granules held the largest share in the PVC Additives market in 2019. Granules help to increase the density of the freshly synthesized polymer since it lacks the flowing properties required to be processed by an extruder. Due to their plasticity property, they can be molded or shaped by application of heat. Other characteristics of plastic are its low electrical conductivity, low density, transparency and toughness which allowed it to be used for the creation of different products. In addition, plastic’s versatility has led to its use in a wide array of industries. In order to produce normal and high-strength concretes, 10%, 20%, and 30% replacement ratios by volume of PVC granules and powder are used.

PVC Additives Market Segment Analysis — By Fabrication Process

Extrusion held the largest share in the PVC Additives market in 2019. Extrusion is used mainly for handling large plastic volumes. The pellets, granules, chips, or powders are fed into the extruder and melted under high temperatures. PVC compounding is a process where additives are mixed with the base resin in order to obtain a homogenous mix. The additives are used either to enhance process capabilities or to improve product efficiency. The use of sizing parts will generate any length of profiles to the desired length. Co-extrusion allows the manufacture of semi-finished multi-layer products with special barrier properties.

PVC Additives Market Segment Analysis — By Application

Pipes is projected to witness highest share in PVC Additives market in 2019. This rise is mainly due to the growing demand for pipes & fittings in piping and plumbing, gas pipeline laying, and telecommunication and electrical cable sheathing. Due to the replacement of traditional concrete, iron, and steel-based pipes & fittings with PVC pipes in the building & construction industry, the market for PVC additives in the pipes & fittings segment is expected to witness significant development. The market for building materials is on high demand, with the continually growing population. The prerequisite for housing is pipes and fittings, which are a critical necessity. Urbanization with a large network of connections has contributed to an increase in drainage requirements. There is a growing demand for pipes and fittings to cope with advanced piping links, which in turn drives market growth. Globally, there has been a rising demand for rainwater harvesting system that has helped to heat up the pipe and fit market. In 2019, recently the commercial sector has slowed as the risk for a downturn in global construction increases due to COVID-19 pandemic which led to temporary lockdown of all economic activities across globe.

PVC Additives Market Segment Analysis — By End Use

Building and construction dominates the PVC Additives market growing at a CAGR of 6.00%. With the growing construction industry and its demand for PVC Additives particularly in the regions of Asia-Pacific, North America and Europe, the demand of PVC Additives for all kinds of buildings is expected to see an upsurge. Residential application segment is witnessing growth due to the rising penetration from untapped markets. First-mover advantage in untapped regions and relatively low acquisition costs remain key driving forces in this application market. Furthermore, R&D in PVC Additives will support the growth of the PVC Additives market.

Schedule A Call :

PVC Additives Market Segment Analysis — Geography

Asia-Pacific (APAC) dominated the PVC Additives market growing at CAGR of 41% followed by North America and Europe. APAC as a whole is set to continue to be one of the largest and fastest growing construction markets globally. Large and more developed markets such China, India, Japan, and South Korea are expected to grow more in the coming years. China is driving much of the PVC Additives market demand in Asia-Pacific region followed by India and Japan. Of the five fastest growing regions in construction sector, other than U.S. all are Asian countries including China and India who majorly drive the demand for construction investment in this regions. The strong and healthy growth in construction sector is associated with growing population and middle class economy, which tend to drive APAC residential construction market further and hence the PVC Additives market. The number of buildings that have illuminated PVC Additives is growing sharply in APAC region. The increasing number of new building constructions, along with the rise in the number of renovation projects has further propelled the market. Currently the construction industry has been affected due to COVID-19 pandemic where most of the industrial activity has been temporarily shut down. In in turn has affected the demand and supply chain as well which has been restricting the growth in year 2020.

PVC Additives Market Drivers

Replacement of conventional material with PVC will drive the market

PVC is replacing traditional building materials such as wood, metal, concrete and clay in many applications. Versatility, cost-effectiveness and excellent use record make it the most important polymer in the construction sector, accounting for 60%. These products are often lighter, less expensive and offer many performance advantages. Making it prominent material than conventional.

Rapid industrialization and infrastructure activity will augment the growth of PVC Additives

Improvement in economic climate along with boom in industrialization and infrastructure activity across the globe is leading the growth of PVC Additives. Oxford Economics has estimated global infrastructure investment needs to be $94 trillion between 2016 and 2040. This is 19 percent higher than would be delivered under current trends. With the increasing rate of industrialization and infrastructure activity, as a result of which PVC Additives growth is augmenting.

PVC Additives Market Challenges

Low R&D expenditure in the emerging markets and high maintenance cost will hamper the market to growth

Innovation is the key to developing new products, but most manufacturers are not investing much into R&D. Rather than cutting-edge technology, they invest in creating relevant technology. These factors are hampering the growth of the market. Because most of the pipes and fittings are located underground in the event of any malfunction or failure, the cost of repairs can be even greater.

Buy Now :

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the PVC Additives market. In 2019 the PVC Additives market has been consolidated by the top five players accounting for xx% of the share. Major players in the PVC Additives market are BASF SE, Arkema SA, Akzo Nobel N.V, Adeka Corporation, Clariant AG and Others.

Acquisitions/Technology Launches/ Product Launches

In April 2017, Lanxess Corporation has completed acquisition of Chemtura. With this acquisition, Lanxess significantly expands its market position for PVC additives. A notable sampling includes: the sale of its proprietary OBS (organic-based heat stabilizers) for rigid PVC applications to Baerlocher; the sale of the rest of its PVC additives business to Galata Chemicals.

Key Market Players

The Top 5 companies in the PVC Additives Market are:

BASF SE

Arkema SA

Akzo Nobel N.V

Adeka Corporation

Clariant AG

For more Chemicals and Materials Market reports — Please click here

0 notes

Text

Your Premier Source for Microcement in Canada

microcement Canada is a cement-based coating that can be applied to floors, walls, and various surfaces, creating a seamless finish. It consists of a blend of cement, polymer resins, and other additives, allowing it to adhere to almost any substrate without the need for extensive preparation. The result is a thin layer that offers the look of polished concrete or plaster, but with the added benefits of flexibility and a broad spectrum of design options

0 notes

Text

Mumbai market sees decline in POM prices

The Mumbai polymer market has experienced a decline in the prices of Polyoxymethylene (POM), grade Pom_moulding today, The analysts of Indian Petrochem has reported that the price of the commodity has recorded Rs 213/kg on November 08, 2024 from Rs 216/kg on November 07, 2024, a cut of Rs 3/kg. Polyoxymethylene (POM), also known as acetal, Delrin, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability (POM, n.d.). The Polyoxymethylene (POM) Market is segmented by End User Industry (Aerospace, Automotive, Electrical and Electronics, Industrial and Machinery) and by Region (Africa, Asia-Pacific, Europe, Middle East, North America, South America). Market Value in USD and Volume in tons are both presented. Key Data Points observed include volume of automobile production, new construction floor area, plastic packaging production volume, plastic resin production, imports and exports, and price of plastic resins. Indian POM Prices, POM Prices In India, Indian Prices POM, Indianpetrochem.

0 notes

Text

Jute Premium ECO Yoga Mat

Size: 24x72x5 mm thick A Natural Fibre Jute Premium Yoga Mat made of natural Jute Fibers & PER Polymer Environmental Resin, is durable, light-weight & has textured surface for Superior Grip. Made of 100% raw materials, it has antimicrobial properties for extra-sweaty practices. The mat can also be used for Pilates and floor exercises. Key Features Eco-friendly Jute Fibres: Jute is a natural…

0 notes

Text

Enhancing Durability With Effective Moisture Barrier Coatings

Moisture barrier coatings play a crucial role in preserving the longevity and functionality of various materials, especially in environments where exposure to moisture could lead to deterioration. These coatings act as a protective layer, preventing water and humidity from seeping into surfaces, which is vital for maintaining durability in construction, electronics, packaging, and more. Here's a closer look at how these coatings work, their benefits, and applications.

How Moisture Barrier Coatings Work

Moisture barrier coatings are applied as thin layers to surfaces that are vulnerable to moisture exposure. Once applied, they form a sealed layer that minimizes the absorption of water and reduces the risk of damage from factors such as corrosion, mold, or warping. Materials like polymers, epoxy, or specialized resins are often used for these coatings due to their high resistance to water infiltration.

Benefits of Moisture Barrier Coatings

Enhanced Durability: By creating a barrier against moisture, these coatings prolong the life of materials, reducing the need for frequent maintenance.

Corrosion Resistance: In metals, moisture can lead to rust and corrosion, significantly weakening structures. Moisture barrier coatings prevent this by blocking water from reaching the surface.

Improved Insulation: In electronics, moisture can cause short-circuits and damage delicate components. Moisture barrier coatings help protect against electrical failures by insulating sensitive areas.

Cost Savings: Preventing water-related damage leads to lower repair costs over time, making these coatings a cost-effective solution.

Common Applications

Building & Construction: Applied to walls, floors, and roofing materials to prevent water damage and structural weakening.

Electronics: Used on circuit boards and components to prevent moisture-related failures.

Packaging: Essential for food, pharmaceuticals, and other products to maintain freshness and prevent spoilage.

Automotive: Applied on parts like brake systems and fuel tanks to ensure longevity despite varying environmental conditions.

Selecting the appropriate moisture barrier coating depends on the specific material, the level of moisture exposure, and environmental conditions. For instance, high-humidity areas may require thicker, more robust coatings, while mild environments might only need basic protection. Additionally, compliance with industry standards ensures coatings meet durability and performance expectations. In summary, moisture barrier coatings offer essential protection that not only enhances the durability of materials but also promotes safety, efficiency, and cost savings across multiple industries. Properly selecting and applying these coatings can make a significant difference in the resilience and longevity of materials subjected to moisture, ensuring that structures and devices function optimally for extended periods.

0 notes

Text

Phenolic Resin Prices Trend | Pricing | News | Database | Chart

Phenolic Resin a synthetic polymer known for its robust thermal resistance, durability, and electrical insulation properties, is widely used across various industries such as automotive, construction, and electrical and electronics. The market for phenolic resin is affected by numerous factors, including raw material prices, production capacities, supply chain dynamics, and global economic conditions. Over the past few years, phenolic resin prices have experienced fluctuations driven by these elements, which impact both producers and consumers within the market. The global demand for phenolic resin continues to grow, fueled by its increasing applications in areas such as adhesives, coatings, and molded components, making it an essential material in sectors that require reliable and heat-resistant products.

The price of phenolic resin is heavily influenced by the cost of its primary raw materials, such as phenol and formaldehyde. Phenol, an aromatic compound derived from petrochemical sources, and formaldehyde, a simple organic compound, form the backbone of phenolic resin synthesis. Volatility in the prices of crude oil and natural gas can have a direct impact on the cost of these key inputs, consequently affecting the production cost of phenolic resin. The global oil market is prone to disruptions due to geopolitical tensions, natural disasters, and shifts in supply and demand. When crude oil prices rise, the cost of production for phenolic resin increases, which can lead to higher market prices. Conversely, when oil prices decrease, the market may experience price stabilization or even a decline in phenolic resin prices.

Get Real time Prices for Phenolic Resin: https://www.chemanalyst.com/Pricing-data/phenolic-resin-1129

Market participants often monitor these fluctuations closely to make strategic purchasing and manufacturing decisions. In recent years, the increased use of bio-based feedstocks and sustainable alternatives has added another layer of complexity to the pricing structure. The move towards greener solutions is driven by stringent environmental regulations and growing consumer demand for eco-friendly products. However, the initial investment costs for manufacturing bio-based phenolic resin can be higher, which in turn can raise prices. Despite these challenges, the long-term benefits of renewable raw materials have encouraged industry stakeholders to explore and adopt them, potentially influencing the market dynamics in the coming years.

The demand for phenolic resin is driven by its various applications. In the automotive sector, phenolic resin is used in the production of brake pads, clutches, and other high-friction components due to its heat resistance and durability. The surge in global automotive production, especially electric vehicles (EVs) that require high-performance materials, has further stimulated demand for phenolic resin. The construction industry also significantly contributes to market growth, utilizing phenolic resins in the creation of laminated panels, flooring, and insulation materials. The increasing focus on sustainable building practices and energy efficiency has made phenolic resin a material of choice for modern construction projects, boosting its market demand.

In the electrical and electronics sector, phenolic resin’s insulating properties make it a preferred option for circuit boards, transformers, and various electronic components. The expansion of the electronics market, particularly with the rise of consumer electronics and renewable energy solutions, has driven further consumption of phenolic resins. The trend toward more compact and efficient devices requires high-quality materials capable of withstanding elevated temperatures, reinforcing the need for phenolic resin in this industry. Additionally, the adoption of advanced technologies like 5G infrastructure and IoT devices presents new opportunities for the phenolic resin market, positioning it as a critical component in high-performance electronic systems.

Global trade policies and economic conditions also contribute to the price dynamics of phenolic resin. Import and export regulations can create trade barriers that impact supply chain logistics and prices. For instance, tariffs on certain chemicals or restrictions on the export of raw materials may cause market prices to fluctuate. Recent years have witnessed an increase in global trade tensions and evolving policies that influence the affordability and availability of phenolic resin. To counteract potential disruptions, companies often seek to diversify their supply sources and adopt risk management strategies to mitigate price volatility.

The competitive landscape of the phenolic resin market is characterized by the presence of major global players and regional producers. Leading manufacturers leverage advancements in production technology, supply chain optimization, and strategic partnerships to maintain a competitive edge. The development of new phenolic resin formulations that offer enhanced properties, such as increased flame resistance or improved adhesive strength, provides additional revenue streams and competitive differentiation for market participants. As the global focus shifts toward more sustainable and eco-friendly manufacturing practices, companies investing in green technology and sustainable production methods are likely to benefit in the long term.

To sum up, the prices of phenolic resin are shaped by a multifaceted array of factors including raw material costs, production capacities, and evolving global economic and regulatory landscapes. While market prices may fluctuate due to geopolitical and economic factors, the increasing demand for phenolic resin across industries such as automotive, construction, and electronics underpins its significance. The trend toward sustainable production, alongside technological advancements and diversification in supply chains, is poised to play an influential role in shaping the market outlook for phenolic resin in the years to come.

Get Real time Prices for Phenolic Resin: https://www.chemanalyst.com/Pricing-data/phenolic-resin-1129

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Phenolic Resin#Phenolic Resin Price#Phenolic Resin Prices#Phenolic Resin Pricing#Phenolic Resin News

0 notes