#plastics machinery exporters

Explore tagged Tumblr posts

Text

Invoit Plast Machinery Pvt. Ltd.

Invoit Plast Machinery Pvt. Ltd. Invoit Plast Machinery Pvt. Ltd. is Plastic processing machinery, Plastic raw materials processing machinery, Plastic waste processing machinery and Plastic scrap processing machinery manufacturer and exporter.

Invoit Plast Machinery Pvt. Ltd. is plastic processing machinery and plastic scrap processing machinery manufacturer, supplier and exporter. Invoit Plast Machinery Pvt. Ltd. is having industrial machineries manufacturing unit in Ahmedabad, Gujarat, India, supplying to Indian cities and overseas clients and exporting to South Africa, Dubai UAE, Nepal, Bangladesh and Qatar.

Invoit Plast Machinery Pvt. Ltd., Being as a much renowned business, since long we have supplied our high-quality manufactured products and furthermore also, have also exported to foreign clients. Our plastic raw materials processing machinery and plastic waste processing machinery supplies and exports are in demand because of its supreme quality.

#Plastic processing machinery#Plastic raw materials processing machinery#Plastic waste processing machinery#Plastic scrap processing machinery#manufacturer#exporter

2 notes

·

View notes

Text

Hi guys for a few days I've been brainstorming a fan zone and, besides the guardian, I have quite a lot of things planned.

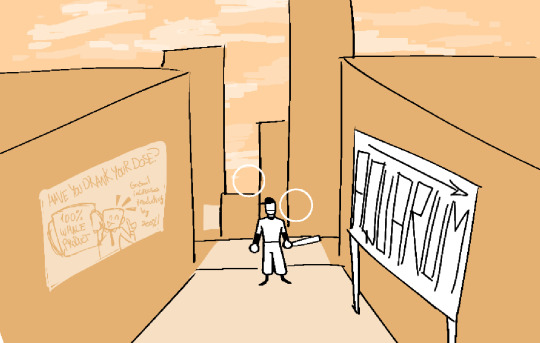

I don't have a name for it, all I know is that it's cream / tan colored.

Behold, because I will go into a bit of detail.

I'm still not totally sure about the architecture of the place. It's like a miniature claustrophobic city, if that makes sense. It's littered with advertisements for some sort of beverage... I wonder what it could be?

More below the cut :}

Ok so since you found this interesting enough to read more, let's directly get into the gist of it:

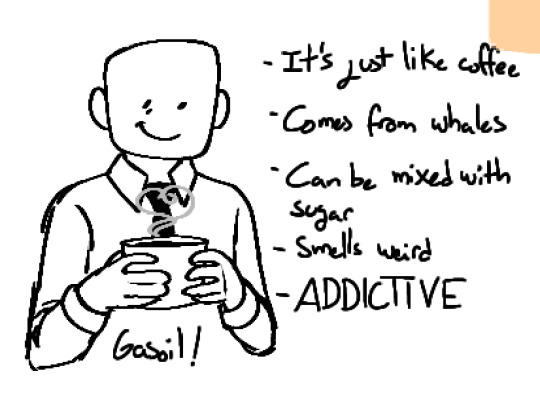

What the hell is gasoil?

Gasoil is the signature element this zone specializes in, it's their main source of income as they also ship it to other zones, either raw or processed.

When raw, it is used as fuel for machinery and electricity.

When processed, it becomes edible. The every-day beverage of every elsen!

Due to the consumption of gasoil, the elsen of this area are friendlier and extroverted, I'd imagine one of them would greet the Batter when he first steps into the place.

And yes! You read that right! It can be mixed with sugar. However, the elsen of this area are immune to sugar craving, as gasoil breaks down the addictive component of sugar, and also gets sweeter. They don't consume sugar unless with a cup of gasoil.

Gasoil also makes elsen more productive! Truly the beverage of all time, this should be sold everywhere and everyone should consume it immediately OUCH YEOCH MY ARM WHAT THE FUCK

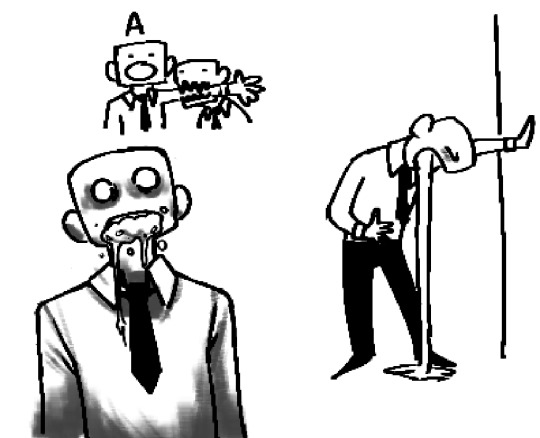

The last bullet point of that little image was that gasoil is addictive.

Elsen can become addicted to it due to the overconsumption of it, resulting in tachychardia, deliriums, vomiting, etc. Upon dying, these elsen immediately turn into sugar, as their insides are burning.

Rabid elsens are extremely dangerous so please don't approach one ever (thumbsup)

What's the aquarium?

Whales produce gasoil by absorbing plastic into their spiracles, to then excrete it in the form of raw gasoil. The raw gasoil is then harvested, and either sold raw or processed.

At the building known simply as "The Aquarium", it's where investigations about the beverage and whales occur. There are groups of people specialized in hunting and breeding these whales to achieve the best quality of gasoil. So far, not much progress has been made.

These seems quite insane and all

But where's the guardian?

This is where my silly drawings end because I have no idea what to do for the guardian, however I do have some other ideas:

(I love writing)

At the beginning, this guardian's plan was to bring out the potential of every man that would step on their land. Fierce like a militar, but caring like a mother. This guardian thought everyone had an ultimate version of themselves that, with a bit of digging, it could be brought out.

However, this guardian didn't really like the performance of their elsen, it saw them as too frail and dependent. With the discovery of gasoil, this guardian saw that the consumption of this beverage would make their elsen more productive in their tasks, however since it was in its raw state, the elsen would fall sick and do even worse after the effect of the beverage wore off.

This guardian then, invested their whole spirit into researching this new element, that could transform men and bring their potential out. Like this, "The Aquarium" was founded. Processed gasoil was invented, and it was perfection in a cup.

Contacting the guardians and signing agreements did really well in the economy of their zone. Zone 1 specially, as it had a lot of the components necessary for elsen to live, in exchange this zone would export gasoil (raw or processed) as well as men, since I don't think Dedan would mind a few more workers.

Zone 3's sugar became important, since it would make gasoil sweeter and friendlier for elsen with a weaker palate.

This zone was simply utopic. Every man had a job that they were comfortable with, with holidays and sick leaves and what not. With a loving guardian and the graph of the economy looking like Mt. Everest, what could possibly go wrong?

The elsen became mad when this guardian decided to put regulations on the consumption of gasoil. The massive production of it made the demand for it weaker, and the only costumers of it would be the elsen of this same area. It was still being exported to other zones though, just not in large quantities.

The guardian had noticed that its elsen were becoming addicted to it, once again dependent on something. The elsen ravaged and rebelled against their governor, wanting an explanation for the sudden cut in their diets and lives.

These manifestations would evolve into threats, and from threats to fights with the guardian. The guardian knew that if they were to answer these attacks it would get significantly worse, and also because they already had certain reputation of being really nice to their men (this would really affect the economy!). It decided to leave and exile themselves in the farthest point of the zone, reflecting on how permissive, and even uncaring, their actions were, thinking that it was their fault that their men became obsessed with it. This wasn't the way they envisioned "bringing someone's full potential out".

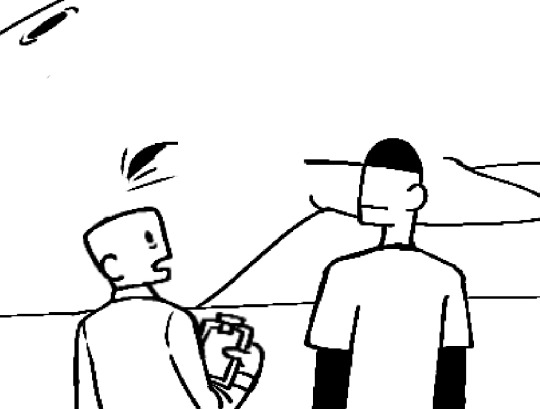

This is basically all I have planned lol. Also the way I see spectres in this is that the player would think that the stupid ghosts are interrupting elsen just wanting to do their work and drink their whale water. What the player wouldn't realize is that they're helping their addictions, spectres are beneficial here, and even the guardian will scold The Batter.

#ruben's art pile#OFF#OFF game#I was watching izzzyzzz's video about dog breeders#so that's how the aquarium came to mind lol

19 notes

·

View notes

Text

Intro: EDELSTAHL VIRAT IBERICA in #portugal An emerging importer Exporter, Supplier & Stockiest of Tool steel, Die & Mold Steels, Recycling products etc.

Tool Steel & Mold Steel Products: https://moldsteel.eu/steel-products/

🏆PLASTIC MOLD STEELS (DIN 2738, 2311 ) – Low / High Hard 🏆HOT WORK STEELS (DIN 1.2714, 2343, 2344) 🏆COLD WORK STEELS (DIN 2379, 2080) 🏆HIGH SPEED STEELS (DIN 3243, 3343, 3355) 🏆CHIPPER KNIFE STEEL (DIN 2631) 🏆ALLOY STEELS, BRIGHT BARS, EN-SERIES ETC.

Scrap / Recycling Products: https://moldsteel.eu/recycling-products/

👉 Used Tools(Carbide, Threading & HSS Cutting Tool Scrap) 👉Die & Mold Steel Blocks, Holder etc. 👉Steel lots, Cut short length, Prime over run 👉2344 Used Mandrel Bars 👉2344 Used Extrusion Dies 👉Forging Dies 👉Electric Motors 👉Used Machineries etc.

We are also involved in trading of Ferrous, Non Ferrous, Alloy steel scrap etc. The dynamic management has enabled the company to grow organically and sustainably in its search for Moving ahead globally with the exploration of Business Opportunities in several nations, including the USA, Canada, Europe, Australia, Middle East, Singapore, Japan, South Korea, India, and Philippines, etc.

Our business scope in B2B and B2C at many stages (finish products, scrap and recycling products, etc.), set us apart from other companies in this sector.

We work with a wide range of industries, including those related to Drop Forging, Aluminum Extrusion, Automotive, Mining, PDC, Power Generation, Petrochemical, Aviation, Railways, Agricultural, Oil and Gas, Drilling, Hand Tools, Bulk Material Handling, etc.

New Development in Special Steels, Recycled Products and Machine tools etc.

TO LEARN MORE >> https://moldsteel.eu/ WhatsApp Chat: +351-920016150 Email: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#din2714#din2343#din2344#din2379

3 notes

·

View notes

Text

ESSEN, Germany (AP) — For most of this century, Germany racked up one economic success after another, dominating global markets for high-end products like luxury cars and industrial machinery, selling so much to the rest of the world that half the economy ran on exports.

Jobs were plentiful, the government's financial coffers grew as other European countries drowned in debt, and books were written about what other countries could learn from Germany.

No longer. Now, Germany is the world’s worst-performing major developed economy, with both the International Monetary Fund and European Union expecting it to shrink this year.

It follows Russia's invasion of Ukraine and the loss of Moscow's cheap natural gas — an unprecedented shock to Germany’s energy-intensive industries, long the manufacturing powerhouse of Europe.

The sudden underperformance by Europe's largest economy has set off a wave of criticism, handwringing and debate about the way forward.

Germany risks “deindustrialization” as high energy costs and government inaction on other chronic problems threaten to send new factories and high-paying jobs elsewhere, said Christian Kullmann, CEO of major German chemical company Evonik Industries AG.

From his 21st-floor office in the west German town of Essen, Kullmann points out the symbols of earlier success across the historic Ruhr Valley industrial region: smokestacks from metal plants, giant heaps of waste from now-shuttered coal mines, a massive BP oil refinery and Evonik's sprawling chemical production facility.

These days, the former mining region, where coal dust once blackened hanging laundry, is a symbol of the energy transition, dotted with wind turbines and green space.

The loss of cheap Russian natural gas needed to power factories “painfully damaged the business model of the German economy,” Kullmann told The Associated Press. “We’re in a situation where we’re being strongly affected — damaged — by external factors.”

After Russia cut off most of its gas to the European Union, spurring an energy crisis in the 27-nation bloc that had sourced 40% of the fuel from Moscow, the German government asked Evonik to keep its 1960s coal-fired power plant running a few months longer.

The company is shifting away from the plant — whose 40-story smokestack fuels production of plastics and other goods — to two gas-fired generators that can later run on hydrogen amid plans to become carbon neutral by 2030.

One hotly debated solution: a government-funded cap on industrial electricity prices to get the economy through the renewable energy transition.

The proposal from Vice Chancellor Robert Habeck of the Greens Party has faced resistance from Chancellor Olaf Scholz, a Social Democrat, and pro-business coalition partner the Free Democrats. Environmentalists say it would only prolong reliance on fossil fuels.

Kullmann is for it: “It was mistaken political decisions that primarily developed and influenced these high energy costs. And it can’t now be that German industry, German workers should be stuck with the bill.”

The price of gas is roughly double what it was in 2021, hurting companies that need it to keep glass or metal red-hot and molten 24 hours a day to make glass, paper and metal coatings used in buildings and cars.

A second blow came as key trade partner China experiences a slowdown after several decades of strong economic growth.

These outside shocks have exposed cracks in Germany's foundation that were ignored during years of success, including lagging use of digital technology in government and business and a lengthy process to get badly needed renewable energy projects approved.

Other dawning realizations: The money that the government readily had on hand came in part because of delays in investing in roads, the rail network and high-speed internet in rural areas. A 2011 decision to shut down Germany's remaining nuclear power plants has been questioned amid worries about electricity prices and shortages. Companies face a severe shortage of skilled labor, with job openings hitting a record of just under 2 million.

And relying on Russia to reliably supply gas through the Nord Stream pipelines under the Baltic Sea — built under former Chancellor Angela Merkel and since shut off and damaged amid the war — was belatedly conceded by the government to have been a mistake.

Now, clean energy projects are slowed by extensive bureaucracy and not-in-my-backyard resistance. Spacing limits from homes keep annual construction of wind turbines in single digits in the southern Bavarian region.

A 10 billion-euro ($10.68 billion) electrical line bringing wind power from the breezier north to industry in the south has faced costly delays from political resistance to unsightly above-ground towers. Burying the line means completion in 2028 instead of 2022.

Massive clean energy subsidies that the Biden administration is offering to companies investing in the U.S. have evoked envy and alarm that Germany is being left behind.

“We’re seeing a worldwide competition by national governments for the most attractive future technologies — attractive meaning the most profitable, the ones that strengthen growth,” Kullmann said.

He cited Evonik’s decision to build a $220 million production facility for lipids — key ingredients in COVID-19 vaccines — in Lafayette, Indiana. Rapid approvals and up to $150 million in U.S. subsidies made a difference after German officials evinced little interest, he said.

“I'd like to see a little more of that pragmatism ... in Brussels and Berlin,” Kullmann said.

In the meantime, energy-intensive companies are looking to cope with the price shock.

Drewsen Spezialpapiere, which makes passport and stamp paper as well as paper straws that don't de-fizz soft drinks, bought three wind turbines near its mill in northern Germany to cover about a quarter of its external electricity demand as it moves away from natural gas.

Specialty glass company Schott AG, which makes products ranging from stovetops to vaccine bottles to the 39-meter (128-foot) mirror for the Extremely Large Telescope astronomical observatory in Chile, has experimented with substituting emissions-free hydrogen for gas at the plant where it produces glass in tanks as hot as 1,700 degrees Celsius.

It worked — but only on a small scale, with hydrogen supplied by truck. Mass quantities of hydrogen produced with renewable electricity and delivered by pipeline would be needed and don't exist yet.

Scholz has called for the energy transition to take on the “Germany tempo,” the same urgency used to set up four floating natural gas terminals in months to replace lost Russian gas. The liquefied natural gas that comes to the terminals by ship from the U.S., Qatar and elsewhere is much more expensive than Russian pipeline supplies, but the effort showed what Germany can do when it has to.

However, squabbling among the coalition government over the energy price cap and a law barring new gas furnaces has exasperated business leaders.

Evonik's Kullmann dismissed a recent package of government proposals, including tax breaks for investment and a law aimed at reducing bureaucracy, as “a Band-Aid.”

Germany grew complacent during a “golden decade” of economic growth in 2010-2020 based on reforms under Chancellor Gerhard Schroeder in 2003-2005 that lowered labor costs and increased competitiveness, says Holger Schmieding, chief economist at Berenberg bank.

“The perception of Germany's underlying strength may also have contributed to the misguided decisions to exit nuclear energy, ban fracking for natural gas and bet on ample natural gas supplies from Russia,” he said. “Germany is paying the price for its energy policies.”

Schmieding, who once dubbed Germany “the sick man of Europe” in an influential 1998 analysis, thinks that label would be overdone today, considering its low unemployment and strong government finances. That gives Germany room to act — but also lowers the pressure to make changes.

The most important immediate step, Schmieding said, would be to end uncertainty over energy prices, through a price cap to help not just large companies, but smaller ones as well.

Whatever policies are chosen, “it would already be a great help if the government could agree on them fast so that companies know what they are up to and can plan accordingly instead of delaying investment decisions," he said.

7 notes

·

View notes

Text

hey if youre on turtle island or still tuesday and feel like trying a quick silly browser game you should check out tradle. (i think it updates at midnight based on time zones?) todays is real fun i prommy.

you get five guesses to figure out a country from its export data, and after each guess they tell you how far away you are and what direction the county youre looking for is. i know it sounds like a ridiculous challenge but this one has a bunch of easy hints and giveaways that are accessible to your average westerner

if its wednesday by now or you want to see the data presented differently check out this silly economy under the cut (bolded 'spoilers' ig)

total export value: 371b (usd)

gold: 86.7b (23%}

packaged meds: 48.5b (13%)

vaccines, blood, cultures, etc: 40.3b (11%)

base metal watches: 15.2b (4%)

nitrogen heterocyclic compounds: 14.2b (4%)

jewlery: 9.35b (2.5%)

precious metal watches: 8.97b (2.5%)

orthopedic appliances: 7.02b (2%)

hormones: 3.38b

coffee: 3.36b

electricity: 3.19b

medical instruments: 3.09b

machinery w indv functions: 3.04b

platinum: 2.54b

chemical analysis instruments: 2.27b

nucleic acids: 2.17b

valves: 2.17b

silver: 2.01b

electric motors: 1.78b

scented mixtures: 1.72b

sulfonamides: 1.71b

diamonds: 1.64b

planes, helicopters, and spacecraft: 1.63b

beauty products: 1.58b

other heating machinery: 1.43b

flavored water: 1.43b

gas turbines: 1.38b

low voltage protection eq: 1.34b

gas and liquid flow measuring inst: 1.3b

carboxyamide compounds: 1.26b

other measuring instruments: 1.24b

air pumps: 1.16b

motor vehicles, parts, and acc: 1.14b

petroleum gas: 1.12b

electrical transformers: 1.11b

aluminum plating: 1.07b

other plastic products: 1.01b

metal working machine parts: 988m

vitamins: 965m

polyamides: 963m

washing and bottling machines: 925m

chocolate: 887m

oxygen amino compounds: 885m

integrated circuits: 884m

iron fasteners: 881m

paintings: 873m

transmissions: 855m

special pharmaceuticals: 837m

insulated wire: 828m

electrical power accessories: 826m

plastic lids: 818m

cheese: 800m

antibiotics: 797m

liquid pumps: 797m

cars: 789m

ink: 752m

non mechanical removal machinery: 737m

trunks and cases: 734m

centrifuges: 730m

interchangeable tool parts: 728m

high voltage protection eq: 705m

hand saws: 693m

other edible preparations: 680m

electric heaters: 679m

electrical control boards: 672m

polyacetals: 664m

plastic pipes: 636m

electric soldering equipment: 616m

precious metal compounds: 608m

industrial fatty acids, oils, and alcohols: 608m

hot rolled iron bars: 590m

self propelled rail transport: 582m

refined petroleum: 577m

hydrazine or hydroxylamine derivatives: 565m

precious stones: 563m

rubber working machinery: 561m

unpackaged meds: 557m

other iron products: 553m

precious metal scraps 550m

computers: 545m

surveying equipment: 523m

other plastic sheetings: 519m

metal finishing machines: 516m

scrap copper: 514m

semiconductor devices: 511m

raw plastic sheeting: 494m

documents or title and stamps: 490m

rolled tobacco: 487m

malt extract: 469m

other electrical machinery: 467m

other paper machinery: 450m

oxygen heterocyclic compounds: 441m

non knit mens suits: 441m

synthetic coloring matter: 436m

locomotive parts: 432m

non knit womens suits: 428m

iron structures: 424m

leather footwear: 421m

industrial printers: 415m

lifting machinery: 415m

scrap iron: 412m

therapeutic appliances: 410m

office machine parts: 410m

other clocks and watches: 405m

metal molds: 403m

other furniture: 403m

glaziers putty: 377m

liquid dispersing machines: 376m

knitting machine accessories: 370m

other small iron pipes: 369m

broadcasting equipment: 367m

aircraft parts: 363m

industrial food prep machinery: 362m

glues: 357m

pesticides: 349m

oscilloscopes: 344m

raw aluminum: 344m

knit sweaters: 339m

optical fibers and bundles: 334m

excavation machinery: 332m

non iron/steel slag ash and residue: 319m

carboxylic acids: 315m

xray equipment: 315m

electric motor parts: 315m

watch straps: 313m

tanks and armoured vehicles: 310m

forging machines: 309m

cleaning products: 306m

metalworking transfer machines: 298m

animal food: 294m

combustion engines: 282m

engine parts: 271m

electric generating sets: 254m

scrap aluminum: 249m

laboratory reagents: 249m

perfumes: 244m

other rubber products: 241m

photo lab equipment: 240m

wheat: 236m

lubricating products: 234m

printed circuit boards: 233m

aluminum bars: 230m

explosive ammunition: 230m

brooms: 224m

lcds: 223m

refrigerators: 223m

motorcycles and cycles: 221m

large construction vehicles: 221m

coal briquettes: 221m

corn: 220m

aluminum cans: 219m

textile footwear: 217m

thermostats: 207m

coffee and tea extracts: 206m

other aluminum products: 204m

ball bearings: 203m

knives: 199m

machines for additive mnf: 195m

raw iron bars: 187m

delivery trucks: 185m

milling stones: 176m

aluminum foil: 170m

collectors items: 169m

soybean oil: 169m

wood fiberboard: 166m

other stainless steel bars: 164m

sculptures: 160m

cutting blades: 159m

baked goods: 150m

navigation equipment: 146m

hydrometers: 137m

watch cases and parts: 134m

laboratory ceramic wear: 134m

wood carpentry: 124m

mirrors and lenses: 117m

#the plastic lids is the most astonishing thing out of all this i think. 800m usd in exports.... to go on what??#i wanted to visualize the data by smaller category#ig sharing my autism again stayed up til 3 last night transfering this lol

2 notes

·

View notes

Text

UHMWPE lining sheet,road mats,soccer rebounder board.plastic cut to size....

Dezhou New Origin Rubber&Plastic CO.,Ltd. is located at the China polyethylene engineering plastic products intensive center, Dezhou City, close to Beijing and Tianjin City. We are engaging in the engineering plastics from 1996.

Kelly Wei

Sales Manager

Email:[email protected]

Cell:+86 17705445030

Whatsapp: +86 17705445030

Website:www.dz-neworigin.com

Our plastic products cover a full range from semi-finished sheets to various machined parts, including CNC machining parts, injection molding parts, marine fender pads, lining sheet, temporary road mats, outrigger pads, synthetic ice rink, curling lanes, cutting board,soccer rebounder boards, as well as plastic irregular machinery parts, which are widely used in marine system, mining, construction, events and projects, sports, food and machinery industries. Which have been exported to United States, United Arab Emirates, India, Russia, Australia, Ukraine, Lithuania, Peru, Germany, Spain Saudi Arabia, South Africa etc. All the customers give good appreciation to our products.

2 notes

·

View notes

Text

The Role of Zinc Stearate in Plastics Manufacturing

Zinc Separate is a commonly used chemical compound in the plastics manufacturing industry. It is a white, fluffy powder that is used as a lubricant, release agent, and stabilizer in plastics processing. Zinc Stearate supplier in Ecuador is made by combining stearic acid with zinc oxide, and it has several benefits in plastic manufacturing. In this blog, we will explore the role of Zinc Stearate in plastics manufacturing and discuss its importance in the industry.

One of the key benefits of Zinc Stearate is its ability to act as a lubricant. In the plastic manufacturing process, the resin can stick to the machinery and cause significant problems. Zinc Stearate helps to reduce friction and allows the plastic to flow more smoothly through the machinery. This results in less downtime and increased productivity.

Another important role that Zinc Stearate Distributor in Ecuador plays in the plastic manufacturing industry is as a release agent. When plastic is being molded or extruded, it can stick to the molds and other surfaces. Zinc Stearate helps to prevent this from happening by creating a barrier between the plastic and the mold surface. This reduces the likelihood of defects and ensures that the final product is of high quality.

Zinc Stearate also acts as a stabilizer in plastic manufacturing. It helps to prevent the breakdown of the plastic due to heat or UV exposure. This is especially important for plastics that are exposed to outdoor environments or high temperatures. By adding Zinc Stearate to the plastic, manufacturers can ensure that their products will last longer and maintain their quality over time.

When it comes to sourcing Zinc Stearate for plastic manufacturing, it is important to find a reliable supplier. In Ecuador, there are several Zinc Stearate Exporter in Ecuador who can provide high-quality Zinc Stearate for plastic manufacturers. These include Zinc Stearate suppliers like Industrias Químicas del Ecuador and Zinc Stearate distributors like J.J. Llobet E.I.R.L. It is important to work with a reputable supplier who can provide consistent and high-quality Zinc Stearate.

In conclusion, Zinc Stearate plays a vital role in the plastic manufacturing industry. It is a versatile compound that can act as a lubricant, release agent, and stabilizer, making it an essential ingredient in the production of high-quality plastics. For plastic manufacturers in Ecuador, there are several reliable Zinc Stearate Distributors in Ecuador who can provide high-quality Zinc Stearate to meet their needs. By using Zinc Stearate in plastic manufacturing, manufacturers can ensure that their products are of high quality and will last longer.

#Zinc Stearate supplier in Ecuador#Zinc Stearate Distributor in Ecuador#Zinc Stearate Exporter in Ecuador#palvichemical

3 notes

·

View notes

Text

Mamata Machinery IPO GMP, Price, Allotment, Profit Estimate 2024

Mamata Machinery IPO Description – Mamata Machinery manufactures and exports plastic bag and pouch-making machines, packaging machines, and extrusion equipment. The company offers end-to-end manufacturing solutions for the packaging industry. The company primarily sells its packaging machinery to direct consumer brands in the FMCG, food, and beverage industries. Additionally, it sells bag and…

0 notes

Text

Adipic Acid Prices Trend | Pricing | News | Database | Chart

Adipic Acid is a critical component within the global chemical industry, primarily used as a precursor for nylon production, polyurethane foams, and a range of other applications such as plasticizers and food additives. The market dynamics of adipic acid prices are influenced by numerous factors, including raw material costs, demand fluctuations, production capacity changes, and broader economic conditions. Adipic acid production heavily relies on the availability and cost of key feedstocks such as cyclohexane and benzene. Given that these feedstocks are derived from crude oil, adipic acid prices are often susceptible to volatility in global crude oil markets. When oil prices rise, input costs for adipic acid increase, often leading to higher market prices. Conversely, periods of lower oil prices tend to provide cost relief, resulting in more competitive pricing in the downstream markets.

The demand for adipic acid has seen significant variations driven by its key end-use sectors, particularly the automotive and construction industries. Nylon 6,6, one of the primary products derived from adipic acid, finds extensive applications in automotive components, textiles, and industrial machinery. The automotive industry's health directly impacts adipic acid demand, with increased automobile production and sales correlating to higher consumption. When automotive demand wanes, as during economic slowdowns or supply chain crises, it can lead to excess adipic acid inventories, pressuring prices downward. Moreover, emerging markets with expanding manufacturing sectors and rising middle-class populations have driven demand growth, though economic uncertainty in these regions can temper market optimism.

Get Real Time Prices for Adipic Acid: https://www.chemanalyst.com/Pricing-data/adipic-acid-1106

Environmental considerations have also played a substantial role in shaping adipic acid prices. Traditional adipic acid production involves the emission of nitrous oxide, a potent greenhouse gas. As regulations around emissions tighten globally, manufacturers face increased compliance costs. This has led to efforts to adopt cleaner and more sustainable production methods. While these greener processes may alleviate long-term regulatory pressures, they also require significant capital investment, potentially exerting upward pressure on prices. Market players are navigating this evolving landscape to balance environmental sustainability with profitability. In regions where stricter environmental regulations are imposed, adipic acid production costs are often higher, which may translate to price increases passed on to consumers.

Supply dynamics are another key determinant of adipic acid pricing trends. Any disruptions in production due to natural disasters, maintenance shutdowns, or geopolitical events can lead to temporary shortages, causing price spikes. For example, unplanned outages at key production facilities in major markets like the United States, China, or Europe have historically led to notable price volatility. Producers often attempt to mitigate such risks through diversification of supply chains and strategic partnerships. On the other hand, when new production capacities come online, particularly in Asia, they can lead to oversupply scenarios. Increased competition among manufacturers can then trigger price declines, providing opportunities for buyers to secure more favorable deals but posing challenges to producers' profitability.

The global adipic acid market has also been shaped by trade dynamics, with fluctuations in tariffs and trade policies affecting cross-border movements and prices. For instance, trade tensions between major economies can introduce barriers to the import and export of adipic acid and its derivatives. Tariff increases can drive up costs for manufacturers dependent on imports, leading to higher domestic prices. Additionally, currency exchange rate variations can affect the competitiveness of adipic acid in different markets, influencing international trade flows and local pricing structures.

The advent of the COVID-19 pandemic further underscored the vulnerability of adipic acid prices to macroeconomic shocks. Demand disruptions, supply chain constraints, and shifts in consumer behavior during and after the pandemic caused significant market volatility. Early in the pandemic, widespread lockdowns and economic downturns led to a sharp decline in demand for nylon and other adipic acid derivatives, exerting downward pressure on prices. As recovery took hold, particularly driven by infrastructure spending and automotive sector growth, prices began to rebound. However, the pace of recovery varied by region, reflecting differing levels of government intervention and economic resilience. The post-pandemic market remains sensitive to supply chain bottlenecks, energy price fluctuations, and inflationary pressures.

Innovation within the industry is another notable influence on adipic acid pricing. The push towards bio-based adipic acid, derived from renewable feedstocks, has gained momentum amid rising environmental concerns and consumer preferences for sustainable products. While bio-based adipic acid is generally more expensive to produce due to higher feedstock costs and production complexity, its price could become more competitive as technology advances and economies of scale are achieved. The transition towards bio-based alternatives introduces both opportunities and risks for traditional adipic acid market players, influencing market prices through shifts in consumer demand and regulatory preferences.

Geographically, Asia-Pacific remains a pivotal region for adipic acid production and consumption. China, in particular, has been a dominant force, both as a major producer and consumer. As the country continues to urbanize and expand its manufacturing sector, the demand for adipic acid is projected to remain strong. However, China's evolving regulatory environment, particularly concerning emissions and energy usage, could impact production costs and pricing trends. Meanwhile, North America and Europe are expected to maintain stable demand, albeit with a stronger focus on sustainable and innovative solutions. Overall, the interplay of regional supply-demand balances, regulatory shifts, and macroeconomic trends will continue to drive adipic acid prices, presenting both challenges and opportunities for industry stakeholders across the value chain.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Adipic Acid#Adipic Acid Price#Adipic Acid Prices#Adipic Acid Pricing#Adipic Acid News#Adipic Acid Price Monitor

0 notes

Text

Aluminium Alloy 2014 Sheets & Plates Manufacturers In India

Aluminium Alloy 2014 Sheets & Plates, manufactured and supplied by Siddhgiri Tubes, present a versatile solution for various industrial applications. As leading Manufacturers, Suppliers, Stockists, and Exporters, we offer ASTM B209 specified plates with a wide range of dimensions. These plates come in thicknesses from 0.2mm to 300mm, widths from 500mm to 2500mm, and lengths ranging from 500mm to 10000mm.

India is home to several leading manufacturers of Aluminium Alloy 2014 Sheets & Plates, with a wide range of products catering to diverse industries such as aerospace, defense, automotive, and engineering. Known for its superior strength and heat-treatable properties, Aluminium Alloy 2014 is widely used in high-performance applications that demand strength and durability. Indian manufacturers, like Siddhgiri Tubes, have established themselves as key suppliers in the global market, delivering top-quality products that adhere to international standards.

Product Overview

Aluminium Alloy 2014 is a high-strength, heat-treatable alloy that is often used in critical applications that require excellent mechanical properties and wear resistance. This alloy contains aluminium as its base metal, with copper as the main alloying element, providing the alloy with superior strength and hardness. While it offers moderate corrosion resistance, it is primarily valued for its strength and machinability in demanding structural applications.

Key Features:

High Strength: Alloy 2014 is known for its exceptional tensile strength and fatigue resistance.

Heat Treatable: It can be heat-treated to further enhance its strength, making it suitable for various structural and high-load applications.

Good Machinability: The alloy is easy to machine and fabricate into sheets and plates, making it suitable for various engineering and manufacturing processes.

Moderate Corrosion Resistance: Though not as corrosion-resistant as alloys like 6061, it performs well in environments where corrosion is not the primary concern, provided proper coatings or treatments are applied.

Applications of Aluminium Alloy 2014 Sheets & Plates

Aerospace Industry: Used in aircraft fuselage, wings, and other high-strength structural components.

Defense & Military: Components for military aircraft, missile parts, and other defense-related equipment.

Automotive Industry: High-performance automotive parts that require high strength and minimal weight.

Heavy Engineering: Structural components in bridges, heavy machinery, and load-bearing applications.

Marine Applications: Used in certain marine structures where high strength is required for critical components.

Leading Manufacturers of Aluminium Alloy 2014 Sheets & Plates in India

Siddhgiri Tubes Siddhgiri Tubes is a well-known manufacturer, exporter, and supplier of Aluminium Alloy 2014 Sheets & Plates in India. They offer a wide range of products that are manufactured in compliance with national and international quality standards. With advanced production techniques, they ensure the alloy's strength, dimensional accuracy, and surface finish meet the highest standards required for various applications.Key Products:

Specification Chart of Aluminium Alloy 2014 Sheets & Plates

GradeAluminium 2014 / UNS A92014ASTM SpecificationsASTM B209 / ASME SB209Thickness Chart0.5mm TO 250mmFormPlates, Sheets, Slatting Coils, Coils, Foils, Plain Sheet, Shim Sheet, Strip, Rolls, Perforated Coils, Flats, Blank , RingHardnessQuarter Hard, Soft, Hard, Half Hard, Spring Hard etc.FinishCold rolled sheet (CR), 2D, Hot rolled plate (HR), 2B, BA NO(8), SATIN (Met with Plastic Coated)Size in Milimeter000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm etcLength in MM1000mm TO 6000mmApplications IndustriesGas Processing, Condensers, Sea Water Equipment, Power Generation, Pharmaceuticals, Specialty Chemicals, Pulp, Pharmaceutical Equipment, Chemical Equipment, Petrochemicals, Paper Off-Shore Oil Drilling Companies, Heat Exchangers, Industry

Advantages

Aluminium Alloy 2014 is a high-strength, heat-treatable alloy that offers several key advantages, particularly in applications that require superior mechanical properties. The following are the main advantages of Aluminium Alloy 2014 Sheets & Plates:

1. High Strength-to-Weight Ratio

One of the primary advantages of Aluminium Alloy 2014 is its exceptionally high strength-to-weight ratio. This makes it a preferred choice for applications where strength is critical, but reducing weight is equally important—such as in aerospace, automotive, and defense sectors. The strength of this alloy ensures that it can withstand high-stress conditions without adding unnecessary weight.

2. Excellent Mechanical Properties

Aluminium Alloy 2014 offers outstanding tensile strength, hardness, and fatigue resistance. Its high strength makes it ideal for structural applications where load-bearing capacity is required. When heat-treated, its mechanical properties are further enhanced, making it suitable for demanding conditions, such as aircraft parts and military components.

Tensile Strength: High tensile strength ensures the material can resist forces pulling or stretching it.

Fatigue Resistance: The alloy resists wear and fatigue under repeated stress, which is especially important for aircraft and transportation applications.

3. Heat Treatable for Enhanced Strength

Aluminium Alloy 2014 can be heat-treated to significantly increase its strength and hardness. This heat-treatment process improves the material’s mechanical properties, making it more suitable for specialized applications that require both high strength and durability. The ability to tailor the properties of the alloy through heat treatment adds to its versatility.

4. Good Machinability

Despite its high strength, Aluminium Alloy 2014 is easy to machine and fabricate, which is a key advantage in manufacturing. The alloy’s machinability allows it to be easily cut, drilled, welded, and formed into complex shapes, making it ideal for the production of intricate components. This machinability is especially valuable in industries such as aerospace, where precision and quality control are critical.

5. Superior Wear Resistance

The high copper content in Aluminium Alloy 2014 gives it excellent wear resistance, making it ideal for applications subject to abrasion or friction. This wear resistance is important in industries like aerospace, automotive, and heavy machinery, where components must withstand frequent or long-term mechanical stress without degrading.

6. Versatility in Applications

Due to its superior mechanical properties, Aluminium Alloy 2014 is highly versatile and can be used in a wide range of demanding applications:

Aerospace: For high-strength aircraft parts, such as fuselage frames, wing spars, and structural components.

Defense: For military applications, including missile components and armor.

Automotive: Used in high-performance vehicles to reduce weight while maintaining strength.

Heavy Engineering: Ideal for load-bearing components in heavy machinery, bridges, and structural engineering projects.

7. Corrosion Resistance with Proper Coatings

Although Aluminium Alloy 2014 does not have the same level of corrosion resistance as some other aluminium alloys, it can still perform well in most environments when proper coatings or surface treatments are applied. Coating or anodizing the material can protect it from corrosion, particularly in marine or highly humid environments. This makes it adaptable for use in harsh conditions when necessary protective treatments are employed.

8. Cost-Effective for High-Performance Applications

While Aluminium Alloy 2014 may be more expensive than other alloys in some cases, its high strength and durability make it a cost-effective solution for applications where performance is a critical factor. When compared to other high-strength alloys, the long-term benefits of reduced maintenance costs and increased reliability often outweigh the initial cost, making it an excellent value for industries requiring high-performance materials.

9. Global Availability and Easy Sourcing

Aluminium Alloy 2014 Sheets & Plates are widely available from reputable manufacturers in India and around the world. This availability, combined with the ability to source the material in custom sizes and specifications, makes it easy for companies to procure Aluminium Alloy 2014 for their projects, regardless of geographic location.

10. Environmentally Friendly

Aluminium alloys are known for their recyclability. Aluminium Alloy 2014 is no exception, and when it reaches the end of its useful life, it can be recycled with minimal loss of properties. The recycling of aluminium requires less energy than producing new aluminium, making it a more environmentally sustainable option in comparison to many other metals.

Conclusion

Aluminium Alloy 2014 Sheets & Plates offer a range of advantages, from high strength and wear resistance to excellent machinability and heat treatability. These properties make them an ideal choice for high-performance applications across industries like aerospace, automotive, defense, and heavy engineering. The alloy's ability to withstand harsh conditions, coupled with its ease of processing and recyclability, makes it a valuable material in critical applications that demand both durability and precision.

0 notes

Text

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine https://www.invoitplast.com/plastic-scrap-grinder-machine/ Each part of this plastic scrap grinder machine is made from superior material, whether it is its body or sharp blades. Plastic Scrap Grinder Machine Manufacturer, Exporter - Plastic Waste Crushing Machine are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc. Invoit Plast Machinery Pvt. Ltd. is also leading exporter of Plastic Scrap Grinder Machine to South #Africa, #Dubai UAE, #Nepal, #Bangladesh and #Qatar. Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is manufacturer and supplier of Plastic Scrap Grinder Machine and to India specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot.

5 notes

·

View notes

Text

Mumbai market sees decline in POM prices

The Mumbai polymer market has experienced a decline in the prices of Polyoxymethylene (POM), grade Pom_moulding today, The analysts of Indian Petrochem has reported that the price of the commodity has recorded Rs 213/kg on November 08, 2024 from Rs 216/kg on November 07, 2024, a cut of Rs 3/kg. Polyoxymethylene (POM), also known as acetal, Delrin, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability (POM, n.d.). The Polyoxymethylene (POM) Market is segmented by End User Industry (Aerospace, Automotive, Electrical and Electronics, Industrial and Machinery) and by Region (Africa, Asia-Pacific, Europe, Middle East, North America, South America). Market Value in USD and Volume in tons are both presented. Key Data Points observed include volume of automobile production, new construction floor area, plastic packaging production volume, plastic resin production, imports and exports, and price of plastic resins. Indian POM Prices, POM Prices In India, Indian Prices POM, Indianpetrochem.

0 notes

Text

EDELSTAHL VIRAT IBERICA: A New Force in the Global teel Industry!

Based in Portugal, is rapidly making a name for itself as a versatile player in the global steel industry. It's making waves as an emerging importer, exporter, supplier, and stockist of Tool Steel, Die & Mold Steels, and Recycling products.

Let’s explore their impressive offerings:

Tool Steel & Mold Steel Products: https://moldsteel.eu/steel-products/

🏆PLASTIC MOLD STEELS (DIN 2738, 2311): Low to high hardness options for precision molding. 🏆HOT WORK STEELS (DIN 1.2714, 2343, 2344): Ideal for close die forging applications. 🏆COLD WORK STEELS (DIN 2379, 2080): Versatile for various cutting and shaping tasks. 🏆HIGH SPEED STEELS (DIN 3243, 3343, 3355): Perfect for high-speed applications. 🏆CHIPPER KNIFE STEEL (DIN 2631): Precision material for chipper knives. 🏆ALLOY STEELS, BRIGHT BARS, EN-SERIES, ETC.: A comprehensive range to meet diverse needs.

Scrap / Recycling Products: https://moldsteel.eu/recycling-products/

👉Used Tools (Carbide, Threading & HSS Cutting Tool Scrap): Sustainable recycling of valuable tools. 👉Die & Mold Steel Blocks, Holder, etc.: Reclaiming steel resources. Steel lots, Cut short length, Prime over run: Efficient utilization of excess materials. 👉2344 Used Mandrel Bars, Extrusion Dies, Forging Dies: Giving new life to pre-owned components. 👉Electric Motors, Used Machineries, and more: Contributing to circular economy practices.

What sets EDELSTAHL VIRAT IBERICA apart is its comprehensive business scope, which encompasses both B2B and B2C markets at various stages, from finished products to scraps and recycling items. This broad spectrum of operations positions them as a unique entity in the sector.

The industries served by EDELSTAHL VIRAT IBERICA are as diverse as their product range. They work closely with sectors involved in drop forging, aluminum extrusion, automotive, mining, power generation, petrochemicals, aviation, railways, agriculture, oil and gas, drilling, hand tools, and bulk material handling, among others.

EDELSTAHL VIRAT IBÉRICA isn’t just about steel; it’s about sustainability, innovation, and global exploration. Their dynamic management has positioned them for success across nations, from the Portugal to India.

TO LEARN MORE >>

WhatsApp Chat: +351-920016150 Email: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#specialsteels#moldsteel#Ribeira#Bolhão#Guimarães#Braga#edelstahl

2 notes

·

View notes

Text

WPC Extrusion Mould For WPC Door Board

WPC extrusion line mould for kinds of WPC door board production, for example, PE WPC door board mould, PP WPC door board mould and PVC WPC door board mould, hollow or solid WPC mould design is available. The mould size and shape can be customized.

Mould Name: WPC door board extrusion mould

HS code: 8480790090

Mould component: die head, calibrator, water cooling tank ,heater

Die head steel: 3Cr17MoNIVEA

Calibrator steel: 3Cr17

Water cooling tank: stainless steel type

Heater: cast-aluminium

Other Accessories: removable location pins, detachable thread insets, etc.

Other mould steel type for choice: 3Cr13, 3Cr17, 3Cr17MoNiV, din1.2316

Mould cavity: one or multiple cavity by the real mould section design.

Mould surface treatment: Mirror Polish

Production machine: CNC

Extrusion speed: 0.2-2m/min

After-sale service: dispatch engineer to customer’s factory for mould commissioning and training.

Value-added service: material formula guidance for improving and optimizing.

Package: Wood /Plywood case(standard export packing)

Lead time: 20 to 30 working days after down payment

Production ability:100 sets of mould per month

Export to: Europe, Middle East, South America, North America, Asia, Africa etc.

Features

Advantage of WPC door board extrusion mould in MG Machinery:

1, high quality mould steel.

2, professional mould design engineer can meet different customized requirements.

3, skilled workers with good technic level for mould making.

4, CNC for precision mould manufacturing.

5, professional mould design engineer can meet different customized requirements.

6, mature team for material formula design and mould commissioning.

7, dispatch engineer quickly.

8, delivery moulds on time.

Main Techincal Parameter

WPC door board extrusion moulds, you can choose the exist model from our product list, or we will make the moulds by your sizes and shape design.

Advantage

Available plastic extrusion mould in MG machinery:

1)Mould for non-foam PE WPC, PP WPC, PVC WPC profiles;

2)Mould for WPC co-extrusion;

3)Mould for PVC+ wood powder surface crusting foaming profile;

4)Mould for PVC low foaming profile, co-extrusion mould for PVC foam decoration profile;

5)Mould for hard PVC door, door panels;

6)mould of color co-extrusion and soft-hard co-extrusion ;

7) Co-extrusion mould for steel-plastic and aluminum-plastic composite;

8) Colors co-extrusion mould for board, wire duct;

9) Mould for PVC quick assembling wallboard;

10) Mould for imitation marble line, door line and water bar.

In conclusion, the WPC Extrusion Mould for WPC Door Board from machinemg.com offers a highly efficient and durable solution for manufacturers looking to produce high-quality WPC door boards. With precision engineering, advanced technology, and a robust design, this mould ensures consistent performance, helping manufacturers meet the growing demand for environmentally friendly, versatile, and long-lasting wood-plastic composite (WPC) products. Whether for large-scale production or customized requirements, this extrusion mould enhances the overall productivity and quality of WPC door board manufacturing, making it an ideal investment for businesses in the industry.

#waste shredder machine#wpc machine#plastic recycling washing machines#pet bottle washing line#wpc extrusion line#plastic crusher machine

0 notes

Text

Protective Coatings Manufacturer & Exporter in Ahmedabad, India

Protective Coatings Manufacturer & Exporter in Ahmedabad, India. high-performance coatings, including Epoxy Top Coats, Epoxy Primers, and Polyurethane Coatings

Protective Coatings Manufacturer & Exporter in Ahmedabad, India. high-performance coatings, including Epoxy Top Coats, Epoxy Primers, and Polyurethane Coatings

Our advanced Protective coatings offer long-lasting protection against corrosion, wear, and harsh environment conditions.

Available in sizes from 500Ml to 20Ltr, Perfect for Industrial Applications.

Trusted by industries in PEB (Pre-Engineered Buildings), Heavy Machinery, Road & Construction Machinery, Textile & Plastic Extrusion Machinery, Pipeline systems.

For More Details 👇 📲 call us: +91 84600 05161 💬 WhatsApp: https://api.whatsapp.com/send?phone=918460005161 📍 86/1/B, Phase — I, GIDC Estate, Vatva, Ahmedabad, Gujarat — 38244

#SatvaCoatings#ProtectiveCoatings#IndustrialSolutions#CorrosionProtection#InfrastructureSafety#Durability#QualityCoatings

0 notes

Text

Article Scrap Plastic Washing Machinery in Oman R Mech Machines LLP is a leading Manufacturer and Exporter of Article Scrap Plastic Washing Machinery in Oman. Our manufacturing unit is in Ahmedabad, Gujarat, India. Materials Used like Stainless Steel, High-Density Polyethylene, Rubber and Plastics. Operators can adjust washing parameters, such as temperature, speed, and time, based on the type of plastic they are processing. Designed to minimize water and energy consumption, lowering operational costs and environmental impact. Built with durable materials to withstand heavy use and harsh operating conditions, ensuring longevity and reliability. What types of plastics can be processed? The machinery can typically handle a variety of plastics, including PET, HDPE, PP, and more, depending on the specific setup. How does the washing process impact recycling efficiency? Thorough washing improves the quality of recycled plastics, leading to better performance in downstream manufacturing processes. Are there specific detergents recommended for washing plastic? We recommend using environmentally friendly detergents, but the specific products depend on the type of plastic and the contaminants present. Working Process:

Feed Preparation: Workers sort the scrap plastic and feed it into the washing machine. Initial Rinsing: The material undergoes a preliminary rinse to remove loose dirt and debris. Washing: The main washing cycle uses water, detergents, and agitation to thoroughly clean the plastic, removing contaminants. Rinsing: After washing, the system rinses the plastic to eliminate any residual cleaning agents. Drying: The system then dries the cleaned plastic using air knives or centrifugal drying techniques to prepare it for the next processing stage. Discharge: Finally, the system discharges the clean plastic for granulation or further processing.

Applications:

Plastic Bottles and Containers Industrial Plastics Agricultural Plastics R Mech Machines LLP is an Exporter of Article Scrap Plastic Washing Machinery in Oman including locations like Ad Dakhiliyah, Ad Dhahirah, Al Batinah North, Al Batinah South, Al Buraymi, Al Wusta, Ash Sharqiyah North, Ash Sharqiyah South, Dhofar, Musandam, Muscat, Muscat, Salalah, Sohar, Nizwa, Sur, Ibri, Rustaq, Bahla, Barka, Al Buraimi, Yanqul, Khasab, Adam, Izki, Al Rustaq, Samail, Al Suwaiq, Al Hamra, Bidbid, Ibra.

Contact us today for inquiries or to place an order!

0 notes