#plastic prototype

Explore tagged Tumblr posts

Text

Acrylic machining

Acrylic is one of the most commonly used plastics for machined parts in a variety of applications. Our acrylic machining includes CNC cutting, bending, mold thermoforming and surface finishing.

0 notes

Text

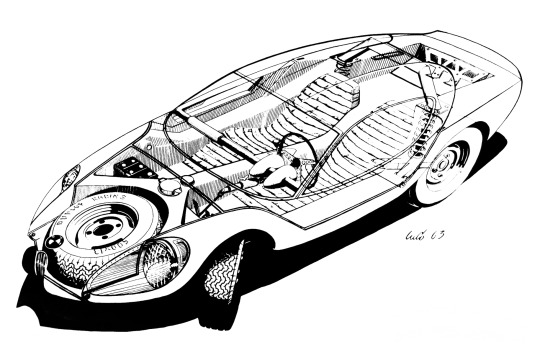

Alpine Marbon CRV, 1966, by OSI. The Cycolac Research Vehicle was commissioned by US company Marbon-Chemical to showcase their ABS plastic material Cycolac for automotive applications. The car toured Europe's car makers and found a taker at Citroën who used Marbon's ABS for their Mehari

#Alpine#Alpine Marbon CRV#OSI#Cycolac Research Vehicle#research vehicle#test vehicle#prototype#Marbon-Chemical#ABS Plastic#1966#coachbuilt#rear engine#1960

390 notes

·

View notes

Text

44 notes

·

View notes

Text

"Frutiger Aero (also known as Web 2.0 Gloss) is a broad design style and aesthetic that was prevalent in advertising, media, stock imagery and technology from roughly 2004 to 2014, following the end of the Cyber Y2K era. Overlapping with the McBling and ElectroPop 08 aesthetics, it is characterized by its vast use of skeuomorphism, glossy textures, cloudy skies, tropical fish, water, bubbles, glass, lens flare, sprawling patterns, "humanism", aero glass, bokeh, Frutiger fonts, abstract tech, auroras and bright, vibrant colors (usually greens and blues)."

so what if. Frutiger Aero-esque Protoscag fankid

#personal babble#oops i dropped a pencil ~art~#ocs#fruti#regretevator#regretevator fanchild#protoscag#regretevator protoscag#prototype regretevator#regretevator prototype#scag regretevator#regretevator scag#frutiger aero#<- an attempt at it anyway#I cannot emulate the frutiger aero style to save my life#oh yeah if you're wondering the blue glowing shell thing isn't gelatinous or anything#it's just flexible semitranslucent plastic

17 notes

·

View notes

Text

Plastic CNC machining services

#prototyping#prototype#rapid prototyping#prototype machining#cnc machining#precision machining#machining parts#cnc plastic part#plastic cnc#cnc plastic#plastic machining#plastic cnc machining#cnc plastic machining#cnc machining service#cnc machining plastic parts#cnc machining parts#cnc plastic parts

2 notes

·

View notes

Text

Another night to hyperfixate on working on the Battle Shell prototype. I'm making a SUPER rough prototype of the plating system right now and I've roughly have the measurements and placements figured out for the top half of the battle shell. I'll make a post later officially updating it on the side blog with pictures, but right now I'm doing tests on positioning and sizes of the plates, and places for the connection points.

Currently I need to adjust my plans for the shoulder pieces. On the prototype it's too weak and causing issues, and the bend isn't holding up to the movement tests. And yeah the prototype is REALLY sad to behold but it's for size measurements and will be destroyed once Project Battle Shell is done. I'm trying to keep the shoulders down to two connection pieces, but it might have to be three? I'm going to reinforce the prototype's shoulders so it can be tested better, and I need to adjust the spine because right now it's completely disconnected from first row side plates.

Plus I gotta figure out the sides for lower back plates and how they'll overlap. They need to be a lot thinner than the top back pieces but the angles will be awkward. Also getting the length right, but I'll get to that when I get to it lol

#project battle shell#rambling#PROJECT BATTLE SHELL PROTOTYPE LETS GOO#It's SOOOO flimsy that it's funny BUT it gives me enough of a basis that once it's done I can move onto the next steps#I'm considering the bio plastics I was talking about earlierr and I'm thinking how funny it would be to make it purple#should I spend extra money on purple dye? probably not! will I? probably! Even though the shell will be wrapped I think it would be#soooo funny of me to make it purple. Really embrace the vibes

1 note

·

View note

Text

Plastic Injection Mold

Looking for a way to create precise shapes and designs for your projects? Look no further than NagualMetal Plastic Injection Mold! With its advanced technology, this mold can help you get the perfect shape every time. Invest in NagualMetal today and have the power to design your own creations! Visit : https://nagualmetal.en.alibaba.com/productgrouplist-919075705/Plastic_Injection_Mold.html?spm=a2700.shop_index.88.7.76bb3f3ftsftKs

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

Transforming nylon plastic sheets into precision-engineered parts tailored to your needs. Experience our bespoke machining services today! 🛠️✨

#custommachining#nylonparts#precisionengineering#oem manufacturing#oem#plastics#cncmachining#industrial design#prototyping#engineering

0 notes

Text

i'm kind of regretting the fact that i lost the metal-cased junior i was issued when i started out in the inkopolis plaza turf war scene, back before they all got standardized to plastic cases for fresh season 2015. not for the fact that they sell for a lot in collector's markets these days but just because those things were hilarious. they were so heavy and dense for their size and a lot of kids got banned for pistol-whipping their opponents with them out of anger

#my debut at the inkopolis plaza twa was sizzle season 2014 and that was around the time the plastic junior prototype was nearly finalized#they weren't really making new metal juniors by then either but refurbished ones were still heavily circulated#and a refurbished metal junior was a little less expensive than a new plastic prototype which is why i went with it despite its weight#🪣 ᱨ𐓑Ꮣᱨ 🜶ⲶИⲶ́ booyahs

1 note

·

View note

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

T&R Tooling has established itself as a leading provider of tooling for plastic injection molding in Texas, delivering innovative solutions that help manufacturers improve productivity and product quality. Our high-precision molds are crafted to the exact specifications of each client, ensuring that your injection-molded products meet the highest standards of quality and consistency.

T&R Tooling 282 Elm Grove Rd., Valley View, TX 76272 (940) 726–6020

My Official Website: http://www.trtooling.com/ Google Plus Listing: https://www.google.com/maps?cid=1529569677814869897

Our Other Links:

plastic injection tooling in Texas: http://www.trtooling.com/new-tooling/ prototyping Texas: http://www.trtooling.com/3d-printing/

Service We Offer:

Plastic Injection Molding 3d Printing Tool Repair New Tooling Design Services Quality Assurance

Follow Us On:

Twitter: https://twitter.com/ToolingR31294 Pinterest: https://www.pinterest.com/trtoolingtx/ Instagram: https://www.instagram.com/trtooling/

#tooling for plastic injection molding texas#injection molding tooling repair texas#plastic injection tooling in texas#rapid prototyping Texas#prototyping texas

0 notes

Text

Automotive prototype

Rapid prototypes in the Automotive industry are key parts of the car development process. due to the long process of the automotive development cycle is a long process, the right prototypes could help the design team validate the design in the right direction at each critical milestone. Below we will introduce our related services.

0 notes

Text

Colani-BMW 700, 1963. A concept car designed by German aerodynamicist Luigi Colani based on the rear-engined BMW 700 saloon. It was notable as the world's first vehicle with a self-supporting plastic monocoque body. With a Cd factor of 0.22 it was capable of 200km/h (120mph) despite being powered by a 700cc flat twin engine.

#BMW#Colani#Colani-BMW#Colani-BMW 700#rear engine#flat twin#aerodynamic#concept#prototype#design study#experimental car#world first#plastic monocoque#1963#Luigi Colani

889 notes

·

View notes

Text

Prototype Plastic Injection Molding

The Prototype Plastic Injection Molding service offers precision-engineered solutions for rapid prototyping and product development. Utilizing advanced techniques, this service ensures high-quality, durable plastic components tailored to meet specific design requirements. For more information call us @ +86-18701918634

0 notes

Text

Uncovering the Mechanisms of Injection Molding and Prototype Sourcing: An All-Inclusive Guide

The path from ideation to realization in the field of product development and manufacturing is complex and exciting. The critical stages of injection molding and prototype sourcing agents, where concepts become physical forms, are at the center of this process.

0 notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes