#plastic injection molding machines

Text

Application of 3+2 CNC Machining in Mold Making Factory

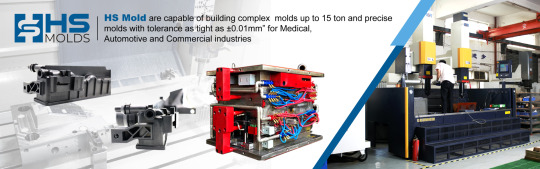

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Hsmolds.net is a reputable CNC machining parts factory based in China, specializing in high-quality manufacturing solutions. With state-of-the-art equipment and skilled technicians, they deliver precision-engineered components for various industries worldwide. Their commitment to quality assurance and efficient production processes ensures timely delivery and customer satisfaction. Trust Hsmolds.net for your CNC machining needs, setting the benchmark for excellence in the industry.

0 notes

Text

Summary of common interview questions for mold design engineers. A total of 91 common knowledge points that must be known

1. Common shrinkage rates of plastic materials?Answer: ABS, PC, PMMA, PS, PA66+30GF: 1..005POM, PVC, PE: 1.020PP, PET, PBT: 1.015-1.0202. Common defects in plastic parts?Answer: Glue deficiency, cloak, bubbles, shrinkage, weld marks, black spots, bubbles, stripes, warping, delamination, peeling, etc.;3. Commonly used plastic mold steel?Answer: 718, 738, S136, NAK80, SKH51, SKD61, 2344, 8407,…

View On WordPress

#Default accuracy of UG#defects in plastic parts#Die-casting molds#electric spark machining#injection molding molds#injection pressure#mold design engineers#Mold designer#mold engineer#mold maker#mold manufacturing#mold structures#plastic molds#plastic product#plug-through#product designer#punch-through#shrinkage rates of plastic materials#two-color mold#What is a PL surface#What is a pouring system#What is a weld mark#What is bone position#What is discharge machining#What is function of air discharging groove#What is overcutting#What is pillow position#What is plastic deformation#What is undercut

0 notes

Text

Progressive Stamping Die

Enhance your manufacturing process with Let's Escape Together's progressive stamping die services. Our expert team delivers precision-engineered dies for efficient, high-volume production. Experience consistent quality and accuracy in every part, from simple to complex designs. With advanced technology and industry expertise, we provide reliable solutions tailored to your needs, ensuring cost-effective and seamless manufacturing.Read more : https://nagualmetal.en.alibaba.com/productgrouplist-919732885/Progressive_Stamping_Die.html?spm=a2700.shop_plgr.88.10

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

International Plastics and Rubber Industry Fair in October at Vietnam

Vietnam Plas 2024 will be held from 16th - 19th October 2024 at Saigon Exhibition and Convention Center - SECC in Ho Chi Minh City, Vietnam. VietnamPlas has consistently stood as the foremost industrial exhibition in Vietnam. Serving as the bridge connecting the global supply chain with the Vietnamese market, the exhibition has played a pivotal role in fostering collaboration and catalyzing the growth of the plastics industry to meet global demands. The fair covers a wide range of topics and sectors within the plastics and rubber industry. This includes plastic machinery, chemicals and raw materials, machinery auxiliary industry, heating and control devices, hydraulic and pneumatic technologies, recycling techniques, and other relevant products and services.

WHY SHOULD YOU ATTEND EXHIBITION?

VietnamPlas has brought together a diverse range of exhibition categories, including machinery equipment for plastics and rubber processing, manufacturing and distribution of injection moulding machines, film blowing machines, etc. VietnamPlas also bring the most promising businesses and exhibitors to participate, creating opportunities for the development of the plastics and rubber industry in Vietnam. VietnamPlas is not only an opportunity to access the latest technologies and products but also a chance to expand cooperation relations.

Visitors Profile:

Aerospace / Railway

Automobile / Auto Parts / Accessories

Building Materials

Chemicals & Raw Materials

Cosmetics / Daily Chemical Products

Environmental Protection / Recycling / Upcycling

Food & Beverages

Machinery & Testing Equipment

Moulds & Dies

Packaging / Printing

Pharmaceuticals / Medical Supplies & Equipment

Plastic Furniture / Lighting

Plastic Products & Parts

Plastics Recycling

Product / Industrial Design

Rubber Products & Parts

Exhibition Highlight

Exhibition Date: 16th To 19th Oct 2024

Time: 16 to 18 October 09.00 to 5.00 and 19 October 2024 09.00 to 3.00 PM.

Exhibition Location Address: 799 Nguyen Van Linh Parkway, Tan Phu Ward, District 7, Ho Chi Minh City, Vietnam

Hall No. – A1, A2 and B1, B2

Entry Fees – Free Ticket for Industry Professionals on advance booking.

Estimated Visitors: 60,000 Visitors

Estimated Exhibitors: 1000 Exhibitors

WHO SHOULD EXHIBIT?

The most promising exhibitors will showcase their latest cutting-edge products based on global trends at the VietnamPlas exhibition. Here, leading suppliers from many countries will meet all your needs in the supply chain of the plastics and rubber industry. A distinguishing feature of the exhibition is its close ties to the local plastics industry, positioning itself as an ideal platform for entry into the Vietnamese market and for the international showcase of products and services.

Organizer Information.

Organizer Name: Chan Chao International Co., Ltd

Organizer Address: 3F, No.185, Kangchien Road Nei-Hu Dist. Taipei, Taiwan

Organizer Phone No.: 886 2-26596000

Organizer Email Id: [email protected]

Stall Booking Number: +886-2-2659-6000

Website: https://www.chanchao.com.tw/en/

Registration Link: https://www.chanchao.com.tw/en/preReg/index.asp?id=FPLSHCM2024&c=

The event fosters collaboration and knowledge exchange, enabling participants to address key challenges such as environmental sustainability, product innovation, and supply chain optimization. As the industry moves forward, the insights and partnerships developed at this event will play a crucial role in shaping the future of plastics and rubber manufacturing in Vietnam and beyond.

0 notes

Text

Because the plant extension, the mold factory chagnged the new name as: Rost mold! We will be your reliable partner in China!

#injectionmold #plastmold #plasticmould #injectionmould #injectionmoulding #imm #inyeccionmold #bucketmold #chairmold #petmold #householdmold #dailyusemold #electricmold #autopartsmold #doublecolormold #irrigationmold

#injection molding#plastic molding#plastic#injection moulding machine#injection manufacturing company#injection mold

0 notes

Text

Injection Moulding Machine Price | SHIPMI

The Systec is a hydraulic injection moulding machine from the European product range of Sumitomo (SHI) Demag. It is characterized by sturdy and compact design, and offers much clearance for large moulding dies.

#Plastics machinery services India#Plastic injection moulding machine Gurgaon#Plastic moulding machine#All electric injection molding machine

0 notes

Text

Ultimate Guide to VR-T5 Series High-Speed Injection Molding Machine | Daoben Machinery

VR-T5 Series High-Speed Injection Molding Machine

DAOBEN is a professional plastic injection molding machine manufacturer, We produce injection molding machines from 108 tons to 2800 tons.

0 notes

Text

Advanced Imported Used Plastic Injection Molding Machine for Sale

Discover a cutting-edge imported used plastic injection molding machine for sale at IndiaBizzness portal. This advanced equipment boasts state-of-the-art technology, ensuring precision and efficiency in manufacturing processes. With its reliable performance and cost-effective operation, it's the ideal solution for businesses seeking to enhance their production capabilities. Don't miss this opportunity to streamline your operations and achieve superior results with this high-quality injection molding machine.

0 notes

Text

Introduction to Mould Manufacturing 2024

Plastic mould manufacturing is the process of creating mould or tools for the production of plastic parts. The mould are designed to shape and form plastic materials into specific shapes and sizes, allowing for the production of identical parts at a rapid pace. This process is widely used in various industries, including automotive, medical, and consumer goods.

The fundamental principle behind plastic mould manufacturing is to create a negative impression of the desired product, which is then used to cast the final product. The mould are made from high-quality materials such as steel or aluminum, which are capable of withstanding high temperatures and pressure. The mould are designed to accommodate the specific properties of the plastic material, including its melting point, viscosity, and shrinkage rate.

There are two primary types of plastic mould manufacturing: injection moulding and compression moulding. Injection moulding involves injecting molten plastic material into a mould cavity, which is then cooled and solidified to create the final product. This process is highly efficient and produces high-quality parts at a rapid pace. Compression moulding involves heating plastic pellets and then placing them into a heated mould cavity, which is then compressed to form the final product. This technique is used for larger parts or when the part requires greater strength and durability.

Plastic mould manufacturing has a wide range of applications, from the production of small plastic components to large automotive parts. The process allows for the creation of complex parts with intricate shapes and sizes. The ability to create identical parts at a rapid pace makes it an essential process in modern manufacturing.

In conclusion, plastic mould manufacturing is a crucial process in the manufacturing industry. It allows for the production of high-quality plastic parts at a rapid pace, making it a highly efficient and cost-effective process. The use of advanced technology and high-quality materials has made plastic mould manufacturing an essential process in various industries, including automotive, medical, and consumer goods.

Mould Manufacturing Process

The process of manufacturing a mould is a complex one, and it's important to note that not all plastic mould manufacturers use the same methods.

The most common method used by manufacturers is CNC machining, which involves using computer-controlled machines to carve out the shape of your product in thin layers. This technique has been around for decades and allows for greater precision than other methods like EDM (electrical discharge machining) or grinding.

Plastic mould manufacturing is a complex process that involves several steps to create high-quality mould for various industries. The process begins with designing the mould using computer-aided design (CAD) software. This software allows engineers to create a detailed 3D model of the mould, including all the intricate details required for the final product.

Once the design is complete, it's time to move onto the manufacturing stage. The first step in manufacturing is to create a mould base using steel or aluminum. This base is what will hold all the various components of the mould together. The base must be designed to withstand the high pressure and temperature required for the moulding process.

Next, the mould is assembled, which involves attaching various components such as the ejector pins, the sprue bushing, and the runner system. These components are essential for the mould to function correctly during the moulding process.

The next step is to machine the mould. This involves using specialized equipment to create the cavities and cores required for the final product. This process involves a high level of precision, and any errors or imperfections can result in a faulty mould.

Once the mould is machined, it's time to test it. This involves running a trial batch of plastic through the mould to ensure that it produces the desired product. Any issues with the mould or the moulding process can be addressed in this stage.

Finally, after the mould is tested and approved, it's ready for production. The mould is attached to an injection moulding machine, and plastic is injected into the cavities to create the final product. This process can be repeated thousands of times to create a large number of identical products.

Overall, plastic mould manufacturing is a complex and intricate process that requires a high level of skill and expertise. From designing the mould to running production, every step of the process must be executed with precision to ensure a high-quality final product.

1. Introduction

Mould manufacturing is an essential process in the production of various products, including automotive parts, consumer goods, and medical devices. Identifying different types of mould is crucial to ensure that the correct type is used for each product. In this guide, we will discuss the different types of mould prevalent in the mould manufacturing industry, their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type.

2. Types of Mould

Plastic Injection Mould:

Thermoset Compression Mould:

Blow Mould:

Rotational Mold:

3. Precautions and Safety Measures

Different types of mould have different safety considerations, but in general, it is important to wear appropriate personal protective equipment (PPE) when working with mould, such as gloves, goggles, and respirators. It is also important to follow proper handling and storage procedures to prevent mould contamination and ensure optimal mold performance.

Conclusion

Identifying different types of mould and understanding their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type is crucial to ensure that the correct type is used for each product. Proper maintenance and cleaning of mould are also essential to prevent mould contamination and ensure optimal mould performance. By implementing the knowledge gained in this guide, manufacturers can improve their mould manufacturing processes and produce high-quality products with greater efficiency and consistency.

#mold manufacturing#mould manufacturing#plastic molding#thermoset compression mould#cnc machining#injection molding#3d printing#manufacturing#compression molding#mumbai#india#blow mould#rotational molding

1 note

·

View note

Text

Are you searching for Plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds#industry#plastic injection molding companies in china

2 notes

·

View notes

Text

Looking for precision-engineered aluminum CNC turning parts in China? Hsmolds.net offers top-notch manufacturing solutions. With a commitment to quality and expertise in CNC machining, they deliver precise components tailored to your specifications. Whether for automotive, aerospace, or electronics, their aluminum parts meet rigorous standards. Trust Hsmolds.net for reliable, efficient, and cost-effective CNC machining solutions in China.

0 notes

Text

Recommended parameters for ABS plastic injection molding performance

ABS, commonly known as acrylonitrile butadiene styrene, is a copolymer of three monomers: acrylonitrile-butadiene-styrene. Due to different proportions of the three monomers, different properties and melting temperatures can be achieved. If ABS with flow properties is blended with other plastics or additives, it can be expanded to ABS with different uses and properties, such as impact-resistant…

View On WordPress

#Gate design#injection molding#injection molding machine#injection pressure#molding#plastic injection molding#plastic processing

0 notes

Text

Sheet Metal Fabrication

Discover top-tier sheet metal fabrication services with Let's Escape Together. Our expert team and advanced technology deliver precision-crafted components for all your projects. From prototyping to full-scale production, we ensure high quality and accuracy. Trust us for cost-effective solutions tailored to your specifications, and experience exceptional craftsmanship in every piece of sheet metal we fabricate.Visit : https://nagualmetal.en.alibaba.com/productgrouplist-924878740/Sheet_Metal_Fabrication.html?spm=a2700.shop_plgr.88.11.646d7b2cmd1SpG

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

Plastic Injection Molding Machine Market; Size, Share, Latest Trends, and Growth Research Report 2024-2036

A comprehensive analysis of the “Plastic Injection Molding Machine Market; Size, Share, Latest Trends, and Growth Research Report 2024-2036” provides an accurate overview and thorough analysis of the market industries in the present and the future. This report provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry. It provides a comprehensive overview of the market, including current market trends, future projections, and an in-depth analysis of the major players in the industry.

Request Free Sample Copy of this Report @

https://www.researchnester.com/sample-request-6007

Report findings provide valuable insights into how businesses can capitalize on the opportunities provided by these dynamic market factors. It also provides a comprehensive overview of the major players in the industry, including their product offerings, contact and income information, and value chain optimization strategies. Furthermore, it offers an in-depth analysis of the leading businesses in the industry based solely on the strength of their business plans, product descriptions, and business strategies.

Key Findings

Plastic Injection Molding Machine Market has experienced significant growth in recent years, driven by factors such as increasing consumer demand and technological advancements.

The market segmentation analysis revealed several key segments, including Machine Type, Application each with unique characteristics and growth potential.

Regional analysis highlighted the strong performance of Plastic Injection Molding Machine Market in regions such as North America, Europe, and Asia-Pacific, with emerging markets showing promising growth opportunities.

Analyzing the Plastic Injection Molding Machine Market

A thorough understanding of the Plastic Injection Molding Machine Market will provide businesses with opportunities for growth such as customer acquisition, enhancements to their services, and strategic expansions.

By incorporating market intelligence into their operations, businesses can anticipate changes in the economy, assess the effect these factors may have on their operations, and create plans to counteract any negative effects.

Market intelligence helps organizations stay ahead of the curve through insights into consumer behavior, technological advancements, and competitive dynamics.

Using Plastic Injection Molding Machine Market data can provide organizations with an edge in the competitive market and establish prices and customer satisfaction levels.

Request for customization @

https://www.researchnester.com/customized-reports-6007

In a dynamic market environment, business validation helps companies develop business plans and assures their long-term survival and success.

What are the most popular areas for Plastic Injection Molding Machine Market?

The North American continent includes Canada, Mexico, and the United States.

The European Union is made up of the United Kingdom, France, Italy, Germany, the Republic of Turkey, and Russia.

The Asia-Pacific region is comprised of China, Japan, Korea, India, Australia, Vietnam, Thailand, Indonesia, and Malaysia.

The region of Latin America, which includes Brazil, Argentina, and Columbia

In addition to Africa, the Middle East includes South Africa, Egypt, Nigeria, Saudi Arabia and the United Arab Emirates.

Report highlights include:

There is a 360-degree synopsis of the industry in question in this study, which encompasses all aspects of the industry.

The report presents numerous pricing trends for the keyword.

Additionally, the report includes some financial data about the companies included in the competitive landscape.

The study enumerates the key regulatory norms governing the keyword market in developed and developing economies.

Additionally, the keyword report provides definitions of the market terms referred to in the document for the sake of convenience.

Future Potential

In the keyword research report, various primary and secondary sources are used to describe the methodology of conceptualizing the study. It has been discussed in the study what the scope of the report is and what elements it contains in terms of the growth spectrum of the keyword. The document also includes financial data of the companies profiled, along with the current price trends of the keyword.

Access our detailed report at@

https://www.researchnester.com/reports/plastic-injection-molding-machine-market/6007

0 notes

Text

Plastic Injection Molding Machine: The Coolest Thing You Never Knew You Needed

1. Hey there, let's talk about something super cool!

Hey there, ever heard of a plastic injection molding machine? If not, get ready to have your mind blown. This incredible device is the secret behind the production of so many items in our everyday lives, from toys to car parts. It's like a magic box that turns molten plastic into any shape you can imagine. Trust me, once you learn about the wonders of plastic injection molding, you'll wonder how you ever lived without it. So, buckle up and prepare to be amazed!

2. What on earth is a plastic injection molding machine?

Well, let me break it down for you. A plastic injection molding machine is like a magician's workshop. It's a fantastic piece of technology that enables manufacturers to create products with precision and efficiency.

So, how does it work? Here's the lowdown: First, the machine heats up plastic pellets until they melt into a molten liquid. Then, it injects this liquid into a mold, which is like a custom-made container that determines the shape of the final product. Once the plastic cools and hardens inside the mold, it's ejected, and voila - you have a perfectly molded item!

It's mind-boggling how versatile these machines are. They can produce anything from tiny components to large-scale products. Plus, they're incredibly fast, capable of churning out thousands of items in a matter of hours.

Trust me, once you see a plastic injection molding machine in action, you'll be in awe of its capabilities. Stay tuned to find out more fascinating facts about this amazing invention!

3. The insane uses and benefits of having one

Now that you know how a plastic injection molding machine works, you'll be amazed to learn about the insane uses and benefits of having one.

First off, these machines have revolutionized the manufacturing industry. They have made it possible to create complex and intricate shapes that were once difficult or impossible to produce. From automotive parts to household appliances, the possibilities are endless.

One of the biggest benefits of using a plastic injection molding machine is the efficiency it offers. With its high-speed production capabilities, manufacturers can produce large quantities of items in a short amount of time. This not only increases productivity but also reduces production costs, making it a cost-effective solution for businesses.

Another benefit is the consistency and precision these machines offer. The molds used in the process ensure uniformity in the final products, eliminating any variations or defects. This means you can expect high-quality and reliable items every time.

Furthermore, these machines are environmentally friendly. The ability to recycle and reuse plastic materials reduces waste and promotes sustainability. Additionally, the energy-efficient nature of these machines reduces energy consumption and lowers carbon emissions.

In conclusion, a plastic injection molding machine is not only a cool invention, but it also has numerous uses and benefits. From enabling complex shapes to increasing production efficiency, these machines have transformed the manufacturing industry. Stay tuned for the next section where we'll dive deeper into the fascinating world of plastic injection molding machines.

4. Where can you get your hands on one? (Spoiler alert: they're not as expensive as you think!)

Where can you get your hands on one? (Spoiler alert: they're not as expensive as you think!)

Now that you're sold on the idea of owning a plastic injection molding machine, you're probably wondering where you can find one. The good news is, these machines are more accessible than ever before.

You may be surprised to learn that there are many companies that specialize in selling plastic injection molding machines. These companies offer a wide range of options to suit different budgets and production needs. From small desktop machines for hobbyists to large industrial machines for mass production, there's something for everyone.

If you're just starting out or have a limited budget, you can consider buying a used machine. Many manufacturers and businesses sell their old machines at a fraction of the cost of a new one. Just make sure to do your research and inspect the machine thoroughly to ensure it's in good working condition.

Another option to consider is leasing or renting a machine. This can be a cost-effective solution, especially if you only need the machine for a specific project or a short period of time.

In conclusion, getting your hands on a plastic injection molding machine is easier and more affordable than you might think. Whether you choose to buy a new machine, find a used one, or explore leasing options, you'll be able to bring your manufacturing dreams to life. In the next section, we'll discuss some tips and considerations to keep in mind when purchasing a plastic injection molding machine. So stay tuned!

5. Saying goodbye to "I wish I had a plastic injection molding machine" dreams

Ah, the satisfaction of turning dreams into reality! In this next section, we'll dive into some tips and considerations to keep in mind when purchasing a plastic injection molding machine. Because let's face it, when you finally have one in your possession, you'll want to make the most of it.

First things first, it's important to assess your production needs. Ask yourself how often you'll be using the machine and what kind of products you'll be manufacturing. This will help you determine the size and capabilities you require.

Next, make sure to do your research on different machine manufacturers. Look for reputable brands with a track record of producing high-quality machines. Reading reviews and asking for recommendations from other users can also be a valuable source of information.

Budget is always a consideration, so take the time to compare prices and features. Remember, the cheapest machine might not always be the best investment in the long run. Look for machines that offer a balance between affordability and functionality.

Lastly, don't forget about maintenance and support. Find out if the manufacturer offers technical support and if replacement parts are readily available. A machine that is well-supported will ensure smooth operation and minimal downtime.

By following these tips, you'll be well on your way to making your plastic injection molding dreams a reality. Stay tuned for the next section, where we'll explore some exciting applications of plastic injection molding that might surprise you. Until then, happy molding!

6. Seriously, you need to check this out!

I know, I know, you're probably thinking "Why do I need a plastic injection molding machine anyway?" Well, my friend, let me tell you, this machine is seriously cool and can open up a world of possibilities for you.

Think about it - with a plastic injection molding machine, you can create all sorts of products right at home. From custom-made phone cases to personalized keychains, the possibilities are endless. And the best part? You have complete control over the design and production process.

Imagine the satisfaction of seeing your ideas come to life, right in front of your eyes. It's like being a magician, turning raw materials into something amazing. Plus, with advancements in technology, these machines are becoming more user-friendly and affordable, making them accessible to everyday hobbyists and professionals alike.

So, if you've ever had a creative itch or a desire to bring your own products to the market, a plastic injection molding machine is definitely something you should consider. Trust me, once you have one, you'll wonder how you ever lived without it.

In the next section, we'll explore some mind-blowing examples of what can be achieved with a plastic injection molding machine. Get ready to be inspired and amazed by the incredible things people are creating. See you there!

7. So, what are you waiting for? Get your hands on a plastic injection molding machine and start creating!

So, what are you waiting for? It's time to dive deeper into the world of plastic injection molding and explore the amazing things you can create with this incredible machine. From intricate jewelry pieces to functional household items, the possibilities are truly endless.

Imagine being able to design your own unique phone cases, perfectly tailored to your style and preferences. Or how about creating custom keychains to give as personal and thoughtful gifts? With a plastic injection molding machine, you have the power to bring your ideas to life and make them a reality.

Not only is the process of using a plastic injection molding machine incredibly rewarding, but it's also surprisingly simple. As technology has advanced, these machines have become more user-friendly, so even if you're a beginner, you'll be able to create professional-quality products.

Whether you're a hobbyist looking to explore your creative side or an entrepreneur wanting to bring your own products to market, a plastic injection molding machine is the perfect tool for you. It's time to unleash your creativity and start bringing your ideas to life. So, what are you waiting for? Get your hands on a plastic injection molding machine and start creating!

0 notes