#pipette calibration standards

Explore tagged Tumblr posts

Text

The Impact of Temperature on Pipetting Accuracy

Pipetting is an essential laboratory process, and depends heavily on precision instruments like micropipettes. Whether you're using an automatic micropipette for high-throughput experiments or a manual micropipette for delicate tasks, maintaining accuracy is essential. However, one often-overlooked factor that can significantly influence pipetting accuracy is temperature.

Let’s explore how temperature affects pipetting accuracy and how you can mitigate these challenges for reliable results.

How Does Temperature Affect Pipetting Accuracy?

Thermal Expansion of Liquids and Instruments Temperature fluctuations directly impact liquid density and volume. For instance, warmer liquids expand, which can lead to inaccurate volume measurements. This is particularly important when working with nanoliter dispensing or small volumes where even minor variations can cause significant errors. The mechanics of micropipettes, including pipette calibration standards, are also influenced by temperature. Plastic components in an auto micropipette or graduated micropipette may expand or contract, affecting their calibration.

Vapor Pressure Changes High temperatures can increase the vapor pressure of volatile liquids, making precise liquid handling more challenging. In such cases, using specialized micropipette tips designed for volatile substances can help.

Operator-Related Factors Human body heat can subtly affect the pipette price you pay in terms of accuracy. For example, holding the micropipette for extended periods might warm it up, leading to slight deviations in the dispensed volume. Understanding this interaction can help you choose the right types of micropipette for your tasks.

Best Practices for Mitigating Temperature Effects

Use Temperature-Adapted Tools Modern micropipette technology includes tools designed to minimize temperature effects. Investing in an automated micropipette or a well-calibrated micropipette pipette ensures consistent performance.

Pre-Equilibrate the Pipette and Liquid Allow both your automatic micropipette and the liquid to equilibrate to room temperature before beginning your work. This reduces discrepancies caused by temperature differences.

Calibrate Regularly Regular pipette calibration ensures your instrument remains accurate despite environmental changes. Calibration services often account for temperature variations when setting pipette calibration standards.

Choose the Right Tools Selecting the right pipette, whether it’s a micropipette pipette, an auto micropipette, or a graduated micropipette, for your specific application is crucial. For high-precision tasks, consider a pipette with nanoliter dispensing capabilities.

Monitor Environmental Conditions Maintain a stable lab environment to minimize temperature fluctuations. Using precision instruments in a controlled setting ensures more consistent results.

Why It Matters

Accurate pipetting is essential in fields like molecular biology, drug development, and clinical diagnostics. Inaccuracies, even if minor, can lead to failed experiments, increased costs, and unreliable results. By accounting for temperature effects and investing in reliable tools like automatic micropipettes or glass micropipettes, you ensure better reproducibility and efficiency.

Final Thoughts

Temperature plays a subtle but significant role in pipetting accuracy. Understanding its impact can help you make informed decisions, whether you're choosing a new micropipette pipette, comparing micropipette cost, or learning about the mechanics of micropipettes. Regular calibration, proper usage, and investing in advanced micropipette technology can mitigate temperature-related challenges, enabling accurate and reliable liquid handling every time.

Whether you're handling nanoliters or milliliters, accuracy is non-negotiable. Choose the right pipettor at the right pipettor price, calibrate regularly, and always consider environmental factors like temperature to achieve the best results in your work.

#liquid handling#pipettes#micropipette#bottle top dispensers#micropipette pipette#types of micropipette#pipette calibration standards

0 notes

Text

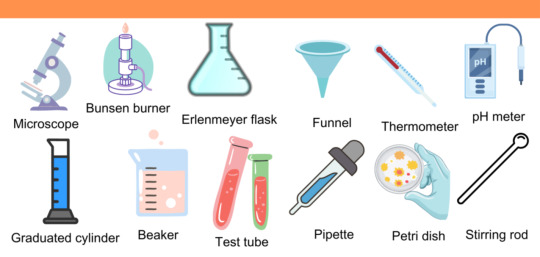

The Importance of Laboratory Glassware in Scientific Research

Scientific Laboratory Glassware constitutes an important aspect of any scientific work since it confers precision, accuracy and reliability in the conduct of experiments in various scientific fields. Being the basis in any laboratory arrangement, Laboratory Glassware allows quantitative assessment of certain features of substances, the process of added reagents, temperature modification, and preservation. The leading Laboratory Glassware manufacturer and supplier in India, provides a variety of quality Laboratory Glassware that include beakers, glass flasks, test tubes, and burettes and pipettes for better results in educational, industrial and research purposes. In this blog, we mentioned the importance of Laboratory Glassware in scientific research.

Significance of Laboratory Glassware in Scientific Research

Chemical Resistance

The chemical durability of laboratory glassware is assured through the utilization of borosilicate glass, enabling most chemical reactions to be safely carried out in such containers. Such a property ensures that all stored or reacted chemicals in glass containers do not alter the results of the experiment in any way.

Thermal Stability

The thermal properties of glass make it quite useful for those kinds of applications which involve the heating or the cooling of substances. A researcher can take a beaker and heat some of the liquids in it, or even boil some samples in a conical flask without having structural issues.

Reusability

Laboratory glassware can be reused multiple times after proper cleaning and sterilization, unlike disposable plastic equipment which can be used once. This adds to the reduction of waste and also makes it an economically viable option for research purposes in the long term.

Transparency

The transparency properties enable scientists to track reactions, changes in color, or even the separation of phases during the course of the experiment. This sight is sighted as very important for control of the processes in order to avoid mistakes.

Accurate Measurements

It is emphasized that laboratory glassware is characterized by precision. In particular, graduated cylinders, burettes and volumetric flasks are calibrated for accuracy, which are essential in quantitative analysis and formulation.

Adaptability

Laboratory glassware encompasses a wide range of activities, from basic combining and heating, to elaborate titration and distillation techniques. Their multiple applications make them a must have in any research setup.

Essential Laboratory Glassware

There are various kinds of laboratory glassware that are crucial for the performance of experiments. Every item has its own uses and is manufactured in relation to specific purposes of the research.

Beakers

Beakers are a set of cylindrical jars in lab working areas which have large openings and markings on their sides that aid rough measurement and accurate estimation. They do not only assist in considerable liquid heating but also liquid blending and storage.

Conical Flasks (Erlenmeyer Flasks)

Also known as Erlenmeyer flasks, conical flasks are a set of cones with narrow necks that allow for gentle swirling of the flask without the liquid spilling out. They are predominantly used during titration and sample preparation mixing.

Test Tubes

The test tube is a piece of equipment that can be defined as a small cylindrical glass container that is used to hold, mix or heat small amounts of liquids. In a more general sense, it is widely utilized in qualitative analysis and educational and research laboratory setups.

Volumetric Flasks

These are made for precision use, and volumetric flasks are intended for preparing or measuring standard volumetric solutions. They have a wide bulging center with a narrow neck that bears a graduation mark.

Burettes

A burette can be defined as a volumetric measuring instrument designed in a long cylindrical tube encased in a graduated scale and has a tap or stopcock at one end. The burette is an essential instrument in titration experiments which requires the volumetric measurement of liquids.

Pipettes

A pipette is simply an elongated glass tube having different diameters and is used to suck and transfer small volumes of liquid. Pipettes can be of many forms: there are graduated pipettes and volumetric ones, depending upon the accuracy and precision of the work planned.

According to Wikipedia, To draw up and dispense liquid, a partial vacuum is created above the liquid-holding chamber and then selectively released. This is how several pipette kinds operate. Depending on the instrument, measurement accuracy can vary significantly.

Graduated Cylinders

Graduated cylinders, also called measuring cylinders, are used in volumetric measurements of liquid substances. They are in the form of tall cylindrical vessels with a spout for pouring out liquids and are easy to handle.

Evaporating Dishes

Evaporating dishes are rounded, inwardly curved pan lids or they are round in shape aimed at use in sample preparation and chemical study as cover lids to beakers or shallow pans for heating liquids.

Why Choose Eduscope India?

Eduscope India is a reputable firm that specializes in laboratory equipment for a long time now especially glassware products. Being the top Laboratory Glassware manufacturers and suppliers in India, Eduscope India has earned a name of providing high quality goods suited for scientific and educational institution requirements.

Laboratory Glassware from Eduscope India are defined with accuracy in volume and great strength. Eduscope India items are made of high quality borosilicate glass which enables them to endure the harshest of conditions such as high heat and chemicals. Therefore, they are compatible with specific research settings where stability and uniformity are important. Eduscope India additionally provides a variety of laboratory glassware with respect to all the branches of science. The company facilitates the customers with all the required instruments including basic beakers for ordinary laboratory functions, burettes for titrations, and volumetric flasks for the preparation of standard solution.

Conclusion

Laboratory glassware is one of the most important components of scientific glassware as it allows measuring, seeing and performing tests. These instruments, right from the simple test tubes to complex volumetric flasks, are important in the enhancement of knowledge across the learned societies. It is therefore important to use good glassware in order to obtain trustworthy results and nurture more ideas in the area of research.

Eduscope India, a trusted and Laboratory Glassware Manufacturer and Supplier in India makes an interesting proposition in terms of quality, variety and customer focus. They have so many strong, accurate and creative items that have earned them a reliable partner in the labs throughout the country. When researchers get good laboratory glassware, they are able to invest more on successful experiments which are sure to lead to exciting findings.

#laboratory glassware manufacturer and supplier in India#laboratory glassware manufacturer and supplier#laboratory glassware manufacturer

0 notes

Text

Life Sciences Laboratory Products

Life sciences laboratory products are the backbone of scientific research, enabling breakthroughs in biotechnology, medicine, and environmental studies. These products are designed to simplify complex experiments, improve accuracy, and speed up processes in labs across the globe.

What Are Life Sciences Laboratory Products?

Life sciences laboratory products encompass tools, equipment, consumables, and software that support research and innovation in the life sciences sector. They are essential for studying biological systems, analyzing DNA, culturing cells, and much more.

Key Categories of Life Sciences Laboratory Products

Instruments and Equipment:

High-precision devices such as centrifuges, incubators, and spectrophotometers.

Consumables and Reagents:

Pipettes, culture plates, and reagents like enzymes and buffers.

Software and Digital Tools:

Solutions for data analysis, lab management, and experimental design.

Importance of Laboratory Products in Life Sciences

Laboratory products are critical for achieving reliable results. They help researchers conduct experiments more efficiently and accurately, reducing human error and enhancing reproducibility.

Essential Life Sciences Laboratory Instruments

Microscopes:

Used for studying microorganisms, cells, and tissues.

Centrifuges:

Essential for separating components of a sample.

PCR Machines:

Vital for amplifying DNA for genetic studies.

Consumables and Reagents for Life Sciences Labs

Pipettes and Tips:

Accurate measurement and transfer of liquids.

Petri Dishes and Culture Media:

Supporting microbial and cell growth.

Buffers and Enzymes:

Maintaining pH stability and catalyzing reactions.

Software Solutions in Life Sciences Research

Advanced software tools are transforming life sciences labs, offering robust data analysis and streamlined workflows. Lab management systems simplify inventory tracking and experiment documentation.

Applications of Life Sciences Laboratory Products

Biotechnology:

Genetic engineering and bioinformatics.

Pharmaceutical Research:

Drug development and toxicity studies.

Academic and Clinical Studies:

Fundamental research and diagnostic testing.

Emerging Trends in Laboratory Products

Automation:

Robotic systems for high-throughput experiments.

Eco-Friendly Solutions:

Sustainable materials and energy-efficient equipment.

Factors to Consider When Choosing Laboratory Products

Quality:

Ensure products meet industry standards.

Cost:

Evaluate budget constraints without compromising on quality.

Compatibility:

Match products with existing lab systems and equipment.

Top Brands in Life Sciences Laboratory Products

Leading names in the industry include Thermo Fisher Scientific, Eppendorf, and Bio-Rad. These brands are known for their innovation and reliability.

How Technology is Revolutionizing Laboratory Products

AI Integration:

Enhancing data analysis and predictive modeling.

IoT Connectivity:

Real-time monitoring of equipment and experiments.

Challenges in Procuring Laboratory Products

Budget Constraints:

Balancing quality with affordability.

Compatibility Issues:

Ensuring new products integrate seamlessly with existing systems.

How to Ensure Proper Maintenance of Laboratory Products

Regular Calibration:

Maintain accuracy and reliability.

Storage Practices:

Follow manufacturer guidelines for optimal lifespan.

Future of Life Sciences Laboratory Products

The future promises further innovation with personalized equipment tailored to specific research needs, as well as greener, more sustainable options.

FAQs

What are the most commonly used laboratory products?Centrifuges, pipettes, PCR machines, and culture media are among the most widely used.

How do I choose the right products for my lab?Assess your research needs, budget, and compatibility requirements.

Are eco-friendly lab products effective?Yes, many sustainable products offer the same performance as traditional ones.

What are the key brands in this industry?Thermo Fisher Scientific, Bio-Rad, and Eppendorf are leading brands.

How do I maintain laboratory instruments?Regular cleaning, calibration, and proper storage are essential for maintenance.

Conclusion

Life sciences laboratory products play a pivotal role in scientific discovery. By investing in the right tools, labs can achieve greater efficiency, accuracy, and innovation. Embracing advanced and sustainable products ensures a brighter future for research.

Contact Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

0 notes

Text

16 strict quality control measures ensuring precision pipetting performance in pipette tip production.

At Cotaus, we understand that the accuracy and reliability of laboratory results depend on the precision of every tool used. That’s why our pipette tips are produced under the strictest quality control standards, ensuring they meet the highest performance benchmarks for accurate pipetting. From the selection of materials to the final inspection, every step of the production process is carefully monitored to guarantee consistency, durability, and precision. Let's see How we do.

1. Tips' volume accuracy and precision

Cotaus each batch of pipette tips undergoes volume calibration to ensure they fall within the standard tolerance range. Random samples are taken from each batch and multiple liquid aspirates and dispenses are performed to check the consistency of the tip’s volume accuracy and precision.

2. Tips' dimensional consistency

Random samples are taken from each batch to test the tip’s dimensions to ensure they conform to standard specifications(Uniformity of product dimension≤0.15), ensuring consistent inner and outer diameters, length and shape to prevent fit issues.

3. Tips' physical integrity

The tips are checked for cracks, air bubbles, or any physical defects that might affect their pipetting performance or lead to contamination.

Pressure and bend tested to ensure they can withstand normal operating pressure and bending without breaking or deforming.

4. Tips' airtight seal and fit

Verifying that the pipette tips fit securely onto pipettes or automatic liquid handling platform, ensuring no air leakage during aspiration or dispensing. Ensure the tips are compatible with various pipette brands and robotic liquid handling systems, ensuring no loosening, slipping, or improper fit.

5. Tips' concentricity

Using precision instruments such as laser scanners or coordinate measuring machines (CMM), to check the roundness of both the inner and outer diameters. Cotaus pipette tips require concentricity errors within ±0.2 mm.

6. Tips' perpendicularity

Using specialized perpendicularity testing instruments to check the angle between the tip's bottom surface and its central axis. The error is typically required within a tolerance of 0.5 millimeters or less.

7. Tips' liquid retention and low-residue testing

Special surface treatments are applied to ensure the inner surface of the tip is smooth and reduces liquid retention, especially when handling viscous liquids. Measurement of liquid residue left in the tip after aspiration and dispensing, particularly when handling small volumes, to ensure minimal liquid carryover.

8. Tips' retention force

Measuring the force required to attach and detach the pipette tips, ensuring they are neither too tight (difficult to remove) nor too loose (which could cause aspiration issues).

9. Tips' surface smoothness

Ensures that both the inside and outside surfaces of the tips are smooth, with no irregularities or roughness, testing for smooth internal and external surfaces to minimize sample retention, avoid contamination, and enhance the efficiency of liquid transfer.

10. Tips' sterility

Ensures that sterile tips are sealed properly during packaging to prevent contamination. Cotaus disposable tips utilize electron beam sterilization which is a safe and efficient method that leaves no chemical residue.

11. Tips' resistance and CV values

Resistance testing ensures the durability and performance of the pipette tip under different physical and chemical conditions. CV testing evaluates the precision of liquid transfer by measuring the consistency of the tip’s performance, ensuring high accuracy and low variability.

12. Tips' material durability

Adopt imported medical-grade polypropylene (PP) materials to ensure the dimensional stability of the tips, Cotaus ensures consistency in the material used to avoid discrepancies in dimensions or performance that could affect pipette accuracy.

13. Tips' manufacture equipment

Cotaus owns 120+ automated manufacturing assembly lines, using high-precision injection molding machines to ensure dimensional consistency and accuracy of the tips, improving efficiency and reducing human error.

Cotaus owns a mold manufacturing company that produces high-precision molds for pipette tip production, ensuring accurate shape, size, concentricity, and perpendicularity.

Quality control equipment including precision balances and measuring devices, laser measurement instruments, automated inspection systems, etc.

14. Tips' production environment

Manufactured in a 100000-class dust-free workshop to avoid contamination from dust, particles, or contaminants.

15. Tips' QC Standards

Ensures the tips comply with quality standards (ISO13485, CE, FDA), guaranteeing their performance, precision, and reliability.

16. Tips' production process management

ERP Systems manage raw materials, production scheduling, inventory, and shipping, ensuring a smooth and timely production process. Critical production parameters and quality inspection data are recorded and stored during production, providing traceability for each batch of tips and facilitating post-production quality tracking.

0 notes

Text

A Comprehensive Guide to Choosing the Best Laboratory Equipment Manufacturers in India

The laboratory industry in India has been expanding at a remarkable pace, fueled by advancements in technology and the growing demand for precise tools across a wide range of sectors. Industries such as healthcare, pharmaceuticals, biotechnology, education, and industrial research are heavily reliant on high-quality laboratory equipment. As a result, identifying the most reliable and efficient laboratory equipment manufacturers in India has become a critical task for businesses and research organizations alike.

This blog explores the importance of choosing the right manufacturer, the benefits of working with Indian manufacturers, and how industry leaders are shaping the future of laboratory innovation.

Why Choose Laboratory Equipment Manufacturers in India?

India boasts a strong manufacturing base with an impressive array of companies producing advanced laboratory equipment. From basic lab tools to complex analytical instruments, laboratory equipment manufacturers in India are known for delivering high-performance products that meet international quality standards.

By choosing local manufacturers, you gain access to:

Diverse Product Offerings: Manufacturers provide everything from glassware and pipettes to cutting-edge machinery like spectrophotometers, centrifuges, and PCR systems.

Cost-Effective Solutions: Indian manufacturers often strike the perfect balance between quality and affordability.

Tailored Services: Many leading companies provide customized equipment designed to cater to the specific needs of diverse industries.

Key Factors to Consider When Choosing a Manufacturer

Selecting the best laboratory equipment manufacturers in India requires a thoughtful evaluation of various aspects. Here are some crucial factors to help you make an informed decision:

Product Range: Ensure the manufacturer offers a comprehensive lineup of equipment to suit the needs of your laboratory, whether you require basic tools or advanced systems.

Certifications and Standards: Reputable manufacturers comply with global certifications such as ISO, CE, and WHO-GMP to guarantee the quality, safety, and performance of their products.

Technological Innovation: Look for companies that stay ahead of industry trends by investing in research and development to create advanced and efficient tools.

Customer Support: Reliable after-sales support, including installation, calibration, maintenance, and repair, is a hallmark of top manufacturers.

Sustainability Practices: Many laboratory equipment manufacturers in India are adopting environmentally friendly production processes, aligning with global sustainability goals.

Benefits of Partnering with Indian Manufacturers

India has emerged as a global hub for laboratory equipment manufacturing, offering numerous benefits:

Cost Savings: Lower production costs, coupled with reduced import duties, make Indian-made laboratory equipment a budget-friendly choice without compromising quality.

Quick Turnaround: Local manufacturers can deliver products faster, ensuring timely availability for time-sensitive projects.

Innovation and Customization: Indian manufacturers excel at providing innovative and customizable solutions, enabling laboratories to stay at the forefront of technology.

Strong Supply Chain: A well-established supply chain ensures smooth delivery and uninterrupted service, even during challenging times.

Leading Players in the Industry

The landscape of laboratory equipment manufacturers in India is diverse, with companies ranging from small-scale suppliers to globally recognized brands. These manufacturers cater to a wide spectrum of industries, ensuring that laboratories across India and abroad have access to the latest technology.

Some companies have earned a reputation for consistently delivering high-quality equipment that meets the stringent requirements of various industries, enabling advancements in scientific research and industrial development.

Conclusion

Investing in the right laboratory equipment is crucial for achieving accurate results, improving efficiency, and fostering innovation in your laboratory. When it comes to choosing laboratory equipment manufacturers in India, quality, reliability, and after-sales support should be your top priorities.

Bionics Scientific stands out as a trusted name in the industry, providing a wide range of laboratory equipment that combines cutting-edge technology with affordability. Their commitment to quality and customer satisfaction makes them a reliable partner for laboratories across India and beyond. Whether you’re setting up a new laboratory or upgrading your current facility, partnering with the right manufacturer, like Bionics Scientific, ensures you have the tools to achieve your research and operational goals effectively.

0 notes

Text

5 Common Laboratory Equipment Mishaps and How to Avoid Them

In every laboratory environment, correct handling of laboratory Equipment is paramount in ensuring that valid outcomes are achieved and accidents are also prevented. Laboratory incidents interfere with research work as well as endangering the safety and health of the people carrying out the work. Partnering with reputable and reliable Laboratory Equipment manufacturers and suppliers in Ambala is very important in maintaining quality and safety standards. In this blog, we will include 5 common laboratory equipment mishaps and we can avoid them.

Common Laboratory Equipment Mishaps and How to Avoid Them

Improper Calibration

It is necessary to routinely check the calibration of the pipettes and microscopes to ensure accuracy and reliability of results. Lack of calibration would result in having varied data and resources being squandered. To avoid this, calibrate regularly and document for easy reference. Regular calibration checks would be able to help make sure that the equipment is functioning properly.

Inappropriate Storage

To avoid breakage and maintain usability, laboratory equipment including laboratory glassware and delicate items should be appropriately stored. It is also possible to cause damage or contamination through inappropriate usage or storage practices. For example, glass beakers can be placed in specific storage racks and cabinets, while electronic equipment can be stored in cabinets to keep dust and moisture out.

Overheating Equipment

Overheating occurs frequently on devices such as hot plates and bunsen burners, which could cause burns, fires or damage to the equipment itself. Therefore, procedures like monitoring the temperature settings, ensuring circuits are not overloaded, and letting the machines rest between uses needs to be practiced. Furthermore, following proper guidelines issued by the Laboratory Equipment manufacturers for use and handling is essential too.

Equipment Contamination

Contamination of laboratory equipment like micropipettes and test tubes can alter the outcomes of research and render them unreliable. This is even more critical in biological and chemical laboratories as even background contamination could compromise experiments. Use equipment such as test tubes for the given purpose only and clean and sterilize them every time they are used so as to avoid cross-contamination.

Lack of Training and Awareness

The absence of training makes a significant contribution for many laboratory accidents. In the absence of proper guidance, users might misuse some of the instruments leading to breakages, injuries as well as wrong data. An organized approach of regular training about equipment handling, safety measures and correct techniques can minimize accidents and confidence on every person is boosted.

Essential Laboratory Equipment

Microscope

Widely employed in laboratories of biology and medicine, a microscope enables examination of the material structure on a cellular level. Its maintenance concerning calibration and storage guarantees its accuracy and durability.

According to Wikipedia, A microscope is a piece of equipment used in laboratories to study items that are too small to be seen with the human eye. The science of using a microscope to examine small objects and structures is known as microscopy. To be microscopic is to be undetectable to the naked eye without the use of a microscope.

Bunsen Burner

These apparatus are widely used in the heating and disinfection of various things in a number of chemistry laboratories. It should be treated with care to avoid accidents, and users must use the burner correctly and avoid excessive heat.

Pipette

In order to conduct chemical and biological experiments, a pipette is indispensable for the transfer of accurate volumes of liquid. For accuracy and to ensure the absence of contamination, proper calibration and routine maintenance are encouraged.

Why Buy From Ambala Science Lab?

Ambala Science Lab is a reputable source for quality laboratory equipment, providing trustworthy instruments such as microscopes, pipettes, Bunsen burners, beakers, among others. As a trusted Laboratory Equipment manufacturers and suppliers in Ambala, Ambala Science Lab has placed priority on safety and durability which in turn satisfied customers. The equipment designed by Ambala Science Lab is ideal for any laboratory. Ambala Science Lab team also provides training resources to ensure users have full knowledge of each piece of equipment and how to handle it.

Conclusion

In order to avoid common laboratory equipment errors, one must exercise great caution, consistently maintain the equipment, and follow instructions. Recognizing and controlling these dangers helps to make sure that experiments in any laboratory are performed under safe conditions. Purchasing laboratory equipment from trusted Laboratory Equipment manufacturers and suppliers in Ambala such as Ambala Science Lab guarantees laboratories premium quality and reliable equipment. This in turn means that with the aid of Ambala Science Lab, the laboratories will find it easy to carry out research and education programs without the fear of equipment failure.

#Laboratory Equipment manufacturer#Laboratory Equipment supplier#Laboratory Equipment manufacturer Ambala

0 notes

Text

Micropipette Troubleshooting: How to Fix Common Pipetting Issues

Accurate pipetting is essential for reliable lab work, and maintaining consistency can be difficult when issues arise. At Accumax, we recognize the significance of precise liquid handling for achieving the best results. Here’s a guide to help you troubleshoot and resolve some common pipetting problems.

1. Inconsistent Volume Dispensing Cause:

This issue often arises from improper calibration or pipetting technique.

Solution: Make it a habit to regularly calibrate your micropipettes and practice smooth, consistent plunger operation. Avoid pressing or releasing the plunger too quickly, as this can lead to inconsistencies.

2. Dripping or Leaking Tips Cause: A poor tip fit or damaged internal seals are common causes.

Solution: Always use high-quality tips that fit securely on the pipette. Regularly check O-rings and seals, replacing them as needed to ensure a proper seal.

3. Air Bubbles in the Sample Cause: Incorrect aspiration techniques, such as tilting the pipette or aspirating too quickly, can introduce air bubbles.

Solution: Keep the pipette vertical while aspirating, and pull the liquid up at a controlled, steady speed. Pre-wetting the tip before aspiration can also help improve volume consistency.

4. Sticky Plunger Movement Cause: This can happen due to residue buildup or mechanical wear over time.

Solution: Clean the piston regularly and lubricate it according to the manufacturer’s guidelines. If the issue persists, consider having the pipette serviced to prevent further wear or damage.

5. Incorrect Volume Delivery Cause: User error or damage to the pipette can lead to inaccurate volume delivery.

Solution: Always pre-wet the pipette tip for viscous liquids, maintain a consistent speed while pipetting, and visually inspect the pipette mechanism for any signs of damage.

Best Practices for Reliable Pipetting Regular Maintenance: Make it a habit to clean and calibrate your pipettes regularly.

Proper Tip Usage: Always check that the tips you use are compatible and of good quality to ensure a proper seal.

Consistent Technique: Develop a steady hand and apply uniform pressure to minimize errors.

Precision in pipetting is essential in any laboratory. At Accumax, we are dedicated to enhancing your workflow with dependable equipment and support. We are a renowned global manufacturer of laboratory liquid handling instruments since last 2 decades. By following these guidelines, you can troubleshoot effectively and uphold the high standards your lab requires.

Read More: Micropipette Troubleshooting: How to Fix Common Pipetting Issues

0 notes

Text

Important Parts of Lab Equipment

Laboratory equipment plays a vital role in scientific research, analysis, and experimentation. Each piece of equipment consists of various important parts that contribute to its proper functioning. Let’s take a closer look at some of the essential parts found in common lab equipment.

1. Body or Structure The body or housing of lab equipment is typically made from durable materials like stainless steel, glass, or high-quality plastics. This structure not only houses internal components but also ensures that the equipment can withstand rigorous usage, chemical exposure, and high temperatures.

Examples

Microscopes — The body supports lenses and focusing mechanisms. Centrifuges — The outer shell protects the rotor and ensures safety during high-speed spinning.

2. Control Systems Modern lab equipment often includes control panels or digital interfaces. These systems allow users to adjust settings such as temperature, pressure, speed, or time, ensuring precision in experiments and processes.

Examples

Incubators — Have digital controls to set and maintain the desired temperature. Autoclaves — Feature control panels for regulating sterilization cycles.

3. Power Supply Every electronic lab instrument needs a stable power supply to function. Power cords and batteries are critical in providing the energy required for operation. Proper voltage and current are essential to ensure equipment reliability and longevity.

4. Heating or Cooling Elements Temperature-sensitive equipment often has built-in heating or cooling systems. These elements are crucial for experiments that require maintaining specific environmental conditions, such as cell culture growth or chemical reactions.

Examples

Water baths — Equipped with heating elements to maintain water temperature. Refrigerators and Freezers — Include cooling mechanisms to preserve biological samples.

5. Sensors and Detectors Lab instruments rely heavily on sensors and detectors to provide accurate readings. These components measure variables like temperature, pH, or pressure, helping researchers monitor and control their experiments.

Examples

Spectrophotometers — Use light detectors to measure absorbance or transmittance. pH meters — Equipped with sensors to determine the acidity or alkalinity of solutions.

6. Sample Holders or Racks Many lab devices use specialized holders or racks to secure samples during analysis or processing. These parts are designed to protect and position the samples correctly within the equipment.

Examples

Test Tube Racks — Hold tubes in place during experiments. Centrifuge Tubes and Rotors — Keep samples balanced during high-speed spinning.

7. Safety Features Lab equipment often includes essential safety mechanisms to prevent accidents. These features are vital to protecting users from electrical hazards, overheating, or exposure to harmful substances.

Examples

Fume Hoods — Include ventilation systems to protect against toxic fumes. Safety Interlocks — Prevent operation of equipment like centrifuges unless lids are securely closed.

8. Calibration Systems For accurate results, many pieces of lab equipment must be regularly calibrated. Calibration systems ensure the equipment is working according to precise standards and measuring data accurately.

Examples

Balances — Require calibration to maintain precision in weighing samples. Pipettes — Need regular calibration to ensure consistent volume delivery.

The importance of each part in lab equipment cannot be overstated. Whether it’s the body that ensures durability or the sensors that guarantee precise readings, every component works together to maintain the accuracy and safety of scientific research. By understanding these vital parts, lab Creator can make informed decisions when selecting, maintaining, or upgrading their equipment.

0 notes

Text

Laboratory Calibration Services

Laboratory calibration services ensure that measuring instruments and equipment provide accurate and reliable results. These services typically include:

Calibration of Instruments: Regular calibration of various laboratory equipment like balances, pipettes, thermometers, and spectrophotometers to meet industry standards.

Traceability: Ensuring that the calibration results are traceable to national or international standards, often through the use of certified reference materials.

On-Site and Off-Site Calibration: Offering calibration services either at the laboratory's location or in an accredited facility.

Documentation: Providing detailed calibration certificates that document the process, results, and any adjustments made to the equipment.

Maintenance Services: Some providers may also offer maintenance services to keep the instruments in optimal working condition.

Compliance: Ensuring that calibration practices comply with relevant regulations and quality standards, such as ISO 17025.

Training and Support: Offering training for laboratory staff on proper use and calibration of equipment.

Global Insignia for Technical Services offers comprehensive laboratory calibration services tailored for various instruments, including electronic balances, temperature chambers, and pressure gauges. They provide quick turnaround times, including rush services, and can manage instrument pickup and delivery. Their onsite calibration services aim to minimize downtime, allowing clients to maintain operational efficiency while ensuring accurate measurements. Additionally, they maintain a robust documentation system to comply with industry standards and regulatory requirements.

1 note

·

View note

Text

How to Choose the Right Microbiology Equipment for Your Lab

Introduction Establishing a microbiology lab requires meticulous planning and a comprehensive understanding of the equipment needed to ensure success. The right tools are essential for precise research, accurate microbial analysis, and lab safety. In this article, we’ll explore the best microbiology lab equipment you need to set up a well-functioning lab. We will also delve into why each piece is crucial and how it contributes to the integrity of your research.

Table of Contents

Microscopes: The Cornerstone of Microbiological Research

Incubators and Their Role in Microbial Cultivation

Autoclaves: Sterilization Essentials for Lab Safety

Centrifuges: Ensuring Accurate Separation of Microbial Samples

Pipettes and Dispensing Tools: Precision in Microbial Handling

Biosafety Cabinets: Protecting Your Samples and Your Staff

Spectrophotometers: Quantifying Microbial Growth and Analyzing Samples

Microbial Culture Media and Preparation Equipment

Data Management and Lab Automation: Streamlining Microbiology Research

1. Microscopes: The Cornerstone of Microbiological Research

Microscopes are the backbone of any microbiology lab, enabling researchers to observe microorganisms invisible to the naked eye. The most common types of microscopes in microbiology labs are light microscopes, electron microscopes, and fluorescence microscopes. Choosing the right microscope depends on the type of microorganisms being studied and the level of detail required. High-resolution microscopes provide crucial insights into microbial morphology and structure. When considering lab equipment for microbiology, investing in a top-tier microscope is non-negotiable.

Microscopes help microbiologists analyze cell structures, diagnose infections, and perform critical research. To ensure precise results, it’s important to maintain your microscope properly with regular cleaning and calibration. Having the best microbiology lab equipment, including advanced microscopy tools, will enhance the accuracy of your microbial investigations.

2. Incubators and Their Role in Microbial Cultivation

Incubators play a crucial role in the growth and maintenance of microbial cultures by providing controlled temperature and environmental conditions. For laboratories that handle microbiological samples, incubators are essential for ensuring that microorganisms thrive under the right conditions. This is vital for producing accurate and reproducible research results.

Types of Incubators in Microbiology Labs:

Standard Incubators: Designed for basic temperature control.

CO2 Incubators: Provide specific gas mixtures, especially for sensitive cultures.

Shaking Incubators: Add a shaking motion to cultures, which can help with oxygenation and even distribution.

Each of these incubators serves unique functions that support different aspects of microbial cultivation.

Benefits of Reliable Incubators for Lab Research:

Consistent Growth Conditions: Helps ensure reproducibility and reliability in experiments.

Energy Efficiency: Reduces overall operational costs and environmental impact.

Precision: Accurate temperature control is critical for cultivating different types of microorganisms.

Durability: A long-lasting incubator reduces the need for frequent replacements and ensures continuity in research.

3. Autoclaves: Sterilization Essentials for Lab Safety

Autoclaves are essential for sterilizing equipment, media, and waste in a microbiology lab. They use high-pressure steam to kill microorganisms, ensuring that the working environment remains contamination-free. Proper sterilization is critical to the success of experiments, as even minor contamination can lead to inaccurate results. Having a reliable autoclave in your arsenal of lab equipment ensures that your lab maintains strict hygiene standards.

Autoclaves come in various sizes, from benchtop models to large, high-capacity machines. Selecting the right autoclave depends on the scale of your operations. Additionally, regular maintenance and validation of autoclave performance are crucial to ensure they operate at peak efficiency. This is why the best microbiology lab equipment always includes top-tier sterilization tools to keep your lab free from contaminants.

4. Centrifuges: Ensuring Accurate Separation of Microbial Samples

Centrifuges are used to separate microbial samples based on their density, making them essential for sample preparation and analysis in microbiology labs. By applying centrifugal force, these machines enable the isolation of different components within a sample, such as separating cells from a culture medium. Different types of centrifuges—such as benchtop, refrigerated, and ultracentrifuges—serve various purposes depending on the nature of your microbial research.

As you plan for your lab equipment, ensure that the centrifuge you choose meets the specific needs of your research. The best microbiology lab equipment will include centrifuges with adjustable speed, capacity, and rotor configurations, allowing you to handle various sample types and volumes with precision and efficiency.

5. Pipettes and Dispensing Tools: Precision in Microbial Handling

Pipettes and dispensing tools are fundamental in handling and transferring small volumes of microbial samples with precision. In microbiology labs, accurate measurement and fluid delivery are crucial, as even slight deviations can impact experimental outcomes.

There are various types of pipettes available, each suited to specific needs:

Manual Pipettes: Ideal for small-scale, infrequent sample transfers.

Electronic Pipettes: Provide enhanced accuracy and reduce user fatigue during repetitive tasks.

Multichannel Pipettes: Useful for transferring multiple samples at once, increasing efficiency in high-throughput environments.

Key Considerations When Selecting Pipettes When setting up your lab, it’s important to invest in high-quality pipettes. Here’s why:

Precision: Ensures accurate results in sensitive microbial experiments.

Ease of Calibration: Simplifies the process of maintaining accuracy over time.

Ergonomics: Reduces strain during extended use, especially in high-volume labs.

Durability: Provides long-term reliability, reducing the need for frequent replacements.

To ensure optimal performance in your microbiology experiments, your lab should be equipped with pipettes that meet the following criteria: easy to calibrate, ergonomically designed, and made from durable materials.

6. Biosafety Cabinets: Protecting Your Samples and Your Staff

Biosafety cabinets are critical for protecting both laboratory staff and microbial samples from contamination. These cabinets provide a sterile working environment, reducing the risk of exposure to hazardous biological materials. In microbiology labs, biosafety cabinets are classified based on the level of protection they offer, ranging from Class I to Class III. Selecting the appropriate biosafety cabinet depends on the risk level of the microorganisms being handled and the specific safety requirements of the lab.

Including a biosafety cabinet in your microbiology lab is essential for maintaining a safe and contamination-free workspace. The best microbiology lab equipment in this category will offer HEPA filtration, airflow control, and easy decontamination features to ensure both safety and functionality.

7. Spectrophotometers: Quantifying Microbial Growth and Analyzing Samples

Spectrophotometers are used to measure the concentration of microbial cells and assess the growth patterns of cultures. By analyzing the absorbance or transmittance of light through a sample, these devices provide valuable data on the quantity and activity of microorganisms. Spectrophotometers are indispensable when performing experiments that require quantifiable results, such as bacterial growth curves or enzyme activity studies.

Including spectrophotometers in your lab equipment will help you obtain accurate, reproducible data. The best spectrophotometers are highly sensitive, easy to calibrate, and capable of handling a wide range of wavelengths for versatile applications in microbial research.

8. Microbial Culture Media and Preparation Equipment

Microbial culture media provide the nutrients required for microorganisms to grow and thrive in a controlled laboratory setting. Different types of media are used depending on the microorganism under study and the research objectives. Solid, liquid, and semi-solid media, along with selective and differential media, play a critical role in microbial cultivation and identification.

Along with culture media, lab equipment such as autoclaves, media dispensers, and agar plate pourers are necessary for preparing and distributing culture media accurately. The right media preparation equipment is key to ensuring consistency and reliability in microbial experiments, making it an important part of your lab equipment list. The best equipment will streamline media preparation, ensuring that your microbial cultures receive the nutrients they need for optimal growth.

9. Data Management and Lab Automation: Streamlining Microbiology Research

Data management and lab automation tools are essential for efficiently handling the vast amount of information generated during microbiology research. Automated systems can streamline routine tasks, such as sample tracking, data collection, and analysis, significantly improving workflow efficiency and reducing the risk of human error. Additionally, laboratory information management systems (LIMS) are crucial for organizing and storing research data securely.

Including data management solutions in your lab equipment will enhance the accuracy and efficiency of your research. The best microbiology lab equipment in this category includes integrated automation tools that can handle repetitive tasks, allowing researchers to focus on more complex aspects of their work while ensuring the integrity and traceability of data.

Conclusion Setting up a microbiology lab requires careful selection of the right equipment to ensure precise, reproducible, and safe research outcomes. From microscopes to data management tools, each piece of microbiology lab equipment plays a vital role in the success of your research. Investing in the best tools not only enhances the accuracy of your experiments but also ensures the safety and efficiency of your lab operations. By equipping your lab with high-quality tools from Neoscience, you'll be better prepared to handle the complex challenges of microbiological research.

In our upcoming posts, we’ll dive deeper into specific equipment categories, explore maintenance best practices, and offer tips on how to extend the lifespan of your lab tools. Stay tuned for expert insights on optimizing lab workflows, comparing emerging technologies, and making informed decisions on microbiology lab innovations.

1 note

·

View note

Text

The Impact of Temperature on Pipetting Accuracy

Pipetting is an essential laboratory process, and depends heavily on precision instruments like micropipettes. Whether you're using an automatic micropipette for high-throughput experiments or a manual micropipette for delicate tasks, maintaining accuracy is essential. However, one often-overlooked factor that can significantly influence pipetting accuracy is temperature.

Let’s explore how temperature affects pipetting accuracy and how you can mitigate these challenges for reliable results.

How Does Temperature Affect Pipetting Accuracy?

Thermal Expansion of Liquids and Instruments Temperature fluctuations directly impact liquid density and volume. For instance, warmer liquids expand, which can lead to inaccurate volume measurements. This is particularly important when working with nanoliter dispensing or small volumes where even minor variations can cause significant errors. The mechanics of micropipettes, including pipette calibration standards, are also influenced by temperature. Plastic components in an auto micropipette or graduated micropipette may expand or contract, affecting their calibration.

Vapor Pressure Changes High temperatures can increase the vapor pressure of volatile liquids, making precise liquid handling more challenging. In such cases, using specialized micropipette tips designed for volatile substances can help.

Operator-Related Factors Human body heat can subtly affect the pipette price you pay in terms of accuracy. For example, holding the micropipette for extended periods might warm it up, leading to slight deviations in the dispensed volume. Understanding this interaction can help you choose the right types of micropipette for your tasks.

Best Practices for Mitigating Temperature Effects

Use Temperature-Adapted Tools Modern micropipette technology includes tools designed to minimize temperature effects. Investing in an automated micropipette or a well-calibrated micropipette pipette ensures consistent performance.

Pre-Equilibrate the Pipette and Liquid Allow both your automatic micropipette and the liquid to equilibrate to room temperature before beginning your work. This reduces discrepancies caused by temperature differences.

Calibrate Regularly Regular pipette calibration ensures your instrument remains accurate despite environmental changes. Calibration services often account for temperature variations when setting pipette calibration standards.

Choose the Right Tools Selecting the right pipette, whether it’s a micropipette pipette, an auto micropipette, or a graduated micropipette, for your specific application is crucial. For high-precision tasks, consider a pipette with nanoliter dispensing capabilities.

Monitor Environmental Conditions Maintain a stable lab environment to minimize temperature fluctuations. Using precision instruments in a controlled setting ensures more consistent results.

Why It Matters

Accurate pipetting is essential in fields like molecular biology, drug development, and clinical diagnostics. Inaccuracies, even if minor, can lead to failed experiments, increased costs, and unreliable results. By accounting for temperature effects and investing in reliable tools like automatic micropipettes or glass micropipettes, you ensure better reproducibility and efficiency.

Final Thoughts

Temperature plays a subtle but significant role in pipetting accuracy. Understanding its impact can help you make informed decisions, whether you're choosing a new micropipette pipette, comparing micropipette cost, or learning about the mechanics of micropipettes. Regular calibration, proper usage, and investing in advanced micropipette technology can mitigate temperature-related challenges, enabling accurate and reliable liquid handling every time.

Whether you're handling nanoliters or milliliters, accuracy is non-negotiable. Choose the right pipettor at the right pipettor price, calibrate regularly, and always consider environmental factors like temperature to achieve the best results in your work.

#micropipette#pipette calibration standards#types of micropipette#liquid handling#liquid handling instruments#pipettes#micropipette pipette

1 note

·

View note

Text

CRP Turbilatex Test: Features, Benefits, and Usage

The CRP Turbilatex test is a diagnostic tool used to measure the level of C-reactive protein (CRP) in the blood. CRP is a marker of inflammation in the body, and elevated levels can indicate various conditions such as infections, chronic inflammatory diseases, and cardiovascular disorders. This guide explores the features, benefits, and usage of the CRP Turbilatex test.

What is the CRP Turbilatex Test?

The CRP Turbilatex test is a latex-enhanced immunoturbidimetric assay used to quantitatively determine CRP levels in serum or plasma. The test is based on the principle of antigen-antibody reaction, where CRP in the sample reacts with specific anti-CRP antibodies coated on latex particles, causing agglutination. The degree of agglutination is measured turbidimetrically and correlates with the CRP concentration in the sample.

Features of the CRP Turbilatex Test Kit

1. Latex Reagent

- Contains latex particles coated with specific anti-CRP antibodies.

2. CRP Standards

- Provided in various concentrations for calibration and establishing the standard curve.

3. Reaction Buffer

- Used to prepare and dilute samples and reagents.

4. Test Tubes or Cuvettes

- Containers for mixing and measuring the reaction mixture.

5. Pipettes

- Used for accurate measurement and transfer of samples and reagents.

6. Calibrators and Controls

- Provided to ensure the accuracy and precision of the test results.

7. Instructions Manual

- Detailed instructions on how to perform the test, interpret the results, and maintain quality control.

Benefits of the CRP Turbilatex Test

1. Quantitative Measurement

- Provides precise quantitative measurement of CRP levels, allowing for accurate assessment of inflammation.

2. Rapid Results

- Delivers quick results, typically within minutes, enabling prompt clinical decision-making.

3. High Sensitivity and Specificity

- The test is highly sensitive and specific for CRP, minimizing the chances of false positives or negatives.

4. Ease of Use

- Designed for ease of use with straightforward procedures, making it suitable for clinical laboratories.

5. Wide Clinical Applications

- Useful in diagnosing and monitoring various conditions associated with inflammation, including infections, autoimmune diseases, and cardiovascular disorders.

How to Use the CRP Turbilatex Test

1. Sample Collection

- Collect a blood sample from the patient using standard procedures. Serum or plasma is then separated from the blood sample.

2. Preparation

- Prepare the reagents, calibrators, and controls according to the kit instructions. Ensure all reagents and samples are at room temperature.

3. Calibration

- Run the calibrators to establish a standard curve. This involves mixing the calibrators with the latex reagent and measuring the turbidity.

4. Sample Testing

- Mix the patient’s serum or plasma sample with the latex reagent in a test tube or cuvette. Incubate the mixture for a specified period at room temperature.

5. Measurement

- Measure the turbidity of the reaction mixture using a turbidimeter or a spectrophotometer set to the appropriate wavelength.

6. Interpretation

- Compare the turbidity of the sample to the standard curve to determine the CRP concentration in the sample.

Applications of the CRP Turbilatex Test

1. Infection Detection

- Helps in identifying bacterial infections and distinguishing them from viral infections, as bacterial infections typically cause higher CRP levels.

2. Chronic Inflammatory Diseases

- Used in the diagnosis and monitoring of chronic inflammatory diseases such as rheumatoid arthritis, inflammatory bowel disease, and systemic lupus erythematosus.

3. Cardiovascular Risk Assessment

- Elevated CRP levels are associated with an increased risk of cardiovascular events, such as heart attacks and strokes. The test can be used for risk stratification and monitoring.

4. Post-Surgical Monitoring

- Helps in monitoring postoperative patients for signs of infection or complications that may cause inflammation.

Conclusion

The CRP Turbilatex test is a valuable diagnostic tool for measuring CRP levels and assessing inflammation in the body. By understanding its features, benefits, and proper usage, healthcare professionals can effectively utilize this test to improve patient outcomes. Ensure to follow the instructions carefully and consider clinical correlations for accurate interpretation of results.

0 notes

Text

Life Sciences Laboratory Products

Categories of Life Sciences Laboratory Products

1. Consumables

Laboratory consumables are single-use items that ensure hygiene and accuracy during experiments.

Examples: Test tubes, petri dishes, pipette tips, and gloves.

2. Instruments

These high-tech devices aid in data analysis and sample processing.

Examples: Spectrophotometers, PCR machines, and centrifuges.

3. Safety Equipment

Products designed to protect researchers and maintain lab safety.

Examples: Fume hoods, safety goggles, and spill kits.

4. Chemicals and Reagents

Critical substances used in experiments for reactions, analysis, and testing.

Examples: Buffers, solvents, and assay kits.

5. Storage and Preservation Products

Used for preserving samples, reagents, and biological materials.

Examples: Cryogenic freezers, refrigerators, and incubators.

Essential Life Sciences Laboratory Products

Pipettes

Used for transferring precise liquid volumes. Adjustable and electronic pipettes are popular for reducing human error.

Centrifuges

Separate substances based on density, essential for molecular biology and biochemistry.

Microscopes

From basic optical microscopes to advanced electron microscopes, these are vital for observing minute structures.

PCR Machines

Widely used for amplifying DNA, essential in genetic research and diagnostics.

Spectrophotometers

Measure the intensity of light absorbed by a sample, crucial in quantifying proteins, nucleic acids, and other molecules.

Applications of Life Sciences Laboratory Products

1. Pharmaceutical Research

Laboratory products are integral to drug discovery, testing, and quality assurance.

2. Academic Research

Universities and institutions utilize these products to train future scientists and conduct cutting-edge research.

3. Clinical Diagnostics

Laboratories use products like ELISA kits and diagnostic instruments for disease detection and monitoring.

4. Environmental Studies

Analyzing soil, water, and air samples to study ecosystems and address environmental issues.

5. Biotechnology Development

Critical for innovations like CRISPR gene editing and biomanufacturing.

How to Choose the Right Laboratory Products

Identify Your Needs

Consider the type of experiments and research you’ll be conducting.

Assess Quality and Reliability

Choose products from trusted brands with a proven track record.

Evaluate Cost-Effectiveness

Look for durable and efficient products that provide long-term value.

Check Compliance

Ensure the products meet industry standards for safety and quality.

Leading Brands in Life Sciences Laboratory Products

Thermo Fisher Scientific Known for its wide range of lab equipment and consumables.

Sigma-Aldrich (Merck) A trusted name for chemicals and reagents.

Eppendorf Famous for its precision pipettes and centrifuges.

Bio-Rad Offers innovative products for molecular biology and clinical diagnostics.

Agilent Technologies Specializes in high-performance analytical instruments.

Emerging Trends in Life Sciences Laboratory Products

1. Automation and Robotics

Automated pipetting systems and robotic lab assistants enhance efficiency.

2. Sustainability

Eco-friendly lab consumables and energy-efficient equipment are gaining popularity.

3. IoT-Enabled Devices

Smart lab equipment connected to cloud platforms for real-time monitoring.

4. Customization

Tailored products to meet specific research needs are becoming common.

Best Practices for Maintaining Lab Products

Regular Calibration

Instruments like spectrophotometers and pipettes should be calibrated regularly for accuracy.

Routine Cleaning

Proper cleaning prevents contamination and extends the life of equipment.

Storage Guidelines

Store chemicals and sensitive equipment as per manufacturer recommendations.

Periodic Training

Train lab personnel on using and maintaining complex instruments.

Challenges in Managing Life Sciences Lab Products

High Costs

The initial investment in quality equipment can be steep.

Complex Maintenance

Sophisticated instruments require regular servicing and skilled technicians.

Supply Chain Issues

Delays in procuring essential consumables can disrupt workflows.

Rapid Technological Advancements

Keeping up with new innovations requires continuous learning and upgrades.

Conclusion

Life sciences laboratory products are the backbone of scientific discovery and innovation. From ensuring accuracy in experiments to advancing global healthcare solutions, these products make groundbreaking research possible. By investing in high-quality tools and maintaining them effectively, laboratories can achieve unparalleled success in their endeavors.

Contact Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

0 notes

Text

Ensuring Accuracy: Pipette Calibration, Burette Calibration, and Beaker Calibration in Dubai, UAE

Maintaining the integrity of your laboratory measurements is crucial for reliable research and quality control. This is where pipette calibration, burette calibration, and beaker calibration become essential practices. Dubai, UAE, boasts a range of calibration service providers to ensure your volumetric instruments meet the highest standards.

The Importance of Calibration

Volumetric instruments like pipettes, burettes, and beakers are the workhorses of many laboratories. Over time, due to wear and tear or even minor manufacturing inconsistencies, their accuracy can drift. Regular calibration helps identify and rectify these deviations, guaranteeing the validity of your measurements.

Pipette Calibration: Pipettes are used for transferring precise volumes of liquids. Inaccurate pipetting can significantly impact your results. Calibration ensures each pipette delivers the intended volume within acceptable tolerances.

Burette Calibration: Burettes are used for dispensing variable volumes of liquids during titrations. Precise burette calibration safeguards the accuracy of your titrations, leading to reliable data.

Beaker Calibration: While not as critical for some applications, calibrating beakers ensures they accurately reflect the volume they contain. This is particularly important for preparing precise solutions.

Benefits of Regular Calibration

Enhanced Data Integrity: Accurate measurements are the foundation of reliable research and quality control. Regular calibration minimizes errors and ensures data integrity.

Compliance with Regulations: Many industries have regulations mandating regular calibration of laboratory instruments. Calibration certificates serve as proof of compliance.

Cost Savings: Inaccurate measurements can lead to wasted materials, failed experiments, and even product recalls. Calibration helps prevent these costly issues.

Finding Calibration Services in Dubai, UAE

Several reputable laboratories in Dubai, UAE, offer pipette calibration, burette calibration, and beaker calibration services. When choosing a provider, consider factors like:

Accreditation: Look for laboratories accredited by a recognized body like ENAS (Emirates National Accreditation System).

Calibration Capabilities: Ensure the provider can calibrate your specific instruments and volume ranges.

Turnaround Time: Consider the time it takes for calibration and the return of your instruments.

Cost: Calibration costs can vary depending on the complexity of the instruments and the volume ranges involved.

By partnering with a reliable calibration service provider in Dubai, UAE, you can ensure your pipettes, burettes, and beakers deliver the precise measurements your research and quality control processes demand.

0 notes

Link

0 notes

Text

Laboratory Calibration Services for Precise Measurements

Laboratory Calibration Services by Custom Calibration ensure the accuracy and reliability of measurement instruments crucial for scientific research, quality control, and regulatory compliance. These services encompass a wide range of equipment, including but not limited to pipettes, balances, pH meters, centrifuges, and incubators. By verifying and adjusting instrument performance to established standards, calibration services uphold the integrity of experimental data and facilitate confident decision-making in laboratories across various industries.

0 notes