#pet bottle blowing machine

Explore tagged Tumblr posts

Text

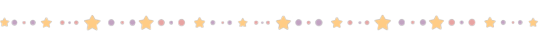

PET Bottle Blowing Machine | Seppa Solutions

Seppa Solutions is located in Chennai and manufactures PET bottle blowing machines with innovative solutions for diverse sectors such as beverage, pharmaceutical, cosmetic, and chemical industries. With decades of experience and precise engineering, they pioneered PET bottle manufacturing machinery. They specialize in fully automatic, semi-automatic, and custom-configured PET bottle blowing machines to suit different shapes, weights, and container production requirements. The hygiene and safety standards maintained by their equipment comply with relevant industry specifications and hence find applications in food-grade and pharmaceutical-grade uses. Seppa Solutions' ingenious machines are powered by state-of-the-art technology, including infrared heating technology, precision mould design, energy-efficient air recovery systems, and advanced control systems. They have supplied machines to over 25 countries for leading beverage brands, pharmaceutical companies, and multinational packaging firms. Their commitment to excellence and customer satisfaction has won them the respect and recognition of being a global forerunner in PET blowing technology.

#automatic pet bottle blowing machine#pet blowing machine#bottle blowing machine#pet bottle blowing machine#pet bottle making machine#pet making machine#pet bottle blow machine#automatic pet blowing machine

0 notes

Text

PET Blowing Machine: A Game-Changer in Packaging Industry

The PET Blowing Machine are revitalizing the packaging industry with the production of quality as well as durable PET containers. Known predominantly for their influence on food and beverage as well as pharmaceuticals and personal care sectors, PET blowing machines can hardly be dispensed with by manufacturers seeking to meet rapidly growing demands for trustworthy and lightweight packaging solutions.

What is a PET Blowing Machine?

This is a highly advanced technology in the scope of PET blow molding machinery as being in molding of PET plastic into bottles and containers of different shapes and sizes. The system involves heating small PET tubes called preforms to a defined temperature prior to blowing them into molds using well-oxygenated compressed air. The system guarantees precise, durable results in the final product.

PET Blowing Machines Applications:

The Beverage Industry: It is widely used in the packaging of water, carbonated drinks, juices, and energy drinks. PET bottles are extremely lightweight and carry great barrier properties which make them perfect for packaging beverages.

The Pharmaceutical Industry: PET Bottle Blowing Machines make containers that hit hard to set standards, especially with regard to the handling and protection of medicines and health products. The bottles do not react, for the safety of what is inside them.

Personal Hygiene Products: PET bottles are used also in packing shampoos, conditioners, hand lotions, and similar hygiene products, offering a nice, sturdy package.

Food Packaging: Such machines make PET containers for preservation purposes including sauces, cooking oils, and other food stuff. PET is a very effective packaging in terms of conserving freshness and lengthening life.

Benefit Statements about PET Blow Moulding Machines

Cost effectiveness: By investing in a PET blowing machine, a manufacturer reduces his dependence on external suppliers and facilities, increasing flexibility to make packaging materials within the company, saving costs.

Faster Production: One PET Blow Moulding Machine could produce thousands of bottles per hour, enabling it to meet high volume production requirements.

Variable: A single PET Blow Moulding Machine can create bottles in different sizes and shapes, so that it can take care of the different demands of multiple markets, all with one machine.

Environmentally friendly: The work of such PET blowing machines indeed goes hand in hand with global sustainability targets.

Durability/Lightweight Construction: The ability to withstand breakages or cracks and simultaneously light weight made PET bottles very easy to transport, which would bring added convenience to both manufacturers and consumers.

Selection of the Most-Beneficial PET Blowing Machine Manufacturer

There are various factors to consider before selecting a PET Blowing Machine Manufacturer.

Reputation: As far as this is concerned, you should look out for those companies that have had some achievements and are well known for producing reliable and efficient machines.

Engineering: The equipment should be created using highly modern technology and hence guarantees accuracy and high productivity.

After-Sales Support: Any good company will offer its customers support, after-sales service support in regard to maintenance or repair services.

Bespoke Options: Any company which manufactures it will at least be customized to one of end-user requirements.

Why PET Bottle Blowing Machines Have Higher Demands

A major part of PET bottles is because they are the most practical, cost-effective, and aesthetic for brands compared to the conventional ones. Companies are responding to the changes in consumer tastes and legislations because pet bottle blowing rates go up. Nowadays, pet bottle blowing machines are included in the packing process which enables product safety and recyclability plus more visual appeal of good-quality packaging solutions.

Conclusion

More than an instrument, a PET Blowing Machine by Aim Technologies for modern packaging solutions is one of its very kinds. It secures the safety of the product, decorates, and makes it more beautiful. Thus, there is no point waiting. Investing in a good PET Blowing Machine Manufacturer will give you a good edge whether you are a small industry or big enterprise in the current market trends.

0 notes

Text

https://www.canadiancrystalline.com/packaging/pet-blowing-machine.html

Pet Bottle Blowing Machine – Canadian Crystalline

PET blowing machines are production equipment for the industry producing efficient, effective, and refined, long-lasting, recyclable plastic bottles. For example, the blowing machines of Canadian Crystalline make varieties of bottle shapes and sizes, for use mostly in the sectors of food and drink, pharmaceuticals, and personal care, by turning a preform of PET into a bottle. The building of generic models includes heating PET, stretching, blowing, and cooling to ensure consistency and quality. Canadian Crystalline offers high-quality, high-speed production, energy efficiency, and customisation.

Also, these machines sustain the environment by reducing waste and enabling recyclable packaging. Investment in technologically advanced equipment increases productivity while keeping up with environmental objectives.

#automatic pet blowing machine#pet blow machine#pet blowing machine#pet blowing machines#pet bottle blowing machine#pet blower machine

0 notes

Text

Water Treatment Plants: Ensuring Clean Water for Every Industry

Introduction

Water treatment plants play a crucial role in ensuring that the water we consume and use in various industries is safe, clean, and fit for purpose. From drinking water to industrial processes, the quality of water directly impacts health, safety, and efficiency. This article explores the different types of water treatment plants and their specific roles in various industries.

Mineral Water Plant

Mineral Water Plant is designed to purify water and infuse it with essential minerals, making it safe and healthy for consumption. The process involves several stages, including filtration, reverse osmosis, UV treatment, and ozonation. These plants are essential in producing bottled water, which is widely consumed around the world. The purity of the water is maintained through rigorous quality checks, ensuring that the final product is free from contaminants.

Juice Production Plant

Juice production plants are specialized facilities where fruit juices are extracted, processed, and packaged for distribution. The process begins with the selection of fresh fruits, which are then washed, peeled, and juiced. The juice is pasteurized to kill any harmful bacteria, and additives like vitamins and minerals may be included to enhance its nutritional value. Finally, the juice is filled into bottles or cartons using advanced filling machines, ensuring that it remains fresh and flavorful.

Soft Drink Plant

Soft drink plants are complex facilities that produce carbonated beverages enjoyed by millions. The production process starts with water purification, followed by the mixing of various ingredients, including sweeteners, flavorings, and carbon dioxide. The mixture is then chilled, carbonated, and filled into bottles or cans. These plants are equipped with state-of-the-art machinery that ensures consistency, quality, and safety in every bottle.

PET Bottle Plant

PET bottles are ubiquitous in the beverage industry due to their durability, lightweight, and recyclability. PET bottle plant is where these bottles are manufactured. The process involves the use of preforms, which are heated and blown into the desired bottle shape using blow molding machines. These bottles are then used to package a wide range of beverages, from water to soft drinks, providing a convenient and safe packaging solution.

Commercial RO Plant

Commercial Reverse Osmosis (RO) plants are designed to purify water on a larger scale, suitable for commercial establishments such as hotels, restaurants, and offices. These plants use a multi-stage filtration process, including sediment filtration, activated carbon filtration, and reverse osmosis, to remove impurities and contaminants from water. The result is clean, safe water that meets the needs of businesses and their customers.

Industrial RO Plant

Industrial RO plants are similar to commercial RO plants but are designed to handle much larger volumes of water. These plants are used in industries such as pharmaceuticals, food and beverage, and chemical manufacturing, where water purity is critical. Industrial RO plants are highly efficient, capable of removing up to 99% of dissolved salts, bacteria, and other impurities, ensuring that the water used in industrial processes is of the highest quality.

Water Softener

Water softeners are essential in areas where water hardness is a problem. Hard water contains high levels of calcium and magnesium, which can cause scale buildup in pipes and reduce the efficiency of appliances. A water softener works by exchanging these minerals with sodium or potassium ions, effectively "softening" the water. This process extends the life of appliances, reduces energy costs, and improves the overall quality of the water.

Carbonated Soft Drink Filling Machine

The filling process for carbonated soft drinks is a delicate one, requiring precise control over pressure and temperature. Carbonated soft drink filling machines are designed to handle this process with efficiency and accuracy. These machines fill bottles or cans with the carbonated beverage, ensuring that the carbonation level is maintained and the drink remains fresh. Different types of filling machines are available, including volumetric and gravity filling machines, each suited to specific production needs.

Juice Bottle Filling Machine

Juice bottle filling machines are used to fill bottles with juice in a hygienic and efficient manner. These machines are designed to handle different types of juices, including those with pulp or other particulates. The filling process is carefully controlled to prevent spillage and contamination, ensuring that the juice retains its quality and freshness from the production line to the consumer.

Water Bottle Filling Machine

Water bottle filling machines are critical in the production of bottled water. These machines are designed to fill bottles with purified water quickly and accurately, minimizing waste and ensuring consistent quality. Modern water bottle filling machines are highly automated, reducing the need for manual labor and increasing production efficiency. These machines are also equipped with sensors and controls to monitor the filling process and detect any issues in real-time.

Automatic and Semi-Automatic Blow Moulding Machine

Blow molding is a process used to create hollow plastic containers, such as bottles. Automatic blow molding machinesand semi-automatic blow molding machines are used in this process to shape plastic preforms into bottles. Automatic machines offer higher efficiency and consistency, while semi-automatic machines provide more flexibility and control. Both types of machines are essential in the production of PET bottles, contributing to the packaging needs of the beverage industry.

BOPP Labeling Machine

BOPP (Biaxially Oriented Polypropylene) labels are widely used in the packaging industry due to their durability, clarity, and resistance to moisture. BOPP labeling machines apply these labels to bottles, cans, and other containers with precision and speed. These machines are designed to handle high-speed production lines, ensuring that labels are applied consistently and accurately, enhancing the appearance and shelf appeal of the products.

Sticker Labeling Machine

Sticker labeling machines are versatile machines used to apply stickers or labels to a wide range of products. These machines can handle different shapes and sizes of containers, making them ideal for various industries, including food and beverage, pharmaceuticals, and cosmetics. The technology behind sticker labeling machines ensures that labels are applied smoothly and securely, enhancing the overall presentation of the product.

Sleeve Applicator

A sleeve applicator is a machine used to apply shrink sleeves or labels to containers. These sleeves are then heat-shrunk to fit tightly around the container, providing a tamper-evident seal and a 360-degree label. Sleeve applicators are commonly used in the beverage industry, where they help enhance the visual appeal of products and provide additional space for branding and information.

Automatic and Semi-Automatic Shrink Wrapping Machine

Shrink wrapping is a packaging process where a plastic film is wrapped around a product and then heat-shrunk to create a tight seal. Automatic and semi-automatic shrink wrapping machines are used in this process to package products quickly and efficiently. Automatic machines are ideal for high-volume production lines, while semi-automatic machines offer more flexibility for smaller operations. Both types of machines are essential in protecting products during transportation and storage.

Jar Washing Machine

Jar washing machines are used to clean jars before they are filled with products such as jams, sauces, or beverages. These machines use a combination of water, detergent, and mechanical agitation to remove dirt, residues, and contaminants from the jars. The clean jars are then ready for filling, ensuring that the final product is safe and free from any contaminants.

Water Pouch Filling Machine

Water pouch filling machines are used to fill pouches with purified water, providing a convenient and cost-effective packaging solution. These machines are commonly used in areas where bottled water is not practical or affordable. The pouches are filled, sealed, and packaged in one continuous process, ensuring that the water remains clean and safe for consumption.

Auto Batch Coding Machine

Auto batch coding machines are used to print batch numbers, expiration dates, and other important information on products. These machines are essential in ensuring product traceability and compliance with regulatory requirements. The codes are printed clearly and accurately, providing vital information to consumers and enabling manufacturers to track products through the supply chain.

Water ATM

A Water ATM is a kiosk or vending machine that dispenses clean drinking water to the public. These machines are particularly useful in areas where access to clean water is limited. Users can purchase water at an affordable price, making it accessible to a wider population. Water ATMs are a significant innovation in providing safe drinking water to communities and reducing the reliance on bottled water.

Water Chiller

Water chillers are used to cool water for various industrial processes. These machines remove heat from water, lowering its temperature to the desired level. Water chillers are commonly used in industries such as food and beverage, pharmaceuticals, and manufacturing, where precise temperature control is essential. Different types of water chillers are available, including air-cooled and water-cooled models, each suited to specific applications.

Conclusion

Water treatment plants and related machinery play a vital role in ensuring that water used in various industries is clean, safe, and suitable for its intended purpose. From mineral water production to industrial processes, the quality of water directly impacts the success and efficiency of operations. As technology continues to evolve, we can expect further advancements in water treatment and packaging solutions, helping to meet the growing demands of consumers and industries alike.

youtube

0 notes

Text

Revolutionizing Bottle Production: The Ultimate Guide to Bottle Blowing Machines

Are you curious about how those perfectly shaped bottles are made? Let's dive into the fascinating world of bottle blowing machines!

Bottle blowing machines are the unsung heroes of the beverage industry. These marvels of engineering transform simple plastic preforms into the bottles we use every day. Here's what makes them so incredible:

• High-speed production: Some machines can produce up to 15,000 bottles per hour! • Versatility: They can create bottles ranging from 500ml to 5 gallons. • Energy efficiency: Modern machines use up to 20% less energy than older models. • Cost-effective: The stretch blow molding process can reduce raw material costs by 10-15%.

But that's just the tip of the iceberg. These machines are complex systems with multiple components working in perfect harmony:

The extruder melts and shapes the plastic.

The die head forms the initial preform.

The blow pin introduces high-pressure air to shape the bottle.

Advanced cooling systems ensure the bottle retains its shape.

Safety is paramount when operating these machines. Proper training and adherence to safety protocols are essential for bottle blowing machine operators.

Maintenance is key to longevity. Regular lubrication, inspection of parts, and cleaning can significantly extend a machine's lifespan.

Intrigued? There's so much more to learn about these incredible machines. From the intricacies of the cooling system to the precise positioning of switches, every detail plays a crucial role in producing the bottles we use daily.

Want to dive deeper into the world of bottle blowing machines? Check out https://ibottling.com/bottle-blowing-machine/ for a comprehensive guide that covers everything from machine components to maintenance tips.

Discover how these machines are shaping the future of the beverage industry – one bottle at a time!

#bottle blow molding machine#bottle blow molder#pet bottle blowing machine#bottle blowing machine#bottle blow molding machine uk

0 notes

Text

0 notes

Text

PET bottle blow molding machine market is projected to reach $1.2 billion by 2032, growing at a (CAGR) of 3.1%

1 note

·

View note

Text

#PLASTIC BLOW MOULDING#Parison Control Blow Moulding Machine#Double Station Parison Blow Moulding Machine#Automatic Blow Moulding Machine#L-Ring Drums Full Range#Accumulator Parison Full Range#IBC Tank Blow Molding Machine#Water Tank Blow Moulding Machine#Plastic Injection Moulding Machine#PET Bottle Stretch Blow Moulding Machine#Plastic Blow Moulding Machine#Extrusion Blow Moulding Machine#PET Blow Moulding Machine

0 notes

Text

heat lamp infrared quartz heating elements heat lamp ir carbon fiber for printing machine 1200w/1600w heat lamp ir carbon fiber heater for poultry chick 220v 500w heat lamp ir carbon fiber heating lamp for pet bottle blowing machine heat lamp ir carbon fiber lamp for warming printing machine

#heat lamp infrared quartz heating elements#heat lamp ir carbon fiber for printing machine 1200w/1600w#heat lamp ir carbon fiber heater for poultry chick 220v 500w#heat lamp ir carbon fiber heating lamp for pet bottle blowing machine#heat lamp ir carbon fiber lamp for warming printing machine

0 notes

Text

Working Mechanism of PET Bottle Blowing Machines

PET Bottle Blowing Machines are an essential part of the modern manufacturing process, playing a crucial role in the production of bottles for various industries including beverages, pharmaceuticals, and personal care products. A PET Bottle Blowing Machines typically operates in three stages - perform heating, bottle blowing, and bottle ejection. In the first stage, the preform is heated in an oven until it reaches the required temperature for blow molding. In the second stage, compressed air is used to blow the heated preform into a mold, forming the desired bottle shape. Finally, the formed bottle is ejected from the mold and is ready for use.

Advantages of Using a PET Bottle Blowing Machine:

Increased Efficiency: The use of a PET bottle blowing machine increases the efficiency of the production process. It reduces the time and labor required to produce bottles, resulting in higher production rates.

Consistent Quality: The use of a machine ensures consistent quality of the bottles produced. This is because the machine operates under controlled conditions and produces bottles with uniform dimensions and features.

Cost-Effective: The use of a PET bottle blowing machine is cost-effective in the long run as it reduces the cost of labor and increases the efficiency of the production process.

What are PET Bottle Blowing Machines

PET (polyethylene terephthalate) bottles are widely used for packaging products like beverages, food, personal care items, and pharmaceuticals. The process of producing these bottles involves a PET bottle blowing machine. These machines play a crucial role in the mass production of PET bottles.PET (Polyethylene Terephthalate) bottle blowing machine is a device used to manufacture plastic bottles from PET material. The process involves heating the preform to a specific temperature, inflating it into a mold, and then cooling it to take the shape of the mold.

0 notes

Text

Semi-automatic 50 to 5000ML Bottle & Jar Making Machine | Shyam Plastic

Check out Tech Specs for Versatile, Semi-automatic Pet Blow Moulding machine for 50 to 5000ML Jar and Bottle Making Machine by Shyam Plastic. Visit us Now.

0 notes

Text

https://www.seppasolutions.com/pet.html

"Customization, Quality, and Care: The Seppa Solutions Promise in Bottle Production"

Seppa Solutions, a pioneer in packaging machinery, has introduced the revolutionary Pet Bottle Blowing Machine, a game-changer that will revolutionize the packaging industry. This eco-friendly machine offers unparalleled efficiency, allowing for the production of high-quality bottles with precision and speed. It caters to market needs from small businesses to large manufacturing facilities, supporting sustainability by lowering the carbon footprint and adhering to ethical manufacturing standards. The machine's versatility in design and customization caters to the dynamic nature of modern packaging demands, catering to unique bottle shapes or specific branding requirements. It complements human expertise, paving the way for a more sustainable and dynamic packaging future.

#pet blowing machine#automatic pet bottle blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine

0 notes

Text

Water Bottle Making Machine: Technology, Types & Industry Applications

Introduction to Modern Water Bottle Making Machine

The plastic bottle manufacturing machine has now become advanced due to the demand for Water Bottle Making Machines in bottled water production, which has been growing substantially worldwide. These advanced plastic bottle manufacturing machines are equipped with almost the latest stretch blow molding (SBM) engineering for effectively producing the much-needed high-quality PET containers for various industries.

The latest and modern-style Blow Molding Machines can boast of:

✔ Precision automation to ensure consistent output

✔ Energy-efficient operating systems

✔ Flexible production capacities

✔ Integration of smart technology

These machines are used in several sectors including but not limited to:

✔ Beverage and drinking water

✔ Pharmaceutical and healthcare

✔ Personal care and cosmetics

✔ Food and household products

A Detailed Dissection of a PET Bottle Manufacturing Process

1. Preform Treatment and Adjustment

The first stage in the whole production cycle is a PET preforming - test-tube shaped plastic blanks which are:

✔ Being automatically loaded into the machine

✔ Heated correctly to optimum temperature (190-210°C)

✔ Rotated for uniform heat distribution.

2. Blow Molding Phase

Preforms at elevated temperatures undergo:

✔ Stretching using precision rods;

✔ High-pressure air expansion (30-40 bar);

✔ Molding for cavity shapes;

✔ then, rapid cooling to set the bottle structure. All this occurs at a speed of about 2-5 seconds per bottle.

3. Quality Control and Output

The processing draughts are:

✔ Automatically ejected from the machine.

✔ Following quality they are subjected to leak and defect testing.

✔ Then put on for packaging and distribution.

Also read, Choosing the Right Water Bottle Making Machine for Your Production Needs

Types and Capacity of Machines

1. Semi-Automatic Systems

✔ Perfect for small production

✔ Manual preform loading

✔ Basic automation

✔ Suitable for product development

2. Fully Automatic Machines

✔ Costs medium or large operations

✔ Robotic material handling

✔ multi cavity mold options

✔ advanced process controls

3. Rotary Blow Systems:

✔ Suited for high-volume production solutions.

✔ Facility for continuous operation.

✔ Design for maximum efficiency.

✔ Output of industrial levels.

Essential Features of Advanced Technology

Energy Management Systems

✔State of-the-art servos

✔Heat recovery systems

✔Smart metering of energy usage

Precision Engineering

✔Microprocessor temperature regulation

✔Extremely accurate stretch rod systems

✔Equal pressure regulation by air

Smart Manufacturing

✔Highly defined HMI touchscreen interfaces

✔Barcoding on production data

✔Remote monitoring facility

✔Predictive Maintenance System – PPM

Factors that can be considered while selecting a Water Bottle Manufacturing Machine

1. Production requirements - volume and speed needs

2. Characteristics of products - sizes and designs

3. Technological considerations - automation and control features

4. Future expansion - scalability options

5. Support services - maintenance and training

Advantages of modern bottle production systems

✔ Consistent high-quality output

✔ Efficient utilization of material

✔ Reduced energy consumption

✔ Flexible production capability

✔ Good long-term performance

Conclusion: Boosting Skills to Produce

The industry of the Water Bottle Making Machine is always advancing by technology which is being improved by means of production and product quality. Aim Technologies present this modern-day PET Blowing Machine to cater to manufacturers of high operation standards and allow greater production to satisfy a growing market.

Understanding such advanced production systems allows a business to make wise decisions for their equipment. For those companies wishing to get started in bottle manufacturing or wish to expand their market, an understanding of advanced production systems is pertinent for wise choices on perfect Bottle Blowing Machines. A very good Bottle Blowing Machine would create a phenomenal difference in production capacity, product quality, and operation efficiency.

#water bottle making machine#PET blowing machine#Plastic Bottle Manufacturing Machine#Bottle Blowing Machine#Water bottle manufacturing machine

0 notes

Text

Canadian Crystalline – Pet Bottle Blowing Machine

Canadian Crystalline PET Bottle Blowing Machines are reshaping the beverage packaging industry with unmatched precision, speed, and efficiency. Designed to produce lightweight, durable, and eco-friendly PET bottles, these machines serve diverse industries such as beverages, cosmetics, and pharmaceuticals. They stand out for their high production speed, energy-saving capabilities, adaptable designs, intuitive operation, and minimal maintenance needs. With cutting-edge technology, a global footprint, and tailored solutions, Canadian Crystalline delivers exceptional packaging quality while prioritizing sustainability. Trusted by businesses worldwide, these machines offer great returns and reliable support. Choose Canadian Crystalline to lead packaging innovation and enhance your brand’s market impact.

#pet bottle blowing machine#pet blowing machines#pet blowing machine#pet blow machine#automatic pet blowing machine#pet blower machine

0 notes

Text

Bedtime for the Baby

CG! Jax and Regressor! Orchid (OC) 🍼

Plot: Jax gets Orchid ready for bed.

Part of the dialogue is heavily inspired and based by an episode of OK K.O. called “Villain’s Night In” and a post by @sleeperton

Orchid was sitting in their sensory swing, chewing on a lightning-shaped teether and watching Barney. The poor stuffed zebra hasn’t regressed for who knows how long, and they regressed to babyspace as a result.

Orchid tried to watch the show, but their eyes were getting heavy. They yawned as they snuggled into the swing. The door to their room was unlocked by Jax, who had a tank of centipedes in his hands.

“Hey, pint-size, can you pet sit my…” Jax started to ask when he spotted Orchid in their sensory corner. He walked over there and saw that the zebra was dozing off. He set the tank over to the side and came down to Orchid’s eye-level. “Hey, squirt. Are you getting sleepy?”

Orchid yawned as a response as they snuggled further into their swing.

“Alright, it’s bedtime,” Jax said.

“Nooo…” Orchid mumbled as they kicked their hooves tiredly. Jax then picked them up from the swing and cradled them in his arms.

“I can see that you’re acting up and getting fussy. That means it’s time for the little baby to go night-night.”

“Noo… no, no, no…” Orchid muttered as they snuggled in the rabbit’s embrace.

“Yes,” Jax cooed as he patted Orchid’s back and gently bounced them. He grabbed the changing mat that sat next to Orchid’s dresser and laid it on their bed. He also grabbed a diaper, some changing materials, and a footed sleeper.

Jax laid Orchid on the mat, who then fussed and whined.

“I know, I know, Bunny’s so mean for not holding you,” Jax said as he grabbed a pacifier and popped it in the zebra’s mouth. Orchid’s fussing slowly ceased as they suckled on the soother. “There we go, no more tears.”

Jax then spotted Orchid’s blankie and stuffed bunny, Maisy, next to their sensory swing. He went over to the swing and grabbed the comfort items. He handed the items to Orchid and changed them into their pajamas.

After putting the changing supplies away, Jax grabbed Maisy and pretended it was playing peek-a-boo with Orchid. The small zebra cheered up and proceeded to giggle.

“Is Maisy being silly?” Jax cooed as he then pretended that the stuffed bunny was blowing raspberries on Orchid’s tummy. He blew raspberries on Orchid’s tummy as well.

Orchid squealed and laughed as Jax handed them their bunny and picked them back up. He walked out of the room, down the hallway, and into the kitchen. He placed Orchid in a high chair and made their bottle.

Once the bottle was made, Jax carried Orchid back to their room and tucked them into bed. He turned off all of the lights except for the lamp that rested on Orchid’s bedside table. He then turned on the sound machine that was in the sensory corner to add a calming ambience.

Orchid whined as they reached their arms out to Jax, wanting to be cradled again.

“Okay, Bunny’s coming,” Jax said as he sat down on the bed and cradled Orchid in his arms. “Better?”

Orchid nodded as the rabbit replaced the pacifier in their mouth with the bottle.

Jax gently scratched Orchid’s back as he fed them. The small zebra snuggled their stuffed bunny and blanket.

Orchid finished their bottle after a few minutes and yawned as they rubbed their eyes. Jax popped the pacifier back into their mouth and continued scratching their back until they finally fell asleep.

Jax tucked Orchid in and grabbed the tank of centipedes. He closed the room door behind him and decided to plant the tank in Ragatha’s room.

#age regression#sfw agere#agere#age regressor#sfw age regression#the amazing digital circus#tadc#age dreaming#agere blog#agere community#padded agere#agere fanfic#fanfic agere#fandom agere#tadc agere#agere tadc#fanfic#fan fiction#sfw interaction only#tadc Jax#Jax tadc#tadc oc

32 notes

·

View notes

Text

youtube

PET BOTTLE BLOW MOLDER

We would be happy to help and advise if you have any questions or inquiries.

PET BOTTLE BLOW MOLDING MACHINE

CAPACITY

Up to 15,000 bottles per hour

CAVITIES

Up to 8 cavities

PERFORMANCE

Satisfaction Guaranteed

2 Years Quality Warranty

On Time Delivery Guaranteed

OVERVIEW

Steplead’s BMA series blow molding machines produce the highest quality PET containers for a wide range of applications, sizes, and production demands. Our blow molders exceed previous blowing capacity, cost, and bottle quality benchmarks. Steplead’s industrial blow molding equipment reliably manufactures PET bottles and containers with precision engineering. Advanced temperature controls and adjustable blowing pressure deliver consistent, high-quality results. Trust Steplead for customizable stretch blow molding systems optimized for your PET bottle production needs. Contact our experts today to learn more about our high-performance blow molders for various industries.

youtube

ADVANTAGES

UP TO 50%

Steplead certified parts with additional warranty

UP TO 25%

Less maintenance

UP TO 20%

Less energy using lower engine speed and larger hydraulic pump.

Save Cost

The great advantage of stretch blow moulding machine is to stretch the container in both the axel and hoop directions, which name biaxial stretching and it will greatly improve the container’s top load, clarity, drop impact tolerance, barrier abilities and tensile strength. As a result, the raw material cost can be save for about 10-15% by reducing the weight of container.

Wide Application

The stretch blow molding process making PET bottles is popular in beverage industry production for juice, water, soda, and many other products. Since 1970’s, this blow moulding technique is applied widely to package chemical detergent and soda bottles.

High Efficiency

This blow moulder can achieve you any extra ambition of blowing production. No matter considering production output, reliability or efficiency, for non-carbonated water, csd (carbonated soft drink), and hotfill products, with maximum 6 cavities to produce up to 6,000 containers per hour.

PRODUCT SPECIFICATIONS

Download

2,000 ~15,000 Bottles500ml / Per Hour

Max Container Volume: 2L

Max Cavities: 8

Clamping Force: 320KN

Power: 120Kw

Dimension: 3,600 x 2,000 x 2,210MM

PREMIUM

LAYOUT COLLECTION

The best way to experience our wide collection of production layouts for your project.

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Previous slide

Next slide

RELATED EQUIPMENT

HOW TO ENSURE THE SAFE AND EFFICIENT PRODUCTION OF BOTTLE BLOW MOLDING MACHINE.

Here is a list of all the types of technical questions concerning bottle blowing molding machine that you can find.

What Safety Precautions Would Be Needed For Blow Molding Machine Operation

Safety Precautions for blow molding machine operation

These precautions are for the sake of preventing operators and other staff from being hurt or preventing machine from being damaged when trouble occurs. Because devices of this machine use pneumatic and electrical control, which features big power and quick working speed, therefore any errors of operation may lead to dangerous consequences. The machine is equipped with some safety devices to protect the operators. Before operation, please check whether these safety devices work properly.

1. Safety Precautions: 1) Operator must wear safety helmet, slip-proof shoes and working clothesduring installation, inspection and maintenance. 2) Make sure to install the machine in a dry, bright and clean location. The ground around the machine should be solid and its surface should be slip-proof. 3) Never put tools and other articles onto the machine or any other moving parts. 4) Don’t climb onto the machine when it is running and don’t touch the moving parts. Before inspection and maintenance, the power and gas source must be switched off and ensure that air pressure of gas circuit is environmentalatmosphere.Note: Once the pressure of operation gas circuit is environmental atmosphere, mold base components will automatically descend. 5) When operate parts of heating devices, turn off the power first and operate after it completely cools down. 6) Please pay special attention to the safety warning board installed on dangerous parts of the machine.

2. The Safety Guard and Safety Door on the Machine 1) A limit switch is installed on the safety door to pick up the bottles. When the safety door opens, this limit switch will be activated to stop the machine from operation. Therefore, it’s important to check whether this limit switch can work normally before operating the machine. 2) It’s forbidden to dismantle the safety door on the machine and the safety cover on automatic chainsunless necessary maintenance and inspection are needed. And after maintenance and inspection, the safety door and the safety cover on automatic chains must be reinstalled as its original way. 3) Emergency Stop Button There are two buttons for emergency stop on the machine. One is on the operation panel and the other is on the back of the machine. They are used for emergencies. If each of the emergency stop buttons being pressed, both the power and gas source are switched off simultaneou sly and the machine stops all operation immediately. 4) Overpressure Protection The machine uses compressed air. The safety valve is respectively installed on high and low-pressure air collector. If the pressure in air intake is too high, the safety valve will be automatically opened to ensure of the safety. Air pressure for operation: Air intake 0.8Mpa Air pressure for blowing: Air intake 3.5MPa 5) Grounding The machine has contact for grounding. Before using the machine, connect the earth wire, which should be chosen according the local standard.

What Are Precautions Else Needed For Operation Of Blow Molding Machine

Precautions Related with Operation of Blow Molding Machine

Before operating the machine, read and understand the operation regulation in the operation manual or have relative training for operation.

(1) Emergency Stop

① There are two emergency stop buttons on this machine. The gas supplies stops and piston of air cylinder at the mold base and press preform falls down when each one of the buttons is pressed. The piston returns when turning and releasing the emergency button clockwise.

② There is a safety lever installed at the right side of bottle picker connected with the switch to prevent the bottle or preform from going to the next circle. If bottles or preform press on the safety lever, the machine will stop immediately until they are

removed. Note: Don’t operate the machine until you are sure of the security.

(2) Adjustment of Position and Speed

The position and speed valve of magnetic switch and approach switch on gas cylinder of movement devices has been properly adjusted before the machine leaves the factory. Don’t try to make the machine run quicker by changing their position or adjust the speed valve. Otherwise, it may cause damage of the machine or lead to malfunction.

(3) Inspections Related with Automatic Operation

① Confirm the safety for the operator. Check with eyes carefully the surrounding of the machine to make sure that it is safe in this area.

② Make sure that all safety devices can function normally.

③ Ensure all limit switches are in position and properly tightened.

④ Check whether the air pressure for operation and blowing is normal.

⑤ Check the adjustment of various speed

⑥ Check the temperature and circulation of cooling water.

(4) Safety during Bottle Blowing

① Never open the guarding gate or climb into it during bottle blowing.

② Never touch movement parts during bottle blowing.

③ Keep close attention to the working status of the machine. If abnormal situation or noise occurs, stop the machine immediately. Look for reasons and get rid of the troubles. If alarm occurs, the machine will stop automatically. The machine can be operated again only after the troubles are eliminated.

What is The Safety of Maintenance and Repairation of Blow Molding Machine

The Safety of Maintenance and Repairation of Blow Molding Machine

(1) Before repairing the machine, switch off the power and hang a warning plate of “Repairing, Switch on Prohibited” at the power switches. Before repairing, use electroscope to check that the power has already being switched off.

(2) It should bear regulated pressure to replace pneumatic units such as gas pipe, valve and connectors. It should get the approval from professional engineers to replace these units. Before replacing, make sure that the air pressure of gas circuit has been reduced to environmental atmosphere.

(3) The capacity should be in accordance with corresponding regulation when replacing fuses or other electric units. It should get approval from professional engineers or technicians for the replacement.

(4) Never touch any electrical devices with wet hands.

(5) When repairing the mold on the machine, insert a cushion (A rectangle wood block of 15×20 cm, which length should be the same with the length when the mold opens to its maximum extent) into the opened mold clamp device.

(6) Lubricate the machine after it stops.

(7) Use proper tools to maintain and repair the machine. Exert proper moment when tightening the bolts and nuts.

(8) Carefully check the repaired area after maintenance and repair to prevent any tools from being left in the machine.

What Precautions You May Need for The Gas Circuit System of Blow Molding Machine

Precautions of Gas Circuit System of Blow Molding Machine

Note: The density of high-pressure air is very high and any leakage of it shall lead to serious consequences.

(1) It’s strictly forbidden to change the position of safety valve on the air collector. (2) Impact of compressed air collector is strictly prohibited. (3) Open the gas outlet valve slightly to discharge the gas slowly when relieving the pressure. (4) Switch off the gas source and open the outlet valve as well as ensure that the reading on pressure meter is zero before removing parts on gas circuit. (5) Discharge the gas thoroughly if the machine has stops operation for a long time. (6) When replacing any pneumatic units, check under low pressure to reconfirm its safety and gradually increase the air pressure.

(7) Check the safety of gas circuit regularly. Check Every Day ① Check pressure meter of air collector to make sure that every pressure value is normal. ② Check and monitor the gas circuit system (air collector, pipes, valves and air cylinder) to make sure that there is no gas leakage. ③ Ensure that hoses are not bent or damaged and every part of gas circuit system is solidly tightened.

Check Every Week ① Dry the accumulated water in high and low pressure air collector and filters. ② Check whether the magnetic coil and bolt is loose. ③ Check and clean the air muffle.

Check Every Six Month Check the accuracy of every pressure meter on air collector and gas circuit.

#pet bottle blowing machine#bottle blowing machine#blowing machine#blow moulding#blow moulding machines#pet bottle blower#pet bottle blower australia#pet bottle blowing machine uk#pet bottle blowing machine australia#pet bottle blow molding machine#Youtube

0 notes