#parts Manufacturin

Explore tagged Tumblr posts

Text

Metalman Auto files draft papers with SEBI to raise funds via IPO

The IPO consists of a fresh issue of Rs 350 crore and an offer for sale of upto 12.64 million shares by its existing shareholders and promoters.

Metalman Auto Ltd has submitted a Draft Red Herring Prospectus (DRHP) to the Securities and Exchange Board of India (SEBI) to raise capital through an Initial Public Offering (IPO). The IPO includes a fresh issuance of shares worth Rs 350 crore and an offer for sale of up to 12.64 million shares by the company’s current shareholders and promoters.

The proceeds from the fresh issue will be allocated as follows: Rs 25 crore will be used to partially finance the capital expenditure for the procurement of plant and machinery at the Pithampur manufacturing unit 2. The company also plans to utilize Rs 240 crore to repay a portion of its existing debt. As of June 2024, Metalman Auto Ltd has a total debt of Rs 314.43 crore.

The firm operates nine manufacturing units across five states in India, strategically located near OEM customers to ensure efficient production and supply. Axis Capital, ICICI Securities, and Motilal Oswal Investment Advisors are the lead managers for this issue.

Metalman Auto Ltd is a leader in the metal fabrication, finishing, and assembly sector in India, specializing in the production of metal components for two-wheelers (including both electric and internal combustion engines), three-wheelers, passenger vehicles, commercial vehicles, agri-vehicles, and off-highway vehicles. Additionally, the company manufactures aesthetic components for white goods, such as panels for washing machines, and offers contract manufacturing services for two-wheeler electric vehicle (2W EV) OEMs.

#metalman auto#oem manufacturing#oemparts#electric vehicles#metal fabrication#fabricationservices#steel fabrication#supplier#manufacturer#stainless steel#transport technology#transport service#transport for london#vehicle transport#transportation#ipo news#ipo alert#markets#stocks#business standard#business magazines#High-Volume Automotive Parts Manufacturing#manufacturing#automotive parts#parts Manufacturin#automotive industry#automotive#car accessories

2 notes

·

View notes

Text

Relationship between plastic products and demoulding angle

Demolding angle: To facilitate demoulding, wall of plastic product should have an draft angle α in demoulding direction, and its value is expressed in degrees.Key points for determining demoulding angle(1) The higher product precision requirement, the smaller demoulding angle should be.(2) For large products, a smaller demoulding angle should be used.(3) For products with complex shapes that are…

View On WordPress

#Demoulding angle#Design of reinforcing ribs#high-precision plastic products#injection pressure#Mold manufacturin#plastic injection molding#plastic parts#Plastic parts structural design#plastic product#Plastic product molding#plastic products#product design#product structure#Relationship between plastic products and demoulding angle

0 notes

Text

The X from Outer Space

Let's talk about space, poozers! I love space. I'm from space! If humanity manages ta' not go extinct, humanity's future is in space. There ain't no doubt about that.

Good talk! Now lets talk about SpaceX.

Years ago little Elon Musk had a dream: To be a technocratic racist and antisemite obsessed with the letter X like his grandfather (seriously, look it up, the man left the Technocracy Movement cuz it wasn't racist an' capitalist enough fer him, that's how Mother Musk's family ended up in apartheid South Africa).

After little Elon failed his way into a fortune by not inventin' Paypal, he thought, "What if I sabotaged humanity's future ta' usher in a horrifyin' dystopia?" An' SpaceX was born.

SpaceX has exactly one claim to fame: It does a few things and only a few things. Since it only does a few things, it can do 'em repetitively an' cheaply.

See, every NASA mission is bespoke. Even reuseable craft, like the Space Shuttle, had to be adaptable enough for bespoke missions. Each mission is designed from nearly the ground up, an' that's very expensive.

SpaceX, on the other hand, decided ta' build a kinda assembly line ta' do one specific thing. The space station needs cargo? Let's build a cargo hauler that just does that over an' over. Cuz it's the same mission profile, everythin' can be streamlined an' cheaper.

Now, SpaceX clearly didn't come up with the idea of a reusable platform. That's a standard thing in manufacturin'. Ya may be askin', why didn't NASA do that? And the answer's simple. Cuz Congress didn't want NASA to do that. Congress wanted SpaceX to do that. Congress was so impressed with Elon Musk not creatin' Paypal and gettin' fired from CEO for incompetence twice that they went with his idea rather than the organization that had put us on the moon with a shoestring budget.

There were a zillion problems, but one was bigger than the others: SpaceX, like all Musk enterprises, was a complete failure and its rockets blew up. Well, that certainly makes it difficult to be the best at space!

But Elon Musk's buddies and cronies in Congress had a solution: Throw money at him. Rocket blows up? Throw more money. And more. And more. SpaceX would have been bankrupt in 2006 without a single success if Congress hadn't kept throwin' taxpayer money at it.

Why didn't they throw that money at NASA? Well if NASA had designed the assembly line launch platform, which they could have done much easier and cheaper, then the assembly line launch platform would have belonged to a public organization, and thus to the people, instead of belonging to literally the worst human being on the face of the earth.

That's it. That's the only reason. I defy you to find me any legitimate reason. And I'm not talking about Musk bribin' them, that's all part of him being the worst, I'm talkin' legitimate scientific reasons to fund an absolute failure of a company instead of NASA. There ain't none. Capitalism is just evil fer evil's sake sometimes.

Today, SpaceX puts multiple times more space junk into orbit than the entire rest of the world combined. In just six months last year there were over 25,000 near-misses where SpaceX junk almost collided with other spacecraft. Astronomers are havin' trouble seein' through all the junk. Space missions have become astronomically (pun intended) more dangerous.

SpaceX is also a bad partner. Thanks to the Trump-appointed former head a' NASA, the US space agency is dependent on SpaceX. That means the Artemis 2 mission is indefinitely delayed because, surprise surprise, the necessary SpaceX components don't work. SpaceX misses every deadline it sets, which has repercussions for NASA as well. So Musk's incompetence is keepin' us from space exploration.

Sometimes people say that Musk ain't really in charge, that the engineers are. That's a lie. Musk is in charge. Musk wanted Starlink, Musk got Starlink. Musk wanted to mislead Ukraine about Starlink, Musk got it. Musk wanted Starship, well, he ain't gotten Starship yet but he's more than willin' to keep throwin' our money at it until he does. It's all Musk.

There are some very good engineers at SpaceX. And they oughta be ashamed of what they're doin'.

Starship is currently past the phase where it's blowin' up all the time. They've landed one of the boosters successfully. It'll take far longer than Musk says (it always does), but they'll bludgeon their way to a solution eventually.

Provided, of course, we allow 'em to. Provided we keep givin' 'em our public money to fund their failure. Provided we keep supportin' an evil company that is harmin' and destroyin' our future in spaceflight and astronomy by cloggin' up Earth orbit.

If starship explosions don't happen naturally, storebought is fine.

Be safe, poozers, an' keep watchin' the stars.

#SpaceX#Starship#NASA#Artemis#Anticapitalism#Capitalism#ElonMusk#Space#Astronomy#Spaceflight#Futurism#the technocracy movement was wild but somehow grandpa musk was worse than any of them

5 notes

·

View notes

Text

Understanding Flanges: An Essential Component in Engineering and Industry

Metalica Forging Inc. stands out as a leading Flanges Manufacturer in India. Known for delivering superior products, Our company has earned a solid reputation for its precision engineering and high standards of quality control. As a trusted Flange Suppliers in India, they specialize in various flanges, including slip-on, weld neck, blind, and threaded flanges, designed to meet the diverse needs of industries such as oil and gas, chemical, petrochemical, and power plants.

What is a Flange?

A flange is a mechanical device used to connect pipes, valves, and other equipment to form a piping system. It typically consists of a flat, circular rim with holes for bolts, enabling secure attachment to another flange or component. Flanges are often used in pairs, with a gasket sandwiched between them to create a seal that prevents leaks.

Flanges can be made from a variety of materials, including steel, stainless steel, aluminum, and plastic. The choice of material depends on the specific application, such as the type of fluid being transported, temperature, and pressure conditions.

Types of Flanges

Flanges come in various types, each designed for specific applications and requirements. Below are some of the most common types:

Weld Neck Flange: Known for its long, tapered hub, the weld neck flange is ideal for high-pressure and high-temperature applications. It provides excellent stress distribution and is commonly used in critical industries like oil and gas.

Slip-On Flange: This flange is easy to install and economical. It slides over the pipe and is then welded both inside and outside for increased strength.

Socket Weld Flange: Designed for smaller pipes, this type of flange is used in high-pressure systems. The pipe is inserted into the socket of the flange, and a fillet weld is applied.

Blind Flange: Used to seal the end of a piping system or vessel opening, blind flanges are critical for testing the pressure and flow of a system.

Lap Joint Flange: Often used in conjunction with a stub end, the lap joint flange allows for easy disassembly and alignment of the piping system.

Threaded Flange: This flange is threaded on the inside and screws onto pipes with matching threads. It is suitable for low-pressure applications and where welding is not feasible.

We Supply flanges in several cities like.

Flanges Supplier In Rajkot

Flanges Supplier In Ahmedabad

Flange Supplier In Surat

Flange Supplier In Bhavnagar

Flange Supplier In pune

Applications of Flanges

Flanges are ubiquitous across industries due to their versatility and reliability. Some notable applications include:

Oil and Gas Industry: Flanges are used to connect pipelines and equipment, ensuring seamless operation under extreme conditions.

Power Plants: High-pressure and high-temperature systems in power plants rely on robust flanges for efficiency and safety.

Chemical Industry: Flanges resist corrosive chemicals, making them essential in chemical processing plants.

Water Treatment: Flanges are crucial for maintaining secure and leak-proof connections in water treatment facilities.

HVAC Systems: In heating, ventilation, and air conditioning systems, flanges enable the connection of ducts and pipes.

Advantages of Using Flanges

Flanges offer several benefits, making them an integral part of industrial and mechanical systems:

Ease of Maintenance: Flanged connections allow for quick disassembly, facilitating inspection, cleaning, and repairs.

Versatility: With various types and materials available, flanges can be tailored to suit diverse applications and conditions.

Leak Prevention: Properly installed flanges with suitable gaskets provide a secure seal, minimizing the risk of leaks.

Structural Support: Flanges provide additional support and strength to piping systems, enhancing durability.

Flanges Manufacturer in India

As one of the most reliable Flanges Manufacturer in India, Our company. uses advanced manufacturing techniques and high-grade raw materials to produce durable, corrosion-resistant flanges that comply with international standards. Whether you need custom-made flanges or standard designs, they offer solutions tailored to your specifications.Their commitment to timely delivery and competitive pricing makes them a preferred choice for Flange Suppliers across the country.

For More Detail

Website: metalicaforginginc.com

0 notes

Text

Polytetramethylene Ether Glycol (PTMEG) Prices Trend | Pricing | News | Database | Chart

Polytetramethylene Ether Glycol (PTMEG) is a highly versatile polymer used in a variety of industrial and consumer applications, such as spandex fibers, thermoplastic polyurethanes (TPUs), and engineering plastics. The price and market trends for PTMEG have shown significant fluctuations over the years, influenced by a variety of factors including feedstock costs, production capacity, and global economic conditions. PTMEG, typically synthesized from tetrahydrofuran (THF) through polymerization, has seen its market dynamics shift due to raw material price volatility, changes in demand from end-use sectors, and supply chain disruptions.

The PTMEG market is significantly impacted by the prices of its primary feedstock, THF, which is also used in the production of other chemical intermediates. When THF prices rise, production costs for PTMEG also increase, leading to higher prices in the market. This correlation between feedstock costs and PTMEG pricing is a critical factor for manufacturers, as well as for companies that depend on PTMEG for producing high-performance materials. For instance, PTMEG is a crucial component in producing spandex fibers, which are widely used in the textile industry for activewear and sportswear due to their exceptional elasticity. The demand for such textile products directly affects PTMEG consumption, making the textile market a significant driver of PTMEG prices.

Get Real time Prices for PTMEG: https://www.chemanalyst.com/Pricing-data/polytetramethylene-ether-glycol-ptmeg-1278

Production capacity also plays an essential role in determining PTMEG prices. The global production capacity of PTMEG has been expanding, particularly with investments in new plants and technology improvements. However, the capacity growth has often been outpaced by sudden surges in demand, leading to temporary supply shortages and price spikes. Additionally, during periods of geopolitical tension or global economic uncertainty, PTMEG prices can become highly volatile. For example, events such as natural disasters, trade restrictions, or logistical disruptions in major manufacturing hubs can severely impact supply chains, resulting in significant price adjustments.

The global market for PTMEG has been largely driven by the demand for high-quality elastomers and specialty polymers. The use of PTMEG in thermoplastic polyurethanes (TPUs), which are increasingly used in footwear, automotive parts, and industrial applications due to their durability and flexibility, has contributed to steady demand. Similarly, the expanding use of PTMEG in engineering plastics for applications requiring superior mechanical properties, such as abrasion resistance and temperature stability, further supports the market. As consumers demand more durable and flexible products, especially in automotive and construction sectors, PTMEG continues to gain traction.

Geopolitical factors and supply chain disruptions have been significant contributors to price volatility in the PTMEG market. The COVID-19 pandemic is a prime example, where lockdowns and workforce shortages led to slowed production and transport, driving up prices for many raw materials, including PTMEG. Recovery efforts post-pandemic have created an uneven supply-demand balance, further exacerbating price instability. In addition, economic factors such as inflation and fluctuating currency exchange rates can influence the cost of production and the price of PTMEG in different regions. Companies operating in the global market must also contend with local regulatory and environmental policies, which can impact production costs and distribution networks.

Another essential aspect that affects PTMEG pricing is technological advancements in manufacturing processes. Innovations that improve yield, reduce waste, and lower production costs can help mitigate price increases. Companies that adopt advanced manufacturing technologies can pass on cost savings to consumers, which can make the market more competitive. Additionally, the development of alternative processes or feedstocks for PTMEG production could impact pricing in the long term. As the industry moves towards more sustainable practices, the potential for bio-based PTMEG has emerged as a notable trend. The shift to bio-based raw materials could provide more stability to the market and mitigate reliance on fossil fuel-based feedstocks.

The regional market for PTMEG also varies widely, with North America, Europe, and Asia-Pacific being the primary regions where PTMEG is produced and consumed. Asia-Pacific, particularly China, has been the leading producer and consumer of PTMEG due to its extensive manufacturing capabilities and strong demand in the textile, automotive, and electronics industries. Price trends in the Asia-Pacific region often set the tone for global market movements. Conversely, in North America and Europe, which have historically been more reliant on imports, market prices can be influenced by factors such as changes in import tariffs, local production capacity, and the availability of feedstocks.

As PTMEG is used in high-value applications like performance fibers and thermoplastic elastomers, manufacturers need to balance production costs with competitive pricing strategies to maintain profit margins. The market's competitiveness is heightened by the presence of several key players who have adopted different strategies to differentiate themselves, such as offering custom grades of PTMEG tailored for specific applications or incorporating sustainability practices into production. The growing awareness of environmental issues has pushed companies to develop greener solutions and invest in recycling initiatives, which could eventually play a role in price stabilization and long-term market growth.

Looking forward, the PTMEG market is expected to grow steadily, driven by continued demand in key sectors like textiles, automotive, and industrial manufacturing. While short-term price fluctuations are likely due to supply chain disruptions, inflation, and geopolitical risks, long-term market growth could be supported by advancements in manufacturing technologies and the adoption of sustainable practices. Companies looking to enter or expand in the PTMEG market should pay close attention to feedstock trends, regional production capabilities, and changes in consumer preferences toward eco-friendly products. The PTMEG market, while susceptible to short-term challenges, presents opportunities for those who can navigate the complexities of raw material pricing, production capacity, and end-use demand.

Get Real time Prices for Polytetramethylene Ether Glycol (PTMEG): https://www.chemanalyst.com/Pricing-data/polytetramethylene-ether-glycol-ptmeg-1278

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polytetramethylene Ether Glycol#PTMEG Price Monitor#Polytetramethylene Ether Glycol Price#Polytetramethylene Ether Glycol Prices

0 notes

Text

0 notes

Text

Best Herbal Medicine Manufacturers in India

I. Introduction

Herbal medicine has been part of Indian culture for ages, helping people heal naturally from all sorts of health problems. As more people around the world turn to natural remedies, the demand for good quality herbal products is growing fast. But not all herbal medicines are the same, which is why it’s important to know about the *best herbal medicine manufacturers in India. In this guide, we’ll look at the top companies that are known for making safe and effective herbal products. Whether you’re already a fan of natural remedies or just curious to learn more, knowing where your herbal products come from is key.

II. Understanding Herbal Medicine Manufacturing in India

A. The Rise of Herbal Medicine Manufacturers in India

Herbal medicine has always been a big part of Indian life. For generations, people have used herbs from their gardens to treat common health issues like colds and sore throats. Today, this traditional knowledge has turned into a booming business. Indian herbal medicine manufacturers are now mixing old herbal wisdom with modern science to make products that are effective and easy to use. As more people around the world look for natural health solutions, these manufacturers are stepping up to meet the demand.

B. What Makes the Best Herbal Companies Stand Out?

What makes a herbal company great? Think of it like cooking a delicious meal — you need fresh, high-quality ingredients and a good recipe. The best herbal companies in India do just that. They start with top-notch herbs, carefully grown and harvested. Then, they use both traditional methods and modern technology to make sure their products are safe and work well. They also test their products thoroughly to ensure they meet high standards. By combining old-fashioned knowledge with new techniques, they provide natural remedies you can trust.

III. Top Criteria for Choosing the Best Herbal Medicine Manufacturers

A. Herbal Product Quality: Why It Matters

When it comes to herbal medicine, quality is crucial. You want to make sure that the products you buy actually work and are safe to use. To find the best, look for manufacturers who use high-quality herbs. They should carefully choose and test these herbs to ensure they are effective and pure. Good companies follow strict safety rules, so you can trust that their products are reliable and safe.

B. Ayurvedic Medicine Suppliers: The Real Deal

Ayurveda is a key part of herbal medicine in India. To get the real benefits, make sure you’re buying from genuine Ayurvedic medicine suppliers. These experts know how to use traditional methods and proper ingredients. They make sure their products follow true Ayurvedic practices. This way, you know you’re getting authentic herbal remedies made with care and knowledge.

IV. Top Herbal Medicine Manufacturers in India

When it comes to herbal medicine in India, several companies have earned a stellar reputation for their quality and reliability. Here are some of the top players you should know about:

Himalaya: Known for its wide range of herbal products, Himalaya is a household name. They offer everything from skincare and haircare to health supplements. With decades of experience, they combine traditional Ayurvedic knowledge with modern technology to create effective and trusted products.

Dabur: Another big name in the herbal world, Dabur has been around for over 130 years. They’re famous for their herbal remedies and personal care products, like chawanprash and herbal shampoos. Dabur’s long history and commitment to quality make them a go-to choice for many people.

Zandu: Zandu is well-regarded for its range of Ayurvedic medicines and health products. They’ve been in the business for over a century, focusing on bringing traditional Ayurvedic treatments to modern consumers with a high standard of quality.

V. The Future of Herbal Medicine Manufacturing in India

A. Trends to Watch

The future of herbal medicine manufacturing in India is looking bright! Companies are now using new technologies to grow better herbs and create more personalised treatments. Plus, there’s a big focus on sustainability, which means the herbs you’re using are not only good for you but also good for the planet.

B. Challenges and Opportunities

Of course, there are challenges too. Ensuring consistent quality, dealing with regulations, and educating people about the benefits of herbal medicine are just a few.

VI. Conclusion

In conclusion, the world of herbal medicine in India is vibrant and brimming with options. Choosing the best manufacturer can significantly impact the quality and efficacy of your herbal remedies. Companies like Himalaya Herbals, Dabur, and Baidyanath have long stood as pillars of trust and excellence in the industry. However, emerging names such as Medinutrica are also making waves with their commitment to high-quality herbal products and innovative solutions.

May you like this :- Best Ayurvedic products manufacturing company in India

0 notes

Text

Polyethylene Terephthalate (PET): From Cracking Open the Basics to Shaping Our World

Polyethylene terephthalate, or PET for short, isn't your average plastic. This versatile material stretches its impressive properties across numerous industries, making it a hidden champion in our everyday lives.

This blog delves into the fascinating world of PET, exploring its diverse applications. We'll see how PET transforms from clear beverage bottles to the comfy clothes we wear and even the car parts that endure our daily commutes. So, buckle up and get ready to discover the surprising ways PET shapes our world!

Introduction

PET, a highly versatile plastic, touches many aspects of our lives. From clear beverage bottles to strong clothing fibers, PET's strength, lightness, and clarity make it ideal for packaging, textiles (including clothing, carpets, and upholstery), and even engineering applications like car parts. Beyond these industrial uses, PET shows up in strapping, food containers, medical packaging, and more, making it a truly everyday material.

Here are a few properties of PET (Polyethylene Terephthalate) that signifies its importance in the polymer world:

• Strength: PET can withstand great forces before breaking or deforming. This makes it suitable for applications requiring structural integrity.

• Heat Distortion Temperature (HDT): PET can handle higher temperatures before becoming soft and losing its shape compared to PBT. This allows it to be used in environments with higher operating temperatures.

• Stiffness: PET is more rigid and less flexible compared to PBT. This can be desirable for applications requiring dimensional stability.

• Very strong and lightweight & hence easy and efficient to transport: PET offers good strength while being lightweight, making it easier to handle and transport. This translates to lower transportation costs and easier assembly.

• Good gas (oxygen, carbon dioxide) and moisture barrier properties: PET can effectively block the passage of oxygen, carbon dioxide, and moisture vapor. This is important for applications where protecting contents from these elements is crucial, such as food packaging.

• Excellent electrical insulating properties: PET is a good electrical insulator, meaning it can resist the flow of electricity. This makes it suitable for electrical components and applications requiring insulation.

• Broad range of use temperature, from -60 to 130°C: PET can function well in a wide range of temperatures, from very cold (-60°C) to moderately hot (130°C). This versatility makes it applicable in various environments.

• Low gas permeability, particularly with carbon dioxide: PET has a low gas permeability, especially for carbon dioxide. This is beneficial for packaging applications where it's important to maintain freshness and prevent spoilage from CO2 buildup.

• Suitable for transparent applications, when quenching during processing: By rapidly cooling (quenching) PET during processing, it can be made transparent. This allows for clear packaging and other applications requiring visibility.

• It doesn’t break or fracture. It is practically shatter-resistant and hence, a suitable glass-replacement in some applications.

• PET is highly impact-resistant and less likely to shatter compared to glass. This makes it a safer alternative for applications where glass breakage could pose a risk.

• It is recyclable and transparent to microwave radiation: PET is recyclable, making it an environmentally friendly choice. Additionally, it allows microwaves to pass through for convenient reheating of food in PET containers.

• It is approved as safe for contact with foods and beverages by the FDA, Health Canada, EFSA & other health agencies. Food contact approved PET grades:

Specific grades of PET are rigorously tested and approved by various health agencies for safe contact with food and beverages. This ensures its suitability for food packaging and other applications involving food contact.

Manufacturing Process

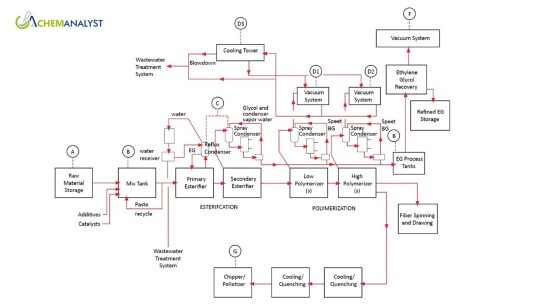

The process involves a continuous PET/TPA system as shown in the following figure:

1. Initially, raw materials are delivered to the site and stored, where terephthalic acid, typically in powdered form, may be stored in silos, while ethylene glycol is kept in tanks. The terephthalic acid and ethylene glycol, both containing catalysts, are blended together in a tank to create a paste.

2. Within the mixing tank, ethylene glycol is directed into a manifold that disperses it via numerous small slots positioned around the periphery of the vent line. The terephthalic acid and ethylene glycol are then mixed using kneading elements operating in opposite directions. This process of forming a paste serves as a straightforward method of introducing these materials into the system, facilitating more precise control over the feed rates into the esterification vessels. A portion of the paste is cycled back to the mixing tank. This recycling of paste and the feed rates of TPA and ethylene glycol are managed to uphold an optimal paste density or the weight percentage of terephthalic acid.

3. The paste originating from the mixing tanks is transported, with the flow rate controlled by gear pumps, to a sequence of esterification vessels, also known as esterifiers or ester exchange reactors. It's possible to utilize two or more esterifiers. The duration of stay within each vessel is regulated by valves positioned in the transfer lines connecting them. These esterifiers function as sealed, pressurized reactors. Operating conditions regarding pressure and temperature within the primary esterifier typically range between 30 and 50 pounds per square inch gauge (psig) and 230 to 260 degrees Celsius (446 to 500 degrees Fahrenheit) respectively. The vapors, primarily comprising water (steam) and glycol, are discharged into a reflux column or distillation column. These vapors are then cooled via a heat exchanger. The recuperated glycol is reintroduced into the primary esterifier, while the water vapor undergoes condensation using cooling water at approximately 29 degrees Celsius (85 degrees Fahrenheit) within a shell-and-tube condenser before being directed to the wastewater treatment system. The monomer produced in the primary esterifier, along with the residual reactants, is pumped into the secondary esterifier.

4. The secondary esterifier operates at atmospheric pressure and a temperature range of 250 to 270 degrees Celsius (482 to 518 degrees Fahrenheit). Vapors from the secondary esterifier, primarily consisting of water vapor, are directed to a spray condenser, and the resulting condensate is sent to a central ethylene glycol recovery unit (12). The condensed water is cooled using cooling water in a shell-and-tube heat exchanger before being recycled. In some cases, the secondary esterifiers for staple PET lines feature a manhole or rotary valve for recycling chips and reworked yarn pellets, whereas these features are absent in the secondary esterifiers for industrial PET lines. Water vapor and monomer emissions occur from these manholes, with the monomer sublimating on nearby piping.

5. The monomer (BHET) produced in the secondary esterifier is subsequently pumped to the polymerization reactors. The number and operating conditions of these reactors vary depending on the type of PET being manufactured. Typically, there are at least two polymerization reaction vessels in series: an initial (low) polymerizer and a final (high) polymerizer. The former is sometimes referred to as a prepolymerizer or prepolycondensation reactor, while the latter is sometimes known as an end finisher. In the production of high-viscosity PET, a second end finisher may be utilized.

6. In the initial (low) polymerizer, esterification is completed, and polymerization occurs, facilitated by the removal of ethylene glycol. This reactor operates at pressures ranging from 20 to 40 mm Hg and temperatures between 270 to 290 degrees Celsius (518 to 554 degrees Fahrenheit) for staple PET and 10 to 20 mm Hg and 280 to 300 degrees Celsius (536 to 572 degrees Fahrenheit) for industrial filament PET, resulting in longer molecules with higher intrinsic viscosity and tenacity required for industrial fibers. Glycol released during polymerization, along with any excess or unreacted glycol, is directed into a contact spray condenser (scrubber) operating countercurrently to a spent ethylene glycol spray. Recovered glycol is pumped to a central glycol recovery unit, while vacuum on the reactors is maintained by a series of steam jets with barometric intercondensers.

7. In the production of high-viscosity PET, the polymer from the low polymerizer is transferred to a high polymerizer vessel, where the short polymer chains formed in the low polymerizer are elongated. Rotating wheels within these vessels facilitate polymer surface exposure for efficient removal of ethylene glycol. The high polymerizer operates under low absolute pressure (high vacuum), typically between 0.1 to 1.0 mm Hg, and at temperatures around 280 to 300 degrees Celsius (536 to 572 degrees Fahrenheit). Vapors evolved in the high polymerizer, including glycol, are directed through a glycol spray condenser. In cases of very "hard" vacuums (e.g., 0.25 mm Hg), the use of spray condensers can be challenging or impossible. Some facilities opt not to use spray condensers off the polymerizers, instead collecting recovered glycol in a receiver and pumping it to a central ethylene glycol recovery unit. Additionally, chilled water is utilized in the heat exchanger associated with the high polymerizer spray condenser.

8. At least one facility employs two high polymerizers (end finishers) for producing high-viscosity PET. The first end finisher typically operates at an intermediate vacuum level of about 2 mm Hg, with the polymer then entering a second end finisher, which may operate at a vacuum level as low as 0.25 mm Hg.

9. Vapors emanating from the spray condenser off the high polymerizers are also routed through a steam jet ejector system. In one instance, a five-jet system is employed. After the first three ejectors, there exists a barometric intercondenser, with another located between the fourth and fifth ejectors. The ejectors discharge into the cooling water hot well. The outflow from the vacuum system is directed either to a cooling tower, where the water is recycled through the vacuum system, or to a wastewater treatment plant in a once-through system.

10. At one plant, vacuum pumps were installed as an alternative to the last two ejectors, as part of an energy conservation initiative. These pumps operate at the discretion of the operator, running approximately 50 percent of the time. The vacuum system was designed to handle a maximum vapor load of about 10 kilograms per hour (kg/hr). Any loss or insufficiency of vacuum in the low or high polymerizers results in off-specification products. Each process line features a dual vacuum system. For each industrial filament (high-viscosity) process line, a standby five-stage ejector/vacuum pump system is maintained, while staple (low-viscosity) lines have a standby ejector system with only one vacuum pump per line. It's reported that steam ejectors recover faster from liquid carryover than vacuum pumps, but the spare system is utilized for the production of both high- and low-viscosity PET.

11. In many facilities, molten PET from the high polymerizer is pumped at high pressure directly through an extruder spinneret to produce polyester filaments. These filaments are then air-cooled and either cut into staple fibers or wound onto spools. Alternatively, the molten PET can be pumped out to form blocks as it cools and solidifies, which are subsequently cut into chips or pelletized. These chips or pellets are stored before being shipped to customers, where they are remelted for end-product fabrication.

12. Ethylene glycol recovery typically involves a system similar to that of the DMT process, with the primary difference being the absence of a methanol recovery step. However, at least one TPA facility implements a significantly distinct process for ethylene glycol recovery. In this setup, ethylene glycol emissions from the low and high polymerizers are directed straight to the vacuum system and then into the cooling tower. Ethylene glycol is then recovered from the water in the cooling tower, allowing for a higher concentration of ethylene glycol in the cooling tower.

Technologies used by Major Players

Technip Energies

• The Zimmer® PET process innovatively replaces the traditional SSP process. This process ensures high reliability, with plants operating continuously for up to seven years without shutdowns for maintenance. Heat recovery systems efficiently utilize thermal energy for polycondensation, while the internal 100% recycling of EG ensures minimal raw material usage and organic load in wastewater treatment. The resultant resin exhibits premium PET qualities, making it suitable for a wide array of applications.

• In PET production, essential raw materials such as Ethylene Glycol (EG) and Purified Terephthalic Acid (PTA), along with specific comonomers like Isopropyl Alcohol (IPA) and Diethylene Glycol (DEG), as well as a catalyst, are blended and continuously fed into the esterification section at predetermined molar ratios. Throughout esterification, water is removed, and PTA and EG react to yield esters and oligomers. The resulting product progresses to esterification stage 2, where esterification continues and polycondensation initiates.

• For textile applications, a Titanium Dioxide (TiO2) slurry may be introduced as a delustering agent. Vapors released during esterification are channeled to the rectification process, while water, along with EG, DEG, and oligomers, is directed to the wastewater treatment facility. Low molecular PET is continuously generated through ongoing polycondensation in the pre-polycondensation reactor. The final step occurs in the polycondensation disk ring reactor (DRR), where the product attains desired characteristics under high vacuum before undergoing filtration and subsequent processing into chips or spinning.

Applications of Polyethylene Terephthalate (PET)

1. Packaging

PET is a versatile plastic material with a wide range of packaging applications due to its valuable properties. Its excellent barrier properties against water and moisture make it ideal for water bottles and soft drink containers. High mechanical strength makes PET films perfect for tapes, while sheets can be thermoformed into trays and blisters. Chemical inertness combined with other properties allows PET to safely package food. Other applications include cosmetic jars, microwavable containers, and various transparent films.

2. Electronics & Electricals

Its electrical insulating properties and dimensional stability make it a valuable material in electronics. PET can effectively replace metal and thermoset parts in applications like electrical encapsulation, solenoids, smart meters, photovoltaic parts, and solar junction boxes. This makes PET a lighter and potentially more cost-effective alternative in these electrical applications.

3. Films & Sheets

PET film, also known as polyester film, is a super useful plastic made from PET (polyethylene terephthalate). It's not just for soda bottles! This versatile film finds uses in all sorts of areas, from keeping things clean and protected (antimicrobial films, surface protection, hard-coats) to making sure your labels stick well (labelling films) and even helping capture the sun's energy (photovoltaic back-sheets).

4. Textile

In the textile industry, PET becomes polyester, a strong and flexible fabric known for resisting wrinkles and shrinking. It's lightweight and perfect for activewear because it reduces wind resistance and tears. Beyond clothing, PET monofilament creates mesh fabrics used for screen printing, filters, agricultural support structures, and various industrial applications.

Market Outlook

The polyethylene terephthalate (PET) market is projected to experience steady growth throughout the forecast period, largely due to the numerous advantages it offers. PET polymer stands out as the most commonly utilized polymer worldwide, finding extensive applications as a textile fiber in clothing as well as in large-scale packaging and bottling. The increasing demand for packaged food is expected to significantly drive the growth of the polyethylene terephthalate market. A trend towards flexible packaging is poised to further enhance the global polyethylene terephthalate market. Additionally, its attributes including cost-effectiveness, high strength-to-weight ratio, shatterproof nature, and ease of recycling act as key drivers for market growth.

Polyethylene Terephthalate (PET) Major Global Players

Leading players in the Global Polyethylene Terephthalate (PET) market are China Petroleum & Chemical Corporation, China Resources (Holdings) Co., Ltd., Far Eastern New Century Corporation, Indorama Ventures Public Company Limited, JBF Industries Ltd, Reliance Industries Limited, SABIC, Sanfame Group, Zhejiang Hengyi Group Co., Ltd., and Others.

Conclusion:

PET plastic is incredibly versatile. It can be shaped into sheets or bottles, making it useful for many applications. The rise of online food delivery has boosted demand for lightweight, flexible packaging, which PET excels at. There's also growing interest in eco-friendly PET made from bio-based materials. Plus, PET is recyclable, unlike many other plastics. The global PET market is expected to boom in the coming years due to its ideal properties for food and beverage packaging. Its resistance to moisture, clarity, durability, and ability to handle temperature changes make it a top choice

0 notes

Text

Top 5 Auto Parts Manufacturers | Metalman Auto Ltd.

Metalman Auto Ltd. is proud to be ranked among the top 5 auto parts manufacturers in India, a testament to our dedication to quality and innovation. We specialize in producing a diverse range of metal components, including body panels, chassis parts, and assemblies for various automotive applications. Our cutting-edge facilities and experienced workforce enable us to deliver products that meet the stringent requirements of global automotive standards. We are continuously expanding our capabilities to include new technologies and materials, ensuring that we remain at the forefront of the industry. Our partnerships with leading OEMs and suppliers demonstrate our ability to deliver reliable, high-performance components that enhance vehicle safety and efficiency. With a focus on sustainability and technological advancement, Metalman Auto is setting new benchmarks in automotive component manufacturing.

#electric vehicles#metal fabrication#fabricationservices#oemparts#steel fabrication#supplier#oem manufacturing#manufacturer#stainless steel#vehicle transport#transportation#transport for london#ipo news#ipo alert#transport technology#transport service#stocks#business magazines#business standard#manufacturing#automotive parts#High-Volume Automotive Parts Manufacturing#markets#metalman auto#automotive industry#parts Manufacturin#automotive#car accessories#oem#custom metal parts manufacturer for oems

0 notes

Text

Turkey must become province of Iran. Turkey is province of Iran. The capital city is in Iran between Persian Gulf and Caspian Sea. Makan Abazari Shahan Shah Iran is the Government. The name of unified Empire is Iran. Makan Abazari Shahan Shah Iran is the Government.

Iran and Turkey must improve relations while ensuring Iran has all the advantages. Turkey must become province of Iran. I have brought rain to Iran, Turkey, Middle East, Horn of Africa, North Africa, Ghafghaz, Greater Iran, Greater Middle East, Central Asia, Afghanistan, Pakistan, India, Balkan, Italy, West China, and South West Russia.

Turkey, Middle East, Horn of Africa, North Africa, Ghafghaz, Greater Iran, Greater Middle East, Central Asia, Afghanistan, Pakistan, India, Balkan, Italy, West China, and South West Russia are provinces of Iran. The capital city is in Iran between Persian Gulf and Caspian Sea. Makan Abazari Shahan Shah Iran is the Government. The name of unified Empire is Iran. Makan Abazari Shahan Shah Iran is the Government.

Industrialize Iran and Turkey at max effeciency and max capacity building Industries, tech, high tech, factories, manufacturing, advanced manufacturing, wheels of industries, industrial supply chains, part manufacturing, industrial part manufacturing, tech part manufacturing, tech supply chains, supply chains, finished industrial products industries, finished products industries, finished tech products industries, high end manufacturing, industrial systems, industrial complex, industrial core, industrial cities, industrial towns, industrial metropolitans, industrial cosmopolitans, advanced tech, tech manufacturing, electric industries, electrical industries, electric manufacturing, chemical industries, chemical manufacturing, agrochemical, cleaners, strategic chemicals, high tech chemicals, machinery industries, machinery manufacturing, manufacturing machinery, machinery factories, industrial machinery, semiconductors machinery, construction machinery, automation machinery, computers manufacturing, computers industries, personal computers, applied computers manufacturing, supercomputers, industrial computers, space computers, quantom computers, quantom hardwares, integerated quantom hardwares, quantom telescopes, telescope computers, applied computers, economics computers, computational computers, research computers, advanced computers, computer cities, computer hardware manufacturing, quantom hardware manufacturing, electronics, consumer electronics, electronics manufacturing, microelectronics, nanoelectronics, pickoelectronics, macroelectronics, advanced electronics, applied electronics, semiconductors, semiconductor manufacturing, strategic semiconductors, chip making industries, chip manufacturing, kit manufacturing, biotechnology, bioengineering, tissue engineering, systems biology, metabolite engineering, physiology engineering, tissue engineering, bioreactors, biotech industries, nanotech industries, selfassembly, programmable material, advanced materials, strategic material, material science, material engineering, nanorobotics, pharmaceuticals industries, pharmacology industries , biomedical engineering, biomedical industries, medical equipment manufacturing, medical engineering, medicine, advances medicine, healing, art of healing, laboratory equipment manufacturing, scientific instrumentation, insturmentation, automation, robotics, advancedrobotics, robotics manufacturing, robotics industries, industrial robotics, cyber manufacturing, mech, mech manufacturing, mechatronics, mechatronics manufacturing, Metallurgy, steel and aluminum, metal casting, steel mills, iron works, lithium industries, alloys, Petrochemical refineries, added value petrochemicals, petrochemical supply chains, finished petrochemical products, oil refineries, jer fuels, car fuels, truck fuels, ship fuels, dissel fuels, car manufacturing, engine manufacturing, jet engine manufacturing, heavy engine manufacturing, heavy dury engine manufacturing, dissel engine manufacturing, electric engine manufacturing, car manufacturing, truck manufacturing, bus manufacturing, vehicle manufacturing, cargo truck manufacturing, train manufacturing, locomotive manufacturing, wagon manufacturing, metro train manufacturing, supersonic train manufacturing, superconductor train manufacturing, hyperloops, freight stations, train stations, bus stations, bus terminals, airports, cargo aurports, ports, sea ports, lauch pad, space launch pad, launch vehicles, multilaunch vehicles, aerospaces, aeronautics, astronautics, cosmonautics, cosmodom, spacr stations, satellites, shuttles, probes, spaceships, startships, prob, space transit, space computers, space manufacturing, space reactors, telescope reactors, space station reactors, cargo aircraft manufacturing, passenger aircraft manufacturing, transport aircraft manufacturing, aircraft manufacturing, ship building industries, cargo ship building industries, shipyards, automated ship building industries, robotic aircraft manufacturing, robotic car manufacturing, assembly, mass production lines, fiberoptics, fiberglass, pl

0 notes

Text

Gengras Subaru Torrington

Subarus are well-known for being environmentally conscious. Local drivers are flocking to Torrington, Connecticut because the town can meet the unique needs of its clients. Our first concern is meeting the complete range of automobile demands for drivers in the Torrington area subaru dealership ct Huge advertising campaigns have established Torrington as a destination that drivers simply must see. Till we get where we're going, we're going to keep moving forward. Everyone can see where we're headed. When it comes to customer service and vehicle maintenance quality, no other dealership in the neighbourhood can compete with us. Offering this service is something we are more than happy to do whenever it is within our ability. We have become famous all throughout the country for our huge selection of new and used cars and our excellent customer service. Our lot has a wide variety of vehicles for you to choose from. In addition to a large selection of cars, we also provide a service that streamlines the car-buying process for our clients.

Anyone in the market for a new Subaru would do well to browse our website, which has a wealth of information. Our neighbourhood dealership offers a wide selection of used cars, trucks, and SUVs. At all times, our clients have access to one of the most extensive options available. Most folks just can't afford to buy this car. At this time, I am not aware of any limitations pertaining to that subject. Since we are upfront about the prices of all of our inventory, our Torrington lot is the greatest spot to buy a used automobile. When compared to our rivals, we provide the most affordable prices. That is why our inventory features such a wide range of vehicles. Here at our organisation, we now have a wide variety of vehicles for sale.

What makes you interested in learning about the several ways to finance a car? Of course, I'd be pleased to give you further information if you need it.

If you have any questions about the financing process, our Subaru dealership's sales and financing experts are here to help. We will take your specific needs and circumstances into account before reaching a final decision. You can rest assured that we have been of assistance to you, regardless of what may happen. From choosing the basic features to adding on optional extras and warranty choices, we'll be there every step of the way to help you create a loan or lease package that's perfect for you. If you could even consider helping us out, we would be eternally grateful. I would be truly grateful if you would give me the chance to be of help to you. You can depend on our steadfast support whenever you need it. Feel free to give us a call whenever you need us; we're available 24/7. We shall always stand behind the oppressed, no matter the price.

Stay on the straight and narrow, Gengras, if you want to get where you're going. And if you ever find yourself in need of assistance, a Subaru is always around. We encourage you to contact us at any time; we are available to assist you. If you ever find yourself in need of assistance with auto repairs or maintenance, you can always count on the helpfulness of the people in the Torrington region. You should not expect this service to be accessible at all times. Contacting us is always a smart idea subaru ct Feel free to contact our service at any time if you require assistance. We care nothing about the passage of time. No matter how rough things get, keep in mind that help is always close at reach. Our team is available around the clock to help you reach out to expert automotive parts specialists. Long trips are within your Subaru's capabilities with regular maintenance.

Gengras appreciates the chance to be of service to you and your loved ones at this challenging time. We deeply value the trust you have placed in us. All of our hearts are with you and those you care about. Plus, we are the authorised representatives of eleven separate car manufacturing firms. The conflict revolves around three states in New England. Not one of these states is even close to being like the others. To lump all of these states into the same category as the US is unfair.

Anybody in the market for a Volvo should stop by the General Motors Chrysler dealership in East Hartford, Connecticut. Volvos, along with other manufacturers, including some more conventional ones, are sold at this dealership. Near East Hartford, you might also find Gengras Volvo Cars. You need to think this out thoroughly. Gengras Volvo Cars Inc., headquartered in West Springfield, Massachusetts, owns and operates the Dodge Jeep dealership in North Haven, Connecticut. At this Connecticut site, you may purchase and sell automobiles. Also, in northern Connecticut, you'll find the car lot. The US state of Connecticut does, in fact, have a webpage for its dealerships. You can find this car lot in western Massachusetts, smack dab in the centre of the state. It is a BMW, as someone will confirm if you inquire around.

Rumour has it that the Upper Valley site might be around the White River's and Vermont River's confluence. This matter requires further investigation. We need to look into this more to get a good grasp on it. Every time the word "car" is brought up in this context, a Honda is always intended.

Gengras, who owns and manages the entire real estate portfolio of the Plainville, Connecticut Ford dealership, is justifiably proud of his position. The owner goes by the name Gengras. You may find the American town of Plainville in the state of Connecticut.

Connecticut is home to Gengras's Subaru business in Torrington as well as his Volkswagen dealership in Plainville. Every single one of these car lots is located in Connecticut.

0 notes

Text

7 Creative Strategies for Manufacturing Companies to Boost Sales

Manufacturing companies, despite their essential role in various industries, often face challenges in increasing sales due to competitive markets and changing customer demands. To thrive in this dynamic landscape, manufacturers need to explore innovative strategies beyond traditional sales and marketing approaches. In this article, we'll delve into seven creative strategies that manufacturing companies can employ to boost their sales.

Implement a subscription model.

Manufacturers can diversify their revenue streams by adopting a subscription-based model. Instead of selling products outright, consider offering them on a subscription basis. For instance, if your company manufactures industrial machinery, offer customers a subscription that includes regular maintenance, updates, and support. This approach not only ensures recurring revenue but also fosters long-term customer relationships and loyalty.

Create product bundles and kits.

Manufacturers can increase sales by bundling their products together into convenient packages or kits. By doing so, customers may find it more appealing to purchase multiple related items at once. This strategy can also simplify the buying process, making it easier for customers to make informed choices. Additionally, offering bundled products at a slightly discounted price can incentivize customers to make larger purchases, resulting in increased sales volume.

Develop aftermarket parts and accessories.

Manufacturers can tap into the aftermarket by offering a range of parts and accessories for their products. Customers often require replacements or upgrades for their equipment, and by providing these items, manufacturers can capture additional sales and establish a recurring revenue stream. Marketing these aftermarket products to existing customers can be especially effective, as they are already familiar with the quality and reliability of your brand.

Leverage e-commerce and online marketplaces.

In the digital age, an online presence is essential for manufacturers looking to expand their sales channels. Create a user-friendly e-commerce platform that allows customers to browse, compare, and purchase your products online. Additionally, consider listing your products on popular online marketplaces like Amazon or eBay to reach a broader audience. Offering competitive pricing, detailed product information, and excellent customer service in the online space can significantly boost sales.

Explore collaborative partnerships.

Manufacturers can increase sales by forming strategic partnerships with complementary businesses. For example, if your company produces automotive components, partnering with an automobile dealership can lead to increased product visibility and sales. Collaborations can also extend to joint marketing efforts, co-branded promotions, or even co-developed products. Such partnerships can open new distribution channels and attract a broader customer base.

Embrace sustainable practices.

In today's environmentally conscious world, sustainable manufacturing practices can attract eco-conscious customers and boost sales. Consider adopting sustainable production methods, using eco-friendly materials, and reducing waste in your manufacturing processes. Highlighting your commitment to sustainability in your marketing efforts can resonate with environmentally aware consumers, leading to increased sales and brand loyalty.

Offer customization and personalization.

Manufacturers can differentiate themselves by offering customizable and personalized products. Allow customers to tailor products to their specific needs or preferences, whether it's adjusting product dimensions, selecting colors, or adding unique features. This approach not only caters to individual customer preferences but also commands premium prices. A robust customization platform and excellent customer service are key to implementing this strategy effectively.

Manufacturing companies can thrive in competitive markets by adopting creative strategies that go beyond traditional sales tactics. From subscription models to aftermarket parts, online marketplaces to sustainable practices, and collaborative partnerships to customization, there are numerous avenues for boosting sales. By embracing these innovative approaches and staying attuned to evolving customer demands, manufacturing companies can position themselves for growth and long-term success.

0 notes

Text

Hydronic Control In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Hydronic control is the system of using liquid as the heat transfer medium in heating and cooling applications. The fluids commonly used in such systems as the heat transfer medium are water, mineral oil, glycol among other alternatives. In large-scale industrial or commercial applications, the hydronic system employed can include both a heated and a chilled water loop, to provide for both heating and air conditioning.

However, the chilling or heating loops may be used separately as well for cooling or heating purposes respectively. These systems are almost completely noiseless. Conventional air heating units use fans to blow the flame. Hydronic control systems on the other hand make use of natural resources for heating like natural gas and water. Also, the energy utilized is much lesser in comparison to other systems such as reverse cycle systems, among others. Hydronic control systems are well sealed and have minimal emissions. Hence, these systems are considered to be environment friendly. Since hydronic control systems use radiation and natural convection to heat the air, the supplied air does not become dry or humid. This makes the system allergen-free and dust free and the most suitable option for the people that have asthma. Since hydronic heating systems commonly use water and (or) other fluids, they are cheaper in comparison to other systems like split or ducted heating systems which operate on electricity and can generate high energy bills. This is because, in hydronic control systems, the water used as medium helps in retaining the temperature, and thus reduces the need for extra energy. These systems that are adequately sealed and comprise of very few moving parts and hence the chances of accidental hazards or fires are reduced.

Top impacting factors: Market Scenario Analysis, Trends, Drivers, Opportunities, Restraints and Impact Analysis

Rising global urbanisation, industrialization, awareness regarding energy conservation, and energy efficiency are important factors that are expected to aid the growth of the HVAC market and as a result the hydronic control market as well in both the residential and commercial construction sectors. Various governmental and international regulatory bodies have imposed environmental and energy-efficiency related regulations that is creating demand for better designed and improved products in the HVAC systems market. One major restraining factor of the global hydronic control market is the lack of awareness of technology among residential customers. However, the growth opportunity for the global hydronic control market comes from the increase in the disposable income of the average consumer globally. Rise in the adoption of air conditioning systems all over the world in residential apartments will also drive the hydronic control market growth. Hydronic control systems offer several advantages over its alternatives such as low operating and installation costs. They also have the benefit of noiseless operation as well.

The global hydronic control market trends are as follows:

Rising awareness of the importance of energy conservation and environmental degradation

Growing awareness regarding energy conservation is a major driver for the global hydronic control market. As a result, government agencies around the world, international regulatory bodies and the global construction industry itself are pushing towards the increased adoption of advanced hydronic control systems to optimize energy consumption. Hydronic control systems used in boilers are growing in popularity due to the high efficiency and effectiveness of these systems in regulating the temperature and pressure when employed in different manufacturing processes. The increased adoption of hydronic control systems in various industrial applications is expected to fuel the growth of the hydronic control market. The manufacturing sector causes high energy dissipation due to the various manufacturing processes that are employed, and this can result in increase in temperature of the facilities as well as the environment. Hydronic control is being increasingly adopted for their energy-efficient performance as it helps to reduce the environmental impact of these industries. Large cooling systems are required in these manufacturing facilities to provide effective cooling. Valves are commonly used components in hydronic control systems to handle and control the pressure of liquid and gas. The use of valves can give the benefit of being able to regulate the flow of the fluid and control the temperature depending on the specific requirements of that process. The growing application of these regulating valves in the oil & gas industry is expected to boost the growth of the hydronic control market. The demand for high performance hydronic controls as a solution to energy-efficiency and environmental problems is increasing globally and this is expected to help the global hydronic control market grow.

Growth of global construction industry with rising population, urbanisation and disposable income around the world

According to data from the United Nations (U.N), more than 54% of global population is living in urban areas. Due to the factors of growing population, urbanisation and increased standard of living of consumers around the world, the global hydronic control market is expected to expand. These factors are expected to aid the global hydronic control market grow as the growth of the global HVAC industry goes hand in hand with growth of urbanisation. With rising disposable income, consumers are increasingly looking for increased comfort in their living or working conditions. Hydronic control systems are almost noiseless in their operation. The energy required for the operation of these hydronic control systems is much lesser in comparison to their alternatives. Growing awareness regarding energy conservation and consumer affinity towards energy-efficient HVAC systems is a major driver for the global hydronic control market. These factors are expected to help grow the demand of Hydronic control in the global food and beverages industry and thus help the global Hydronic control industry grow.

Full Report With TOC:-https://www.alliedmarketresearch.com/hydronic-control-market-A09694

0 notes

Text

Ok so, I headcannon that the Dialtown mob was an actual mob back in the day. A genuinely dangerous mafia who you didn't want to wrong. And the Moores were a part of that. And it was somethin they were secretly proud of back then. When they were feared.

See, the Moore family is famous for their firearm manufacturin, makin their own models n such. Best guns in Wisconsin. And of course, the mob could benefit from havin good weapons at their disposal. So the Moores and the mob formed a connection. They protect each other. But fast forward to present day, the Dialtown mob ain't really a mob anymore. I mean, yall saw how Stabby and Shooty are like. And the Moore family don't associate with those two (despite those two idiots boastin that they do)

Stabby: "You really wanna mess with us, pal? We gots the best guns around town backin us up!" *WAYY too proud about sayin that shit out loud to a stranger who bumped into them.*

Tobias: "No- No, they don't. They're-... I don't know these people. Just- ignore them. Please..." *Extremely ashamed of bein so much as hinted at knowin those two.*

Shooty: "Whaddaya mean? We go way back! Heh, we're practically bros, Toby! Remember when-" *Cut off by Tobias holdin a hand out as if to cover Shooty's mouth, even though he doesn't have one.*

Tobias: "First of all, don't call me that. My name is Tobias. In fact, that's Mr. Moore to you two. Second of all, we're not 'bros'. And third, I DON'T KNOW YOU... I'm probably 30 years older than both of you, and I have a library to run. Leave. Me. Alone." *Said in an exasperated, "I'm gettin too old for this" way*

Stabby and Shooty bother the Moores often, while the Moores act like they don't even know those guys. Which sucks for Tobias cuz they drive people away from the library. Not because "Oh, they're mobsters! Scary!" No, they just don't wanna be seen around those two dumbasses. And neither does Tobias. The only Moore that willingly interacts with the remnants of the Dialtown mob is Tobias' older brother, Carter Moore. Cuz he's actually tryin to bring the mob back to its former glory and whip Stabby and Shooty into shape. Tryna make them actual mobsters. And of course failin repeatedly cuz 2 for 1 can't do jackshit without fuckin up. But because Carter actively interacts with them, it makes them think Tobias wants to associate with them as well.

I think personally it's funny and it builds Tobias some character. I also think it's funny how Stabby and Shooty continually try to interact with him and gain his friendship (and maybe approval?) even though they genuinely DON'T know him. Idk what ages 2 for 1 are, but I think they're in their late 20s-early 30s. Tobias is in his late 50s. So there's a bit of a gap there. Tobias knew their predecessors, but not them. Yet S&S act like they've been close friends with him for years. I could go on and on about this, but I think I'll leave it at that for now since I'm tired. If yall have any questions or anythin to say, feel free to ask or whatever!

To the few Tobias Moore fans out there, did I ever tell yall that the Moore family has ties to the Dialtown mob? The Moores are deeply ashamed of this, and if you ask any of them about it, they'll deny havin anythin to do with it.

#dusty yaps#long ish lore post!#i dont know why i went so long without talkin bout this#this is so fun#dialtown tobias moore#stabby and shooty mention#dialtown

7 notes

·

View notes

Text

Best Automotive Parts Manufacturer

Metalman Auto Ltd. is recognized as one of the best automotive parts manufacturers in the industry, delivering high-quality metal components for a wide range of vehicles, including two-wheelers, three-wheelers, passenger vehicles, commercial vehicles, and off-highway vehicles. With state-of-the-art manufacturing facilities, we specialize in sheet metal fabrication, tubular fabrication, and precision metal finishing, ensuring that every product meets the highest standards of quality and durability. Our commitment to innovation and excellence has earned us a strong reputation among OEMs (Original Equipment Manufacturers) and in the aftermarket industry. We pride ourselves on our ability to adapt to the evolving needs of the automotive sector, offering custom solutions for electric vehicles (EVs) and sustainable mobility. Whether you need body panels, chassis components, or other critical parts, Metalman Auto delivers products that enhance the performance and longevity of your vehicles. Choose Metalman Auto for unparalleled expertise, quality, and customer service in automotive component manufacturing.

#electric vehicles#metal fabrication#fabricationservices#oemparts#steel fabrication#supplier#oem manufacturing#manufacturer#stainless steel#vehicle transport#transportation#transport for london#ipo news#ipo alert#transport technology#transport service#stocks#business magazines#business standard#manufacturing#automotive parts#High-Volume Automotive Parts Manufacturing#markets#metalman auto#automotive industry#parts Manufacturin#automotive#car accessories#best company

1 note

·

View note

Text

Cold Iron | Endgame Part 3

As you all absorb everything that has just happened, a somewhat rushed and surreal end to an experience that felt like a lifetime, a silence settles briefly over the ferry. After any echoes from the destruction of Verdant Gardens have faded, someone finally speaks up.

“So, hey I… I didn’t want to say anythin’ during the trial, in case it derailed shit or made ya all suspect…” It’s Trik Sparks, standing up somewhat unsteadily from his seat near the front of the submarine. He clears his throat, looking around at you with an expression of open relief, and a touch of sheepishness.

“Look, I just want to explain that Iron Grip Industries couldn’t actually have had anythin’ to do with this. Like, ya all know Sen an’ Komugi are the ones who did this now, so… it should be safe to tell ya that I think Sen was tryin’ to frame me. See, Iron Grip Industries is actually my father’s company. Though it’s more of a conglomerate. It’s kind of a mega-corp, encompasses a lot o’ other companies an’ manufacturin’ and… ugh I won’t get into it, but bottom line is that among other shit it’s one o’ the biggest weapons manufacturin’ companies in the Western hemisphere, with some holdings in Japan. So it makes sense that Sen would want to take us out, especially if he was plannin’ on restartin’ with his own company, or buyin’ into Komugi’s. They could make a goddamn sickening fortune in the stock market if nothin’ else, with that kind o’ move. Destabilize a lot o’ shit.”

He’s talking a bit faster and his gaze moves between all of you and there’s something almost… pleading in it, as he meets each of your eyes.

“You guys understand why I didn’t bring it up earlier, right? I know I’ve told some lies an’ done some shit before, I wouldn’t blame any of ya for not trustin’ me, so I had to keep quiet. I had to make sure we stayed on the right track. And we did! We got it right! We’re all free now! So… that’s all. And I’m sorry I didn’t explain sooner, I was just… really scared. Okay? I admit it. I was scared. I didn’t want to lose anyone else.” Trik lets out a heavy breath, then runs a hand through his hair and grins hopefully around the room.

“Alright, glad that’s off my chest. Jesus. Uh, so, how’s everyone feelin’…?”

It’s a perfectly reasonable explanation, if somewhat startling, and something about Trik’s demeanor and attitude really does seem in earnest. Convincing, even. And yet many of you feel as if there’s some sort of choice being posed here. It’s a simple question though, really, requiring only a simple answer to move on. Do you believe him, or not?

> BELIEVE HIM

> DON’T BELIEVE HIM

1 note

·

View note