#overload relay manufacturer in india

Explore tagged Tumblr posts

Text

Key Benefits of Custom Electrical Control Panels

Custom Electrical Control Panels have become a necessity across industries in India, offering a tailored solution for managing power distribution, automating processes, and enhancing safety. From manufacturing plants to commercial buildings, these panels centralize and simplify control over electrical systems, allowing industries to boost productivity, maintain efficiency, and ensure consistent quality.

In this blog, we’ll explore the key benefits of custom electrical control panels and how they support operations by meeting specific industrial needs.

What are Custom Electrical Control Panels?

Before diving into the benefits, let’s understand what a Custom Electrical Control Panel is. Control panels house electrical devices such as switches, relays, circuit breakers, and more, enabling the safe and efficient control of machinery and processes. Custom electrical control panels are designed to meet the unique requirements of each facility, considering factors like equipment type, safety standards, and operational complexity.

Whether it’s controlling motors, monitoring energy consumption, or automating processes, custom panels bring tailored functionality to electrical systems, offering several advantages over generic panels.

1. Enhanced Operational Efficiency

One of the primary benefits of custom electrical control panels is improved operational efficiency. Since these panels are tailored to fit the specific requirements of your equipment, they streamline power usage, reduce energy waste, and improve overall system performance.

Customized panels can incorporate features like automation, speed control, and real-time monitoring, allowing operators to adjust settings for optimal efficiency. This makes them ideal for industries that need precise control over their operations, such as manufacturing, textiles, and pharmaceuticals.

Key Points:

Optimizes power consumption and reduces energy costs

Allows for process automation, reducing manual interventions

Enhances overall system performance and productivity

2. Improved Safety for Operators and Equipment

Safety is paramount in industrial environments, and custom electrical control panels come with built-in safety features that protect both operators and equipment. These panels can be designed with circuit breakers, overload relays, emergency shut-off buttons, and other safety mechanisms specific to the equipment and processes they control.

By reducing the risk of electrical faults, short circuits, and overloads, custom panels help prevent accidents, downtime, and damage to expensive machinery. This level of customization ensures that safety is not compromised, even in demanding or hazardous environments.

Key Points:

Protects against electrical faults and equipment damage

Reduces risk of accidents and increases workplace safety

Ensures compliance with industry-specific safety standards

3. Flexibility and Scalability

Another significant benefit of custom electrical control panels is their flexibility. Industries often expand or change their processes, and custom panels can be designed with scalability in mind. This means they can easily integrate new equipment, support additional functionalities, or handle higher power loads as the facility grows.

For example, a manufacturing unit may need additional control for new machines over time. A custom panel can be designed to accommodate these changes, providing long-term value and reducing the need for frequent replacements.

Key Points:

Adapts to changing operational needs and expansions

Supports the addition of new functionalities or equipment

Cost-effective and sustainable solution for long-term use

CTA: Want a Flexible Electrical Control Panel for Your Industry?

Contact us today to learn how our custom electrical control panels can meet your specific requirements and support your facility’s growth and success.

4. Centralized Monitoring and Control

Custom electrical control panels provide centralized control over complex systems, allowing operators to monitor and manage equipment from one location. This is especially beneficial for industries like power generation, oil and gas, and manufacturing, where monitoring multiple motors or processes is essential.

Centralized control allows operators to detect faults, make adjustments, and perform maintenance quickly, improving response times and minimizing disruptions. With features like touchscreen interfaces and remote monitoring, custom panels make it easy to oversee entire systems with precision.

Key Points:

Allows real-time monitoring and fault detection

Centralizes control over multiple systems for ease of operation

Enables quicker response to system issues, reducing downtime

5. Energy Efficiency and Cost Savings

Energy efficiency is a critical factor for most industries in India, where energy costs are a significant part of operational expenses. Custom electrical control panels are designed to meet specific power needs, ensuring that energy is only used where and when necessary. By avoiding unnecessary energy consumption, these panels contribute to lower energy bills and a reduced carbon footprint.

For example, custom panels can be integrated with Variable Frequency Drives (VFDs) that control motor speeds based on demand, helping industries save energy and improve the longevity of their equipment.

Key Points:

Minimizes energy wastage, leading to cost savings

Contributes to a more sustainable and eco-friendly operation

Helps industries comply with energy efficiency standards and policies Looking to Reduce Energy Costs?

Discover how a custom electrical control panel can optimize your energy usage and save costs. Reach out to us today for a personalized solution!

6. Easy Maintenance and Troubleshooting

Custom panels are designed with the specific layout, wiring, and components of each facility in mind, making maintenance easier. Technicians can quickly access components for repair or replacement, reducing downtime and ensuring smooth operations. With clear labeling and organized wiring, custom panels simplify troubleshooting and maintenance, ensuring minimal interruption to critical processes.

In addition, custom panels can be integrated with diagnostic tools that help identify issues before they become serious, allowing for preventive maintenance and extending the lifespan of equipment.

Key Points:

Simplifies maintenance and reduces troubleshooting time

Supports preventive maintenance, minimizing downtime

Ensures efficient handling of repairs and component replacements

7. Compliance with Industry Standards

Different industries follow specific safety, operational, and environmental standards, especially in sectors like pharmaceuticals, food processing, and petrochemicals. Custom electrical control panels can be built to meet these regulatory requirements, ensuring compliance and avoiding potential penalties or operational shutdowns.

Panels can be designed according to industry-specific codes, like IS, IEC, or UL standards, with added protective features for environments prone to dust, moisture, or explosive gases. This ensures safe and compliant operations tailored to the needs of each industry.

Key Points:

Custom-built to comply with industry-specific regulations

Ensures safe and legally compliant operations

Reduces the risk of regulatory fines or shutdowns

Final Thoughts on the Key Benefits of Custom Electrical Control Panels

The key benefits of custom electrical control panels go beyond simple power management; they offer efficiency, safety, flexibility, and significant cost savings. Whether it’s enhancing energy efficiency, centralizing control, or simplifying maintenance, custom panels are an essential investment for any industry looking to optimize their electrical systems.

By providing a tailored solution that meets the unique needs of each facility, custom panels help businesses stay competitive, eco-friendly, and prepared for future growth. For industries looking to streamline operations, reduce costs, and improve safety, custom electrical control panels are a reliable and effective choice.

Ready to Upgrade to a Custom Electrical Control Panel?

Looking to enhance the efficiency and safety of your facility? Contact us to explore how our custom electrical control panels.

0 notes

Text

Are you looking for MCC Panel ?Motor Control Center Panels Manufacturer and Supplier in India

If you are looking for MCC Panel, Motor Control Center Panels Manufacturer and Supplier in India

A Motor Control Center (MCC) panel is a centralized assembly of one or more motor starters, feeders, and other control equipment used to control and distribute power to electric motors. These panels are commonly found in industrial settings where numerous electric motors need to be controlled and monitored efficiently. The main function of a Motor Control Center panel is to centralize the control of various electric motors in an industrial setting. Some of the key functions and features of an MCC panel include.

Motor Control: MCC panels provide a centralized location for controlling and monitoring electric motors.

Overload Protection: MCC panels often include overload relays and other protective devices to prevent damage to motors in case of overload or other faults.

Distribution: MCC panels distribute power to various motors and equipment in an industrial facility through a common power bus, simplifying the wiring and reducing installation costs.

Monitoring and Diagnostics: MCC panels may include monitoring and diagnostic features such as meters, indicators, and communication interfaces to monitor the status of motors and troubleshoot any issues.

Safety: MCC panels are designed with safety features such as circuit breakers, disconnect switches, and interlocks to ensure safe operation and maintenance of the equipment.

Modularity and Scalability: MCC panels are often modular in design, allowing for easy expansion or modification of the control system as the industrial process evolves or new equipment is added.

For more details Click here : https://www.nextgenpowercontrols.com/

0 notes

Text

Plastic Granules Mixer Machine in Chennai

Plastic Granules Mixer Machine in Chennai: Company Overview: Invoit Plast Machinery Pvt. Ltd. is located in Ahmedabad, Gujarat, India. Invoit Plast Machinery Pvt. Ltd., is manufacturer, supplier and exporter of plastic processing machineries. We are Specializes in Manufacturer and Supplier of Plastic Granules Mixer Machine. Offers Plastic Granules Mixer Machine as well as plastic raw material mixer machines. Emphasizes stringent quality criteria to ensure high-quality products for customers. Advantages: Overcomes traditional deficiencies and ensures even and adequate blending. Ideal for plastic extrusion, animal feed mixing, and building materials blending. Offers numerous benefits in various industrial applications. Features: Precisely engineered for fast and homogeneous mixing. Easy to operate with control panel featuring overload motor relay protection. Three-side material discharge options (Left, Right, Back). Equipped with inspection and cleaning windows for convenience and safety. Applications: Essential for achieving the perfect recipe of raw materials in plastic component production. Used in various industries including injection molding, blow molding, blown film production, etc. Facilitates homogeneous mixing of masterbatch, virgin granules, and regrind materials. Invoit Plast Machinery Pvt. Ltd. Provide Plastic Granules Mixer Machine in Chennai, Tamil Nadu Including Poonamallee to Sriperumbudur across Irrungattukottai, Mannur, Sengadu, Mappedu & Pillaipakkam, Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam. For further details and inquiries, interested parties are encouraged to contact the company. Read the full article

#Arcot#Ariyalur#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Easytooperate#Erode#Exporter#Irrungattukottai#Kallakurichi#kanchipuram#Kanniyakumari#Karur#Krishnagiri#Madurai#Mannur#Manufacturer#Mappedu&Pillaipakkam#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur#PlasticGranulesMixerMachine#PlasticGranulesMixerMachineinChennai#PlasticGranulesMixerMachineinIndia

0 notes

Text

Electrifying Efficiency: Industrial Controller Transformer Market Trends

Industrial controller transformers’ key function is to save energy to help countries to meet their energy-efficiency targets. They offer step-down voltages to machine tool control devices. These transformers also provide a high degree of secondary voltage stability and excellent voltage regulation during a fleeting period of overload condition.

Industrial controller transformers market are specifically made for industrial applications that need relays, solenoids, and other electromagnetic devices. These can also be customized as per the end-user’s requirement. Further, industrial controller transformers help utilities in improving power reliability and the quality of power supplied to customers.

COVID-19 scenario analysis:

COVID-19 pandemic has severely affected many industries. It has put a halt on the production process as well as led to shortage of raw materials, thereby hampering the trade cycle. Therefore, the industrial controller transformers market is also getting affected to a considerable extent. Moreover, the electronics sector is a key factor driving the market, but even this sector is suffering due to decline in disposable income of customers due to the pandemic.

Top impacting factors: Market scenario analysis, trends, and drivers

With the growing concern for safety in electronics equipment and to prevent the equipment from any damages, the need for industrial controller transformers has grown and contributed to the overall market growth.

The industrial controller transformer market is anticipated to witness growth over the forecast period due to better efficiency of the three-phase segment in industrial applications in comparison with the single-phase segment.

Moreover, the primary factors boosting the industrial controller transformer market include amplified use of industrial control transformer in major industries and the flourishing power sector. Furthermore, amplified power generation capacities across the world and need to reduce equipment failure caused by frequent voltage spikes also drive the growth of this market.

Need to decrease the equipment fiasco triggered by frequent voltage spikes and augmented implementation of industrial control transformers across industries are expected to boost the industrial controller transformer market.

However, the failure of the industrial controller transformers due to voltage spikes and lightning transients may lead to damages of various devices in which these transformers are used, for example, motors, contactors, solenoids, relays, and others.

Regional analysis

The global industrial controller transformer market is studied across the major four regional markets, including North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific is expected to be the largest revenue generator in the global market over the coming years in response to the industrialization and infrastructural developments in India and China. Besides, the Middle East is expected to register significant growth due to increase in focus on expanding its manufacturing capabilities. This is mainly attributed to change the region’s role as a raw material supplier to a finished goods provider, within the manufacturing industry.

Key benefits of the report:

This study presents the analytical depiction of the global industrial controller transformer market along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global industrial controller transformer market share.

The current market is quantitatively analyzed to highlight the global industrial controller transformer market growth scenario.

Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed analysis based on competitive intensity and how the competition will take shape in coming years.

Key Market Players : Siemens, GE, Eaton, ABB, Boardman Transformers, Schneider, Emerson, Rockwell, Electric Hammond Power Solutions, Hubbell

0 notes

Text

What is the relay used for ?

A relay is an electronic device used to control a high-power circuit using a low-power signal. It is essentially an electromagnetic switch that uses a small amount of current to control a larger current.

Relays are commonly used in various types of circuits, including:

Control circuits: Relays are often used in control circuits to turn on or off other components such as motors, lights, and valves. They are used in industries such as manufacturing, automation, and process control.

Automotive applications: Relays are used in cars to control various systems such as the starter motor, fuel pump, and headlights.

Protection circuits: Relays can be used in protection circuits to disconnect a circuit if an abnormal condition such as an overload or short circuit is detected.

Communication systems: Relays can also be used in communication systems to amplify and switch signals.

Overall, relays are an essential component in many electronic and electrical systems, and they provide a reliable and safe way to control high-power circuits using low-power signals.

0 notes

Photo

Ganesh Engineering is one of the leading Monorail Hoist Manufacturers in India. These hoists are used in a variety of industries, including automotive, steel, and construction. It has a lifting capacity of 1 to 10 tonnes and a lift height of 3 to 50 meters, depending on the needs of the customer.

Safety Features:-

-> Overload Relays

-> Hook Safety Latch

-> Travelling limit switch

-> Brakes in Hoisting as well as c.t

-> All 4 core cables with Earth cable

#monorailhoist#hoist#liftingequipment#crane#lifting#materialhandling#heavyliftingequipment#suppliers#exporters#manufacturers#ahmedabad#gujarat#india

0 notes

Text

Best Electrical Switchgear Dealers in Ahmedabad, Gujarat, India

Electrical Switchgear Manufacturers in India by Darshil Enterprise

What is the electrical switchgear?

Electrical switchgear alludes to a brought together of circuit breakers, fuses and switches (circuit protection gadgets) that function to protect, control and isolate electrical equipment.

What are the different types of switchgear?

- Low voltage switchgear

- Medium voltage switchgear

- High voltage switchgear

Electrical switchgear manufacturers in Ahmedabad, Gujarat, India provide high voltages of power passing through them continually, the electricity can be tossed out of the switchgear and be destructive to individuals. Extraordinary matting is accessible to be set under and at the foot of the equipment. Elastic is an obstacle for electricity; it does not lead it and is hence a defensive measure against power.

An electric Power System utilized in association with the term switchgear alludes to a mix of circuit breakers, electrical disconnects or fuses. This electrical switchgear is used to clear blames downstream and furthermore to de-stimulate equipment (permitting work to be performed on the gear). Switchgear is never said as switchgear because it is already a plural much like numerous different terms.

Depending upon what the switchgear is utilized for it might be housed in various different ways and areas, switchgear for low voltage circumstances are regularly completely encased in a building. At the point when the voltage levels surpass 66kV the switchgear is frequently be found mounted in an outside environment where it can be protected by the air. They are not small gadgets using any all means and require a ton of space, there are approaches to save on space by utilizing Gas protected switchgear, anyway the expense of the equipment is increased so it turns into a matter of weighing up which is more significant.

The electrical switchgear manufacturing company India, are offering their variety in exclusive power ratings so one can meet the varied necessities of the industry. Their top goal is to offer the marketplace with world-elegance variety. To achieve this goal, they use premium grade fabric at the side of the superior era. The modern-day era helps in preserving a great threshold price of the voltage. This reduces the probabilities of circuit failure. Moreover, the efforts are also made in order to so one can losses of power at these junctions. Contact Address for more information:

Darshil Enterprise

303, "ONYX" 3rd Floor,

Nr IDBI BankCross Road Gulbai Tekra,

Ahmedabad - 380009 Gujarat, India

Email: [email protected];

Tel: 9998713713

Website: http://www.siemensdealer.com/

#electrical switchgear dealers in india#overload relay manufacturer in india#air circuit breaker manufacturers in india#moulded case circuit breaker manufacturers in india#fuse manufacturers in india#digital soft starter manufacturers in india#electronic timer manufacturers in india#digital timer manufacturers in india#air circuit breaker dealers in india#fuse suppliers in india

1 note

·

View note

Text

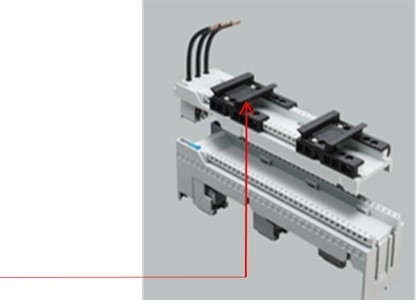

Messung-Wöhner CrossBoard® Modular power distribution system

Copper or aluminum busbars are present in any power distribution system. While the traditional busbar systems are cost-effective and robust, they suffer from several drawbacks. These shortcomings include lack of safety due to open installation and time consuming laborious operation for making connections. Despite its downsides, the traditional busbar system did not have a viable alternative – until the launch of Wöhner CrossBoard® system of covered busbar with a family of add-on adapters.

Introduction to CrossBoard®

CrossBoard® is a premium-quality covered copper busbar system for 3 phase loads up to 125 Amperes.

A ready-to-use product, CrossBoard® busbar offers plug-and-play operation for mechanically mounting components and making incoming electrical connection – literally in a snap!

Features of Wöhner CrossBoard® system

•SAFETY:

The CrossBoard® module has all-round touch-safe protection to prevent user contact of busbar and connection.

•SPEED OF INSTALLATION:

Ready to work out-of-the-box, saves significant time and efforts for mounting and wiring.

Unpack> snap to DIN rail> fit the components. Also possible to mount by direct bolting to panel plate or fastening to panel surfaces with additional holders.

No need to drill or wire incoming feeders.

Reduction of downtime while replacing components.

•SIMPLICITY:

Snap the components on to the CrossBoard®.

Mount parts to the CrossBoard® without fasteners.

Connect electrical incoming power to components automatically.

Ensure reverse polarity protection.

Prevent accidental detachment of an installed CrossLink® adapter with a self-closing mechanical lock.

•EXTENDIBILITY:

•Available in two convenient sizes of 405 mm or 225 mm length and a height of 160 mm.

•Combine several CrossBoard® modules to meet the actual requirement.

•COMPATIBILITY:

Universal compatibility for fitting any standard electrical component from a variety of vendors.

•Termination grid of 4.5 mm, to match any electrical product with 4.5 mm or 9 mm pitch.

• ADAPTABILITY :

WöhnerEQUES® universal adapter allows use of standard 3rd party devices like contactors, MCBs, MCCBs, safety relays on the CrossBoard® module.

The EQUES® uses CrossLink® technologyforfittingregular electrical switchgear from all standard manufactures to the CrossBoard® module.

The EQUES® universal adapter creates an open architecture for using the switchgear of your choice, while retaining the outstanding flexibility of CrossBoard® module.

The EQUES® universal adaptersaves time and input wiring during installation and service by allowing quick installation of new components and easy maintenance or replacement of the device.

Extension modules available to mount additional switchgear for motor starter application on the same EQUES® universal adapter.

Wöhner fulfils the requirements of power distribution equipment with high availability as well as high system and personal safety with the innovative CrossLink® Technology which is also used in CrossBoard®. This lets you realize systems and tailor them to different requirements in the simplest way.

• THE ADVANTAGES

Optimum touch-safe protection for the busbar system

and the components

Direct and secure connection of components to the

busbar system is always an option

Planning advantages through standardized grid system layout

Top portion of the device mounted can be separated &

faulty device can be changed outside with safety

•FUNCTIONALITY: •To extend functionality for your application, Wöhneroffers stand-alone modules that quickly mount and connect on the CrossBoard®.These modules save time as well as space while allowing you to build a wide array of functional blocks. Available with several variants to suit your requirement, thesebest-in-class modules, include:

•CRITO® connection module •Available in 2 variants. •Feeds incoming power to the CrossBoard® module. •Simultaneously feeds incoming power to two CrossBoard® modules, if they are stacked longitudinally. •BROOME10® power supply •High quality 24 VDC power supply to feed low-voltage consumers inside the control panel. •MOTUS® hybrid motor starter •Available in 3 variants. •Hybrid design combining TRIAC and relay. •Integrated heat sink, inbuilt logic for motor reversing, overload protection, and emergency stop. •OMUS® hybrid resistive load switching device •Available in 2 variants. •Hybrid design combining TRIAC and relay. •Integrated heat sink,internal fuses for overload protection and logic for emergency stop. •QUADRON® switch fuse disconnector •Switch fuse disconnector unit for NH type fuses up to 125 Amperes. •Narrow 49.5 mm width accommodating a NH fuse size 000. •Connection possible at bottom or top.

•COMPLIANCE: •Use ofCrossBoard® modules ensures compliance to IEC 61439 and UL 508 standards including IP20 touch-safe protection. •These compliancesare mandatory for any professional quality electrical installation in equipment, infrastructure, or property. •REDUCTION: •Smaller panel size, while increase accessibility due to reduced wiring and elimination of cable trays.

Application examples of CrossBoard® technology •Rotary Friction Welding Machine from ETA Technology •Reduction of panel size by 250 mm. •Improved aesthetics and increased reliability. •Extended touch-safe protection for panel interiors. •Speed-up replacement of parts to reduce machine downtime.

•Concrete Mixing Machine from Sicoma Mixers. •Replacement of traditional MPCB and Contactor for starting motor with Motus® hybrid motor starter. •Mounting the Motus® starter directly on the CrossBoard® module, with forward and reverse controls and motor safety. •Reduction of size to directly mount control panel on the machi

•VFD PANEL •Minimize wiring and size for this panel with VFD drives, DOL starter, and a CrossBoard® module. •Elimination of additionally lugs for wiring of the main feed. •Connect CrossBoard® module directly with incoming supply, mount all switchgear on the CrossBoard®.

•VILLA PANEL •Distribute power from several sources to various types of load in the luxury villas. •Follow IEC 61439 standards for efficient distribution of power. Mount switchgear and relays directly onCrossBoard® to save wiring and panel space.

Messung Electrical Engineering is Master Distributor-India for Wohner Gmbh. Messung partners with OEMs and end users to deliver the most efficient electrical panel components and solutions that answer today’s critical electrical power distribution & management challenges. Messung provides turnkey solutions to OEMs and end users by manufacturing smart low voltage electrical distribution control panels using the latest Wohner Busbar solutions for safe, compact installations as per IEC 61439 standard. These panels are also fitted with world class IoT based Smart Energy Management Systems and Analysers with solutions to remove Harmonics and ensure clean power to end user applications. For the most advanced power distribution and control solutions, and versatile energy management systems, contact Messung Electrical Engineering.

#electrical panel components#electrical power distribution#smart low voltage electrical distribution control panels#IoT based Smart Energy Management Systems#energy management systems#power distribution and control solutions

1 note

·

View note

Photo

Schneider overload relay price in India | Eleczo

Are you looking for the finest Overload Relay in Schneider at the lowest cost? In India, Eleczo is the leading manufacturer, retailer, and distributor of industrial contactors. Place your order as soon as possible to enjoy simple shopping.

Read more :

Schneider overload relay price list

1 note

·

View note

Text

Darshil Enterprise is one of the Best Overload Relays Manufacturer in Gujarat, India. Darshil Enterprise, since 1987. We provide Contactors, Overload Relays, Microprocessor Based O/L Relay, Air circuit Breaker,Moulded Case Circuit Breakers,Load Break Switches,Fuses, Digital Soft Starters, Electronic Timers, Get the Overload Relays catalogue and pricing list. Visit at - https://www.darshilenterprise.com/overload-relay-india.php

0 notes

Text

Applications of Motor Control Centre: The Innovation of Industrial Power Management

MCCs are regarded as critical systems employed in industries worldwide for the purpose of control and management of electric motors. Regarding industrial operations, an MCC plays a vital role in enhanced power distribution and security, coupled with higher efficiency. For this reason, these centre are usually employed to deal with several motors located in one place, making it necessarily vital in handling industries with various motor-driven equipment in everyday activities.

On this blog, we're going to discuss in detail applications of Motor Control Centre and how they are supporting many sectors in India and even worldwide.

What is a Motor Control Centre (MCC)?

MCC stands for a Motor Control Centre, which is a centralized system that has a number of motor control units housed in a single cabinet. Items like motor starters, circuit breakers, transformers, and relays are stored inside it. Operators can easily monitor, control, and protect the motors as one MCC in an industry uses many motors, and performance maintains and optimizes it easily.

Now, let us see where Motor Control Centres get their applications and how they benefit different sectors.

1.Manufacturing Industry

The manufacturing industry is one of the larger consumers of Motor Control Centre in India. In fact, large manufacturing plants with all their machinery, conveyor belts, and other automated systems require hundreds of motors running there. MCCs make it possible to handle all these motors through a centralised panel, ensuring efficient power distribution and control.

MCCs are also employed for speed and torque control of motors to save on energy efficiency and cut costs in the long run. These are a mandatory feature for producers wishing to rationalize their operations and avoid energy losses.

Major advantages:

Large number of motors can be controlled centrally

Improvement in energy efficiency, thus reduced operations cost

Easier to maintain and troubleshoot

2. Power Generation Plants

The motor control centre is widely installed in power generation plants where the motor control centre helps with their reliability and safety in governing the operation of motors driving turbines, generators, and auxiliary equipment. The plants have such high levels of reliability and safety due to the downtime and loss in production attributed to motor failures.

MCCs in power plant help reduce wear and tear on motors, maximize their performance, and protect equipment against electrical faults. It ensures an uninterrupted power supply. Thus, MCCs are widely accepted in power generation systems.

Key Benefits:

Reliable Operation of Critical Motors

Protection against electrical faults and overloads Less

maintenance costs and minimal time down

3. Oil and Gas Industry

The applications of MCCs extend to oil and gas industries where operations are wholly dependent on heavy-duty motors in pumps, compressors, and drilling equipment. Control over location can easily be centralized thus simplifying the monitoring performance of this motor operation and safety in hazardous environments.

MCCs are built to be used in extreme temperatures, dust, and humidity, considering that the environments for oil and gas facilities are not easy. The explosion-proof enclosures of these products also enhance protection in hazardous locales.

Key Benefits:

Control of motors for pumps and compressors in one central location

Used in harsh environments

Ideal for hazardous locations

4. Water and Wastewater Treatment Plants

These plants require some amount of precise control over motor speed and performance, and this leads to the most effective water treatment and distribution. MCCs make monitoring conditions of motors, fault detection, and prevention from equipment failure easier.

MCCs enable contribution to the water treatment plant through ensuring right power levels at which the motors have set the sail down, hence yielding reduced energy consumption while ensuring that there are no disturbances in operations within the water treatment plant.

Key Benefits

Controls Motors for Pumps, Blowers, and Filtration Systems

Enhances Reliability and Minimizes Downtime

Enhances energy efficiency associated with water management

5. Mining Industry

Other significant applications of Motor Control Centre are in mining operations. Mines largely use high power motors for running conveyor belts, crushers, drilling machines, and ventilation systems. Heavy mining conditions demand easy and effective management of such high-power motors. MCCs make centralised control possible for this.

Real-time monitoring of motor performance with automatic fault detection helps avert unnecessary downtime, which is lifeblood in mining where continuous operation is the only source of income.

Overload protection features for motors are also integrated in MCCs to protect motors from electrical faults.

Benefits

Centralized motor control for heavy-duty equipment

Reduces motor failures and minimizes downtime

Protects motors from electrical overloads and faults

6. Cement and Steel Plants

Cement and steel industries are very energy intensive as they consume a considerable number of motors in their operation. In cement and steel industries, Motor control centre is crucial in controlling motors installed in mixers, kilns, conveyors, among other machines considered critical.

MCCs provide flexibility as it is able to regulate the speed of a motor or the adaptation of power consumption from motors while monitoring the performance of equipment. This will assure high operational efficiency and low energy consumption while it is an industry that needs energy consumption at its maximum.

Key Benefits

Energy usage on high-energy processes is optimized.

Motor efficiency and performance are improved.

Operational costs and wastage of energy are reduced.

Need a custom-built Motor Control Centre for your industry? Contact us today to discuss how we can tailor an MCC to meet your operational and safety needs!

7. Textile Industry

Motor control centre is utilized in the management of motors that run looms, spinning machines, among other forms of equipment for textile processing. These systems play a critical role in ensuring accuracy and uniformity in textile production processes.

Motor Control Centre helps textile manufacturing companies gain maximum productivity while focusing on energy efficiency by providing centralized control of motor speed and performance.

Key Advantages

Accurate control of textile machinery

Produces smooth and efficient production

Enhances energy saving and reduces operational cost

Conclusion on Applications of Motor Control Centre

There are specific areas of application for motor control centre in varying industries across India and the rest of the world. Some of these sectors are manufacturing, mining, power generation, and water treatment, all of which are vital sectors in which the application of improves motor control, enhances safety, and conserves energy. All these application areas will add substantial significance to MCCs when more mature motor-driven technologies are adopted by industries.

MCC saves businesses a significant amount of money by streamlining their operations and minimizing energy consumption. Besides, the motor control centre is structured in such a way that motor management is centralized, electrical faults are protected, and so on; some can even be customized to fit various industries. So, in this regard, modern industrial facilities cannot run without MCCs.

Want to boost productivity? Contact us today to learn how our custom Motor Control Centre can improve

0 notes

Text

India Electromechanical Relay Market

India Electromechanical Relay Market

is expected to reach $602 million by 2026 estimated to grow at a CAGR of 9.2% during the forecast period 2021-2026. Growing demand for advanced electromechanical relays to reduce power consumption across several industry verticals is major factor driving the India Electromechanical Relay Market size.

The emergence of renewable energy projects, Wide usage of electromechanical relays and relay switch in electronic appliances and in fuse box of automobile sector to prevent the circuits from overload and faults is also fueling the growth of the market.

Moreover, increasing demand for electrically operated switch due to low cost, long operation life, less power consumption, easy maintenance and advantage of these relay in switching up four different loads than solid state relays are analyzed to drive the India Electromechanical relay Industry in the forecast period 2021-2026.

Report Coverage

The report:

“India Electromechanical Relay Market report– Forecast (2021-2026)”

, by IndustryARC covers an in-depth analysis of the following segments of the India Electromechanical Relay Market.

By Poles:

Single Pole, Double Pole, Triple Pole and Others.

By Throw:

Single Throw, Double Throw.

By Types:

Latching, Non Latching.

By Mounting Types:

Flange, Bracket and Panel Mount, PCB Mount, DIN Rail, Socket/Plug in, Others.

By Application:

GPUs, NICs, Storage Devices, PCIe Switches, Servers and Others.

By End User:

Industrial, Residential, Commercial, Automotive and Others.

Request Sample

Key Takeaways

Electromechanical relay in automotive industry is growing at a CAGR of 10.2% in the forecast period owing to rising adoption of relay switch in cars to turn on and off the equipped electronic devices within the vehicle. This electrically operated switch further enhance the market.

Emergence of Renewable energy generation in the country provides opportunities for Electromechanical Relays as it is used for several applications in this sector

Growing applications of electromechanical relay in the motor control, automotive applications and industrial applications in assisting alteration of the voltage & current is enhancing the market.

India Electromechanical relay top 10 companies Panasonic, Teledyne Relays, Honeywell International In, General Electric, Omron Corporation, Schneider Electric, Rockwell Automation, Inc., Siemens, Ashida electronics, Electronic Relays India Pvt Ltd, Rao ElectroMechanical Relays Private Limited and FUJITSU among others.

India Electromechanical Relay Market Segment Analysis - By Poles

Triple pole segment is anticipated to grow at a CAGR of 12.0% during the forecast period, owing to the application of controlling power system. Similarly, these relays are frequently being used in power system networks, electro-hydraulics and electro-pneumatics for controlling, automation, and protection purpose. In addition the triple pole relay is used for routing and signaling in railways segment with the combination of switch fuse or circuit breaker with relay helps in protection of the transformer in this sector. Hence these advantages are analyzed to drive the market in the forecast period 2021-2026.

India Electromechanical Relay Market Segment Analysis - By End User

Electromechanical relay in automotive industry is growing at a CAGR of 10.2% in the forecast period. Owing to rising adoption of these relays in cars to turn on/off equipped electronic devices within the vehicle. In addition to this, modern car manufacturers are incorporating relay panels into fuse boxes, as it supports easy maintenance of the vehicle. Auto manufacturers in India are playing a crucial role in selecting the most suitable relays, especially in the case of modern device manufacturing.

In the automobile vehicles, relays use a low current signal to control a high current circuit particularly in the applications such as starter solenoid. This application makes EMR indispensable for the automotive sector. These cars also deal with heavy electrical loads. Electronic devices such as fans, horns, wipers, ignition, air-conditioning, and headlamps which are equipped in the vehicle consume a large amount of current to process their operations. Thus, efficient relays installation is in demand to lower the power consumption in different automotive vehicles including lightweight commercial vehicles, cars, and trucks.

Moreover rising investments, production and sales of automotive vehicles significantly will boost the relay market. According to the report given by international organisation of automobile manufacturers (OICA), automobile production in India declined by 12% in 2019 followed by a similar decline projected in 2020 due to the current Covid-19 situation. This drastic fall made several companies focus on investment into future production as the automotive sector in India is set to recover by 2021.

Hyundai is planning to invest US$ 1 billion in India by 2022. SAIC Motor has also announced to invest US$ 310 million in India. Mercedes Benz has increased the manufacturing capacity of its Chakan Plant to 20,000 units per year. The growing investments, expansions accelerate the market to grow constantly post the Covid-19 recovery. Hence, the growing number of motor vehicles in India will augment the need of electromechanical relays fixation, thereby contributing to an increment in the India EMR market size.

Inquiry Before Buying

India Electromechanical Relay Market Drivers

Significant investments in Renewable Sector

Emergence of Renewable energy generation in the country provides opportunities for Electromechanical Relays as it is used for several applications such as providing very big contact gap, powerful switching capabilities and so on in this sector. In addition to this, the government and several companies in the country have been investing heavily for the development of this sector.

In 2019, Overseas Private Investment Corporation (OPIC), a development finance institution of the US government, has invested USD 350 million in six new solar and wind-power generation facilities in India. Similarly, EverSource Capital plans to invest $1 billion in India's renewable energy sector. In addition to this, the Indian government plans to invest $330 billion on a renewables push by 2030. As electromechanical relays are used for several applications in this sector, these developments are analyzed to drive the market in the forecast period 2021-2026.

Growing application of Electromechanical relays in various verticals

Growing applications of electromechanical relay in the electronics projects to assist the alteration of the voltage & current is enhancing the market. Relays are effective in detecting and isolating the faults during power transmission and distribution system in the application areas pertaining to electrical supply. Lighting control systems, industrial process controllers, traffic control, telecommunication, motor drives control, and protection systems of an electrical power system are some of the most lucrative application areas for ERM. Moreover the industrial growth in the country has also increased the demand for these electromechanical relays.

India Electromechanical Relay Market Challenges

Design and technical concerns related to EMR

Although Electromechanical Relays market is analyzed to grow at a significant rate, the design concerns are set to hamper the growth of the market. The challenge lies in blending the right mix of miniaturization and technical specifications to meet the designer's specific needs. Applications and technical specifications of these relays vary widely from one industry vertical to other. For instance, emerging broadband communications applications need relays to operate at higher frequencies, while industrial applications need lower power consumption and the automotive industry is demanding higher reliability. Hence these design concerns are set to hamper the market in the forecast period 2020-2025.

Buy Now

India Electromechanical Relay Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the India Electromechanical Relay Market. In 2019, the market of India Electromechanical relay has been fragmented with several companies vying for top share. India Electromechanical relay top 10 companies Panasonic, Teledyne Relays, Honeywell International In, General Electric, Omron Corporation, Schneider Electric, Rockwell Automation, Inc., Siemens, Ashida electronics, Electronic Relays India Pvt Ltd, Rao ElectroMechanical Relays Private Limited and FUJITSU among others.

Acquisitions/Technology Launches

In April 2019, Teledyne has manufactured the unique product called GRF172-5 which is an ultra-miniature, hermetically sealed, armature relay for 2.5 GHz RF applications.

Related Reports

Ring Main Unit Market - Forecast(2021 - 2026)

Report Code: AIR 0061

Electromechanical relay Market - Forecast(2021 - 2026)

Report Code: AIR 0375

For more Automation and Instrumentation Market reports, please click here

#India Electromechanical Relay Market size#India Electromechanical Relay Market share#India Electromechanical Relay Market price

0 notes

Text

Mixer with Dryer Machine in Bangalore

Mixer with Dryer Machine in Bangalore: Invoit Plast Machinery Overview: Invoit Plast Machinery is a well-known Indian company recognized for its reliable solutions in the plastic processing field. The company specializes in the manufacturing and supply of high-quality Mixer with Dryer Machines in Bangalore, India. Mixer with Dryer Machine: Dual Functionality: Designed to blend and dry materials simultaneously, eliminating the need for separate equipment. Mixing Elements: Features mixing elements such as paddles, blades, or agitators to ensure thorough blending and uniform mixture composition. Drying Mechanisms: Incorporates drying mechanisms like hot air circulation or direct heat transfer to remove moisture from materials, achieving the desired level of dryness in the final product. Features Precisely engineered for fast and homogeneous mixing. Easy to operate. Control panel with overload motor relay protection. Three Side Material Discharge (Left, Right, Back). Front side inspection window. Back bottom side cleaning window with safety limit switch. Batch timing indicator on control panel Auto cut off after completion of setted batch time. Safety grill to prevent entering the bag into mixer. Remixing facility. Low power consumption compare to gear motor type mixer. Available in M.S. and S.S. mixer body. Mixer with heating also available to dry the outer moisture from granules. Application: Used to manufacture plastic components or products by ensuring moisture-free plastic raw material, eliminating defects like black dots, pins, holes, etc. Ideal for mixing and drying the perfect recipe of raw materials required for plastic components or products, catering to industries such as Injection Moulding Machine, Blow Moulding Machine, Tape Plant, etc. Supplier Coverage in Bangalore: Invoit Plast Machinery provides Mixer with Dryer Machine in Bangalore, including Peenya, Doodannakundi, Rajaji Nagar, DDK Industrial Area, Petechannappa, Kamakshipalya, Kiadb, Dobbaspet, Bidadi, Dyavasandra, Jigani, Kumbalgudu, Mahadevpura, Rajaji Nagar, Kamakshi Palya, Attibele, Kolar, Tumakuru, Belagavi, Dharwar, Dakshina Kannada, Udupi region, Ballari, Raichur, Koppal, Mysuru, and Mandya. Read the full article

#Attibele#Ballari#Bangalore#Belagavi#Bidadi#DakshinaKannada#DDKIndustrialArea#Dharwar#Dobbaspet#Doodannakundi#Dyavasandra#India#Jigani#KamakshiPalya#Kamakshipalya#Karnataka#Kiadb#Kolar#Koppal#Kumbalgudu#Mahadevpura#Mandya#Manufacturer#ManufacturerofMixerwithDryerMachineinBangalore#ManufacturerofMixerwithDryerMachineinIndia#MixerwithDryerMachine#MixerwithDryerMachineinBangalore#Mysuru#Peenya#Petechannappa

0 notes

Text

Global Industrial Controller Transformer Market Analysis and Forecast

Industrial controller transformers market key function is to save energy to help countries to meet their energy-efficiency targets. They offer step-down voltages to machine tool control devices. These transformers also provide a high degree of secondary voltage stability and excellent voltage regulation during a fleeting period of overload condition.

Industrial controller transformers are specifically made for industrial applications that need relays, solenoids, and other electromagnetic devices. These can also be customized as per the end-user’s requirement. Further, industrial controller transformers help utilities in improving power reliability and the quality of power supplied to customers.

COVID-19 scenario analysis:

COVID-19 pandemic has severely affected many industries. It has put a halt on the production process as well as led to shortage of raw materials, thereby hampering the trade cycle. Therefore, the industrial controller transformers market is also getting affected to a considerable extent. Moreover, the electronics sector is a key factor driving the market, but even this sector is suffering due to decline in disposable income of customers due to the pandemic.

Top impacting factors: Market scenario analysis, trends, and drivers

With the growing concern for safety in electronics equipment and to prevent the equipment from any damages, the need for industrial controller transformers has grown and contributed to the overall market growth.

The industrial controller transformer market is anticipated to witness growth over the forecast period due to better efficiency of the three-phase segment in industrial applications in comparison with the single-phase segment.

Moreover, the primary factors boosting the industrial controller transformer market include amplified use of industrial control transformer in major industries and the flourishing power sector. Furthermore, amplified power generation capacities across the world and need to reduce equipment failure caused by frequent voltage spikes also drive the growth of this market.

Need to decrease the equipment fiasco triggered by frequent voltage spikes and augmented implementation of industrial control transformers across industries are expected to boost the industrial controller transformer market.

However, the failure of the industrial controller transformers due to voltage spikes and lightning transients may lead to damages of various devices in which these transformers are used, for example, motors, contactors, solenoids, relays, and others.

Regional analysis

The global industrial controller transformer market is studied across the major four regional markets, including North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific is expected to be the largest revenue generator in the global market over the coming years in response to the industrialization and infrastructural developments in India and China. Besides, the Middle East is expected to register significant growth due to increase in focus on expanding its manufacturing capabilities. This is mainly attributed to change the region’s role as a raw material supplier to a finished goods provider, within the manufacturing industry.

Key benefits of the report:

This study presents the analytical depiction of the global industrial controller transformer market along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global industrial controller transformer market share.

The current market is quantitatively analyzed to highlight the global industrial controller transformer market growth scenario.

Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed analysis based on competitive intensity and how the competition will take shape in coming years.

Key Market Players: Hubbell, Boardman Transformers, Electric Hammond Power Solutions, Eaton, Rockwell, GE, ABB, Schneider, Emerson, Siemens.

#IndustrialControllerTransformer#TransformersMarket#ManufacturingIndustry#IndustrialAutomation#EnergyEfficiency

0 notes

Text

Jib Crane Suppliers in India

Jib Crane manufacturers in India provides high-quality cranes for moving and lifting heavy material. However, a good crane must be durable and able to meet the user's needs. This is where the importance of buying from a reputable manufacturer comes into play. Venus Engineer is one such manufacturer and a leading JIB Crane Supplier in India. Apart from Jib Cranes, this company also offers Overhead EOT Single Girder Cranes, Overhead Hot Cranes, Electric Chain Hoist, Geared Motors and Chain Pulley Block.

SMJC-1

Venus Crane SMJC-1 Jib crane is a versatile machine that can be used for various lifting and lowering purposes. It has a four-way articulation that allows it to be positioned as per the needs of the job site. Its heavy-section I beam and gusset plate give it additional rigidity. Its double-roller self-aligning type bearings can withstand both vertical and horizontal loads. The jib arm can be swivelled manually or electrically. These jib cranes are designed with a high level of specification and are suitable for a variety of applications.

When used for lifting large objects, jib cranes are ideal for indoor and small-space environments. They can easily reach objects that are too high for laborers to reach. These cranes can be used to transfer materials and parts between workstations or production lines. They can also be used to lift heavy apparatuses from one office to another.

Goliath Gantry Crane

If you are looking for a reliable supplier of Goliath gantry cranes, you have come to the right place. The Goliath crane from Sparkline is a versatile, heavy-duty building crane, and is used in construction sites, steel stockyards, and pre-cast segment yards.

The crane features a control panel which can be installed in a cabin, pendant, or radio remote. The control panel has standard contactors, overload relays, timers, transformers, and other components. The crane can be fitted with a VVFD drive for short or long travel.

One of the leading manufacturers of Goliath cranes in India is Meeka Machinery. This company offers a wide range of cranes, which are classified into four major categories. They include: Overhead cranes, Flame Proof Cranes, Jib Cranes, and Goliath Cranes.

Hoist HOT Crane

If you're looking for Hoist HOT Crane suppliers in India, you've come to the right place. Venus Crane is one of the leading manufacturers of this type of crane. The company has years of experience and is backed by quality and reliability. They offer several types of cranes and provide quality raw materials.

These cranes are a popular choice in industries requiring heavy lifting capacity. They're equipped with an operator cabin and control pendant and are operated electrically. You can choose from single or double girder EOT cranes. In order to find the right crane for your business, you'll need to find a reputable supplier. When shopping around for a crane, ask about their certification and quality assurance policies.

Hoist HOT Crane suppliers in India can provide you with a variety of options when it comes to sizing and installation. The company's expertise can help you determine what you need and help you decide which model is best for your needs.

0 notes

Text

Features And Benefits of Astronomical Street Light Timer

The street light timer is made up of a solar panel and a timer controller. When the street light is fully charged, the controller will Astronomical Street Light Timer control the street light and stop the charging process. During the daytime, the solar panel will continue to convert sunlight into electric energy and store it in the controller. After sunset, the controller will take power from the battery and supply it to the street lamp.

We offer products at very cost-effective prices and facilitate our clients with the best supply-chain network service. If you want to get the best and most cost-effective Astronomical Street Light Timer supplier in Nashik, Bhopal, Bangalore, Udaipur, Coimbatore, Jaipur, Kolkata, Chennai, Mumbai, Noida, Hyderabad, Delhi, and Ahmedabad, India.

Features of Astronomical Timer for Street Lights:

Digital time relays with astronomical programs.

Sealable front panel cover.

Setting by four push-buttons.

Automatic change in summer/winter time.

Liquid crystal display (LCD).

Working hours for day breaks.

Single-channel.

Installed a dual module on a 35mm DIN-rail.

Benefits of Astronomical Timer for Street Lights:

Turn the streetlight on and off at a predetermined time.

ASTRONOMICALLY can control on and off time.

Light detectors are used to resist light levels, moonlight, and streetlights.

Streetlight load on/off facility, manually bypassing the programmed circuit.

Late-night switching of the load is provided to ensure power savings.

Overvoltage / Undervoltage Protection.

Overload and short circuit protection.

We are one of the leading Astronomical Street Light Timer supplier and manufacturers in India. We have a wide range of Astronomical Street Light Timer, which is widely appreciated by our clients. Our products are genuine, reasonably priced, and can be delivered within the specified time frame. Aaradhya Electronics offer customization on products as per the requirement of clients.

The Astronomical Street Light Timer is easy to use and operate, and it is always connected to the internet. It allows you to control your outdoor lights using an app or computer. This is a good way to make sure you are not wasting energy. You need to make sure you're using the timer correctly, though. The astronomical street light timer has been proven to effectively save power.

If you looking for the best Astronomical Street Light Timer supplier and manufacturer in India, so Aaradhya Electronics is the best choice for you, contact us at +91 9657455169 / +91 7972428271 and visit our website https://www.aaradhyaelectronics.in/product-details/2/rtc-base-street-light-controller-5-amp

0 notes