#jibcrane

Explore tagged Tumblr posts

Text

Ambica Engineering: Best Jib Crane Manufacturer

Transform your operations with Ambica Engineering’s Jib cranes. Designed for maximum load handling and smooth execution—trust us for all your crane needs. Call us: +91 9898139820 Visit: https://www.ambicaengineering.com/jib-crane/

0 notes

Text

Lift Smart, Work Easy with Jib Cranes – Your Perfect Lifting Partner!

Effortless lifting, precision handling, and space-saving design – Jib Cranes are your ultimate solution for material handling. Perfect for workshops, warehouses, and industries, they offer:

✔️ 180°-360° rotation for precise handling. ✔️ Space-saving compact design. ✔️ High load capacity for versatile lifting.

Upgrade your operations today!

🔗 Visit us at www.endeavourweigh.com/product/jib-crane/ to know more.

Request a Quote Now 📞 Call us today: +91-98-2413 5305 📧 Email: [email protected]

0 notes

Text

youtube

Wall Travelling Jib Crane

MOVING MATERIAL RESOURCES SAFELY WITH CARE

Harsiddhi Crane Wall Travelling Jib Cranes Are Available In Capacities Up To 20 T Incorporating The Harsiddhi Crain ZX Wire Rope Hoist Or In Capacities Less Than 5 T Incorporating The Harsiddhi Crain LX Chain Hoist. The Travelling Cantilever Structure With Hook Coverage Over A Continuous Work Area Makes This Type Of Crane Ideal For Servicing A Line Of Machines Or Workstations Especially Where Loads Must Be Moved From One To Another. Wall Travellers Are Ideal For Overlapping Use With Overhead Cranes Where The Travelling Jib Services The Work Stations Down One Side Of A Bay And The Overhead Crane Provides General Service Of The Whole Bay. Generally Speaking Building Structures For Wall Travelling Jib Cranes Need To Be Specifically Designed To Take The Crane Loads.

ADVANTAGES OF HARSIDDHI CRAIN WALL TRAVELLING JIB CRANES WITH ZX HOISTS.

Extra Hoist Brake Safety.Additional Protection Against Overloading.

No External Hoist Gears.

Double Band Rope Guide.

Hoist Gear Inspection Facility.

Unique Fail-Safe Hoist Drum.

Variable Speed Travel And Traverse.

No External Trolley Gears.

Sturdy Trolley Side Rollers.

Trolley Reaction Roller Obviates The Need For Counter Weight.

#goliathgantryeotcrane#semigantryeotcrane#underslungeotcrane#wireropehoistcrane#doublerailtrolleytypecrane#walltravellingjibcrane#eotcrane#hoistcrane#jibcrane#goodslift#crane#crain#Industrial#factory#steelstructurefactory#steelstructureproject#steelstructure#steel#preengineered#preengineeredbuildings#industrialsheds#homeshopmachinist#safety#workplacesafety#workwear#structure#manufacturing#fabrication#machine#Youtube

0 notes

Text

We Are Introducing the Jib Crane | Malik Agro Industries.

Our Jib Crane is a versatile and indispensable tool for lifting and moving heavy loads precisely and efficiently. Designed and manufactured by Malik Agro Industries, a leading name in industrial equipment, this crane is engineered for exceptional performance and reliability.

#MalikAgroIndustries#JibCrane#IndustrialLifting#HeavyDutyEquipment#MaterialHandling#PreciseLifting#ReliablePerformance#IndustrialSolutions#WorkplaceEfficiency#EngineeringExcellence#IndustrialInnovation#LiftingTechnology#SafetyInOperations#DurableCrane#VersatileLifting#MalikAgroJibCrane#QualityLiftingEquipment#EfficientMaterialHandling#TrustedIndustrialEquipment#GulfIndustries#MiddleEastManufacturing

0 notes

Text

Understanding Cranes: A Comprehensive Guide for All Types of Cranes

Cranes are essential machinery in various industries, particularly in manufacturing and construction. They play a critical role in lifting, transporting, and arranging heavy objects and machinery. This guide will explore how cranes work, the different types available, and their specific applications, focusing on manufacturers of all types of cranes, including the cranes exclusively manufactured by Shri Bhagwati Machines Pvt. Ltd.

How Do Cranes Work?

Cranes operate on fundamental principles that allow them to lift heavy loads with ease. Here’s a breakdown of the basic operational principles:

1. Mechanical Advantage

Cranes utilize mechanical components such as levers and pulleys to gain a mechanical advantage. This reduces the amount of effort required to lift heavy objects, making it easier for operators to manage large loads.

2. Distribution of Loads

Cranes are designed to distribute weight evenly across their structure. This distribution minimizes structural stress and enhances stability during lifting operations. Key components such as the base, boom, and counterweights work together to maintain balance.

3. Control Systems

Modern cranes are equipped with sophisticated control systems that allow operators to maneuver loads precisely. These systems may include levers, joysticks, or remote controls, enabling smooth operation even in complex environments.

Types of Cranes and Their Purposes

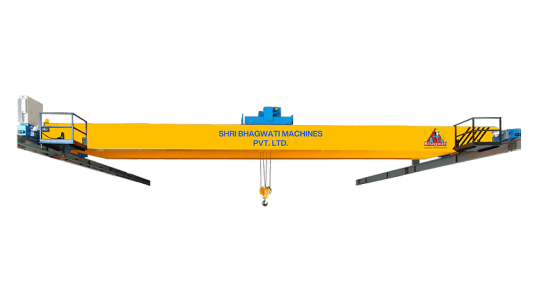

1. Overhead & Gantry Cranes

Shri Bhagwati Machines Pvt. Ltd. is a prominent manufacturer of Electric Overhead Traveling (EOT) cranes, known for their exceptional quality and reliability. EOT cranes are essential in various industrial applications, providing efficient solutions for lifting and transporting heavy loads with ease. Designed to operate on a fixed track, these cranes feature a robust construction that ensures stability and safety during operation. The EOT cranes manufactured by Shri Bhagwati Machines are equipped with advanced control systems, allowing for precise maneuverability and enhanced operational efficiency. Their design maximizes workspace utilization, making them ideal for factories, warehouses, and construction sites. With a commitment to excellence,SBMPL has established itself as a trusted name in the crane industry, delivering high-performance EOT cranes tailored to meet the diverse needs of clients across various sectors.

Visit : https://bhagwatimachines.com/eot-cranes.html

2. Wall Mounted Cranes

SBMPL specializes in manufacturing high-quality wall-mounted cranes, designed to optimize space and enhance efficiency in various industrial settings. These cranes are ideal for environments where floor space is limited, as they utilize overhead areas effectively, allowing for the lifting and moving of loads without occupying valuable ground space.

Visit : https://bhagwatimachines.com/wall-cranes.html

3. JIB Cranes

We are a leading manufacturer of high-quality jib cranes, designed to enhance efficiency and productivity in various industrial applications. Jib cranes are versatile lifting solutions that feature a horizontal arm (jib) mounted on a vertical mast, allowing for flexible load handling within a defined radius.

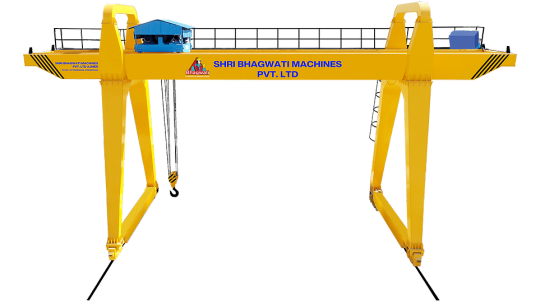

4. Gantry/Goliath Cranes

We manufacturer high-quality gantry and goliath cranes, designed to meet the diverse needs of various industries. These cranes are essential for lifting and transporting heavy loads, making them invaluable in manufacturing, construction, and logistics.

Visit : https://bhagwatimachines.com/gantry-cranes.html

4. Semi Gantry Cranes

We are a prominent manufacturer of semi-gantry cranes, designed to provide efficient lifting solutions in various industrial applications. These cranes are characterized by their unique design, featuring one leg that runs on a track while the other is fixed to a wall or column. This configuration allows for greater flexibility in confined spaces where traditional gantry cranes may not fit.

Visit : https://bhagwatimachines.com/semi-gantry-cranes.html

5. Additional Crane Types

Mobile Cranes: These cranes offer mobility on job sites and can be driven on highways.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Rough Terrain Cranes: Designed for off-road use with enhanced stability on uneven surfaces.

Crawler Cranes: Feature tracks for mobility and can lift extremely heavy loads.

Floating Cranes: Used in maritime applications for loading and unloading cargo from ships.

Operational Procedures for Planning and Setup

Preoperative Planning: Engineers and operators assess the site, calculate load weights, and plan the lifting procedure to ensure efficiency and safety.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Lifting Procedure: Operators use control systems to raise the load while counterweights help maintain balance

Weight Shifting: Once lifted, the operator carefully moves the load horizontally using the boom or gantry system while ensuring precise synchronization to avoid obstructions.

Positioning: The operator gently lowers the load into place, often guided by signals from ground crew members to ensure accuracy.

Frequently Asked Questions regarding types of manufacturing and construction cranes

How do cranes work? Cranes used in manufacturing and construction are essential for lifting, transporting, and arranging large objects and machinery.

What is the Basic Crane Operation Principles Mechanical Advantage ? Cranes have an edge when lifting large objects because they use mechanical components like hydraulic cylinders, levers, and pulleys. This lowers the amount of work required to move objects.

How cranes helps in Distribution of Loads ? Cranes disperse weight uniformly, reducing structural stress and guaranteeing stability. To balance loads, the base, boom, and counterweights cooperate.

What are System Of Control in Cranes ? Control systems installed on cranes enable operators to precisely move loads. Levers, joysticks and occasionally remote controllers that are manipulated by hand fall under this category.

What are Overhead Cranes ? These tracks-based cranes are commonly observed in production facilities and have the ability to lift and transport objects within a predetermined region. They are very handy when transferring large items between warehouses or assembly lines.

What are wall-mounted Cranes ? ? Wall-mounted cranes serve a specific and valuable purpose in the manufacturing and construction industries. Here’s a detailed overview of their functions and benefits: Wall-mounted cranes allow for lifting and moving loads in areas where floor space is limited. They utilize overhead space, leaving the floor clear for other activities.Their installation against walls helps free up valuable floor space, making them ideal for smaller workshops or factories.

What are JIB Cranes ? Jib cranes are adaptable lifting tools that are frequently utilized in a variety of sectors, such as building, manufacturing, and warehousing. Jib cranes can raise and move big loads both horizontally and vertically, which makes them appropriate for a variety of tasks, including handling commodities and moving industrial parts.

What are the Operating Procedures for Planning and Setup in Manufacturing and Construction ? Engineers and operators arrange the lifting procedure, calculate load weights, and evaluate the site before starting up. Efficiency and safety are guaranteed by a proper setup.

0 notes

Text

Leading Cranes & Hoists Manufacturer in Hyderabad – 18+ Years of Excellence

Sri Gajanana Cranes & Hoists is a leading manufacturer in Hyderabad with over 18 years of expertise in the industry. We specialize in designing, manufacturing, and supplying high-quality Cranes, Hoists, and Lifting Solutions tailored to meet diverse industrial needs. Our commitment to innovation, safety, and durability ensures efficient material handling for businesses across various sectors. Whether you need EOT Cranes, Goliath Cranes, Jib Cranes, or Custom Hoisting Solutions, we deliver reliable and cost-effective equipment to enhance productivity. Contact us today to explore our advanced lifting solutions and experience excellence in crane and hoist manufacturing.

#Cranes

#cranesandhoists

#MaterialHandling

#LiftingSolutions

#IndustrialCranes

#EOTCranes

#GoliathCranes

#JibCranes

#HeavyLifting

#Manufacturing

#HyderabadIndustry

#SriGajananaCranes

#sri gajanana cranes and hoists#Cranes#Hoists#Cranes and hoists#Cranes and hoists manufacturer in hyderabad#jib crane#Goliath cranes#stacker cranes#glantry cranes

0 notes

Text

Wall mounted jib crane, small jib crane 1 ton, Customized up to 3 ton for sale

#walljibcrane #wallmountedjibcrane #jibcrane #smalljibcrane

0 notes

Photo

The single main beam gantry crane is mainly composed of a mast, a crane trolley, a cart operating mechanism, a driver's cab and an electrical control system.

The mast is a box-shaped single main beam and two-leg structure. When the lifting capacity is less than 20t, the trolley adopts the vertical reverse roller type, and when it is greater than 20t, the trolley adopts the horizontal reverse roller type and runs on one side of the main beam. The main beam adopts the single-beam off-track form. The outriggers and the lower cross beam form an L-shape. Both sides of the outriggers are generally cantilevered. The ability to cross the span is strong when lifting objects, which is convenient for transporting objects from the span to under the cantilever. The trolley is suspended from the side, and the spreader is arranged on the side of the main beam. When the lifting capacity is ≤20t, the vertical anti-roller two fulcrum form is adopted, and when the lifting capacity is >20t, the horizontal anti-roller three fulcrum form is adopted.

The operation method adopts a closed driver's cab with adjustable seats, insulating mats on the bottom plate, and tempered glass for window glass, which can be equipped with heating and cooling air conditioners, buzzers, walkie-talkies and other items according to user requirements.

There are two forms of power supply: cable reel and high-altitude sliding line.

whatsApp +86-15038267159

www.doriaequip.com

1 note

·

View note

Text

Best Jib Crane Manufacturers in India

When it comes to buying a jib crane, a lot of factors need to be taken into account. First, you should choose a manufacturer who has a good market reputation. You can ask around from people in the business or read online reviews and testimonials. Always ask questions and make sure you select a manufacturer that has a good track record and is experienced in the field.

A jib crane manufacturers is a multipurpose crane that is not as large as a tower crane but is very powerful. These cranes are fixed to the ground or free-standing and are capable of lifting heavy loads up to 15 tons. They are manufactured with many features that improve productivity and workplace safety.

Jib cranes are used in many industries to move and lift materials. They are also used in construction sites. They normally have fixed jibs, although there are also developments available. These developments make it easier to move heavier loads. If you need to lift a heavy load, a jib crane is the way to go.

The jib crane is one of the most important pieces of machinery in any factory or warehouse. It helps employees in handling heavy loads and increases productivity by reducing labor costs. It also eliminates the need for manual operation.

0 notes

Link

Searching for Electric Winch Manufacturers in India, Select Stalmac Enterprise for Electric Winch Machine. Visit now to check Winch Machine specifications.

1 note

·

View note

Link

Smart, customized solutions Jib Cranes from 1t to 5T. Higher productivity, ease in operation resulting in higher revenue for industries

0 notes

Text

Lifting Technology With Ambica Engineering

Explore the pinnacle of lifting technology with Ambica Engineering, a renowned leader in JIB crane manufacturing. Introducing our high-performance JIB Crane: Elevate with Precision and Power! With an impressive load capacity of up to 6 tons, it guarantees reliability and efficiency for all your heavy lifting operations. For more information, Call us: +91 9898139820 Visit: https://www.ambicaengineering.com/jib-crane/

0 notes

Text

JIB Cranes: Your Ultimate Lifting Solution

Struggling with material handling? JIB cranes could be your secret weapon!

✔️ Easy installation & operation ✔️ Maximizes workspace efficiency ✔️ Improves lifting productivity ✔️ Wide range of capacities & configurations

Looking for the perfect JIB crane for your requirements? Endeavour offers a diverse selection of JIB cranes tailored to suit any application.

Here are some popular user searches to guide you:

✔️ Types of JIB cranes (wall-mounted, freestanding, etc.) ✔️ JIB crane capacity (from 250 kgs to 10 tons) ✔️ Swing facility options of 90°, 180°, 270° & 360° ✔️ Arm length customization up to 8 meters ✔️ Explore our JIB crane manual here: https://youtu.be/8L26FeKigoc?si=j-xCbl0LIdVcKDJb

Get a free quote today!

Contact us: 📞 +91-98-2413 5305 | ✉️ [email protected] | 🌐 www.endeavourweigh.com/product/jib-crane/

#JIBCrane#MaterialHandling#LiftingSolutions#Endeavour#EndeavourWeigh#EndeavourInstruments#WeighWithEndeavour#ElevateWithEndeavour#EIPLOfficial

0 notes

Text

Single Girder Crane

SAFE AND SMOOTH MATERIAL HANDLINGMoving Material Resources Safely With Care : Harsiddhi Crane Single Girder and Double Girder E.O.T. Cranes are designed and manufactured in accordance with IS/BS/DIN. Considering adequate factors of safety with respect to appropriate duty, the structural parts of the cranes are designed in accordance with IS/BS/DIN. Harsiddhi Crain also manufactures / utilises standard components and controls to ensure reliability

Span : 3 mtrs. to 20 mtrs.

Safe Working Load : 0.5 ton to 15.0 ton

Crane Control : From floor through Pendant Push Buttons, Optionally through Radio Remote Control / cabin with master control.

Power Supply System : To Hoist and Cross Travel through Trailling Cables / Drag Chain to Crane through Shrouded Bus Bars / Trailling Cable / MS Angle Iron Conductors / Bare Copper Conductors (depending on customer’s choice and application).

Motors : Squirrel Cage Slip Ring Motors based on application requirements, built-in separator electrically operated fail to safe brakes for all three motions. Motors with “F” class insulation provided in all motions

Single Girder Crane, Wire Rope Hoist Crane, Cranes, EOT Crane, Goliath Gantry Crane, Semi Gantry Crane, Under Slung Crane, Trolley Crane, Crane, Crain

#harsidhicrain#harsidhicrane#craneharsidhi#crane#singlegirdereotcrane#doublegirdereotcrane#goliathgantryeotcrane#semigantryeotcrane#underslungeotcrane#wireropehoistcrane#doublerailtrolleytypecrane#walltravellingjibcrane#eotcrane#hoistcrane#jibcrane#goodslift#crain

0 notes

Photo

The WOLFF 166 B US hydraulic luffing jib crane. @wolffkranofficial @cranegrams #wolffkran #wolff #wolff166b #wolff166us #wolffcrane #luffingjibcrane #luffingjib #farnborough #luffingjibtowercrane #jibcrane (at Farnborough, Hampshire) https://www.instagram.com/p/CNyShb-pNhE/?igshid=1qcl3na6pnzq1

#wolffkran#wolff#wolff166b#wolff166us#wolffcrane#luffingjibcrane#luffingjib#farnborough#luffingjibtowercrane#jibcrane

0 notes

Text

The Most Popular Crane Types For Construction And Manufacturing

Because they can lift big objects and equipment to a safe and effective location, cranes are a vital component of the manufacturing and construction sectors. Selecting the ideal crane for your requirements can be made easier if you are aware of the different kinds that are available. The most popular kinds of cranes, such as wall-mounted cranes, jib cranes, semi-gantry cranes, Goliath cranes, EOT cranes, and gantry cranes, will all be covered in this blog.

1. Electric overhead traveling cranes, or EOT cranes

One of the most popular varieties of cranes in manufacturing and construction are EOT cranes. They are intended to run on a system of tracks that are mounted to a factory or workshop ceiling. With these cranes, loads are raised and lowered by a trolley that can move along a bridge that spans the width of the workspace.

Important Characterstics

Versatility: Fit for a range of uses, such as material handling and heavy lifting.

Space Efficiency: Because they run overhead, they maximize floor space.

Precision Control: Accurate and seamless movements are made possible by electric drives.

2. Gantry Cranes

Important Characterstics

Mobility: Able to relocate to new places with ease.

Height Adjustability: Lifting at different heights is possible thanks to adjustable legs.

Economical: Usually less costly than cranes overhead.

3. Goliath Cranes

Important Characterstics

High Load Capacity: Able to move very heavy objects.

Outside Use: Designed to endure outside environments.

Durability: A long service life is guaranteed by a sturdy structure.

4. Semi Gantry Cranes

Semi-gantry cranes are cranes that combine elements of EOT and gantry cranes. They walk on the ground with one leg and sprint along an overhead track with the other. Because to their special design, they can reach places that full gantry cranes cannot, which makes them especially helpful in spaces that are limited in size.

Important Characterstics

Compact Design: Ideal for spaces with little headroom.

Operation Flexibility: Suitable for a range of environments, such as warehouses and workshops.

Simple Installation: Compared to larger cranes, this one is easier to erect.

5. Wall Mounted Cranes

Important Characterstics

Space Efficiency: Preserves important floor area.

Easy to Use: They are easy to use and may be used for a variety of purposes.

Low Maintenance: Compared to larger cranes, these often require less maintenance.

6. JIB Cranes

Important Characterstics

Versatility: Adaptable to different settings (wall, floor, or portable).

Enhanced Reach: Offers a longer reach for activities involving lifting.

Economical Solution: Perfect for workshops or smaller companies.

In Summary

For maximum productivity and safety in your industrial or construction operation, use the appropriate crane. Every kind of crane has particular benefits and is appropriate for a given set of uses. Knowing your alternatives can help you make an informed choice, regardless matter whether you require the flexibility of a jib crane or the enormous lifting capacity of a Goliath crane. To make sure you choose the ideal crane for your purposes, always seek professional advice and bear in mind elements like weight capacity, workspace configuration, and operational requirements. Happy weightlifting! .

0 notes