#nickel chromium heating element

Explore tagged Tumblr posts

Text

High-Grade Nichrome Heating Element Wire

TempSens offers high-grade nichrome heating wire, tailored for your heating elements. Engineered for longevity and efficiency, our wires are the ideal choice for high-temperature operations. Browse our catalog for the best in heating technology.

#nichrome heating wire#heating element wire#nichrome heating element#nickel chromium heating element

0 notes

Text

Machine learning unlocks secrets to advanced alloys

New Post has been published on https://thedigitalinsider.com/machine-learning-unlocks-secrets-to-advanced-alloys/

Machine learning unlocks secrets to advanced alloys

The concept of short-range order (SRO) — the arrangement of atoms over small distances — in metallic alloys has been underexplored in materials science and engineering. But the past decade has seen renewed interest in quantifying it, since decoding SRO is a crucial step toward developing tailored high-performing alloys, such as stronger or heat-resistant materials.

Understanding how atoms arrange themselves is no easy task and must be verified using intensive lab experiments or computer simulations based on imperfect models. These hurdles have made it difficult to fully explore SRO in metallic alloys.

But Killian Sheriff and Yifan Cao, graduate students in MIT’s Department of Materials Science and Engineering (DMSE), are using machine learning to quantify, atom-by-atom, the complex chemical arrangements that make up SRO. Under the supervision of Assistant Professor Rodrigo Freitas, and with the help of Assistant Professor Tess Smidt in the Department of Electrical Engineering and Computer Science, their work was recently published in The Proceedings of the National Academy of Sciences.

Interest in understanding SRO is linked to the excitement around advanced materials called high-entropy alloys, whose complex compositions give them superior properties.

Typically, materials scientists develop alloys by using one element as a base and adding small quantities of other elements to enhance specific properties. The addition of chromium to nickel, for example, makes the resulting metal more resistant to corrosion.

Unlike most traditional alloys, high-entropy alloys have several elements, from three up to 20, in nearly equal proportions. This offers a vast design space. “It’s like you’re making a recipe with a lot more ingredients,” says Cao.

The goal is to use SRO as a “knob” to tailor material properties by mixing chemical elements in high-entropy alloys in unique ways. This approach has potential applications in industries such as aerospace, biomedicine, and electronics, driving the need to explore permutations and combinations of elements, Cao says.

Capturing short-range order

Short-range order refers to the tendency of atoms to form chemical arrangements with specific neighboring atoms. While a superficial look at an alloy’s elemental distribution might indicate that its constituent elements are randomly arranged, it is often not so. “Atoms have a preference for having specific neighboring atoms arranged in particular patterns,” Freitas says. “How often these patterns arise and how they are distributed in space is what defines SRO.”

Understanding SRO unlocks the keys to the kingdom of high-entropy materials. Unfortunately, not much is known about SRO in high-entropy alloys. “It’s like we’re trying to build a huge Lego model without knowing what’s the smallest piece of Lego that you can have,” says Sheriff.

Traditional methods for understanding SRO involve small computational models, or simulations with a limited number of atoms, providing an incomplete picture of complex material systems. “High-entropy materials are chemically complex — you can’t simulate them well with just a few atoms; you really need to go a few length scales above that to capture the material accurately,” Sheriff says. “Otherwise, it’s like trying to understand your family tree without knowing one of the parents.”

SRO has also been calculated by using basic mathematics, counting immediate neighbors for a few atoms and computing what that distribution might look like on average. Despite its popularity, the approach has limitations, as it offers an incomplete picture of SRO.

Fortunately, researchers are leveraging machine learning to overcome the shortcomings of traditional approaches for capturing and quantifying SRO.

Hyunseok Oh, assistant professor in the Department of Materials Science and Engineering at the University of Wisconsin at Madison and a former DMSE postdoc, is excited about investigating SRO more fully. Oh, who was not involved in this study, explores how to leverage alloy composition, processing methods, and their relationship to SRO to design better alloys. “The physics of alloys and the atomistic origin of their properties depend on short-range ordering, but the accurate calculation of short-range ordering has been almost impossible,” says Oh.

A two-pronged machine learning solution

To study SRO using machine learning, it helps to picture the crystal structure in high-entropy alloys as a connect-the-dots game in an coloring book, Cao says.

“You need to know the rules for connecting the dots to see the pattern.” And you need to capture the atomic interactions with a simulation that is big enough to fit the entire pattern.

First, understanding the rules meant reproducing the chemical bonds in high-entropy alloys. “There are small energy differences in chemical patterns that lead to differences in short-range order, and we didn’t have a good model to do that,” Freitas says. The model the team developed is the first building block in accurately quantifying SRO.

The second part of the challenge, ensuring that researchers get the whole picture, was more complex. High-entropy alloys can exhibit billions of chemical “motifs,” combinations of arrangements of atoms. Identifying these motifs from simulation data is difficult because they can appear in symmetrically equivalent forms — rotated, mirrored, or inverted. At first glance, they may look different but still contain the same chemical bonds.

The team solved this problem by employing 3D Euclidean neural networks. These advanced computational models allowed the researchers to identify chemical motifs from simulations of high-entropy materials with unprecedented detail, examining them atom-by-atom.

The final task was to quantify the SRO. Freitas used machine learning to evaluate the different chemical motifs and tag each with a number. When researchers want to quantify the SRO for a new material, they run it by the model, which sorts it in its database and spits out an answer.

The team also invested additional effort in making their motif identification framework more accessible. “We have this sheet of all possible permutations of [SRO] already set up, and we know what number each of them got through this machine learning process,” Freitas says. “So later, as we run into simulations, we can sort them out to tell us what that new SRO will look like.” The neural network easily recognizes symmetry operations and tags equivalent structures with the same number.

“If you had to compile all the symmetries yourself, it’s a lot of work. Machine learning organized this for us really quickly and in a way that was cheap enough that we could apply it in practice,” Freitas says.

Enter the world’s fastest supercomputer

This summer, Cao and Sheriff and team will have a chance to explore how SRO can change under routine metal processing conditions, like casting and cold-rolling, through the U.S. Department of Energy’s INCITE program, which allows access to Frontier, the world’s fastest supercomputer.

“If you want to know how short-range order changes during the actual manufacturing of metals, you need to have a very good model and a very large simulation,” Freitas says. The team already has a strong model; it will now leverage INCITE’s computing facilities for the robust simulations required.

“With that we expect to uncover the sort of mechanisms that metallurgists could employ to engineer alloys with pre-determined SRO,” Freitas adds.

Sheriff is excited about the research’s many promises. One is the 3D information that can be obtained about chemical SRO. Whereas traditional transmission electron microscopes and other methods are limited to two-dimensional data, physical simulations can fill in the dots and give full access to 3D information, Sheriff says.

“We have introduced a framework to start talking about chemical complexity,” Sheriff explains. “Now that we can understand this, there’s a whole body of materials science on classical alloys to develop predictive tools for high-entropy materials.”

That could lead to the purposeful design of new classes of materials instead of simply shooting in the dark.

The research was funded by the MathWorks Ignition Fund, MathWorks Engineering Fellowship Fund, and the Portuguese Foundation for International Cooperation in Science, Technology and Higher Education in the MIT–Portugal Program.

#3d#advanced materials#aerospace#alloys#applications#approach#arrangement#Artificial Intelligence#atom#atomic#atoms#biomedicine#book#Building#Capture#Casting#challenge#change#chemical#chemical bonds#chemical elements#chromium#classes#classical#complexity#Composition#computer#Computer modeling#computer models#Computer Science

2 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Haynes 188 Sheet Suppliers in India

Haynes 188 Sheet in Mumbai, Haynes 188 Sheet Importers in Mumbai, Haynes 188 Sheet Suppliers in Mumbai, Haynes 188 Sheet Exporters in Mumbai, Haynes 188 Sheet Stockists in Mumbai.

HAYNES 188 Sheets is a cobalt-nickel-chromium-tungsten alloy that may be readily fabricated for aerospace and commercial gas turbine engine applications, including combustion cans, flame holders, liners, transition ducts, and afterburner parts. HAYNES 188 Coils is generally found in hot sections of engines in burner cans, ducting and afterburner components. In recent years, Udimet 188 Coils has been eclipsed by Alloy 230 for many applications due to improved properties. Udimet 188 Plates has good forming characteristics and is capable of being forged, hot worked or cold worked, although it does work-harden very rapidly so frequent intermediate annealing treatments are recommend for complex forming operations. Buy Alloy 188 Plates at reasonable price from us.

What are Haynes 188 Plates?

Haynes 188 Plate is a cobalt-based alloy that is composed of nickel, chromium, tungsten, and molybdenum, along with other elements. It is known for its excellent high-temperature strength, resistance to corrosion and oxidation, and good weldability.

What are the properties of Haynes 188 plates?

Haynes 188 plates have excellent high-temperature strength, good oxidation resistance, and good resistance to corrosion and erosion. They also have good weldability and formability, making them suitable for a wide range of industrial applications.

What are the applications of Haynes 188 plates?

Haynes 188 plates are commonly used in high-temperature applications, such as gas turbine components, exhaust systems, and heat exchangers. They are also used in chemical processing, power generation, and aerospace applications.Specifications:AMS 5608 / AMS 5609Standard:AMS, AMS and APISpecialize:Shim Sheet, Perforated Sheet, B. Q. Profile.Size:0.5 MM TO 200 MM THICK IN 1000 MM TO 2500 MM WIDTH & 2500 MM TO 12500 MM LENGTHForm:Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange)Finish:Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)Hardness:Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.Grade:Haynes 188 (UNS R30188)

Haynes 188 Plates Equivalent Grades

STANDARDWERKSTOFF NR.UNSHaynes 188–R30188

188 Haynes Plates Chemical Composition :

GradeCMnpSSiCrNiCoBFeLaWHaynes 18805-151.25 max020 max.015 max20-.5021.0 -23.020.0 -24.0Bal.015 max3.0 max03-1513.0 -15.0

Special Products

Haynes 188 Sheet

Alloy 188 Sheet

Conicro 4023 Sheet

2.4683 Sheet

Uns R30188 Sheet

Cobalt Alloy Haynes 188 Sheet

AMS 5772 Sheet

Cobalt Nickel 188 Sheet

Stellite 188 Sheet

Haynes 25 Sheet

L605 Sheet

Udimet L605 Sheet

Stellite 25 Sheet

UNS R30605 Sheet

2.4964 Sheet

AMS 5537 Sheet

Ams 5759 Sheet

HS25 Sheet

Cocr20w15ni Sheet

Cobalt Alloy Haynes 25 Sheet

Cobalt L605 Sheet

Inconel X750 Sheet

X750 Sheet

Haynes X750 Sheet

Nicrofer 7016 Sheet

Udimet X750 Sheet

Pyromet X750 Sheet

Superimphy 750 Sheet

2.4669 Sheet

UNS N07750 Sheet

Nickel Alloy X750 Sheet

NiCr15Fe7TiAl Sheet

Nickelvac X750 Sheet

AMS 5699 Sheet

Alloy X750 Sheet

Nimonic C263 Sheet

Nickel Alloy C263 Sheet

UNS N07263 Sheet

Haynes 263 Sheet

2.4650 Sheet

NiCo20Cr20MoTi Sheet

AMS 5872 Sheet

Hastelloy C263 Sheet

Nicrofer 5120 Coti Sheet

Nicrofer 5120 Coti Round Bar

Inconel 945 Round

Inconel 945 Bar

UNS N09945 Round

Inconel 945X Round

2 notes

·

View notes

Text

How did you find DIN 1.2714 Steel in India? If you need a tool steel that can handle high temperatures, pressures, and stresses, look no further than DIN 1.2714 Steel. It’s the best in class for close die forgings.

DIN 1.2714 is a Hot Work Tool Steel that conforms to the German DIN (Deutsches Institut für Normung) standard. It is also known by other designations such as 55NiCrMoV7 or L6 in different international standards.

DIN 1.2714 (DB6 Steel) is a tool steel grade that is commonly used in the manufacturing of forging dies and plastic molds. It belongs to the group of hot work tool steels and is known for its high-temperature stability, wear resistance, and toughness. DIN 1.2714 (DB6 Steel) is often used in applications where the material needs to withstand elevated temperatures during the manufacturing process, such as in forging and die-casting operations.

The chemical composition of DIN 1.2714 (DB6 Steel) typically includes elements such as:

Carbon (C): 0.50-0.60% Silicon (Si): 0.10-0.40% Manganese (Mn): 0.60-0.90% Chromium (Cr): 1.00-1.50% Nickel (Ni): 1.00-1.50% Molybdenum (Mo): 0.20-0.30% Vanadium (V): 0.10-0.30%

These alloying elements contribute to the steel's properties, such as hardness, strength, and heat resistance. The specific composition may vary slightly depending on the manufacturer and the standard to which it adheres.

Virat Special Steels is the largest stockiest and supplier of #DB6/ DIN 2714 in flat, square and round bar. We provide steel in all sizes as your requirements.

To know about more specific details of DIN 1.2714 ( DB6 Steel ), please visit the website. https://www.viratsteels.com/din-2714.html https://www.viratsteels.com/db6.html

Email us: [email protected] Call Us Now: +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#db6 steel#db6#din 2714#aisil6#tool steel suppliers#forging#close die forging

2 notes

·

View notes

Text

Chapter 199 Trivia (Part 2)

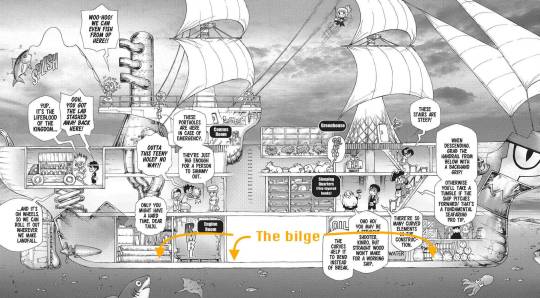

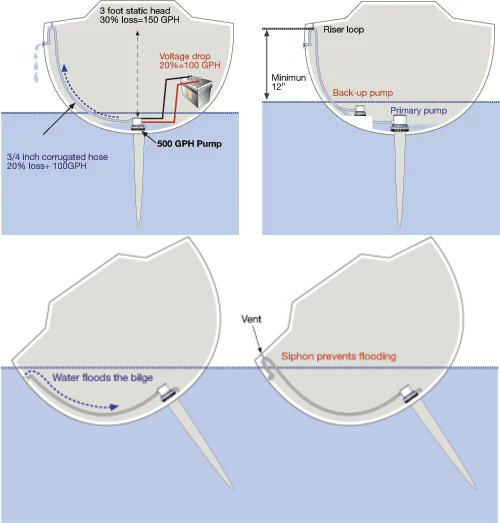

(Previous part)

The drainage function Xeno is talking about here that caused the Perseus to sink is probably the bilge pump. The bilge is the lowest part of the ship. As any water on a ship drains downwards, a pump is needed to remove the water so it doesn't collect.

Without anyone ensuring the pump didn't stop, the hull filled with water and the Perseus sank. Bilge water also isn't usually just water, but can be full of other things like oil, chemicals, pitch, and dirt.

The KoS used pillow lift bags to recover the Perseus. To do this, someone needs to dive down and attach them (Taiju and Ryusui again, maybe?), then inflate them with compressed air.

A lifting bag filled with 1L of air lifts 1kg of weight, so if we knew the total size of the bags we could approximate the weight of the Perseus… Except they grossly overestimated, since the ship is flying out of the water rather than lifting slowly in a controlled manner.

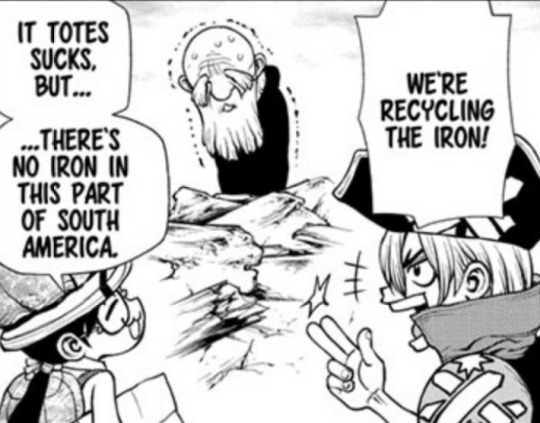

Chelsea's iron comment here confuses me because several of the ores they collected include iron in them? Maybe there's just not enough.

The simplicity of the lower half of the mecha shown here along with the briefs reminds me of Astro Boy. The top half I believe is just the "DR" from Dr. Stone along with rocket-ship-inspired arms and Senku's face. Alternatively, it could be a reference to Tetsujin 28, also known in the western audiences as Gigantor, or even Mazinger Z.

Isla Martin Garcia is on the mouth of the Río de la Plata, between Uruguay and Argentina. It's less than 2km^2, and 150 people live there permanently (=Dunbar's number?)

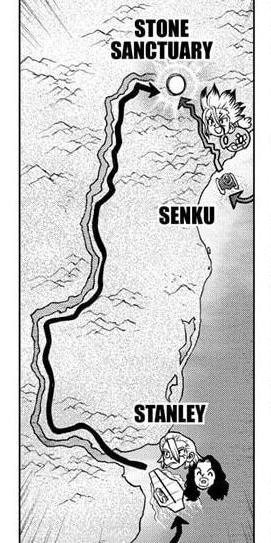

If you're wondering why the KoS is suddenly so far away from Fort Medusa, it's because it's where Stanley docked the Perseus several chapters ago.

Stainless steel uses approximately 11% chromium to get its heat- and rust-resistant properties, but can include other elements as well.

Senku had already introduced bottling to the Ishigami villagers, but the addition of canning means less glass. Canning is especially good because while both methods can last several years, cans don't shatter and also protect from light. They also weigh less!

Francois is making cans of fish meat and "gibier", which is the French word for game, or any kind of hunted meat. Going by the size of the carcasses and the picture on the can, I think it may be cow as Uruguay also eats the most beef per person in the world.

Francois is serving sashimi on a generic model boat. How fancy!

I assume this won't be the design for the next Perseus, since it's made of wood rather than superalloys (and also covered in fish).

Is Carlos jealous or uncomfortable with the fact that Max is reviving someone who looks just like him? I wonder if there's any blood relation…

Taiju is tired for what may be the first time ever! Though it could be because he somehow managed to wear out a pickaxe of all things…

Maya is revival #75 according to the bottle Taiju is holding. It also means Taiju returned back to Fort Medusa to mine rather than staying at Isla Martin Garcia.

Communication between Fort Medusa and Isla Martin Garcia is established thanks to the usual radio setup, but with the addition of a Yagi-Uda antenna. This is a directional antenna, so they may be trying to hide from Whyman.

Senku and Chrome simply mark dangerous items with a skull and crossbones. Xeno? He makes the entire thing into the shape, with gas coming out of the eyes.

Can you get any more cartoonishly villainous, Xeno!?

Xeno uses the Mond process to purify nickel.

The toxic gas he mentions is nickel carbonyl, which can be fatal if absorbed through the skin or inhaled. The gas smells musty or sooty, and decomposes to carbon monoxide quickly. Special gas masks are required to block the fumes.

Xeno loves referring to people as the "mindless/ignorant masses". I wonder if his parents were the original "ignorant masses" telling him to stop messing around with dangerous chemicals in the backyard…

I think this rock that Taiju finally manages to break with the help of Maya (and a new pickaxe) is the same one from before, but from a different angle.

A few outfit changes: Suika's lenses are now full circles and not broken, Xeno's zipper is straight rather than zig-zagged and Charlotte has a little skirt to cover herself up better.

The timeline isn't very clear here, but at least 2 weeks pass between Maya and Charlotte's revival and Xeno's discussion with Senku going by moon phase.

Many people have been revived, but because of the location they likely speak Spanish. We know several of the KoS know English and Japanese, and Francois knows French, so who's translating here?

I think it's funny Xeno didn't get a team-up high-5 from Senku even though everyone else does. They may be superallies now but not even Senku wants to go near those claws…

#trivia#dr stone#chapters#199#I had to remove so many images because I hit the max despite putting this into two parts...

6 notes

·

View notes

Text

Exploring the Strength and Versatility of Incoloy 925 Fasteners!

In fasteners, strength, corrosion resistance, and durability are paramount. Incoloy 925 fasteners have gained recognition as a reliable and robust choice for various applications. In this blog post, we will dive into the world of Incoloy 925 fasteners, exploring their properties, applications, and advantages.

What Is Incoloy 925?

Incoloy 925 is a nickel-iron-chromium alloy with the addition of molybdenum, copper, titanium, and aluminium. This combination of elements gives it outstanding corrosion resistance in various harsh environments. Incoloy 925 is known for its excellent strength, making it suitable for applications requiring high tensile strength.

Properties of Incoloy 925 Fasteners

Corrosion Resistance: Incoloy 925 fasteners exhibit remarkable resistance to various corrosive environments, including sulfides and chlorides. This makes them ideal for use in chemical and petrochemical industries where exposure to harsh chemicals is common.

High Strength: Incoloy 925 has excellent tensile and yield strength, making it suitable for high-stress resistance applications. These fasteners maintain their integrity under extreme mechanical loads.

Heat Resistance: These fasteners offer excellent thermal stability and can withstand high-temperature applications, making them a popular choice in power generation and aerospace industries.

Applications of Incoloy 925 Fasteners

Oil and Gas Industry: Incoloy 925 fasteners are commonly used in the oil and gas sector, particularly in offshore drilling platforms and downhole equipment. Their resistance to sour gas environments and high-pressure conditions makes them a preferred choice.

Chemical Processing: The chemical industry utilizes Incoloy 925 fasteners to resist corrosive chemicals and solutions. They are essential components in pumps, valves, and vessels.

Aerospace Industry: Incoloy 925's high strength and heat resistance properties make it a valuable material for critical aerospace applications. It is used in jet engines, turbine blades, and other high-temperature components.

Power Generation: Incoloy 925 fasteners find applications in power generation facilities, such as gas turbines and nuclear power plants, where they are exposed to high temperatures and aggressive environments.

2 notes

·

View notes

Text

Understanding the Benefits of 321H Stainless Steel Round Bar

If you are looking for a reliable, durable, and corrosion-resistant stainless steel round bar, then the 321H stainless steel round bar is a perfect choice. This type of alloy is composed of 18% chromium, 8% nickel, and 0.08% carbon and is ideal for engineering projects that require high strength at elevated temperatures. Let's look at the benefits of 321H stainless steel round bars.

High Corrosion Resistance

One of the main advantages of using 321H Stainless Steel Round Bars is its superior corrosion resistance compared to other metal alloys. The chromium content in this alloy helps it resist oxidation and other forms of corrosion at elevated temperatures up to 900°C (1650°F). This mixture makes it an ideal material for use in industries operating under high-temperature conditions, such as petrochemical or power generation plants.

Strength and Durability

This alloy's combination of chromium and nickel makes it incredibly strong yet still malleable enough to be used in various engineering applications. It also has excellent creep strength, which means it can withstand extended periods under extreme pressure without becoming deformed or damaged. This property suits it for applications where parts must withstand prolonged exposure to high temperatures, such as engine components, valves, and turbine blades.

Heat Resistance

The heat resistance properties of 321H stainless steel round bars make them ideal for applications that require exposure to extreme heat or corrosive elements, such as jet engines or chemical processing tanks. The 8% nickel content protects against oxidation and other forms of corrosion under these conditions, making this alloy resistant up to 925°C (1700°F).

Conclusion

321H stainless steel round bar offers many advantages over traditional metal alloys, especially when working with extreme heat or corrosive elements. Its superior corrosion, strength, durability, and heat resistance make it an ideal choice for demanding engineering projects requiring high-performance materials capable of withstanding extreme environments. Whether you need parts for a petrochemical plant or a turbine blade component, 321H stainless steel will ensure your project operates safely and efficiently in any environment.

2 notes

·

View notes

Text

Also! Why go through all that nonsense inventing antibiotics when you could invent electricity? For a lot less effort (or rather, fewer steps to remember)

WHAT YOU WILL NEED

Iron

Copper

A blacksmith with tools

A way to find north (compass if you have it, sun if you don't)

The wheel

Tar or rubber

Take a bar of iron and line it up north-south. Clamp it down. Smack it real hard with a hammer for a while. You'll know you're done when little bits of iron stick to it. Congrats! You have made a permanent magnet.

Have your blacksmith make copper wire. Any thickness will do to start, but as shit gets more complicated you'll need it thinner. Bend the wire into this shape:

The size does not matter, apart from where you're planning to install it.

Attach the hoop end to the wheel, and slot the stick-out-y bits into a bigger copper hoop that you have cut in half to make two semicircles, so that they are just barely touching and can scrape by, like so:

The wheel can be attached to a watermill or a windmill or a small child turning it, whatever works. The two semicircles are then attached to whatever circuit you want to make (we'll get to that in a sec).

Now put two permanent magnets (you did make a second one, right? go back and make a second one) on either side of the original hoop (in orange, not white). Make sure they're pointed the same way, so one has a north pole closest to the hoop, and one has a south pole closest. Congratulations! You have invented alternating current.

As the hoop is turned by the wheel, the electrons inside will want to flow to counteract the changing magnetic field inside it caused by it turning inside a uniform magnetic field. This flows to the stick-out-y bits, and then to the hoop. However, it doesn't flow at a constant rate, and in fact changes direction halfway through. That's why we cut holes in the second hoop - this keeps the current flowing in the same direction the whole time.

The faster you can get the wheel to spin, the stronger your current will be. The easiest way to do this is use gears to go from, say, a big water wheel to a small wheel spinning your copper hoop. (Yes, they will know what gears are in medieval Europe, ask your blacksmith.)

Now what do you do with your electricity? Well, you need some resistive element placed in circuit with your broken hoop, like so:

The resistor is going to be the hardest part here, as modern resistors are made of nichrome, a nickel-chromium alloy. Medieval Europeans did not know how to find, let alone smelt, nickel or chromium, and you can't be expected to just find some wherever you land. What you could expect to find would be graphite, then called "black lead" or "plumbago". It makes a decent resistor. Lacking that, wrap some of your copper wire around a non-flammable insulator, like a ceramic.

The resistor can then be used as a heating element! You can start fires, warm homes, make toast, whatever your creative heart can think of. Lightbulbs are a bit more complicated, because those typically require a vacuum, which I wouldn't expect a medieval village to be able to make.

However, you could use this to rotate things! Just make this whole set up again, on the other side of your circuit. Why mill your flour right next to the waterwheel, when you can run wires from the waterwheel to your mill and do it there? And that's what the tar/rubber is for - if you're going to be moving electricity any appreciable distance, you'll want to coat your copper wires with an insulator, to protect them, as well as anyone who happens to touch them.

One last thing - if instead of fully completing the circuit with a resistor, you just hold the two copper wires real close to each other but not actually touching, you can make a spark jump, showing your new medieval friends that there is lightning inside metals.

I can understand how "modern person thrown into the past gets by pretending to be a healer/doctor" is as surprisingly common of a trope as it is. I mean I'm fluent enough at bullshitting to be pretty sure I could pull it off to impersonate a doctor in any time pre-1800s. If I have no idea what something is or how to treat it, I could just get the opinion of the other whatever-passes-as-medical-professionals around, but if their suggestions sound like bullshit I'm not doing it. And I'll beat the shit out of anyone suggesting bloodletting or mercury. With my healing stick. I've tied little bells on it, that jingle comically with every smack.

The awesome curative powers of my healing stick come from two separate sources: Placebo, and me using it to beat anyone trying to give my patients mercury.

35K notes

·

View notes

Text

Alloy Steel Plate Suppliers

Vandan Steel & Engg. co. supplies alloy steel plate in an extensive variety of elite evaluations from stock held over our worldwide conveyance and transforming focuses. Vandan Steel & Engg. co. stock 100% prime alloy steel plate with full factory affirmations for complete traceability.

Alloy steel is a type of steel that contains a mix of elements other than carbon to improve its mechanical and physical properties. These elements are added in varying proportions depending on the desired characteristics of the material. The addition of these elements enhances the steel's strength, hardness, toughness, and corrosion resistance.

Alloy steels are alloys that have been created to enhance basic properties of steel. As plates, these incorporate qualities, hardness, durability, wear safety and consumption safety. A large portion of the alloys steels are not difficult to machine, stamp and manufacture and can be fabricated to exact tolerances.

Alloys steel plates are characterized as steel plates with an unequivocal reach or distinct least amount of extra components, contingent upon the alloys. Regular alloying components incorporate aluminium, Nickel, Titanium etc.

Vandan Steel & Engg. co. is one of the business' heading merchants of transformed alloy steel plate products, with clients working all around in requesting commercial enterprises, for example, aviation, oil & gas and other mechanical sections, for example, construction equipment and power generation, depending on Vandan Steel & Engg. co. to supply superior alloy steel plate.

Key Properties of Alloy Steel Plates

High Strength: Alloy steel plates have a higher tensile strength compared to carbon steel plates, making them suitable for heavy-duty applications.

Corrosion Resistance: The addition of elements like chromium and nickel improves the corrosion resistance of alloy steel, allowing it to perform well in harsh environments.

Wear Resistance: These plates are highly resistant to wear and abrasion, making them ideal for applications where durability is critical.

Versatility: Alloy steel plates are available in various grades and thicknesses, making them adaptable to different industrial needs.

Heat Resistance: Certain grades of alloy steel can withstand high temperatures, making them suitable for use in heat-intensive industries such as power generation and petrochemical processing.

Applications of Alloy Steel Plates

Alloy steel plates are used across various industries due to their superior properties. Some of the key applications include:

Construction and Infrastructure:

Used in bridges, buildings, and structural frameworks for their high load-bearing capacity.

Automotive Industry:

Utilized in the manufacturing of heavy-duty vehicles, chassis, and components requiring durability and strength.

Oil and Gas Industry:

Ideal for storage tanks, pipelines, and pressure vessels due to their corrosion and heat resistance.

Shipbuilding:

Used in the construction of ship hulls and decks for their resistance to harsh marine environments.

Power Generation:

Employed in turbines, boilers, and other equipment where heat and pressure resistance are essential.

Defense and Aerospace:

Used in armor plating and aircraft components due to their lightweight yet robust properties.

Benefits of Using Alloy Steel Plates

Enhanced Performance: The unique combination of alloying elements provides superior performance in demanding conditions.

Cost-Effectiveness: Despite being more expensive than carbon steel, their long lifespan and low maintenance costs make them a cost-effective choice.

Environmentally Friendly: Alloy steel plates can be recycled, contributing to sustainable practices.

Conclusion

Alloy steel plates are a cornerstone of modern industry, offering unmatched strength, versatility, and durability. Their ability to withstand challenging environments makes them indispensable across sectors such as construction, automotive, oil and gas, and power generation. By understanding their properties and applications, businesses can make informed decisions to leverage their full potential.

For more information

Contact: 8828813630

Email id: [email protected]

Address: Vandan Steel & Engg. co. 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai-400 004.

0 notes

Text

Alloy Steel Sheets & Plates Exporters

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

Specification Schedule of Alloy Steel Sheets & Plates

SpecificationsASTM A387 / ASME SA387Thickness1mm-300mmWidth 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, 4050mm etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm, 15000mm etcSurface2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching Manufacturer and SupplierFinishHot rolled plate (HR), Cold rolled sheet (CR)FormCoils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip Manufacturer and Supplier

Chemical Properties of Alloy Steel Sheets & Plates

GradesCMnPSSICrMoASTM A387 Grade 50.15 max0.3 – 0.60.0350.030.5 max4.00 – 6.000.45 – 0.65ASTM A387 Grade 90.15 max0.30 – 0.60.030.031.0 max8.0 – 10.00.9 – 1.1ASTM A387 Grade 110.05 – 0.170.4 – 0.650.0350.0350.5 – 0.801.0 – 1.50.45 – 0.65ASTM A387 Grade 120.05 – 0.170.4 – 0.650.0350.0350.15 – 0.40.8 – 1.150.45 – 0.6ASTM A387 Grade 220.05 – 0.150.3 – 0.60.0350.0350.5 max2.0 – 2.50.9 – 1.1

Mechanical Properties of Alloy Steel Sheets & Plates

Tensile StrengthYield StrengthElongationin 200mm (%)Elongation in 50mm (%)70-90 ksi, 485-620 MPa45 Ksi, 310 MPa1822

Equivalent Standard of Alloy Steel Sheets & Plates

Material GroupCommon NameTypeUNSForging Spec.Casting Spec. EquivalentDINDIN W. NoApplicationLow ASMoly SteelC-1/2MoK12822A182-F1 cl2A217-WC115M031.5415Up to 470ºC* (875ºF)AS Chrome Moly1.1/4Cr-1/2MoK11572A182-F11 cl2A217-WC613CRM0441.7335Up to 593ºC (1100ºF)2.1/4Cr-1MoK21590A182-F22 cl3A217-WC910CRM09101.7380Up to 593ºC (1100ºF), HP steam5Cr-1/2MoK41545A182-F5/F5aA217-C512CRMO1951.7362High temp refinery service9Cr-1MoK90941A182-F9A217-C12X 12 CrMo 9 11.7386High temp erosive refinery service9Cr-1Mo-VA182-F91A217-C12AX 10 CrMoVNb 9 11.4903High pressure steam

0 notes

Text

Understanding Stainless Steel Coil: A Comprehensive Guide

R H Alloys is a prominent Stainless Steel Coil Manufacturer in India. Stainless steel coils are a cornerstone in the manufacturing and industrial sectors, playing an essential role in a wide range of applications. Their versatility, durability, and resistance to corrosion make them an invaluable material for countless industries. In this blog, we delve into the world of stainless steel coils, exploring their composition, benefits, applications, and significance in modern industry.

What is a Stainless Steel Coil?

Stainless Steel Coil is a long, continuous sheet of stainless steel that is rolled and coiled for easier storage, transportation, and processing. Stainless steel itself is an alloy primarily composed of iron, chromium (at least 10.5%), and other elements such as nickel, molybdenum, and carbon. The chromium content creates a protective oxide layer on the surface, giving stainless steel its renowned corrosion resistance.

Key Properties of Stainless Steel Coils

Stainless Steel Coil Manufacturers are celebrated for their unique combination of properties:

Corrosion Resistance: Thanks to the presence of chromium, stainless steel coils resist rust and corrosion, making them ideal for harsh environments.

Durability: The material’s inherent strength ensures long-lasting performance, even under extreme conditions.

Aesthetic Appeal: Stainless steel offers a polished, modern look that’s widely used in architectural and decorative applications.

Heat Resistance: Certain grades of stainless steel can withstand high temperatures without losing structural integrity.

Versatility: Stainless steel coils are available in various grades, thicknesses, and finishes, catering to diverse industrial and commercial needs.

Types of Stainless Steel Coils

Stainless Steel Coil Suppliers are classified into several types based on their chemical composition and mechanical properties. Some common types include:

Austenitic Stainless Steel (300 Series): High corrosion resistance and excellent weldability make this type ideal for applications in the food, chemical, and medical industries.

Ferritic Stainless Steel (400 Series): Known for its magnetic properties and affordability, this type is often used in automotive and household appliances.

Martensitic Stainless Steel: High strength and moderate corrosion resistance make this type suitable for applications like cutlery and surgical instruments.

Duplex Stainless Steel: A combination of austenitic and ferritic properties offers enhanced strength and corrosion resistance, commonly used in marine and chemical industries.

Cities We Supply Stainless Steel Coils

Stainless Steel Coil Manufacturer in Europe

Stainless Steel Coil Manufacturer in Indonesia

Stainless Steel Coil Manufacturer in Japan

Stainless Steel Coil Manufacturer in USA

Applications of Stainless Steel Coils

Stainless steel coils are indispensable in a wide array of industries. Some notable applications include:

Construction and Architecture: Used in cladding, roofing, and structural components for their strength and aesthetic appeal.

Automotive Industry: Found in exhaust systems, trim, and structural components due to their heat resistance and durability.

Food and Beverage: Stainless steel’s non-reactive nature makes it ideal for processing, packaging, and storing food products.

Medical Equipment: High hygiene standards and resistance to sterilization processes make stainless steel indispensable in medical devices.

Chemical Industry: Used in tanks, pipelines, and reactors for their ability to withstand corrosive chemicals.

Types of Stainless Steel Coils

Stainless Steel 405 Coil: We supply a large variety of grades in the size range of 6mm OD to 610mm OD, with thicknesses up to 30mm.

Stainless Steel 409 Coil: 409 Coils are thoroughly tested to international quality standards using high-grade factor inputs. We supply a large variety of grades in the size range of 6mm OD to 610mm OD.

Stainless Steel 409L Coil: 409L Coils are thoroughly tested to international quality standards using high-grade factor inputs.

Stainless Steel 410 Coil: We manufacture suitable and reliable SS 410 Coil at a reasonable price based on the needs and specifications provided by clients.

Benefits of Using Stainless Steel Coils

Cost-Effective: Though the initial cost may be high, stainless steel’s durability reduces long-term expenses.

Eco-Friendly: Stainless steel is 100% recyclable, contributing to sustainable practices in industries.

Customizability: Available in various grades, finishes, and dimensions to suit specific requirements.

Maintenance and Handling

Proper maintenance ensures the longevity of Stainless Steel Coil Supplier in India. Cleaning with non-abrasive solutions, avoiding prolonged exposure to harsh chemicals, and regular inspections for surface damage are essential practices.

0 notes

Text

Hastelloy C276 Sheets And Plates Exporters in India

When it comes to corrosion resistance and durability, few materials can match the performance of Hastelloy C276 sheets and plates. At Metcore Steel & Alloys, we pride ourselves on offering top-quality products that meet the stringent demands of various industries. In , we will explore what Hastelloy C276 sheets and plates are, their advantages, and their wide range of applications across different sectors.

What is Hastelloy C276 Sheets And Plates?

Hastelloy C276 is a nickel-molybdenum-chromium alloy that includes tungsten, designed to offer exceptional resistance to pitting, stress corrosion cracking, and oxidizing atmospheres. Known for its robustness, Hastelloy C276 sheets and plates are extensively used in environments that require superior performance against corrosive elements. Metcore Steel & Alloys, a trusted name among Hastelloy C276 Sheets and Plates Manufacturers, ensures that these products are fabricated to meet the highest quality standards, making them an ideal choice for critical applications.

Hastelloy C276 sheets and plates are flat-rolled products made from the Hastelloy C276 alloy. These sheets and plates are known for their exceptional resistance to a wide range of severe environments, including chemical processing, petrochemical, and power generation industries. The alloy's unique composition, which includes high levels of nickel, molybdenum, and chromium, along with the addition of tungsten, enhances its resistance to both localized and uniform corrosion. As a result, Hastelloy C276 Sheets and Plates Suppliers like Metcore Steel & Alloys ensure that these products offer unparalleled performance in aggressive settings.

Advantages of Hastelloy C276 Sheets And Plates?

Outstanding Corrosion Resistance: Hastelloy C276 sheets and plates provide superior protection against a variety of corrosive chemicals, including chlorides, sulfur compounds, and organic acids. This makes them suitable for applications where other materials would quickly fail.

High Temperature Stability: These sheets and plates maintain their integrity even at elevated temperatures, making them ideal for high-heat environments such as chemical reactors and power plants.

Resistance to Stress Corrosion Cracking: The alloy's nickel and molybdenum content significantly reduce the risk of stress corrosion cracking, which is a common issue in highly corrosive environments.

Versatility: Available in various sizes and thicknesses, Hastelloy C276 sheets and plates can be customized to suit specific project requirements. This versatility makes them a preferred choice for Hastelloy C276 Sheets and Plates Stockists who cater to diverse industrial needs.

Ease of Fabrication: Despite its toughness, Hastelloy C276 is relatively easy to fabricate using conventional methods. This characteristic allows for efficient manufacturing of complex components without compromising the material's inherent properties.

#metal#heavy metal#metal sheets#pipesupplier#industrial metal#metalcore#metal family#metal sonic#sheets and plates#plates#Hastelloy C276 Sheets And Plates Manufacturers#Hastelloy C276 Sheets And Plates Suppliers#Hastelloy C276 Sheets And Plates Stockists#Hastelloy C276 Sheets And Plates Exporters

0 notes

Text

Why Exotic Steel Alloys Are the Future of High-Performance Industries

Exotic steel alloys have become a cornerstone of innovation in industries that demand superior strength, resilience, and performance. Whether it's the aerospace sector, automotive manufacturing, or energy production, these advanced materials are playing a pivotal role in the ongoing evolution of technology and machinery. In this post, we'll explore why exotic steel alloys are the future of high-performance industries and how they are revolutionizing various sectors.

What Are Exotic Steel Alloys?

Exotic steel alloys are specially engineered materials created by combining steel with other elements like nickel, cobalt, titanium, and chromium. These alloys are designed to have superior properties such as heat resistance, corrosion resistance, and exceptional strength. Unlike standard steel alloys, high-performance steel alloys can withstand extreme conditions like high temperatures, pressure, and chemical exposure, making them ideal for industries that operate in challenging environments.

Why Are Exotic Steel Alloys Essential for High-Performance Industries?

Aerospace Industry In aerospace, the demands on materials are incredibly high. Components must be both lightweight and strong, capable of enduring extreme temperatures and pressures. Steel alloys for aerospace are used in parts like turbine blades, landing gear, and airframes. For example, the heat-resistant steel alloys used in jet engines allow them to operate at high speeds and altitudes without compromising safety or performance.

Case Study: A leading aerospace manufacturer recently switched to exotic steel alloys for their turbine engines, which resulted in a 20% increase in fuel efficiency due to the alloys' superior heat resistance and strength-to-weight ratio.

Automotive Industry The automotive sector is increasingly turning to advanced steel alloys to improve vehicle performance, safety, and fuel efficiency. Exotic alloys are used in critical parts such as engine blocks, exhaust systems, and suspension components. Their ability to resist corrosion, maintain strength at high temperatures, and reduce weight has led to lighter, more fuel-efficient vehicles.

Example: A luxury car manufacturer adopted high-performance steel alloys for their engine components, reducing weight and increasing engine efficiency by 15%, all while maintaining durability and strength.

Energy Production In the energy sector, particularly in power plants and nuclear reactors, exotic steel alloys are crucial for withstanding the extreme conditions created by high temperatures and chemical environments. These alloys are used in turbines, heat exchangers, and reactor components, where durability is key for maintaining operational efficiency and safety.

Case Study: An energy company replaced conventional steel alloys with heat-resistant steel alloys in their turbine blades, which significantly extended the life of the turbines, reducing maintenance costs by 30%.

Marine Industry Corrosion resistance is paramount in the marine industry, where steel components are constantly exposed to harsh saltwater environments. Exotic steel alloys provide the necessary corrosion resistance while maintaining strength, making them ideal for shipbuilding, offshore drilling rigs, and subsea equipment.

Example: A shipbuilding company incorporated high-performance steel alloys in their hulls and equipment, resulting in longer-lasting vessels and reduced maintenance needs.

Benefits of Exotic Steel Alloys

Heat Resistance: Heat-resistant steel alloys can withstand extremely high temperatures without losing their structural integrity, making them essential for high-temperature environments like engines and turbines.

Corrosion Resistance: Exotic alloys are highly resistant to corrosion, ensuring that components last longer, even in harsh environments like seawater or acidic conditions.

Strength-to-Weight Ratio: Many exotic alloys are lighter than traditional steel but just as strong, making them ideal for industries where weight reduction is critical, such as aerospace and automotive.

Durability and Longevity: The superior properties of these alloys mean that parts last longer, which translates to cost savings and less downtime for maintenance.

Frequently Asked Questions (FAQs)

Q: What makes exotic steel alloys different from regular steel alloys? A: Exotic steel alloys are created by adding elements such as nickel, titanium, or chromium to steel, giving them enhanced properties like heat resistance, corrosion resistance, and superior strength compared to regular steel alloys.

Q: In which industries are exotic steel alloys used? A: Exotic steel alloys are primarily used in aerospace, automotive, energy production, and marine industries, where high performance and durability are critical.

Q: Why are heat-resistant steel alloys important in the aerospace industry? A: Heat-resistant steel alloys are essential in aerospace because they allow components like turbine blades to endure the high temperatures experienced during flight without losing their strength or structural integrity.

Q: Are exotic steel alloys more expensive than regular steel alloys? A: Yes, exotic steel alloys tend to be more expensive due to the specialized materials and production processes involved. However, their superior performance often results in long-term cost savings due to reduced maintenance and longer lifespans.

How Accromet Can Help

At Accromet, we specialize in providing high-performance steel alloys for industries that demand the best. Whether you're in aerospace, automotive, energy, or marine, our exotic steel alloys are designed to meet the toughest standards. Contact us today to learn how our advanced steel alloys can help improve the performance and durability of your products.

Call to Action (CTA): Ready to take your industrial applications to the next level? Explore our range of exotic steel alloys and discover how they can enhance the performance and longevity of your products. Contact Accromet for more information or request a quote today!

0 notes

Text

Alloy Steel Chains in Construction: Applications for Heavy-Duty Use

In the world of construction, where strength, reliability, and durability are paramount, alloy steel chains play a vital role. These chains are indispensable tools that enable the lifting, securing, and transportation of heavy loads with precision and safety. As construction projects become more ambitious, demanding larger equipment and greater efficiency, the importance of using high-performance materials like alloy steel chains becomes even more pronounced.

Understanding Alloy Steel Chains

Alloy steel chains are manufactured from high-grade steel that is heat-treated and alloyed with elements such as chromium, molybdenum, and nickel. These elements enhance the chain’s strength, toughness, and resistance to wear and tear. Compared to ordinary steel chains, alloy steel chains exhibit superior mechanical properties, making them ideal for heavy-duty applications in construction.

Key properties of alloy steel chains include:

High Tensile Strength: The ability to withstand heavy loads without deformation or failure.

Resistance to Corrosion: Essential for construction sites exposed to moisture, chemicals, or extreme weather conditions.

Durability: Enhanced wear resistance ensures a longer service life even in demanding environments.

Flexibility: Allows for smooth operation and adaptability to various load configurations.

Applications in Construction

Alloy steel chains are integral to numerous construction activities. Here are some of the most common applications:

1. Lifting and Hoisting Operations

In construction, lifting and hoisting are routine tasks. Cranes, hoists, and other lifting equipment often rely on alloy steel chains to handle massive loads, such as steel beams, concrete blocks, and machinery. These chains are designed to bear extreme tension without snapping, making them a trusted choice for:

Tower Crane Operations: Transporting materials to elevated construction levels.

Mobile Cranes: Handling diverse loads in tight or temporary spaces.

Overhead Hoists: Precision lifting in controlled environments, such as assembling steel frameworks.

2. Load Securing and Tie-Downs

Alloy steel chains are also used for securing loads during transportation. Construction materials often need to be moved from suppliers to job sites, and proper load securement is crucial to prevent accidents or damage. Chains with high tensile strength provide reliable anchoring for:

Flatbed Trailers: Securing heavy machinery or prefabricated components.

Transporting Bulk Materials: Preventing shifts during long hauls.

Container Securing: Ensuring stability during intermodal transport.

3. Rigging Applications

Rigging involves assembling equipment to lift and move objects safely. Alloy steel chains are an essential component in rigging systems due to their strength and reliability. Construction projects frequently employ rigging for:

Erecting Structural Steel: Positioning steel beams and girders.

Installing Precast Concrete: Hoisting and positioning concrete panels or blocks.

Bridge Construction: Supporting and moving heavy segments during assembly.

4. Demolition and Debris Removal

The construction process is not limited to building; it often involves demolition and debris removal. Alloy steel chains are used in heavy-duty equipment like wrecking balls and grapple machines to break down structures and clear rubble. Their ability to withstand extreme forces ensures that they remain functional in such harsh conditions.

5. Anchoring and Stabilization

Temporary structures, scaffolding, and heavy equipment require secure anchoring to maintain stability. Alloy steel chains are employed to anchor large construction machinery, stabilize cranes, or reinforce temporary supports. This use is particularly critical in high-wind or unstable soil conditions.

Advantages of Alloy Steel Chains in Construction

The preference for alloy steel chains in construction stems from their numerous advantages:

Safety and Reliability Safety is a top priority on construction sites. Alloy steel chains are engineered to meet rigorous safety standards, offering peace of mind during critical operations. Their high breaking strength minimizes the risk of catastrophic failure.

Load Capacity Alloy steel chains have a high working load limit (WLL), enabling them to handle exceptionally heavy loads. This capacity is essential for construction projects that involve large-scale materials and equipment.

Resistance to Environmental Factors Construction sites are often exposed to harsh environments. Alloy steel chains’ resistance to corrosion, heat, and abrasion ensures consistent performance, even in challenging conditions.

Versatility These chains are compatible with various attachments, such as hooks, shackles, and slings, allowing them to adapt to multiple tasks and configurations.

Cost-Effectiveness While alloy steel chains may have a higher upfront cost compared to standard chains, their durability and low maintenance requirements make them a cost-effective choice in the long run.

Selecting the Right Alloy Steel Chain

Choosing the appropriate alloy steel chain for a specific application is crucial to ensuring safety and efficiency. Key factors to consider include:

Grade and Strength Alloy steel chains are classified by grade, with higher grades indicating greater strength. Common grades include:

Grade 80: Suitable for lifting and rigging applications.

Grade 100: Offers 25% higher strength than Grade 80, ideal for demanding tasks.

Grade 120: The strongest option, used for the heaviest loads.

Chain Size The diameter of the chain links determines their load capacity. Larger links can handle heavier loads but may be less flexible.

Coating and Finish To enhance resistance to corrosion, chains are often coated with protective finishes such as zinc plating or powder coating.

Compatibility with Equipment Ensure the chain is compatible with the lifting or securing equipment being used, including hooks, slings, and tie-down devices.

Compliance with Standards Always select chains that meet industry standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the International Organization for Standardization (ISO).

Maintenance and Inspection

Proper maintenance and regular inspection are essential to maximize the lifespan and safety of alloy steel chains. Best practices include:

Routine Inspections Check for signs of wear, corrosion, cracks, or deformation. Replace chains that show significant damage or fail to meet safety criteria.

Cleaning Remove dirt, grease, and debris that can cause premature wear. Use appropriate cleaning agents that do not degrade the chain material.

Lubrication Apply suitable lubricants to minimize friction and prevent rust.

Storage Store chains in a dry, clean environment to protect them from moisture and contaminants.

Training Ensure that all personnel handling alloy steel chains are properly trained in their use and maintenance.

Alloy steel chains are indispensable in the construction industry, providing unmatched strength, reliability, and versatility for heavy-duty applications. From lifting and securing loads to stabilizing structures and enabling demolition, these chains play a crucial role in ensuring the success and safety of construction projects. By selecting the right chain, adhering to maintenance best practices, and staying informed about industry advancements, construction professionals can harness the full potential of alloy steel chains to meet the demands of modern construction.

0 notes