#multi core electric cables manufacturers

Explore tagged Tumblr posts

Text

#Best Electrical Wires Manufacturers#Multi Core Electric Cables Manufacturers#Best Electrical Wires Suppliers#Multi Core Electric Cables Suppliers#Best Electrical Wires Exporters#Multi Core Electric Cables Exporters#Best Electrical Wires#Multi Core Electric Cables

0 notes

Text

The Best Electric Wire Companies in India for High-Quality Products

it can be difficult to know which manufacturers to trust. In this Blog, we will look at the Top 10 wire company in India and highlight the best electric wire companies in India for high-quality products.

#multi cores cable#aluminium cable#aluminium wires#submersible cable#submersible wire#submersible pump wire#wires and cable manufacturers#2.5 mm wires#best wire for house wiring#pvc wire#4mm wire price#best wires in india#top 10 wire company in india#best wire company in india#cable manufacturers#best electric wire company in india#copper wire manufacturers#best wire for wiring

0 notes

Text

Best Copper Submersible Cables Manufacturers

Copper Submersible Cables Manufacturers: A Reference to Flexon Cable

Copper submersible cables manufacturers are designed specifically for use in water pumps, deep wells, and other submerged applications. These cables are crucial in the operation of various systems, particularly in industries such as agriculture, mining, and water treatment. Copper, as the material of choice for these cables, offers excellent conductivity, durability, and resistance to corrosion—attributes that are essential for submersible operations in harsh underwater conditions.

Key Characteristics of Copper Submersible Cables

High Electrical Conductivity: Copper is known for its superior ability to conduct electricity, which ensures that submersible pumps operate efficiently, minimizing energy losses and enhancing performance.

Corrosion Resistance: Submersible cables are exposed to water for prolonged periods, and the ability of copper to resist corrosion makes it an ideal material. This longevity is critical to reducing maintenance costs and ensuring the continued operation of the system.

Durability Under Pressure: Submersible cables need to endure high-pressure environments when used deep underwater. Copper cables are known for their mechanical strength, allowing them to withstand such conditions without significant degradation.

Flexibility and Workability: Copper cables offer superior flexibility, which is crucial for installation, especially in tight spaces or complex systems. Flexible cables are easier to maneuver during the installation process, which reduces labor costs and installation time.

Flexon Cable: A Leading Manufacturer of Copper Submersible Cables

Flexon Cable is one of the renowned manufacturers specializing in the production of copper submersible cables. Known for its commitment to quality and innovation, Flexon has established itself as a trusted name in the industry. The company focuses on designing cables that meet the highest standards in terms of safety, efficiency, and performance.

Product Range Offered by Flexon Cable

Flexon Cable manufactures a wide range of copper submersible cables that cater to various applications and industries. These cables are specifically designed to meet the demanding requirements of water pumping systems. Some of the key products offered by Flexon include:

Submersible Pump Cables: Designed for deep-well applications, these cables are built to perform in extreme conditions and under heavy load.

Flexible Copper Cables: These cables offer the perfect balance of flexibility and durability, making them ideal for installations in tight spaces or dynamic environments.

Multi-Core Submersible Cables: These cables are equipped with multiple copper cores to support various electrical systems and are designed for safe underwater usage.

PVC Insulated Cables: Flexon offers cables with high-quality PVC insulation to prevent short-circuiting and damage from external factors like water, chemicals, and temperature variations.

Technological Advancements

Flexon Cable integrates modern manufacturing technologies to produce cables with superior insulation and protection. Their cables are designed to resist both electrical and mechanical stress, ensuring long-lasting performance in submerged applications. Additionally, Flexon invests in research and development to continuously improve the efficiency of their products.

Manufacturing Process at Flexon Cable

Copper Conductor Production: Flexon starts by sourcing high-quality copper wire, which is drawn and twisted to form the conductors. This step is critical as the purity and quality of the copper directly impact the electrical performance of the cable.

Insulation and Sheathing: The copper conductors are insulated with layers of high-quality PVC or other materials, depending on the specific requirements. This insulation serves to protect the conductors from water damage, physical wear, and electrical hazards.

Sheath Formation: After insulation, a protective outer sheath is applied to provide further resistance against external physical and environmental stresses. This step enhances the cable's ability to withstand exposure to chemicals, heat, and mechanical wear.

Testing and Quality Control: Flexon Cable ensures that all products undergo rigorous testing. This includes electrical tests for conductivity and resistance, as well as physical tests to verify the strength of the insulation and the integrity of the sheath.

Applications of Copper Submersible Cables

Water Supply and Irrigation: Copper submersible cables are essential for powering pumps in wells, boreholes, and other water supply systems. They ensure consistent and reliable water delivery for agricultural, municipal, and industrial use.

Mining: Copper submersible cables are used to power pumps in mining operations, where they are often submerged in deep water sources to extract materials.

Aquaculture and Fisheries: Copper cables are commonly employed in aquaculture to supply oxygen and nutrients to fish farms, ensuring proper environmental control.

Industrial and Commercial Applications: Copper submersible cables are also used in large-scale industrial processes, such as wastewater treatment plants, where they help in the operation of pumps and other submerged machinery.

Why Choose Flexon Cable for Copper Submersible Cables?

Reliable Performance: Flexon Cable’s products are known for their high reliability, ensuring that your water pumping systems run efficiently for long periods without breakdowns.

Expertise and Experience: With years of experience in the manufacturing of submersible cables, Flexon brings unmatched expertise to the table, helping customers with tailored solutions that meet their specific requirements.

Quality Assurance: Flexon adheres to stringent quality control processes, ensuring that all their products meet the highest standards of safety and performance.

Customization Options: Flexon Cable offers customized solutions to suit particular client needs, whether that be cable length, insulation materials, or specific environmental conditions.

Conclusion

Copper submersible cables are an essential component for various submerged applications, offering long-lasting performance, flexibility, and superior conductivity. Flexon Cable has established itself as a leading manufacturer of high-quality copper submersible cables, offering innovative solutions that cater to diverse industries. Whether you're in agriculture, mining, or water treatment, Flexon provides reliable and durable cables to ensure optimal performance in even the most challenging environments.

By investing in copper submersible cables from reputable manufacturers like Flexon Cable, industries can ensure efficient, safe, and long-term operation of their pumping and submerged systems.

Visit:-https://www.flexoncable.com/copper-submersible-cables.html

0 notes

Text

The Manufacturing Process of Electrical Wires and Cables: From Concept to Delivery

In today’s electrified world, wires and cables are the invisible lifelines that keep homes, businesses, and industries connected. From powering your household appliances to ensuring seamless industrial operations, wires and cables are integral to modern living. But have you ever wondered how these essential components are made?

The journey of a wire or cable begins as a concept on the drawing board and ends as a finished product delivered to the end user. Understanding this intricate process not only highlights the expertise of an Electrical Wires & Cables Manufacturer Supplier but also underscores the precision and care involved at every stage.

Step 1: Concept and Design

Every wire or cable begins with a purpose. The design stage is where manufacturers define specifications based on the intended application. Engineers and designers collaborate to determine key attributes such as:

Conductor Material: Usually copper or aluminum for their excellent conductivity.

Insulation Requirements: Depends on voltage levels, operating environment, and safety standards.

Outer Sheathing: Protects the cable from external wear and environmental damage.

For example, industrial cables require heavy-duty insulation, while household wires prioritize flexibility and durability.

Step 2: Raw Material Selection

The quality of raw materials plays a critical role in ensuring the performance of electrical wires and cables. Trusted manufacturers source high-grade materials to meet stringent industry standards. The main components include:

Copper or Aluminum Rods: These are the backbone of electrical conductors.

Insulation Materials: PVC, XLPE, or rubber are commonly used to provide electrical and thermal resistance.

Protective Coatings: Materials like polyethylene or nylon offer additional durability.

As a leading Electrical Product Company, Asio Electricals ensures that only premium-grade materials are used in the manufacturing process to guarantee reliable performance and longevity.

Step 3: Drawing

The first physical step in manufacturing is drawing, where copper or aluminum rods are stretched into thin wires. This process involves:

Wire Drawing Machines: Reduce the diameter of the rods to the desired thickness using a series of dies.

Lubrication: Ensures smooth passage of the wire through the dies and minimizes heat generation.

Annealing: The drawn wires are heated to restore ductility and improve conductivity.

The result is fine, uniform wires that are ready for further processing.

Step 4: Stranding

For cables requiring multiple conductors, individual wires are stranded together to enhance flexibility and conductivity. Stranding involves twisting several thin wires to form a single, cohesive conductor.

Tightly Stranded Wires: Offer better conductivity and strength for high-performance applications.

Loosely Stranded Wires: Are more flexible, suitable for household and portable uses.

This stage is crucial for manufacturing multi-core cables, often used in complex electrical systems.

Step 5: Insulation

Insulation is applied to the stranded wires to prevent electrical leakage and ensure safety. This process involves coating the wires with materials such as PVC, rubber, or polyethylene.

Extrusion Process: Heated insulation material is applied uniformly over the conductor.

Testing: Insulated wires are rigorously tested for resistance, voltage endurance, and thermal properties.

High-quality insulation is vital for withstanding voltage fluctuations and environmental factors, such as moisture or heat.

Step 6: Cabling

In this stage, multiple insulated wires are bundled together to form a cable. The cables are twisted or aligned in specific patterns to ensure:

Uniform transmission of electrical signals.

Enhanced mechanical strength.

Reduced electromagnetic interference (EMI).

A protective sheath is then applied to the bundled wires, further enhancing durability and safety.

Step 7: Armoring (Optional)

For heavy-duty cables used in industrial and outdoor applications, an additional layer of armoring is added. This involves wrapping the cable with metal strips or wires to provide extra protection against mechanical stress and environmental hazards.

Armored cables are commonly used in underground installations and high-risk environments.

Step 8: Quality Testing

Before reaching the market, every batch of wires and cables undergoes stringent quality checks. Renowned Electrical Wires & Cables Manufacturer Suppliers like Asio Electricals follow a rigorous testing protocol, including:

Conductor Resistance Testing: Ensures optimal conductivity.

Voltage Testing: Checks the insulation's ability to handle specified voltage levels.

Flame Retardant Testing: Verifies fire resistance properties.

Durability Testing: Assesses the cable’s ability to withstand mechanical and environmental stresses.

These tests guarantee that the product meets national and international safety and performance standards.

Step 9: Packaging

Packaging plays a significant role in preserving the quality of wires and cables during transportation and storage. The cables are wound onto reels or spools, labeled with specifications, and wrapped to protect them from moisture and physical damage.

For larger shipments, protective pallets or drums are used to ensure safe delivery.

Step 10: Distribution and Delivery

The final step in the process is distributing the finished product to end users. Whether it’s a residential project, commercial building, or industrial plant, a reliable supply chain ensures timely delivery.

As a trusted Electrical Product Company, Asio Electricals has an extensive distribution network, ensuring their products reach clients efficiently and in perfect condition.

The Asio Electricals Advantage

When choosing an Electrical Wires & Cables Manufacturer Supplier, quality, innovation, and reliability are paramount. Here’s why Asio Electricals stands out:

State-of-the-Art Manufacturing: Equipped with advanced technology to produce premium-quality products.

Commitment to Standards: Compliance with global safety and performance benchmarks.

Tailored Solutions: Customizable cables to meet unique project requirements.

Sustainability: Eco-friendly manufacturing practices to minimize environmental impact.

Exceptional Support: A dedicated team to guide clients from selection to installation.

Conclusion

The manufacturing process of electrical wires and cables is a meticulous journey, combining engineering expertise with cutting-edge technology. From the selection of raw materials to the final delivery, every step is designed to ensure quality, safety, and performance.

For those seeking top-tier products, Asio Electricals is the name to trust. With their unwavering commitment to excellence, they continue to power homes, industries, and dreams across the globe.

Also Read:

Best Electrical Product Company in India: Why Asio Electricals Stands Out

The Basics of Conduit Pipe Fittings: Types and Applications

Originally published at https://asioworld.blogspot.com

#asio#asio world#asio electricals#Electrical Wires & Cables Manufacturer Supplier#Electrical Product Company

0 notes

Text

PVC Flexible Cable Supplier: Ensuring Reliable Electrical Solutions

When it comes to high-quality PVC flexible cables, a reliable PVC flexible cable supplier plays a vital role in meeting diverse industrial and residential needs. PVC flexible cables are essential for applications requiring flexibility and durability in challenging environments, such as construction sites, manufacturing units, and home installations. Withstanding wear, moisture, and varying temperatures, these cables are designed to last, ensuring safety and consistency. A dependable PVC flexible cable supplier understands the importance of high-grade PVC insulation, providing a protective layer against environmental stresses. This insulation not only enhances safety by preventing short circuits and fire hazards but also ensures the cable’s longevity, making it ideal for high-demand applications. From flexible single-core cables for compact installations to multi-core options for complex wiring, a PVC flexible cable supplier offers customized solutions that align with both specific technical requirements and industry standards, contributing to efficiency and safety in various projects.

High-Quality Standards from a PVC Flexible Cable Supplier

A reliable PVC flexible cable supplier ensures each product adheres to high-quality standards, delivering durable and safe solutions. These suppliers follow strict manufacturing protocols, incorporating high-grade PVC that can withstand various environmental pressures, including heat, moisture, and physical wear. Choosing the right PVC flexible cable supplier guarantees that your cabling meets both safety and performance requirements.

Why Choosing a PVC Flexible Cable Supplier Matters for Industrial Projects?

Industrial projects require durable and versatile wiring solutions. A PVC flexible cable supplier provides cables that are essential for industrial machinery, offering enhanced flexibility and resistance to abrasion and heat. Partnering with a dedicated PVC flexible cable supplier ensures smooth operations and minimizes maintenance costs, optimizing project longevity and reliability.

Key Advantages of Partnering with a PVC Flexible Cable Supplier

Working with a trusted PVC flexible cable supplier comes with advantages like access to diverse cable types, customization, and dedicated customer service. These suppliers understand the unique needs of various industries, offering cables that meet precise electrical and physical demands. This support ensures safe and efficient installations across different applications.

The Role of a PVC Flexible Cable Supplier in the Construction Industry

Construction projects demand flexible and resilient cables that perform well under rigorous conditions. A PVC flexible cable supplier offers cables that are perfect for construction, ensuring flexibility and safety in installation. These cables handle frequent movement, rough handling, and exposure to environmental elements, making them an excellent choice for construction needs.

Safety and Durability: Benefits of PVC Cables from a PVC Flexible Cable Supplier

Safety is paramount in any electrical installation, and a PVC flexible cable supplier prioritizes both safety and durability. These cables are insulated with high-quality PVC that minimizes risks such as short circuits and fire hazards. Selecting a reliable PVC flexible cable supplier helps ensure that all cables installed will last while maintaining a secure environment.

Understanding the Versatility of PVC Cables from a PVC Flexible Cable Supplier

PVC flexible cables are designed for various applications, from residential setups to complex industrial wiring. A dedicated PVC flexible cable supplier provides cables that can adapt to different needs, with options for single-core and multi-core variants. This versatility makes them a reliable choice across various sectors, all provided by your trusted PVC flexible cable supplier.

What Sets a Top PVC Flexible Cable Supplier Apart?

Quality, consistency, and reliable delivery set the best PVC flexible cable supplier apart. Leading suppliers invest in top-tier manufacturing practices and adhere to international standards, ensuring all products meet or exceed performance expectations. Partnering with such a supplier guarantees access to high-performance cables that stand up to rigorous use.

Conclusion

In any industry that relies on dependable electrical systems, choosing a trusted PVC flexible cable supplier is essential. From construction and residential wiring to large-scale industrial projects, a reliable supplier provides high-quality cables designed to withstand challenging conditions while ensuring safety and durability. With a range of customized solutions, a quality PVC flexible cable supplier guarantees that each cable meets specific project requirements, contributing to efficiency and cost-effectiveness. By partnering with a reputable PVC flexible cable supplier, businesses and contractors benefit from reliable support and high-performance products that enhance the lifespan and safety of their installations.

0 notes

Text

DICABS’ Advanced Cable Solutions for the Power Industry

DICABS stands as one of India’s largest and most integrated manufacturers of power transmission equipment, as well as a leading provider of turnkey services. Our state-of-the-art manufacturing facilities, combined with a team of highly skilled professionals and a track record of pioneering new technologies, have positioned us as a leader in the power transmission and distribution (T&D) sector.

We play a pivotal role in powering India's growth, offering comprehensive solutions across the entire power transmission and distribution value chain. Our extensive product portfolio covers 80% of the infrastructure needs in the T&D industry. With groundbreaking innovations, we have significantly expanded our range of products and services, continuously pushing the boundaries of excellence.

Our in-house manufacturing capabilities span cables, conductors, and transmission towers, offering tailored solutions for various applications:

Cables

LV Cables - Manufactured in our advanced facility for voltage grades up to 1.1 kV, meeting both Indian and international standards.

HV Cables - Produced in our sophisticated plant for voltage grades up to 33 kV, in compliance with Indian and global standards.

EHV Cables - Our EHV cables, ranging from 66 kV to 400 kV, are crafted in one of the most modern manufacturing facilities, adhering to Indian and international regulations.

Control Cables - We provide a diverse range of control cables designed for precise power transmission and regulation. These are essential in industrial machinery, HVAC systems and other control applications, ensuring smooth operations across components.

Solar Cables - Specifically engineered for photovoltaic (PV) systems, our solar cables ensure reliable power transmission under harsh outdoor conditions for both residential and industrial solar installations.

Fire Survival/ Resistant Cables - In fire emergencies, the use of fire-resistant and non-halogenated cables is critical in minimising risks posed by smoke, heat and toxic fumes, ensuring safer evacuation processes.

Communication Cables - Our communication cables enable seamless data transmission across platforms. We offer high-performance solutions including CCTV cables, Telephone cables, CAT 6 UTP cables and Coaxial cables.

Marine and Offshore Cables - We specialise in high-performance marine and offshore cables, designed for durability and performance in demanding environments through continuous technological advancements.

Single and Multi-Core Cables - Our Single & Multi-Core Flexible Copper Cables are widely used in low-voltage applications such as motors, control panels, DC transformers, battery cables, and electrical appliances.

Instrumentation Cables - Designed to meet the stringent demands of industries like power generation, chemical production, and engineering, our instrumentation cables support accurate measurement, monitoring, and control of industrial processes.

DICABS is one of the leading transmission line cable manufacturers and continues to set new benchmarks in quality and innovation. To explore our full range of products and services, visit our website https://dicabs.com/

#Transmission tower manufacturers#Transmission Line Cables Manufacturer#Energy transmission tower manufacturers

0 notes

Text

Cable/Wire Harness Assembly

In today’s technologically advanced world, the demand for reliable and efficient cable assemblies and wire harnesses spans across numerous industries. From automotive to aerospace, consumer electronics to industrial machinery, these components are vital for the functionality and reliability of countless devices and systems. At inYantra, we specialize in providing top-tier cable and wire harness assembly services that meet the specific needs of our customers across a wide range of industries.

Our Commitment to Excellence

At inYantra, we adhere to the highest standards of quality and workmanship. Our cable and wire harness assemblies are manufactured following the IPC/WHMA-A-620 workmanship standards, ensuring that every product we deliver is built to perform reliably under various conditions. We understand that every application has unique requirements, and our facility is equipped to manufacture both power and signal cable assemblies to your exact specifications.

Comprehensive Cable & Wire Harness Assembly Services

Our cable and wire harness assembly services are designed to cater to diverse industry needs. We offer a wide range of services that ensure precision, quality, and reliability in every assembly we produce.

Single Core Wires and Multi-Core Cables

Whether your project requires single core wires or complex multi-core cables, we have the expertise and capabilities to meet your needs. Our team is skilled in handling a variety of materials and configurations, ensuring that each assembly is tailored to your exact specifications.

Automated Wire Processing

We utilize advanced automated wire processing technologies, including cut, strip, crimp, and tinning processes. This automation ensures consistent quality and precision across all assemblies, reducing the potential for errors and enhancing overall efficiency.

Crimp Force Monitoring

As part of our commitment to quality, we incorporate crimp force monitoring as a standard practice in our assembly processes. This ensures that all crimps are secure and meet the required standards, providing reliable electrical connections in every product.

100% Electrical Testing

Quality assurance is paramount at inYantra. That’s why we perform 100% electrical testing on all our cable and wire harness assemblies. This rigorous testing process ensures that every assembly meets the required electrical performance standards before it leaves our facility.

IPC/WHMA-A-620 Standards

We adhere strictly to the IPC/WHMA-A-620 standards, which are the industry benchmarks for cable and wire harness assemblies. These standards cover all aspects of assembly, from materials to workmanship, ensuring that our products are of the highest quality.

Design for Manufacturability (DFM) Assistance

Our team provides Design for Manufacturability (DFM) assistance, helping you optimize your designs for production. This ensures that your cable and wire harness assemblies are not only functional but also cost-effective and efficient to produce.

Global Sourcing and Vertical Integration

We offer global sourcing for Approved Vendor List (AVL) and alternative components, giving you access to high-quality materials from trusted suppliers worldwide. Additionally, our vertical integration opportunities allow you to leverage our group manufacturing capabilities in raw cable production, further enhancing the efficiency and cost-effectiveness of your projects.

Industries We Serve

Our cable and wire harness assemblies are used in a variety of end-use applications across multiple industries. Whether you’re in the automotive, aerospace, telecommunications, medical, or industrial sector, inYantra has the expertise to deliver the solutions you need.

Conclusion

At inYantra, we take pride in delivering high-quality cable and wire harness assemblies that meet the stringent requirements of our diverse customer base. Our commitment to following industry standards, combined with our advanced manufacturing capabilities and global sourcing strategies, ensures that we can provide reliable, cost-effective solutions for your cable and wire harness needs. Trust inYantra to be your partner in delivering excellence in every assembly.

1 note

·

View note

Text

Global Optics Fiber Market Outlook and Forecast till 2023-2030.

Global Optics Fiber Market Size, Trends, and Growth Opportunity, By Type (Optic Cable – Multi Mode, Optic Cable - Single Mode, Optic Cable - Plastic Optical Fiber), By Application ( IT & Telecom, BFSI, Defense & Aerospace, Manufacturing), By Region and forecast till 2030.

The Global Optics Fiber Market was valued at USD 8,760.8 million in 2022 and is slated to reach USD 14933.8 million by 2030 at a CAGR of 6.89% from 2023-2030.

A fiber-optical string, also known as an optic-fiber string, is an assembly analogous to an electrical string but containing one or further optic filaments that are used to carry light. The optic fiber rudiments are generally collectively carpeted with plastic layers and contained in a defensive tube suitable for the terrain. Different types of strings are used for different operations. Ultramodern fiber lines can contain up to a thousand fiber beaches in a single string although the loftiest beachfront- count single-mode fiber string generally manufactured is the 864-count, conforming to 36 lists each containing 24 strands of fiber. It's especially useful in situations where it's desirable not to have a metallic captain as in the case of use near MRI machines, which produce strong glamorous fields. Optical filaments can be used as detectors to measure strain, temperature, pressure, and other amounts by modifying a fiber so that the property being measured modulates the intensity, phase, polarization, wavelength, or conveyance time of light in the fiber.

Request Sample Link:

https://qualiketresearch.com/request-sample/Optics-Fiber-Market/request-sample

Market Drivers: The rising adoption of fiber optic is major driving the growth of the fiber cable market. Bandwidth communication and growth in the healthcare sector have a positive impact on the market. Telecommunication infrastructure also accelerates growth, the government is a useful asset that is helping in investing in research for upgrading and also further drives market growth.

Key players:

Some of the major players in the Global Optics Fiber Market request include Dron Edge, Aksh Optifibre Limited, Illumination Systems Pvt Ltd, M- Core, Finolex cables Ltd., Vindhya Telelinks Ltd, Next Generation Technologies, Aares Telecom (p) Ltd, Yangtze Optical Fibre and Cable JSC Ltd, Belden Inc.

Get More Information Link:

https://qualiketresearch.com/reports-details/Optics-Fiber-Market

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Text

Industrial Wire & Cable Manufacturers

Modern-day industries have customized needs for wires and cables to meet their specific work demands. The industrial needs of wires and cables vary considerably from domestic needs. Paraflex is set to provide customers with advanced and multi-functional industrial cables and wires. Let us have a look at the various types of Industrial cables and their uses:

Housing Wires: It is widely used in the construction and interior decor industry. As the name suggests, these wines are used in domestic spaces such as residences or corporate offices.

Industrial Wire Upto 400sq mm: These wires are ideal for use with any gadgets or equipment. They have flexible cords with a copper center.

Multicore Round Cables up to 91 core: Used in heavy equipment such as cooling units and motors. They are ideally used for running various heavy machinery in industries.

Three/ Four Core Flat Cables: PVC insulated cables and wires are mostly used for pump connections. The covering s a sheath to protect the inner core from external physical aberrations.

Aluminum Cables up to 50 sq mm core: They have a greater cross-section area and pass higher current than copper wires, but the advantage is that they are lighter than copper wires.

Co-Axial Cables: They are used to transmit radio frequency signals. They are greatly used for computer networking.

CCTV Cables: Various cables are used to aid CCTV surveillance, such as RCA Plug, Play cable, and CAT5 Cable. They can directly transmit signals to observe the CCTV video in your NVR and DVR.

Speaker Cables: As the name suggests, they connect speakers with amplifiers. The event management industries need this type of cable most of the time.

Camera Wires: Security camera cables like Ethernet and Siamese are used for security purposes.

Paraflex – One Stop Destination for Industrial Cables

Paraflex is the trusted Industrial Wire & Cable Manufacturers. Paraflex uses only the best raw materials to produce premium quality wires. All the industrial cables from our brand are capable of qualifying the standard benchmark for industrial requirements. The best industrial wires and cables from Paraflex can bear high loads, are fire resistant, and are all set to serve the latest and modern equipment and gadgets. We assure you of safe electricity conduction through our marvelous and wide range of industrial cables and wires. Get the best industrial cables and wires at affordable rates from Paraflex – the leading manufacturer and supplier of a wide range of industrial cables and wires.

0 notes

Text

Submarine Cable System Market Top Key Players, and Forecast by 2030

The latest “ Submarine Cable System Market Forecast | Share and Size - 2030” report by The Insight Partners offers a detailed analysis of prime factors that impact the market growth such as key market players, current market developments, and pivotal trends. The report includes an in-depth study of key determinants of the global market including drivers, challenges, restraints, and upcoming opportunities.

This market report is ideal for businesses opting to enter or excel in the Submarine Cable System market. This strategic market forecast not only makes businesses aware of present market scenarios but also presents future market forecasts. These insights profoundly cover Submarine Cable System market size, share, growth, and projected revenue in the forecast duration.

The Submarine Cable System market report encompasses driving factors of the market coupled with prime obstacles and restraining factors that hamper the Submarine Cable System market growth. The report helps existing manufacturers and entry-level companies devise strategies to battle challenges and leverage lucrative opportunities to gain a foothold in the global market.

How is the Submarine Cable System Market Report Beneficial for Your Business?

Figure out the Submarine Cable System market dynamics altogether | 2030

Inspect and scrutinize the competitive scenario and the future Submarine Cable System market landscape with the help of different strictures including Porter's five forces.

Understand the impact of different government regulations throughout the global Submarine Cable System market and evaluate the market condition in the tough time.

Consider the portfolios of the protruding players functional in the market in consort with the thorough study of their products/services.

Have a compact idea of the highest revenue-generating segment with the help of a thorough Submarine Cable System market analysis by our seasoned research experts.

A cost-effective way to gain valuable insights into the Submarine Cable System market without the need to host an independent team of researchers at their own cost.

Submarine Cable System Market diagrams, pie charts, regional market share maps, inventory network examination, and import/trade subtleties help you pitch investors.

The Submarine Cable System market report offers an in-depth analysis of the various prime market players that are active in the market. Moreover, it provides their thorough financial analysis, business strategies, SWOT profile, business overview, and recently launched products & services. In addition, the report offers recent market developments such as market expansion, mergers & acquisitions, and partnerships & collaborations. The prime market players observed in the report are Companies Fujitsu Limited, Hawaiki Cable Limited, HMN Technologies, Mitsubishi Electric Corporation, NEC Corporation, Nexans Sa, Nokia Corporation, Prysmian Group, Subcom, Llc, Sumitomo Electric Industries, Ltd.On the Basis of Services this market is categorized further into-

Installation Services and Maintenance and Upgrade

On the Basis of Cable Capacity this market is categorized further into-

Less than 10 Tb/s

10?20 Tb/s

20?30 Tb/s

and More than 30 Tb/s

On the Basis of Application this market is categorized further into-

Communication and Energy & Power

On the Basis of Type this market is categorized further into-

Single-core and Multi-core

The report offers an in-depth study of every segment, which helps market players and stakeholders understand the fastest-growing segments with maximum Submarine Cable System market share and highest-grossing segments in the market.

The Submarine Cable System market is analyzed across the globe and highlights several factors that affect the performance of the market across the key regions –

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of Latin America)

The Middle East and Africa (Turkey, GCC, Rest of the Middle East and Africa)

Rest of the World

The Submarine Cable System market research offers revenue forecasts for every year coupled with sales growth of the market. The forecasts are provided by skilled analysts and after an in-depth analysis of the Submarine Cable System market trends. These forecasts are essential for gaining investment insights into the prospects of any industry.About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

#Submarine Cable System Market#Submarine Cable System Market Size#Submarine Cable System Market Share

0 notes

Text

#Electrical Wires Manufacturers in Delhi#Electrical House Wires Manufacturers in Delhi#FR Wire Suppliers in India#multi core electric cables manufacturers#cctv wire manufacturers#electrical house wires manufacturers#electrical house wires manufacturers in delhi#best electrical wires#electric cables manufacturers

0 notes

Text

The Best Cable Manufacturers for Superior Quality

Baid Wires is one of the most renowned and trusted names in the Indian electrical industry. They offer a wide range ofwires and cables that are designed to meet the highest standards of quality, safety, and performance. Their products are known for their durability, efficiency, and longevity. read more

#multi cores cable#aluminium cable#aluminium wires#submersible cable#submersible wire#submersible pump wire#wires and cable manufacturers#2.5 mm wires#best wire for house wiring#pvc wire#4mm wire price#best wires in india#top 10 wire company in india#best wire company in india#cable manufacturers#best electric wire company in india#copper wire manufacturers#best wire for wiring

0 notes

Text

Reflectometers for metal cables: noise filtering, propagation coefficient, and its determination methods

Let's see how the cables measure influence the range of the reflectometer. How do the noise filtering mode and methods for determining the unknown propagation coefficient affect the measurement accuracy?

KEY FACTORS FOR CABLES

The reflectometer's detection range depends on the cross-section of the cable cores, the overall quality of the cable, as well as on the way the reflectometer is connected to the cable being tested. The larger the cross-section of the cable cores, the less attenuation the electrical pulse supplied by the reflectometer to this cable undergoes and the longer the distance it covers. Old or defective cables may have reduced insulation resistance or increased attenuation. This significantly reduces the ability of the cable cores to conduct electrical signals and, as a result, reduces the maximum distance. The connection of the reflectometer to the cable must be done so that a pulse with the maximum possible amount of energy is emitted from the reflectometer to the cable.

NOISE FILTERING

I want to eliminate the noise in more detail, as it is on any cable. Many reflectometers have a digital noise filtering mode that obliterates the noise from 50 Hz to 1 GHz. This mode is designed primarily for lineworkers dealing with cables near sources of strong electromagnetic interference (for example, railway contact networks, power lines, or antenna poles). The operator can select a filter type with the required characteristics for each test to ensure the acceptable quality of the resulting reflectogram. Suppose an unexpected random voltage value appears in the line during the measurement. In that case, the noise-filtering mode gets turned on automatically. A multi-level and multifunctional filtering system allows one to check antennas and cellular nodes with some received signal interference.

In some cases, the noise-filtering subsystem may slow down the OTDR operation to such an extent that the display becomes unusable. A good example is filtering the noise the power supply induces (60 Hz). One period of alternating current with a frequency of 60 Hz is 16.7 ms. Therefore, it also takes 16.7 ms to generate one point on the reflectometer display. It will take no less than 5.12 seconds to refresh all the 256 image pixels on the display. One way to compensate for this delay is to store the denoised reflectogram. Writing data to the device memory will take some time, but subsequent operations will be as fast as if the filter were turned off. The "averaging" mode, often provided by the manufacturer to eliminate interference at maximum gain, is no exception. This mode also decreases the refresh rate of the display. Four times less noise means the screen is refreshed sixteen times slower. When the image refresh speed is reduced significantly, it becomes difficult to work with the display, so this mode should be used only when necessary. One more thing to mention: cables for digital data transmission should be tested using short pulses with a duration of 2, 10, or, in extreme cases, 100 ns. They do not affect nearby pairs under load, so the data transmission devices' error detection system will not flag them as such.

PROPAGATION COEFFICIENT AND METHODS FOR ITS DETERMINATION

As already mentioned, the reflectometer determines the distance to the abnormal spot based on the signal propagation speed in the cable and the time it takes to reach the point in question and return. In most cases, speed is expressed as a unitless coefficient, the ratio of the signal propagation speed in a given cable to the speed of light. It is an empirically determined value. Reflectometers from different manufacturers require one to set the wave propagation speed, called the Velocity of Propagation (VOP) or Velocity Factor (VF). Typically, this parameter is expressed as a fraction of the speed of light and can have a value from 0.3 to 1. A cable with a VOP value of 0.66 allows an electrical signal to be transmitted at 66% of the speed of light. Some manufacturers express this parameter in terms of actual speed, and then it can range from 45 to 150 m/ms. The choice of the VOP (VF) parameter significantly impacts the accuracy of any measurement made. Therefore, to obtain the most correct results possible, it is necessary to learn the methods for determining the propagation factor for each specific cable.

VOP DETERMINATION METHODS UNDER DIFFERENT CONDITIONS

Suppose the pulse propagation coefficient for the cable is unknown. In that case, an experiment can either calculate or determine it.

1. The insulating material's dielectric constant (ε) is a known value.

VOP=1/√(ε),

where ε is the relative dielectric constant for a given cable. For example, for polyethylene, ε = 2.25. Therefore, VOP = 1/√2.25 = 0.667.

2. For the first experiment, one needs a short cable of the same type as the tested cable. Connect the reflectometer to the cable section and adjust it so that the pulse reflected from the end of the section is clearly visible on the display. Move the cursor to the beginning of the pulse and start changing the VOP coefficient until the measured distance to the end of the cable is equal to its actual length (mind the length of the leads). The longer the cable, the more accurate the obtained VOP value will be.

3. A similar experiment occurs when the cable length is known, and it has a non-defective pair. Connect the reflectometer to the pair and adjust VOP until you get the cable length you already know on the screen. Again, account for the probing leads. Suppose this technique is applied to thick multi-pair cables. In that case, ensuring that the reference and tested pairs belong to the same cable layer is necessary. The length of a pair of outer layers significantly exceeds the length of a pair of inner ones.

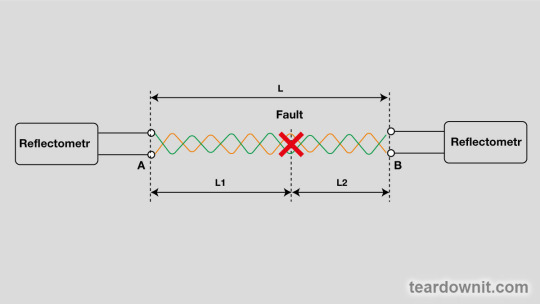

4. If the cable length is known, but there is no suitable pair for comparison, then it is necessary to have access to the cable from both sides.

Roughly pick a VOP value and determine the approximate distance (L1) to the fault on side A. Using the same VOP value, determine the approximate distance (L2) to the fault on side B. The exact distance to the damage can be calculated with L1 and L2.

From side A, according to the formula: (L1/(L1 + L2)) x L, where L is the known cable length. From side B, according to the formula: (L2/(L1 + L2)) x L, where L is the known cable length.

0 notes

Text

Multi-Room Audio: Mistakes to Avoid in a Distributed Audio System

When designing and installing a multi-room audio system for your home, it's important to avoid common pitfalls that can negatively impact the user experience. A well-planned distributed audio system should provide seamless music playback throughout the home without drops in audio quality or sync issues between zones. However, there are many potential mistakes that can undermine such a system if not addressed properly. In this blog post, we will explore some of the most common mistakes to avoid when planning and implementing a multi-zone home audio solution, including issues related to equipment choices, wiring, and configuration. We'll also take a look at some emerging technologies like XtenAV's X Draw wireless distribution system that aim to simplify multi-room audio.

Equipment Choices

The backbone of any distributed audio system is the core equipment used to route and process audio signals between zones. Choosing incompatible or underpowered equipment is a big mistake that can cause issues down the line.

Amplifier Power

A common error is underestimating the power needs of different speaker configurations. For example, using a 5-channel amplifier to power 5 different in-wall or in-ceiling speaker zones may not provide enough headroom, especially if you plan to crank up the volume. Consider factoring in the efficiency of the speakers and the size of the rooms when sizing amplifiers. It's better to have surplus power than come up short.

Compatibility

Look for an amplifier or receiver with networking capabilities that is compatible with your streaming sources and controller apps. Confirm support for common multi-room audio standards like AirPlay, Chromecast, and Spotify Connect. Mismatched equipment from different manufacturers may not play nicely together, causing unstable performance.

Future Proofing

When investing in a whole-home audio system, consider future expansion needs as well. Buy amplifiers, receivers, and streaming components with ample channel and connection capacity to accommodate adding new speaker zones down the road. Avoid being limited by your initial equipment choices early on.

Wiring Installation

Even with the right equipment powering a distributed audio system, pitfalls during the wiring installation can sabotage the finished result. Here are some common wiring mistakes:

Inadequate or Damaged Cabling

Undersized or damaged cabling will strangle an audio system's performance. Use pro-grade, oxygen-free copper (OFC) speaker wire suitable for the run distances. Inspect cable sheathing for nicks that could cause shorts. Measure cable runs conservatively to avoid coming up short.

Improper Termination

Take care terminating speaker cables correctly at both the amplifier and speaker ends. Loose, switched, or crossed connections lead to issues. Color code wires or label ends clearly to avoid mix-ups. Consider binding posts, push-in spring clips, or screwing down to ensure solid connections.

Interference from AC Wiring

Maintain separation between low-voltage speaker cable runs and 120V/240V AC circuits to prevent induced noise. bundle audio cables together and keep them away from noisy electrical lines wherever possible. Consider shielded cable for extra RFI protection if running near fluorescent lights.

Configuration

Even with the right equipment and clean wiring installation, mistakes in configuring the system can still lead to poor performance and user frustration.

Zone Grouping

Carefully group zones, considering complementary space uses. For example, avoid grouping a bedroom with family/living spaces as they have different use cases. Strategic zone combinations optimize the shared listening experience.

Volume Matching

Take time balancing volumes between speakers in each zone for a consistent perceived volume level wherever in the home. Consider the speaker proximity to listeners and room sizes for accurate level matching.

Multi-Room Features

Confirm the amp/receiver interface and controller apps are configured to support multi-room features like synchronous playback, independent volume control, grouping, and source sharing between zones. These features enhance usability.

Emerging Solutions

With the growing popularity of whole-home distributed audio, new technologies aim to streamline installation complexity and minimize potential pitfalls. One such innovation is XtenAV's wireless X Draw system which eliminates in-wall speaker wiring hassles.

XtenAV's X Draw

The X Draw system incorporates small X Draw in-wall transmitters paired with matching ceiling or in-wall speakers with integrated receivers. Audio signals are wirelessly distributed between compatible transmitters and receivers using proprietary mesh networking for reliable coverage. Installation simply involves mounting matching transmitter/receiver pairs in each space - no cable runs required. Initial setup and configuration is handled by the XtenAV app for intuitive multi-room control.

By removing wiring complications entirely, the XtenAV X Draw system helps installers avoid common distributed audio mistakes related to cabling runs, connections, and interference. Wireless distribution also enables adding new zones much more easily down the road without construction projects. For users, it delivers a seamless whole-home audio experience without the downsides that often plague wired systems. As wireless technology advances, we'll likely see more solutions that simplify multi-room integration.

Commissioning and Calibration

Even after installation, distributed systems require proper commissioning and calibration to achieve their full potential. Take time during initial setup to:

Configure sources and stream services on all playback devices Run room calibration on any digital signal processors (DSPs) Set levels, delays and eq for each speaker zone Tweak grouping, zones and multi-room preferences Test full functionality from all user control points Proper commissioning ensures elements are optimized for quality playback. Consider having an experienced custom installer perform these tuning tasks if you lack the tools or expertise. A properly commissioned multi-room system will provide years of frustration-free enjoyment.

Common Issues and Troubleshooting

No distributed system is foolproof, so knowing how to troubleshoot is important when issues do arise. Some signs that something may be wrong:

Dropouts, fading or distortion in certain zones Volume level inconsistencies between areas Source switching delays between grouped zones Control app not detecting all playback devices Mismatched or out of sync audio/video Start by power cycling components and testing equipment layer by layer - sources, amps/receivers, wiring and speaker connections. Use diagnostic tools like cable testers when signal issues are seen. For app/software issues, try firmware updates and re-pairing devices. Escalate to support if problems persist. Proper diagnosis helps resolve problems efficiently.

Conclusion

With intentional planning and by avoiding common mistakes, you can create a seamless multi-room audio experience for your home. The right equipment choices, clean cabling installation practices, thoughtful configuration, and meticulous commissioning lays the foundation for reliable whole-home audio. Emerging technologies also promise simpler installation processes down the road. By keeping these tips in mind, your distributed system upgrade is more likely to impress long-term.

0 notes

Text

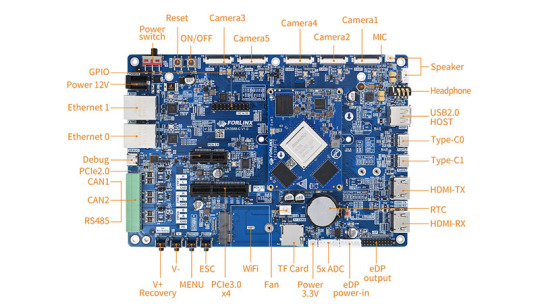

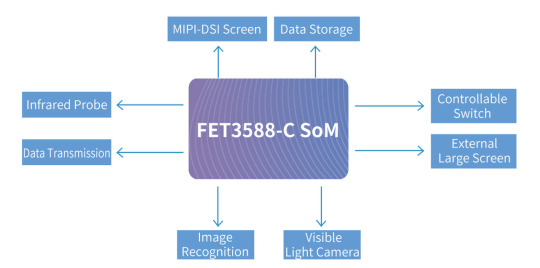

Forlinx FET3588-C SoM Facilitating the Intelligent Development of Infrared Thermal Imaging

According to Maxtech International data, the global civil infrared market size will exceed 7.6 billion US dollars in 2023, and in the past four years, the infrared industry has maintained a growth rate of over 11%. Moreover, according to data from Huajing Industrial Research Institute, the market size of China's infrared thermal imaging industry reached 65.534 billion yuan in 2021.

With the development of non-cooled infrared thermal imaging technology, infrared thermal imagers have been widely used in civil applications. This statement is attributed to Huajing Industrial Research Institute.

Against this backdrop, manufacturers and institutions that specialize in the research and production of infrared thermal imaging products have begun to lay out strategies for the civilian infrared thermal imaging market, which is a blue ocean market. The breast surgery research team from Peking Union Medical College Hospital in Beijing has applied their independently developed artificial intelligence-based infrared thermal imaging system (AI-IRT) to pre-screening for breast cancer.

The team has also developed a portable AI-IRT system, which includes an infrared miniature camera connected to a smartphone, AI software, and a real-time updated infrared thermal imaging database.

When using this system for pre-screening of breast cancer, the real-time captured infrared thermal images of the breasts are uploaded to the artificial intelligence software, which then provides a risk assessment rating. The system is non-invasive, radiation-free and easy to use, and can be used in families and community health service centers for screening.

Infrared thermal imaging can be used as an electrical equipment monitoring system, which is installed around the transformer, etc. Through optical fiber transmission, the monitoring of equipment can be completed in the monitoring room. 24 hours, all-weather, full coverage of all substation power equipment for real-time monitoring of thermal distribution field, real-time grasp of equipment operation status, found abnormal temperature rise immediately alarm.

In addition to equipment monitoring, it is also widely used in substation inspection, distribution inspection, transmission and distribution cable inspection industry, so that inspectors can grasp the temperature while helping the power industry inspection work become more efficient and easier.

In order to adapt to the development of infrared thermal imaging industry, Forlinx Embedded recommends FET3588-C System on Module(SoM) as the main control of highly integrated infrared thermal imager.

FET3588-C has 8K video codec + 8K display supporting 8K @ 60fps H.265 and VP9 decoders, 8K @ 30fps H.264 decoders and 4K @ 60fps AV1 decoders, supporting 8K @ 30fps H.264 and H.265 encoders. High quality JPEG encoder/decoder.

Optimization of 12V power supply can reduce losses, while PMIC dynamic frequency scaling can improve stability.

Powerful: Quad-core Cortex-A76 + Quad-core Cortex-A55, main frequency height of 2.4 GHZ, NPU with 6 TOPS

Support multi-channel video access and display output

Complete functional interfaces such as mipi-csi, mipi-dsi, USB, SATA, UART, CAN and Gigabit Ethernet

Originally published at www.forlinx.net.

0 notes

Text

Understanding Different Types Of Wires And Cables

Wires and cables are the unsung heroes of our modern world, silently powering our homes, offices, and industries. Understanding the different types of wires and cables and their specific applications is crucial for ensuring safety, efficiency, and functionality in electrical systems. In this comprehensive guide, we’ll delve into the various types of wires and cables used for different purposes, shedding light on their unique characteristics and applications.

As we explore the world of wires and cables, we’ll also highlight how Tony Enterprises, a trusted Schneider Electric Authorized Distributor in Kochi, Kerala, can provide you with the right electrical solutions tailored to your specific needs.

Wires & Cables

The key difference between wires and cables lies in their construction. Wires typically consist of a single conductor, whereas cables are composed of multiple conductors bundled together within a single sheath. This bundling of cables provides better organization and protection, making them suitable for more complex electrical systems where multiple connections are required. Additionally, cables often have more robust insulation and sheathing, enhancing their durability and resistance to environmental factors, which are crucial in various industrial and commercial applications. Understanding these distinctions is essential for selecting the right solution to meet your specific electrical needs.

Understanding the Basics: Conductors, Insulation, and Sheathing

Before we dive into the various types of wires and cables, it’s important to grasp the fundamental components of these electrical conduits:

Conductors: These are the core components that carry electrical current. They are typically made of copper or aluminum due to their excellent electrical conductivity.

Insulation: The insulation material surrounds the conductor, preventing electrical current from escaping and ensuring safety. Common insulation materials include PVC (Polyvinyl Chloride), XLPE (Cross-Linked Polyethylene), and rubber.

Sheathing: This outer layer protects the cable from external elements like moisture, heat, and physical damage. Materials for sheathing include PVC, nylon, and thermoplastic.

Types of Wires and Cables

Electrical Wires:

* Single Conductor Wires: These are the most basic form of wires, consisting of a single conductor insulated with PVC or rubber. They are used for general electrical wiring in homes and buildings.

* Multi-Conductor Cables: These cables contain multiple insulated conductors within a single sheath. They are commonly used in applications where multiple wires are required, such as power distribution and control circuits.

Power Cables:

* THHN/THWN Cable: Thermoplastic High Heat-resistant Nylon-coated cables are commonly used for residential and commercial electrical wiring.

* MC (Metal-Clad) Cable: MC cables have a metallic sheath, providing extra protection against physical damage and are often used in industrial settings.

– Coaxial Cables: These cables consist of an inner conductor, insulating layer, metallic shield, and an outer insulating layer. They are used for transmitting high-frequency signals, such as in cable television and internet connections.

– Fiber Optic Cables: Fiber optic cables use light signals to transmit data and are vital for high-speed internet, telecommunications, and long-distance communication.

– Control Cables: These cables are designed for signal transmission in control and automation systems, making them essential in manufacturing and industrial applications.

– Instrumentation Cables: Instrumentation cables are used to transmit low-energy electrical signals from sensors and instruments to control equipment. They are common in industries such as petrochemical and pharmaceutical.

– Fire-Resistant Cables: These cables are specially designed to maintain functionality during a fire, making them crucial in life safety systems and emergency power applications.

Factors to Consider When Choosing Wires and Cables

– Voltage Rating: Ensure the cable’s voltage rating matches the requirements of your application.

– Temperature Range: Different cables have different temperature ratings, so choose one that suits the operating conditions.

– Environmental Conditions: Consider factors like moisture, chemicals, and UV exposure that the cables may encounter.

– Installation Method: The method of installation, whether underground, overhead, or in conduit, will affect your choice of cable.

Understanding the different types of wires and cables is vital for any electrical project. Choosing the right cable not only ensures safety but also optimizes the performance and longevity of your electrical systems. Whether you’re wiring your home, setting up an industrial facility, or expanding your network infrastructure, knowing the specifics of each cable type will empower you to make informed decisions and ensure the success of your project. If you’re in Kerala, you can rely on Tony Enterprises, a trusted Legrand Authorized Dealer in Kochi, to provide you with top-quality electrical solutions tailored to your needs.

0 notes