#Multi Core Electric Cables Suppliers

Explore tagged Tumblr posts

Text

#Best Electrical Wires Manufacturers#Multi Core Electric Cables Manufacturers#Best Electrical Wires Suppliers#Multi Core Electric Cables Suppliers#Best Electrical Wires Exporters#Multi Core Electric Cables Exporters#Best Electrical Wires#Multi Core Electric Cables

0 notes

Text

Rubber Cable Suppliers Offering Customized Solutions for Unique Need

Rubber cable suppliers play a vital role in providing durable, flexible, and high-performance cables for various industries. These cables, known for their resistance to abrasion, heat, moisture, and chemicals, are ideal for demanding applications in construction, mining, marine, automotive, and renewable energy sectors. Suppliers offer a wide range of rubber cables, including power cables, welding cables, and multi-core cables, designed to meet specific industry standards and safety regulations. Reliable suppliers focus on delivering high-quality products with exceptional conductivity and durability, ensuring efficiency and longevity. Many suppliers also provide custom solutions to match unique project requirements. By partnering with trusted rubber cable suppliers, businesses can secure reliable power distribution and connectivity for both standard and extreme environmental conditions.

Introduction to Rubber Cable Suppliers and Customization

Rubber cable suppliers are pivotal in providing tailored solutions for industries with unique electrical requirements. Unlike standard cables, custom rubber cables are designed to address specific needs, such as resistance to extreme temperatures, chemical exposure, or mechanical stress. These cables are essential for sectors like mining, marine, automotive, and renewable energy, where unique operating conditions demand specialized products.

Why Choose Customized Rubber Cables?

Customization allows industries to optimize performance, safety, and efficiency. Rubber cables can be engineered to include specific features, such as:

High Flexibility: For dynamic environments requiring constant movement.

Enhanced Insulation: For protection against heat, moisture, and chemicals.

Unique Lengths and Configurations: Tailored to fit exact project specifications. Customized cables reduce waste, improve reliability, and often result in cost savings over time.

Applications of Customized Rubber Cables in Various Industries

Rubber cables designed for unique needs serve a variety of industries, including:

Construction: Flexible and durable cables for heavy machinery and tools.

Marine: Saltwater-resistant cables for shipboard and offshore installations.

Mining: Tough cables capable of withstanding harsh underground conditions.

Renewable Energy: Weatherproof cables for solar panels and wind turbines.

Automotive: High-performance cables for vehicle wiring and EV applications. These cables ensure reliable power transmission and safety in demanding environments.

Key Features of Rubber Cables Offered by Top Suppliers

Rubber cables provided by leading suppliers come with essential features to meet unique needs:

Material Versatility: Natural and synthetic rubber options, such as EPDM or silicone, tailored for specific requirements.

Temperature Resistance: Designed to perform in extreme heat or cold.

Abrasion and Impact Resistance: Ideal for rugged conditions.

Flexibility: Ensures easy installation in confined spaces or dynamic systems. Suppliers work closely with clients to understand their operational challenges and incorporate these features into the cable design.

Choosing the Right Rubber Cable Supplier for Customized Solutions

Selecting the right supplier is crucial for receiving high-quality customized rubber cables. Key factors to consider include:

Experience and Expertise: Look for suppliers with a proven track record in customization.

Product Range: Ensure the supplier offers a wide variety of rubber materials and configurations.

Certifications: Verify compliance with industry standards and safety regulations.

Technical Support: Reliable suppliers provide expert consultation and after-sales services to ensure the cables meet performance expectations. By partnering with the right supplier, businesses can secure cables perfectly suited to their unique needs.

The Process of Customizing Rubber Cables

Customizing rubber cables involves several steps, ensuring the final product meets the client’s specifications:

Consultation: Suppliers collaborate with clients to understand their requirements, including environmental conditions, load capacities, and cable dimensions.

Design and Material Selection: Engineers design cables with the appropriate rubber material, insulation, and reinforcement.

Prototyping: A sample is produced and tested for performance and durability.

Production: After approval, the cables are manufactured in bulk to the specified lengths and configurations.

Quality Testing: Final cables undergo rigorous testing to ensure compliance with industry standards. This structured approach guarantees a solution that aligns with operational demands.

Advantages of Partnering with Rubber Cable Suppliers for Custom Solutions

Collaborating with suppliers for custom rubber cables offers several benefits:

Tailored Performance: Cables are optimized for specific applications, enhancing operational efficiency.

Cost Efficiency: Customization eliminates unnecessary features and reduces material waste.

Enhanced Longevity: Designed to withstand specific environmental challenges, custom cables have a longer lifespan.

Improved Safety: Ensuring compliance with regulatory standards reduces risks associated with electrical systems. By working with experienced suppliers, businesses gain access to innovative solutions that drive productivity and reliability in their operations.

Conclusion

Rubber cable suppliers offering customized solutions play an essential role in powering industries with unique needs. Through careful material selection, advanced design techniques, and adherence to stringent quality standards, these suppliers deliver products that meet the most demanding operational requirements. By partnering with the right supplier, businesses can ensure safety, efficiency, and sustainability in their electrical systems, regardless of the challenges posed by their environments. Custom rubber cables are not just a product—they’re a strategic investment in long-term operational success.

0 notes

Text

The Manufacturing Process of Electrical Wires and Cables: From Concept to Delivery

In today’s electrified world, wires and cables are the invisible lifelines that keep homes, businesses, and industries connected. From powering your household appliances to ensuring seamless industrial operations, wires and cables are integral to modern living. But have you ever wondered how these essential components are made?

The journey of a wire or cable begins as a concept on the drawing board and ends as a finished product delivered to the end user. Understanding this intricate process not only highlights the expertise of an Electrical Wires & Cables Manufacturer Supplier but also underscores the precision and care involved at every stage.

Step 1: Concept and Design

Every wire or cable begins with a purpose. The design stage is where manufacturers define specifications based on the intended application. Engineers and designers collaborate to determine key attributes such as:

Conductor Material: Usually copper or aluminum for their excellent conductivity.

Insulation Requirements: Depends on voltage levels, operating environment, and safety standards.

Outer Sheathing: Protects the cable from external wear and environmental damage.

For example, industrial cables require heavy-duty insulation, while household wires prioritize flexibility and durability.

Step 2: Raw Material Selection

The quality of raw materials plays a critical role in ensuring the performance of electrical wires and cables. Trusted manufacturers source high-grade materials to meet stringent industry standards. The main components include:

Copper or Aluminum Rods: These are the backbone of electrical conductors.

Insulation Materials: PVC, XLPE, or rubber are commonly used to provide electrical and thermal resistance.

Protective Coatings: Materials like polyethylene or nylon offer additional durability.

As a leading Electrical Product Company, Asio Electricals ensures that only premium-grade materials are used in the manufacturing process to guarantee reliable performance and longevity.

Step 3: Drawing

The first physical step in manufacturing is drawing, where copper or aluminum rods are stretched into thin wires. This process involves:

Wire Drawing Machines: Reduce the diameter of the rods to the desired thickness using a series of dies.

Lubrication: Ensures smooth passage of the wire through the dies and minimizes heat generation.

Annealing: The drawn wires are heated to restore ductility and improve conductivity.

The result is fine, uniform wires that are ready for further processing.

Step 4: Stranding

For cables requiring multiple conductors, individual wires are stranded together to enhance flexibility and conductivity. Stranding involves twisting several thin wires to form a single, cohesive conductor.

Tightly Stranded Wires: Offer better conductivity and strength for high-performance applications.

Loosely Stranded Wires: Are more flexible, suitable for household and portable uses.

This stage is crucial for manufacturing multi-core cables, often used in complex electrical systems.

Step 5: Insulation

Insulation is applied to the stranded wires to prevent electrical leakage and ensure safety. This process involves coating the wires with materials such as PVC, rubber, or polyethylene.

Extrusion Process: Heated insulation material is applied uniformly over the conductor.

Testing: Insulated wires are rigorously tested for resistance, voltage endurance, and thermal properties.

High-quality insulation is vital for withstanding voltage fluctuations and environmental factors, such as moisture or heat.

Step 6: Cabling

In this stage, multiple insulated wires are bundled together to form a cable. The cables are twisted or aligned in specific patterns to ensure:

Uniform transmission of electrical signals.

Enhanced mechanical strength.

Reduced electromagnetic interference (EMI).

A protective sheath is then applied to the bundled wires, further enhancing durability and safety.

Step 7: Armoring (Optional)

For heavy-duty cables used in industrial and outdoor applications, an additional layer of armoring is added. This involves wrapping the cable with metal strips or wires to provide extra protection against mechanical stress and environmental hazards.

Armored cables are commonly used in underground installations and high-risk environments.

Step 8: Quality Testing

Before reaching the market, every batch of wires and cables undergoes stringent quality checks. Renowned Electrical Wires & Cables Manufacturer Suppliers like Asio Electricals follow a rigorous testing protocol, including:

Conductor Resistance Testing: Ensures optimal conductivity.

Voltage Testing: Checks the insulation's ability to handle specified voltage levels.

Flame Retardant Testing: Verifies fire resistance properties.

Durability Testing: Assesses the cable’s ability to withstand mechanical and environmental stresses.

These tests guarantee that the product meets national and international safety and performance standards.

Step 9: Packaging

Packaging plays a significant role in preserving the quality of wires and cables during transportation and storage. The cables are wound onto reels or spools, labeled with specifications, and wrapped to protect them from moisture and physical damage.

For larger shipments, protective pallets or drums are used to ensure safe delivery.

Step 10: Distribution and Delivery

The final step in the process is distributing the finished product to end users. Whether it’s a residential project, commercial building, or industrial plant, a reliable supply chain ensures timely delivery.

As a trusted Electrical Product Company, Asio Electricals has an extensive distribution network, ensuring their products reach clients efficiently and in perfect condition.

The Asio Electricals Advantage

When choosing an Electrical Wires & Cables Manufacturer Supplier, quality, innovation, and reliability are paramount. Here’s why Asio Electricals stands out:

State-of-the-Art Manufacturing: Equipped with advanced technology to produce premium-quality products.

Commitment to Standards: Compliance with global safety and performance benchmarks.

Tailored Solutions: Customizable cables to meet unique project requirements.

Sustainability: Eco-friendly manufacturing practices to minimize environmental impact.

Exceptional Support: A dedicated team to guide clients from selection to installation.

Conclusion

The manufacturing process of electrical wires and cables is a meticulous journey, combining engineering expertise with cutting-edge technology. From the selection of raw materials to the final delivery, every step is designed to ensure quality, safety, and performance.

For those seeking top-tier products, Asio Electricals is the name to trust. With their unwavering commitment to excellence, they continue to power homes, industries, and dreams across the globe.

Also Read:

Best Electrical Product Company in India: Why Asio Electricals Stands Out

The Basics of Conduit Pipe Fittings: Types and Applications

Originally published at https://asioworld.blogspot.com

#asio#asio world#asio electricals#Electrical Wires & Cables Manufacturer Supplier#Electrical Product Company

0 notes

Text

PVC Flexible Cable Supplier: Ensuring Reliable Electrical Solutions

When it comes to high-quality PVC flexible cables, a reliable PVC flexible cable supplier plays a vital role in meeting diverse industrial and residential needs. PVC flexible cables are essential for applications requiring flexibility and durability in challenging environments, such as construction sites, manufacturing units, and home installations. Withstanding wear, moisture, and varying temperatures, these cables are designed to last, ensuring safety and consistency. A dependable PVC flexible cable supplier understands the importance of high-grade PVC insulation, providing a protective layer against environmental stresses. This insulation not only enhances safety by preventing short circuits and fire hazards but also ensures the cable’s longevity, making it ideal for high-demand applications. From flexible single-core cables for compact installations to multi-core options for complex wiring, a PVC flexible cable supplier offers customized solutions that align with both specific technical requirements and industry standards, contributing to efficiency and safety in various projects.

High-Quality Standards from a PVC Flexible Cable Supplier

A reliable PVC flexible cable supplier ensures each product adheres to high-quality standards, delivering durable and safe solutions. These suppliers follow strict manufacturing protocols, incorporating high-grade PVC that can withstand various environmental pressures, including heat, moisture, and physical wear. Choosing the right PVC flexible cable supplier guarantees that your cabling meets both safety and performance requirements.

Why Choosing a PVC Flexible Cable Supplier Matters for Industrial Projects?

Industrial projects require durable and versatile wiring solutions. A PVC flexible cable supplier provides cables that are essential for industrial machinery, offering enhanced flexibility and resistance to abrasion and heat. Partnering with a dedicated PVC flexible cable supplier ensures smooth operations and minimizes maintenance costs, optimizing project longevity and reliability.

Key Advantages of Partnering with a PVC Flexible Cable Supplier

Working with a trusted PVC flexible cable supplier comes with advantages like access to diverse cable types, customization, and dedicated customer service. These suppliers understand the unique needs of various industries, offering cables that meet precise electrical and physical demands. This support ensures safe and efficient installations across different applications.

The Role of a PVC Flexible Cable Supplier in the Construction Industry

Construction projects demand flexible and resilient cables that perform well under rigorous conditions. A PVC flexible cable supplier offers cables that are perfect for construction, ensuring flexibility and safety in installation. These cables handle frequent movement, rough handling, and exposure to environmental elements, making them an excellent choice for construction needs.

Safety and Durability: Benefits of PVC Cables from a PVC Flexible Cable Supplier

Safety is paramount in any electrical installation, and a PVC flexible cable supplier prioritizes both safety and durability. These cables are insulated with high-quality PVC that minimizes risks such as short circuits and fire hazards. Selecting a reliable PVC flexible cable supplier helps ensure that all cables installed will last while maintaining a secure environment.

Understanding the Versatility of PVC Cables from a PVC Flexible Cable Supplier

PVC flexible cables are designed for various applications, from residential setups to complex industrial wiring. A dedicated PVC flexible cable supplier provides cables that can adapt to different needs, with options for single-core and multi-core variants. This versatility makes them a reliable choice across various sectors, all provided by your trusted PVC flexible cable supplier.

What Sets a Top PVC Flexible Cable Supplier Apart?

Quality, consistency, and reliable delivery set the best PVC flexible cable supplier apart. Leading suppliers invest in top-tier manufacturing practices and adhere to international standards, ensuring all products meet or exceed performance expectations. Partnering with such a supplier guarantees access to high-performance cables that stand up to rigorous use.

Conclusion

In any industry that relies on dependable electrical systems, choosing a trusted PVC flexible cable supplier is essential. From construction and residential wiring to large-scale industrial projects, a reliable supplier provides high-quality cables designed to withstand challenging conditions while ensuring safety and durability. With a range of customized solutions, a quality PVC flexible cable supplier guarantees that each cable meets specific project requirements, contributing to efficiency and cost-effectiveness. By partnering with a reputable PVC flexible cable supplier, businesses and contractors benefit from reliable support and high-performance products that enhance the lifespan and safety of their installations.

0 notes

Text

Electrical Cable Suppliers in Dubai, UAE

Electrical cables are the unsung heroes of modern life, quietly powering our homes, businesses, and industries. These unassuming wires play a crucial role in ensuring that electricity flows seamlessly, enabling our gadgets to function and our appliances to run smoothly.

When it comes to earthing and electric fitting cables, we cover a wide range of armoured cables, which include single-core armoured cables, multi-core XLPE/PVC/AWA armoured cables that contain a voltage rating from 600-1000V and protection for particular applications like traffic signals and more. As a leading XLPE cable supplier, we also have a complimentary range of quality cable accessories designed and tested to ensure a perfect fit with our cables. To learn more visit here Electrical Cable Suppliers in Dubai, UAE

Trans Light Electricals LLC

Ras Al Khor Industrial Area – Ras Al Khor Industrial Area 2 – Dubai – United Arab Emirates

+97143399627

0 notes

Text

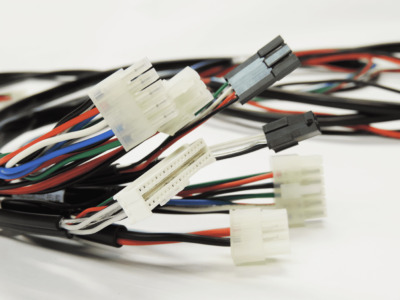

Cable/Wire Harness Assembly

In today’s technologically advanced world, the demand for reliable and efficient cable assemblies and wire harnesses spans across numerous industries. From automotive to aerospace, consumer electronics to industrial machinery, these components are vital for the functionality and reliability of countless devices and systems. At inYantra, we specialize in providing top-tier cable and wire harness assembly services that meet the specific needs of our customers across a wide range of industries.

Our Commitment to Excellence

At inYantra, we adhere to the highest standards of quality and workmanship. Our cable and wire harness assemblies are manufactured following the IPC/WHMA-A-620 workmanship standards, ensuring that every product we deliver is built to perform reliably under various conditions. We understand that every application has unique requirements, and our facility is equipped to manufacture both power and signal cable assemblies to your exact specifications.

Comprehensive Cable & Wire Harness Assembly Services

Our cable and wire harness assembly services are designed to cater to diverse industry needs. We offer a wide range of services that ensure precision, quality, and reliability in every assembly we produce.

Single Core Wires and Multi-Core Cables

Whether your project requires single core wires or complex multi-core cables, we have the expertise and capabilities to meet your needs. Our team is skilled in handling a variety of materials and configurations, ensuring that each assembly is tailored to your exact specifications.

Automated Wire Processing

We utilize advanced automated wire processing technologies, including cut, strip, crimp, and tinning processes. This automation ensures consistent quality and precision across all assemblies, reducing the potential for errors and enhancing overall efficiency.

Crimp Force Monitoring

As part of our commitment to quality, we incorporate crimp force monitoring as a standard practice in our assembly processes. This ensures that all crimps are secure and meet the required standards, providing reliable electrical connections in every product.

100% Electrical Testing

Quality assurance is paramount at inYantra. That’s why we perform 100% electrical testing on all our cable and wire harness assemblies. This rigorous testing process ensures that every assembly meets the required electrical performance standards before it leaves our facility.

IPC/WHMA-A-620 Standards

We adhere strictly to the IPC/WHMA-A-620 standards, which are the industry benchmarks for cable and wire harness assemblies. These standards cover all aspects of assembly, from materials to workmanship, ensuring that our products are of the highest quality.

Design for Manufacturability (DFM) Assistance

Our team provides Design for Manufacturability (DFM) assistance, helping you optimize your designs for production. This ensures that your cable and wire harness assemblies are not only functional but also cost-effective and efficient to produce.

Global Sourcing and Vertical Integration

We offer global sourcing for Approved Vendor List (AVL) and alternative components, giving you access to high-quality materials from trusted suppliers worldwide. Additionally, our vertical integration opportunities allow you to leverage our group manufacturing capabilities in raw cable production, further enhancing the efficiency and cost-effectiveness of your projects.

Industries We Serve

Our cable and wire harness assemblies are used in a variety of end-use applications across multiple industries. Whether you’re in the automotive, aerospace, telecommunications, medical, or industrial sector, inYantra has the expertise to deliver the solutions you need.

Conclusion

At inYantra, we take pride in delivering high-quality cable and wire harness assemblies that meet the stringent requirements of our diverse customer base. Our commitment to following industry standards, combined with our advanced manufacturing capabilities and global sourcing strategies, ensures that we can provide reliable, cost-effective solutions for your cable and wire harness needs. Trust inYantra to be your partner in delivering excellence in every assembly.

1 note

·

View note

Text

Trusted Electrical Cable Suppliers in Dubai, UAE | Translight Electricals

Electrical cables are essential for powering homes, businesses, and industries. As one of the top-rated electrical cable suppliers in Dubai, UAE, we offer a wide range of armoured cables, including single-core and multi-core XLPE/PVC/AWA armoured cables with voltage ratings from 600-1000V. Our cables are ideal for various applications such as traffic signals and more.

We are among the best electrical cable suppliers in Dubai, UAE, providing low-smoke, flame-resistant rubber cables perfect for commercial buildings, residential complexes, hotels, and hospitals. These cables minimize smoke and toxic gas emissions during fires and restrict fire spread, making them suitable for industrial use, renewable energy projects, telecommunications, and data centers. Choose us for reliability, performance, and peace of mind.

1 note

·

View note

Text

Industrial Wire & Cable Manufacturers

Modern-day industries have customized needs for wires and cables to meet their specific work demands. The industrial needs of wires and cables vary considerably from domestic needs. Paraflex is set to provide customers with advanced and multi-functional industrial cables and wires. Let us have a look at the various types of Industrial cables and their uses:

Housing Wires: It is widely used in the construction and interior decor industry. As the name suggests, these wines are used in domestic spaces such as residences or corporate offices.

Industrial Wire Upto 400sq mm: These wires are ideal for use with any gadgets or equipment. They have flexible cords with a copper center.

Multicore Round Cables up to 91 core: Used in heavy equipment such as cooling units and motors. They are ideally used for running various heavy machinery in industries.

Three/ Four Core Flat Cables: PVC insulated cables and wires are mostly used for pump connections. The covering s a sheath to protect the inner core from external physical aberrations.

Aluminum Cables up to 50 sq mm core: They have a greater cross-section area and pass higher current than copper wires, but the advantage is that they are lighter than copper wires.

Co-Axial Cables: They are used to transmit radio frequency signals. They are greatly used for computer networking.

CCTV Cables: Various cables are used to aid CCTV surveillance, such as RCA Plug, Play cable, and CAT5 Cable. They can directly transmit signals to observe the CCTV video in your NVR and DVR.

Speaker Cables: As the name suggests, they connect speakers with amplifiers. The event management industries need this type of cable most of the time.

Camera Wires: Security camera cables like Ethernet and Siamese are used for security purposes.

Paraflex – One Stop Destination for Industrial Cables

Paraflex is the trusted Industrial Wire & Cable Manufacturers. Paraflex uses only the best raw materials to produce premium quality wires. All the industrial cables from our brand are capable of qualifying the standard benchmark for industrial requirements. The best industrial wires and cables from Paraflex can bear high loads, are fire resistant, and are all set to serve the latest and modern equipment and gadgets. We assure you of safe electricity conduction through our marvelous and wide range of industrial cables and wires. Get the best industrial cables and wires at affordable rates from Paraflex – the leading manufacturer and supplier of a wide range of industrial cables and wires.

0 notes

Text

Multi-Core Fibers (MCF) Market Size, Growth, Trends Analysis & Opportunities 2030

A New Market Study, titled “Multi-Core Fibers (MCF) Market” Upcoming Trends, Growth Drivers and Challenges” has been featured on Refined Reports Data.

Multi-Core Fibers (MCF) Market report is latest report published by Refined Reports Data which provides comprehensive information, overview of the demands on the market during the forecast period.

Get Free Sample Report @ https://www.refinedreportsdata.com/request-sample/8338/multi-core-fibers-(mcf)-market-global-outlook-and-forecast-2030

Refined Reports Data (RRD) has conducted a survey of the Multi-Core Fibers (MCF) producers, suppliers, distributors, and industry professionals on this market. The survey covered sales, revenue, demand, price change, product type, current development and strategy, industry trends, drivers, difficulties, barriers, and potential risks.

This report contains market size and forecasts of Multi-Core Fibers (MCF) including the following market information:

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Multi-Core Fibers (MCF) sales share in global market, 2023 (%)

Further, the report presents profiles of competitors in the market, key players include

Furukawa Electric Yangtze Optical Fibre and Cable Fiberhome iXblue Humanetics Fujikura Sumitomo Electric

Competitive Landscape:

Multi-Core Fibers (MCF) Market is highly competitive and fragmented.

Continue….

Inquiry before purchase Report @ https://www.refinedreportsdata.com/enquiry/8338/multi-core-fibers-(mcf)-market-global-outlook-and-forecast-2030

About Refined Reports Data: Refined Reports Data is one of the largest collections of market research reports from numerous publishers. We have a team of industry experts who provide unbiased insights on reports that best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from numerous global leaders across industry segments.

Contact us:

Phone: + (210) 775-2636 (US) + (91) 853 060 7487

0 notes

Text

Are you looking for high-quality and affordable LV cables for your electrical needs? Look no further than Neelkanth Cables, the leading manufacturer and supplier of LV cables in Zambia. Neelkanth Cables offers a wide range of LV cables for various applications, such as power distribution, lighting, appliances, and more. Whether you need single-core, multi-core, or flexible cables, Neelkanth Cables has the right product for you. All our cables are made from premium materials and comply with international standards. Contact us today at +260 212 671 661 to get a quote or place an order. Neelkanth Cables, the trusted name in LV cables.

#neelkanthcables#cablesandwires#electriccables#powercables#electricalwiring#electricalcablemanufacturer#cable#wires#cables#wire#electrical#wiring#electric#electricalprojects#power#circuit#topcableglobal#controlcable#copper#copperconductor#aluminum#copperrodsandwires#copperrod#copprrods#lv#lvcables#electricwires#electrician#a#network

0 notes

Text

#Electric Cable Manufacturers in Delhi#Electric Wire Manufacturers in Delhi#Best Electric Wire Manufacturer in Delhi#Electrical Wires Manufacturers#Best Multi Core Electric Cables Suppliers Exporters in Delhi#Best Electrical Wires Manufacturers in Delhi.

0 notes

Text

Top 10 Best MCB Switch Manufacturers in India

With the exception of the fact that it also produces kitchen appliances, house wire, LED lights, fans, MCB switches, and MCB socket modular plates, Smart PG Electrical is the largest and most prominent TOP 10 MCB MANUFACTURERS, electrical appliance producer in India.

Indicator MCB Manufacturers SMART MCB manufacturers smart wires manufacturer Modular plate Manufacturer BEST QUALITY MCB Manufacturer MCB Manufacturers in India TOP 10 WIRE Manufacturers SUBMERSIBLE wire Manufacturers house wire Manufacturer Modular switch Manufacturer TOP 10 MCB Manufacturers SWITCHES Manufacturers in India COPPER wires Manufacturers Change over switch Manufacturer

Find Out Our Other Product Pages URL

Click Here –

Smart Wires – Manufacturer, Supplier From Delhi, India

https://www.smartelectrical.in/about.html

Top 10 Wire Manufacturers, Supplier from Delhi, India

https://www.smartelectrical.in/multi-strand-wire.html

https://www.smartelectrical.in/multi-core-cable.html

Submersible cables – Manufacturers, Suppliers Delhi, India

https://www.smartelectrical.in/fr-ls-Cable.html

https://www.smartelectrical.in/aluminium-cable.html

https://www.smartelectrical.in/zhfr-wire.html

https://www.smartelectrical.in/automotive-wires-cables.html

Top 10 Best Quality MCB – Smart MCB Manufacturers from India

https://www.smartelectrical.in/miniature-Circuit-breakers.html

https://www.smartelectrical.in/modular-mcb.html

https://www.smartelectrical.in/suew-type-tiny-mcb’s.html

Indicator MCB Manufacturer | Supplier From Delhi, India

https://www.smartelectrical.in/isolaters-rccb.html

Changeover Switch – Manufacturer, Supplier from Delhi, India

Electric Switch – Switches Manufacturers from India

Modular Switch – Manufacturer, Supplier From Delhi, India

https://www.smartelectrical.in/modular-grey-switches.html

https://www.smartelectrical.in/chrome-silver-grey-plates.html

https://www.smartelectrical.in/wooden-plates.html

https://www.smartelectrical.in/screw-type-pc-switches.html

https://www.smartelectrical.in/screw-type-urea-switches.html

https://www.smartelectrical.in/swicthgears.html

https://www.smartelectrical.in/mcb-box.html

https://www.smartelectrical.in/db-heavy.html

https://www.smartelectrical.in/changeover-porcelain.html

https://www.smartelectrical.in/main-switches.html

https://www.smartelectrical.in/kit-kat-fuse.html

https://www.smartelectrical.in/electrical-accessories.html

https://www.smartelectrical.in/lamp-holder.html

https://www.smartelectrical.in/ceiling-rose.html

https://www.smartelectrical.in/plug-top.html

https://www.smartelectrical.in/bed-switch.html

https://www.smartelectrical.in/dp-switch.html

https://www.smartelectrical.in/multi-plug.html

https://www.smartelectrical.in/flex-box-power-strip.html

https://www.smartelectrical.in/heating-press-element.html

https://www.smartelectrical.in/musical-bell.html

https://www.smartelectrical.in/line-tester.html

https://www.smartelectrical.in/insulation-tape.html

https://www.smartelectrical.in/smart-catlog.pdf

https://www.smartelectrical.in/gallery.html

https://www.smartelectrical.in/contact.html

www.smartelectrical.in Site Map – Generated by www.xml-sitemaps.com

Modular Plate – Manufacturer, Supplier From Delhi, India

Copper Wire – Copper Wires Manufacturers, Suppliers from India

House Wire Manufacturer, Electrical House Wires from Delhi, India

Submersible Wire – Manufacturers, Suppliers from Delhi, India

#top 10 mcb manufacturers#change over switch manufacturer#mcb manufacturers in india#copper wires manufacturers#modular plate manufacturer#indicator mcb manufacturers#best quality mcb manufacturer#house wire manufacturer

0 notes

Text

Flexible Cable Supplier in India | Amco Electrical

The Flexible Cable Supplier in Kolkata, West Bengal, Bihar, Odisha, Jharkhand & all over India is used in machine tools, electrical appliances, and control panels. In these cables, the insulated cores are laid up to form the core assembly. The inner cores are coded for the ease of identification as per national/ international coding practices. Here, the sheathing is provided with a specially formulated PVC compound to facilitate not only simplification in stripping, but also withstanding mechanical abrasion capacity while in operations.

With the assistance of our supplying units our firm is specialized in offering superior quality Flexible Cables. The cables are produced using latest technology machineries and best quality resources. These cables are passed through specific parameters to check its quality. Amco Electrical & Engineering Co. provide our clients with these cables at an economic range along with their varied specifications. Get the best Flexible Cable Wire Price in India from us.

Other details:

Multi Strand flexible annealed copper conductor, PVC Insulated and sheathed Multi – core flexible cables conforming to IS: 694 / 90.

Range:

5 sq. mm to 4 sq. mm up to 61 cores

6 sq. mm to 35 sq. mm up to 7 cores

50 sq. mm to 300 sq. mm up to 4 cores

These cables possess some attractive features which are:

Resistant to high temperature, heat

Flexible and durable

Longer service life

High tensile strength

Specifications:

Type: Low Voltage

Conductor Material: Copper

Features:

Fire proof

Reliable

Resistant to chemicals

Durable

Functional efficiency is optimum

High performance

Type of Flexible cable

5 core flexible cable

5 core flexible cable

3 core flexible cable

4 core flexible cable

1 note

·

View note

Photo

The welding rotator is auxiliary welding equipment. It uses the friction between the welding workpiece and the roller to drive the cylindrical (or conical) welding workpiece to rotate. The welding rotator is often used in combination with the welding manipulator. They can weld the inner and outer longitudinal seams and inner and outer circumferential seams of cylindrical workpieces.

The welding rotator consists of a base, a power driving device, active and driven rollers, and other structures. The welding rotator mainly uses the driving device to perform the active rotator operation, and there will be friction between the active rotator and the cylindrical workpiece. This friction force can mainly drive the rotation of the workpiece, thereby realizing effective displacement. Let the inner and outer circumferential seams and inner and outer longitudinal seams of the cylindrical workpiece be in the horizontal position where welding is needed, and the welding manipulator can realize automatic welding work. This can not only improve welding quality to the greatest extent but also effectively improve work efficiency.

Welding rotator composition

Next, we will introduce the main parts, main parts and parts details of the welding rotator.

The main unit of the welding rotator

The traditional welding rotator consists of two parts:

Roller support unit

Electric drive

Roller support unit

The idler bracket, or more commonly referred to as the "base", is the component that carries the wheel or the medium that performs the rotation or twisting of the workpiece.

The components of the idler support unit include:

Drive steering wheel

Driven wheel frame

Electric drive unit

Similar to the idler support unit, the electric drive unit is also composed of different parts. For the benefit of everyone, the electric drive is a part of the rotator, which emits power and energy to make the welding rotator work.

The main parts of the welding rotator

Different welding rotators have different parts. In addition, some manufacturers have added certain components to it.

However, the parts that will never be taken out include:

Idler

Driving wheel (something used to rotate material or workpiece)

Wheel frame (thing that supports the wheel)

Transmission (device that controls the speed of rotation)

Controller (something used to change and modify the rotation speed)

Direct current (DC) motor (what makes movement concrete and real)

Even if only one of the components is missing, the welding rotator will not work properly.

These are the parts of the welding rotator. Some welding rotator manufacturers and suppliers may add some parts to supplement it, but these are parts of traditional rotators and are indispensable.

Part details of the welding rotator

The rollers can be steel wheels or polyurethane wheels.

The drive motor adopts an AC variable frequency motor. If high precision is required, servo motors can be used.

The roller support bearing adopts the spherical roller bearing, which has the characteristics of strong load-bearing capacity and impact resistance.

All shaft parts are quenched and tempered, and the tooth part is quenched and tempered.

Welding the base profile and plate welding, stress relief. In addition, the frame has undergone shot blasting and rust removal treatment, which has sufficient strength to ensure long-term use.

The electric control system consists of a control box and a hand control box. The control box and the hand control box are connected by super soft multi-core cables to ensure reliable use.

The role of welding rotator

During the welding process, the welding rotator will be used to complete related operations. The design and production of the rotator frame adopts advanced technology, and at the same time, the automatic tracking system is used to achieve the application purpose, so that the positioning is more accurate. When the roller frame is processed and produced, the process design can be carried out according to the operation requirements, so that the roller frame can better meet the needs of the industry.

In the process of processing and production, any problems encountered can be analyzed, controlled and adjusted by appropriate methods. In addition, the welding rotator will be tested with appropriate process parameters, which can make the parameter setting more reasonable, make the processing operation consistent with the equipment setting, and achieve better operation control effects.

When processing by welding the rotator, the welding process is more stable and reliable. It can not only reduce the probability of failure, but also has a good isolation effect, preventing air from entering the equipment, and the equipment will not be affected by the high temperature environment.

The use of welding rotators can improve the quality of machining operations. Make the product processing and production effect more reasonable and achieve a more ideal application effect.

The difference between welding rotator and welding positioner

The welding positioner is a device that can clamp and rotate the workpiece according to the set angle. It can be at different angles so that you can weld on a stable level. Workpieces of any shape can be loaded on the welding positioner.

Welding rotators are different. After the workpiece is loaded, it will continue to rotate according to the speed you want. The wheels on the rotator allow movement; this is why only round and cylindrical objects can be used with it.

Why does the workpiece move on the welding rotator?

When using the welding rotator, the rotator and the weldment are round and the length is the same, and the axis is also parallel, it will not cause movement. If one of the rollers of the roller frame is broken, the selection of the workpiece on the roller frame may cause movement. Of course, if the shape or size of the workpiece is irregular, it will also cause movement. This is because the axis of the rotator and the axis of the workpiece are not parallel.

What are the effects of using the welding rotator on the processing quality?

In the welding process, the welding rotator will be used to complete the related operations. The design and production of the rotator frame use advanced technology, and at the same time achieve the application purpose through the automatic tracking system, so that the positioning is more accurate. When processing and producing through the roller rack, the process design can be carried out according to the operating requirements, so that the roller rack can better meet the needs of the industry.

In the process of processing and production, any problems encountered can be analyzed, and controlled, and adjusted through appropriate methods. In addition, the welding rotator will be tested with appropriate process parameters, which can make the parameter setting more reasonable, make the processing operation and the equipment setting consistent, and achieve better operation control effects.

When processing through the welding rotator, the welding process is more stable and reliable. It can reduce the probability of failure, and can also achieve a good isolation effect, prevent air from entering the equipment, and the equipment will not be affected by the high-temperature environment.

The use of a welding rotator can improve the quality of processing operations. Make the product processing and production effect more reasonable and achieve a more ideal application effect.

Application of welding rotator

Welding rotators are widely used, suitable for many industries and adapted to many processes.

Which industries can benefit from welding spinners

In the application scenarios of welding rotors, storage and pressure vessels are one of the most common parts produced by welding rotators. The most common applications include welding:

Oil storage tank

Water tank

Shipyard and ship parts

Pressure vessel

And more

Which welding processes can the welding rotator assist?

Available processes for welding rotators:

Submerged arc welding (SAW)

Tungsten inert gas (TIG) welding

Metal inert gas (MIG) welding

Arc welding

And more

If you choose to use welding rotators to complete any of these processes, then you can get higher quality and higher production efficiency products. We are a welding rotator supplier. Please feel free to contact us if you need them!

0 notes

Text

Best Electrical Cable Supplier in Dubai, UAE | Trans-Light Electricals

At Best Electrical Supplier in Dubai, UAE, we take pride in being your premier destination for top-quality electrical cables. Our extensive range includes armoured cables, from single-core to multi-core XLPE/PVC/AWA variants, tailored for diverse applications with voltage ratings spanning from 600 to 1000V. Complemented by high-quality cable accessories, our offerings ensure seamless integration and optimal performance.

From mains electricity supply to backup control cables, our solutions excel in various environments, boasting features such as fire resistance, extended service life, and flexibility for versatile applications. With a commitment to safety and reliability, we provide low-smoke flame-resistant rubber cables, ideal for commercial buildings, residential complexes, and hospitals.

Choose Best Electrical Supplier in Dubai for unparalleled reliability, performance, and customer satisfaction. With timely deliveries and a comprehensive selection, we ensure that your projects are powered with confidence and efficiency, every step of the way.

1 note

·

View note

Text

Auto Wires & Cables | Fargo Auto Electricals

Whether it’s a 300-mph dragster, the slowest of bracket cars, or a high-performance (or even low-performance) streetcar, they all have one thing in common: Wiring.

Wires power everything in your car. You name it: fans, pumps, gauges, and lights. The car will not start, run, or allow you to travel very far if there is no wiring. The ordinary car certainly has as much wiring as an early Space Shuttle in today’s high-tech environment.

Fargo AutoElectricals has been a prominent supplier of wiring harnesses and other electrical hardware for the automotive industry.

How to Select the right wire?

Understanding the fundamentals of automotive and electrical wire is the first step in selecting the right product, especially given the many options available. Continue reading to learn about the five most important factors to consider when selecting the proper automotive or electrical wire.

Right Material

The most common types of automobile wire materials are copper and aluminium. Copper wire is more conductive, flexible, and less likely to corrode than aluminium wire. However, because the copper wire is heavier and more susceptible to price swings, you’ll need a reputable distributor to keep your prices down. Aluminium is lighter and less expensive, but it is less robust and more prone to rusting or developing increased electrical resistance over time.

Wire Size/ Gauge

The gauge number corresponds to the thickness of the wire, which is the contrary of what newbies might think: the thicker the wire, the lower the gauge number. 8-gauge wire, for example, is thicker than 20-gauge wire. The gauge you’ll need is determined by the circuit’s current draw and the distance between the circuit and the power source.

If you’re buying for repairs, make sure you have the technical manuals for any tractors, equipment, or other vehicles you’ll be working on hand. The handbook will typically specify which gauge of wires are required for which components, allowing you to keep the correct cables on hand. Keep in mind that wire with a gauge of 8 or greater is commonly referred to as “cable.”

Amperage

The “load” a cable can carry is measured in amperes, commonly abbreviated as “amps.” The entire quantity of electricity that can flow across a wire is measured in amps. Every wire in your workplace should have a current rating, and it should be clearly labelled. Overloading a wire is hazardous to your employees and your customers; a wire with the incorrect current rating might short out, causing equipment to stall in hazardous areas, vital damage systems, and even spark fires in extreme circumstances. Always double-check that the automotive wire you’re ordering can handle the load by knowing your amps.

Wire Types

“Primary” Wire

This is the most frequent wire seen in car dealerships. It’s a good general-purpose automobile wire, as the name says. It has a multi-stranded core and flexible insulation that makes it perfect for squeezing through tiny places.

“Motor” Wire

The main distinction between GPT and Motor wire is that motor wire has finer wire strands. This enables it to work with greater voltages. Grease, oil, acids, water, solvents, and fungus are all resistant to it. The motor wire is increasingly being used in automotive applications, despite its ubiquitous use as internal wiring in appliances and HVAC equipment.

SXL Wire

SXL Wire has a cross-linked polyethene jacket that is more resistant to heat, abrasion, and ageing than GPT wire. It is frequently chosen in high-stress applications such as race or industrial vehicles. This is a wonderful option if you want something that will last a long time.

The GXL and TXL wire insulation is the same, but the walls are thinner to make it simpler to pull through small areas.

Speaker Wire

Speaker wire is a stranded wire with two strands used in audio applications. Its purpose is to carry the sound from a stereo receiver to the speakers, as the name implies. It’s only meant for low-voltage applications and should never be used to carry a load.

Battery cable

Battery Cable connects the battery to the car’s electrical system and ground (usually at the starter). It’s a thicker wire with a larger gauge. Corrosion is most common in battery cables, and it can often be visible inside the cable where it can’t be seen. Check your battery cables if you’re having trouble starting your automobile.

Trailer Wire

Trailer wire is usually GPT or Primary wire that has been coloured and arranged to meet the needs of popular trailer applications. Most trailers use a standard colouring system for the various lighting tasks that use Green, Yellow, Brown, and White. Buying ‘Trailer’ Wire makes rewiring or repairing a trailer much easier. It also aids in future problem diagnosis.

Brands are available with us-

Veethree: Venthree is known for having specialization in auto wires & cables

Kamei Autoelectrik: Kamei Autoelectrik produces auto wires & cables. They produce very high-quality wires and that too at a very reasonable rate.

Uno Minda: Uno Minda is a leading manufacturer of auto wires and cables, fulfilling all the demands of their customer.

Our auto wires are built from full gauge pure copper wires and fire-resistant, extremely flexible PVC to ensure maximum current flow, minimal transmission loss, minimize heating of electrical parts, passenger safety, and vehicle longevity. Auto Cables from Veethree and Minda are also available, with excellent connectivity, long life, and precision.

Our products are also available on Amazon, Flipkart, and many e-commerce sites.

Visit Us for More Information - https://fargoautoelectricals.com/blog/2022/02/15/auto-wires-cables/

0 notes