#EDMS

Explore tagged Tumblr posts

Text

2 notes

·

View notes

Text

Cut costs and boost productivity with electronic document management

In today’s corporate operations, document management is undeniably critical. As digital transformation advances, traditional paper-based document management has revealed numerous shortcomings, such as limited storage capacity, low retrieval efficiency, and poor document security. To address these challenges, an increasing number of businesses are adopting Electronic Document Management Systems (EDMS). These systems not only enhance file management efficiency but also significantly reduce operational costs and boost productivity. This article explores how to achieve these benefits, particularly through the adoption of efficient systems like 8Manage EDMS.

1.Overview of Electronic Document Management Systems

An Electronic Document Management System (EDMS) is a specialized software platform designed to store, manage, retrieve, and track electronic documents. Compared to traditional paper-based document management, EDMS offers higher efficiency and lower costs. It allows businesses to categorize, archive, share, and retrieve documents quickly and accurately.

EDMS enables organizations to store all critical documents and data in a centralized database, ensuring secure, convenient access and compliance. With advancements in technology, many EDMS platforms now incorporate features like Optical Character Recognition (OCR), artificial intelligence, and automated workflows, further improving document management efficiency and intelligence.

2.How EDMS Reduces Operational Costs

1. Lower Physical Storage Costs

Traditional document management relies heavily on paper files, requiring extensive physical storage space, especially as businesses expand and paper documents proliferate. By digitizing documents and storing them electronically, EDMS drastically reduces the need for physical storage space and associated costs.

For example, 8Manage EDMS can swiftly scan paper documents into electronic formats and store them in the cloud or on servers, eliminating the issue of accumulated archives and significantly cutting physical space and storage costs.

2. Enhanced Document Management Efficiency

Manual document handling is time-consuming and prone to inefficiencies. EDMS allows for organized categorization and keyword-based searches, saving substantial time and labor. Automated classification and tagging further enhance the intelligence and efficiency of document management.

3. Minimized Errors and Redundancy

Manual document management often leads to errors, such as misplaced files, archiving mistakes, or version inconsistencies, which impact operational efficiency and pose compliance risks. EDMS automates processes to ensure accuracy and standardization. With systems like 8Manage EDMS, each document update is automatically version-controlled, minimizing human error and redundant tasks.

4. Improved Remote Work and Collaboration

In modern enterprises, team members often work from various locations. EDMS facilitates seamless information sharing and collaboration, regardless of geography. With cloud-based access and real-time collaboration features in 8Manage EDMS, team members can share and edit documents anytime, anywhere, greatly enhancing efficiency.

3. How EDMS Boosts Productivity

1. Streamlined Document Review and Approval

Traditional document approval processes are cumbersome, often involving physical signing and passing documents back and forth. EDMS automates approval workflows, ensuring faster and more transparent processes. With 8Manage EDMS, automated approval flows notify relevant personnel, record feedback, and eliminate delays associated with manual handling.

2. Intelligent Data Analysis and Reporting

EDMS can analyze and summarize vast amounts of document data, providing valuable insights for decision-making. Businesses can track document access, version history, and usage frequency, identifying opportunities for better document management or archiving. This supports data-driven, strategic decisions.

3. Improved Employee Efficiency

A unified document management platform reduces the time employees spend searching, organizing, and managing files. With smart search and one-click archiving features in 8Manage EDMS, employees can quickly locate and process needed documents, focusing more on core tasks and improving overall efficiency.

4. Ensured Document Security and Compliance

EDMS platforms typically include robust access controls to restrict document access based on roles, preventing sensitive information from leaking. For instance, 8Manage EDMS provides granular permissions, enabling tailored access according to employee roles and responsibilities, ensuring document security. Moreover, operation logs are automatically recorded, ensuring compliance with regulatory standards.

4. The Future of EDMS

With continuous advancements in artificial intelligence, big data, and cloud computing, EDMS will become even more intelligent and automated. Future systems will not only enhance document management efficiency but also provide stronger decision support through deep learning and data analysis. Additionally, with the widespread adoption of 5G technology, real-time document management and collaboration capabilities will further improve.

FAQs

1.What are the main features of an EDMS?

Key features include document storage, categorization, retrieval, sharing, version control, access management, approval workflows, and data analysis. EDMS helps businesses efficiently manage vast amounts of documents while ensuring security and compliance.

2.How to choose the right EDMS for your business?

Consider factors like functionality, security, compliance support, cloud storage options, intelligent automation features, user-friendliness, and customer support. For example, 8Manage EDMS provides comprehensive solutions to meet diverse business needs.

3.Can EDMS improve collaboration efficiency?

Yes, EDMS enhances collaboration by enabling real-time sharing, online editing, and automated approvals, allowing team members to work efficiently across locations and reducing delays caused by manual processes.

Conclusion

In summary, EDMS offers significant potential to reduce operational costs and boost productivity. With intelligent and automated features, systems like 8Manage EDMS empower businesses to manage documents more effectively, enhancing overall operational efficiency and employee productivity. For businesses seeking to maintain a competitive edge, adopting an efficient EDMS is undoubtedly a wise choice.

0 notes

Text

Transform Business Efficiency with Comprehensive Content Management Services

In today’s fast-paced business landscape, managing a growing volume of content efficiently is paramount for companies to stay competitive. Whether it’s for internal processes, customer interactions, or compliance, content management is critical. Comprehensive content management services (CMS) helps streamline operations, improve collaboration, and ensure the security of data across all business functions. This article explores the importance of adopting an enterprise-level CMS and how it can transform business efficiency.

Understanding Content Management Services

Content management services (CMS) are essential for organizing, storing, and tracking business documents, multimedia content, and other digital assets. These systems not only allow businesses to store content but also manage workflows, monitor versioning, and enable easier access to key resources.

Effective CMS solutions offer businesses the ability to centralize all content in a single, easy-to-access location. The value lies not just in storing information but also in the automation, collaboration, and governance features that come with the system.

Key Benefits of Content Management Services

1. Streamlined Workflow Management

One of the most significant advantages of a comprehensive CMS is the improvement in workflow management. With an organized structure, businesses can automate repetitive tasks, such as document approvals, data entry, and content publication. This frees up employees to focus on more strategic tasks and reduces the chances of human error.

Moreover, automated workflows help ensure that the correct version of a document or content is always available, reducing delays caused by version control issues. Additionally, the ability to route documents through approval chains quickly enhances productivity and decision-making.

2. Improved Collaboration Across Teams

For businesses that rely on team collaboration, CMS tools provide a centralized platform where employees can work together more effectively. Teams can access, edit, and comment on documents in real time, no matter where they are located. This eliminates the need for back-and-forth emails and helps ensure everyone is working with the most up-to-date information.

In addition, content management services support role-based access control, allowing businesses to define who can access, edit, and distribute specific content. This provides an added layer of security, ensuring that sensitive information is only available to authorized personnel.

3. Enhanced Data Security and Compliance

As businesses handle sensitive and confidential data, security is a primary concern. A well-implemented CMS provides robust security features that help protect your content from unauthorized access, theft, and data breaches. CMS solutions often offer encrypted storage, user authentication, and audit trails, ensuring that every action taken within the system is logged and tracked.

For industries with strict compliance requirements, content management services make it easier to adhere to regulations by offering features like document retention policies, compliance tracking, and data integrity checks. These ensure that businesses can meet legal requirements and pass audits without disruption.

4. Increased Efficiency and Cost Savings

The ability to access and manage content easily reduces the time spent searching for files or manually sorting through documents. This improved efficiency can translate into direct cost savings as resources are optimized, and business processes are streamlined. By reducing the reliance on physical documents and implementing digital workflows, businesses can also cut costs related to printing, shipping, and storing paper records.

Furthermore, the automation of repetitive tasks reduces the need for manual input, saving both time and money. Employees can spend more time on high-impact activities, such as creative development or strategic decision-making, rather than administrative tasks.

5. Better Content Quality and Consistency

A CMS ensures that content is standardized across an organization. Whether it's marketing materials, internal documents, or customer-facing content, consistency is key to maintaining a professional image. By centralizing all content, businesses can create templates, apply uniform formatting, and ensure that branding is adhered to at every touchpoint.

Furthermore, version control ensures that content is always up to date, minimizing the risk of outdated or conflicting information being used. This helps build trust with customers and clients, who rely on accurate and consistent communication.

Types of Content Management Services

When selecting a content management service, businesses have several options based on their specific needs. Below are the primary types of CMS solutions:

1. Document Management Systems (DMS)

DMS are designed to store and track business documents. These systems typically include features such as document storage, version control, document search capabilities, and access controls. DMS solutions are ideal for businesses that focus on managing a high volume of written documents, such as contracts, legal papers, and financial reports.

2. Enterprise Content Management (ECM) Systems

ECM systems are more comprehensive and are used to manage the entire lifecycle of business content, from creation to archiving. ECM systems are typically integrated with other enterprise applications like Customer Relationship Management (CRM) or Enterprise Resource Planning (ERP) systems. They provide businesses with a robust solution for managing documents, records, multimedia content, and workflows across the organization.

3. Web Content Management (WCM)

WCM solutions are specifically focused on managing digital content on websites. These tools allow businesses to create, manage, and optimize content for the web, including images, videos, articles, and blogs. WCM systems are crucial for businesses that prioritize content marketing, customer engagement, and SEO optimization.

4. Cloud-Based CMS

Cloud-based CMS solutions offer the flexibility of storing content remotely on secure cloud servers. These systems are ideal for businesses that need to provide remote access to content for teams across multiple locations. With cloud CMS, businesses can scale storage and functionality as needed, without the need for on-site infrastructure.

How to Implement Content Management Services

Implementing content management services within a business requires careful planning and execution. Below are the key steps to ensure successful CMS integration:

1. Assess Business Needs

Before selecting a CMS, businesses should evaluate their content management needs. This includes understanding the type and volume of content they manage, the required workflows, and security needs. By assessing these factors, businesses can select a CMS that best aligns with their operational goals.

2. Select the Right CMS

There are numerous CMS platforms available, each offering different features and capabilities. It’s crucial to choose a system that can meet both the current and future needs of the organization. Consider factors such as scalability, ease of use, and integration capabilities when selecting a CMS.

3. Train Employees

Proper training is essential for ensuring that employees can effectively use the new system. Providing training on how to navigate the CMS, manage content, and leverage key features will help businesses realize the full benefits of the system.

4. Monitor and Optimize

After implementing a CMS, businesses should regularly monitor its performance and make adjustments as needed. This includes evaluating system efficiency, gathering feedback from employees, and optimizing workflows to improve productivity.

Conclusion

Comprehensive content management services are not just a luxury but a necessity for businesses looking to streamline their operations, enhance collaboration, and maintain data security. By investing in an effective CMS, businesses can transform their content management process, improve workflow efficiency, and reduce operational costs. The ability to automate processes, maintain consistency, and ensure regulatory compliance positions businesses for long-term success in today’s competitive environment.

Adopting the right CMS solution will allow companies to stay agile, adapt to changing business needs, and ultimately, drive growth and profitability. A well-managed content strategy is a powerful tool in enhancing overall business efficiency and delivering value to both internal teams and customers.

#dms system#electronic document management system#cloud based document management#document management companies#electronic document management solutions#enterprise document management#electronic data management system#dms document management system#dms services#document management system india#dms software india#best document management software in india#document management system dms#document management company#dms software company#edms#online document management system#document management software india#document management system companies in india#document management system in india#document storage systems#Document Storage#physical records management#physical document management#physical document management system#records management system software#record management system#Record management software#Record storage software#records management solutions

0 notes

Text

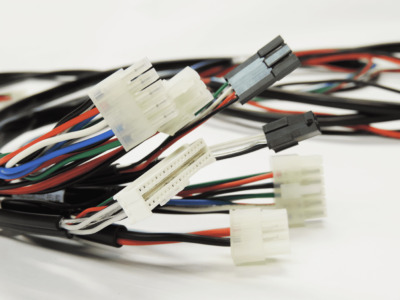

Cable/Wire Harness Assembly

In today’s technologically advanced world, the demand for reliable and efficient cable assemblies and wire harnesses spans across numerous industries. From automotive to aerospace, consumer electronics to industrial machinery, these components are vital for the functionality and reliability of countless devices and systems. At inYantra, we specialize in providing top-tier cable and wire harness assembly services that meet the specific needs of our customers across a wide range of industries.

Our Commitment to Excellence

At inYantra, we adhere to the highest standards of quality and workmanship. Our cable and wire harness assemblies are manufactured following the IPC/WHMA-A-620 workmanship standards, ensuring that every product we deliver is built to perform reliably under various conditions. We understand that every application has unique requirements, and our facility is equipped to manufacture both power and signal cable assemblies to your exact specifications.

Comprehensive Cable & Wire Harness Assembly Services

Our cable and wire harness assembly services are designed to cater to diverse industry needs. We offer a wide range of services that ensure precision, quality, and reliability in every assembly we produce.

Single Core Wires and Multi-Core Cables

Whether your project requires single core wires or complex multi-core cables, we have the expertise and capabilities to meet your needs. Our team is skilled in handling a variety of materials and configurations, ensuring that each assembly is tailored to your exact specifications.

Automated Wire Processing

We utilize advanced automated wire processing technologies, including cut, strip, crimp, and tinning processes. This automation ensures consistent quality and precision across all assemblies, reducing the potential for errors and enhancing overall efficiency.

Crimp Force Monitoring

As part of our commitment to quality, we incorporate crimp force monitoring as a standard practice in our assembly processes. This ensures that all crimps are secure and meet the required standards, providing reliable electrical connections in every product.

100% Electrical Testing

Quality assurance is paramount at inYantra. That’s why we perform 100% electrical testing on all our cable and wire harness assemblies. This rigorous testing process ensures that every assembly meets the required electrical performance standards before it leaves our facility.

IPC/WHMA-A-620 Standards

We adhere strictly to the IPC/WHMA-A-620 standards, which are the industry benchmarks for cable and wire harness assemblies. These standards cover all aspects of assembly, from materials to workmanship, ensuring that our products are of the highest quality.

Design for Manufacturability (DFM) Assistance

Our team provides Design for Manufacturability (DFM) assistance, helping you optimize your designs for production. This ensures that your cable and wire harness assemblies are not only functional but also cost-effective and efficient to produce.

Global Sourcing and Vertical Integration

We offer global sourcing for Approved Vendor List (AVL) and alternative components, giving you access to high-quality materials from trusted suppliers worldwide. Additionally, our vertical integration opportunities allow you to leverage our group manufacturing capabilities in raw cable production, further enhancing the efficiency and cost-effectiveness of your projects.

Industries We Serve

Our cable and wire harness assemblies are used in a variety of end-use applications across multiple industries. Whether you’re in the automotive, aerospace, telecommunications, medical, or industrial sector, inYantra has the expertise to deliver the solutions you need.

Conclusion

At inYantra, we take pride in delivering high-quality cable and wire harness assemblies that meet the stringent requirements of our diverse customer base. Our commitment to following industry standards, combined with our advanced manufacturing capabilities and global sourcing strategies, ensures that we can provide reliable, cost-effective solutions for your cable and wire harness needs. Trust inYantra to be your partner in delivering excellence in every assembly.

1 note

·

View note

Text

Box Build Assemblies at InYantra Technologies

What is Box Build Assembly?

Box Build Assembly is a comprehensive manufacturing process that involves integrating multiple components and subassemblies into a complete product. This includes everything from PCB assembly to final system integration, functional testing, packaging, and even logistics support. Essentially, it’s the process of taking a product from concept to reality, ensuring that every aspect meets the highest standards of quality and reliability.

inYantra’s Box Build Assembly and Manufacturing Services

At inYantra, our Box Build Assembly services are designed to deliver fully integrated solutions tailored to our customers' specific needs. With our state-of-the-art manufacturing setup and a team of highly skilled professionals, we ensure that every product we build is of the highest quality, from the initial assembly stages to final delivery.

Comprehensive System/Box-Build Activities

Our Box Build Assembly services encompass a wide range of activities, ensuring that we can deliver a complete product to our customers:

Vendor Development: We work closely with a network of trusted vendors to source high-quality components and materials, ensuring the best possible outcomes for our customers.

Product Life Cycle Management: From the initial design phase through to end-of-life management, we provide full product life cycle support, helping our customers manage their products efficiently and cost-effectively.

In-House Manufacturing of PCBAs: Our in-house PCB Assembly services are the foundation of our Box Build capabilities, allowing us to maintain strict quality control and streamline the manufacturing process.

Functional Testing: We perform rigorous functional testing on all assemblies to ensure they meet the required specifications and operate as intended.

Heat-Run Tests: To ensure reliability and performance under real-world conditions, we conduct heat-run tests that simulate the operational environment of the product.

Drop-Shipping and Logistics Support: We offer comprehensive drop-shipping and logistics support across India, ensuring that your products are delivered on time and in perfect condition.

Packaging & Labeling: We provide packaging and labeling services that meet industry standards, ensuring that your products are ready for retail or direct shipment to customers

Why Choose inYantra for Box Build Assemblies?

Choosing inYantra for your Box Build Assembly needs means partnering with a company that is committed to delivering quality, reliability, and customer satisfaction. Our end-to-end manufacturing services ensure that your product is handled with the utmost care at every stage of the process. From vendor development to final logistics, we take responsibility for the entire product build, allowing you to focus on your core business.

Conclusion

inYantra’s Box Build Assembly services are designed to provide our customers with a complete manufacturing solution that extends beyond PCB assembly. Our integrated approach, combined with our advanced manufacturing capabilities and skilled team, ensures that every product we build meets the highest standards of workmanship, quality, and reliability. Whether you’re looking to bring a new product to market or need support with an existing one, inYantra is here to deliver the results you need.

1 note

·

View note

Text

PCB Assembly at inYantra Technolgies

In the fast-paced world of electronics, finding a reliable partner for Printed Circuit Board (PCB) Assembly and related services is crucial. inYantra, a leading Electronics Design and Manufacturing Services (EDMS) company in India, has established itself as a premier provider of comprehensive PCB Assembly services.

Why Choose inYantra for PCB Assembly Services?

At inYantra, we understand that our customers’ success depends on the quality and reliability of their products. That’s why we offer end-to-end electronics services, from Printed Circuit Assembly to complete system integration and box build. Our goal is to ensure that our customers’ objectives are met through on-time delivery, superior quality, and cutting-edge manufacturing processes.

Quick-Turnaround for Complex and Advanced Needs

In today’s dynamic business environment, the ability to adapt quickly is key to staying competitive. We specialize in quick-turnaround services for highly complex and advanced PCB assembly and systems manufacturing. Whether you need a small batch of prototype boards or a large-scale production run, our flexible approach ensures that we meet your deadlines without compromising on quality.

Expertise in Latest Technologies

Our highly skilled and competent engineering and manufacturing team is at the forefront of the latest technology and processes in the industry. We are well-equipped to provide complete solutions for all kinds of PCB assembly requirements, ensuring that every project is handled with the highest level of expertise and precision.

Highlights of Our PCB Assembly Services

At inYantra, we offer a wide range of PCB Assembly services to meet the diverse needs of our customers. Here are some of the key highlights:

SMD Assembly: We offer Surface Mount Device (SMD) assembly services, ensuring precision and reliability for complex PCB designs.

Through Hole Assembly (Auto MI): Our automated through-hole assembly services are designed for high-volume production with consistent quality.

Hybrid Board (SMD + Through Hole): For products that require both SMD and through-hole components, we provide hybrid board assembly services.

Conformal Coating: To protect your PCBAs from environmental factors, we offer conformal coating services that enhance durability and performance.

3D X-Ray: Our state-of-the-art 3D X-Ray inspection technology ensures that even the most complex assemblies are free from defects.

Programming: We provide programming services for microcontrollers and other programmable components, ensuring that your PCBs are ready for deployment.

Testing: Comprehensive testing services are available to verify the functionality and reliability of your assembled PCBs.

Sub-Level Assembly: We offer sub-level assembly services, integrating your PCBs into larger systems with precision and care.

Conclusion

When it comes to PCB Assembly services in India, inYantra stands out as a leader in the industry. Our focus on quality, quick-turnaround, and advanced technology ensures that we can meet the needs of even the most demanding projects. Whether you are looking for a reliable partner for your next product launch or need ongoing support for your manufacturing processes, inYantra is here to help. Trust us to deliver the high-quality PCB Assembly services you need to succeed in today’s competitive market.

1 note

·

View note

Text

Our Expertise

inYantra Technologies have two decades of experience in PCB Assembly and Box-Build, currently we are producing around 500+ varieties of PCBAs per month & 10 million PCBAs per annum. We support our customers from concept till commercialization while ensuring handholding until the new product is stabilized. We help our customers establish their complete supply chain and ensure ‘Design for Manufacturability’ that reduces/eliminates their field failure for longer product durability.

End-to-End Support

We pride ourselves on our ability to support our customers from concept to commercialization. This means that we are there every step of the way, ensuring that every aspect of the product development process is seamless and efficient. Our commitment doesn’t end with product launch; we continue to offer hand-holding support until the new product is fully stabilized in the market.

Supply Chain Management

In today’s global market, establishing a reliable and efficient supply chain is crucial. We assist our customers in building their complete supply chain, ensuring that all components and materials are sourced from trusted suppliers. This not only reduces costs but also enhances the overall quality and reliability of the final product.

Design for Manufacturability (DFM)

Our expertise in Design for Manufacturability (DFM) ensures that the products we develop are not only of the highest quality but also optimized for production. By focusing on DFM, we help reduce or eliminate field failures, leading to longer product durability and greater customer satisfaction.

Our Technology

At inYantra, we believe that cutting-edge technology is the key to producing the best products. Our expert and dynamic design team leverages advanced techniques and world-class processes for both Surface-Mount Device (SMD) and Through-Hole technology. This allows us to manufacture best-in-class products that are ‘first-time right’—meaning they meet all specifications and quality standards on the first attempt.

Lean Manufacturing

Our focus on lean manufacturing principles ensures that we minimize waste and maximize efficiency throughout the production process. This approach not only reduces costs but also leads to faster turnaround times for our customers.

Quality Assurance

We take quality seriously, which is why we conduct comprehensive Gauge R&R (Repeatability and Reproducibility) studies, CP (Capability) & CPK (Process Capability Index) measurements, and maintain a Kaizen-focused approach to continuous improvement. Our commitment to consistent quality and reliability is evident in every product we manufacture.

Customized Testing

Understanding that each product has unique requirements, we offer product-specific customized testing to ensure that every unit meets the highest standards. Our process-driven production is guided by detailed DFM analysis, process flow charts, control plans, and Process Failure Modes and Effects Analysis (FMEA), all of which contribute to producing reliable and robust products.

Conclusion

At inYantra, our combination of deep industry expertise and cutting-edge technology allows us to deliver superior PCB Assembly and Box-Build services. Whether you’re a start-up bringing a new concept to life or an established company looking to optimize your supply chain and manufacturing processes, we are here to support you every step of the way. With a focus on quality, reliability, and customer satisfaction, inYantra is your trusted partner in the world of electronics manufacturing.

1 note

·

View note

Text

MAYHEM by Lady Gaga (2025)

#lady#gaga#ladygaga#lady gaga#portrait#art#artpop#fashion#artwork#woman's fashion#goth art#goth#gothic#Victorian#vampire aesthetic#vampire#interview with the vampire#grammy#grammys#2025#valentines#valentines day#Valentino#mayhem#Bruno mars#edm#music#edm music#artist#singer

4K notes

·

View notes

Text

They're Just Like Us: This Dolphin That Passed The Mirror Test Five Years Ago Is Posting About Being A Former Gifted Kid

4K notes

·

View notes

Text

Madonna dancing at a Parisian nightclub, 1990

#madonna#90s music#90s fashion#90s aesthetic#90s icons#aesthetic#vintage#old school cool#style#beauty#dancing#dance girl#dance music#clubbing#Paris#edm#justify your love

2K notes

·

View notes

Text

#cyber goth#rivethead#gothic metal#gothic rock#gothic#mall goth#goth aesthetic#goth girl#gothic style#gothgoth#gothcore#goth subculture#edm#agrotech#dark aesthetic#goth#alt style#alternative fashion#alt girl#alternative rock#alternative style#90s alternative#alternative#hot topic#vampire freaks#web finds#old internet#photography#lip service#2000s fashion

2K notes

·

View notes

Text

Unlocking Maintenance Excellence: Wrench's Cutting-Edge EDMS Solutions

In today's technologically advanced world, businesses across industries are continuously seeking innovative solutions to optimise their maintenance processes. Electronic Document Management Systems (EDMS) have emerged as a powerful tool to revolutionise maintenance operations, providing a streamlined approach to document management and data organisation. At the forefront of this transformation is Wrench, a leading provider of cutting-edge EDMS solutions designed to unlock maintenance excellence and elevate businesses to new heights of efficiency.

Chapter 1: Understanding the Impact of EDMS Solutions on Maintenance Management

Maintenance management involves handling a vast array of critical documents, including equipment manuals, service records, work orders, and compliance certificates. In the past, these documents were often stored in physical files, making retrieval time-consuming and prone to errors. The adoption of EDMS solutions has paved the way for a digitized, centralized, and secure platform, enabling businesses to efficiently manage maintenance-related data. Wrench's EDMS solutions play a key role in simplifying complex maintenance tasks and optimizing the entire process.

Chapter 2: Exploring Wrench's Comprehensive EDMS Features

Wrench's EDMS solutions offer a host of powerful features tailored to meet the unique needs of maintenance management:

Document Digitization: With Wrench's advanced scanning technology, physical documents are seamlessly transformed into digital formats. This process ensures data accuracy, reduces manual data entry, and facilitates quick data retrieval.

Centralized Data Repository: All maintenance-related documents and data are securely stored in Wrench's centralized EDMS repository. This centralized approach simplifies document organization, promotes collaboration among maintenance teams, and facilitates efficient information sharing.

Real-Time Accessibility: Leveraging the cloud-based nature of Wrench's EDMS, authorized personnel can access maintenance data and documents in real-time from any location. Field technicians benefit from instant access to critical information, resulting in faster decision-making and improved response times.

Workflow Automation: Wrench's EDMS automates routine maintenance workflows, streamlining processes such as work orders and inspection checklists. This automation reduces manual intervention, minimizes errors, and ensures that tasks are completed efficiently.

Chapter 3: Advantages of Implementing Wrench's EDMS Solutions

Heightened Productivity: By eliminating manual paperwork and optimizing maintenance workflows, Wrench's EDMS solutions significantly reduce administrative burdens, allowing maintenance teams to focus on core responsibilities. This boost in productivity enhances overall efficiency.

Enhanced Data Security: Wrench's EDMS incorporates robust security measures to protect maintenance data from unauthorized access and potential data breaches. Organizations can confidently manage sensitive information while ensuring compliance with data privacy regulations.

Data-Driven Decision-Making: Real-time access to critical maintenance data empowers maintenance teams to make informed decisions promptly. This capability enables proactive problem-solving, reduces downtime, and enhances asset reliability.

Scalability and Customization: Wrench's EDMS solutions are scalable to accommodate the needs of businesses of all sizes. Additionally, the platform can be tailored to align with specific industry requirements, offering a personalized approach to maintenance management.

Chapter 4: Real-Life Success Stories with Wrench's EDMS Solutions

The success stories of organizations that have implemented Wrench's EDMS solutions showcase the transformative impact on maintenance practices. These case studies highlight how businesses have experienced streamlined operations, improved asset performance, and significant cost savings through the integration of Wrench's cutting-edge EDMS.

Conclusion

Wrench cutting-edge EDMS solutions have redefined maintenance management, empowering businesses to unlock excellence in their operations. By harnessing the power of digitization, centralized data storage, and real-time accessibility, Wrench provides businesses with a comprehensive platform to drive maintenance efficiency. The seamless integration of EDMS not only enhances productivity and data security but also fosters data-driven decision-making for improved asset reliability. As industries continue to evolve, Wrench remains committed to leading the way with innovative EDMS solutions, propelling businesses toward maintenance excellence and continued success.

0 notes

Text

GLOW | DARK

Entry for @glowweek day 1!

I'm a huge fan of raves and EDM, so when i saw the prompt "Glow" i couldn't help but think of the amazing glowing from blacklight, UV paint, and of course the glow bracelets that are at these shows!

I took inspiration from the scene of Steven and Connie dancing at Sour Cream's party in the episode "Alone Together" and also some colors from clips of various Porter Robinson Dj sets.

#glowweek#connverse#steven universe#connie maheswaran#steven x connie#su#suf#steven quartz universe#steven universe future#art#glowweek day 1#my art#fanart#digital art#edm#i have to put his full name for comedy's sake#steven quartz cutiepie demayo diamond universe#i hope this looks okay bc this sort of lighting is was difficult for me😓 i had some trouble with it

3K notes

·

View notes

Text

Couldn't resist 😂

Thick Thighs save Lives 💪🏻

#feedee belly#feeding kink#gaining fat#fatty#get me fatter#gaining weight on purpose#gainer boy#fat belly#edm#belly gainer

1K notes

·

View notes