#mouldmaker

Explore tagged Tumblr posts

Text

Professional long -term partner mould manufacture .High quality delivery&efficient communications.

WhatsApp/wechat +008613781126253

0 notes

Text

Cat and Fish ceramics (2022) slipcast salt and pepper shakers, spoons, and bowl/mugs

---

General concept/theme with these is that the cat spoon goes fishing in whatever beverage/soup you put in the mug! And the salt/pepper shakers is the cat licking their lips satisfied with their caught fish hehe

Process details + photos under the cut:

made for my 2nd year ceramics class; Which was such. a pain. in the fucking. ass. Like good things came out of it but the amount of really draining work this class put me through was ROUGH

its also the time I got literally the sickest I've ever been, during a time where I had to be coming into the studio to work every single weekday just to meet deadlines. My cough did not go away for so long and when it did, a few months later it even came back for a while (only popping up near nighttime??) Until it seemed to finally completely resolve itself after like a YEAR. I'm 95% sure it was covid tbh... The test came back negative but I didn't trust those lil at home test guys very much considering how many variations were flying around orz ugh

This ceramics class was also a bummer because I went into it expecting to do at least some wheel throwing (as was on the course description...) But it was all slipcasting and plaster mould making and! I hated it!!! Don't get me wrong slipcasting is v cool, I just hated Doing it lol its hard fuckin work and working with plaster stressed me out orz

But! The nice thing about a ceramics class is you get some fun objects out of it which I always love...

Here's my sketches/ideation:

oh yeah also made some test tiles which was our v first assignment; used these throughout to test underglazes/glazes/colour combos:

Salt n pepper shaker maquettes! testing out two different designs:

Plaster mouldmaking my beloathed (salt/pepper shaker, Bowl, and Spoon+mug handle):

Slipcast the boys; drying before bisque. I'd have to redefine the details on the shakers and mug by hand because they weren't super visible right out of the moulds:

a Bunch o colour/glaze tests:

Also ran into a pretty major issue with the spoons... I 100% should have been putting a little hole in the top of the spoon handle so I could fire it via having it hang suspended in the kiln. Eventually I started poking holes by hand into the spoons, But having overlooked that from the beginning I had a good amount of spoons that were too dry to have a hole poked into and with the deadline so close... (and even with some new spoons I fucked up and broke a few spoons when I tried to poke holes augh) the techs in the studio said they could put em on lil stilts and fire them that way. And I thought ok that sounds good! But... I didn't realize I'd have to be sanding the lil bit of metal from the stilts off from where it gets stuck to the glaze... :((

(see that spoon on the far right with the hole on top? that's the ideal orz)

So I had to take like a diamond tip grinder sander thing and sand that off, but it was very difficult and unpleasant and loud and still left some grey blemishes. And I was still so worried that usability-wise, you'd put the dang spoon in your mouth and feel a sharp bit of metal cut the inside of your very delicate gums :((

Yeah so this whole class and all its projects were a big ordeal for me orz but at least I got some fun salt n pepper shakers out of it (I use the brown/white cat shaker to hold my cinnamon sugar now hehe)

Also storage was an issue, I had to get a locker space just for this class. I'd be cramming all my guys into my locker; kinda funny to open my locker and see a bunch of lil guys lmao:

I ended up giving 4 of my friends a mug and salt/pepper shaker combo each for Christmas that year! I hope they still use them lol but I'm not sure? The sad thing is that my own two mugs I had in my kitchen cupboard have. fucking vanished????? my parents say they don't know where they went n I literally have no idea either and it fucking sucks (if one goes missing it's like fine that sucks. But both of them?? What the fuck happened). I still have like two bowls (ie no handles) in my closet at least but those were the ones that I'm not sure were food safe lol

5 notes

·

View notes

Text

Marq Quinn || Self 2011

Sculpture

C. 2011

Medium: Blood (artist's), stainless steel, perspex and refrigeration equipment

Dimensions: 208h x 63w x 63d cm

1 note

·

View note

Text

Why Is 1.2311 Plastic Mould Steel Important?

1.2311 is a type of Plastic Mold Steel that holds significance in various Industrial Applications, especially in the manufacturing of Plastic Injection Molds. Here's why it's important:

1. Good Machinability: 1.2311 Plastic Mold Steel possesses good machinability properties, which means it can be easily machined into desired shapes and forms using conventional machining techniques. This attribute is crucial in mold making where precision is key.

2. Excellent Wear Resistance: It offers excellent wear resistance properties, which is essential for Plastic Molds that undergo repeated cycles of molding and demolding. This ensures that the mold maintains its shape and functionality over a long period of time.

3. High Hardness: 1.2311 Steel can be hardened to a high level, providing the necessary hardness required for withstanding the pressures and stresses encountered during the injection molding process.

4. Good Polishability: The Steel is capable of being polished to a smooth finish, which is important for achieving high-quality surface finishes on Molded Plastic Parts.

5. Good Dimensional Stability: It exhibits good dimensional stability under high temperatures and pressures, ensuring that the molds retain their shape and dimensions throughout the molding process.

6. Cost-Effective: Compared to some other mold steels, 1.2311 Steel is relatively cost-effective while still offering good mechanical properties, making it an attractive choice for many mold-making applications.

In summary, 1.2311 Plastic Mold Steel is important due to its combination of machinability, wear resistance, hardness, polishability, dimensional stability, and cost-effectiveness, all of which are critical factors in the production of high-quality plastic components through injection molding processes.

Sandeep Enterprises reputation as a respected entity within the Steel Industry is well-earned and reflects its unwavering dedication to excellence, quality, and customer satisfaction. By consistently prioritizing these core values, Sandeep Enterprises has solidified its position as a trusted partner for clients across diverse sectors.

The company's commitment to delivering superior Products and Services is evident in its adherence to stringent quality control measures. By maintaining high standards throughout the production process, Sandeep Enterprises ensures that its steel products consistently meet or exceed industry requirements and customer expectations.

#SandeepEnterprises hashtag#Steel hashtag#PlasticMoulding hashtag#InjectionMoulding hashtag#MouldMaking hashtag#SteelAlloy hashtag#Manufacturing hashtag#IndustrialEngineering hashtag#ToolAndDie hashtag#MouldSteel hashtag#InjectionMoulds hashtag#PrecisionMachining

0 notes

Video

youtube

I told you machining is magic! check with your own eys

#youtube#machinery moldmaking mouldmaking machining Plasticmold StampingMold punching CNC Tooling connectors JCTOOLING stamping pressfit EDM Grinding

0 notes

Text

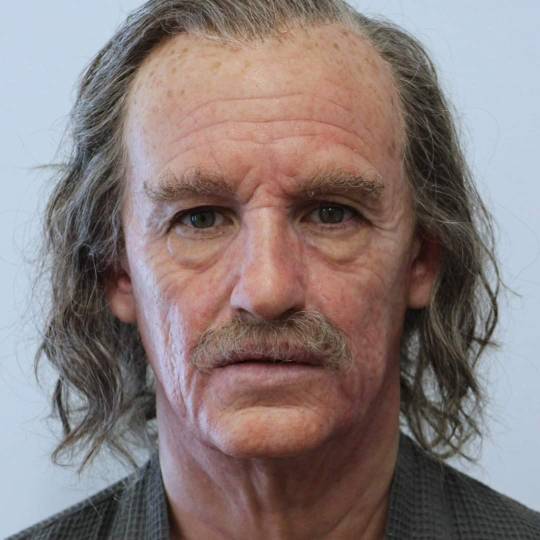

@twlightcreations: ❗️Prosthetic Make-up❗️

•

„The Hunger Games - The Ballade of Songbirds and Snakes“ 2022

@balladofsongbirds

•

Make up test footage from the on camera head shave of Coriolanus, probably the most nerve wracking effect we created for the film.

We designed a partial silicone bald cap including a forehead, that covered the top of the head and blended off the transition with a nape/hair piece in the back and on the sides.

We made 3 copies that got completely hairpunched and took the brave crew so many hours …

•

Make up effects design by @twilightcreations

Sculpted by @jordi_morera_studio

Mold making and Silicone running by @dennis.penkov

Prepainted by @julietteruetz

Hair punching by @transferbrows @chris_mufx @julianhutcheson

Hair piece by @ju.leschauske

Hair color adjustment @maskeberlin

Application on set by @julietteruetz and @anna.kiesser

Supervised by Jörn Seifert

Thank you to hair designer @nikkigooleymakeup and key hair Chrissi Zemura for your support.

•

Thank you to all involved for your untiring effort to get this effect done and achieving such a nice result! 🙏🏼

•

@panem_propaganda

•

#thehungergames #prosthetics #silicone #headshaving #buzzcuts #realisticart #painting🎨 #theballadeofsongbirdsandsnakes #mouldmaking #sculpting #hyperrealism #shavedhair #buzzcutchallenge #lionsgate #twilightcreations #dietributevonpanem #setlife🎬 #haircutdesigns #specialmakeupeffects #specialeffectmakeup #fxmakeupartist #sfxwounds #sfxgore #sfxmakeupart #sfxmakeuptutorial #makeupeffect #specialmakeupfx #specialmakeup

(April 21, 2024)

60 notes

·

View notes

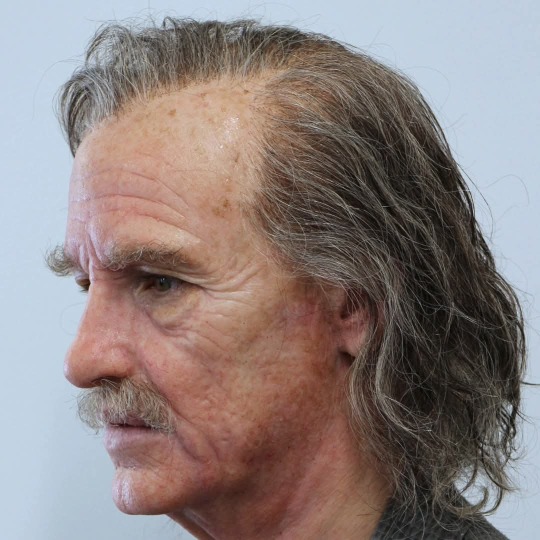

Text

Amazing!!!

#Repost Make up Artist Richard Martin on Facebook : "Now #thedayofthejackal is out in America, I can finally start showing the work we did on the series I can't explain how proud I am of the work we did on this and will be forever greatfull for the opportunity to be Prosthetic Designer to Mr Redmayne for this show.

In episode 1, I was tasked with creating Ralph Becker. A heavy smoking down and out janitor. Director Brian Kirk explained it was to be the opening scene, and he wanted Eddie to be completely unrecognisable. He also had to face the real Ralph Becker who he had killed, so we had to create a full Becker dummy which was very exciting.

Here's Eddie in his Becker disguise without his aged contact lenses. I'll post more behind the scenes on how we created the make up and the body next week.

Prosthetic designer: Richard Martin

3d digital artist: Adam Edwards

Mouldmaker: Tim Quinton

Sculptor: Richard Martin

Silicone runner :Richard Martin

Wigs and facial hair: Andrew Whiteoak

Teeth: Fangs FX

Contact Lenses: Cantor Barnard

15 notes

·

View notes

Text

Nov 11 - Long-ass day. Had two different appointments at the diabetes clinic in town. Started the morning off with the dietitian, which went quicker than the allotted time since it turns out I was already doing almost everything right and had decent ideas, based on what he covered, on what changes I could try making to improve things further (mostly more veggies, some additional things I could keep on hand for snacking purposes, and being more consistent about always having proteins/fats with any fruit or starches). The legacy of having a father, brother, and BIL who are (or were) all Type II diabetic.

Then I had a couple hours to kill, which I spent crocheting in the waiting room; got several inches more of the scarf done, and my yarn spinner admired by one of the desk staff who has a friend who knits (and who now has an Xmas present idea). Will definitely finish off the current skein of yarn tomorrow, but thankfully tracking says the second cake of it will probably also be delivered tomorrow.

Afternoon appointment was with the chiropodist, to get casts made of my feet for orthotics to be made, so my bad right foot will be properly supported. That was fun, I spent it lying on my stomach and gossiping while she did things with plaster that my surface neuropathy meant I couldn't really feel, and the position meant I couldn't see either. Only have any idea of what she was actually doing because there was a handy chart on the wall nearby explaining how to apply the casting kit (and also in my attempt at art college back in prehistoric times, I took mouldmaking & foundry as an elective, so I already knew the general process of making moulds of an object - and yes, I have some small bronzes I cast).

Once I was finally home again in late afternoon, I had yesterday's vat of spaghetti sauce to divide up and freeze, plus a couple bulk packs of ground beef to do ditto with. Also the load of laundry from yesterday to put away, since I didn't do it right away. Argh. Must stop that particular procrastination. That way lies bad habits. Like living out of the laundry basket. Or floor closets.

Supper was pasta with meat sauce and a salad.

1 note

·

View note

Text

Okay but I think I know what the difference is between these two.

My guess is that the grungy non-stinky clay is a sulfur-free clay.

Sculpted clay is often what's used as the model for silicone mouldmaking and if you try to cast sulfur clay in silicone, it'll never set.

The stinky clay is a little easier to work with, but the non stinky stuff you can cast.

Labels that leave you with more questions than they answer

401 notes

·

View notes

Video

youtube

RAYING MOULD THANK YOU & WISH YOUR BUSINESS IS BOOMING

Mold was shipped out.🥳🥳🥳

Thank you for all the supports and trust❤️❤️❤️

wish all of your business is booming🌹🌹🌹

#casting #injectionmold #molding #toolings #mouldmaker #plasticinjectionmould #diecastings #pressuremachine #injectionmachine #toolingsolutions #mouldmaker #moulds

0 notes

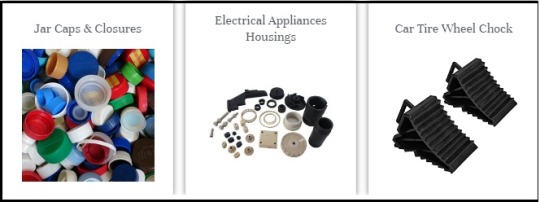

Photo

As an injection molding company in China, Oem plastics manufactures plastic products used in food and drink packaging, medicine and other applications.

China Oem plastics provides advanced injection molding, high pressure blow molding, injection moulding and other related services. You can get a customized service from us as per your requirement. We are capable to meet all your expectations while providing products at the best price to our clients all over the world.

Precision injection molding companies in china is one of the most powerful manufacturing techniques available to you. Unlike other processes, precision injection molding can produce parts at incredibly high speeds without any damage to the part or significant additional costs. This offers great advantages in terms of product performance and efficiency as well as reducing production costs, realizing cost savings and enhancing competitiveness in production.

China Advanced Materials Equipment Co. Ltd (Trading) is a leading manufacturer of injection molding machines, mold transfer machines and CNC machining equipment in China. We also provide high-performance mouldmaking services such as injection moulding and tool room technology.

China Plastic Injection Molding can solve your plastic mold problems for any size and model. Our injection molding Companies in china technology is the most advanced in the world, with more than 30 years of excellent experience. We are able to produce prototypes of all types of plastic molds from small scale to large series production.

China E-Molding, who possesses a highly efficient and professional molding equipment and experienced mould engineers, is achieving their growth by establishing cooperation with many famous enterprises in the United States and overseas. The main products are injection molded plastic cups, various bottles and jars, display structure parts and all kinds of decorative materials. We can also provide injection molding services according to your requirements.

China Omeplastics produces injection molding machines, thermal mixing machines and other large precision plastic processors.

Welcome to CIM Plastic, one of the leading injection molding companies in China. We are ready to make your plastic parts as you wish.

China OE Plastic is an injection molding company located in China. Providing moulds, covers and core/inner components; our services includes engineering design, tooling design and prototype production. We pursue mutual success through quality service to our customers.

0 notes

Video

youtube

Mould Making Process | Precision CNC Machining

Mould making with precision CNC machining ensures high-quality, durable parts. Watch our detailed process in action. Ideal for industries needing custom moulds.

Website: https://kd-cncmachining.com/ Email: [email protected]

0 notes

Text

What are the key properties and applications of P20 Steel Grade, and how does it compare to other tool steel grades in terms of performance and versatility?

P20 Steel, also known as P20 tool steel, is a versatile and widely used mold steel with several key properties and applications:

Key Properties of P20 Steel:

1. Excellent Machinability: P20 Steel exhibits good machinability, allowing for easy shaping and fabrication of molds and components.

2. High Hardenability: It has high hardenability, meaning it can be hardened throughout its cross-section when properly heat-treated, resulting in excellent wear resistance.

3. Good Polishing Ability: P20 Steel can be polished to a high surface finish, making it suitable for applications requiring fine detail and aesthetic appeal.

4. Good Toughness: P20 Steel offers good toughness, which helps prevent cracking and chipping during use, enhancing the durability of molds and components.

5. Excellent Dimensional Stability: It maintains its shape and size even under high temperatures and pressures, ensuring precision and consistency in molded products.

Applications of P20 Steel:

1. Injection Molding: P20 Steel is widely used for manufacturing injection molds for plastic components due to its excellent polishability, wear resistance, and dimensional stability.

2. Extrusion Dies: It is also used in the production of extrusion dies for plastic and rubber processing, where high wear resistance and toughness are required.

3. Die Casting: P20 Steel finds applications in die casting dies for non-ferrous metals, providing good thermal conductivity and resistance to thermal fatigue.

4. Forming Tools: P20 steel is used to manufacture forming tools, such as bending and stamping dies, where high wear resistance and toughness are essential.

Comparison with Other Tool Steel Grades:

1. Compared to H13 Steel: While H13 Steel offers higher heat resistance and hardness retention at elevated temperatures, P20 steel is preferred for applications requiring polishability, ease of machining, and excellent wear resistance at lower temperatures.

2. Compared to D2 Steel: D2 Steel offers higher wear resistance and edge retention compared to P20 steel, but it may be more difficult to machine and polish. P20 steel is often chosen for applications where polishability and machinability are critical.

3. Compared to S7 Steel: S7 Steel provides superior impact resistance and toughness compared to P20 steel, but P20 steel offers better wear resistance and dimensional stability, making it more suitable for applications requiring high precision and surface finish.

In summary, P20 Steel stands out for its excellent combination of machinability, polishability, wear resistance, toughness, and dimensional stability, making it a preferred choice for a wide range of tooling and mold-making applications in the manufacturing industry.

Sandeep Enterprises stands as a respected entity within the Steel Industry, underscored by its unwavering dedication to excellence, quality, and customer satisfaction. With a steadfast commitment to delivering superior products and services, Sandeep Enterprises has established itself as a trusted partner for clients across various sectors. From stringent quality control measures to innovative solutions tailored to meet diverse industry needs, Sandeep Enterprises consistently strives to exceed expectations. This dedication to excellence permeates every aspect of its operations, cementing its reputation as a leader in the Steel Industry.

#SandeepEnterprises#P20Steel#ToolSteel#Engineering#MoldMaking#InjectionMolding#ExtrusionDies#DieCasting#FormingTools#SteelIndustry#Manufacturing#PrecisionEngineering#P20PlasticMouldSteel#MouldMaking#Tooling#InjectionMoulding#PlasticManufacturing#SteelAlloy#MouldDesign#P20#PlasticIndustry

0 notes

Text

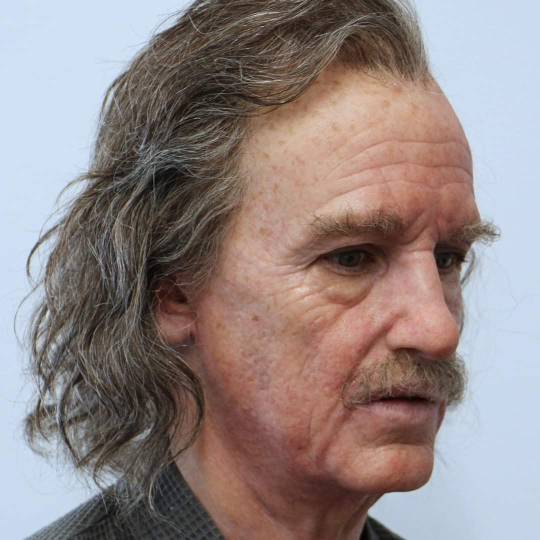

More behind the scenes of The Day of the Jackal.

📸 & 🎥 #Repost Prosthetic Designer Richard Martin on Instagram and Facebook.

Prosthetic designer: @richard_martin4

3d digital artist: @adamedwardstech

Mouldmaker: @tim_quinton_art

Sculptor: @richard_martin4

Silicone runner :@richard_martin4

Wigs and facial hair: @alexrousewigs

Teeth: @fangsfx

Contact Lenses: @cantorbarnard

On Set application: @richard_martin4 and @sarahpanigadasfx

On set lens technician:@saram.kovacs

Hair, make up, and prosthetic designer: @frannyvdfeyst

instagram

#eddie redmayne#eddieredmayne#redmayne#the day of the jackal#the jackal#behind the scenes#richard martin#Instagram

14 notes

·

View notes

Photo

Zoom Technologies is a professional service provider in the field of mould manufacturing and die cast mould tooling industries. ZT offers built-to-order standard mould bases, custom machined mould tooling and variety of mould tooling components gun drilling jobs, all kind of critical machining jobs

1 note

·

View note

Photo

So been waiting to post this one, my first ever 2 part lead casting mould made for my good man @clemence_roofing thanks for having faith in me with it. #finial #finaials #leadroofing #leadfinials #leadmould #leadsmelting #leadcasting #2partmould #metalcasting #leadart #leadworkersuk #smellycatcreations #smellycatcreationsproducts #mouldmaking #mouldmaker #roofers #ukroofers #leadchillcast #chillcast #aluminiummoulds #kingslynn #norfolkuk #norfolkmaker #smallbusiness #architecture #metalart (at King's Lynn, Norfolk) https://www.instagram.com/p/Cc5qUL1Ivaq/?igshid=NGJjMDIxMWI=

#finial#finaials#leadroofing#leadfinials#leadmould#leadsmelting#leadcasting#2partmould#metalcasting#leadart#leadworkersuk#smellycatcreations#smellycatcreationsproducts#mouldmaking#mouldmaker#roofers#ukroofers#leadchillcast#chillcast#aluminiummoulds#kingslynn#norfolkuk#norfolkmaker#smallbusiness#architecture#metalart

0 notes