#microfluidic cartridges

Explore tagged Tumblr posts

Text

High-Transparency Ostemer 322 Crystal Clear Polymer for Microfluidics and MEMS Applications

Discover Ostemer 322 Crystal Clear, a dual cure polymer with exceptional transparency and bonding capabilities. Ideal for microfluidic cartridges, MEMS antennas, and rapid prototyping, this material ensures high precision and reliability in advanced applications. Contact A-Gas Electronic Materials for expert solutions.

#Ostemer 322 Crystal Clear UK#dual cure polymer UK#microfluidic cartridges#MEMS antennas#hybrid material integration UK#UV cure polymer UK#heat cure polymer UK#microfluidics#rapid prototyping#A-Gas Electronic Materials#high transparency polymer UK#lab-on-chip technology UK

0 notes

Text

0 notes

Text

AlphaFold2 Rapid Drug Discovery Vision Break Boundaries

Nuclera wants to use Google DeepMind to expedite the drug discovery process &Vertex AI’s AlphaFold2

The rapid protein access benchtop system from Nuclera, a biotechnology company based in the US and the UK, is being combined with AlphaFold2 (ref 1), a ground-breaking protein structure prediction tool from Google DeepMind, to serve the life science community. AlphaFold2 is hosted on Google Cloud’s Vertex AI machine learning platform.

Since proteins make about 95% of therapeutic targets, there is a growing need to generate various variants of active proteins to facilitate drug development. In particular, the discovery of compounds and biological leads requires accurate protein structure prediction.

The structural biology and drug development industries have been enthralled by AlphaFold2, a groundbreaking artificial intelligence tool that DeepMind published in 2021, since it represents a significant advancement in the accuracy of protein structure prediction (ref 2).

Combining the technologies of Google and Nuclera offers drug developers a new integrated approach to enhance protein construct creation and speed up the drug discovery process. Laser-guided protein design will soon be possible with the availability of high grade structures in a matter of minutes or hours. Furthermore, available will be dependable structures for proteins deemed “impossible” to describe experimentally.

Producing meaningful protein

Drug development relies heavily on the accessibility of proteins for lab-based research, which is notoriously expensive and difficult to acquire, placing time and budget constraints on research potential.

With its benchtop eProtein Discovery technology, Nuclera enables life science researchers to extract active proteins from DNA with the goal of improving human health. By combining digital microfluidics with cell-free protein synthesis on Smart Cartridges, Nuclera’s technology enables quick development on protein projects using an automated, high-throughput benchtop protein access system.

How Nuclera’s AlphaFold2 fits in: guided protein design

AlphaFold2 is an artificial intelligence (AI) model created by DeepMind that predicts the 3D structure of a protein based on its 1D amino acid sequence. It has been widely lauded as a breakthrough in biological research and a step forward in the production of vaccines and synthetic materials.

Nuclera’s cloud-based software will use AlphaFold2, which runs on Google Cloud’s Vertex AI, as a key component to enhance the quality and obtainability of proteins. With the use of Nuclera’s cloud software, users may now determine the best protein designs and conditions for protein scaling based on the results of expression and purification screens.

By providing an additional in silico filter during the experiment design phase, AlphaFold2’s integration with the eProtein Discovery Software improves the quality of constructs screened on the system and increases the likelihood of finding a truly optimal target protein on which to develop discovery programs. Moreover, AlphaFold2 will give users of eProtein Discovery profound insights into potential target protein designs, including any effects on folding, structural characteristics, and drug interactions.

Alphafold2 implementation on Vertex AI pipelines

Even though the AlphaFold2 algorithm has enormous potential, it’s vital to remember that it needs an operational model and serving infrastructure.

Predicting the structure of a protein requires a lot of computing power. Scaling up inference workflows can present difficulties, including as managing experiments, maximizing hardware resource consumption, and minimizing inference elapsed time.

In order to enable inference at scale, the Vertex AI solution for AlphaFold 2 prioritizes the following optimizations:

Parallelizing separate phases in the inference pipeline optimizes it.

utilizing the best hardware platform for each stage to maximize hardware usage and, consequently, expenses. The solution automatically provisioned and deprovisioned the computing resources needed for a step as part of this optimization.

presenting a strategy to experiment tracking that is both flexible and resilient, making it easier to execute and analyze hundreds of concurrent inference operations.

In order to create a scalable and resource-efficient AlphaFold pipeline, Nuclera will leverage the Vertex AI platform. Additionally, the company will leverage other Google Cloud services to expose the pipeline via an API and link it with its eProtein Discovery system.

What does the implementation setup entail?

The first goal that AlphaFold2 and Nuclera will accomplish is building a scalable API service that will allow users to access an AlphaFold2 instance running on Google Cloud. Secondly, a dashboard for analytics will be developed that will enable users to compare projected 3D structures for protein variations both statistically and graphically. Third, a feature called “protein of interest” (POI) recommendation will use intelligent selection algorithms to suggest to users potential synthetic protein variants (isoforms, truncations, mutations, orthologs, or fusions), while accounting for a number of constraints like conserved domains or computationally generated scores.

The relevance of eProtein Discovery/AlphaFold2’s application

With the aid of AlphaFold2’s 3D structural insights, Nuclera and its clients will be able to enhance the efficiency of their protein variant manufacturing procedure and learn more about the intricate relationships that exist between residues and the 3D folding protein structure.

The composite predictions provided by the AlphaFold2 module of the eProtein Discovery Software will help customers all over the world gain a better understanding of their proteins and make more informed decisions more quickly. This will ultimately save time needed to advance academic research and successfully find new drugs.

“AlphaFold2 integrated with Nuclera’s eProtein Discovery System is a really exciting demonstration of its practical use in drug discovery, enabling researchers to rapidly and efficiently design and produce proteins with the desired structure and function,” said Shweta Maniar, Global Director, Healthcare & Life Sciences Solutions, Google Cloud.

They are thrilled to be leading the way in the development of AI/ML-assisted drug discovery tools, which believe will accelerate the development of next-generation treatments. They are collaborating with Google Cloud and utilizing the amazing capabilities of AlphaFold2. Visit our GitHub repository to explore this solution in more detail and to test the universal and monomer pipelines that are included. The repository’s artifacts are made to allow for customization.

Read more on Govindhtech.com

0 notes

Text

Microfluidics

Microfluidics, Nature Biotechnology, Published online: 17 April 2023; doi:10.1038/s41587-023-01739-2Recent patents relating to microfluidic devices and methods for high-throughput phenotyping and sample preparation methods…, 2023-04-17 00:00:00, US 11598707 A handheld medical analyzer platform and biological microelectromechanical systems (BioMEMS) cartridges. The combined system uses…

View On WordPress

0 notes

Text

Space Station Science Highlights: Week of June 22, 2020

ISS - Expedition 63 Mission patch. June 26, 2020 Crew members aboard the International Space Station conducted research on liquid phase sintering in space, measuring neutron radiation aboard the station, and the properties of wet foam during the week of June 22.

Image above: This image of Earth taken from the space station shows a Saharan dust cloud that has blown over the Atlantic Ocean nearing the Caribbean Sea. The Progress 74 resupply ship from Russia is in the left foreground. Image Credit: NASA. Now in its 20th year of continuous human presence, the space station provides a platform for long-duration research in microgravity and for learning to live and work in space. NASA’s Commercial Crew Program, once again launching astronauts on American rockets and spacecraft from American soil, increases the crew time available for science on the orbiting lab. Here are details on some of the microgravity investigations currently taking place: Sintering space exploration materials

Image above: NASA astronaut Doug Hurley works on operations for the Electrolysis Measurement investigation, which examines the influence of gravity on electrolytic gas evolution. Animation Credit: NASA. The crew exchanged cartridges to run the Materials Science Laboratory Sample Cartridge Assembly-Gravitational Effects on Distortion in Sintering (MSL SCA-GEDS-German) investigation. Sintering is the process of heating different materials to compress their particles together. Liquid phase sintering is a way to fabricate materials for a wide range of applications such as tools and automotive engine parts. In the future, the process could be used for in-space fabrication and repair, making replacement components from metal powder during extraterrestrial exploration, and fabricating structures on the Moon using lunar regolith. This experiment focuses on forecasting density, size, shape, and properties for liquid phase sintered bodies in different gravity conditions.

Image above: Example of a liquid phase sintered tungsten alloy. The MSL SCA-GEDS-German investigation looks at forecasting density, size, shape, and properties for liquid phase sintered bodies in different gravity conditions. Image Credit: San Diego State University. Rating radiation risk Neutrons produced when cosmic rays strike the atoms of a spacecraft or the human body can pose a risk to the health of astronauts. An investigation from the Canadian Space Agency, Radi-N2 Neutron Field Study (Radi-N2), characterizes the neutron radiation environment aboard the space station using eight bubble detectors that measure only this type of radiation. During the week, crew members deployed detectors for the investigation, which are attached at fixed locations inside the space station and carried by a crew member. Radi-N2 follows a previous investigation, RaDI-N, to help reveal the sources of neutron exposure and support development of appropriate protective measures for future spaceflights. Watching bubbles grow and rearrange

Image above: Image from a run of the Electrolysis Measurement investigation examining the influence of gravity on electrolytic gas evolution. The process passes an electric current through a substance to separate out gases in the form of bubbles and could be used in microfluidic devices to produce oxygen in spacecraft and future human habitations on the Moon and Mars. Image Credit: NASA. Solid and liquid foams are used in everything from detergents to food products, medicine, oil cleanup, and firefighting. On Earth, it is difficult to study foams because gravity quickly breaks them down, but that problem goes away in microgravity. Using the Fluid Science Laboratory (FSL), a multiuser facility designed by the ESA (European Space Agency) for conducting fluid physics research in microgravity, FSL Soft Matter Dynamics - Hydrodynamics of Wet Foams (FOAM) studies bubble size and rearrangement dynamics for wet or liquid foams. A better understanding of those properties could help industry improve processes using foams. During the week, crew members exchanged sample containers for the ESA investigation. Other investigations on which the crew performed work: - Capillary forces, the interaction of a liquid with the solid sides of a narrow tube that acts to draw the fluid up the tube, act even in the absence of gravity. Capillary Driven Microfluidics examines capillary flow in small devices to improve understanding of how it works in microgravity. Microfluidic devices could be used to develop more portable, robust, and affordable medical diagnostic tools to protect the health of astronauts on future long-term missions. https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7377 - Electrolytic Gas Evolution Under Microgravity (Electrolysis Measurement) examines the influence of gravity on electrolytic gas evolution. This process, which uses electrodes to pass an electric current through a substance and separate out gases in the form of bubbles, could be used in microfluidic devices to produce oxygen in spacecraft and future human habitations on the Moon and Mars. https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1939 - Acoustic Diagnostics, an investigation sponsored by ESA (European Space Agency), tests the hearing of crew members before, during, and after flight to assess possible adverse effects of noise and the microgravity environment of the space station. https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7898 - Plasma Kristall-4 (PK-4), a collaboration between the ESA (European Space Agency) and the Russian Federal Space Agency (Roscosmos), studies complex plasmas, low temperature gaseous mixtures of ionized gas, neutral gas, and micron-sized particles. The particles can become highly charged and interact with each other, leading to self-organized structures called plasma crystals. https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1192

Space to Ground: Channeling Energy: 06/26/2020

Related link: Expedition 63: https://www.nasa.gov/mission_pages/station/expeditions/expedition63/index.html Commercial Crew Program: https://www.nasa.gov/exploration/commercial/crew/index.html MSL SCA-GEDS-German: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1762 Radi-N2 Neutron Field Study (Radi-N2): https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=874 RaDI-N: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=190 FOAM: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7934 Spot the Station: https://spotthestation.nasa.gov/ ISS National Lab: https://www.issnationallab.org/ Space Station Research and Technology: https://www.nasa.gov/mission_pages/station/research/overview.html International Space Station (ISS): https://www.nasa.gov/mission_pages/station/main/index.html Images (mentioned), Animation (mentioned), Video (NASA), Text, Credits: NASA/Michael Johnson/John Love, Lead Increment Scientist Expedition 63. Best regards, Orbiter.ch Full article

12 notes

·

View notes

Text

Application of Parylene film in rubber seals and MEMS

1 Rubber seal

Because the mechanical properties and chemical resistance of parylene film are good, and its friction coefficient is small, close to that of PTFE, it has been used to improve the performance of rubber seals and prolong the service life of the seals.

The researchers filmed parylene coating thickness of 0.1 to 3 μm on the surface of the silicone rubber gasket to reduce the surface energy and volatile content of the silicone rubber material, and reduce the adsorption of particles and fibers in the air by the silicone rubber gasket. . This silicone rubber gasket can be used in computers and electronic equipment.

The researchers filmed N-type, C-type, or D-type parylene on the surface of the silicone rubber gasket to improve the oil absorption and exudation resistance of the silicone rubber gasket. The parylene coating thickness is at least 2.5 μm, preferably 5.0 μm, which is very effective in improving the hydrocarbon oil resistance of the silicone rubber and reducing the permeability of the hydrocarbon oil to the silicone rubber gasket. This surface-modified silicone rubber gasket can be used as a gasket in an engine.

Researchers filmed parylene on typical laboratory bell-shaped coupons, rubber sheets, and blocks, as well as fuel system rubbers made from fluoroelastomers, hydrogenated nitrile rubbers, nitrile rubbers, and silicone rubbers. Basic research was carried out on the item. It was concluded that the parylene coating on the elastomeric seal improved the volume swell performance. Especially for silicone rubber, it not only improves the volume swelling performance but also improves or maintains the key physical properties of silicone rubber. Parylene coating has a wide range of applications in automotive fuel systems, especially for alcohol-containing fuel systems, such as O-rings, static seals, fuel level indicator systems, entire filter cartridges, buoys, etc.

2 MEMS

With the further development of microelectromechanical systems (MEMS) technology, parylene is more and more favored in the field of MEMS due to its unique advantages, and it is used in microstructures to integrate microfluidic systems. Silicone rubber has a low modulus of elasticity and high elongation is compatible with integrated circuit processes and can achieve good sealing even on rough surfaces. But silicone rubber is permeable and absorbs a lot of fluid for driving. Therefore, a composite membrane composed of silicone rubber and parylene can be used in micromechanical fluid membrane valves and pumps, and the respective advantages of silicone rubber and parylene can be retained. The parylene film can effectively block the vapor of 3M fluorine-containing liquid, and the silicone rubber layer further improves the firmness of the composite film.

In the thermally actuated microvalve made of etc., a silicone rubber film coated with parylene is used. Due to the good mechanical strength of parylene, the microvalve has no effect under high fluid pressure. damage, while effectively preventing the leakage of steam while ensuring that the film has a larger stroke. The development of biological microelectromechanical systems (BioMEMS) requires the use of biocompatible materials, which further promotes the application of parylene films on BioMEMS such as implantable microsystems, which contain silicone rubber and parylene films. Microsystems can be used to deliver therapeutic drugs.

Maggie Nano Technology (Suzhou) Co., Ltd. provides customers with high-quality parylene coating services for supporting automated intelligent equipment. We are committed to manufacturing professional parylene conformal coating equipment. Parylene conformal coating equipment Model MQP-9001 is one of our products, you can click to view more details.

Related news of parylene coating

Examples of protective applications of parylene coatings

The application value of parylene ink and wash element clothing

Color fixation of parylene coating in ink element clothing

0 notes

Text

New smartphone clip-on can detect Zika virus in blood samples -- LiveScience.Tech

As seen with the COVID-19 pandemic, detection methods that are rapid, simple, accurate, and sensitive are vital for detecting viral pathogens and for controlling the spread of infectious diseases. Unfortunately, laboratory-based methods often require trained personnel and involve complex procedures. In a new study, researchers at the University of Illinois Urbana-Champaign have combined their efforts to develop an instrument that can be clipped on to a smartphone to rapidly test for Zika virus in a single droplet of blood.

Zika virus is primarily transmitted through Aedes aegypti mosquitoes. Although the disease is largely asymptomatic or results in mild symptoms in adults, it causes developmental disorders in newborn babies if their mothers are infected during early pregnancy. Currently, the virus is circulating in more than 87 countries, infecting thousands of people annually, necessitating better testing and control measures.

“Mosquito-borne viruses cause serious diseases, but they have similar symptoms. If you have Zika, malaria, dengue, or chikungunya, you just might show up to the doctor with a fever and they won’t know why,” said Brian Cunningham (CGD Director/MMG), the Intel Alumni Endowed Chair of Electrical and Computer Engineering. “But it’s important to know whether it’s Zika, especially if the patient is a pregnant woman, because the consequences to a developing fetus are really severe.”

Zika virus infections are currently detected through polymerase chain reaction tests performed in a laboratory, which can amplify the genetic material of the virus, allowing scientists to detect it. In the new study, researchers used Loop-Mediated Isothermal Amplification to detect the virus in the blood samples using an approach suitable for point-of-care clinics. While PCR requires 20-40 repeated temperature shifts to amplify the genetic material, LAMP only requires one temperature — 65 °C — making it easier to control. Additionally, PCR tests are very sensitive to the presence of contaminants, especially the other components in a blood sample. As a result, the sample is first purified before it can be used. On the other hand, LAMP does not require any such purification step.

A cartridge, that contains reagents required to detect the virus, is inserted into the instrument to perform the test while the instrument is clipped onto a smartphone. Once the patient adds a drop of blood, one set of chemicals break open the viruses and the blood cells within five minutes. A heater below the cartridge heats it up to 65 °C. A second set of chemicals then amplifies the viral genetic material, and the liquid inside the cartridge fluoresces bright green if the blood sample contains the Zika virus. The entire process takes 25 minutes.

“The other cool aspect is that we’re doing the readout with a smartphone,” Cunningham said. “We’ve designed a clip-on device so that the smartphone’s rear camera is looking at the cartridge while the amplification occurs. When there’s a positive reaction, you see little green blooms of fluorescence that eventually fill up the entire cartridge with green light.”

The researchers are now developing similar devices to simultaneously detect other mosquito-borne viruses and are working on making the devices even smaller. “Although our clip-on detector is pretty small, a lot of the space is taken up by the batteries. In the next version, it will be powered by the phone’s battery,” Cunningham said.

The study “Smartphone clip-on instrument and microfluidic processor for rapid sample-to-answer detection of Zika virus in whole blood using spatial RT-LAMP” was published in the journal Analyst and can be found at 10.1039/d2an00438k.

The work was carried out in collaboration with Rashid Bashir (CGD/M-CELS), an Abel Bliss Professor of Engineering; Enrique Valera, a research assistant professor of bioengineering; Minh Do, a Thomas and Margaret Huang Endowed Professor of Electrical and Computer Engineering; and William King, a professor of electrical and computer engineering. The study was funded by the National Institutes of Health and the National Science Foundation Partnership for Innovation program.

New post published on: https://livescience.tech/2022/07/30/new-smartphone-clip-on-can-detect-zika-virus-in-blood-samples-livescience-tech/

0 notes

Text

Microfluidic Immunoassay Market - worldwide Forecast to 2025

Microfluidic Immunoassay Market by Product type (Lab-on-chip, percent Analyzers, Reagents and Assay), generation, application (Cardiac, Troponin, BNP) - worldwide Forecast to 2025

• The immunoassay is one of the essential analytical techniques based totally on molecular reputation among antibody and antigen that permits for detection of molecules with excessive specificity and sensitivity. Immunoassays are being extensively used for the quantification of target molecules in lots of programs, which include proteomics, medical diagnostics, pharmaceutical research, and primary organic investigations.

• In recent years, the usage of microfluidic chips for immunoassay has been significantly explored. mixture of microfluidics and immunoassays offers a promising platform for various sensitive and automated point-of-care (p.c) diagnostics.

• Microfluidic systems, additionally termed as lab-on-a-chip and the micro general analysis gadget, have shown promising consequences in immunosensor structures. Microfluidic immunosensors offer huge advantages over conventional immunoassay techniques, which includes a excessive surface-to-quantity ratio for green mass transport in immunoreactions, for that reason permitting for immediate evaluation; a miniaturized micro channel measurement to decrease the intake of samples and reagents; and automatic integration with other features, such as pumps, valves, detectors, and mixers to reap a point-of-care (%) goal.

• Global Microfluidic Immunoassay marketplace is predicted to grow at a CAGR of 12.7% from 2019 to reach $2.01 billion via 2025. Microfluidic immunoassay is swiftly developing enterprise with capability of improving patient health in low-aid settings. % tests are accomplished in vital-care settings, ambulatory centers, physician workplace laboratories, or at patient’s domestic. The % enterprise is growing at a faster pace because of demographic shift and want for excessive throughput prognosis in value effective manner. but, the various present percent gadgets need sample pre-treatment before engaging in the take a look at, produce variable effects, and offer both qualitative, semi-quantitative or negative quantitative check effects. This caused rising recognition on achieving specific and quantitative effects; and miniaturization of p.c devices. microfluidic structures (lab-on-a-chip) have attracted a awesome deal of interest as a miniaturized immunodiagnostic platform. major blessings of LOC include consumption of small volumes of reagents and sample; and transport of precise results with fast turnaround time.

𝐅𝐨�� 𝐌𝐨𝐫𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧, 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐏𝐃𝐅 𝐇𝐞𝐫𝐞➦

https://www.meticulousresearch.com/download-sample-report/cp_id=5034

Key Players

The report includes competitive landscape based on extensive assessment of the key strategic developments adopted by the leading market participants in the industry over the past 4 years (2016-2019). The key players profiled in the global microfluidic immunoassay market are Abaxis, Inc. (a subsidiary of Zoetis Inc.), NanÅmix, Inc., Abbott Laboratories, Koninklijke Philips N.V., Biosurfit SA, Micropoint Bioscience, Inc., Siloam Biosciences, NanoEnTek Inc., OPKO Health, Inc., and Quidel Corporation among others.

Any Doubt, Enquire Here :

https://www.meticulousresearch.com/enquire-before-buying/cp_id=5034

Scope of the Report:

Market by Product Type

Microfluidic Analyzers

Microfluidic Cartridges

POC Analyzers

Reagents and Assays

Market by Technology

Electrochemical LOC POC Technology

Optical POC LOC Technology

Market by Application

Troponin

Brain Natriuretic Peptide (BNP)

Other Cardiac Biomarkers

Market by Geography

Japan

China

India

Rest of Asia-Pacific (RoAPAC)

Key questions answered in the report-

How does the LOC/microfluidics diagnostics increase the efficiency and adoption of quantitative POC immunoassay diagnostics?

How are the leading players utilizing the advantages of LOC/microfluidics diagnostics in their products?

What factors are contributing to the frequent usage of cardiac biomarkers in various end users?

How does the adoption of cardiac biomarker differ from other application?

What are the top competitors in this market and what strategies do they employ to gain shares?

What factors are driving growth and which market segments have the most potential for revenue expansion over the forecast period?

What strategies should new companies look to enter this market use to compete effectively?

What are the major drivers, restraints, challenges, and opportunities, in the global microfluidic immunoassay market?

Who are the major players in various countries and what share of the market do they hold?

What are the geographical trends and high growth regions/countries?

About Us :

We are the trusted research partners for leading businesses around the world, providing market intelligence focused towards building revenue transformation strategies. Our research is used by Fortune 500 organizations to attain success by scouting next generation revenue opportunities well ahead of their competition.

Through our mixed bag of research offerings – syndicated research, custom research, and analyst engagement — we enable smart decision making to enhance business performance for global organizations. Our focus is also on finding answers to the challenging questions that global business leaders face on a daily basis. Each year, we deliver more than 300 syndicate studies and 60+ consulting projects across eight industry verticals in 20+ geographic markets.

𝐅𝐨𝐫 𝐌𝐨𝐫𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧, 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐏𝐫𝐞𝐦𝐢𝐮𝐦 (Pages 194)𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞➦

https://www.meticulousresearch.com/Checkout/74264832

Contact: Mr. Khushal Bombe Meticulous Market Research Inc. 1267 Willis St, Ste 200 Redding, California, 96001, U.S. USA: +1-646-781-8004 Europe : +44-203-868-8738 APAC: +91 744-7780008 Email- [email protected]

1 note

·

View note

Photo

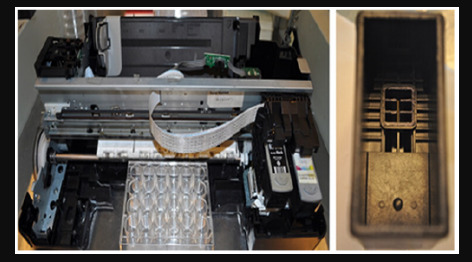

. This type of lens does not change over time. Simple static lenses can be fabricated straight onto cartridges. For instance, bent surfaces assembled into microfluidic channels can be used as cylindrical lenses.

On the other hand, periodic arrays of microlens arrays can be fitted and attached over a cartridge's detection area. This allows concurrent detection at various sites. Also, lenses with varying focal lengths can be incorporated on microfluidic cartridges.

0 notes

Text

Biomed Grid | Automatic Generation of Drug Concentration Gradient by a Modified Ink-jet Printer and its Application in Drug Screening

Abstract

Manual preparation of drug concentration gradient is labor-intensive and limits the efficiency of a drug screening to some extent, especially at large scale. In this study, we reported an automatic method to generate drug concentration gradient in 24-well plate. We loaded drug solution in a modified hot ink-jet printer, designed printing pattern in the WORD software, customized the concentration gradient in the WORD software by RGB coding, and finally printed the drug concentration gradient in the 24-well plate. A drug concentration gradient can be automatically generated within 5s in arbitrary pattern. Based on this flexible technology, we developed an ink-jet printer-based drug screening assay. Concentration gradient of 5-fluorouracil, as well as Mcf-7 cells, were printed in the 24-well plate, and the inhibition rate of Mcf-7 cells was measured by MTT method. This was the first time that hot inkjet printing technology was used in drug screening.

Keywords: Bioprinting; Drug screening; Concentration gradient; Ink-jet printer; RGB

Introduction

Preparation of a concentration gradient of drug candidate is a prerequisite to study cell-drug interaction quantitatively. Currently, this step is manually operated in the laboratory, which is labor intensive and annoying. Automation is desirable in practice. Derringer et al. developed an automatic method to generate concentration gradient [1], and Ye et al. [2] used this method in drug screening [2,3], however, this method was only applicable in microfluidic device, not in 96-well or 24-well plate, thus its applications were limited. Previously, we established drug screening device based on biomedical engineering methods [4]. In this study, we developed a method to generate concentration gradient in plate automatically, using normal commercial ink-jet printer and WORD software. We also used the same printer to print the cell suspension, thus we finally developed a drug screening assay based on hot ink-jet printing. Hot ink-jet printing technique is useful for printing cells in biomedical engineering. It works by the principle in which the heating element turns the “biological inks” into bubbles at bottom of the nozzle instantly and the pressure generated makes a certain amount of inks free from the surface tension there and pushed from the nozzle. As an approach for cell printing, hot ink-jet printer has been used in tissue engineering [5], biological microarray construction [6], stem cell research [7] and gene transcription [8]. However, there are few reports in its application in drug screening at cellular level

In this paper, a hot ink-jet printer was custom-modified as an automatic dispensing tool for the engineering of cell arrays and generation of concentration gradient of drugs in a 24-well plate. By means of this apparatus, cell/drug composite arrays can be automatically generated for drug screening. RGB value was used as the output gauge of drug concentrations for the first time. A Mcf-7 cell/5-fluorouracil composite array was engineered to demonstrate the applicability of the hot ink-jet printer in the drug screening.

Experimental

Materials

Hoechst 33342 fluorescence dye and 3-(4,5-dimethylthiazol-2- yl)-2,5-diphenyltetrazolium bromide (MTT) were purchased from Kubolai inc. Beijing. Propidium iodide was obtained from Jingchun technology inc. Shanghai. 5-fluorouracil was purchased from Sigma- Aldrich, United Kingdom. Phosphorate buffer saline (pH7.4) was prepared and sterilized in lab. DMEM cell culture medium and fetal bovine serum from HyClone, New Zealand, was used in this study. Methanol of HPLC grade from local company was used. Ultrapure water was obtained with Millipore water purification system.

Instruments

Canon PIXMA ip 1980 ink-jet printer with PG830 ink box from Canon, Japan, was modified in this study. Inverted fluorescence microscope IX71 from Olympus, Japan, was used. Agilent 1200 HPLC was from Agilent, USA. Synergy H1 microplate reader was from BioTek, USA (Figure 1). A Canon PIXMA ip 1980 printer and a Canon PG830 ink box for biological printing after modification. The white plate was a 24-well plate used as “paper”.

Modification of the Printer and the Cartridge

A Canon PIXMA ip 1980 hot-injet printer was modified as follows the front cover, paper support, rear tray, paper thickness lever and paper guide were dissembled sequentially while cartridge holder and paper sensor being kept intact. The printer after modification was shown as in Figure 1 (left part). Before use, the body of the printer was sterilized and kept inside an ultraviolet-lighted laminar hood overnight. A Canon PG830 ink box was modified as follows: after the top cover of the ink box was ripped from the main body of the box, the sponge inside the ink box was discarded and the metal filter at the bottom of the box was dismantled with the ink reservoir exposed, followed by a thorough cleanup. The ink box after modification was shown as in Figure 1 (right part). Prior to use, the box was emerged in 75% ethanol and air dried in a laminar airflow, followed by being exposed with ultraviolet light for at least 30 mins.

Figure 1: A Canon PIXMA Ip 1980 Printer and a Canon PG830 Ink Box.

Printing Concentration Gradient of 5-Fluorouracil in the 24-Well Plate

10ml 8mg/ml 5-fluorouracil solution was precisely obtained when 0.08g 5-fluorouracil was dissolved in PBS solution in a 10 ml volumetric flask and filtered through a 0.22 μm diameter membrane to remove possible bacteria. This working solution was loaded in the ink box. The printing pattern was designed in the WORD software with designated RGB values. Clicked the “print” button in the WORD software and the concentration gradient of 5-fluorouracil was automated created in the 24-well plate within 5s. We collected the drug solution printed in each well and analyzed their concentrations with HPLC. In a typical setup, a SB-C18 HPLC column (4.6mm diameter, 250mm long) was used and the sample was detected by ultraviolet absorption with a single wavelength of 265 nm. The temperature of the column was set at 35℃. The volume of each sample was 10 μl and the mobile phase was made of methanol and water (5:95) with a flow rate of 1.0ml/min.

Preparation and Printing of Cell Suspension

Mcf-7 cells of the third generation with a high viability was chosen as the main raw material for preparation of the cell suspension. Prior to being loaded into the ink box, a Mcf-7 cell suspension were prepared by pancreatic digestion, centrifuging, collection, counting and re-suspending. The Mcf-7 cell suspensions were prepared at four different concentrations, 3×106, 6×106, 9×106 and 1.2×107/ml. Following the pattern of a round spot with the diameter of 5 mm, the cell suspension with different densities were printed into a 24-well plate with the modified printer as above. Observation was made with an inverted microscope equipped with a X4 zoom objective.

Counting of Printed Cell Numbers and Viability Analysis

400 μl 10% NCBS culture media was added into the plate loaded with the printed Mcf-7 cells to keep their viability. And 10μl 0.4mg/ml Hoechst 33342 solution was added into the plate at 37℃ for 35mins in the dark, followed by the addition of 10 μl 0.2mg/ ml PI solution for another 10 mins. Then the cell suspension in the plate were collected and centrifuged. The cells from the bottom of centrifuge tube were collected and washed with PBS solution for 3 times. Then the cells washed were re-suspended in 1 ml cell culture medium to form a new cell suspension. 20μl new cell suspension was pipetted out and added dropwise onto a cell counter. Counting of cell number and observation of cells were conducted with an inverted fluorescence microscope with a X 10 zoom objective.

Procedure of Drug Screening

Mcf-7 cells with a high viability was selected for construction of cell/drug arrays. The Mcf-7 cell suspension were prepared by pancreatic digestion, centrifuging, collection, counting, and resuspension with a concentration of 9×106/ml. The Mcf-7 cell suspension was loaded into sterilized a PG830 ink box and printed into 5-mm-diameter round spots in a 24-well plate to form a Mcf-7 cell array. 400μl 10% NCBS culture media was immediately loaded into the plate. After being cultured at 37℃ under 5% CO2 for 24hrs, 8 mg/ml 5-fluorouracil solution were printed into the plate which were already loaded with Mcf-7 cells, with different RGB codes. As a result, cell/drug composite arrays (n=3) were formed. After being at 37℃, 5% CO2 for another 48 hrs, 40μl 5mg/ml MTT solution were loaded into the plate and incubated at 37℃ for 4hrs. Then the supernatant was discarded and 500 μl DMSO was added. The plate was shaken for 15mins to achieve DMSO thoroughly dissolved. Then 200 μl supernatant was collected and transferred into a 96-well plate and the adsorption under 490 nm wavelength was recorded.

Results

Printed Concentration Gradient of 5-Fluorouracil

The printing pattern was designed in WORD software, as shown in Figure 2. Each round spot, corresponding to a well in 24-well plate in location, was 5mm in diameter. These round spots varied in RGB values. We printed drugs following the pattern in Figure 2 and measured the concentration of drug in each well. We plotted the drug concentration in each well, as shown in Figure 3. This technology has five advantages compared to manual method

a) It is automatic;

b) We can obtain arbitrary concentration gradient by customizing the RGB values (Figure 3 A-D);

c) The RGB code value was linearly related to the concentration of printed 5-fluorouracil. This can be expressed as Y = -0.7691X+53.975 with R2 being equal to 0.9878 (Figure 3A);

d) It is fast, and a concentration gradient can be generated within 5s;

e) THE hot inkjet printer was cheaper than a micropipette which is used for manual preparation. (Figure 2)

Figure 2: The Printing Pattern Designed in The WORD Software.

Figure 3: Different Types of Drug Concentration Gradient Printed in the 24-Well Plate.

The printing pattern designed in the WORD software. Each row was designed for generation a specific drug concentration gradient. In the first row, the RGB values from left to right were (20,20,20), (30,30,30), (40,40,40), (50,50,50), (60,60,60), (70,70,70). In the second row, the RGB values from left to right were (70,70,70), (20,20,20), (70,70,70), (70,70,70), (20,20,20), (70,70,70). In the third row, the RGB values from left to right were (20,20,20), (20,20,20), (50,50,50), (50,50,50), (70,70,70), (70,70,70). In the fourth row, the RGB values from left to right were (70,70,70), (70,70,70), (50,50,50), (50,50,50), (20,20,20), (20,20,20). (Figure 3) On the top of each plot was the printing pattern designed in the WORD software, and the number below was RGB value. (Figure 4) (from left to right: 3×106/ml, 6×106 /ml,9×106 /ml), scale bar: 500 μm.

Printing of Mcf-7 Cell Suspension

Figure 4: The Bright Field Images of Printed Round Spots of Mcf-7 Cells with Varied Cell Concentration.

Figure 4 shows the printed pattern of Mcf-7 cells, with different concentration of Mcf-7 suspension loaded in the printer. When the concentrations were 3×106 /ml and 6×106 /ml, the printed round spots were incompletely constructed with sparse distributions of cells. It might be caused by the low concentration of cell suspension. When the concentration was 1.2×107/ml, few inks were injected from the nozzle and the printed round spot was hard to be identified. It might be attributed to the high concentration of the cell suspension which jammed the nozzle. However, when the concentration was 9×106/ml, the printed round spot was full of well-distributed cells. It showed that the cell suspension with a concentration of 9×106/ml is the best-performed one and should be adopted in the experiment.

After counting, the average number of cells in each round spot in the cell array was 3×104. After printing, the viability of the cells was the main gauge which reflects the validity of the cell printing process. Hot ink-jet printing was suspected to cause heat damage or mechanical damage on cells [8]. Hoechst33342 is a membrane permissive dye and emits blue fluorescence under 350 nm excitation after combining with DNA in cells. And PI is only capable of penetrating into dead cells. After PI combines with DNA in cells and emits red fluorescence under 543 nm excitation. Therefore, we can investigate the viability of cells when coupling Hoechst33342 and PI dyes after cell printing. As seen in Figure 5, the number of dead cells which emit red fluorescence is negligible and it supports that the negative effect of our cell printing technique on the viability of printed cells can be ignored (Figure 5).

Figure 5: Microscopic observations of printed cells dyed by Hoechst33342(left) and PI (right), under excitations of 350 nm and 543 nm wavelengths, respectively. Scale bar: 500 μm.

Drug Screening Assay Based on Printing

Table 1: Absorbance by MTT and relative inhibition rate (n = 3).

The concentration of the printed 5-fluorouracil can be pretuned with the RGB code setup from the WORD software. A Mcf-7 cell/5-fluorouracil composite array was formed after incubation for 48 hrs. And the inhibition rate of the experimental group at varied concentrations and the control group were tested with MTT method. And the statistics of their optical absorbance at different RGB values and the relative inhibition rates were listed in Table 1. It can be seen from Table 1 that within the range we investigated, the biological viability of the cells in the composite array increased as the RGB value ramped up. In our experimental setup in which RGB code value was kept between 20 and 70, the concentration of the printed 5-fluorouracil increased as the RGB value dropped. In another word, a low RGB value yielded a cell/drug composite array with a relatively high concentration and dose of 5-fluorouracil. Therefore, as the RGB value was lowered, a stronger interaction between Mcf-7 and 5-fluorouracil was achieved, and a higher inhibition phenomenon occurred. This suggested that the Mcf-7 cell/5-fluorouracil composite array established by our method can be used for the inhibition study of 5-fluorouracil at different concentrations and it possessed the potential of evaluating in vitro cellular viability.

Discussion

Cell printing technique has demonstrated remarkable advantages as following :

a) High precision, cells can be precisely localized and distributed in three dimensions [9];

b) Rapid speed, tissue samples with biological viability can be constructed in a short time;

c) High automation grade, it has the possibility to be industrialized at a large scale [10];

d) Simple to be established and operated, it is straightforward to be modified or upgraded [11].

In our experiment, RGB tuning was used for controlling the output doses of 5-fluorouracil and the hot inkjet technique was adopted to build cell/drug composite arrays. And the viability of the cells in the composite arrays were evaluated. Inspired by the model from Boland ‘s group [11,12], a Canon hot inkjet printer and an ink box were successfully modified into a biological printer. And a Mcf- 7 cell suspension with a concentration of 9×106 cells/ml showed the best printing performance in cell distribution and density on the array. The printed cell array demonstrated patterns with the most complete morphology. By testing the concentration of drug solutions with HPLC, we were able to identify the concentration of 5-fluorouracil on the printed matrix produced from different RGB code value. The results show that high-definition Mcf-7 cell arrays can be constructed with our modified printer and ink box. And moreover, the concentration of 5-fluorouracil arrays can be tuned by changing the RGB color code value. The viability of cells by printing is the major indicator for the feasibility of the printing operation. We used Hoechst33342 and PI to dye the printed cells and applied excitations of 350 nm and 543 nm, respectively. The results showed that hot inkjet printing has little damage on the Mcf-7 cells, and they are in consistency with the literatures [13,14]. Also, we used MTT method to identify the inhibition rate of 5-fluorouracil on Mcf- 7 in the cell/drug array. When RGB code value was 30, the dose of the 5-fluorouracil was 30.09±2.69 μg/ml with a relative inhibition rate of 49.02%. These results supported the feasibility of applying the cell/drug printing method in investigating in vitro cellular viability and it provides new possibility of drug screening based on biological printing.

Conclusion

In this study, we developed an automatic method to generate drug concentration gradient in 24-well plate based on hot inkjet printer. The total time was less than 5s. Arbitrary concentration gradient can be easily generated by RGB coding. The cost of printing equipment was very low. This method is expected to make drug screening experiment more user-friendly.

Read More About this Article: https://biomedgrid.com/fulltext/volume5/automatic-generation-of-drug-concentration-gradient-by-a-modified-ink-jet-printer-and-its-application-in-drug-screening.000876.php

For more about: Journals on Biomedical Science :Biomed Grid | Current Issue

#biomedgrid#american journal of biomedical science & research#Journals on vaccination#Health science Journal of Open access

0 notes

Text

Engineers make clear droplets produce iridescent colors

Engineers at MIT and Penn State University have found that under the right conditions, ordinary clear water droplets on a transparent surface can produce brilliant colors, without the addition of inks or dyes.

In a paper published today in Nature, the team reports that a surface covered in a fine mist of transparent droplets and lit with a single lamp should produce a bright color if each tiny droplet is precisely the same size.

This iridescent effect is due to “structural color,” by which an object generates color simply due to the way light interacts with its geometric structure. The effect may explain certain iridescent phenomena, such as the colorful condensation on a plastic dish or inside a water bottle.

The researchers have developed a model that predicts the color a droplet will produce, given specific structural and optical conditions. The model could be used as a design guide to produce, for example, droplet-based litmus tests, or color-changing powders and inks in makeup products.

“Synthetic dyes used in consumer products to create bright colors might not be as healthy as they should be,” says Mathias Kolle, assistant professor of mechanical engineering at MIT. “As some of these dyes are more strongly regulated, companies are asking, can we use structural colors to replace potentially unhealthy dyes? Thanks to the careful observations by Amy Goodling and Lauren Zarzar at Penn State and to Sara’s modeling, which brought this effect and its physical explanation to light, there might be an answer.”

Sara Nagelberg of MIT, along with lead author Goodling, Zarzar, and others from Penn State, are Kolle’s co-authors on the paper.

Follow the rainbow

Last year, Zarzar and Goodling were studying transparent droplet emulsions made from a mixture of oils of different density. They were observing the droplets’ interactions in a clear Petri dish, when they noticed the drops appeared surprisingly blue. They took a photo and sent it off to Kolle with a question: Why is there color here?

Initially, Kolle thought the color might be due to the effect that causes rainbows, in which sunlight is redirected by rain drops and individual colors are separated into different directions. In physics, Mie scattering theory is used to describe the way spheres such as raindrops scatter a plane of electromagnetic waves, such as incoming sunlight. But the droplets that Zarzar and Goodling observed were not spheres, but rather, hemispheres or domes on a flat surface.

“Initially we followed this rainbow-causing effect,” says Nagelberg, who headed up the modeling effort to try to explain the effect. “But it turned out to be something quite different.”

She noted that the team’s hemispherical droplets broke symmetry, meaning they were not perfect spheres — a seemingly obvious fact but nevertheless an important one, as it meant that light should behave differently in hemispheres versus spheres. Specifically, the concave surface of a hemisphere allows an optical effect that is not possible in perfect spheres: total internal reflection, or TIR.

Total internal reflection is a phenomenon in which light strikes an interface between a high refractive index medium (water, for instance) to a lower refractive index medium (such as air) at a high angle such that 100 percent of that light is reflected. This is the effect that allows optical fibers to carry light for kilometers with low loss. When light enters a single droplet, it is reflected by TIR along its concave interface.

In fact, once light makes its way into a droplet, Nagelberg found that it can take different paths, bouncing two, three, or more times before exiting at another angle. The way light rays add up as they exit determines whether a droplet will produce color or not.

For example, two rays of white light, containing all visible wavelengths of light, entering at the same angle and exiting at the same angle, could take entirely different paths within a droplet. If one ray bounces three times, it has a longer path than a ray that bounces twice, so that it lags behind slightly before exiting the droplet. If this phase lag results in the two rays’ waves being in phase (meaning the waves’ troughs and crests are aligned), the color corresponding to that wavelength will be visible. This interference effect, which ultimately produces color in otherwise clear droplets, is much stronger in small rather than large droplets.

“When there is interference, it’s like kids making waves in a pool,” Kolle says. “If they do whatever they want, there’s no constructive adding up of effort, and just a lot of mess in the pool, or random wave patterns. But if they all push and pull together, you get a big wave. It’s the same here: If you get waves in phase coming out, you get more intensity of color.”

A carpet of color

The color that droplets produce also depends on structural conditions, such as the size and curvature of the droplets, along with the droplet’s refractive indices.

Nagelberg incorporated all these parameters into a mathematical model to predict the colors that droplets would produce under certain structural and optical conditions. Zarzar and Goodling then tested the model’s predictions against actual droplets they produced in the lab.

First, the team optimized their initial experiment, creating droplet emulsions, the sizes of which they could precisely control using a microfluidic device. They produced, as Kolle describes, a “carpet” of droplets of the exact same size, in a clear Petri dish, which they illuminated with a single, fixed white light. They then recorded the droplets with a camera that circled around the dish, and observed that the droplets exhibited brilliant colors that shifted as the camera circled around. This demonstrated how the angle at which light is seen to enter the droplet affects the droplet’s color.

The team also produced droplets of various sizes on a single film and observed that from a single viewing direction, the color would shift redder as the droplet size increased, and then would loop back to blue and cycle through again. This makes sense according to the model, as larger droplets would give light more room to bounce, creating longer paths and larger phase lags.

To demonstrate the importance of curvature in a droplet’s color, the team produced water condensation on a transparent film that was treated with a hydrophobic (water-repelling) solution, with the droplets forming the shape of an elephant. The hydrophobic parts created more concave droplets, whereas the rest of the film created shallower droplets. Light could more easily bounce around in the concave droplets, compared to the shallow droplets. The result was a very colorful elephant pattern against a black background.

In addition to liquid droplets, the researchers 3-D-printed tiny, solid caps and domes from various transparent, polymer-based materials, and observed a similar colorful effect in these solid particles, that could be predicted by the team’s model.

Kolle expects that the model may be used to design droplets and particles for an array of color-changing applications.

“There’s a complex parameter space you can play with,” Kolle says. “You can tailor a droplet’s size, morphology, and observation conditions to create the color you want.”

This research was supported, in part, by the National Science Foundation and the U. S. Army Research Office through the Institute for Soldier Nanotechnologies at MIT.

Description of Filtration Products WebPage: Filtration-Products.com forum assembles the up to date information, conclusions and separation items right from the filtrations business. Filtration-Products.com keeps you familiar on filter and all the main industrial innovation including string wound filters, pleated cartridges, meltblown cartridges, sock filtration, Pre-RO filtration, from brands such as United Filters utilized in air filtration, and anything else the separation field has to reveal.

from Filtration Products https://ift.tt/2H5qspa

0 notes

Text

Better Treatment for Diabetic Foot Ulcers

Better Treatment for Diabetic Foot Ulcers

People with type 2 diabetes often suffer from poorly-healing infected wounds on their feet. Using existing methods, however, it takes two days to grow a bacterial culture used to identify the pathogens infecting the wound and their antibiotic resistance – and thus to find an effective antibiotic. With the help of a new rapid test developed by Fraunhofer researchers, it will take just one hour to…

View On WordPress

0 notes

Text

Microfluidic Immunoassay Market by Product type (Lab-on-chip, percent Analyzers, Reagents and Assay), generation, application (Cardiac, Troponin, BNP) - worldwide Forecast to 2025

• The immunoassay is one of the essential analytical techniques based totally on molecular reputation among antibody and antigen that permits for detection of molecules with excessive specificity and sensitivity. Immunoassays are being extensively used for the quantification of target molecules in lots of programs, which include proteomics, medical diagnostics, pharmaceutical research, and primary organic investigations.

• In recent years, the usage of microfluidic chips for immunoassay has been significantly explored. mixture of microfluidics and immunoassays offers a promising platform for various sensitive and automated point-of-care (p.c) diagnostics.

• Microfluidic systems, additionally termed as lab-on-a-chip and the micro general analysis gadget, have shown promising consequences in immunosensor structures. Microfluidic immunosensors offer huge advantages over conventional immunoassay techniques, which includes a excessive surface-to-quantity ratio for green mass transport in immunoreactions, for that reason permitting for immediate evaluation; a miniaturized micro channel measurement to decrease the intake of samples and reagents; and automatic integration with other features, such as pumps, valves, detectors, and mixers to reap a point-of-care (%) goal.

• Global Microfluidic Immunoassay marketplace is predicted to grow at a CAGR of 12.7% from 2019 to reach $2.01 billion via 2025. Microfluidic immunoassay is swiftly developing enterprise with capability of improving patient health in low-aid settings. % tests are accomplished in vital-care settings, ambulatory centers, physician workplace laboratories, or at patient’s domestic. The % enterprise is growing at a faster pace because of demographic shift and want for excessive throughput prognosis in value effective manner. but, the various present percent gadgets need sample pre-treatment before engaging in the take a look at, produce variable effects, and offer both qualitative, semi-quantitative or negative quantitative check effects. This caused rising recognition on achieving specific and quantitative effects; and miniaturization of p.c devices. microfluidic structures (lab-on-a-chip) have attracted a awesome deal of interest as a miniaturized immunodiagnostic platform. major blessings of LOC include consumption of small volumes of reagents and sample; and transport of precise results with fast turnaround time.

𝐅𝐨𝐫 𝐌𝐨𝐫𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧, 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐏𝐃𝐅 𝐇𝐞𝐫𝐞➦

https://www.meticulousresearch.com/download-sample-report/cp_id=5034

Key Players

The report includes competitive landscape based on extensive assessment of the key strategic developments adopted by the leading market participants in the industry over the past 4 years (2016-2019). The key players profiled in the global microfluidic immunoassay market are Abaxis, Inc. (a subsidiary of Zoetis Inc.), NanÅmix, Inc., Abbott Laboratories, Koninklijke Philips N.V., Biosurfit SA, Micropoint Bioscience, Inc., Siloam Biosciences, NanoEnTek Inc., OPKO Health, Inc., and Quidel Corporation among others.

Any Doubt, Enquire Here :

https://www.meticulousresearch.com/enquire-before-buying/cp_id=5034

Scope of the Report:

Market by Product Type

Microfluidic Analyzers

Microfluidic Cartridges

POC Analyzers

Reagents and Assays

Market by Technology

Electrochemical LOC POC Technology

Optical POC LOC Technology

Market by Application

Troponin

Brain Natriuretic Peptide (BNP)

Other Cardiac Biomarkers

Market by Geography

Japan

China

India

Rest of Asia-Pacific (RoAPAC)

Key questions answered in the report-

How does the LOC/microfluidics diagnostics increase the efficiency and adoption of quantitative POC immunoassay diagnostics?

How are the leading players utilizing the advantages of LOC/microfluidics diagnostics in their products?

What factors are contributing to the frequent usage of cardiac biomarkers in various end users?

How does the adoption of cardiac biomarker differ from other application?

What are the top competitors in this market and what strategies do they employ to gain shares?

What factors are driving growth and which market segments have the most potential for revenue expansion over the forecast period?

What strategies should new companies look to enter this market use to compete effectively?

What are the major drivers, restraints, challenges, and opportunities, in the global microfluidic immunoassay market?

Who are the major players in various countries and what share of the market do they hold?

What are the geographical trends and high growth regions/countries?

About Us :

We are the trusted research partners for leading businesses around the world, providing market intelligence focused towards building revenue transformation strategies. Our research is used by Fortune 500 organizations to attain success by scouting next generation revenue opportunities well ahead of their competition.

Through our mixed bag of research offerings – syndicated research, custom research, and analyst engagement — we enable smart decision making to enhance business performance for global organizations. Our focus is also on finding answers to the challenging questions that global business leaders face on a daily basis. Each year, we deliver more than 300 syndicate studies and 60+ consulting projects across eight industry verticals in 20+ geographic markets.

𝐅𝐨𝐫 𝐌𝐨𝐫𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧, 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐏𝐫𝐞𝐦𝐢𝐮𝐦 (Pages 194)𝐑𝐞𝐩𝐨𝐫𝐭 𝐇𝐞𝐫𝐞➦

https://www.meticulousresearch.com/Checkout/74264832

Contact: Mr. Khushal Bombe Meticulous Market Research Inc. 1267 Willis St, Ste 200 Redding, California, 96001, U.S. USA: +1-646-781-8004 Europe : +44-203-868-8738 APAC: +91 744-7780008 Email- [email protected]

0 notes

Text

ISS Daily Summary Report – 6/24/2020

TangoLab-2 (Space Tango MultiLab Locker): The crew successfully performed troubleshooting steps to recover commanding capability for Tangolab-2 card 14. TangoLab-2 is a reconfigurable general research facilities designed for microgravity research and development and pilot manufacturing in the ISS. Capillary Driven Microfluidics: The crew performed a plate changeout in order to begin the 4th cartridge run. … from NASA https://ift.tt/31nqu5I via IFTTT

0 notes

Link

https://ift.tt/2LMQtKW

The RAPID Hardware Accelerator program that provides early-stage startups with funding and product development support switched from in-person to completely virtual until NextFab’s facilities reopen to the public.

After the City of Philadelphia announced restrictions on commercial activity in March, NextFab closed its facilities to the public, but decided to move forward with its 12-week RAPID Hardware Accelerator program known for its funding and product development support available to early-stage companies.

“We received 140 applications from startup teams from around the world. And after a rigorous selection process only 5 companies were accepted in NextFab’s 2020 Spring Cohort. This happened just before the City of Philadelphia made the announcement and we decided that using web conferencing instead of postponing the program would help us keep the momentum going for these startups.” says Todor Raykov, NextFab’s Venture Services Manager.

“Switching to virtual meetings actually proves very helpful right now, because some of the teams are based in different cities. Now, they can still get support from the program’s business and technical advisors without having to relocate here.” Todor Raykov, NextFab’s Venture Services Manager.

Meet the five teams:

THE MOST

THE MOST designs and manufactures new tech-enabled products for textured hair maintenance and styling. As is the case for many businesses, COVID has presented unanticipated challenges and obstacles for them. Luckily, their team has taken these challenges in stride. It has offered them an opportunity to think critically and entrepreneurially about this new world and the opportunities it offers.

With NextFab, THE MOST had the opportunity to sit in on virtual programming and learn from region experts. They’re also shoring up on the fundamentals and putting the right accounting, legal, and other infrastructure in place. With NextFab, they have had some breakthroughs about their business and the true value they can offer their consumers. These type of business epiphanies have allowed them to build out their brand and connect with consumers more deeply so that they are better positioned for the sale post-product development. When asked, they said in many ways, their team is stronger because of COVID-19. It forced them to come off of auto-pilot and engage more thoughtfully in the creative and entrepreneurial process. Grounded in NextFab’s expert guidance, they’re eager to see the yields over the coming months.

GoGGa

According to the World Health Organization (WHO), 1 in 10 people are affected by foodborne disease, leading to the loss of 33,000,000 healthy life years annually. Globally, food poisoning accounts for 420,000 deaths every year, with children accounting for almost 1/3 of those deaths. This is in addition to almost 40% of fresh fruits and vegetables that go to waste due to spoilage.

GoGGa LLC, in collaboration with AAPlasma LLC, is developing an inexpensive and scalable solution for sanitation of fresh fruits and vegetables from harvest, processing, transportation, and storage. Within 30 minutes of treatment, they observed an 8-log (99.999999%) reduction in E.coli, Listeria, Salmonella, and B.cereus on the surfaces of spinach, kale, lettuce, and strawberries. With the help of the NextFab Accelerator team, GoGGa is scaling up their lab system for mass production.

Running a business during the COVID-19 pandemic can be challenging. But, the team at GoGGa had an opportunity to pivot their technology for disinfection of personal protective equipment (PPE). Together with NextFab and other manufacturing partners, they have designed, prototyped, and are now producing the personal PPE Sterilizer (model CP-PPE-2020-1) that can sterilize PPEs for up to three users in about 20 minutes.

Ravata Solutions

For hundreds of couples struggling with infertility, they ultimately seek out assistance from the medical practice of in-vitro fertilization. Unfortunately, this experience can be a frustratingly emotional and fiscally challenging. Infertility can be caused by both physiological and social factors, and with limited insurance coverage for procedures, combined with a 70% failure rate, makes these procedures impossible for those with limited time and resources.

Ravata Solutions is a medical device company in the Assisted Reproductive Technologies (ART) industry developing a suite of automated systems for the $1.1B animal and $4.76B human In-Vitro Fertilization (IVF) markets. They have developed a microfluidic diagnostic sensor to assess the quality of oocytes, sperm, and embryos during the IVF process. This will help address challenges in reproducible and expected outcomes for patient treatments.

Ravata Technology

With their process standardization and by collecting information on patients, human single embryo transfer success rates have the potential to improve up to 40%. Preceding fulfillment of human IVF regulatory requirements, Ravata now provides IVF laboratory automation by offering application specific bio-chips for gene editing, viability based sorting of in vitro fertilized embryos, and sorting of cryo-recovered sperm.

Andluca Technologies

Buildings are the leading consumer of energy in the United States. Most were constructed over three decades ago with windows that are responsible for up to 30% of building energy consumption. Window replacement is disruptive and often expensive, yet over half of existing buildings will still be in use in 2050.

Andluca, a Princeton University spin-out, has developed UV-solar-powered smart glass for improving the energy efficiency of buildings. Andluca’s patented solar-powered electrochromic glass can reduce building energy use by up to 30% and improve occupant productivity by 2+%. Their smart windows are easily installed in existing buildings, unlike the current wired smart window products.

NextFab’s support and the RAPID hardware accelerator curriculum have allowed Andluca to accelerate product development and maintain their go-to-market roadmap, despite COVID-19 disruptions. Resources like industry mentors and connections have positioned them for success through and beyond the pandemic.

VOLTA Therapeutics

Volta Therapeutics is dedicated to creating automation technology platforms that enable end-to-end cell therapy process development and accelerate the delivery of life saving solutions to the patient’s bedside. The Volta platform focuses on automating various biological processes such as cell isolation, gene editing, final formulation. It’s also testing the processing cartridges linked in a closed system environment.

They are developing this platform for therapy organizations in need of customizable and scalable solutions. The benefits of their technology could disrupt the cell therapy industry by reducing the supply chain complexity, overhead costs and clean room infrastructure requirements. This is in addition to improving the scalability and quality needed to develop cellular therapies.

Come see the 5 startups pitch their ideas during Venture Café Philadelphia’s virtual Thursday Gathering on June 18. Registration link will be available HERE.

Interested in joining a future hardware accelerator cohort and receiving funding and product development support for your hardware startup? The application window for the RAPID Hardware Accelerator’s 2020 Fall cohort opens on June 19th.

Apply Here

The post NextFab’s Hardware Accelerator Goes Digital Due to COVID-19 appeared first on NextFab.

0 notes

Text

Innovation in Micro-fluidic Technology

Microfluidic technology basically refers to the manipulation, precise control and behavior of small scale volumes of fluids. It is a technology that basically processes liquids by separation, mixing and transporting. The fluids are supplied continuously with the help of a micro pump within a micro-fluidic device.

On chip bio surface technology was primarily used in the fabrication of micro-thermal devices, micro-propulsion equipment, Lab on a Chip devices, DNA chips and inkjet printers in the early 1980s. It has applications in many fields such as biotechnology, nanotechnology, biochemistry, physics, chemistry and engineering. Despite the low volume of the liquids on a microfluidics device, it performs many complex functions automatically.

Micro-Fluidic Devices

Micro fluidic devices are the apparatus which contains and processes the micro-fluidics liquids. Some of these devices may require modifications even after the complete production process such as coatings and treatments to their surfaces, integration of specific molecules, inclusion of magnets etc.

These treatments result in the device to be more repulsive or attracted to water. They are then packed into cartridges or holders made of plastic. These devices are proving to be very useful in biological applications, as the experiments can be controlled and precise with a lower cost and a faster pace. The point of use also remains direct which is not possible in conventional laboratories.

The Next Generation of Immunoassay Analysis

The immunoassay testing device is simple to use, reliable and scalable. These devices work on detecting or identifying the presence of certain substances in the sample, with the help of an antibody as a reagent. These devices are widely being used in laboratories and hospitals to perform various tests for cancer, allergies and therapeutic drugs.

A clinical lab can run thousands of tests on a daily basis, but the results come out with the same quality each time with these testing devices. All these devices have a standard set of features such as assay protocols, test menus, reference ranges or instrumental processes.

Liquid Biopsy Cancer Detection

Liquid biopsy cancer detection refers to the monitoring of the dynamic alterations of a tumor through exosomes or other fluid samples. It is proving to be a multimodal diagnostic tool in the hands of clinical oncology. The process includes sample preparation, data analysis and data interpretation.

It has facilitated a timely monitoring of the progression of a tumor when compared to a traditional biopsy. The Liquid Biopsies are helping the hospitals in identifying the cancer drivers, monitoring the progression of the cancer and detection of the recurrence of the tumor.

Liquid Biopsy is providing a complete and precise picture of the cancer genome. It is resolving many technical hurdles in a wide range of settings in the field of cancer. It is also creating a revolution by opening avenues to unexpected perspectives. They are proving to become the future standards of cancer management all over the world.

Zepto Life Technology, LLC offers a variety of micro-fluidic and immunoassay testing devices that will help in optimizing the time in a clinical laboratory, guaranteeing a reliable performance of the testing devices.

0 notes