#mica strip heaters

Explore tagged Tumblr posts

Text

Mica Strip Heaters: Your Ultimate Guide to Safe and Effective Heating

Safety meets efficiency with our range of mica strip heaters. Designed to meet diverse heating requirements, these heaters are a cut above the rest.

#mica strip heaters#mica heater#flexible mica heater#band heater with thermostat#custom mica band heater#mica band heater manufacturer#band heaters for pipe

0 notes

Text

Radiant Heat: Unveiling the Excellence of Chhaperia – Premier Mica Heater Manufacturers in India

Introduction:

In the realm of electrical heating solutions, Chhaperia Electro Components Pvt. Ltd. stands tall as a beacon of excellence, particularly renowned for its expertise in mica heaters. As one of India's foremost manufacturers in this niche, Chhaperia has garnered acclaim for its commitment to quality, innovation, and customer satisfaction. In this article, we delve into the world of Chhaperia, exploring its contributions to the field of mica heaters and its impact on the Indian market.

Pioneering Excellence:

Chhaperia's journey in the realm of mica heater manufacturing is marked by a legacy of pioneering excellence. With decades of experience and a relentless pursuit of perfection, the company has established itself as a trusted name in the industry. From its inception, Chhaperia has been driven by a passion for innovation, continuously pushing the boundaries of technology to deliver cutting-edge heating solutions tailored to diverse applications.

Uncompromising Quality:

At the core of Chhaperia's ethos lies an unwavering commitment to quality. Each mica heater produced undergoes rigorous testing procedures to ensure adherence to international standards and specifications. Utilizing premium-grade materials and advanced manufacturing techniques, Chhaperia maintains impeccable quality control throughout the production process, guaranteeing the reliability, efficiency, and longevity of its heaters.

Diverse Product Portfolio:

Chhaperia offers a comprehensive range of mica heaters catering to a myriad of industrial and commercial applications. Whether it's band heaters, strip heaters, cartridge heaters, or custom-designed solutions, the company boasts versatility in its product offerings. With the ability to tailor heaters to specific requirements such as voltage, wattage, dimensions, and mounting options, Chhaperia ensures optimal performance and compatibility across various sectors.

Technological Innovation:

Innovation is the cornerstone of Chhaperia's success story. The company continually invests in research and development to stay abreast of emerging trends and technological advancements in the field of electrical heating. By embracing state-of-the-art machinery, materials, and design methodologies, Chhaperia enhances the efficiency, functionality, and safety features of its mica heaters, setting new benchmarks for industry standards.

Customer-Centric Approach:

Chhaperia places utmost importance on customer satisfaction, adopting a proactive and responsive approach to meet client needs. With a focus on prompt delivery, after-sales support, and continuous feedback mechanisms, Chhaperia fosters enduring relationships built on trust and mutual success.

Sustainable Practices:

As sustainability takes center stage in today's global landscape, Chhaperia remains committed to eco-friendly manufacturing practices. The company emphasizes resource efficiency, waste minimization, and recycling initiatives to reduce its environmental footprint. By prioritizing sustainability, Chhaperia not only fulfills its corporate social responsibility but also contributes to a greener, more sustainable future for generations to come.

Conclusion:

In the dynamic arena of electrical heating solutions, Chhaperia Electro Components Pvt. Ltd. shines as a beacon of excellence, redefining standards of quality, innovation, and customer satisfaction. With a rich legacy of pioneering excellence, a diverse product portfolio, and a customer-centric ethos, Chhaperia continues to lead the way in mica heater manufacturing in India. As the company charts a course towards greater heights, it remains steadfast in its commitment to excellence, driving progress, and innovation in the ever-evolving landscape of electrical heating technology.

0 notes

Text

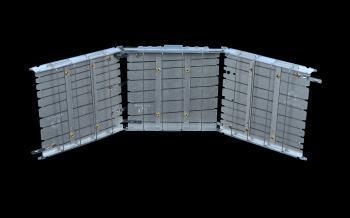

Mica Strip Heater

Searching for a dependable Mica Strip Heater manufacturer in Canada? Your Search ends here! We are your reliable partner, offering top-of-the-line Mica Strip Heaters for all your industrial heating requirements. Embrace the ease of same-day delivery on your orders. Don’t wait any longer – secure your heating needs with our efficient solutions. Trust in our quality products and order your Mica Strip Heaters today for consistent and reliable performance in industrial applications.

We provide special mica band heaters capable of 800 ⁰F Operating Temperatures which is required temperatures in many plastic, packaging and medical laboratories. The construction normally involves a high temperature mica sheet uniformly wound with Nickel-chrome resistance wire housed in aluminized steel sheath for maximum heat transfer. Clamping and terminals have various option.

Mica strip heaters have become an integral part of industrial heating systems, delivering reliable and efficient heat transfer across a broad range of applications. As a leading manufacturer, we take pride in producing high-quality mica strip heaters that excel in performance, durability, and versatility

As a leading manufacturer of mica strip heaters, we provide reliable and efficient heating solutions for a wide range of industrial applications. Our commitment to quality, performance, and customization options ensures that our customers receive tailored heating solutions that meet their specific requirements. With rapid heat-up, uniform heating, temperature stability, and energy efficiency, our mica strip heaters offer exceptional performance and versatility. Count on us to deliver reliable and efficient heating solutions that maximize productivity and ensure consistent results across various industries.

#heatingsolutions#efficientheating#heatingexperts#industrialapplications#reliableheating#temperaturecontrol#industrialheating#qualityproducts#energyefficiency#samedaydelivery

0 notes

Text

I've been through this many times on many forums, even with electricians, so what's one more time? Yes, a cheap no-name power strip might melt etc. It's truly scary what's inside some of those, and you shouldn't be using them with anything really. But a good power strip will provide more protection than your wall outlet. At most your outlet will have an AFCI and a circuit breaker behind it, possibly just an old-fashioned fuse in older construction. A good power strip will often have full voltage/current and thermal protection as well. Stick to vendors who have a reputation to protect (I like Anker or Tripp Lite), and check the specs - especially current rating - for the particular item you're using.

Lastly, there's an important warning that's missing here. Try not to plug anything else, especially other high-current devices, into the same circuit (breaker/fuse) as a heater. That applies regardless of who you believe on the power-strip issue. No matter what any outlet or power strip is rated for, multiple devices will push it closer to its limits.

Also, different types of heaters have different safety profiles. Anything with a fan is inherently very unsafe. Anything with resistance coils that glow red will scarcely be better. Oil heaters are better except for the tipping hazard. The safest option is a heater that distributes the heat across a larger mass and surface area, with mica being a popular option. Such heaters will usually come with a thermostat and their own electrical/thermal protection, making them safer than many laptop chargers which people almost universally leave on overnight.

Be cautious with any kind of high-current electrical devices in your house, certainly, but also be rational about what the risks are and how to minimize them.

SPACE HEATER WARNING

As this cold front is moving in I wanna remind everyone of some space heater safety tips!

1: ALWAYS plug them into a wall outlet, never ever into an extension cord or surge protector! It will melt!!!!

2: Keep clothes, curtains, bedsheets, and any other flammable materials away from the heater, especially the coils!

3: Never leave your space heater on over night!! My rule is that the space heater cannot be turned on if I’m not in the room, or I’m not conscious.

Please reblog this (and feel free to add other safety tips) to help keep some people safe!

3K notes

·

View notes

Text

Why Is Mica a Popular Choice for Heating Elements?

Mica heating elements are quite popular in industrial heating systems. Mica is used in strip heaters, plate heaters, and integrated temperature control and monitoring systems designed for industrial applications. Mica has gained significant popularity in industrial heating systems due to its typical properties , and it is an integral part of several high-temperature industrial heating systems. What makes mica a popular heating element? This post discusses the different properties of mica and its significance as a heating element in industrial heating systems.

Properties of Mica

Mica is a natural mineral that occurs in the form of thin sheets. This mineral possesses varying concentrations of potassium, aluminum, iron, magnesium, and water. It is greatly popular in temperature-centric operations due to its high watt density and high temperature capabilities. Mica provides crystal stability in humid locations and offers excellent insulating properties; therefore it is very popular in electronic heating systems.

The thermal properties of mica sheet are not the only reason for its popularity. Its electrical, chemical, and mechanical properties also make this material desirable in industrial applications. The following pointers will help you understand its properties better.

Electrical Properties: Mica offers a wide range of electrical properties such as uniform capacitance, low power loss, high dielectric strength, high electrical resistance, and a low thermal coefficient. These properties allow mica to be stable under electrical exposure, making it suitable for use in electric heating systems.

Chemical Properties: Mica is a stable mineral. It does not react with water, alkalis, acids, oils, etc. Since mica maintains its stability during chemical interactions, it is highly suitable for tactical industrial applications.

Thermal Properties: Mica can resist temperatures up to 1000°C. It offers high thermal stability as it non-flammable, and its low thermal conductivity makes it an excellent thermal insulator.

Mechanical Properties: Mica sheet offers mechanical properties such as high tensile strength, toughness, elasticity, etc. This means that mica can be easily machined or hand-cut while maintaining the flexibility of the material.

Different Applications of Mica in Thermal and Temperature Control Systems

Mica has a wide scope of applications in different industries that require thermal systems. The following are a few examples.

Mica heaters are used in various types of industries such as chemical detection, semiconductors, commercial and industrial thermal control, and monitoring units. They are also used in various complex thermal industrial systems.

Mica strips or plate-type heaters are also used in temperature control and monitoring units across industries.

Although mica is of great significance and has a wide scope of applications throughout industries, its performance depends on the quality of the mica used and of the manufacturing. These factors impact the effectiveness of mica-based heating systems. This is why mica-based industrial heating systems must be sourced from trusted manufacturers. Changchun Taiyuan Fluorophlogopite Co. Ltd. is One of The Leading Mica Sheet, Synthetic Mica Flake, Fluorophlogopite Mica Manufacturer & Suppliers in China. Wholesale Synthetic Mica Flake for Sale.

0 notes

Text

Choosing the right Industrial Heaters in Bangalore

ELECTRON Systems has started producing high-quality Industrial Heaters in Bangalore because of its considerable knowledge and experience in the industrial heaters industry. There are many KW levels and capacities for these air heaters. These air heaters come in various designs, including Finned Strip Heaters and Tubular Air Heaters. These are created and constructed using premium materials, including nickel chrome and SS 304.

How to Choose a Commercial Heater?

Numerous applications for industrial heaters exist. Heat is employed in drying procedures to produce steam, which evaporates moisture from materials. Additionally, the production of many other goods, such as concrete and asphalt, requires industrial heaters.

Here, you will see how to choose the best industrial heating element for your needs and selecting the right kind of heater for your project.

Commercial Heaters

Industrial heaters convert thermal energy from fuel or another energy source into that energy in a closed environment, process stream, or system. The process by which thermal energy is transferred from an energy source to a system is known as heat transfer.

Industrial heating elements are the most crucial parts of any industrial heating system. No matter the application, choosing the right industrial heating element will boost efficiency and save time and money.

Important Inquiries to Make When Choosing an Industrial Heater

Ask the right questions to acquire the necessary data before you purchase a heater. These inquiries should centre on the best methods for heating the solid, liquid, or gas in your industrial process and the heating components needed to get those outcomes. Some of the most crucial factors to take into account are as follows:

What type of heat source ought to be used? What temperature should your heating element operate at? What kind of control are you looking for? What voltage is the bare minimum? What is the anticipated duration of the heating element's operation?

You'll be able to make a speedier and more educated purchase if you know the answers to these questions in advance.

Applications for Different Industrial Heaters

Buyers should consider the qualities of various heater types when purchasing industrial heaters. Industrial heaters are available in various combinations, sizes, and shapes. Some of the most typical types are as follows:

An air heater

Examples of this type of heater include forced air appliances, space heaters, and radiators.

Rotational Heaters

Warming moving, flowing, or circulating fluid streams are done with circulation heaters. As the fluid flows through the heater, it warms.

HVAC Systems

Duct heaters warm the moving air or gas that travels through a duct.

Adaptable heaters

Flexible heaters can be shaped to heat a certain shape.

Heaters for Immersion

Such a heater needs to be inserted into the material it is heating.

Space heaters

The best solution for small rooms is a space heater. In general, they are safe to use, non-emitting, and portable.

Industrial heaters are crucial in various industrial applications, such as annealing, heat treating, curing/tempering, drying, melting, and OEM/custom heating. Long-term safety, cost-effectiveness, and efficiency benefit from selecting the proper heater for the task.

Ready to Choose an Industrial Heater?

One of the biggest providers and manufacturers of industrial heaters in Bangalore, India, is us. Since more than 20 years ago, Electron Systems has specialized in manufacturing industrial heaters, temperature controllers, thermocouples, sensors, and other products. Ceramic heaters, mica band heaters, cartridge heaters, bobbin heaters, manifold heaters, air heaters, tubular heaters, oil immersion heaters, cast-in heaters, coil heaters, infrared heaters, and more are among the industrial heaters we provide. Behind the company are several driven individuals who work incredibly hard to bring innovative ideas to market so that you may buy the greatest items for the lowest costs. These individuals include testers, designers, product developers, and others.

0 notes

Text

Flat heaters

Elmec mineral filled heaters are designed and developed to replace Mica Strip heaters. These heaters provide trouble free long lasting service even at high temperatures and watt density. Helically wound coil is placed inside a tube filled with MgO and pressed to get a flat surface.

Features

Available in SS304,SS316 and Iconel sheath.

Max watt density 10w/sq cm

Max operating temperature 450 °C

Screw or Wire terminals.

Applications

Plastic processing machinery

Tank heating.

Zinc and Lead melting pots.

Bag cutting and sealing machine.

0 notes

Text

3 Ways Mica Strip Heaters Can Boost Your Production Line Efficiency

In the industrial sector, efficiency is not just a buzzword but the backbone of profitability and productivity. One of the unsung heroes in the realm of industrial machinery is the mica strip heater. These versatile and durable heaters play a crucial role in various manufacturing processes. Here's how incorporating mica strip heaters can significantly enhance the efficiency of your production line.

1. Precise Temperature Control

Mica strip heaters are renowned for their ability to provide uniform and precise temperature control. This precision is vital in manufacturing processes where even a slight deviation in temperature can result in product defects or inconsistencies. For instance, in the plastic industry, accurate temperature control ensures that the material is heated uniformly, leading to better moldability and higher-quality end products.

Moreover, these heaters are designed to respond quickly to temperature adjustments, minimizing downtime between production cycles. This rapid response is crucial in maintaining a continuous and efficient production line, reducing waste, and increasing output.

2. Energy Efficiency

Energy consumption is a significant concern for any industry. Mica strip heaters are engineered to be energy-efficient, offering high thermal conductivity and ensuring that the heat is distributed evenly across the surface. This efficiency means that less energy is wasted in the form of excess heat or uneven heating, leading to lower energy bills and a smaller carbon footprint for your business.

In addition, mica strip heaters' robust construction ensures their long service life, reducing the need for frequent replacements and the associated downtime and costs.

3. Versatility and Durability

The versatility of mica strip heaters allows them to be used in a wide array of applications, from heating tanks and platens to providing heat for processing pipes and other cylindrical objects. This adaptability means they can be integrated into various points of a production line, wherever precise heat is needed.

Furthermore, these heaters are built to withstand harsh industrial environments. They are resistant to moisture and chemicals, reducing the likelihood of failure and ensuring consistent performance over time. This durability translates to fewer interruptions in the production process, maintaining a steady and efficient workflow.

Conclusion

Incorporating mica strip heaters into your production line can offer significant advantages in terms of efficiency, energy consumption, and consistent quality. Their precision, durability, and versatility make them an invaluable asset in various industrial applications, ultimately boosting your bottom line. By leveraging the capabilities of these heaters, you can enhance the overall productivity and efficiency of your manufacturing processes, setting your business on the path to greater success.

#mica heater#mica strip heater#band heaters for pipe#mica band heater manufacturer#band heater with thermostat#custom mica band heater#mica band heater supplier#flexible mica heater

0 notes

Text

Innovative Heating Solutions: Exploring the Features and Benefits of Band Heater with Thermostat Technology

In the realm of industrial heating solutions, precision, efficiency, and reliability are paramount. Manufacturers across various industries rely on advanced technologies to ensure consistent and controlled heating processes that meet their specific production requirements. One such innovative solution gaining traction is the utilization of band heater with thermostat technology. In this blog, we'll delve into the features and benefits of these cutting-edge heating solutions and explore how they are revolutionizing industrial applications.

Understanding Band Heater with Thermostat Technology

Band heaters are versatile heating elements designed to wrap around cylindrical surfaces such as pipes, barrels, or extruder barrels to provide uniform and efficient heat transfer. When combined with thermostat technology, these band heaters offer precise temperature control, allowing users to maintain desired heating levels with ease. Thermostat-equipped band heaters utilize sensors and control systems to monitor and regulate temperatures, ensuring optimal performance and energy efficiency.

Features

Integrated Temperature Control: The primary feature of band heater with thermostat technology is their ability to regulate temperatures automatically. Integrated sensors detect variations in temperature and adjust heating output accordingly, maintaining consistent and precise levels of heat.

Customizable Temperature Settings: Users can program thermostat-equipped band heaters to achieve specific temperature ranges tailored to their application needs. This customization ensures optimal heating performance and prevents overheating or underheating of materials.

User-Friendly Interface: Many band heaters with thermostat technology feature user-friendly interfaces, allowing operators to monitor temperature settings, adjust parameters, and troubleshoot any issues quickly and efficiently.

Compact and Space-Saving Design: These band heaters are designed to be compact and space-saving, making them suitable for installations where space is limited. Their low-profile design ensures minimal interference with existing equipment and processes.

Benefits of Band Heaters with Thermostat Technology

Enhanced Precision: Band heater with thermostats ensure precise temperature control, minimizing overheating or underheating for improved efficiency and reduced waste.

Energy Efficiency: Thermostat-equipped band heaters maintain optimal temperatures, minimizing energy consumption and promoting sustainable practices.

Increased Productivity: Automated temperature control allows operators to focus on other tasks, boosting productivity and overall manufacturing efficiency.

Extended Equipment Lifespan: Consistent heating from thermostat-equipped band heaters prolongs equipment life by preventing overheating and reducing maintenance needs.

Conclusion

Band heater with thermostat technology represent a significant advancement in industrial heating solutions, offering precise temperature control, energy efficiency, and enhanced productivity. With their customizable settings, user-friendly interfaces, and compact design, these heaters are well-suited for a wide range of industrial applications across various industries. By harnessing the features and benefits of band heaters with thermostat technology, manufacturers can optimize their heating processes, improve product quality, and drive innovation in their operations. Shop these from Marathon Heaters for adding a quality unit to the heating devices. There are multiple kinds of these available.

#flexible mica heater#mica band heater supplier#custom mica band heater#band heater with thermostat#mica band heater manufacturer#band heaters for pipe#mica strip heater#mica heater

0 notes

Text

Chhaperia: Redefining Comfort with Innovative Mica Heaters in India

In the dynamic landscape of heating solutions, Chhaperia emerges as a beacon of innovation and excellence, particularly in the domain of Mica heaters. Renowned as one of the premier mica heater manufacturers in India, Chhaperia has consistently raised the bar by blending advanced technology with a commitment to quality, reliability, and customer satisfaction.

Craftsmanship and Quality: At the heart of Chhaperia's ethos lies an unwavering dedication to craftsmanship and quality. Each mica heater manufactured by Chhaperia undergoes rigorous quality control processes, ensuring impeccable performance and longevity. With meticulous attention to detail and adherence to international quality standards, Chhaperia's mica heaters are trusted by clients across diverse industries.

Customization Capabilities: Recognizing that every heating requirement is unique, Chhaperia prides itself on its unparalleled customization capabilities. Whether it's size, shape, wattage, or voltage specifications, Chhaperia's team of experts collaborates closely with clients to design and fabricate bespoke mica heaters tailored to their specific needs. This commitment to customization ensures that clients receive heating solutions that seamlessly integrate into their processes and deliver optimal performance.

Innovative Engineering: Innovation is the cornerstone of Chhaperia's approach to mica heater manufacturing. This relentless pursuit of innovation has led to the development of cutting-edge mica heaters that are energy-efficient, reliable, and cost-effective, setting new benchmarks for the industry.

Comprehensive Product Range: From mica band heaters to mica strip heaters, Chhaperia offers a comprehensive range of mica heating solutions to cater to diverse applications. Whether it's plastic processing, packaging machinery, or food processing equipment, Chhaperia's extensive product portfolio ensures that clients find the perfect mica heater for their specific requirements.

Responsive Customer Support: Chhaperia places immense value on building long-term partnerships with its clients, and responsive customer support is integral to this commitment. From initial consultation to after-sales service and support, Chhaperia's dedicated team is readily available to address client queries and ensure a seamless experience throughout the lifespan of their mica heaters.

Commitment to Sustainability: As a socially responsible organization, Chhaperia is committed to sustainability and environmental stewardship. The company continually explores eco-friendly materials and manufacturing processes to minimize its carbon footprint and contribute to a greener future.

Global Presence: While rooted in India, Chhaperia's influence extends far beyond national borders. The company exports its high-quality mica heaters to a global clientele, earning acclaim for reliability, performance, and innovation.

In conclusion, Chhaperia stands as a testament to excellence in mica heater manufacturing in India. With a steadfast focus on quality, customization, innovation, and customer satisfaction, Chhaperia continues to redefine comfort and efficiency in the realm of heating solutions. Whether it's enhancing industrial processes or ensuring thermal comfort, Chhaperia's mica heaters are synonymous with reliability, performance, and unparalleled craftsmanship.

0 notes

Text

Mica Strip Heater Manufacturer Canada (Same Day Delivery)

Looking for reliable Mica Strip Heater solutions in Canada? Your search ends here! We are the leading Mica Strip Heater Manufacturer, specializing in top-quality heating solutions with same-day delivery services.

🇨🇦🔧🚚

Experience the superior performance and durability of our Mica Strip Heaters, meticulously crafted to meet your specific requirements. Whether you need them for industrial processes, packaging machinery, or other applications, our heaters deliver exceptional heat transfer and consistent results.

✅ High-quality Mica Strip Heaters ✅ Same-day delivery across Canada ✅ Customizable solutions ✅ Trusted manufacturer ✅ Unparalleled customer support

Choose us as your go-to Mica Strip Heater Manufacturer in Canada and enjoy reliable and efficient heating solutions. Contact us today to place your order and elevate your heating systems to the next level!

0 notes

Text

Top Mica Band Heaters Manufacturers

Chhaperia is a company that specializes in manufacturing various industrial heating solutions, including mica heaters. Mica strip heaters are commonly used in applications where a uniform and efficient heat source is required, such as in the plastics industry, packaging equipment, and food processing machinery.

Mica strip heaters consist of a resistance heating element embedded in high-quality mica insulation, which is then encased in a metal sheath. The mica insulation provides excellent electrical insulation and thermal conductivity, allowing for efficient heat transfer from the resistance element to the target surface.

Chhaperia's mica strip heaters are designed to deliver consistent and reliable heat distribution. They offer customizable options in terms of dimensions, wattage, voltage, and terminations to suit specific application requirements. These strip heaters are known for their durability, temperature stability, and long service life.

When using mica strip heaters, it's essential to ensure proper installation and follow safety guidelines provided by the manufacturer. Consulting the product documentation or contacting Chhaperia directly would be the best way to obtain detailed information on their specific mica strip heaters and any guidelines or recommendations they provide.

0 notes

Text

Top Mica Band Heaters Manufacturers

Mica Heaters are electrical devices designed to provide even and consistent heat in various applications.

They are constructed using mica sheets, which have excellent thermal properties. The mica acts as an insulator and helps in distributing heat evenly across the heating element.

This design makes Mica Heaters suitable for a wide range of industries, including packaging, plastics, automotive, textiles, and more.

Why Choose Mica Heaters?

Energy Efficiency: Mica Heaters are known for their high energy efficiency, which helps in reducing operational costs. The even heat distribution ensures optimal utilization of energy, making them an economical choice for businesses.

Rapid Heating: Mica Heaters heat up quickly, allowing for faster warm-up times and increased productivity. This feature is particularly advantageous in industries where time is of the essence, such as manufacturing processes.

Versatility: Mica Heaters come in various shapes and sizes, making them adaptable to different applications. Whether you need a flat panel heater, strip heater, band heater, or custom-designed heater, Chhaperia can provide you with the perfect solution.

Durability: Mica Heaters are designed to withstand harsh operating conditions, making them highly durable. The mica sheet protects the heating element from moisture, chemicals

0 notes