#metal plating service

Explore tagged Tumblr posts

Text

Elevate your design projects with our exquisite brushed gold and brushed chrome finishes in Fairfield. Perfect for adding a touch of elegance and sophistication, these finishes are ideal for both residential and commercial applications. Our expert team ensures high-quality results that enhance the aesthetic appeal of your spaces. Explore the beauty of brushed metals and transform your project today!

#brushed gold fairfield#silver plating sydney#metal plating service sydney#chrome plating#brass plating#architectural finish#brushed chrome#metal plating service#aluminum finishes

1 note

·

View note

Text

About Navneet Metal Corporation

In a world of industrial metal supply, it is crucial to find a reliable partner that combines quality, precision and customer -centric values. For over two decades, the Names Metal Corporation has been the partner for many who provide top-tier metal products and unique service.

Navneet Metal Corporation, headquartered in India, has grown from a small local supplier to a well-known name in the metal industry, known for its commitment to quality and comprehensive portfolio of metal products.

What is unique about Navneet Metal Corporation?

Wide range of products

Navneet Metal Corporation offers a wide range of metal products such as coils, sheets, pipes, rods, bars, etc. They offer metals in various grades and sizes to meet various industrial needs, serving industries ranging from engineering and infrastructure to manufacturing and construction.

Unsurpassed quality standards

Quality is the focus of the metal industry.

Navneet Metal Corporation uses only reliable manufacturers who maintain strict quality control throughout the process.

Each product is thoroughly tested to ensure it meets national and international standards, providing durable and reliable materials for all applications.

Why Choose Navneet Metal Corporation?

Partnering with Navneet Metal Corporation means choosing a supplier that prioritizes quality, reliability, and customer satisfaction. Their longstanding relationships with both clients and manufacturers have enabled them to maintain competitive pricing without compromising on quality. From helping clients find the right product to providing efficient logistics and after-sales support, Navneet Metal Corporation is a full-service metal supplier.

Industries Served by Navneet Metal Corporation

Navneet Metal Corporation caters to a wide range of industries, including:

Construction and Infrastructure – supplying high-strength metals for building and infrastructure projects.

Manufacturing and Engineering – offering raw materials for machinery, automotive parts, and other manufactured goods.

Energy and Power Generation – providing metals that meet the demanding standards for energy applications.

Medical and Pharmaceutical – with metals suitable for equipment and sterile environments.

Conclusion

In an industry where quality, reliability, and precision are paramount, Navneet Metal Corporation stands out as a leader. Their commitment to excellence, combined with a focus on innovation and sustainability, makes them a preferred partner for companies across various sectors. As Navneet Metal Corporation continues to expand, they remain dedicated to providing exceptional products and solutions that meet the evolving needs of the metal industry.

For more information on products, services, or to discuss a custom order, reach out to Navneet Metal Corporation’s team of experts. Discover a supplier that not only understands your needs but is committed to exceeding your expectations.

#Stainless Steel Suppliers#Industrial Metal Supplier#Navneet Metal Corporation#Quality Metal Distributor#Stainless Steel Coil Supplier#Precision Metal Manufacturing#High-Quality Steel Distributor#Metal Sheets and Plates Supplier#Stainless Steel Bar Supplier#Alloy Steel Supplier#Navneet Metal Steel Products#Metal Tubing and Pipes Supplier#Metal Stockist and Distributor#Metal Fabrication Services#Steel and Metal Distributor#Stainless Steel for Industrial Use#Metal Sheets and Coils Supplier#Stainless Steel Strip Supplier#Industrial Metal Manufacturer#Quality Metal Supply India#Wholesale Stainless Steel Supplier#Stainless Steel Sheets and Plates#Stainless Steel Pipe Manufacturer#Leading Metal Corporation India#Metal Product Exporter#Stainless Steel Bars and Rods#Metal Supply for Construction#Metal Industry Supplier#Premium Stainless Steel Products#Industrial Metal Stockists

0 notes

Text

Metal Finishing: A Comprehensive Guide to Coating and Plating Techniques

Metal finishing is the process of treating metal surfaces to enhance their appearance, durability, and functionality. Various techniques are employed to achieve different desired outcomes, such as corrosion resistance, conductivity, or aesthetic appeal. Here's a look at some of the most common metal finishing methods:

1. CED Coating (Cathodic Electrodeposition Coating)

CED coating is an electrochemical process used to apply a uniform coating of paint or other materials to metal surfaces. An electric current is passed through a bath containing the coating material, causing it to deposit onto the metal. This technique is widely used in the automotive industry for its efficiency and ability to produce high-quality finishes.

2. ED Coating (Electrophoretic Deposition Coating)

Similar to CED, ED coating involves the application of a coating material using an electric current. However, ED coating is more commonly used for applying primer coatings to metal surfaces. It offers excellent corrosion resistance and adhesion properties.

3. Zinc Plating

Zinc plating is a process of applying a zinc coating to metal surfaces to protect them from corrosion. Zinc is a sacrificial metal, meaning it corrodes preferentially to the base metal, protecting it from damage. Zinc plating is commonly used in industries such as automotive, construction, and electronics.

4. Electroplating

Electroplating is a broad term that encompasses various processes for applying a metal coating to another metal surface using an electric current. Different metals can be used for electroplating, such as nickel, chromium, copper, and gold. Electroplating service is used for a variety of purposes, including decorative finishes, corrosion protection, and improved conductivity.

5. Liquid Spray Painting

Liquid spray painting is a traditional method of applying a coating to a metal surface using a spray gun. The coating material is sprayed onto the surface in a fine mist, allowing for a uniform and even finish. Liquid painting is widely used in various industries, including automotive, aerospace, and furniture manufacturing.

Choosing the Right Metal Finishing Technique

The best metal finishing technique for a particular application depends on several factors, including:

Desired properties: What properties do you want the coating to provide, such as corrosion resistance, conductivity, or aesthetic appeal?

Metal type: Different metals require different finishing techniques.

Application: The specific application will influence the choice of technique.

Cost: The cost of different metal finishing techniques can vary significantly.

In conclusion, metal finishing is vital for enhancing the durability, appearance, and performance of metal products. Techniques like CED, ED coating, zinc plating, electroplating, and spray painting each offer unique advantages. Choosing the right technique ensures optimal performance and longevity, making it essential to align the process with the specific application and budgetary constraints.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–9311813406

Email ID: [email protected]

Website: www.sarcoatings.com

#zinc plating#zinc plating service#liquid painting#metal finishing#electroplating#ced coating#sarcoatingsllp

0 notes

Text

Commercial Roofing Services: Services de toiture commerciale

The state of your roof is important when it comes to protecting your house. With unmatched quality and service, Toiture Plus Roofing stands out as a top option for all your roofing needs. Their crew is committed to ensuring your roof is both long-lasting and aesthetically beautiful, and they specialize in a wide range of roofing solutions, from repairs and replacements to new installations Residential Roofing Services: Services de toiture résidentielle.

Toiture Plus Roofing's dedication to quality is what makes them stand out. They provide results that not only meet but surpass industry standards by using only the best materials and cutting-edge processes. Their skilled experts tackle every job with painstaking attention to detail, making sure that every facet of your roofing is taken care of with accuracy and care Emergency Roofing Repair: Réparation de toiture d'urgence.

The primary goal of Toiture Plus Roofing is client happiness. Roofing Contractors: Entrepreneurs en toiture , the easy and hassle-free roofing experience is made possible by their transparent procedure and individualized service, which guarantee that each client's needs are met. You can count on Toiture Plus Roofing to deliver dependable and efficient solutions, regardless of the extent of your roof's needs, from small fixes to a full restoration. To find out more and arrange a consultation with their knowledgeable staff, go to their website right now.

#Roofing Contractors: Entrepreneurs en toiture#Commercial Roofing Services: Services de toiture commerciale#Residential Roofing Services: Services de toiture résidentielle#Emergency Roofing Repair: Réparation de toiture d'urgence#Roof Installation: Installation de toiture#Roof Maintenance: Entretien de toiture#Eco Flat Roof: Toiture plate écologique#Flat Roof Contractors: Entrepreneurs en toiture plate#Metal Roofing Installation Companies Near Me: Entreprises d'installation de toitures en métal près de chez moi#Metal Roofing for Flat Roofs: Toiture en métal pour toitures plates#Shingle Roof Installers Near Me: Installateurs de toitures en bardeaux près de chez moi#Shingle Roofing Near Me: Toiture en bardeaux près de chez moi

1 note

·

View note

Text

Discover A-Gas Electronic Materials' laboratory services, offering expert testing and analysis of production line metal plating solutions. Our ISO-registered facilities provide accurate results and quick turnaround times. Hire our experts for research and development to optimise your products.

#laboratory services#metal plating solutions#ICP-OES#UV spectrometry#CVS#titrations#pH measurement#Hull Cell testing#SEM#A-Gas Electronic Materials#ISO registration#research and development#production line testing#UK laboratory services#plating analysis

0 notes

Text

Comparing the Aesthetics of Different Metal Plating

Metal plating or metal finishing is a very useful technique used in a range of processes, whether decorative or industrial. Using the right metal finish can completely transform the look, feel and usability of the product. If you are looking to aesthetically improve a product, then understanding the different metal finished would be greatly helpful. One of the most common plating is silver plating in UAE because of its remarkable properties. There are other plating options too, check them out as well.

Need for metal plating

The metals ideally used in metal plating are: Gold, Silver, Tin, Copper, Chrome, Rhodium, Zinc, Zinc Nickel, Zinc Iron and Black Nickel. With the right metal plating option, it is possible to improve the product’s surface, increase corrosion resistance, improve paint adhesion, reduce friction, act as a shield against radiation and even change the conductivity of the material. Metal plating is also used in jewelry to improve their look, and make cheap jewelry alluring and attractive.

Gold Plating

Gold plating is often done on copper to provide a corrosion-resistant electrically conductive layer. Hence, it is used on electronic spare parts, mainly electrical connectors, printed circuit boards etc. This chemical process is also known as gold electroplating, and before doing it, the technician will ensure that the surface is clean with no dirt or oil on them. This is a great option because not only will it look good, but it will also prevent oxidation and thus no rusting.

Silver Plating

Silver Plating in UAE is also almost similar to Gold plating, and is thus excellent for electrical conductivity. Since it is a cost-effective option to gold, many people switch to silver to plate parts made from copper. Silver is beautiful and elegant, and gives off an excellent metal finish.

Tin Plating

Tin plating provides an even cheaper option when compared to gold, platinum, etc. This is used mainly for industrial works and is used in a variety of industries including electronics, jewelry making, aerospace, etc. You will also find tin plating solution in cans where food products are stored.

Rhodium plating

This is also used for plating jewelry because of its qualities like durability, aesthetics and light reflecting qualities. A thin coating on a piece of jewelry will work wonders.

Nickel plating

Nickel plating is quite often used for that lovely finish on plumbing and household appliances, furniture and supplies. You will find this used on wire racks because of its striking, mirror-like finish. It is also corrosion-resistant.

Silver plating in UAE is most often the commonly used plating metal because it is resistant to heat, and a number of common chemicals and acids. It does not oxidize or degrade, so used in high-temperature environments like the automotive industry. Engine manufacturers use silver instead of lubricants because of its remarkable temperature resistance. Silver is also often used as a base material before other kinds of plating is applied, especially matte coating.

For more details -

0 notes

Text

Best Foot Over Bridge Services in Kolkata - VR Global

VR Global offers premier foot over bridge services in Kolkata, ensuring safe passage for pedestrians. Our bridges combine innovation, durability, and aesthetic appeal, enhancing urban connectivity seamlessly.

For more information visit us:https://vrglobalindia.com/

#Pre-Engineered Building Services in Kolkata#Sheet Metal Extra Large Fabrication in West Bengal#Plate girder Services in West Bengal

1 note

·

View note

Text

Understand the Electroplating with Zinc Plating Barrels

In the world of metal finishing, Zinc Plating Barrels stand as indispensable tools, playing a pivotal role in ensuring the quality and durability of metal parts. At www.mechfin.com, we understand the intricate workings of these barrels and the critical role they play in the electroplating process.

Ready to experience the difference with Mechanical Finishing Services? Contact us today at +1-513-641-5419 to discuss your zinc plating and metal parts cleaning services requirements. Let us be your partner in achieving superior quality and performance for your metal components.

0 notes

Text

#BMS Cutting Solutions#Melbourne laser cutting#Custom steel cutting#Steel laser cutting services#Precision laser cutting#Large steel fabrication#Bespoke steel cutting#Melbourne metal fabrication#High-quality laser cutting#Metal fabrication specialists#Steel sheet cutting#Industrial laser cutting#Steel plate cutting#Laser cutting solutions#Custom metal work Melbourne#Steel cutting experts#Laser cutting Melbourne#Melbourne steel fabricators#Steel fabrication and cutting#Stainless steel laser cutting#Custom steel products#Unique metal designs#Laser cut steel components#One-off metal creations

0 notes

Text

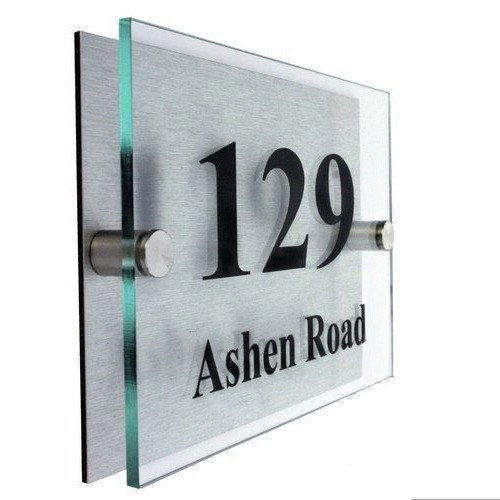

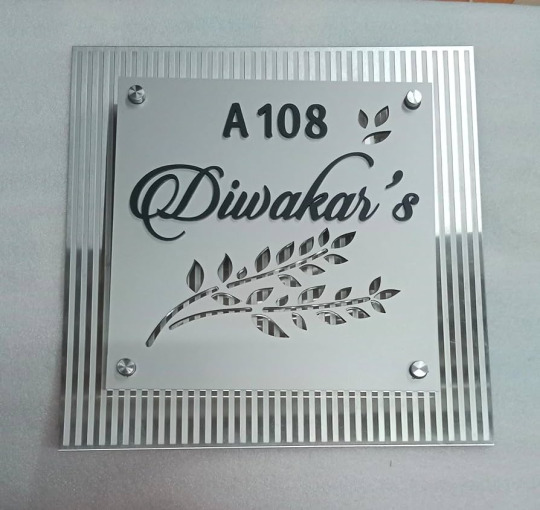

Which Nameplate is best for home?

The best nameplate for your home depends on personal preference, but options like classic brass, modern acrylic, wooden plaques, ceramic tiles, and stainless steel address plaques offer durability and style.

Choose one that complements your home’s architecture and reflects your unique personality. In the realm of home & office décor, nameplates serve as more than just identifiers; they are an extension of your home’s personality and a welcoming beacon for guests.

Selecting the right nameplate is crucial as it sets the tone for the entire ambiance of your home’s exterior. With an array of materials, designs, and customization options available, finding the ideal nameplate can be a daunting task.

This comprehensive guide aims to simplify the process by exploring various factors to consider and highlighting the best nameplate options for different preferences and requirements.

Factors to Consider:

Material:

Nameplates come in a diverse range of materials, each offering unique characteristics in terms of durability, aesthetics, and maintenance. Common materials include:

Metal: Brass, stainless steel, aluminum, and wrought iron are popular choices for their durability and timeless appeal. Metal nameplates are resistant to weathering and can withstand outdoor elements.

Wood: Wooden nameplates exude warmth and natural beauty, making them an excellent choice for rustic or traditional-style homes. However, wood requires periodic maintenance to prevent rot and weather damage.

Ceramic: Ceramic nameplates are known for their intricate designs, vibrant colors, and durability. They are resistant to fading and can withstand harsh weather conditions, making them suitable for outdoor use.

Acrylic: Acrylic nameplates offer a modern and sleek appearance, with the flexibility to customize colors, shapes, and fonts. They are lightweight, weather-resistant, and easy to clean.

Design:

The design of the nameplate should complement the architectural style of your home while reflecting your personal taste. Consider factors such as:

Traditional vs. Modern: Choose a design that aligns with the overall aesthetic of your home. Traditional homes may benefit from classic designs with ornate details, while modern homes may opt for clean lines and minimalist typography.

Typography: Pay attention to the font style, size, and readability of the nameplate. Bold, easy-to-read fonts are essential for ensuring visibility from a distance.

Customization: Many homeowners prefer personalized nameplates with their family name, house number, or a meaningful quote. Customization adds a personal touch and makes the nameplate truly unique.

Size and Visibility:

The size of the nameplate should be proportionate to the facade of your home and easily visible from the street. Consider the following guidelines:

House Number: Ensure that the house number is large enough to be legible from a distance, especially for properties set back from the road.

Placement: Mount the nameplate at eye level near the entrance to ensure maximum visibility. Avoid placing it in areas obstructed by foliage or other objects.

Contrast: Choose colors and finishes that provide sufficient contrast against the background to enhance visibility, particularly in low-light conditions.

Weather Resistance:

Given that nameplates are exposed to outdoor elements year-round, it’s essential to select a material that can withstand various weather conditions:

Rust and Corrosion Resistance: Metal nameplates should be treated with a protective coating to prevent rust and corrosion, particularly in humid or coastal regions.

UV Protection: Choose materials that are resistant to fading and discoloration caused by prolonged exposure to sunlight.

Waterproofing: Ensure that wooden and ceramic nameplates are sealed with a weatherproof finish to prevent moisture absorption and deterioration.

Installation and Maintenance:

Consider the ease of installation and maintenance requirements when selecting a nameplate:

Mounting Options: Choose a nameplate that offers versatile mounting options, such as screws, adhesive, or hooks, depending on the surface and location.

Cleaning and Maintenance: Determine the cleaning and maintenance procedures required for each material. Metal nameplates may need periodic polishing, while wooden nameplates may require resealing to maintain their appearance.

Best Nameplate Options:

Classic Brass Nameplate:

Timeless and elegant, a brass nameplate adds a touch of sophistication to any home. Brass is highly durable and develops a unique patina over time, enhancing its vintage charm. Look for engraved brass nameplates with intricate detailing for a traditional yet stylish look.

Modern Stainless Steel Address Plaque:

Sleek and contemporary, a stainless steel address plaque offers a minimalist aesthetic with maximum durability. Stainless steel is resistant to rust, corrosion, and fading, making it ideal for outdoor use. Opt for laser-cut lettering for precise detailing and a polished finish for a sleek, sophisticated look.

Rustic Wooden Plaque with Custom Engraving:

For a rustic and personalized touch, consider a wooden plaque engraved with your family name or house number. Choose high-quality hardwoods such as oak, cedar, or mahogany for durability and natural beauty. Add a protective sealant to prevent weather damage and preserve the wood’s integrity.

Colorful Ceramic Tile Nameplate:

Ceramic tiles offer endless possibilities for customization with their vibrant colors and intricate designs. Opt for hand-painted ceramic tiles featuring motifs that reflect your personal style or cultural heritage. Mount the tiles on a sturdy backing for easy installation and long-lasting beauty.

Contemporary Acrylic House Sign:

Acrylic house signs are sleek, modern, and highly customizable, making them a popular choice for contemporary homes. Choose from a variety of colors, shapes, and fonts to create a unique design that complements your home’s exterior. Consider backlighting options for added visibility and visual impact.

Conclusion:

Choosing the perfect nameplate for your home involves careful consideration of factors such as material, design, size, visibility, weather resistance, installation, and maintenance requirements.

Whether you prefer the timeless elegance of a brass nameplate, the contemporary allure of a stainless steel plaque, or the rustic charm of a wooden plaque, there are options available to suit every style and preference. Invest in a high-quality nameplate that not only enhances the curb appeal of your home but also reflects your personality and hospitality.

With the right nameplate, you can make a lasting impression and welcome guests with style and flair.

#3d printing#3d sign#3d signage#signage#branding#digital art#print on demand#print on demand services#printing company#digital painting#home & lifestyle#modern home#home alone#home decor#design#acrylic#metal#wood#modern acrylic#name plate#name plates

1 note

·

View note

Text

Skye metal coating is a company in dubai that offers Chrome Plating services in UAE.

#chrome plating#chrome plating dubai#chromeplating#chromeplatingindubai#metalcoating#metal coating#skye metal coating#chrome plating in dubai#chrome plating service#chrome plating company

1 note

·

View note

Text

#brushed gold fairfield#silver plating sydney#metal plating service sydney#brushed gold#architectural finish#zinc plating#aluminum finishes#lacquer finish#nickel finish#electroplating

1 note

·

View note

Text

The Importance of Industrial Spray Painting for Heavy Equipment

At first glance, industrial spray painting may not appear as an art form, but it demands a level of skill and expertise that rivals that of the finest artists. It's a craft that works with various liquid materials, including paints, stains, and primers, to transform heavy equipment into more than just machines. The benefits of industrial spray painting extend far beyond aesthetics, offering unparalleled control and a flawless finish on a wide array of surfaces.

Why Does Heavy Machinery Need Industrial Spray Painting?

Many individuals and companies turn to experts like SAR Coatings for industrial or commercial spray painting services for their heavy machinery. But what drives this demand? The primary objective is to safeguard these colossal machines from rust and maintain their appearance, eliminating the risk of old paint chips contaminating the products they handle.

Industrial spray painting techniques are carefully tailored to protect the underlying materials, shielding them from the natural wear and tear that heavy equipment inevitably faces. The choice of coatings can vary based on the equipment and materials involved, with popular options including epoxy, urethane, and Line X paints.

How Is Industrial Spray Painting Done?

To ensure the success of an industrial spray painting project, meticulous preparation is essential. Whether the equipment is made of steel or has undergone sandblasting, the surface must be free from rust, debris, or stains. Any imperfections in the surface can cause the paint to fail to adhere properly, leading to premature peeling.

The process typically begins with a high-pressure wash using specialized equipment, effectively cleaning the surface and preparing it for painting. Following this, a primer is applied to facilitate paint adhesion and create a smooth finish. Once the primer has set, the industrial spray painting process can commence. The final step involves applying a top coat, providing added protection against environmental elements and further reducing the risk of rust.

Key Considerations in Industrial Spray Painting

Industrial spray painters are not mere technicians; they are artisans in their own right. They carefully consider various factors to ensure a flawless finish. Here are some critical aspects they focus on:

Substrate Preparation

Preparing the surface for painting is a pivotal step. Industrial spray painters must ensure that the substrate is impeccably cleaned, as nearly 80% of painting failures can be traced back to inadequate surface preparation.

Paint Thinning

Paint sometimes needs thinning for proper application and coverage. The choice of thinners can vary depending on the type of paint being used. While mineral spirits are suitable for most paints, others may require different thinners.

Spraying

Achieving the desired metal finishing requires precise spraying techniques. Factors such as the type of finish, paint type, and substrate material come into play. Industrial painters have a wide array of spraying devices and guns at their disposal, allowing them to customize the painting process to meet specific requirements.

Commercial Spray Painting Methods

Different industrial spray painting methods offer distinct advantages and disadvantages. Airless sprayers, for instance, provide greater control over the finish and reduce paint waste by recirculating excess paint. Here's a breakdown of a few industrial spray painting methods:

Air Gun Spraying

Air gun spraying is ideal for delicate work, including lacquers, paints, varnishes, shellac, and other finishes. It utilizes air and fluid compression for atomization, ensuring even application.

Electrostatic Spray Painting

This modern technique, widely used in the automotive sector, ensures even coverage on various surfaces, including metals, doors, windows, railings, and metal fencing. Specialized equipment such as air-assist guns and HVLP sprayers is employed.

HVLP (High Volume Low Pressure)

HVLP spray painting relies on turbines and heat to stabilize paint, reducing atmospheric condensation and improving adhesion. This method is suited for glossy, smooth-textured coatings.

LVLP (Low Volume Low-Pressure)

LVLP spray painting utilizes less air volume and lower air pressure compared to HVLP. It can still achieve a transfer efficiency of 65% or better.

Airless Spray Guns

This technique involves pushing paint through a nozzle via a hose, eliminating the need for compression. It's ideal for glossy, glass-smooth-textured coatings.

Liquid Painting at SAR Coatings

SAR Coatings stands as a testament to the art of industrial liquid painting. They continually invest in high-quality machinery to meet customer demands. We excel at providing high-quality painted finishes that meet exacting standards. They offer specialized coatings, enhancing insulative or conductive properties using electrostatic spray, fluid bath, or heat shrink processes. Furthermore, our team also conducts rigorous testing of finishes, including gloss level, coating thickness, adhesion strength, porosity, colour shade, dielectric strength, and insulative or conductive properties.

If you're interested in discussing your industrial spray painting requirements, don't hesitate to contact SAR Coatings today. For more captivating articles on manufacturing and technology, explore our blog.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–9311813406

Email ID: [email protected]

Website: www.sarcoatings.com

0 notes

Text

Nickel Plating Service in Pune, India | Sidhant Enterprises

Experience the finest in metal finishing with our Nickel Plating Service in India by Sidhant Enterprise. We specialize in providing top-quality nickel plating solutions that enhance the durability and aesthetics of your metal components. With a commitment to excellence, we offer reliable and precise nickel plating services to meet your industry needs. Explore our range of solutions for superior metal finishing. Contact us today to transform your metal pieces into shining examples of quality craftsmanship.

#Nickel Plating Service#Nickel Plating Components#Plating Services#Tin Plating#Tin Plating Services#Industrial Tin Plating Services#Powder Coating#Industrial Powder Coating#Powder Coating Services#Sheet Metal Stamping Services#Industrial Sheet Metal Stamping#Silver Plating Services#Industrial Silver Plating Services#Gold Plating Services

0 notes

Text

Discover A-Gas Electronic Materials' EIF solutions for high-performance PCB production and electronic components. Our advanced chemistries ensure superior quality and reliability in electronic devices. Trust A-Gas for innovative industrial finishing technologies.

#Electronic Industrial Finishing#EIF solutions#high-performance PCBs#electronic components#plating solutions#metal stripping#cleaning agents#soldermask resists#A-Gas Electronic Materials#UK electronic manufacturing#electronic finishing services#PCB production#electroplating#metal treatment products

1 note

·

View note

Text

Get Excellent Quality Electroplating Services to Protect Your Metals From Rust & Corrosion Only at PGV Sun Chemicals

👀 Tired of looking at rust on your metal objects? 😍 Our top-notch electroplating services👷 leave your metals🧱 shiny and protected from corrosion. Contact us for more details on the best quality electroplating services around 🔧. Contact us for more details!

#Electroplating Services#Electropalting#Metal Electroplating Process#Metal Plating#Electroplating Metals

0 notes