#metal industry microscope

Explore tagged Tumblr posts

Text

0 notes

Text

notes on Primo's characterization 💖

let's talk about Primo! i think he's a really, really interesting character!

i've said before that i think Primo is the only one of the brothers who takes the whole ~satanic death cult trying to bring the end of the world~ thing seriously.

Primo was indeed very serious about the cult. maybe too serious? even some other members of the cult dislike that about him.

NAMELESS GHOUL: The first Papa Emeritus was someone very rigid, very strict, and very solemn. A real son of a bitch! (laughs) To be honest, we don’t miss him at all! MyRock #44 (2017) translated from French by @ a-wandering-ghoulette)

the best source of Primo characterization is a 2010 interview with Sweden Rock Magazine where Primo and the Nameless Ghouls kidnapped the interviewer. though i quote *a lot* of it here, i strongly recommend reading the full interview because it is truly fascinating. notably, Primo himself speaks in this interview rather than a Nameless Ghoul.

Primo is a misanthrope who believes humans are "vermin" that have doomed themselves due to their "intellectual decline". in his eyes, they are unworthy of life and will eventually be destroyed.

“Human beings are vermin, thus the end of humanity is ultimately a good thing. We play but a vanishingly microscopic role in this cosmos of nothingness.”

The devil-worshipping organization that the Ghost leader speaks of is claimed to operate on a worldwide level and among many different areas: from politics and business to religious movements, in the entertainment industry and on the street. It does not have a name, but its existence “can most easily be explained as a living and ongoing result of humanity’s intellectual decline and eventual decay.”

Primo affirms Ghost's mission statement as originally presented in the band's old Myspace page: to spread the devil's influence and convince other people that humanity deserves its inevitable end.

According to the statement on the band’s page, Ghost’s main mission is to trick mankind into believing that the end of the world is ultimately a good thing. “Our only task is to accompany the world’s downfall.”

A question comes to mind: wouldn’t the band, which with its poppy hard rock could by all means appeal to a much wider audience than ordinary black metal acts, gain more attention by engaging in more commercial modes of expression? “We have other entertainment groups within our organization who are doing just that. Our task is to emphasize the devil’s message in the part of society that has, to varying degrees, already accepted it. It’s directed at the social grouping that goes to the type of concerts that we perform. Our goal is to be able to carry out our black mass, our ritual, for them. Other members of the cult work with far more subtle modes of expressions, better suited for consumers who are not as receptive to the truth.”

though he openly calls the organization a cult, his religious belief is sincere.

to Primo, the band's anonymity and use of costumes are a way of showing reverence and humility in their task. if Satan is the Father, and Antichrist is the Son, the band is the (unholy) Ghost: the force which connects humanity to the power of the Father and the Son. for the audience to think of Primo or the Nameless Ghouls as individual people would distract from their message. when he takes on the role of Papa, he becomes one with their cause.

You refer to yourselves as a group of nameless spirits - should this be taken literally? Is the band actually something other than human? “To make it easier for mortals to deal with the fact that we, as individuals, have no significance in this experience, we have chosen to act as ghosts - hollow and diffuse.”

Why did you, as a leader, choose an outfit so similar to the one worn by the Catholic Pope? “For the Pope it is a way of showing reverence and seriousness, and at the same time humility before his task. He uses it to step into the body that is the essence and the fog, something we advocate too. It is our way of becoming one with the fog.” Things become clearer when the leader speaks of the meaning behind the name of the band: “Akin to the tripartite view so stubbornly proclaimed by the Christian faith, we too believe there is magic in the concept of three and we are part of it: there is a god, Satan, a son, Antichrist, and a ghost in the middle that is the inexplicable - the fog.”

Primo has a theistic view of Satan, believing he is real deity who speaks through / inspires the band's music. in this way, the Ghoul Writer could be considered a sort of prophet to him.

That’s right. Ghost have their music written for them. In one online interview, a so-called “ghoul writer” is mentioned who supposedly composes melodies and lyrics with the help of ungraspable powers from beyond – devilish whispers instruct him which words should accompany which chords, and so forth. “There is indeed a human individual who composes patterns of tones and words which operate ever so beautifully in unison. However, I am of the belief that there is a higher being who speaks through this individual,” asserts the Pope.

like a proper cultist, Primo cannot imagine having a life / identity outside of the cult. he remembers that there was once a time when he was not a member of the cult, but he cannot remember what it was like to be that person. his devotion to the cult has been a core part of who he is for a very long time.

How he got involved in this movement and dedicated his life to Satan, he has a hard time answering. After a long silence, the singer says: “I find it very difficult to remember the life I had before I found the darkness. It is therefore very difficult to answer your question. My memory doesn’t go that far.” Surely the Pope must remember something? “I cannot remember a time when I did not find myself part of the dark energy. That does not mean that I remember nothing from my past life, only that I cannot remember how I felt then. This is because it was a time when I did not know very much.” Was it by coming into contact with other members of the organization that you found this darkness? “As I said, I do not remember when this happened. But I think…” He chooses his words carefully. “… I believe that, like many others, I was woven into this dark through subtle, human components found within it. Once again, my intellect was not as developed as it is now, so I have great difficulty in explaining what happened - when and where, and to what extent.”

while he cannot say exactly what happened to him or when, Primo seems to have had genuine spiritual experiences. he was always connected to the dark energy, and he feels that he became awakened and that his intellect has developed since he truly found his faith.

despite being a misanthrope, Primo admits he was brought into the darkness by some sort of human connection. he might actually have the capacity to care about some people.

in a Kerrang feature where Primo gets quizzed on "demonology, serial killers and stuff like that", he says the cult knew witches who were burned at the stake, but he doesn't like to talk about it. it stood out to me that he says he doesn't want to talk about it, because he speaks so openly and matter-of-factly about other dark / upsetting topics. at the very least, it appears he doesn't like it when bad things happen to other members of the cult.

WHAT DOES THE PHRASE MALLEUS MALEFICARUM TRANSLATE AS IN ENGLISH? A) HAMMER OF THE WITCHES B) HAMMER OF THE DEMONS C) HAMMER OF THE GODS PAPA: “That would be the witch-hammer. We knew some Witches, but unfortunately a lot of them were taken away.” KERRANG!: “As in burned at the stake?” PAPA: “Correct. But I don’t like to talk about that. (Answer: A) ✔

he seems to be quite pleased about other people dying, though. and he is certain they all go to Hell.

6. NAME ANY TWO OF THE THREE ORIGINAL MEMBERS OF MAYHEM. PAPA: “Though one was not an original member two of the band are actually burning in Hell, and they’re good guests, certainly. But yes, I will say Euronymous and Necrobutcher.” (Answer: Euronymous, Necrobutcherr, Manheim) ✔ 7. WHAT WAS THE NAME OF THE SHIP THAT WAS DISCOVERED FLOATING ABANDONED AND UNMANNED IN THE ATLANTIC OCEAN IN DECEMBER 1872? PAPA: “It was that ship with such a heavenly name, the lady Mary Celeste.” KERRANG!: “And can you finally tell us where all the people went?” PAPA: I’ll check the records. Obviously they’re all in Hell now, but the way they got there is a little cloudy. But then our Lord too works in mysterious ways…“ (Answer: Mary Celeste) ✔

some of Primo's other responses in this article reveal he has a dark sense of humor and perhaps cruel inclinations. when talking about possessions done by the cult, he says "sometimes you just want to do it for the hell of it" and "you want to make a bit of sport out of it", referring to a possession that (allegedly) influenced a serial killer. he refers to the victims of these possessions as "poor [name]", but his remarks on their misfortune don't indicate any actual remorse or sympathy. it might even be intentionally ironic.

5. WHICH PAINTER ALLEGEDLY UNDERWENT AN EXORCISM IN 1947? PAPA: “Poor Salvador Dali. You know we had his missus possessed as well, all in the name of Satan…” KERRANG!: Is possession something that’s done for serious reasons or just to pass the time? “Well sometimes you just want to do it for the hell of it…” (Answer: Salvador Dali) ✔

13. WHAT AMERICAN SERIAL KILLER CLAIMS HE WAS COMPELLED TO COMMIT HIS MURDERS BY A DEMON THAT POSSESSED HIS NEIGHBOUR’S DOG? PAPA: 'That was that poor boy, the Son Of Sam. That sure was a successful possession, although it did involve far too much crotch-sniffing and turd-eating.“ KERRANG: "Is it easier to possess a dog than to possess a person?” PAPA: “Not necessarily, but you want to make a bit of sport out of it.” (Answer: David Berkowitz/Son Of Sam) ✔

also, many of the events Primo speaks about would've happened before he was born or when he was very young, so it seems he's studied the cult's history very well, and he keeps tabs on their current activities. he does his research!

and as a fun fact: Primo is pretty good at math :)

14. IF YOU’RE TRICK OR TREATING AND THREE HOUSES GIVE YOU SEVEN SWEETS, TWO GIVE YOU FOUR, AND ONE GIVES YOU NINE, AND YOUR PARENTS THEN DOUBLE WHAT YOU HAVE, HOW MANY SWEETS DO YOU END UP WITH? PAPA: “76.” KERRANG!: “That was alarmingly fast, sir. Are good mathematical skills important when you’re burning in the fiery pits of Hell?” PAPA: “We all have our different strengths, but of course the number we are most used to is 666…” (Answer: 76) ✔

there's not a lot of information about Primo, and what exists is hard to find, but i live to bring knowledge to the people 🫡. these are all the sources i have on hand that talk about Primo. if anyone else has other articles / videos talking about Primo, i'd really appreciate it if you shared them!

#this one is more of a notes post than an analysis post#but i think this stuff is worth sharing!#papa emeritus i#primo#analysis#quotes#the band ghost lore#radley post#headcanon#? not really but i'll put it in the tag anyway

244 notes

·

View notes

Text

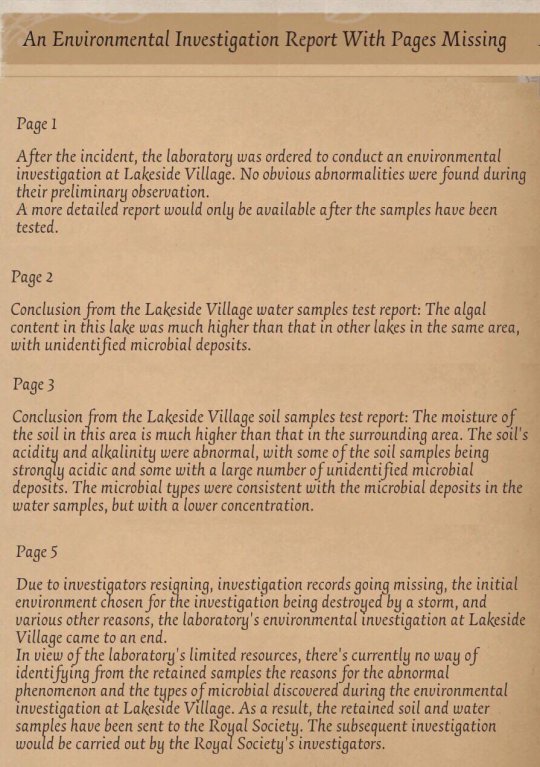

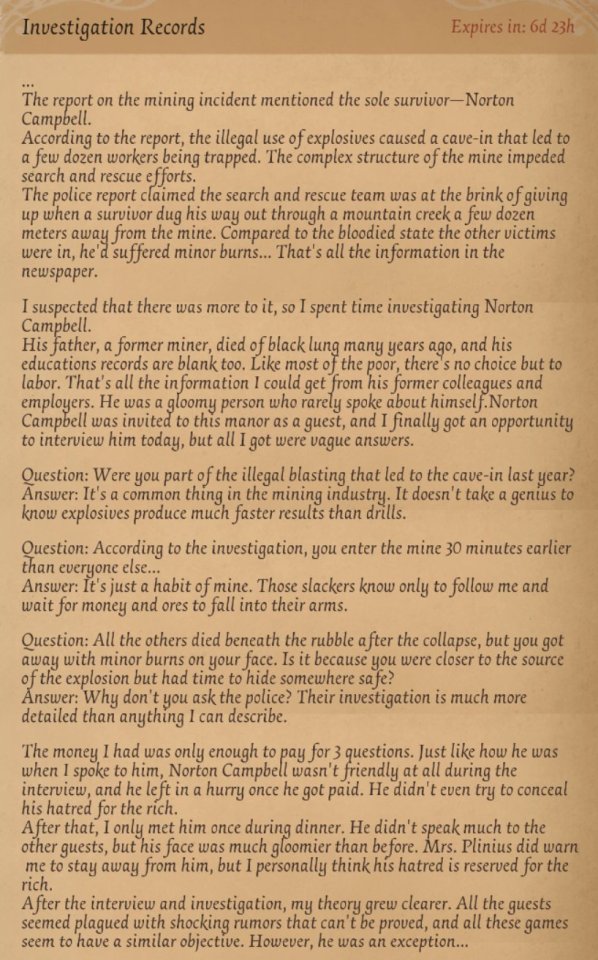

Facts and Theories related to Fool's Gold and Norton

Part 1: Facts and Theories about Pyrite aka Fool's Gold

TLDR - Facts:

comes from the Greek word for fire

the dangers of pyrite oxidation (sulfuric acid, sulfur dioxide)

pyrite can contain small amounts of real gold, called “invisible gold”

TLDR - Theories

Pyrite containing real gold parallel to Norton being good deep down

Fire connection to Infernal Sin

Pollution in Lakeside water and soil as well as cause of fish and plants dying because of Golden Cave?

Part 2: Facts and Theories about how Norton escaped Golden Cave

TLDR:

Norton didn't just simply dig himself out

Facts about mines, mine collapses, dangers, potential escape routes, etc...

Part 1

Facts

Pyrite (aka fool’s gold) comes from the Greek word ‘pyros’ meaning ‘fire’, and will create sparks when struck against metal or a hard surface.

It is capable of scratching glass while most knives won’t be able to scratch it.

In the presence of moisture and oxygen, pyrite oxidizes, releasing its sulfur content as sulfuric acid.

Pyrite rich waste from mining operations can increase acidity of surface water. This can harm downstream ecosystems, animals, and even pose a risk to humans.

Sulfur dioxide is produced by burning the pyrite in coal, which can combine with moisture in the atmosphere to create acid rain.

Pyrite oxidation is sufficiently exothermic enough to produce heat, and as the temperature rises, the coal heats up and in some cases cause it to self-ignite and cause fire. This is called spontaneous combustion, a very real problem in coal mines. Pyrite dust can burn even with only a little oxygen, and it burns well due to its sulfur content. Sulfide fires can burn for years.

Despite its reputation, pyrite can sometimes contain small amounts of real gold, although it is notoriously hard to extract. This gold is sometimes referred to as “invisible gold” because it isn’t observable by the naked eye or standard microscopes (you need sophisticated scientific instruments). It can come in different forms: either as particles of gold, an alloy where the pyrite and gold are finely mixed, and in defects (imperfections created when the pyrite crystals are forming) in the crystal structure . With the latter form, the more deformed it is, the more gold there is in the defects.

And the discovery of new gold deposits declining world wide, with the quality of ore degrading in parallel to the value of precious metal increasing.

Invisible gold is primarily found in pyrite and arsenopyrite, and this is now a common resource for the gold mining industry.

Theories

I really wanted to bring up pyrite having some real gold (even if the amounts are very small). Especially as I can draw a parallel with that to Norton, who may normally seem suspicious, but he isn’t entirely bad. He may seem unapproachable, but you may make progress if you dig deep enough and try hard enough. He isn’t completely “worthless”.

Pyrite coming from the word for fire connects well to Infernal Sin, while pyrite being a fire starter in the fast due to its ability to create sparks fits well with Norton’s how we see Norton causing the explosion in Golden Cave in his trailer.

Then regarding the sulfuric acid, this actually made me wonder if the contamination in Lakeside, revealed in Yidhra’s letters, could be related to or from Golden Cave.

Ground water is water that seeps into the ground via rain or snow melt. As it makes its way underground, it can collect or react to the minerals and rocks down there, including pyrite, which can eventually result in the oxidation (and all its problems) I described earlier. This can percolate to form sediment at the bottom of rivers with mine drainage, which is water drained from mines. Acid runoff further dissolved heavy metals into water, and acid mine drainage can be increased by the action of certain bacteria (aka, sulfuric acid from pyrite can leech heavy metals from rock, and the acid can be worsened by bacterial action, resulting in this drainage becoming highly toxic).

Problems with mine drainage include contaminated drinking water, disrupted growth and reproduction of plants and animals, and corroding effects of acid on structures.

In general, sulfide rich and carbonate poor materials produce acid drainage. In contrast, alkaline rich materials, even with significant sulfide concentrations, often produce alkaline conditions in water.

Abandoned mines can fill with water (flood) because there’s no pumping occurring (the steam engine was 1st invented to solve mine flooding). This results in unabated chemical reactions, potentially making it very toxic, and this water can even discharge into lakes and streams, killing aquatic life and polluting the environment.

Further acid drainage can result from waste rock, which is material that must be removed to reach the ore. It is often deposited in piles close to the mine, and as it is exposed to air and moisture, it causes weathering, which can generate acid drainage.

Yidhra’s 3rd letter does mention “microbial deposits” in the water and soil as well as the soil’s “acidity and alkalinity”. So maybe it could be connected…?

Part 2

Thoughts regarding specifically how Norton escaped Golden Cave

Norton’s 3rd letter states the police report claimed Norton “dug his way out through a mountain creek a few dozen meters away from the mine”.

It is unlikely Norton simply dug himself out from the mine.

Golden Cave’s backstory states it was “hundreds of meters” deep at least. Mines back in that day (late 19th century) were already 1000s of feet deep (1 was 700-900m = 2300 – 3000ft). Prior to the 1850s, miners could simply walk in to a mine to get where they needed to go, but later on, the mines became so deep, they had to use steam elevators to enable access to deeper seems.

We know Norton was trapped in Golden Cave for some time after the mine collapse considering we know he came out with meteorite chunks. Based on what we see on the lowest level of Golden Cave in game, this likely implies the meteorite was potentially at the bottom, meaning there’d be quite some distance to dig himself out.

The other issue is most miners don’t simply dig themselves out after a collapse. There’s nothing to support the roof and sometimes little space to put the material you remove, not to mention usually a lack of suitable tools. Trying to dig yourself out of a collapsed mine may even weaken the area near the collapse, potentially causing further collapses. This is why most miners usually have to wait to be rescued.

It is possible that Norton was able to access an alternate escape route. Mines were required to have more than 1 shaft following the Hartley mine disaster in 1862. If it or a raise (vertical or inclined passage) had a safety ladder, it’s possible he could work his way back up. During the Barnes-Hecker mine disaster (the mine was flooded), the sole survivor saved himself by climbed 80 stories (around 800 feet) in just about 14 minutes.

Another option is via an intake airway (or downcast shaft), which brings fresh air from the surface into the underground mine. Miners could feel the air to figure out a way out of the mine, and this was breathable air, free from fumes and dust in the case of a fire or explosion. A return airway (upcast shaft) is also an option, but not as nice of one due to the fact it carried air out of the mine to the surface, and this air could include dust, toxic fumes, and such. But miners have escaped via vents before (such as in the Quecreek Mine disaster, which they did to escape the mine as it started flooding).

And if acid mine drainage is potentially related to the pollution and dead animals/plants in Lakeside (Yidhra’s 3rd letter, Grace trailer/deductions), maybe that means there was drainage or some other hole into or out of the mine around there that Norton could’ve used to escape. Norton’s deduction 9 does make it sound like police didn’t expect anyone to survive, which could imply the normal entrances or exits were inaccessible following the collapse, meaning using an alternate, less known route might make sense. We know Norton was knowledgeable, and in the trailer we see him with a map, though based on how his coworkers in that scene look like they might take it from him, he might not have had that, but he may have at least memorized the different ways in and out, and thus how he could manage to escape (especially as explosions can damage the lifts they use to normally get down to the deeper levels).

Norton likely survived due to being some distance from the blast. Some of his coworkers likely died from the initial explosion. The others potentially could’ve succumbed to lack of oxygen, potentially aided if any fires started as a result (which could further weaken supports or cause more collapses), or due to potentially high concentrations of firedamp further down. Afterdamp (choking gas) is a mix of toxic gases (carbon dioxide, carbon monoxide, and nitrogen) after a methane explosion, and it is just as deadly as the actual explosion. Symptoms include head swimming/disorientation, feeling very tired, difficulty doing anything or exerting yourself, and a desire to just close your eyes and go to sleep (followed soon by death from the lack of oxygen).

#idv#identity v#norton campbell#prospector#idv norton#identity v norton#idv prospector#identity v prospector#Fool's Gold#hunter norton#idv fool's gold#idv hunter norton#identity v fool's gold#identity v hunter Norton#sirenjose analyses and theories

73 notes

·

View notes

Note

We may have a problem with the so-called fiancé, @artofdeductionbysholmes I lost sight of him…

Any update on the lab results? @artofdeductionbysholmes @mollyatthemorgue

The question is: did he disappear on his own terms, or was his disappearance forced?

And yes, I just received @mollyatthemorgue Molly's lab report. See below.

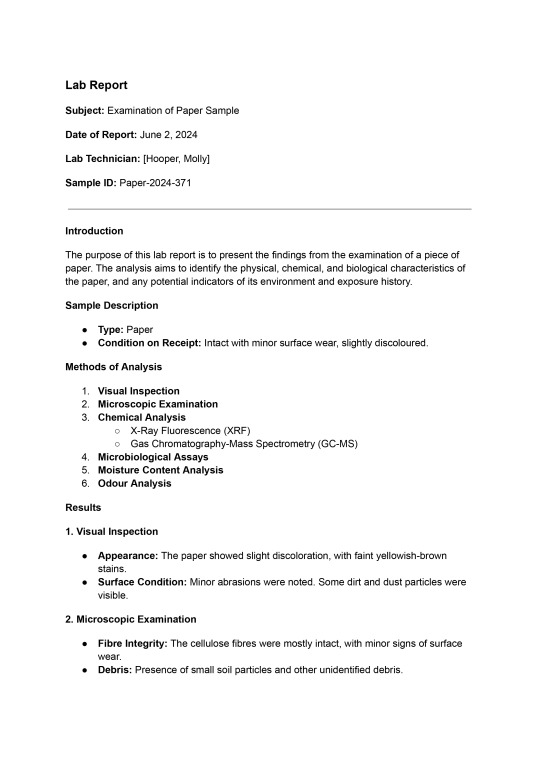

[ID: 3 screenshots of a lab report

Lab Report

Subject: Examination of Paper Sample

Date of Report: June 2, 2024

Lab Technician: Hooper, Molly

Sample ID: Paper-2024-371

Introduction

The purpose of this lab report is to present the findings from the examination of a piece of paper. The analysis aims to identify the physical, chemical, and biological characteristics of the paper, and any potential indicators of its environment and exposure history.

Sample Description

Type: Paper

Condition on Receipt: Intact with minor surface wear, slightly discoloured.

Methods of Analysis

Visual Inspection

Microscopic Examination

Chemical Analysis

X-Ray Fluorescence (XRF)

Gas Chromatography-Mass Spectrometry (GC-MS)

Microbiological Assays

Moisture Content Analysis

Odour Analysis

Results

1. Visual Inspection

Appearance: The paper showed slight discoloration, with faint yellowish-brown stains.

Surface Condition: Minor abrasions were noted. Some dirt and dust particles were visible.

2. Microscopic Examination

Fibre Integrity: The cellulose fibres were mostly intact, with minor signs of surface wear.

Debris: Presence of small soil particles and other unidentified debris.

3. Chemical Analysis

X-Ray Fluorescence (XRF):

Detected Elements: Trace amounts of heavy metals such as lead (Pb), cadmium (Cd), and chromium (Cr).

Surface Contaminants: Minor presence of inorganic substances.

Gas Chromatography-Mass Spectrometry (GC-MS):

Organic Compounds: Detected small amounts of hydrocarbons and other organic pollutants.

Residues: Identified residual chemicals from inks and dyes, with some degradation products.

4. Microbiological Assays

Bacterial Presence: Identified bacterial species including Bacillus and Pseudomonas spp.

Fungal Presence: Traces of fungal spores, likely Aspergillus and Penicillium spp.

5. Moisture Content Analysis

Moisture Level: Moderate moisture content of 12%.

Chemical Composition: The moisture contained slight acidic properties.

6. Odour Analysis

Detected Odours: Mild, musty odour with hints of organic decay.

Discussion

The examination of the paper sample indicates several key findings:

The physical condition and minor wear suggest it was exposed to an environment with abrasive materials and some physical stress.

The presence of heavy metals and organic pollutants detected by XRF and GC-MS indicates exposure to a polluted environment, potentially involving industrial or waste materials.

Microbial assays revealed early stages of microbial colonisation by bacteria and fungi typically associated with organic material decomposition.

The moderate moisture content and slight acidity suggest exposure to a moist environment with some chemical interactions.

Odour analysis confirmed the presence of organic decay-related gases.

The combination of physical wear, chemical contaminants, microbial presence, and environmental indicators suggests that the paper may have been exposed to a mixed waste or polluted environment. The findings are consistent with environments such as waste disposal sites, polluted industrial areas, or other locations with significant organic and inorganic contaminants.

Conclusion

The paper sample shows signs of exposure to a polluted and possibly waste-rich environment. The results indicate physical wear, contamination by heavy metals and organic pollutants, microbial activity, and environmental interactions that are typical of such conditions. Further context about the paper's origin could provide more specific insights.

Lab Technician Signature:

[signature of Molly Hooper]

Reviewed By:

Patrick Miller

/end ID]

22 notes

·

View notes

Text

Unveiling the microscopic mechanism of superconducting metallic transistors

Transistors are the basis for microchips and the whole electronic industry. The invention of transistors, by Bardeen and Brattain in 1947, awarded with a Nobel prize, is regarded as one of the most important discoveries of the 20th century. Traditional transistors are based on modulating an electric current under an electric field, which is possible only using semiconductor materials. In semiconductors, there are fewer free charge carriers compared to metals, and the Fermi level (which is the thermodynamic work required to add one electron to the system) sits in an energy band gap, which implies that electrons are more difficult to excite. By doping semiconductors, one can create a certain number of free carriers, e.g., in an empty band, which now can be excited to larger momenta and therefore can carry electric current through the material.

Read more.

12 notes

·

View notes

Text

just dropped in; PROLOGUE

[A SONG FROM YOUR CHILDHOOD STARTS PLAYING, A MELODY THAT REMINDS YOU OF A TIME WHEN YOU WERE A HAPPY CHILD — ONCE.]

Laying on the floor of the living room, the top of her head is settled against the top of Mark's. Like they're mirror images; her arms splayed out to the exact angle of his. The boombox is too close to their faces and in a minute their mother will come in from the kitchen and chide them for it, tell them how bad it is for their hearing. But for now, it's just Mark's crown against hers and the reverb of a slouched guitar sliding through the bridge of Heart-Shaped Box. The CD is secondhand and has a rough crackle behind the sound. In a month or so it will give out, finally, listened to over and over again by both its previous owner and the twins. Mark's breathy voice weaves through Kurt Cobain's and Nadia joins in without realizing: "Hey. Wait. I got a new complaint." Over and over again, on that chopper bringing her to whatever the fuck this new assignment is going to be, Nadia mouths that ending loop. Hey. Wait. I got a new complaint. Forever in debt to your priceless advice.

[A FIDGETABLE, ANALOG ITEM, CAN BE KNIFEY THOUGH YOU BETTER HAVE A GOOD REASON FOR IT TO BE]

Mark had given it to her, on her twenty-fifth birthday. A joke gift because she had been on a string of missions that all dealt with anomalies in the form of priceless pieces of art. Nadia ended up loving the small, handheld microscope, joke though it was. Especially much later, when the transfer to Xi-13 meant endless stake-outs and recon drops in the middle of nowheres. Everything in nature was ten times cooler under the loupe: leaves, and insect nests, and patches of fungi. They took all her knives (which was a major fucking red flag but she was already in too deep to argue) and her sidearm, so Nadia reaches for the loupe from her pack. Doesn't look through it -- not much to fucking look at aside from metal and industrial storage -- just folds it out of the protective sheath and back, listening to the hinge click and the air slide over the glass.

[A PLACE OF GREAT PERSONAL SIGNIFICANCE, BE THAT POSITIVE OR NEGATIVE]

Four blocks down and one over from Nadia's childhood house sat the Pine Grove Towship Park. There was a playground, a shade awning with picnic tables and a stretch of field that came up against a scrubbysuburban forest. Nothing you could really get lost in, but dense enough to make late night, summer games of Manhunt interesting. Adjacent to the drifting tall-grass was a baseball diamond (more often home to charity softball games between fire department and police force, or impromptu kickball matches as long as someone was able to lift one of the Franklin rubber balls from the school gym). It smelled like mud and grass and gravel and damp wood, from the chips that lined the ground under the play structures. Nadia had memories tied to every inch of that corner lot: smoking under the child-sized climbing wall as a teenager, swinging silently with Mark while the sun set further and further, running through the trees in pitch black and holding back laughter so she wouldn't tip off the other team. It doesn't really smell like the park when the copter finally touches down. And, when Nadia hauls the door open, it certainly doesn't look anything like a suburban, middle America public park. But something of that place, those memories, linger at the back of the mind. Maybe it's the feeling of darting through dark-touched trees to a stretch of underbrush, hoping the person hunting you couldn't hear you breathing. Whatever it is, Nadia shakes it off and steps onto frigid concrete.

11 notes

·

View notes

Text

Electropolishing for Deburring Critical Metal Parts

Stamping and machining processes can leave metal parts with burrs that can affect the fit, function and durability of metal parts.

When these parts are destined for food or pharmaceutical production equipment or fuel lines and gear assemblies used in aerospace manufacturing, burrs are more than just a surface imperfection – they’re a potentially catastrophic defect that can prevent the proper sealing or connection between two parts, become dislodged near moving parts, or cause seizing of screws and other fasteners.

To prevent such risks, manufacturers in many industries often specify electropolishing as the final step in finishing their critical metal parts.

How Does Electropolishing Work?

Electropolishing is a highly effective finishing process for removing metal surface defects like microburrs caused by processes like broaching, fine blanking, grinding, lapping or milling.

Using a combination of a chemical bath and a rectified electrical current, electropolishing removes a precise and uniform layer of surface material, leaving behind a shiny, smooth, passive and defect-free surface.

Among other advantages, electropolishing can remove a microscopically precise amount of surface material with surface roughness improvement of up to 50%, eliminating surface defects for high-quality results within very tight tolerances.

By eliminating microcracks and other defects that can harbor bacteria or become initiation sites for corrosion, electropolishing also leaves metal parts with significantly improved resistance to corrosion and pathogen growth. The ultrasmooth surface finish that electropolishing leaves behind has been shown to inhibit the formation of bacterial biofilms that can be resistant to ordinary cleaning methods. The finish also leaves behind a surface that is easier to clean, without cracks or defects where pathogens can hide – a critical advantage for medical, pharmaceutical and food and beverage production.

Why Use Electropolishing for Deburring?

Fragile or intricate metal parts, like those used for medical devices and implants, are not well suited for finishing processes like mechanical or vibratory polishing, which can damage fragile parts or create inconsistent results for parts with complex shapes.

Successful deburring for critical metal parts is contingent upon the ability to remove a precise layer of surface material. No other process can match electropolishing for its ability to control the material removal to +/- .0002”.

By deburring the threads on metal fasteners, for example, electropolishing can reduce the risk of adhesion between two mating surfaces, also known as “galling,” which can cause material between the surfaces to deteriorate and seize up when parts are pressed together.

Burrs can also shorten the lifespan of a part, by breaking off or becoming an initiation site for corrosion.

Larger burrs that occur as the result of rough milling or displaced metal from drilling operations, however, may need pre-treatment using other methods. Likewise, heavy die break burrs caused by improper tooling maintenance will generally require additional treatment.

Much in the way that lightning is drawn to the highest points, electropolishing delivers higher current density on the high points or edges which makes it ideal for micro-deburring The customized nature of the electropolishing process, from racking to chemical formulation to timing, would be of little value if it could not be reproduced consistently. But unlike other finishing processes, electropolishing is prized for its consistent results.

Electropolishing also offers a key advantage for parts with critical microfinishes or made from the lighter, more fragile materials increasingly used in the manufacturing of medical devices, electrical components and semiconductors, among other industries. These parts are not suitable for mass finishing techniques that can create distortion, nicks and scratches. Electropolished parts are individually racked to prevent contact and ensure the even application of the process for even the most fragile parts.

Advantages of Electropolishing for Deburring

The electropolishing process can be customized by alloy, by application and by the desired results. Beyond its ability to remove a uniform layer of surface material to eliminate surface defects like microburrs, microcracks, scale and staining, electropolishing offers many collateral benefits for the manufacturers of critical metal parts.

Microscopically precise removal of surface material with control to +/-.0002”

Customized racking to accommodate fragile and complex parts small and large

Leaves parts with enhanced durability and cycle life

Creation of a pathogen-resistant surface

Superior cleanability

Ultraclean finish

Decorative finish

One stop process for cleaning and removing surface defects

30X more corrosion resistance than passivation alone

Parts are also left passivated in the process

Improves conductivity of copper and aluminum alloys

What Alloys Can Be Electropolished?

A long list of alloys can be effectively deburred using electropolishing. The process is also equally effective on parts that are fully annealed or hardened. That is one reason that electropolishing is frequently specified for the final deburring and finishing of parts after all fabrication and heat treating processes have been completed.

Electropolishing is effective for a wide variety of alloys including:

Stainless Steel 200-300 Series

Stainless Steel 400 Series

Stainless Steel: Precipitating Hardening Grades

Nitinol

Titanium

Aluminum

Carbon Steels

Copper

Brass

Nickel Alloys

Specialty Alloys

And more

Electropolishing for Critical Metal Parts

As the world’s largest electropolishing specialist with seven decades of electropolishing expertise and innovation, Able Electropolishing provides consultation and collaboration from the earliest stages of prototyping through production to create highly customized electropolishing processes for a wide variety of metal parts.

6 notes

·

View notes

Text

Last Monday of the Week 2024-01-08

My guests have just boarded their plane. It was good and now I get to learn exactly what happens when you make my apartment handle three people for two weeks.

Listening: Between the frigid weather and the Maladies, the back half of this trip featured a lot of crashing on the couch. Putting on various background music while people were around featured a lot of Jack de Quidt specials, here's "The Valentine Affair" from Marielda.

The second best part of having an extremely specific music collection that you put together yourself is being shockingly good at telling people who did a particular song when they ask.

Reading: "Small Scale Farmers and Peasants Still Feed The World", a defense of some older UN FAO numbers, and a rebuttal to the paper "How much of our world’s food do smallholders produce?" and by extension Hannah Ritchie's article "Smallholders produce one-third of the world’s food, less than half of what many headlines claim", which was an earlier Reading entry. I think I saw this paper when @probablyasocialecologist posted it.

(PDF linked from that page)

The paper makes some interesting points about the status of the data these studies are based on. It makes me less convinced of their point than it makes me doubtful that anyone has a good number on this, which is valuable on its own. It seems like both the FAO claims and the newer World Development papers have some very arbitrary choices that make it difficult to pin down, but that there is clear value in measuring agricultural productivity differently for these applications.

It mainly brings up the value of including utilization of agricultural calories instead of just looking at raw value output, basically incorporating that a huge amount of the value AND calories produced in highly productive agronomies like the USA end up in cattle feed or biofuels instead of in humans. A good point, we were just talking about this the other day in the biofuel hate tag! It also notes that if you ignore small scale animal agriculture and non-agricultural calorie sources you throw away a lot of calorie conversion in poorer parts of the world.

This is a big deal! Industrial vs Smallholder agriculture is a thing I care a lot about, each one has very variable upsides and downsides and where to focus attentions (yields, transport, industrialization) changes dramatically based on what is the main driver of land use and carbon emissions.

Basically I need to read some more things. Notes to follow maybe.

Watching: I continue to find Jet Lag The Game extremely good.

Playing: Nothing! Busy...

Making: Slides and slips arrived for the Microscope, so I can start doing real mounts. Did a very hasty saliva sample just to check it out, and like. Man it's so nice to have a real scope, you can see epithelial tissue so clearly even with plain old brightfield and no staining. Started working on some printed mounts for a camera. My brother brought my reliable old point-and-shoot up and that's perfectly suited to do some microscopy capture.

Tools and Equipment: I got a basic stylist's comb with a metal tail and it so dramatically simplifies handling long hair when you're washing it. Highly recommended.

7 notes

·

View notes

Text

Osmium Market Explained: The World's Most Densely Valuable Metal

The Osmium market is a niche sector within the broader precious metals industry, often overshadowed by its more well-known counterparts like gold and silver. Osmium is a remarkable element with unique properties that make it a valuable asset for various industries, especially in cutting-edge technologies and scientific applications. In this article, we will explore the Osmium market, its uses, sources, and its potential for growth and investment.

Understanding Osmium

Osmium market is a chemical element with the symbol Os and atomic number 76. It is one of the densest naturally occurring elements and belongs to the platinum group metals (PGMs), which also includes platinum, palladium, rhodium, ruthenium, and iridium. Osmium is characterized by its bluish-white color and extreme density, making it twice as dense as lead.

Historically, osmium was used in various applications, such as fountain pen tips and electrical contacts, due to its hardness and corrosion resistance. However, modern applications for osmium have evolved, and its market dynamics have changed significantly.

Osmium in Modern Applications

Osmium Alloys in Industry Osmium is often alloyed with other metals, like iridium, to create exceptionally hard and durable materials. These alloys find applications in the aerospace and automotive industries, where they are used for electrical contacts, spark plug tips, and turbine engine components. The extreme heat resistance of osmium alloys makes them invaluable in these high-temperature environments.

Scientific Applications In scientific research, osmium tetroxide (OsO4) is a widely used staining agent for electron microscopy and other microscopic imaging techniques. It can highlight cellular structures and biological tissues, aiding researchers in understanding complex biological processes.

Investment Potential The rarity of osmium and its diverse applications make it an attractive option for investors looking to diversify their portfolios. As a tangible asset, osmium can act as a hedge against economic instability and currency devaluation. However, investing in osmium requires careful consideration and knowledge of the market, as it is less liquid than more common precious metals.

Sources of Osmium

Osmium is a rare element found in trace amounts in various ores, with primary sources being platinum and nickel ores. The largest producers of osmium are countries with significant platinum mining operations, such as South Africa and Russia. Extraction of osmium from these ores is a complex and expensive process, which contributes to its scarcity.

Osmium Market Trends

The Osmium market is characterized by its limited supply and steady demand. Over the past decade, the market has experienced modest growth, driven by technological advancements and increasing demand for its unique properties. Some notable trends in the Osmium market include:

Growing Demand in Aerospace and Automotive Sectors The use of osmium alloys in aerospace and automotive applications is expected to increase as manufacturers seek materials that can withstand extreme conditions. Osmium's remarkable hardness and resistance to high temperatures make it a preferred choice in these industries.

Expanding Scientific Research Advancements in scientific research and the increasing need for advanced microscopy techniques are expected to drive the demand for osmium tetroxide, a key component in staining and imaging. This is particularly relevant in the fields of biology, medicine, and materials science.

Investment Opportunities While osmium is not as commonly traded as other precious metals, its investment potential has piqued the interest of collectors and investors. Some institutions and individuals are exploring the possibility of adding osmium to their investment portfolios as a store of value and a hedge against economic volatility.

Challenges in the Osmium Market

Despite its unique properties and applications, the Osmium market faces several challenges:

Limited Supply Osmium's scarcity poses a significant challenge for both industrial users and investors. The small quantities of osmium available and the complex extraction process contribute to its high cost.

Market Awareness The general public and even some investors remain relatively unaware of osmium as an investment option. Increasing awareness and education about the metal's unique characteristics and market dynamics is essential to foster growth.

Conclusion

The Osmium market may be small compared to other precious metals, but its unique properties and applications make it a valuable and intriguing element within the world of commodities and investments. As technology continues to advance and scientific research expands, the demand for osmium is likely to grow, offering opportunities for those willing to explore this less-known sector of the precious metals industry. While challenges such as limited supply and market awareness persist, the Osmium market's potential for growth and investment remains an exciting prospect for those who see beyond the bluish-white surface of this remarkable element.

#Osmium Market Share#Osmium Market Growth#Osmium Market Demand#Osmium Market Trend#Osmium Market Analysis

17 notes

·

View notes

Text

OH i know this one. Your first step is to figure out whether your fantasy setting is more western or eastern based. This has a bunch of nuanced ways to discuss, but the most important one for the purposes of modern medicine is: do the locals drink tea, or do they drink wine. If they're a tea-based society, their primary storage vessels will be earthenware. This'll be a problem. If you want modern medicine you need to first popularise wine, this'll create the supply/demand impetus for the locals to create a proper glass-blowing industry. You cannot have modern medicine without having access to a good glass-blowing industry. Because glass is chemically inert it is the one material you absolutely need for your any proper lab-setting. You cannot store your medicines in reactive containers after all, nor can you safely make medicine in reactive metal pots. Even if you are already in a wine-based society with a functional glass-blowing industry, you still need to get some glassworkers to switch into glass-cutting from glass-blowing though. This to gain access to microscopes and glasses. The glasses especially matter a lot more then you might think, the main source of scientist retirement is age-related eye-deteriation. Prescription Lenses earn every scientist an aditional 5-10 years in which to work. From thereon, you can expect modern medicine to slowly emerge as a result. (alongside modern chemistry, remember to warn them about the leaded gasoline and PFAs)

#Look i know the answer the streamer is looking for is “how can I great-man-theory-of-history this shit” but that just doesnt work#Best case scenario that ends with him a monopolistic force with a Coca-Cola secret formula for insulin#which is a societal-level single-point failure#the entire fantasyworld would collapse the moment he dies of old age

29K notes

·

View notes

Text

Microscope for the metal industry is an indispensable tool for materials analysis and quality control. With advanced optics, precision mechanics, and specialized illumination, these microscopes empower metallurgists, engineers, and researchers to explore the convoluted details of metal samples with consummate clarity.

0 notes

Text

How RO Water Filter Systems Work: The Science Behind Pure Water

Clean and safe drinking water is essential for life, yet many water sources are contaminated with harmful substances such as heavy metals, chemicals, and microorganisms. To tackle these challenges, advanced purification technologies have been developed, with reverse osmosis systems standing out as one of the most effective methods.

In this article, we will explore how RO water filter systems work, the science behind their operation, and why they are essential for ensuring pure and safe water for households and businesses alike.

What is a Reverse Osmosis (RO) Water Filter System?

A Reverse Osmosis (RO) system is a water purification technology that uses a semi-permeable membrane to remove impurities from water. It operates on the principle of osmosis but in reverse—hence the name.

While osmosis is a natural process where water moves from a region of lower solute concentration to higher solute concentration through a semi-permeable membrane, reverse osmosis applies external pressure to move water in the opposite direction. This process separates contaminants and leaves behind clean, purified water.

The Science Behind Reverse Osmosis

To fully understand how RO systems work, let’s delve deeper into the scientific principles that underpin the process.

Osmosis vs. Reverse Osmosis

Osmosis: In a natural setting, water moves from an area of low solute concentration to an area of high solute concentration to achieve equilibrium. This process occurs through a semi-permeable membrane, which allows only water molecules to pass.

Reverse Osmosis: In contrast, reverse osmosis uses external pressure to overcome natural osmosis, forcing water from a high solute concentration (contaminated water) to a low solute concentration (purified water).

The external pressure is key to reversing the natural flow of water and separating impurities.

Semi-Permeable Membrane

The semi-permeable membrane is a critical component of the RO system. It acts as a barrier, selectively allowing water molecules to pass while blocking larger molecules and contaminants.

The membrane’s efficiency lies in its microscopic pores, which are small enough to trap impurities such as:

Dissolved salts and minerals.

Heavy metals like lead and arsenic.

Microorganisms, including bacteria and viruses.

Chemical pollutants, such as pesticides and herbicides.

Pressure and Flow

The pressure applied during the RO process plays a crucial role in determining its effectiveness.

Higher pressure ensures that water is forced through the membrane efficiently, even when dealing with high levels of dissolved solids.

Flow rate affects the system’s output. RO systems are designed to balance purification speed with water quality.

What Contaminants Does an RO System Remove?

RO systems are highly effective at removing a wide range of contaminants, including:

Dissolved Salts: Sodium, chloride, and other salts that cause water hardness.

Heavy Metals: Lead, arsenic, mercury, and cadmium.

Chemicals: Chlorine, fluoride, nitrates, and VOCs.

Microorganisms: Bacteria, viruses, and cysts.

Sediments and Particles: Dirt, sand, and rust.

The result is water that is free from harmful substances and safe for consumption.

Advantages of Using an RO Water Filter System

1. Exceptional Water Purity

RO systems remove up to 99% of contaminants, making them one of the most reliable water purification methods available.

2. Improved Taste and Odor

By eliminating chlorine, sulfur, and other impurities, RO systems enhance the taste and smell of your water.

3. Health Benefits

Consuming purified water reduces the risk of exposure to harmful substances, promoting overall health and well-being.

4. Versatility

RO systems can be used in homes, offices, and industries to meet diverse water purification needs.

5. Environmentally Friendly

By reducing the need for bottled water, RO systems help minimize plastic waste.

Challenges and Solutions in RO Systems

While RO systems are highly effective, they do come with some challenges:

1. Water Wastage

Challenge: RO systems produce wastewater during filtration.

Solution: Opt for water-saving models or reuse wastewater for non-drinking purposes.

2. Removes Beneficial Minerals

Challenge: RO systems strip water of essential minerals like calcium and magnesium.

Solution: Install a remineralization filter to add beneficial minerals back into the water.

3. Maintenance Requirements

Challenge: RO systems require regular filter and membrane replacements.

Solution: Follow the manufacturer’s maintenance schedule to ensure optimal performance.

Conclusion

RO water filter systems are a game-changer in the quest for pure and safe drinking water. By leveraging advanced scientific principles, these ro water filter system effectively remove a wide range of contaminants, ensuring the water you consume is clean, healthy, and refreshing.

Understanding how RO systems work highlights their value as a long-term investment for health, convenience, and sustainability. Whether for residential or commercial use, an RO system provides peace of mind by delivering the highest water quality standards, empowering you to make water safety a priority in your life.

0 notes

Text

Electron Microscope Market: Advancements in High-Resolution Imaging and Analysis up to 2033

Market Definition

The electron microscope market involves the creation and use of electron microscopes, which are special tools that use electron beams instead of visible light to magnify objects to very high levels. These microscopes include transmission electron microscopes (TEMs), scanning electron microscopes (SEMs), and scanning transmission electron microscopes (STEMs). They are commonly used in fields like scientific research, materials science, nanotechnology, and industry to closely examine the structure and composition of samples at the atomic level.

To Know More @ https://www.globalinsightservices.com/reports/electron-microscope-market

The component content management systems market is anticipated to expand from $3.9 billion in 2023 to $8.2 billion by 2033, with a CAGR of 7.5%.

Market Outlook

The electron microscope market is growing quickly, fueled by technological progress, more research and development, and expanding uses in various industries. These microscopes offer exceptional imaging abilities, allowing scientists and engineers to study materials and biological samples with remarkable detail and precision.

A major reason for this growth is the increasing demand for advanced imaging in scientific research and materials science. Electron microscopes are key tools for studying the structure and properties of materials at the nanoscale, supporting discoveries in areas like nanotechnology, semiconductor production, and biomaterials. As research projects become more complex and the need for higher-resolution images grows, more research labs and academic institutions are adopting electron microscopes.

In healthcare and life sciences, electron microscopes are used to create detailed images of biological samples like cells, tissues, and viruses. This is vital for understanding how cells work, disease processes, and developing new medical treatments. The rise in biomedical research and the growing number of complex diseases are increasing the demand for electron microscopy in medical research and diagnostics.

The industrial sector is also benefiting from advancements in electron microscopy. In semiconductor manufacturing, electron microscopes are used to inspect and analyze microelectronic parts and integrated circuits. These microscopes help detect defects, check material properties, and ensure quality control, all of which are crucial for maintaining the performance and reliability of electronic devices. In materials science, electron microscopes are used to examine the microstructure of metals, polymers, and composites, helping to develop new materials and improve product quality.

Technological innovations are playing a key role in the growth of the electron microscope market. New developments like aberration-corrected electron microscopy, cryo-electron microscopy, and high-throughput imaging systems are expanding what electron microscopes can do. These improvements allow researchers to achieve even higher-resolution images, study dynamic processes, and explore new fields in science and technology.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS10164

0 notes

Text

Not all calcite crystals perfect; synthesis methods can alter internal structure, affect chemical reactivity

When looking at calcite under a microscope, a scientist would immediately recognize the crystalline form of calcium carbonate by its rhombohedral appearance. That is, calcite is shaped like a distorted cube. One of Earth's most abundant minerals, calcite is a major component of limestone and marble. It is also the most stable of the three common, naturally occurring crystal forms of calcium carbonate; the other two forms are aragonite and vaterite. Studying calcite is important as it has broad relevance in several ways. When calcium carbonate is synthesized, it transforms carbon dioxide (CO2) into solid carbonate, the final reaction product needed for long-term carbon storage in the fight against climate change. Additionally, as researchers recently discovered, the presence of defects in calcite can be controlled by how it is synthesized and can alter many of its properties. For example, defects can affect calcite's ability to soak up harmful substances in the environment like heavy metals. They can also affect the mechanical strength of calcite—which has implications for the development of more durable materials—and the ability to improve catalysts used in industrial processes.

Read more.

#Materials Science#Science#Calcite#Minerals#Materials characterization#Calcium carbonate#Crystals#Crystallization

10 notes

·

View notes

Text

Improving Efficiency with Advanced Tools from Diamond Wire Dies Manufacturers

In the competitive world of industrial production, maximum efficiency and precision are key factors. This is where the diamond wire die manufacturer plays an important role. A good die maker guarantees quality tools capable of improving performance, limiting downtime, and maximizing productivity. The following section takes a look into how advanced tools offered by diamond wire dies manufacturers contribute to increasing efficiency, along with why industries like IMAT-CVD survive in this specialized field.

Diamond Wire Dies Explained

Diamond wire dies are punched in the wire drawing process when fine metal wires are shaped into specified diameters. These dies employ industrial diamonds, allegedly the hardest of all known substances. For diamond wire dies, low wear and long service life are a reality.

Importance of Diamond Wire Dies

The automotive, aerospace, electronics, and telecommunications industries remain heavily dependent on diamond wire dies to produce high-quality metal wires with uniform diameters and smooth surfaces. The efficiency of the wire-drawing process directly contributes to the efficiency of production as a whole. Further Contributions To The Enhancement Of Efficiency

A competent diamond wire dies manufacturer embraces modern technologies and has quality-inclusive improvements in productivity and operational efficiency. Here is how:

Increased Life and Durability

Compared to conventional tungsten carbide dies, diamond wire dies have better resistance to wear. This results in better working conditions because of reduced frequency in replacement, which for the maintenance sector amounts to lowered costs.

Precision and Uniformity

High-quality diamond dies to yield uniform wire dimensions and sizes with high precision. This reduces waste of the raw material and ensures consistency of the finished product, which is very important for companies producing highly performing wires.

Higher Drawing Speeds

With better heat resistance and reduced friction, diamond wire dies push "the drawing speed to achieve higher levels without impacting quality." This promotes enhanced production efficiency allowing manufacturers to meet tighter deadlines and larger volume product demands.

Choosing a Diamond Wire Dies Manufacturer

A diamond wire dies manufacturer should be chosen based on many considerations, for the company to secure quality products that benefit its specific needs.

Expertise and Industry Exposure

An established manufacturer with years of experience, amid other things with producing diamond wire dies, like IMAT-CVD, is most likely to offer reliable and innovative solutions. Its deep understanding of the material's properties and wire drawing techniques will guarantee optimal performance.

Advanced Manufacturing Technology

Leading manufacturers use modern technologies, such as laser-cutting and precision grinding in making high-performance wire dies to ensure better dimensional accuracy and extended tool life.

Customization Options

Each industry is different and needs specialists. A diamond wire dies manufacturer of good repute will engineer a customized die size and shape with its respective grade of diamond according to individual needs.

Quality Assurance and Testing

All wire dies produced by manufacturers like IMAT-CVD will meet the highest standards in the industry through extremely rigorous quality control procedures that include microscopic inspection and wear-resistance qualification tests.

Future Trends in Diamond Wire Dies Manufacturing

The trade is ever-evolving, and the industry gets reshaped by manifesting new technologies into 'drawing' the future.

Integration of Nanotechnology

With nanomaterials incorporated into diamond wire dies, wear-resistance quality and drawing efficiency will be taken to the next level.

Automation and AI in Manufacturing

AI-based manufacturing processes are assisting diamond wire dies manufacturers in optimizing production, avoiding errors, and ensuring uniform quality.

Sustainable Manufacturing Practices

Ecologically minded practices are being adopted by manufacturers like IMAT-CVD to keep pollution down while achieving a level of quality in the product.

Conclusion

No doubt investing in good-quality diamond wire dies manufacturers is a step toward improving manufacturing efficiency. Working with a company that has experience in the manufacture of diamond wire dies provides the company with long die life, enhanced precision, and better productivity. In particular, IMAT-CVD has proven to be the leader in the field, offering growth products for the sake of the constant change and evolution of a modern industry.

0 notes

Text

Evaluation of Different Surface Treatment Methods

Overwhelmed by the countless surface treatment processes and their confusing definitions? Don’t worry! This blog simplifies everything for you with clear definitions and detailed process diagrams, helping you grasp the essentials of various surface treatment processes in just minutes!

1. PVD (Physical Vapor Deposition)

PVD is an industrial manufacturing process, belonging to a type of coating technology, primarily using physical means to heat or excite materials to deposit thin films. This technique, also known as vacuum coating or vapor deposition, is commonly employed in surface treatments of cutting tools, various molds, and in the manufacturing processes of semiconductor devices.

AD: Compared to chemical vapor deposition, physical vapor deposition has a wider range of applications. Almost all materials can be used to prepare thin films through physical vapor deposition.

DIS: The uniformity of film thickness is indeed a concern in physical vapor deposition.

PVD Physical Vapor Deposition 01

PVD Physical Vapor Deposition 02

2. Mechanical Polishing

Mechanical polishing relies on the grinding and rolling action of very fine polishing particles, as well as cutting and plastic deformation of the material surface, to remove protrusions from the polished surface of the metal sample, thus obtaining a smooth surface.

AD: The equipment structure is relatively simple, and the price is generally lower compared to other methods.

DIS:

Mechanical polishing is challenging for polishing workpieces with complex shapes or surfaces featuring special patterns or textures.

It tends to generate metal dust, which can affect the health of polishing workers.

It requires a high level of skill from workers, making it difficult to control the consistency and stability of workpiece quality.

Mechanical processing inevitably leaves microscopic cracks and residual stress on the workpiece surface, which may affect the quality and lifespan of the workpiece and pose safety hazards for production.

mechanical polishing

3. Chemical Polishing

Chemical polishing is a method that relies on the selective dissolution of surface irregularities on samples through the chemical etching action of chemical reagents, eliminating scratches and leveling surfaces.

AD: Chemical polishing does not require special fixtures or DC power supply equipment. It is simple to operate, energy-efficient, and not limited by the size or shape of the workpiece. Additionally, the direct cost of polishing is relatively low.

DIS: The pollution issue is particularly severe, as handling the waste liquid generated during the polishing process can increase costs.

Chemical Polishing

4. Electropolishing

Electropolishing, also known as electrochemical polishing or electrolytic polishing, utilizes the phenomenon of electrochemical dissolution generated by the anode in an electrolytic cell to selectively dissolve micro-protrusions on the anode surface, resulting in a smoother surface. In this process, the workpiece to be polished serves as the anode, while an inert metal acts as the cathode. Both poles are immersed in an electrolyte solution, and a direct current is passed through to achieve selective anodic dissolution, thereby increasing the brightness of the workpiece surface.

AD:

Consistent internal and external color, long-lasting luster, and the ability to smooth out concave areas that mechanical polishing cannot reach.

High production efficiency and low cost, suitable for large-scale sample preparation.

Enhanced corrosion resistance of the workpiece surface, applicable to all stainless steel materials.

DIS:

The quality of electrolytic polishing is influenced by the specifications of the electrolyte, as well as the current and voltage settings, making it difficult to determine the correct parameters.

Achieving satisfactory results for samples with cast iron or impurities is more challenging.

The electrolyte composition is complex, requiring careful attention to safety during use.

Electropolishing 01

Electropolishing 02

5. Spray Painting

spray painting is a coating method where the liquid is dispersed into uniform and fine droplets using a spray gun or disk atomizer, typically with the aid of pressure or centrifugal force, and applied to the surface of the object to be coated.

AD: Fast construction, good surface smoothness, no texture differences.

DIS: Spray painting machines are relatively expensive, and there is a significant amount of paint wastage.

Spray Painting

6. Powder Coating

Powder coating is a process where powder coating material is sprayed onto the surface of a workpiece using powder coating equipment (electrostatic spray gun). Under the influence of static electricity, the powder evenly adheres to the surface of the workpiece, forming a powdery coating layer.

AD:

Powder coatings do not contain VOCs (volatile organic compounds), eliminating issues such as fire hazards, toxicity, and environmental pollution.

Minimal material loss and high utilization.

Easy control of coating thickness, high construction efficiency, low construction difficulty, and energy and labor-saving.

Scratch-resistant, impact-resistant, durable, and excellent chemical resistance.

DIS:

The investment required for manufacturing powder coatings and replacing coating equipment is significant.

Color matching for powder coatings can be challenging, and changing colors or types during coating is more cumbersome and costly.

Cannot be used on substrates with poor heat resistance such as plastic, wood, or paper.

Powder coatings are susceptible to clumping during storage due to pressure, temperature, and humidity fluctuations.

Powder Coating

7. Sandblasting

Sandblasting, using compressed air as the driving force, involves high-speed jet streams of abrasive materials (such as copper ore sand, quartz sand, emery, iron sand, and sea sand) being sprayed onto the surface of workpieces, causing changes in the appearance or shape of the workpiece surface. Due to the impact and cutting action of the abrasives on the workpiece surface, the surface cleanliness and roughness of the workpiece are altered. This process improves the mechanical properties of the workpiece surface, enhancing fatigue resistance, increasing adhesion between the workpiece and coatings, prolonging the durability of the coatings, and facilitating coating leveling and decoration.

AD:

Sandblasting can quickly clean the surface of objects, and the surface quality after sandblasting is good, effectively prolonging the lifespan of objects.

Sandblasting can be adapted to various types of objects, whether they are made of steel, ceramic, or plastic.

Simple operation.

DIS:

Sandblasting generates a large amount of dust and waste, causing environmental pollution.

Sandblasting operations require certain knowledge and skills; incorrect operation may damage the surface of objects.

Sandblasting requires regular maintenance and cleaning to ensure its proper functioning.

Sandblasting

8. Shot Peening

Shot peening is a widely used surface strengthening process in factories. It involves bombarding the surface of workpieces with shot particles to implant residual compressive stress, thereby enhancing the fatigue strength of the workpiece through cold working. This technique is extensively used to improve the mechanical strength, wear resistance, fatigue resistance, and corrosion resistance of components. Types of shot particles include steel shot, cast iron shot, glass beads, ceramic beads, etc.

AD:

Simple equipment, low cost

Not restricted by the shape and position of the workpiece

Convenient operation

DIS:

Poor working environment

Low unit output

Lower efficiency compared to shot blasting

Shot Peening

9. Electroplating

Electroplating is a process that involves using electrolysis to deposit a metal film onto the surface of metal or other material components. This process helps prevent metal oxidation (such as rusting), enhances wear resistance, conductivity, reflectivity, corrosion resistance, and improves aesthetics.

AD: Attractive surface appearance, excellent corrosion resistance, strong mechanical properties.

DIS: Improper handling of generated wastewater and exhaust may lead to environmental pollution, high energy consumption, and potential health hazards to humans.

Electroplating

10. Anodizing (Anodic Oxidation)

Anodizing refers to the process where aluminum and its alloys, under specific electrolyte and process conditions, form an oxide film on the surface of aluminum products (the anode) due to the action of an external electric current.

AD:

Anodizing can form a dense oxide film on the surface of metal, effectively preventing oxidation and corrosion.

It increases the hardness of the metal surface, making it more resistant to wear and scratches, thus extending its lifespan.

Different colors of oxide films formed on the metal surface enhance its aesthetic appearance and decorative properties.

The roughness of the metal surface increases after anodizing, which promotes adhesion between coatings and substrates, making the coating more durable.

An insulating oxide film formed on the metal surface improves its insulation properties.

DIS:

Particularly when dealing with large areas or thicknesses of metal products, significant energy consumption increases production costs.

Strict control of processing conditions and operating standards is required, leading to longer processing times that may affect production efficiency.

The oxide film formed during anodizing may affect the dimensions and shapes of the metal, posing a certain risk to the normal operation of high-precision or high-demand components.

The anodizing process is mainly suitable for certain metals such as aluminum, magnesium, and titanium. For other metals like steel, copper, and silver, the anodizing process may not be applicable or effective.

Although the oxide film formed by anodizing has high hardness and corrosion resistance, it may be damaged under certain conditions such as mechanical wear or chemical corrosion, requiring regular maintenance and repair.

Anodizing Anodic Oxidation

11. EPD (Electrophoretic deposition)

Electrophoretic deposition is a process where, under the influence of an applied voltage between positive and negative poles, charged paint particles in an electrophoretic coating migrate toward the cathode. They react with alkaline substances generated on the cathode surface, forming insoluble deposits on the surface of the workpiece.

AD:

Safety in production: Electrophoretic coating uses water as a solvent, making it non-toxic and non-flammable.

High-quality coating: Electrophoretic paint has strong adhesion, uniform thickness, and excellent corrosion resistance.

High utilization rate: Electrophoretic paint is efficiently used.

DIS:

Limited applicability to small and medium-sized parts due to equipment constraints.

Restricted to conductive substrates and single-layer coating: Once a part is coated with electrophoretic paint, it becomes an insulator, preventing further electrophoretic coating.

Limited color options: Electrophoretic paint colors are predominantly dark.

EPD Electrophoretic deposition

12. Micro-arc Oxidation

Micro-arc oxidation, also known as micro-plasma oxidation, is a process where, through a combination of electrolyte and specific electrical parameters, an instant high-temperature and high-pressure effect is generated on the surface of aluminum, magnesium, titanium, and their alloys via arc discharge. This process results in the growth of a ceramic coating layer primarily composed of metal oxide on the substrate.

AD:

The metal oxide layer formed by micro-arc oxidation is metallurgically fused with the substrate, resulting in high bond strength. The ceramic layer has a dense structure, good toughness, and exhibits characteristics such as wear resistance, corrosion resistance, high-temperature shock resistance, and electrical insulation. It can also meet requirements for thermal insulation, catalysis, antibacterial properties, etc.

The process has a wide range of applications and is environmentally friendly during processing.

DIS: The surface may be rough and uneven.

Micro arc Oxidation

13. Metal Brushing

Metal brushing is a manufacturing process involving repeatedly scraping aluminum plates with sandpaper to create lines. The main process consists of three parts: degreasing, sanding, and washing. During the brushing process, a special film technique applied after anodizing treatment enables the metal surface to form a film layer containing metal components. This process makes each fine scratch clearly visible, allowing the metal to exhibit a subtle sheen amidst its matte finish.

AD:

Wear-resistant, high-temperature-resistant, and corrosion-resistant.

Easy maintenance and cleaning in daily use.

Fine texture.

Long lifespan.

DIS: Relatively expensive price.

Metal Brushing

14. Etching

Etching is a technique that removes part of the material through chemical reactions or physical impacts. Etching typically refers to photolithographic etching, where after exposure and development, the protective film on the area to be etched is removed. When exposed to a chemical solution during etching, it dissolves and corrodes the material, creating a concave or hollow effect.

AD:

Metal etching processes can create extremely precise shapes and patterns, and the consistency of the metal etching process ensures that each product in mass production has the same quality and characteristics.

Etching processes can be applied to various metals, including copper, nickel, gold, silver, iron, and some non-metallic materials.

Metal etching processes generate relatively little waste, and in many cases, waste can be recycled and treated.

High efficiency.

DIS:

Etching processes require precise control of factors such as chemical solution concentration, temperature, and etching time, leading to high complexity.

High equipment and manufacturing costs: Etching processes require specialized equipment and materials such as etching tanks, power supplies, heat exchangers, etc. Additionally, precise control of the production process is needed to ensure product quality and consistency.

Workers may be exposed to hazards such as chemical substances, high temperatures, and noise.

Etching

15. IMD (In-Mold Decoration technology)

IMD, also known as non-painting technology, is an internationally popular surface decoration technique. It involves applying a surface-hardened transparent film, printing the pattern layer in the middle, and injecting the back molding layer. The ink is sandwiched between layers, making the product resistant to friction, preventing surface scratches, and maintaining color brightness for an extended period without fading.

AD:

Strong scratch resistance and corrosion resistance.

Long service life.

Excellent three-dimensional effect.

Strong resistance to dust, moisture, and deformation.

Color can be changed as desired.

Patterns can be easily modified.

DIS:

Long lead time.

Prone to issues such as film detachment and distortion.

High defect rate in products.

IMD In Mold Decoration technology 01

IMD In Mold Decoration technology 02

16. OMD (Out Mold Decoration)

OMD is an extension of IMD (In-Mold Decoration) technology that integrates visual, tactile, and functional elements. It combines printing, texture structure, and metallization characteristics to achieve 3D surface decoration.

AD:

Substrate material is not limited, can be metal or plastic.

Can achieve 3D shapes.

Can encapsulate internal structures (back-molding).

Allows for simultaneous processing of multiple small products.

DIS:

High equipment investment.

Unable to achieve complex 3D shapes.

OMD Out Mold Decoration

17. Laser Engraving