#medical non woven fabric

Explore tagged Tumblr posts

Text

How To Distinguish Between Woven And Non-Woven Fabrics?

Fabrics are a crucial element in our daily lives, and we use them for various purposes. From clothing to upholstery and even medical products, fabrics are ubiquitous. Woven and non-woven fabrics are two major types of fabrics, each with its distinct characteristics.

Understanding the difference between these two types of fabrics is essential to choose the right fabric for the intended purpose.

Woven Fabrics

Woven fabrics are produced by interlacing two or more sets of yarns at right angles to each other. These yarns are called warp and weft yarns. The warp yarns run lengthwise and are held taut on a loom, while the weft yarns run crosswise and are interlaced with the warp yarns. The result of this interlacing is a strong, durable fabric.

Woven fabrics come in various weaves, including plain, twill, and satin weaves. Plain weave fabrics have a simple over-under pattern, while twill weaves have a diagonal pattern, and satin weaves have a smooth, lustrous surface.

One of the main advantages of woven fabrics is their strength and durability. The interlacing of the warp and weft yarns creates a strong, stable fabric that can withstand wear and tear. Woven fabrics are also breathable and can be easily dyed or printed on, making them ideal for clothing and home décor.

Non-Woven Fabrics

Non-woven fabrics, on the other hand, are produced by bonding or felting fibers together using heat, chemicals, or pressure. Unlike woven fabrics, non-woven fabrics do not have a distinct warp and weft yarn. Non-woven fabrics are typically made from synthetic fibers, such as polyester or polypropylene, although natural fibers like cotton and wool can also be used.

Non-woven fabrics can be produced using a variety of techniques, including spunbond, melt blowing, and needle punching. Spunbonded non-woven fabrics are made by extruding molten polymer onto a conveyor belt, while melt-blown fabrics are made by blowing hot air onto a thin stream of molten polymer. Needle-punched non-woven fabrics are made by mechanically entangling fibers with a series of needles.

Non-woven fabrics have several advantages over woven fabrics. They are lightweight, cost-effective, and can be produced in a range of thicknesses and densities. Non-woven fabrics are also easy to work with and can be cut or sewn without fraying. Non-woven fabrics are used in a variety of applications, including medical products, geotextiles, and filtration media.

Distinguishing Between Woven and Non-Woven Fabrics

The easiest way to distinguish between woven and non-woven fabrics is by looking at the fabric's structure. Woven fabrics have a distinct weave pattern, with visible warp and weft yarns. Non-woven fabrics, on the other hand, do not have a visible weave pattern and appear more random in their fiber placement.

Another way to distinguish between woven and non-woven fabrics is by their texture. Woven fabrics tend to have a smoother, more consistent texture, while non-woven fabrics may have a more varied texture, depending on the production method used.

The strength and durability of the fabric can also be a distinguishing factor. Woven fabrics are typically stronger and more durable than non-woven fabrics, although the specific application and production method can influence the strength of both types of fabrics.

Finally, the intended use of the fabric can also help distinguish between woven and non-woven fabrics. Woven fabrics are ideal for applications where strength and durability are required, such as clothing and upholstery. Non-woven fabrics are often used in applications where cost-effectiveness and ease of use are more important, such as medical products and so on. If you are glazed to know more about the difference between Woven and Non-Woven fabrics then Manjushree spntek can simply help you with it and you can also reach us at [email protected].

0 notes

Text

Why Nonwoven Medical Cambric? The best material to use for medical applications is nonwoven fabric.

Cambric Non Woven Medical Non Woven Fabric is one material that is frequently used in medical applications and has a number of advantages that make it a great option for medical products. Safety and cleanliness are of the utmost significance in medical settings, and the components used in medical devices must exceed strict performance and quality requirements. The ideal option for medical purposes is Cambric Non Woven Medical Non Woven Fabric for the following reasons:

Safety: Cambric Non Woven Medical Non Woven Fabric is free of dangerous chemicals and allergens and is made to high safety requirements. This indicates that there is no risk of harmful health effects for patients or medical personnel when using it in medical products.

Durability: Cambric Non Woven Medical Non Woven Fabric is capable of withstanding the rigours of use in healthcare settings, which is required of medical items. It is made to endure a long time and can resist numerous washings and use without losing its quality or function.

Breathability: It's crucial that medical items are pleasant for both patients and medical professionals when they're used for prolonged periods of time. Non-woven Cambric for Medical Non-woven fabric is breathable, allowing air to flow and preventing moisture buildup, which lowers the possibility of skin irritation and discomfort.

Fluid resistance: There is always a chance of exposure to fluids and pathogens in medical settings. Non-woven Cambric for Medical Non-woven fabric is a great option for items like surgical gowns, drapes, and masks because it is made to be fluid-resistant.

5.Cambric Non Woven Medical: Versatility Numerous medical applications, such as face masks, surgical gowns, and wound dressings, can make use of non-woven fabric. Due to its adaptability, it may be utilised in a variety of medical items, which eliminates the need for additional materials and streamlines the manufacturing process.

As a result, Cambric Non Woven Medical Non Woven Fabric is the ideal option for healthcare settings and is a great option for medical applications. Manufacturers of medical products frequently choose Cambric Non Woven Medical Non Woven Fabric because of its emphasis on safety, toughness, breathability, fluid resistance, and adaptability. Consider Cambric Non Woven Medical Non Woven Fabric if you're seeking for a dependable and superior material for your medical items.

0 notes

Text

Polyester I.V. Gowns: Ensuring Comfort, Protection, and Easy Care—Is Your Healthcare Facility Equipped?

The healthcare industry requires polyester I.V. gowns for patient comfort and protection while allowing comfortable access to their upper body during intravenous (I.V.) treatment procedures. These gowns enable medical personnel to reach patients' upper body and arms without hindrance so they can quickly provide I.V. therapy as well as medication and blood transfusion services. Durable Polyester I.V. gowns for healthcare settings demonstrate their most significant advantage through their long-lasting properties. High-quality synthetic fibers in the gowns show resistance to damage, thus enabling healthcare facilities like hospitals and clinics to use them multiple times. The lightweight nature and breathable properties of polyester fabric create comfort for patients requiring lengthy medical procedures. Polyester I.V. gowns demonstrate excellent resistance to fluids as one of their essential characteristics. The protective features of polyester materials surpass those of traditional cotton gowns because they shield healthcare providers from spills and bodily fluids more effectively. Cost-effective polyester I.V. gowns for hospital patients are chosen by healthcare facilities because they maintain themselves easily. Polyester gowns remain intact even after high-temperature washing, which enables proper hygiene maintenance.

#Polyester patient gowns#hospital gowns#medical gowns#disposable patient gowns#reusable hospital gowns#fluid-resistant gowns#breathable medical gowns#durable patient gowns#infection-control gowns#IV-access gowns#lightweight hospital gowns#synthetic fabric gowns#patient wear for hospitals#protective medical gowns#easy-care hospital gowns#hygienic patient gowns#washable medical gowns#comfortable patient gowns#healthcare apparel#polyester surgical gowns#non-woven hospital gowns.

0 notes

Link

Park Non Woven presents Medical non-woven fabric, as ultimate packaging material for sterilised medical products. Read these ten features of medical nonwoven fabric to monitor their quality.

0 notes

Text

RULE #2 | CS55

summary : "You promised," he choked out. "You promised you wouldn’t break rule two."

warning/s : sickness, vomiting, hurt/no comfort, death

an : yall have been begging for angst so 🤷🏽 here’s pt 1 of my dead wives series

Carlos Sainz loves you. It is inevitable. It is woven into the fabric of who he is. Just as the earth revolves around the sun, just as a fire burns.

Some things in this world are simply destined to be, and his love for you is one of them.

He remembers the first time he saw you like it happened yesterday.

College had been a blur of stress and sleepless nights for him, drowning in a relentless tide of engineering coursework, circuits, and mechanics that left no room for anything else.

Then you walked into his life, unannounced, unassuming, and shattered the monotony with a force he couldn’t comprehend.

You had been a medical student, your schedule just as demanding, yet you carried yourself with a lightness that seemed impossible.

He remembers watching you in the library, bent over your notes, your lips moving slightly as you memorized terms he couldn’t begin to pronounce.

He hadn’t meant to stare. But then you’d looked up, catching his eye, and smiled. It was the kind of smile that stuck with him, that sank its claws into his mind and refused to let go.

The first time you laughed at one of his jokes, something about thermodynamics, of all things, he had stared at you, stunned, like the world had stopped spinning for just a moment.

And when you’d matched his nerdy humor with a quip of your own, so quick and sharp that he was left speechless, he had known.

That night, he went home and called his sister, still dazed, still unable to believe what had happened.

"I've met the love of my life," he’d told her, voice shaking with an excitement that bubbled over uncontrollably.

"You’re being ridiculous," she’d replied, unimpressed, as always. "You don’t even know her."

But he had known.

—

It had started as a joke.

One of those silly, late-night conversations in the library, where exhaustion made everything funnier than it really was.

The campus was dead silent that night, save for the faint hum of fluorescent lights and the occasional rustle of pages being turned. It was nearly 2 a.m., the kind of hour where the world felt unreal, where time stretched and blurred, where reality felt softer at the edges.

Carlos had been sitting across from you, his laptop open to a problem set he wasn’t even pretending to understand anymore.

His fingers drummed against the table as he watched you work, hunched over your thick textbook, scribbling furiously.

You looked up, catching his stare. “What?”

Carlos smirked. “Nothing. Just thinking how much easier my life would be if I had your brain.”

You snorted, rolling your eyes. “And I was just thinking how much better mine would be if I had your charm. You could probably flirt your way into a free degree.”

“Or at least free snacks from the vending machine,” he added, grinning.

You laughed, the sound soft but rich, the kind that still echoed in his mind years later.

Then, suddenly, his expression shifted. Something thoughtful creeping into his gaze. “We should make a pact.”

You raised an eyebrow. “A pact?”

“Yeah.” He leaned forward. “Rules for life. So we don’t screw things up.”

Intrigued, you set your pen down. “Okay. Rule number one?”

“No betraying each other.”

You smiled, nodding. “Agreed. No betrayal.” You tapped a finger against your chin. “What’s rule number two?”

Carlos hesitated, then, with mock seriousness, leaned in like he was about to tell you the secret to the universe. “No one dies.”

You barked out a laugh, the librarian across the room shooting you a glare. “That’s your rule?”

“Absolutely,” he said. “It’s non-negotiable.”

Shaking your head, you held out your hand. “Fine. No betraying each other. No one dies. Deal?”

“Deal,” he said, gripping your hand firmly.

At the time, it had been a joke. Just another of a thousand little moments between the two of you.

Carlos had no idea then how much those words would mean to him.

—

The first time you got sick, really sick, Carlos didn’t take it seriously.

It was a cough at first. A rough, hacking thing that made you wince but still had you waving him off with a half-smile.

"Relax, cariño," you’d said, voice scratchy but amused. "It’s just a cold."

Carlos narrowed his eyes at you, unconvinced. “You have a fever.”

"It’s a dramatic fever," you shot back, tugging the blanket up over your shoulders. "I’m merely suffering for the aesthetic."

He snorted, shaking his head. “Dramatic is right.”

He had kissed your forehead that night, tucking you into his side, his lips warm against your too-hot skin. And you had sighed, sinking into him like you always did, like you belonged there.

It had been easy then.

A flu, he’d told himself. Something temporary.

Nothing permanent. Nothing real.

—

But the cough never really went away.

Neither did the fevers, or the way your limbs felt heavier with each passing day.

You stopped stealing fries off his plate. Stopped nudging him awake in the mornings, rolling your eyes at how deeply he slept. Stopped teasing him about the way he could fall asleep anywhere.

On a plane, in a car, once even in the middle of a club when the music was loud enough to shake the walls.

One afternoon, when you had been too tired to get out of bed, he had finally said it out loud.

"Maybe we should see a doctor."

You had smiled at him, but it was too soft, too thin. "It’s nothing, Carlos. I just need rest."

He had believed you.

God help him, he had wanted to believe you.

—

The hospital came later.

By then, it wasn’t something you could wave away with a joke, wasn’t something you could cover up with sheer willpower.

By then, you were struggling to catch your breath after walking across the room.

By then, Carlos had started waking up in the middle of the night to find you curled in on yourself, your whole body trembling, your hands clenched into fists beneath the sheets.

By then, even you had stopped pretending.

"Okay," you had whispered, one night, your fingers gripping his. "Maybe it’s not just a cold."

Carlos had swallowed hard, his throat tight. But he had smiled anyway, because that was what he did. He stayed steady, he stayed strong, even when the ground was crumbling beneath his feet.

"No pasa nada," he had murmured, pressing a kiss to your temple. "We’ll figure it out."

And for a while, just a little while, you both still believed that was true.

—

The early hospital visits weren’t so bad.

You made them an adventure, the way you did with everything.

"We should start a ranking system," you had said one day, swinging your legs over the side of the exam table. Best hospital coffee. Best waiting room magazines. Best nurses who let me steal extra blankets."

Carlos grinned, leaning against the wall, arms crossed over his chest. "That depends. Is this going to be a five-star system, or are we working on a ten-point scale?"

"Oh, five stars, obviously," you said, deadly serious. “We have to account for dramatic flair.”

"And yet you still insist you’re not dramatic."

"I contain multitudes, Carlos."

And God, you were still you then.

A little tired, a little pale, but still full of light. Still brimming with something sharp and teasing and warm.

Carlos had let himself believe it would last.

That the doctors would find the problem and fix it. That this was a detour, not a dead end.

That you were too strong for this.

That he would not have to watch you disappear, piece by piece, until there was nothing left of the girl who had once laughed in the middle of a silent library, who had once stood beside him and made a promise that neither of you ever really thought would matter.

—

Some nights were better than others.

There were nights when you were yourself again. When you teased him about the dark circles beneath his eyes, your voice carrying that familiar warmth, something alive and teasing and so you that he could almost convince himself this was temporary.

That this, this hospital bed, these wires, these endless nights of waiting, was just a phase, something the two of you would look back on one day and laugh about.

"You look like hell," you’d whisper, your voice hoarse but still edged with amusement.

Carlos would scoff, pressing a damp cloth to your forehead. "And you look stunning, obviously."

You'd grin, even as exhaustion weighed down your eyelids. "I try."

Nights like those, he let himself believe.

But then there were nights like this.

Nights when you couldn't stop shaking from the pain, your body curling in on itself as he held you, whispering reassurances you were too far gone to hear. Nights when you sobbed into his chest, when your breath came in ragged, broken gasps, when you whispered, "I can't do this anymore, Carlos. I can't."

And Carlos, who had spent his entire life fixing things, who had built his world on the certainty that every problem had a solution, could do nothing.

So he held you. Ran his fingers through your hair. Pressed desperate kisses to your temple.

And when sleep finally dragged you under, he would slip into the bathroom, shutting the door behind him before collapsing to the floor.

He would grip the sink so hard his fingers went numb, bow his head until his forehead pressed against the cold tile.

His body would shake with the weight of it, with the sheer unfairness of it all, with the grief that felt too large to be contained within his chest.

Carlos Sainz was not a religious man.

But on nights like these, he prayed.

Begged.

For a miracle. For a cure. For just a little more time.

—

One night, when your breathing was too shallow, too slow, something in him snapped.

The moment he noticed it, the unnatural stillness, the faintest hitch in the beeping of the monitors, he was out of his chair, panic sharp and immediate in his chest.

His hands trembled as he pressed the call button.

"Nurse," he barked, his voice hoarse. "Something's wrong."

The nurses rushed in, their voices a blur, their hands moving quickly as they adjusted your oxygen, checked your vitals. Carlos stood frozen, helpless, as they worked.

And then, as quickly as the panic had come, the moment passed. Your breathing steadied. The machines quieted.

And Carlos, who had spent the last several minutes standing motionless, fists clenched, lungs burning, finally let himself collapse into the chair beside your bed.

His elbows rested on his knees, his head dropping into his hands. He tried to steady his own breathing, tried to remind himself that you were still here.

You were still here

You were still here.

A moment later, he felt the faintest touch on his arm.

Carlos lifted his head so fast it made him dizzy.

Your fingers barely managed to curl around his wrist, your touch so weak he could barely feel it. But your eyes were open, heavy-lidded and exhausted, searching for him.

"Hey," he whispered. His voice felt raw, scraped down to nothing.

Your lips parted, but no words came.

Carlos exhaled shakily, reaching out to press a hand against your cheek. Your skin was too warm, feverish, but you leaned into his touch anyway.

"You scared me," he admitted, his voice thick.

You tried to smile. It didn't reach your eyes.

Carlos swallowed, his throat burning. He forced himself to hold your gaze, even as the words clawed their way out of his chest, raw and desperate and entirely true.

"You promised," he choked out. "You promised you wouldn’t break rule number two."

A flicker of something passed through your expression. Regret, sadness, something heavier than the both of you combined.

"Carlos," you whispered.

"No," he said, shaking his head. "No. You don’t get to break this one. You don’t."

Your eyes shimmered with unshed tears. He could see it, the truth you were too kind to say out loud. The truth he refused to accept.

Carlos bent down, pressing his forehead to your knuckles. His grip on your hand was too tight, but he couldn't make himself let go.

"Please," he whispered. "Please don’t leave me."

You didn’t answer.

And somehow, that silence was worse than anything else.

—

Days passed. Then weeks.

Carlos barely left your side. He learned the names of every nurse on the floor. Memorized the dosages of your medications. Knew the precise moment when your painkillers would wear off, when you'd need him to press the call button before you were in too much agony to speak.

And still, he held on.

Because Carlos Sainz loves you.

It is inevitable. It is constant. It is everything.

And even as your breaths grew shallower, even as your hands trembled when you reached for him, even as the hope he had clung to for so long withered beneath the weight of reality-

He stayed.

—

One night, when exhaustion was too heavy for you to fight, you whispered, “You should go home, Carlos. You need rest.”

Carlos exhaled sharply. Shook his head. "I am home."

You tried to argue, but he silenced you with a kiss to your temple, lingering there for a moment longer than necessary. He could feel your pulse beneath his lips, slow and unsteady.

"I’m not going anywhere."

You sighed, a soft exhale against his shoulder, and for a moment, for a moment, he let himself pretend everything was okay.

—

He lost count of the days.

There was no clear marker for when hope turned into grief. No defining moment where he realized you weren’t going to make it.

It just happened.

Like a tide pulling out to sea.

Like the quiet between heartbeats.

A promise broken, too softly to hear.

And when you were finally gone, when the world felt too quiet, too empty, too wrong, Carlos sat in the chair beside your bed, your hand still in his.

And he whispered, “You broke the rules.”

---

Permanent taglist: @papichulomacy @softhecreator @claimingharrystigertattoo @mel164 @rendezvoushn @trashyy-004 @330bpm-whiplash @lilorose25 @alilcloudy @residentdemonhunter

#x reader#formula one x reader#formula one#formula 1#carlos sainz x reader#formula 1 x female reader#formula 1 x reader#carlos sainz#carlos sainz x you#carlos sainz jr x you#carlos sainz jr x reader#cs55 x y/n#cs55 imagine#cs55 x you#cs55 x reader#cs55 fic#cs55

509 notes

·

View notes

Text

Breathe Easy: The Science Behind Breather Fabric

Introduction

In today's fast-paced world, comfort and functionality are paramount. One innovative material that's revolutionizing various industries is breather fabric. Let's delve into the science behind this remarkable fabric and explore its diverse applications.

What is Breather Fabric?

Breather fabric is a specialized textile engineered to allow air and moisture to pass through while preventing water and other liquids from penetrating. This unique property is achieved through a combination of factors:

Porous Structure: The fabric's structure contains microscopic pores that allow air and moisture molecules to pass through.

Hydrophobic Properties: The fabric's surface repels water, preventing it from being absorbed.

The Science Behind Breather Fabric

The breathability of a fabric depends on several factors, including:

Fiber Type: Synthetic fibers like polyester and nylon are often used in breather fabrics due to their durability and moisture-wicking properties.

Weaving Technique: The way fibers are woven together influences the fabric's porosity and breathability.

Finishing Treatments: Chemical treatments can enhance a fabric's water resistance and breathability.

Applications of Breather Fabric

Breather fabric has a wide range of applications, including:

Apparel: Used in athletic wear, outdoor gear, and everyday clothing to keep you cool, dry, and comfortable.

Automotive Interiors: Used in car seats and headliners to prevent moisture buildup and mold growth.

Medical Devices: Used in wound dressings and medical garments to promote healing and prevent infection.

Industrial Applications: Used in filtration systems, protective clothing, and other industrial products.

Benefits of Breather Fabric

Enhanced Comfort: Allows your skin to breathe, preventing sweat buildup and discomfort.

Moisture Management: Wicks away moisture, keeping you dry and reducing the risk of skin irritation.

Temperature Regulation: Helps maintain a comfortable body temperature by allowing excess heat to escape.

Durability: Resists wear and tear, ensuring long-lasting performance.

Versatility: Suitable for a wide range of applications, from casual wear to high-performance gear.

Conclusion

Breather fabric is a testament to the innovation and ingenuity of textile technology. By understanding the science behind this remarkable material, we can appreciate its many benefits and choose products that enhance our comfort and well-being.

[email protected] 0124-4816111 Corporate Office: Park Non Woven Pvt. Ltd., Gurugram, HR

#pet acoustic panel#non woven battery gaunlets#breather fabric#light weight insulation#compressor felt#pp + pet felt#fiber glass felt#high efficiency media#plastic extrusion profile#lint free wipes

2 notes

·

View notes

Text

Unveiling the Latest Advancements in Non-Woven Fabric Technology

Non-woven fabrics have revolutionized numerous industries with their versatility, durability, and eco-friendly properties. As a leading non-woven fabric manufacturer, Mavazi Fabrics is committed to staying at the forefront of technological advancements in this dynamic field. Let's explore some of the latest innovations shaping the landscape of non-woven fabric technology.

1. Sustainable Materials and Processes

In response to growing environmental concerns, non-woven fabric manufacturer are increasingly focusing on sustainable materials and processes. Innovations such as recycled fibers, bio-based polymers, and biodegradable additives are being incorporated into non-woven fabric production to reduce environmental impact and promote circularity. At Mavazi Fabrics, we embrace sustainable practices and offer a range of eco-friendly non-woven fabrics that meet the highest standards of environmental responsibility.

2. Enhanced Performance and Functionality

Advancements in non-woven fabric technology are leading to fabrics with enhanced performance and functionality. Manufacturers are developing fabrics with specialized properties such as moisture-wicking, antimicrobial, flame-retardant, and UV-resistant capabilities to meet the diverse needs of various industries. These advanced fabrics offer improved comfort, protection, and durability, making them ideal for applications ranging from healthcare and hygiene to automotive and construction.

3. Nanotechnology and Microfibers

Nanotechnology is revolutionizing the non-woven fabric industry by enabling the production of ultrafine fibers with unprecedented properties. Nanofibers exhibit superior strength, filtration efficiency, and surface area compared to conventional fibers, making them ideal for applications such as filtration, medical textiles, and protective apparel. Manufacturers are leveraging nanotechnology to develop non-woven fabrics with enhanced breathability, barrier properties, and filtration performance.

4. Smart and Intelligent Fabrics

The integration of smart and intelligent technologies is another exciting development in non-woven fabric technology. Manufacturers are incorporating sensors, conductive fibers, and microelectronics into non-woven fabrics to create smart textiles capable of monitoring vital signs, detecting environmental conditions, and transmitting data wirelessly. These smart fabrics have applications in healthcare, sports, military, and wearable technology, offering unprecedented levels of comfort, convenience, and functionality.

5. 3D Printing and Additive Manufacturing

Advancements in additive manufacturing technologies such as 3D printing are revolutionizing the production of non-woven fabrics. Manufacturers can now create complex fabric structures with precise control over fiber orientation, porosity, and thickness, allowing for the customization of fabrics according to specific requirements. 3D printing enables rapid prototyping, cost-effective production, and design flexibility, paving the way for innovative applications in fashion, aerospace, and consumer goods.

Conclusion

The latest advancements in non-woven fabric technology are driving innovation and opening up exciting possibilities across industries. From sustainable materials and enhanced performance to nanotechnology, smart fabrics, and additive manufacturing, non-woven fabric manufacturer like Mavazi Fabrics are at the forefront of these developments. By embracing cutting-edge technologies and pushing the boundaries of what is possible, we are proud to offer our customers innovative non-woven fabric solutions that meet the evolving needs of the market.

#nonwovenfabric#manufacturer#fabricmanufacturer#sustainabletextiles#textileindustry#ecofriendlymaterials#innovativefabrics#textiledesign#sustainablefashion#environmentallyfriendly#manufacturingindustry#nonwovenmaterials#supplychain#textileproduction#businessgrowth#industryinsights#sustainability#localbusiness#globalmanufacturing#fabricinnovation

3 notes

·

View notes

Text

After a couple find a woman to buy eggs from for up to $250,000 they have to “find a surrogate, the uterus-bearing person who will carry your baby.” Meaning a Woman to build a baby in her womb for 9 months then give birth to it.

By NICK WOLNY

MAY 20 2023 10:04 AM EST

Let’s have a baby together. It’ll only set you back $250,000.

To become a gay dad with a biological child, you’ll first need some eggs (human ones). You can buy some from an egg bank or try to find a donor who will cycle just for you. If doing the latter, it’s good to have contracts, so you’ll need a lawyer too.

Then you need to get your eggs to a fertility clinic. If you have a donor, you’ll be paying for their travel and appointments. If you’ve got the eggs, a freezer truck transportation service will do. Embryologists at the clinic do their thing with the eggs and your sperm, and voilà — you have embryos on ice. If embryologists sound expensive, it’s because they are.

We’re done with the “less hard” part. Now you need to find a surrogate, the uterus-bearing person who will carry your baby. You’ll either pay a surrogacy agency, which can be pricey, or find a surrogate of your own, which “sounds hard because it is,” says Janene Oleaga, attorney and founder of Oleaga Law, a family formation law firm. “Then there’s the actual embryo transfer, which may or may not be covered by insurance. You’ve also been paying this whole time to keep the embryos cryogenically preserved,” Oleaga says.

Feeling the cash crunch yet? There’s another cost to consider. The stigma against gay parenthood runs deeper than rhetoric alone. It’s woven into the very fabric of our health care system.

As LGBTQ+ acceptance makes hard-fought progress, today’s young people are coming out earlier than previous generations. In a 2018 survey conducted by the Family Planning Council, respondents over the age of 60 said they came out at an average age of 37; for respondents in their 30s, the average age was 21, and for respondents ages 18 to 24, the average age was 17.

When Obergefell v. Hodges granted federal marriage equality protections in 2015, LGBTQ+ interest in family planning spiked, with solutions like assisted reproductive technology (ART), foster parenthood, and private adoption leading the way. Nearly half of LGBTQ+ millennials are actively planning to grow their families, a difference of just 7 percentage points from non-LGBTQ+ millennials, and a marked difference from previous generations.

If queer intended parents (IPs) take the ART route, financial challenges loom. The average cost of in vitro fertilization (IVF) hovers around $12,400 per cycle, according to the American Society for Reproductive Medicine. But the chances of success are less than 50 percent, according to ART data from the CDC, adding considerably to the financial pressure. Subsequently, an entire boutique industry has emerged to help intended parents navigate the medical, legal, and emotional terrain of the process.

“To be very frank and honest with you, a lot of this is a mega, mega business,” says Harout Cracchiolo, who together with his husband became a first-time father last year. “We went with a friend who donated her eggs and paid for all her treatments. Then we went with a family member who ended up carrying the baby for us and got a separate surrogacy insurance for her. We still had to pay all the hospital bills, anesthesia, and doctor’s visits [out of pocket], because insurance wouldn’t cover it. We ended up at around $175,000.”

(In other words they had a baby by taking eggs from one woman then exposing another women to the dangers of a pregnancy with heightened risks just to create a baby that neither the egg donor or the woman who gave birth will feel a connection to and will have a harder time in court if they sue for custody or visitation)

Cracchiolo says he and his husband were lucky, “because we did our IVF and got pregnant the first time.” He partially attributed this success to the care he and his husband received from their chosen fertility center, and he called some agencies “a scam.”

“One quote included a $60,000 agency fee,” Cracchiolo says. “Then it’s about another 20 or 30 grand for the egg donor, another 70 or 80 grand for the surrogate, and all the attorney’s fees.” Cracchiolo also says he and his husband calculated another quote’s projected total cost to be over $250,000, with the agency wanting most of that money in escrow upfront.

Family planning professionals said the $60,000 agency fee figure sounded high and noted that every industry has its bad actors. For many intended parents, finding and working with a good agency to mitigate the risks of surrogacy will be worth the investment. “There are a number of reputable agencies protecting both intended parents and surrogates alike,” Oleaga says in a follow-up email. “An ethical, knowledgeable agency provides valuable guidance and support throughout the surrogacy journey.”

Oleaga adds that many lawyers offer to review agency agreements with both intended parents and surrogates to ensure individuals understand what they are agreeing to, along with what services the agency will and will not provide.

Nevertheless, for gay male couples, the fertility financial benefits that come with health insurance are often stunted, since they may only apply when policy holders themselves are the ones who are pregnant. “The majority of gay men,” says Oleaga, “should expect a six-figure bill.”

(So it’s gay males and egg donors and uterus bearing persons)

The unpredictable costs of fertility have led some intended parents to seek out agencies whose financial safeguards help keep their family planning hopes alive, says Taylor Frey, who with his husband Kyle Dean Massey opened Elevate, an egg donation and surrogacy agency, after their own decade-long fatherhood journey.

“When Kyle and I went through the process, we were both working in Broadway shows, and we started a savings account to create embryos with an egg donor,” Frey says. “I was 25 at the time. We created embryos, then put them on ice for eight years so we could replenish funds.”

Frey and Massey say they founded Elevate to innovate on industry setback and cancellation policies. “If you do not end up with what you need to transfer to a surrogate, your recycle fees are on us,” says Frey, referring to fertility fees incurred when eggs turn out to be unviable.

“The reason why [surrogacy] is so expensive is that, from deciding you want to be a parent to having a baby, hundreds of people will touch your case,” Massey says. “All the attorneys, and psychologists, and counselors, and lab technicians, and nurses, and physicians, and monitoring clinics, and labs — it’s a lot of people.”

Oleaga agreed with the idea of meeting with several prospective fertility service providers as a best practice. “I always advise intended parents and potential surrogates to meet with multiple agencies and review their agency agreements before signing on,” she says.

For female same-sex couples, the dynamics are different, albeit no less demeaning.

“We knew we wanted to have kids. My only stipulation was that we be married first because we’re gay,” says Samantha Davis, who with her wife Leni had their son via intrauterine insemination (IUI) on their second attempt in 2019. “I just didn’t want the government to feel like we weren’t both equally the parent.”

If heterosexual couples have unexplained infertility, they need to have been trying to conceive for at least a year (or six months if over the age of 35) before a doctor will make the diagnosis official, a declaration that unlocks health insurance benefits for some fertility services. But for same-sex couples, the waiting period is waived. “Because we’re gay, I wanted to make sure that I was automatically considered infertile [from the start] so that the insurance would cover some of the stuff we would be going through,” Samantha says.

The couple’s infertile status unlocked an allowance of $16,000. “That’s not per child, or per year,” Leni says. “That’s for life.” The Davises’ expenses included storage for sperm and paying to have embryos created and tested, all of which quickly burned through the stipend. They also say they had to pay out of pocket for psychiatric evaluations and blood work.

“The first time, we weren’t in a great financial place,” Samantha says. “We were scraping every time we needed to pay for something.” Samantha touched her belly. She’s pregnant again, this time through IVF.

“After our son, I really wanted to have a girl,” she says. The couple decided to do IVF to produce a female embryo, but after two attempts, the only remaining healthy embryos were males. “We could have tried again to see if we could get that girl, but financially it wasn’t feasible.”

(And there it is once enough money is spent it’s not just about having a baby, it’s about having a certain type of baby)

The path to biological parenthood shouldn’t be this expensive for anyone. For LGBTQ+ people, however, the journey remains especially taxing as we navigate systems ill-suited to our family planning interests.

“A lot of LGBTQ+ people don’t have children, so it’s not such a big movement,” Cracchiolo notes. “But it needs to be. You want to feel included. You’re having a baby — you don’t want to feel strange when you go to the hospital.”

Horror stories aside, the parents agree their journey was worth every step.

“It’s the coolest thing to wake up and know that every day you’re working towards making this child’s life something you didn’t have,” Cracchiolo says. “It’s just the best thing ever.”

The Davises echo this sentiment. “It’s rewarding in so many ways,” Samantha says. “I think I’ve learned so much about myself, my upbringing, things that I hope to do differently.”

Queer people deserve to become biological parents regardless of socioeconomic status. But reform is needed to make LGBTQ+ parenthood more financially accessible.

(No one is entitled to biological offspring. And how do they reform it to make it “financially accessible” without fairly compensating the women going through the egg donation process or the birth mother who will be carrying a pregnancy with a greater risk of complications?)

In the interim, anticipating the future cost of parenthood might influence how you spend and save your money today.

Oh, and if people start to give you shit for tightening the budget to fund your legacy — “Fuck ‘em,” Samantha says. “Don’t worry about what anyone says. Find what works for you and your family.”

Leni laughs. “You can quote her on that.”

Nick Wolny is a journalist, speaker, and entrepreneur. He writes about the intersection of LGBTQ+ life and personal finance, and has previously contributed to CNET, Entrepreneur, and Business Insider. Join his newsletter at NickWolny.com.

This article is part of the Out May/June issue, available on newsstands May 30. Support queer media and subscribe -- or download the issue through Amazon, Kindle, Nook, or Apple News.

I wonder how many women have received requests to be surrogates for family members and the rest of the family piled on over the hope of more grandkids for the family? Women need to learn the side effects and risks associated with egg donation and surrogacy so they can back up their “NO”.

#Anti surrogacy sunday#Babies are not commodities#No one is entitled to biological offspring#Anti exploiting women#Maybe parents with this money should consider adoption?#Anti creating children with no mother to check in on them

15 notes

·

View notes

Text

the simplest notion of politics is this: sitting in a room, around a table, waiting for someone to blink first. it is as much a craft as any other and the supreme leader has not the patience for it, though he had been making steady efforts to school himself in tolerance following his ascension, plainly to uphold the institution, behind which is himself, exploiting its might, therefore to uphold himself. his mind’s eye divulges ten corpses for the oval of seated dignitaries, sentence passed with the mere crook of his fingers — he forces the endearing sight away and heeds the diplomat speaking, a glance stolen toward the small projected name tag. subconsciously, he finds an anchor in @acharnemcnt's composed force aura, which soothes his own wild one.

❝ we will direct the allotted funds toward the military units. ❞ he drawls eventually when the topic of budgetary concerns is brought up. one unit had recently been lost between the teeth and claws of a wild beast on kalsunor, in a quest for a lost sith artefact. another had suffered losses when he had miscalculated a route to a hidden planet. they serve a purpose beyond him, which is easy to forget in the throes of his agenda. with increased rebel activity targeting their strongholds in the outer rim, necessitating a parallel increase in militant enforcement, ren thinks he will have to mind his wastefulness. the sentiment had been echoed by the officials whose planets are concerned, though it is done so in that ornate way of politicians, saying everything and nothing at all. no one dares, of course, to challenge his word directly.

the chancellor’s caress over the dark fabric covering his leg is non-tangible, ren assumes when it first happens. an imagined thing woven of tedium, but his blood flutters and he knows it’s real, an elusive act, covertly tucked away beneath the table where their guests cannot espy. he cannot comprehend the action, at first. the heart is a muscle like the rest and it atrophies with disuse — the warmth that seeps betwixt the ribs is wildfire, swift and scorching, burning through the blood and blazing within the tendons. the muscle of his thigh twitches beneath the touch as the hand moves up, languidly, lingering, rubbing circles into the skin beneath the fabric. his jaw clenched, ren does not turn toward the chancellor for fear of the nonchalance he'll see etched into the man's features, the facade hux wears as an ensemble.

and what of the welfare campaigns? one of the diplomats inquires. another inquires into the construction of educational facilities for the youth, as well as medical centres.

it is a testament to ren's newfound patience that he maintains his composure and austerity, the imposing figure he presents, masking the fervour as agitated boredom, as though the conference and everyone within it were beneath him and he was merely eager to leave.

❝ a quarter of the funds, that is, ❞ the supreme leader rectifies, masquerading the correction as clarification, as fingers drum against the holopad atop the tabletop in front of him, throwing a cursory look over the texts, recalling something about the outer rim and the planets there whose misery under the new republic had been easier to mould into support for the first order. he had not spared much care for the chancellor’s programme, though his interest in it had been ignited now, in a way. ❝ and divert the rest to the proposed initiatives. ❞

instead of easing the agony, the hand moves upward still, provoking. ren doesn’t turn to look, though he can sense the triumphant amusement through the force, as it ripples in waves from his companion, who is no doubt enjoying tormenting him. violence and desire are lovers, and for a split moment, ren wishes to snap his wrist to save himself the affront. he clenches his fist instead.

there is a noise trapped at the back of his throat, and he has to lean back to swallow it, shooting hux a warning scowl. the coy look he finds there has him reeling, the subtle provocation alighting a coiling thrill. with eyes on him he clears his throat, ❝ the chancellor is eager to elaborate, i'm certain, as he put forth the motion to begin with. ❞ were it anyone else, he would not care for the display nor would it rouse him — but touch is sparse between him and his ally, a foreign novelty they do not indulge in. he has to wonder if this is endorsement or chastisement.

chancing a look at the time, ren laments the remainder.

&.

the conference hall is stilled to silence at the supreme leader’s wordless behest, and as the officials took their leave, thus shroud by his shadow upon rising. in the adjournment of the conference, ren is at last left privy to his own considerations, and the ashes of allure which still flutter within him, in the scorched terrain of his heart. allure and anger, an irritation induced by the indignity of the ordea, that audacious caress that had turned his thoughts to smoke.

ren cards a hand through his hair, uncoiling the neat curls into dishevelment.

the chancellor makes a remark, and ren’s temper snaps, torn off its hinges. he knows the man plays him, in theory, and had been cautioned as much by karitza, though observing the conduct in practice is not unlike looking for snakes under stones, a straining effort that he does not bother to descry further. this display had been overt. bold, bolder still considering the relevance of the discussion. it leaves ren questioning the meaning, the idea, the intent — political discussions between them often possess more tact and sensibility, and in the presence of others they are never so intrepid in their arrangement. he doesn’t entertain the notion that it was a genuine gesture, because nothing between them ever is, nor can he imagine the chancellor to have been suffering the same bouts of boredom he had been, because that would unravel the statuesque figure of his husband into flesh and bone. this is an alliance that cannot afford to be compromised by sentiment.

❝ did you think i would overlook your little display? ❞ even through the blaze of ardour, ren’s arm comes to soften the manoeuvre, one gloved hand braced against the wall to which he has hux pinned, chest–first, the other holding him in place by his waist. the hold is loose enough that hux can slip away with ease if he so wishes, but ren implores him to stay with his gloved hand descending lower, grasping his hip through the fabrics. an animal’s hunger starves him and makes a creature of him in turn; he has long learnt to control base impulses, a stratified numbing of the mind and body to douse the debauchery that blazes in the being. his mind whirls this time, wild, and he cannot.

❝ you demand of me to behave, ❞ ren murmurs into the shell of hux's ear, teeth lingering, a hint of bared sharpness, breath pooling in the crook between his jaw and neck. the force sways like a caress over his cheek, tracing down to the exposed column of his neck. coarse uniform to fine silk, their flesh does not meet but it does not have to. the proximity does nothing to quell ren’s desires. ❝ then make it impossible for me to do so. careful, or i'll begin to suspect a ploy. ❞ what he had initially meant as an act of rebuke melts in the fire between them, the tension that drips like molten gold in the minimal space between their two bodies. it lacks the bite of one, the severity, and the note of dalliance in his tone does nothing to sharpen his words either.

in the warm nearness, he steps back, permitting for the man to turn so they may face each other, ren’s chin tipped downward to interlock their eyes. the regret that surges through him is immediate when he feels hux’s gaze on him, undressing him to bone, and his eyes unwittingly flicker down, before he forces them up and takes another step back, crossing his arms over his chest, ❝ are you satisfied with the concession? ❞ the irritation is evident. the fondness is not, but it is surely there, too. ❝ i’m not. ❞ he retorts after a beat. another step is taken backwards, and soon he’s propped up against the conference table, leaning against the smooth surface with his arms. the cold grounds him and allows him a reprieve, in tandem with a clear mind to facilitate conversation. how simple it had been, to awaken hunger in him. such a small gesture. he loathes to admit it; through sheer will alone, he quells the blood rushing to his face. ❝ reliance on strength is a safer bet than your schemes; i can secure the outer rim quicker with armies than you will subdue them with policies. ❞

prompt, [thigh touch] during a very important meeting &. [wall slam] amidst argument.

#acharnemcnt#suggestive /#( ✦ ) script — is it death that you are bringing ?#( ✦ ) arc / third — where there is a monster / there is a miracle.#look away kids they're doing ✨politics✨#this basically turned into a drabble. enjoy some k*lux for the holidays.

5 notes

·

View notes

Text

5 Weekly Trending Products in TikTok (July 2023)

Finding trending products to sell is an important part of running an online store. You need to know what goods will be popular before they peak. By ‘catching the wave’ you’ll be able to make money from growing sales rather than the product’s decline. But finding popular products to sell can be a challenge. That’s why we made this list to help you find trending products online.

Source: Goodsfox

In this list, you’ll find 5 trending products in TikTok that will activate your small business ideas in 2023-or maybe help you to discover a great product to add to your existing online store.

Top trending products to sell online in 2023

Browse our list of highest trending products in TikTok, you can use to start your online business.

01 3D mask

3D mask is a medical care and health care product that claims to be comfortable, breathable, and fit well on the face. It is made of non-woven fabric and comes in various colors.

Source: Goodsfox (Store: Benyamook)

Source: Goodsfox (Store: Benyamook)

According to Goodsfox, there are two kinds of 3D mask ranking in the top five of the sales rank. The product from Benyamook tops the sales list, with 41,877 sales in the latest 24 hours, and a price of 12 THB (0.35 USD). The product from sanahfashion ranks fifth in the sales rank, with 12,950 sales in the last 24 hours, and a price of 19 PHP (0.37 USD). Both products have been listed since October 2022, but now the 3D mask from Benyamook has already been sold out and the other is still on sales.

Source: Goodsfox (Store: sanahfashion)

Source: Goodsfox (Store: sanahfashion)

02 Panty Women Underwear

The underwear is a product of Umiwear, a brand that sells women’s underwear and loungewear on TikTok. The underwear is made of ice silk Lycra, which is a high quality and comfortable material. And it comes in different sizes and colors, with a price of 30 PHP(0.58 USD).

Source: Goodsfox

Sales trend data from Goodsfox shows a significant increase in the sales of the underwear since early July. In the last 30 days, it has been sold 620,809 units, which is a 14.43% increase from the previous month. This indicates that the underwear is popular and in high demand among the customers.

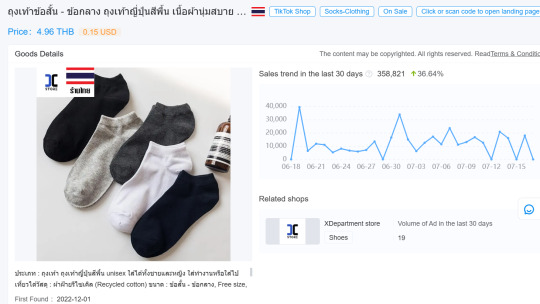

03 Socks-Clothing

This is a pair of plain socks that are unisex and suitable for work or leisure. They are made of recycled cotton and a soft texture, which have a good breath ability and elasticity, and are durable and resistant to fading. The socks come in two sizes: short and medium, and fit shoe sizes EUR 38-44 or US 4-7. Besides, Various colors are available.

Source: Goodsfox

According to Goodsfox, The last 30 days witnessed a fluctuation in the sales trend of this socks, reaching its peak at 39,326 on June 19. And it has been sold 358,821 units in the last 30 days, a month-on-month rise of 36.64 percent.

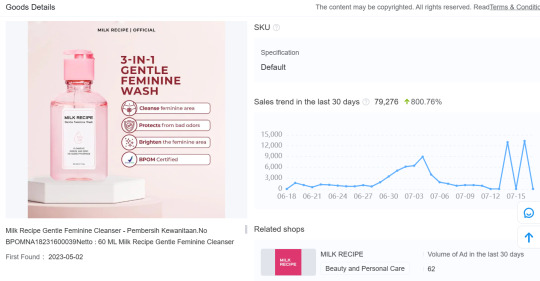

04 Gentle Feminine Cleanser

This a gentle feminine cleanser called Milk Recipe. It is a low pH formula that balances the pH of the intimate area and contains natural ingredients such as betel leaf extract, chamomile extract, lactic acid, and ceramide. It claims to clean, reduce odor, and brighten the intimate area.

Source: Goodsfox

The new sales of the cleanser have increased by 800.76% from June 18 to July 17, 2023. Before increasing to its highest at 12,957 on July 14 and 16, the new sales of this products has already risen to 8,942 on July 4.

Conclusion

In conclusion, these are some of the trending products in TikTok that you can sell online in 2023. They are popular among the customers and have high sales potential. Whether you are looking for a new product to start your online business or a great product to add to your existing store, you can find inspiration from these products. You can also use Goodsfox to track the sales trends and ad creatives of these products and others. By doing so, you can stay ahead of the competition and catch the wave of the market demand.

2 notes

·

View notes

Text

India’s Top Triangular Bandage | Tubular Bandage | IV Cannula Fixator | Gauze Swab | Manufacturers

Triangular Bandage Manufacturers

We are the forefront manufacturer, exporter, and supplier of high-quality Triangular Bandage. It has earned us wide appreciation due to its quality, durability, and hygienic nature. Available in different forms either plain or pictorial, this bandage is generally used for first aid purposes.

Fabricated as per the medical standards using high-grade fabric and is free from external contaminants, this bandage is highly durable as it is manufactured(Triangular Bandages Manufacturers) with high precision. Further, clients can avail of this product at the most affordable price.

Features:

Material: Strong unbleached cotton fabric.

Bandage in the shape of a triangle.

Application / Usage: Hospital / Clinics

Made of 100% cotton

Complete with two heavy-duty safety pins

Most essential emergency First Aid equipment

Sizes:

96 cm x 96 cm x 135/136 cm

90cm x 90cm x 127cm

90cm x 90cm x 125cm

60cm x 60cm x 90cm

Also available in non-woven fabric.

Triangular Bandage is being manufactured and supplied by a company reputed because of excellent product quality.

Medilivescare Manufacturing is known as India’s Top Triangular Bandage Manufacturers. We provide high-quality Cotton Triangular Bandages at a very affordable price. We provide OEM Service and are known as a leading Triangular Bandage Supplier and Triangular Bandage Exporters in India. Our Triangular Bandages are exported to various African and Middle East countries.

Gauze Swab Manufacturers

Due to its extensive software Gauze swabs(Gauze Swab Manufacturers) are available both in sterile and unsterile shapes, with different ply and types relying on the absorbency required. We manufacture extensive specification and packing, and packaging SKUs for Gauze Swabs.

Sterile Gauze Swabs – Non-Sterile is a high-quality product and is trusted all across the globe. Non Sterile is being synthetic and supplied by the business enterprise reputed because of its fantastic product fine, pleasant service, and professional approach. Scroll all the way down to see specifications and evaluations.

We have also manufactured(Gauze Swab Manufacturers) a Non-Sterilized Gauze Swab. We offer the best quality highly absorbent non-sterilized Gauze Swabs in accordance with the Pharmacopeia Standards. Our product serves the desires of several commercial fitness care provider companies such as hospitals, nursing houses, etc. Our Swabs skip via rigorous assessments for quality manipulation, cloth structures, and softness due to uniform discovery free especially absorbent gauze cloth.

We are Top Gauze Swab Manufacturers in India. We offer Sterile Gauze Swab, No sterile gauze swabs, Gauze Swabs with or without X-Ray Detectable Thread, Surgical Gauze Dressing, and/or Gauze Pads at the lowest prices. Superior quality and affordable prices are guaranteed. We provide OEM also for numerous customers for Gauze Swab. We deliver Gauze swabs in specific qualities and percent sizes in step with customer requirements. We are Top Gauze Swab Manufacturers and the Best Gauze Swab Exporters in India.

Features:

Made of 100% cotton. Bleaching is done by Hydrogen peroxide & de-mineralized water.

All swabs are with folded edges - therefore No loose threads.

Available with or without an X-Ray detectable line.

Available in Quality B.P. Type 13 & B.P. Type 17.

Sizes available :

5 x 5cm (4 / 8 / 12 ply)

7.5 x 7.5cm (4 / 8 / 12 ply)

10 x 10 cm (4 / 8 / 12 ply)

10 x 20cm ((4 / 8 / 12 ply)

Available in 1, 2, 4, 5 & 10 pcs packing and Sterile / Non-sterile as per customer/project requirements.

Available in 100 pcs. packing as non-sterile.

Other customized sizes are also available such as:

35x40cm

10 x 60cm.

Product Features List :

High Absorption Capacity.

Swabs have Folding Edges, so there is no chance of loose thread.

Made from Cotton Gauze Fabric

Usage :

For cleaning and swabbing wounds.

For dressing low exudates wounds

Tubular Bandage is a high-quality product and is trusted all across the world. Tubular Bandage is being manufactured and supplied by a reputed company because of its excellent product quality, friendly service, and professional approach. We are known as India’s Top Tubular Bandage Manufacturers in India.

Tubular Elastic Bandage presents uniform compression and guide of the appendages with minimal threat of constriction. It is easy to apply and comfy to wear, without the need for any clips or tape to hold it in location. Compressive power stays regular over a long length of use.

This versatile, bandage is low in cost and a better replacement for elastic wraps and other trendy supports. Holds bloodless/hot packs or bandages in place.

Washable

Breathable and Hypoallergenic

Uniform compression

Soft to the touch, good to feel

Dermophilic, hypo-allergic, causes no rash, is soft to touch, good to feel, washable and breathable.

Tubular(Tubular Bandage Manufacturers) design allows pull-on, quick and easy wearing and fitting without any pins or tapes.

The fawn color matches skin color for better aesthetics and can be worn inconspicuously under clothing.

Product Information

Cotton Stockinet Roll / Cotton Ribbed Stockinet.

Stockinet roll crafted from pleasant lengthy-staple cotton yarn and woven on a circular loom.

A free loop knitted fabric has inherent four-way stretch assets.

Hypoallergenic Seamless Product Made from high high-quality, excellent, long stapled cotton that stays cool all through summers and warm at some point in winter.

The cloth is hypoallergenic, cleanable, breathable, soft to the touch, and feels good. Knitted on modern-day machines for a four-way stretch.

Lightweight, seamless, long-lasting, snug healthy and remains in the role for a long time.

Easy pull-on put-on is made possible with the aid of the tubular design. The packaging is convenient and in particular designed with aspect slits for smooth unrolling.

Smooth texture, shrink-resistant, and skin-friendly.

Available sizes:

4.2cm x 10m.

5cm x 10 meters.

6.25cm x 10 meters.

7.5cm x 10 meters.

10cm x 10mtrs.

12.5cm x 10 meters.

15cm x 10 meters.

Customized sizes are also available.

IV Cannula Fixator is very helpful for fixing IV Cannula and for general use. Made as per B. P. standards. Skin-collared elastic foam grip cannula fixator and porous adhesive used for air circulation. Cannula Fixators(IV Cannula Fixator Manufacturers) are highly elastic bandages that are for supporting the syringe entered into the human body to resist any strain and pain. It is made up of top-quality fabric which allows the passing of air and humidity very easily. The adhesive used is free from any toxins which makes the product skin friendly.

Product Information:

IV Cannula Fixator is shaped well to give a perfect grip over the I.V. Cannula(IV Cannula Fixator Manufacturers) during hospitalization.

Moisture-responsive High Moisture Vapour Transmission rate Film.

Low allergy grid pattern adhesive.

Porous adhesive to allow skin breathing.

Easy and Painless to do away with, because of skinny-non adhesive edges and leaves no residue after removal.

The IV Cannula fixator fastens the tube firmly to the pores and skin, whilst the pad covers the point of injection. The dressing allows air and humidity to skip freely.

The Material used does now not irritate the pores and skin and no strains of the adhesive continue to be at the pores and skin after removal.

Advanced Features:

Fixes the cannula prevents plain

Prevents infusion-related phlebitis

Breathable pores on a bandage for better skin health.

Better flexibility gives better support, the patient can move easily

Instruction for use:

Tear the pouch

Remove the release paper

Note: If you have any quarry about the quality and Price then please click the given below:

Gauze Swab Manufacturers in India

IV Cannula Fixator Manufacturers in India

Tubular Bandage Manufacturers in India

#Hospital#Medical Bandages#Hospital Uniforms#Triangular Bandages#Tubular Bandages#IV Cannula Fixator#Gauze Swab Manufacturers#Gauze Swab Manufacturers in India#Surgical Gloves#Surgical Gown#Nitrile Gloves#Manufacturer#Exporter#Supplier#India

2 notes

·

View notes

Text

Choose the Best in the Industry - Our High-Quality Medical Non Woven Fabric

Cambric non-woven fabric is an essential material used in various industries, including the medical industry. It is a kind of non-woven fabric manufactured from natural fibres like flax, cotton, or wool. These fibres are compressed throughout the production process to create a sheet, which is then chemically treated to increase its tensile strength and longevity.

Applications for cambric non-woven cloth in the medical sector include curtains, surgical gowns, and wound care. Its qualities, which include being very absorbent, breathable, and offering great barrier protection, make it the perfect option for various applications.

Several factors make Cambric non-woven cloth the best option for medical applications, including the following:

Highly Absorbent

The absorbency of Cambric non-woven fabric is among its most crucial qualities. It is perfect for use in wound dressings and other medical applications where fluid management is important since it can quickly absorb significant amounts of liquids. In addition to being very permeable, cambric non-woven fabric provides good fluid transmission.

Barrier Protection

The good barrier that cambric non-woven fabric offers against germs and other pollutants makes it perfect for use in surgical gowns and drapes. Because of its barrier qualities, it helps to stop the transmission of infection, safeguarding both patients and medical staff.

Breathable

The non-woven cambric material is very breathable and promotes optimal air flow. This characteristic is crucial in medical settings such as wound dressings and other areas where appropriate airflow is necessary for healing. Cambric non-woven fabric is more comfortable to wear for long periods of time since it is breathable.

Soft and Comfortable

The softness and comfort of cambric non-woven fabric make it a great option for wound dressings and other medical uses where patient comfort is important. Its gentle texture lessens skin irritability and promotes quicker healing.

Sterilisable

Cambric non-woven fabric is a great option for usage in medical applications because it is very simple to sterilise. It can be sterilised using a number of techniques, such as steam sterilisation, ethylene oxide sterilisation, or gamma irradiation, without losing any of its qualities.

In conclusion, the absorbency, barrier protection, breathability, softness, and sterilizability of Cambric non-woven fabric make it a great option for medical applications. Due of its qualities, it is a crucial material utilised in many medical applications, such as drapes, surgical gowns, and wound care. We may anticipate many more applications for Cambric non-woven fabric in the medical sector as technology develops.

0 notes

Text

what is underpad

An underpad is a protective sheet designed to absorb moisture and provide a dry, hygienic surface. Commonly used in hospitals, nursing homes, and home care settings, underpads help protect beds, chairs, and other surfaces from leaks, spills, or incontinence.

Types of Underpads

Disposable Underpads – Single-use pads with a waterproof backing, ideal for hospitals and elderly care.

Reusable Underpads – Washable and eco-friendly, made with absorbent layers for long-term use.

Key Features of Underpads

✔ Super Absorbent Core – Locks in moisture to keep the surface dry. ✔ Waterproof Backing – Prevents leakage and protects furniture. ✔ Soft & Skin-Friendly – Reduces irritation and enhances comfort. ✔ Various Sizes Available – Suitable for beds, wheelchairs, and baby changing areas.

Where Are Underpads Used?

Healthcare & Hospitals – For patient care and post-surgery recovery.

Elderly & Home Care – Helps manage incontinence efficiently.

Baby & Pet Care – Used as changing mats or pet training pads.

Conclusion

Underpads are essential for maintaining hygiene and preventing leaks in various settings. Whether for medical use or home care, they provide comfort, protection, and peace of mind.

Looking for quality underpad raw materials? Contact Favourite Fab for premium non-woven fabric solutions!

0 notes

Text

The Growing Demand for Non-Woven Interlining in China

Non-woven interlining has become an essential factor in the fabric and apparel industry, particularly in China, which stands as one of the world's biggest producers of garments. The growing call for non-woven interlining is pushed by its fee-effectiveness, ease of utility, and versatility in diverse material packages. This article explores the factors behind the development call for non-woven interlining in China, its packages, manufacturing improvements, and the effect on the worldwide fabric market.

The Rise of China's Textile Industry

China has been a dominant pressure inside the global fabric enterprise for a long time, with its large manufacturing capacity, technological improvements, and competitive pricing. The increasing use of non-woven interlining aligns with the USA's goal of improving fabric exceptional even as maintaining value efficiency. The following elements contribute to the developing demand:

Rapid Growth in Apparel Manufacturing: China remains the biggest manufacturer and exporter of clothes, necessitating green and value-effective materials, including non-woven interlining.

Technological Advancements: Innovations in material bonding and lamination procedures have advanced the performance of non-woven interlining.

Environmental Considerations: The shift closer to sustainable and recyclable substances has made the non-woven fabric more excellent and desirable.

Economic Growth and Urbanization: Rising disposable earnings and converting fashion traits pressure elevated garment production, similarly boosting interlining demand.

Advantages of Non-Woven Interlining

Non-woven interlining gives several benefits that contribute to its significant adoption in China:

Cost Efficiency: Less high priced in comparison to the woven interlining, making it a favoured choice for mass manufacturing.

Easy Application: This can be implemented via warmness pressing, reducing hard work and production time.

Durability and Stability: Provides excellent form retention and structure to garments.

Versatility: Suitable for diverse material sorts, together with cotton, polyester, and blends.

Applications of Non-Woven Interlining in China

The demand for non-woven interlining spans diverse industries past just garb. Some key programs encompass:

Garment Industry: Used in collars, cuffs, waistbands, and linings to provide shape and assist.

Automotive Textiles: Applied in automobile seat covers and insulation substances for stronger durability.

Home Furnishings: Utilized in curtains, upholstery, and bed covers to improve power and longevity.

Medical Textiles: Incorporated into surgical gowns, masks, and disposable clinical put on due to its lightweight and breathable properties.

Key Manufacturers and Suppliers in China

With growing demand, numerous leading producers and suppliers cater to the non-woven interlining marketplace in China. Some distinguished companies consist of:

Freudenberg & Vilene: A global chief in interlining manufacturing, supplying advanced answers.

Wendler Interlining: Known for excellent fusible and non-woven interlining materials.

H&V (Hollingsworth & Vose): Specializes in non-woven fabric solutions for numerous applications.

China Non-Woven Fabric Industry Association (CNFIA): A regulatory frame promoting innovation and best manipulation inside the enterprise.

Challenges and Future Trends

Despite the growing demand, the non-woven interlining marketplace in China faces some challenges:

Environmental Regulations: Stricter sustainability requirements demand eco-friendly manufacturing practices.

Raw Material Fluctuations: Price versions in polyester and different artificial fibres affect manufacturing charges.

Competition from Other Asian Markets: Countries like Vietnam, Bangladesh, and India are rising as robust competition.

However, the destiny of non-woven interlining in China appears promising due to:

Development of Biodegradable Interlining: Innovation in sustainable materials will form the market.

Smart Textiles Integration: Advanced interlining with moisture-wicking and antibacterial properties.

Increased Automation in Manufacturing: AI-pushed manufacturing tactics to beautify efficiency and consistency.

The call for non-woven interlining in China is anticipated to preserve growth as the fabric and garb industries evolve. With technological advancements, sustainability efforts, and increasing packages, non-woven interlining remains a critical fabric inside the global fabric delivery chain. Chinese manufacturers need to adapt to new traits and improvements to maintain their management within the industry even as assembly the growing demand for the best and eco-friendly merchandise.

#non woven interlining#woven interlining#china interlining#fusible interlining suppliers#fusible interlining manufacturer#woven fusible interlining#woven interlining manufacturer#china elastic webbing#down-proof fabric#china elastic band

0 notes

Text

"Electrically Conductive Textiles: Fashion Meets Function ⚡, A Market Worth $8.2 Billion by 2034"

Electrically Conductive Textiles Market is revolutionizing textiles by integrating conductive materials that transmit electrical signals. These advanced fabrics are pivotal in applications like wearable electronics, smart textiles, and medical devices, enhancing functionality and connectivity. The market’s growth is driven by technological advancements, rising demand for smart wearables, and the increased adoption of electronic textiles in healthcare and military sectors, paving the way for significant innovation and expansion.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10949 &utm_source=SnehaPatil&utm_medium=Article

This market is experiencing robust growth, primarily fueled by the demand for smart textiles in wearable technology. Conductive yarns and fabrics lead the market due to their extensive application in sportswear and healthcare monitoring devices. Conductive polymers are gaining traction as a cost-effective, flexible alternative. The military and defense sector also plays a vital role, utilizing these textiles in advanced uniforms and equipment.

Regional Insights:

North America dominates the market, thanks to technological advancements and a strong presence of key players.

Europe follows, with increasing investments in innovative textile solutions, particularly in the United States and Germany.

The Asia-Pacific region, especially China and Japan, is expected to witness significant growth due to rapid industrialization and rising consumer awareness of smart textiles.

Market Segmentation:

Type: Woven, Non-Woven, Knitted Textiles

Product: Conductive Yarns, Fabrics, Fibers, Inks, Coatings

Technology: Nanotechnology, Coating, Printing, Weaving, Knitting

Application: Smart Clothing, Medical Textiles, Military, Sports, Automotive, Home, Industrial Textiles

Material: Copper, Carbon, Silver, Aluminum, Nickel, Graphene-Based

Process: Knitting, Weaving, Coating, Printing, Spinning

End User: Consumer Electronics, Healthcare, Automotive, Aerospace, Defense, Textile Manufacturing

Functionality: Antistatic, Electromagnetic Shielding, Thermal, Electrical Conductivity

Installation: Embedded, Integrated

Solutions: Conductive, Insulation Solutions

In 2023, the market volume was estimated at 300 million square meters, projected to reach 500 million square meters by 2033. The woven textiles segment holds the largest market share at 45%, followed by non-woven (35%) and knitted textiles (20%). This distribution reflects the growing demand for smart textiles in wearable tech and medical applications. Leading players include Toray Industries, Seiren Co., and Bekaert, with Toray Industries at the forefront of innovation and Seiren Co. expanding globally.

Competitive Dynamics: Technological advancements and strategic alliances drive the market, with regulatory frameworks like the EU’s REACH regulation shaping trends through stringent quality standards. Future projections suggest a 10% annual growth rate, spurred by heightened R&D investments and eco-friendly manufacturing processes. While opportunities in the automotive and healthcare sectors abound, challenges such as high production costs and the need for continuous innovation remain crucial for market participants.

#SmartTextiles #ConductiveTextiles #WearableTechnology #ETextiles #MedicalDevices #MilitaryInnovation #TechFabric #FutureFashion #NanoTech #EcoFriendly #TextileInnovation #SmartWearables #MedicalTech #ElectromagneticShielding #ConductiveYarns #TechIntegration #SmartClothing #DefenseTechnology #HealthcareInnovation #AdvancedTextiles

0 notes

Text

Sanitary Napkin Manufacturing Plant Report – Business Plan & Setup

Sanitary napkins are an essential hygiene product used by millions of women worldwide. With the growing awareness of menstrual hygiene and government initiatives promoting affordable sanitary products, the demand for sanitary napkins is increasing rapidly. Setting up a sanitary napkin manufacturing plant can be a profitable business venture with significant growth potential. This article provides a sanitary napkin manufacturing plant project report covering business plans, setup requirements, cost estimation, and profit margins.

Market Overview of Sanitary Napkin Manufacturing

The global sanitary napkin market is expected to witness substantial growth due to increasing awareness, improved affordability, and innovative biodegradable products. Key factors influencing the market include rising female population and awareness about menstrual hygiene, government programs promoting sanitary hygiene products, increasing preference for eco-friendly and biodegradable sanitary napkins, and the growth of e-commerce platforms enabling easy accessibility.

Business Plan for Sanitary Napkin Manufacturing Plant

Business Model

The business can operate under different models, such as small-scale or cottage industry, where sanitary napkins are manufactured on a small scale with manual or semi-automatic machines. Medium-scale industries use automated machinery to produce high-quality napkins at a competitive price. Large-scale industries set up fully automated plants with high production capacity and multiple product variations.

Target Audience