#fabricmanufacturer

Explore tagged Tumblr posts

Text

Unveiling the Latest Advancements in Non-Woven Fabric Technology

Non-woven fabrics have revolutionized numerous industries with their versatility, durability, and eco-friendly properties. As a leading non-woven fabric manufacturer, Mavazi Fabrics is committed to staying at the forefront of technological advancements in this dynamic field. Let's explore some of the latest innovations shaping the landscape of non-woven fabric technology.

1. Sustainable Materials and Processes

In response to growing environmental concerns, non-woven fabric manufacturer are increasingly focusing on sustainable materials and processes. Innovations such as recycled fibers, bio-based polymers, and biodegradable additives are being incorporated into non-woven fabric production to reduce environmental impact and promote circularity. At Mavazi Fabrics, we embrace sustainable practices and offer a range of eco-friendly non-woven fabrics that meet the highest standards of environmental responsibility.

2. Enhanced Performance and Functionality

Advancements in non-woven fabric technology are leading to fabrics with enhanced performance and functionality. Manufacturers are developing fabrics with specialized properties such as moisture-wicking, antimicrobial, flame-retardant, and UV-resistant capabilities to meet the diverse needs of various industries. These advanced fabrics offer improved comfort, protection, and durability, making them ideal for applications ranging from healthcare and hygiene to automotive and construction.

3. Nanotechnology and Microfibers

Nanotechnology is revolutionizing the non-woven fabric industry by enabling the production of ultrafine fibers with unprecedented properties. Nanofibers exhibit superior strength, filtration efficiency, and surface area compared to conventional fibers, making them ideal for applications such as filtration, medical textiles, and protective apparel. Manufacturers are leveraging nanotechnology to develop non-woven fabrics with enhanced breathability, barrier properties, and filtration performance.

4. Smart and Intelligent Fabrics

The integration of smart and intelligent technologies is another exciting development in non-woven fabric technology. Manufacturers are incorporating sensors, conductive fibers, and microelectronics into non-woven fabrics to create smart textiles capable of monitoring vital signs, detecting environmental conditions, and transmitting data wirelessly. These smart fabrics have applications in healthcare, sports, military, and wearable technology, offering unprecedented levels of comfort, convenience, and functionality.

5. 3D Printing and Additive Manufacturing

Advancements in additive manufacturing technologies such as 3D printing are revolutionizing the production of non-woven fabrics. Manufacturers can now create complex fabric structures with precise control over fiber orientation, porosity, and thickness, allowing for the customization of fabrics according to specific requirements. 3D printing enables rapid prototyping, cost-effective production, and design flexibility, paving the way for innovative applications in fashion, aerospace, and consumer goods.

Conclusion

The latest advancements in non-woven fabric technology are driving innovation and opening up exciting possibilities across industries. From sustainable materials and enhanced performance to nanotechnology, smart fabrics, and additive manufacturing, non-woven fabric manufacturer like Mavazi Fabrics are at the forefront of these developments. By embracing cutting-edge technologies and pushing the boundaries of what is possible, we are proud to offer our customers innovative non-woven fabric solutions that meet the evolving needs of the market.

#nonwovenfabric#manufacturer#fabricmanufacturer#sustainabletextiles#textileindustry#ecofriendlymaterials#innovativefabrics#textiledesign#sustainablefashion#environmentallyfriendly#manufacturingindustry#nonwovenmaterials#supplychain#textileproduction#businessgrowth#industryinsights#sustainability#localbusiness#globalmanufacturing#fabricinnovation

3 notes

·

View notes

Text

Responsefabrics is a prominent name in the realm of furniture fabric manufacturing in India, renowned for its commitment to quality, innovation, and sustainability. With a rich legacy spanning decades, Responsefabrics has carved a niche for itself in the industry by consistently delivering superior products and customer satisfaction.

Established with a vision to redefine the standards of upholstery fabrics, Responsefabrics blends traditional craftsmanship with modern technology. The brand prides itself on using state-of-the-art manufacturing processes that ensure precision and durability in every fabric produced. From yarn selection to weaving and finishing, each step undergoes stringent quality checks to maintain international standards.

One of the key strengths of Responsefabrics lies in its extensive range of fabric designs and textures. Whether it's contemporary patterns, timeless classics, or bespoke solutions, the brand caters to diverse aesthetic preferences and functional requirements. Their fabrics not only enhance the visual appeal of furniture but also offer comfort and resilience, making them ideal for both residential and commercial spaces.

Moreover, Responsefabrics places a strong emphasis on sustainability and eco-friendliness. Recognizing the environmental impact of textile manufacturing, the brand implements eco-conscious practices throughout its operations. This includes using eco-friendly dyes, reducing water consumption, and promoting recyclable packaging materials. By prioritizing sustainability, Responsefabrics ensures that their products not only meet high-quality standards but also contribute positively to environmental conservation efforts.

In addition to its commitment to quality and sustainability, Responsefabrics is distinguished by its customer-centric approach. The brand collaborates closely with furniture manufacturers, interior designers, and architects to create bespoke fabric solutions tailored to specific project needs. This collaborative approach not only fosters creativity but also ensures that every client receives personalized service and support.

Furthermore, Responsefabrics maintains a strong focus on innovation and research. Constantly exploring new materials, weaving techniques, and design trends, the brand stays ahead of industry developments. This proactive stance enables Responsefabrics to introduce cutting-edge products that anticipate market demands and inspire trends in furniture fabric design.

As a testament to its excellence, Responsefabrics has garnered a loyal clientele both domestically and internationally. Their fabrics adorn furniture in homes, offices, hotels, and public spaces across the globe, reflecting their reputation for reliability and superior quality.

In conclusion, Responsefabrics stands as a beacon of excellence in the furniture fabric manufacturing sector in India. Combining craftsmanship, innovation, and sustainability, the brand continues to set benchmarks for quality and customer satisfaction. With a diverse range of fabrics, a commitment to eco-friendly practices, and a passion for innovation, Responsefabrics remains a preferred choice for discerning customers seeking exceptional upholstery solutions.

READ MORE...Best Fabric Manufacturers In India, Upholstery Fabrics • Best Fabric Manufacturers In India, Upholstery Fabric

0 notes

Text

0 notes

Text

Non-Woven Fabric Manufacturing Process: A Detailed Guide

This article provides a comprehensive guide to the non-woven fabric manufacturing process, covering key techniques and their applications. Non-woven fabrics are created by bonding fibers using methods like spunbonding, melt blowing, needle punching, and hydroentangling. Each technique imparts unique properties to the fabric, tailored for specific uses.

The manufacturing process involves several steps:

Fiber Preparation: Selecting and blending fibers suitable for the intended fabric.

Web Formation: Using techniques like spunbonding and melt blowing to create a web of fibers.

Web Bonding: Employing methods like heat bonding and chemical bonding to stabilize the fabric.

Finishing: Enhancing the fabric's properties through calendering, coating, and cutting.

Non-woven fabrics offer advantages such as cost-effectiveness, customization, durability, and versatility. They are used in various industries, including medical, automotive, construction, and consumer goods. Choosing the right non-woven fabric involves

Application: Consider the specific requirements of your project, such as strength, absorbency, or flexibility. This is crucial when choosing between woven interlining and non-woven interlining.

Material: Choose from different materials like polyester, polypropylene, or blends based on your needs. This decision affects the performance of interlining fabrics.

Manufacturing Process: Select the process (spunbonding, melt blowing, etc.) that best suits the desired characteristics of the fabric, whether it’s for woven interlining fabric or non-woven fusible interlining.

Understanding the non-woven fabric manufacturing process is key to appreciating the versatility and functionality of these materials. From fiber preparation to web formation and bonding, each step plays a crucial role in creating high-quality non-woven fabrics.

By mastering the intricacies of non-woven fabric production, you can make better choices for your projects, ensuring you achieve the desired results in terms of performance, durability, and cost-effectiveness. So, whether you’re working on medical supplies, automotive components, or consumer products, knowing the ins and outs of non-woven fabric manufacturing will set you up for success.

#nonwovenfabric#nonwoven#fabricmanufacturing#textileindustry#manufacturingprocess#industrialprocess#textiletechnology#textileinnovation

0 notes

Text

Printed Packaging Bags Manufacturers: Marudhara PolyPack Pvt Ltd

Marudhara PolyPack Pvt Ltd stands tall among the leading manufacturers of top-tier printed packaging bags. Established with a vision to revolutionize the packaging industry, the company has consistently delivered premium quality products tailored to meet diverse client needs.

About Marudhara PolyPack Pvt Ltd

Marudhara PolyPack Pvt Ltd boasts a rich legacy of crafting innovative and durable packaging solutions. Their expertise spans various industries, catering to the unique demands of food packaging, retail, pharmaceuticals, and more.

Product Portfolio

The company prides itself on a comprehensive range of printed packaging bags, encompassing:

1. Customized Designs

Marudhara PolyPack specializes in creating custom designs, ensuring that each bag aligns perfectly with the client's branding and product requirements. From vibrant colors to intricate details, their printing capabilities are exceptional.

2. Diverse Materials

With cutting-edge technology, they provide a variety of materials fit for many uses:

Polyethylene (PE) Bags: Their longevity and adaptability make them perfect for a range of packaging requirements.

Polypropylene (PP) Bags: Known for their strength and resistance, perfect for heavy-duty applications.

Biodegradable Bags: Keeping environmental concerns in mind, they provide eco-friendly options without compromising quality.

3. Specialized Applications

Marudhara PolyPack excels in providing specialized packaging solutions, such as:

Zipper Bags: Offering convenience and reusability, perfect for storing various items.

Vacuum Bags: Ensuring product freshness and extended shelf life for perishable goods.

Quality Assurance

Quality remains at the core of Marudhara PolyPack's ethos. Their stringent quality control measures guarantee that each bag meets industry standards and exceeds client expectations.

Client-Centric Approach

One of their key strengths lies in their customer-centric approach. The company values client feedback and collaborates closely to ensure bespoke solutions that resonate with its brand image.

Sustainability Initiatives

Marudhara PolyPack is committed to sustainability. They actively explore eco-friendly materials and processes to reduce environmental impact, aligning their operations with global sustainability goals.

Conclusion

Marudhara PolyPack Pvt Ltd emerges as a frontrunner in the realm of printed packaging bags manufacturers. With a relentless pursuit of innovation, unwavering commitment to quality, and a customer-centric approach, they continue to set new benchmarks in the packaging industry.

For businesses seeking reliable and top-notch packaging solutions, Marudhara PolyPack Pvt Ltd stands as a beacon of excellence and trust.

#pp woven fabric roll manufacturers#PPWovenFabric#FabricManufacturers#WovenFabricRolls#PolypropyleneFabric#PPWovenRolls#IndustrialFabric#PackagingMaterial#TextileIndustry#WovenPolypropylene#FabricProduction#BulkFabricSuppliers#QualityWovenMaterial#CustomFabricManufacturing#PPMaterialRolls#DurableWovenFabric

0 notes

Text

KSS & Co is a premium textile and fabric manufacturer. We have a state-of-the art design studio and over 70+ yrs of excellence in the textile business.

1 note

·

View note

Text

Jute Fabric/Grey Sofa Upholstery Fabric

Product Name: Grey Sofa Upholstery Fabric

Manufacturer: Hengsheng Textile

Color: Grey

Material: High-quality yarn

Thickness: Moderate thickness

Abrasion Resistance: Exceptionally strong abrasion resistance, capable of withstanding 100,000 double rubs

Width: 54 inches

Fire Rating: UFAC Class 1

Description:

Our Hengsheng Textile manufactures various grey sofa upholstery fabrics using high-quality yarn. The fabrics come in different shades of grey, offering a classic and versatile appearance that can complement various interior decor styles. We carefully select premium yarn as the material to ensure the fabric's softness and comfort. We also provide OEM/ODM customization services. If you are interested in our products, please feel free to contact us!

0 notes

Text

Fabric Manufacturing Process: Woven, Nonwoven and Knit

Fabric Manufacturing Process: Woven, Nonwoven and Knit #fabricmanufacturing #weaving #knitting #nonwoven

Fabric Manufacturing Process: Woven, Nonwoven and Knit Md. Amir Khasru B.Sc. in Textile Engineering Department of Yarn Engineering, SARSTEC Email: [email protected] The word fabric comes from “fabrique” of French origin. This word refers to meaning “to build, make, construct, create, etc.” In Textile, fabric refers to something that helps to cover our body or another thing. In…

View On WordPress

0 notes

Link

Ethical | Organic | Eco-friendly | Fair trade | Artisan made

Five P Venture is a GOTS certified sustainable clothing & home furnishings manufacturer with a deep commitment to ethical fashion manufacturing processes using eco-friendly raw materials such as organic cotton, tencel, linen & recycled fibres.

Founded as a social enterprise in 2013 to promote the Indian textile heritage and uplift the lives of the weaving community in Chennimalai (South India), Five P now offers finished apparels, home furnishings, fabrics (both handwoven and machine woven) & accessories for global brands, international designers, buyers & retailers that share similar values.

Our purpose at Five P Venture is to inspire a movement of sustainable production and consumption of clothing and textiles by showing that conscious manufacturing and consumption is the way to a livable future. By employing full time handloom weavers, tailors, craftsmen, designers, brands, and consumers, we develop a better understanding of their needs and how brands & consumers that align with our purpose can impact their lives. We share every step of our supply to ensure transparency and get improve each stage in a garment’s lifecycle to transform into a circular economy.

Five P makes textiles using sustainable fibre materials such as organic cotton, recycled and up-cycled cotton, linen, recycled polyester/PET, Peace silk (also known as Eri-silk or Ahimsa silk) using handloom (which does not use any electricity) and machine looms as well. Natural dyed (vegetable dyes) Cotton, Denim and organic cotton fabrics are our specialty.

Five P has a 100% solar-powered GOTS certified modern handloom weaving studio and apparel, home-furnishing manufacturing unit making high-quality sustainable fashion products for global brands, designers, premium and luxury brands, boutiques and retail buyers.

READ MORE

#handloom#artisan#sustainable\#clothingmanufacturer#ethicalmanufacturer#GOTS#GRS#fivep#organiccotton#modal#tencel#recycledpet#recycledcotton#fabricmanufacturer#SEDEX#FTA#fairtrade

1 note

·

View note

Text

What Are the Top Qualities to Look for in a Fabric Exporter in Delhi?

When searching for a fabric exporter in Delhi, it's crucial to find a partner who not only meets your needs but exceeds your expectations. Delhi, a major hub in the Indian fabric industry, boasts numerous fabric exporters, but distinguishing the best from the rest requires careful consideration of several key qualities. Here's a guide to the top qualities you should look for in a non woven fabric exporter in Delhi.

1. Quality Assurance and Certification

The foremost quality to look for in a non woven fabric exporter is their commitment to quality. Reputable fabric exporters in Delhi should adhere to strict quality control standards and possess relevant certifications. Certifications such as ISO 9001:2015 are indicative of a company's dedication to maintaining high standards throughout their manufacturing process. Quality assurance ensures that the fabric meets international standards and is free from defects, making it suitable for a wide range of applications Read more...

0 notes

Text

"Enhance the Durability of Concrete with Fabric Reinforcements"

Fabric reinforcements are an essential component of modern construction and engineering projects. Typically made from high-strength fibers such as fiberglass, carbon, or aramid, these materials are woven into a fabric mesh or grid that is then embedded into concrete or other building materials. The result is a structure that is more resistant to cracking, deformation, and other forms of damage.

Fabric reinforcements offer several advantages over traditional reinforcement materials such as steel, including a higher strength-to-weight ratio, corrosion resistance, and greater flexibility. They can also be easily customized to fit the specific requirements of a project, making them a popular choice for a wide range of applications.

From bridges and tunnels to high-rise buildings and sports arenas, fabric reinforcements have become an essential tool for engineers and architects looking to create structures that are both strong and durable. Whether you are planning a new construction project or looking to upgrade an existing structure, fabric reinforcements are a smart and effective way to ensure long-lasting performance and reliability.

Visit here for more information:

https://bhor.com/product-details/fabric-reinforcements

0 notes

Text

Floral Sofa Upholstery Fabric

Product Name: Floral Sofa Upholstery Fabric

Manufacturer: Hengsheng Textile

Color: Various floral patterns available, including tulips, roses, peonies, lotus flowers, and more

Material: Made from polyester short fibers

Thickness: Moderate thickness

Abrasion Resistance: Exceptionally strong abrasion resistance, capable of withstanding 100,000 double rubs

Width: 54 inches

Intended Use:

Fire Rating: UFAC Class 1

Description:

Our floral sofa upholstery fabric, produced by Hengsheng Textile, is specifically designed for sofas and is renowned for its exquisite floral patterns. It is made from polyester short fibers, ensuring consistent thickness and excellent durability. With its exceptional abrasion resistance, it can withstand 100,000 double rubs without damage. The fabric has a width of 54 inches, making it suitable for various sofa sizes.

Our floral sofa upholstery fabric blends classical and modern styles, making it suitable for indoor sofas, hotel sofas, casino sofas, lounge areas, and more. We use the softest fabric, making it an ideal choice for both residential and commercial spaces.

0 notes

Photo

As @parisfashionweek recently closed out the Fall/Winter 2022-2023 calendar, it’s critical that textile shows, which are the engines of the industry, get just as much coverage. @modtissimo , held in @portofashionweek , in Portugal, is one of the world's largest textile fairs that includes a contemporary sustainability focus. Held in Porto, Portugal, the trade show welcomes all twice a year and will be celebrating its 30th anniversary in September 2022. I attended the February edition, which had 300 exhibitors making the event insightful and inspiring given the apparel industry's multifaceted influence. Fashion is the way to express ourselves; with the rise of social media and the desire to present our best selves to the world on and off digital platforms, clothing and fashion are the never-ending way for us to do this. However, the global fashion industry is a major contributor to the climate emergency we face, and lowering its impact is critical… read story @reveriepage | @iambrucereynolds ✍🏾| https://www.reveriepage.com/blog/fashion-textiles-to-help-save-the-planet-at-modtissimo #portofashionweek #modtissimo #portugalfashion #portugaltravel #fashionweekparis #parisfashionweek #fabricmanufacturer #fabricproduction #fabricprinting #organiccotton #organicmaterials #recycledmaterials #upcycledmaterials #recycledfabric #upcycledfabric #consciousfashion #ethicallymade #madeinportugal #highqualityproducts #fashionproduction #materialgirl #fashionfabrics #fashionfabric (at New York City, N.Y.) https://www.instagram.com/p/Cb79TZluUIf/?utm_medium=tumblr

#portofashionweek#modtissimo#portugalfashion#portugaltravel#fashionweekparis#parisfashionweek#fabricmanufacturer#fabricproduction#fabricprinting#organiccotton#organicmaterials#recycledmaterials#upcycledmaterials#recycledfabric#upcycledfabric#consciousfashion#ethicallymade#madeinportugal#highqualityproducts#fashionproduction#materialgirl#fashionfabrics#fashionfabric

0 notes

Photo

Caps Manufacturer with customised logo and design 🧢 . . #manufactureroyale #lightingmanufacturer #lashesmanufacturer #tweezersmanufacturers #turkishexporter #tilesmanufacturer #importerscoffee #exporterfurniture #larimarmanufacturer #juttimanufacturere #eveningdressmanufacturer #plasticmanufacturernigeria #sareemanufacturer #carexporter #eyelashmanufacturer #exporterindia #tilesmanufacturers #indianexporters #fabricmanufacturer #rawhairexporterindia #paithanimanufacturers #intags (at Sialkot Cantt.) https://www.instagram.com/p/CVfQFtboLnv/?utm_medium=tumblr

#manufactureroyale#lightingmanufacturer#lashesmanufacturer#tweezersmanufacturers#turkishexporter#tilesmanufacturer#importerscoffee#exporterfurniture#larimarmanufacturer#juttimanufacturere#eveningdressmanufacturer#plasticmanufacturernigeria#sareemanufacturer#carexporter#eyelashmanufacturer#exporterindia#tilesmanufacturers#indianexporters#fabricmanufacturer#rawhairexporterindia#paithanimanufacturers#intags

0 notes

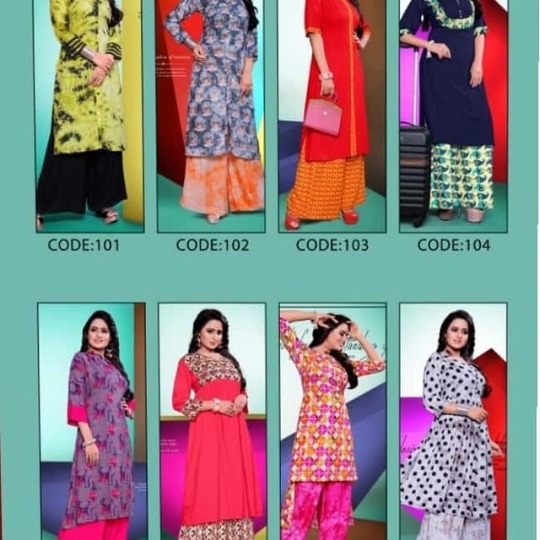

Photo

#kurti #Rayon #cottonfabric #rayonkurtis #cottonprinted #cottonprints #rayonfabrics #rayonprinted #rayons #garment #garments #fancyfabric #cotton #kurtimanufacturer #ladieswear #bottomwear #palazzofabric #plazzo #kurtifabric #fabricmanufacturer #fabric #jodhpur #jodhpurfabric #jodhpurtextiles #jodhpurrayon #anandcottonmills #acmjodhpur #acm #shankheshwar #shankheshwarfabrics #premiumrayon #tyeanddye #rayontyeanddye #tyedye #tye&dye #batik #handblockprint #bandhej #lehariya #9314714689 https://www.instagram.com/p/BnOGqXQHs9U/?utm_source=ig_tumblr_share&igshid=19sm9mvkfvh6s

#kurti#rayon#cottonfabric#rayonkurtis#cottonprinted#cottonprints#rayonfabrics#rayonprinted#rayons#garment#garments#fancyfabric#cotton#kurtimanufacturer#ladieswear#bottomwear#palazzofabric#plazzo#kurtifabric#fabricmanufacturer#fabric#jodhpur#jodhpurfabric#jodhpurtextiles#jodhpurrayon#anandcottonmills#acmjodhpur#acm#shankheshwar#shankheshwarfabrics

1 note

·

View note

Text

What Makes Indian Fabric Exporters Stand Out in the Global Market?

The fabric industry is a dynamic and competitive sector, with numerous players vying for prominence on the global stage. Indian fabric exporters non woven fabric manufacturer, including leading companies like Mavazi Fab India Pvt. Ltd., have carved a niche for themselves in this competitive landscape. But what exactly sets them apart from their international counterparts? Let’s explore the key factors that make Indian non woven fabric manufacturer exporters stand out in the global market.

1. Diverse Fabric Range and Specialization

Indian fabric exporters offer a diverse range of non woven fabric manufacturer, including traditional textiles, innovative materials, and specialized non-woven fabrics. This variety caters to a wide array of global markets and consumer preferences. For instance, Mavazi Fab India Pvt. Ltd. excels in manufacturing non-woven fabrics and PP sunbound fabrics, meeting the demands of various industries with high-quality and versatile products. This specialization allows Indian exporters to provide unique and tailored solutions that can satisfy specific market needs.

2. High-Quality Standards and Certification

Quality assurance is paramount in the global fabric market. Indian non woven fabric manufacturer exporters adhere to stringent quality control measures and certifications to ensure that their products meet international standards. Mavazi Fab India Pvt. Ltd., for example, is ISO 9001:2015 certified, demonstrating its commitment to maintaining high quality throughout its production processes. This adherence to global quality standards helps Indian fabric exporters build trust and credibility with international clients.

0 notes