#mass flow meter

Explore tagged Tumblr posts

Text

The Assurance of Precision: Customized Mass Flow Solutions from a Dedicated Manufacturer

As a leading manufacturer of mass flow meters, we take immense pride in our commitment to quality and innovation. Our state-of-the-art independent research and development center allows us to stay at the forefront of technology in flow measurement.

We have independently developed DSP tecnology and core processor. This capability enables us to not only meet but also exceed the diverse needs of our clients across various industries.

E-mail: [email protected]

WhatsApp/Skype: +86 198 6212 5430

0 notes

Text

Unveiling Precision: Nagman Flow's Coriolis Mass Flow Meter

Welcome to Nagman Flow, where precision instrumentation meets cutting-edge technology. In this blog post, we dive into the world of flow measurement with a focus on the Coriolis Mass Flow Meter. We will explore the intricacies of this innovative device, its applications, and how Nagman Flow's expertise ensures unparalleled accuracy in mass flow measurement.

Coriolis Mass Flow Meter: A Breakthrough in Flow Measurement

The Coriolis Mass Flow Meter represents a revolution in flow measurement technology. Operating on the principle of the Coriolis effect, this meter offers unparalleled accuracy in measuring mass flow rates. Nagman Flow's Coriolis Mass Flow Meter is engineered to deliver precise measurements across various fluid mediums, from liquids to gases.

Advantages of Nagman Flow's Coriolis Mass Flow Meter

Precision Measurement: Nagman Flow's Coriolis Mass Flow Meter provides precise measurement of mass flow rates, ensuring accuracy and reliability in critical processes.

Versatility: Whether measuring liquids or gases, Nagman Flow's Coriolis Mass Flow Meter offers unmatched versatility, making it suitable for a wide range of applications.

Low Maintenance: Built with robust construction and advanced technology, Nagman Flow's Coriolis Mass Flow Meter requires minimal maintenance, reducing downtime and operational costs.

Coriolis Gas Flow Measurement: With specialized configurations for gas flow measurement, Nagman Flow's Coriolis Mass Flow Meter excels in accurately measuring gas flow rates, providing valuable insights for various industries.

Applications of Coriolis Mass Flow Meter

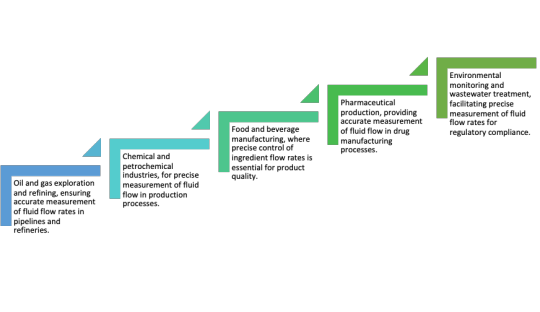

Nagman Flow's Coriolis Mass Flow Meter finds applications across diverse industries, including:

In the realm of flow measurement, Nagman Flow's Coriolis Mass Flow Meter stands as a beacon of precision and reliability. With its advanced technology and unparalleled accuracy, Nagman Flow ensures that industries can rely on precise mass flow measurements for optimal performance and efficiency. Trust Nagman Flow to deliver exceptional solutions for all your flow measurement needs. Contact us today to learn more about Nagman Flow's Coriolis Mass Flow Meter and experience the difference in precision instrumentation.

0 notes

Text

Calibration of Mass flow meter

1 note

·

View note

Text

We manufactures Insertion Thermal Mass Flow Meter in India for various application like Compressed air flow meter, Gas Flow meter, air flow meter

0 notes

Text

5WK9620 Car Air Flow Sensor

Air flow sensors, tire air sensors, and auto air flow meters are critical components in various industries, particularly in the automotive and industrial sectors. These devices are designed to measure and monitor the flow of air, which is essential for maintaining efficiency, safety, and performance.

Leading Automotive Air Flow Meter Manufacturer Seeks Partners We are a professional China air flow sensor manufacturer and wholesale air flow sensor factory with a history of over 10 years, specializing in major components, namely air flow meters, for the automotive industry. Our team has more than 9 years of export experience, possessing abundant practical experience in trade. We are familiar with market characteristics as well as relevant laws and regulations. We can ensure fast and timely delivery, eliminating any concerns for our customers. Please let us know the product information you wish to know. We will provide you with the most professional response.

0 notes

Text

#Insertion type Thermal Mass Flow Meter#Insertion type Thermal Mass Flow Meter Supplier#Insertion type Thermal Mass Flow Meter Manufacturer#Insertion type Thermal Mass Flow Meter in Pune#Insertion type Thermal Mass Flow Meter in Mumbai

0 notes

Text

Thermal Mass Flow Meter

Burak Metering is a leading manufacturer of Thermal Mass Flow Meters in India, specializing in high-quality, reliable flow measurement solutions. As a trusted Thermal Mass Flow Meter manufacturer, Burak Metering provides precision-engineered products designed for accurate measurement and efficiency in various industrial applications. With a commitment to innovation and quality, Burak Metering’s flow meters cater to industries requiring precise flow control. Explore our range of advanced flow meters to meet your unique process needs. Buy thermal Mass Flow Meter from Burk Metering

0 notes

Text

Target Flowmeters: Precision in Measuring Challenging Fluids

Introduction

Target flowmeters are specialized devices designed to measure the flow rate of liquids, gases, and slurries in various industrial applications. Known for their durability and precision, these flowmeters are particularly effective in handling challenging fluids that may be corrosive, viscous, or contain suspended solids.

How Target Flowmeters Work

The working principle of a target flowmeter is based on the force exerted by the flowing fluid on a target or disk placed in the flow path. As fluid moves through the pipe, it strikes the target, which is connected to a sensor or strain gauge. The force applied by the fluid deflects the target, and this deflection is proportional to the flow rate. The sensor converts the mechanical force into an electrical signal, which is then processed to determine the flow rate.

Advantages of Target Flowmeters

Robust Design: Target flowmeters are built to withstand harsh operating conditions, including high pressures, high temperatures, and abrasive or corrosive fluids.

Versatility: They can measure the flow of a wide range of fluids, including slurries, viscous liquids, and gases, making them ideal for challenging environments.

Accuracy: These flowmeters provide accurate flow measurements even in applications with fluctuating flow rates or irregular fluid properties.

Low Maintenance: The simplicity of their design, with minimal moving parts, results in reduced maintenance requirements and a longer operational life.

Applications

Target flowmeters are widely used in industries such as oil and gas, chemical processing, water treatment, and pulp and paper. They are particularly beneficial in situations where other flowmeters might struggle, such as with highly viscous or particulate-laden fluids.

ConclusionTarget flowmeters offer a robust and reliable solution for measuring the flow of challenging fluids in demanding industrial environments. Their durability, accuracy, and versatility make them an essential tool for applications where traditional flowmeters may not suffice. By understanding the benefits and applications of target flowmeters, industries can ensure precise fluid measurement even under the most challenging conditions.

#electromagnetic flow sensors#electromagnetic flowmeter#target flowmeter#thermal mass flowmeter#ultrasonic flow meter

0 notes

Text

Pressure Gauge Suppliers in Dubai are one of the main things that Kevitits does. Kevitits knows how important it is to measure pressure correctly and offers a wide range of pressure gauges to meet the needs of different industries. Kevitits has all the pressure measure tools you need, whether you need a digital pressure gauge, a differential pressure gauge, or something else.

#Water Meter Supplier in Dubai#mass flow meter suppliers in dubai#check valves suppliers in india#water meter supplier in uae

0 notes

Text

Big News! We are heading to HANNOVER MESSED Germany 2025!

Booth No.: D04-16, Hall 4 Date: 31st March to 4th April Looking forward to discussing how our trusted products can meet your needs.

0 notes

Text

Unlocking Accuracy: Thermal Mass Flow Meters and Trusted Suppliers

Unlock accuracy with thermal mass flow meters, understanding their principles and applications. Highlight the importance of selecting a trusted supplier. Consider Burak Metering for accurate and efficient flow measurement solutions.

0 notes

Text

Trusted Thermal Mass Flow Meter Suppliers - Burak Metering

Connect with reliable thermal mass flow meter suppliers offering high-quality solutions for your gas flow measurement needs.

#Thermal Mass Flow Meter Suppliers#Mass Flow Meter Manufacturer in India#mass flow meter manufacturer#thermal mass flow meter manufacturer#mass flow meter india#thermal mass flow meter in india#mass flowmeter manufacturer

0 notes

Text

A renewable energy source that can be created from several types of organic waste is biogas. Accurate and effective compressed biogas flow metering systems are essential for maximising biogas production efficiency and ensuring appropriate energy management.

Inserting thermal mass flow metres is one of the most effective and economical methods for measuring the flow of biogas. In this blog post, we’ll look at the benefits of measuring biogas flow with insertion thermal mass flow metres.

THE NEED FOR RELIABLE BIOGAS FLOW MEASUREMENT For effective energy management and production, biogas flow must be measured. Accurate compressed biogas flow monitoring aids in cost-savings, safety, and process control optimisation. Inaccurate biogas flow measurement can result in decreased energy output, equipment damage, and safety risks.

Furthermore, proper reporting and adherence to regulatory standards depend on precise biogas flow measurement.

BENEFITS OF INSERT THERMAL MASS FLOW METRE USE Due to a number of benefits, insertion thermal mass flow metres are a great option for determining the flow of biogas.

Firstly, even in situations with variable gas composition and temperature, insertion thermal mass flow metres offer great accuracy and repeatability. Additionally, they offer real-time measurement of gas flow rate and totalized flow and are insensitive to variations in pressure. When static pressure is too low, it functions pretty effectively. It may be adjusted to fit different pipe diameters.

Additionally, insertion thermal mass flow metres don’t need any additional pressure or temperature correction components, are simple to install, and require no maintenance. Overall, the installation of thermal mass flow metres offers a dependable and affordable alternative for measuring the flow of biogas.

THE BEST WAYS TO USE INSERTION THERMAL MASS FLOW METRE FOR MEASURING BIOGAS FLOW It is crucial to adhere to best practises to guarantee accurate biogas flow measurement with the insertion of thermal mass flow metres. For instance, the flow meter’s insertion point should be situated in a segment of the pipe where the flow is unhindered by turbulence or obstructions and is fully developed.

Additionally, the flow metre needs to undergo routine calibration and verification against a reference standard. Furthermore, the flow meter’s accuracy can be impacted by how it is installed, particularly the depth and direction, thus this should be carefully taken into account.

APPLICATIONS OF INSERTION THERMAL MASS FLOW METERS IN BIOGAS FLOW MEASUREMENT

Insertion thermal mass flow meters have a wide range of applications in biogas flow measurement, including biogas plants, landfills, wastewater treatment plants, and agricultural operations.

In biogas plants, insertion thermal mass flow meters are used to monitor the feedstock and optimize the fermentation process, resulting in increased gas yield and quality. In landfills, insertion thermal mass flow meters are used to monitor the gas generated by organic waste decomposition and ensure compliance with environmental regulations.

In wastewater treatment plants, insertion thermal mass flow meters are used to monitor the waste gas produced during the digestion process and optimize energy recovery. In agricultural operations, insertion thermal mass flow meters are used to monitor the gas produced from manure and optimize biogas production.

CONCLUSION

In conclusion, insertion thermal mass flow meters are an excellent choice for biogas flow measurement due to their high accuracy, repeatability, and cost-effectiveness.

Following best practices for installation and calibration can ensure accurate measurement and optimize energy production and management in various industries and applications. Insertion thermal mass flow meters offer a reliable and efficient solution for biogas flow measurement, providing significant benefits for both the environment and the bottom line.

At Leomi Instruments, we offer a wide range of high-quality insertion thermal mass flow meters for biogas flow measurement. Our products are designed to provide accurate and reliable measurements in various applications, ensuring optimal energy management and compliance with regulatory requirements.

We also offer expert installation and calibration services, ensuring that our products perform at their best. Contact us today to learn more about our biogas flow measurement solutions and how we can help maximize efficiency in your operations.

0 notes

Text

Comprehensive Thermal Mass Flow Meter Specifications

Explore the comprehensive specifications of thermal mass flow meters. Designed for a wide range of gases with low pressure drop. Ideal for industrial applications.

#Thermal Flow Meter#Thermal Mass Flow Meter Manufacturer#Thermal Mass Flow Meter Manufacturer in Mumbai#Thermal Mass Flow Meter Suppliers#Thermal Mass Flow Meter#Thermal Mass Meter Suppliers

0 notes

Text

★ crimson tension rafe cameron x reader

summary: who knew rafe getting beat up and being vulnerable would end up giving him what he needed most - comfort

warnings: blood, wound description

a/n: ughh this took so long to write but it was worth it cuz I made myself giggle and kick my feet a few times. maybe this is a little cliche but I’m a sucker for these so sorry not sorry

loud music blasted over the speakers, laughter and unfamiliar voices rang around the manor, people spilled out from every room, clutching red plastic cups. the air was thick with the smell of beer and something sweet mixed with a faint undertone of sweat, the wide open doors leading to the cameron garden offered little relief, serving more as a passage to the outdoors than a true escape from the stifling atmosphere of tannyhill

the kitchen was a maze of half-empty bottles, red solo cups, and a few glasses perched on the edge of every counter. it was hard to believe none had shattered, considering the steady flow of people jostling past each other

right as you are about to take yet another shot you hear some barely audible shouting

curiosity overtaking your body faster than your mind and your legs start moving on their own accord, shot getting lost on the counter. making your way through the crowd but merely getting to the hallway as a mass of people block off the way and view to the living room, you hear a loud voice that undoubtedly belongs to rafe

whispers and 'oohs' pass through the crowd, before you notice rafe pushing past people with practiced ease, not bothering to acknowledge anyone as he moves forward. his focus unwavering, his movements deliberate as he makes his way toward you, a destination in mind

you catch a glimpse of the huge gash right above his eybrow - your eyes widen and you move towards him

after seeing his look and eyes you realize why he doesn’t react to you calling out his name - whatever substance he had taken prior was showing on his face, the haze clouding his expression, a disheveled look, glassy eyes with dilated pupils, fluoride stare as well as furrowed brows were noticeable as he brushes right past you

you glance around the room and the absence of attention on rafe doesn’t go unnoticed. you realise whoever had been on the other end of his rage must look worse - a chill runs down your spine imagining the ugly sight

being sarahs friends, tannyhill was not a foreign place for you so you knew where he was headed as he moved up the stairs

you hesitate but decide to follow him, once you’ve reached his room you rethink whether or not to knock, uncertainty creeping in but the worry gnaws at you too strongly - after calling out to him and getting no answer you enter the dimly lit room

the music dampens as you close his door. you pay no attention to his room, a already familiar space, your eyes immediately noticing him right ahead

the weight of the silence between you both grows heavier as you step closer, torn between reaching out and giving him space

he’s standing on his balcony, slumped onto the railing all though theres so much tension present in his shoulders that you can see it from a few meters away. his eyes are fixed on the ocean, the smoke lingering in the air making it evident that there was a cigarette resting between his fingers

he merely spares you a glance when you say his name again, turning around without muttering a single word

carefully you make your way toward him, situating yourself onto his right in complete silence, taking in the scene before you - the music has gotten louder and you look down at the people dancing below you, they payed absolutely no mind to rafe above them and in comparison to the loud laughs and voices the ocean before you was calm - the steady motion of the water, the endless horizon, seeming to soothe him

analysing his face you conclude that whatever fight had just occured - it was a heavy one - rafe had a busted lip, bruised knuckles, a bruise was already forming on his nose and the eybrow gash that was bleeding rather harshly. your face twists imagining how much his head must be throbbing

right now was not the time - but you also couldn’t stop thinking about the fact that he has never looked hotter

the moonlight hit his face just right, highlighting his tired eyes, making the blood adorning his face less unsettling, cigarette held between blood covered fingers, his knuckles bruised and bleeding, yet there’s something almost striking about the way his hands look, the way they’re still so perfectly shaped, even in their damaged state - his pain and his beauty so closely intertwined. even in this state, even with blood streaked across his face, there’s something undeniably captivating about him.

quickly pushing those thoughts aside you catch rafe looking at you for a second with a seemingly emotionless look, tension still present in his eybrows

you know he probably wanted to be left alone, his body language said it all. the desire to comfort him tugs at you, wanting to step forward and reach out, to brush your fingers along his jaw, to caress the sharpness of his stern yet tender face

''why are you here?'', he bites in a monotone tone, ripping you out of your thoughts

you clear your throat, ''I just wanted to see if you’re alright... maybe help you,” you say, the words feel awkward, out of place, like you’re intruding

his eyes snap to you, and for a moment, there’s a flicker of something sharp, almost like a reflex. then, it morphs into a cold, bitter look of disgust. “I don’t need any help,” he mutters

''rafe you’re bleeding - badly'', you utter throwing a glance toward the gash which, even in bad lightning, was clearly deeper than he realized as it had oozed so much blood that it had almost covered the right side of his face. ''I just-'' you falter before sighing, ''I didn’t know what happened and I was concerned''

you weren’t entirely sure why you were confessing your concern - it wasn’t exactly something that came naturally with rafe cameron. the alcohol in your system seemed to loosen the edge

seemingly bother by you answer, not even sparing you a look he replies, ''I don’t need your pity, run back to sarah or something'' he motions you away with his hand

you bite your lip, clearly fighting a mental battle whether or not to leave him alone. you notice his hands shaking, not sure whether it was from anger pain or something else

slightly tipsy you gather the courage to ask once again, pushing his annoyance aside because you so desperately want to help him, feeling your heart hurt seeing him like this

you try one last time, ''your hands are shaking, you sure you can patch yourslef up? I really just wanna help you rafe. but if you really want me to go say it - then Ill leave'', finishing you realize how pathetic you sounded, internally cringing but hoping it would convince him and make him see that you really did care about him

silence

rafe looks at you quickly noticing your concerned face filled with worry, even though his look was quick you notice that it changed, something changed, but before you can even get close to figuring out what he turns back around and takes a long drag from his cigarette, the smoke curling up in the cool air, his gaze fixed straight ahead, not meeting yours again

he exhales slowly, the smoke drifting up in a haze, but the tension in the air thickens instead of easing

defeated, you turn away, the weight of the silence too much to bear. you don’t say anything, no last attempt to reach him

suddenly you hear a quiet ''wait'' from rafe, so faint it wouldn’t have been audible if you had taken two more steps

you turn your head around quickly, trying to figure out if he really just said that but when you catch him putting out his cigarette into the ashtray you realise that he did

he turns around as you take a few steps towards him. his face barely visible from his dark room - only illuminated lightly by the moonlight and the soft glow from the party below - holds a stern and tense look, his jaw clenched with tension, vulnerability present in his eyes

rafe still hasn’t said another word but you’re easily able to read his expression and figure out what he wants you to do

relief washing over you you exhale a big breath, ''okay where’s the med kit?''

''bathroom'', is the only thing he says, voice low, eyes still focused on you - unwavering

you turn around and step into the bathroom, the small space a contrast to the size of his bedroom. quickly you begin searching the cabinets, your mind already running through the steps you’d need to take. already thinking about where would be the best place to clean and dress his wound, somewhere where he can sit down, somewhere you can work without too much trouble - before finding the med kit under his sink

a subtle warmth creeps up your neck, and you can’t shake the feeling that you’re being watched. you turn around noticing him standing in the doorway, leaning against the door - watching you with those empty yet pleading eyes before his gaze flickers over to the mirror - he’s lost in his reflection for a moment, studying himself

rafe stands there for a moment, seemingly lost in thought. then, with a quiet click, he closes the door behind him, fully stepping into the bathroom. the music muffles and the air between you tightens. you swallow, heart racing - you try to focus on the medkit in your hands. he moves past you slowly, sitting down on the toilet lid

right now, in the bright light of the bathroom, you’re finally able to see the full extent of his wounds as he holds his head up, avoiding your gaze. examining his wounds you settle on tending to his eyebrow first

you can tell that he’s not ready to talk about the fight or whatever happened. the air is heavy and something in his silence tells you not to push. so, you don’t, you stay quiet. setting the med kit down on the counter searching for the right tools, you feel suffocated by the silence, so awfully aware of every, rigid and nervous, breath you took

ready you turn back to rafe whose gaze is set onto the ground, still lost in thought - you try to clear your throat to catch his attention, to notify him that you’re ready and willing to tend to his wounds

he looks at you with a look, a look so vulnerable and hurt that it pulled at your heart. whatever he was just thinking must’ve hit him hard - the weight of it is there, written across his face, and you feel it in your chest. rafe’s eyes still carry that glassy, fluorid stare, as if he's still not fully aware of everything around him, making you wonder if he even realizes how much he’s letting slip

you figure that however you were to approach this - it would be awkward either way

you looked at him with a nervous look, alcohol-soaked cotton pad in hand - standing right in front of him, you hesitated as your eyes met his. he lifts his head a little farther up for you to get better access to his wounds. rafe is leaning forward, legs spread with his forearms resting on his knees, crossing his hands slightly in front of him infront - still at an awkward length until he fully uncrosses his hands, resting them on his knees. you waited, unsure if you’re allowed to enter the space, looking for a look of approval in his distant eyes. he nods - the faintest movement of his head, barely visible

his eyes carry a look that’s hard to read, an expression that makes you wonder if there’s a storm raging inside his mind or if he’s drifting into an unsettling emptiness

settling in between his knees - still trying to keep some sort of distance, unsure what was or wasn’t crossing the line, you bring the cotton pad up to his face. you gently start cleaning off the, mostly already, dried blood before moving on to his gash. the second it hits his skin again his eyes - which have been avoiding yours from the second he nodded - close, his jaw clenching pain evident although he tried not to show it, putting up some sort of barrier to, even in this vulnerable state, seem unbothered - strong

while cleaning you notice his hands, resting on his knees, and fingers lightly grazing against the fabric of your shorts, the lightest of touches—almost like a subconscious gesture. it’s a small movement, barely noticeable, but the tension it creates fills the space between you

you focus on your task, but it’s harder now, your hand faltering slightly with each light graze of his fingers

the delicate movement of his fingers almost like a distraction from the physical discomfort he’s trying to hide so well. it makes you wonder if he’s trying to ground himself, or if he’s just too lost in the moment to notice what he’s doing

after cleaning everything off in the best way you could you apply some zip stitches to at least momentarily close the wound. his breath hitches as you press the last stitch into place, but he doesn’t move or make a sound, the mask of stoic restraint still firmly in place

you couldn’t figure out if rafe was actually aware that he was pulling you closer to himself

by the time you were ready to clean his lip the distance between you was so minimal that you could barely clean it properly. the closeness making every slight movement feel amplified now, the soft brush of his breath, the faint tension in his jaw, the way his eyes flicker between avoiding yours and briefly meeting your gaze

you gently press the cotton to his lip, your fingers grazing his skin in the process. the way his gaze flicks up to meet yours for a split second makes your heart skip, throwing off your rhythm.

you hesitate for a moment, your heart racing in the silence between you. the closeness is overwhelming, and you know you need to steady yourself, to find a way to regain control. your fingers tremble slightly as you lift your hand, almost instinctively, and you gently place it on the side of his face. the warmth of his skin is a shock, he lets out a soft exhale which you wouldn’t have noticed if you werent holding his face with your hand - but he doesn’t pull away.

you angle his face just enough to get a better view, but the movement feels more like an anchor for yourself, the subtle pressure of your hand on his skin keeps you tethered, even as the air between you thickens with something unsaid

you press the pad to his lip slowly, careful and deliberate, but your fingers linger on his skin longer than necessary, your thumb lightly brushing the edge of his jaw. his breath brushes against you, warm and shallow

it’s hard to focus with the way his gaze lingers on you, the way your hand feels on his face

his lips part quickly as you tend his wound - the area lightly swollen, thankfully not comparable to his eyebrow gash

you finish tending to his face, placing a last small plaster, hurting at the loss of contact. you take a look back and admire your work and him. the quiet stillness between you both feels oddly heavy, but the comfort of knowing he’s patched up - protected for now - settles in

you dread saying the words a loud, not wanting to lose this moment, not wanting to end it - not sure what it even was

''done''

the hands behind you tighten their grip, slowly pulling you even closer, eliminating the space between you. your body freezes for a second - caught off guard. his head reasts on your upper body, sending a wave of warmth through you, and for a moment, you're aware of every breath, every beat of your heart

his breath is steady, slow, but there’s an unmistakable force in the way he holds you, a quiet urgency that makes your mind go blank

his grip, though firm, isn't forceful - more like an unspoken invitation, urging you, pleading you, to stay within the space he's created. he held on with such a purpose - it made it seem like you would evaporate the second he let go

you place one hand gently in his hair, testing the waters, seeing if he'd be comfortable with you running your fingers through it. the other one rests on his back

rafe flinches when you tryto pull him closer, putting pressure on his back

you let the moment linger for a few seconds more before speaking up, breaking the comforting silence which rested between you, ''rafe let me see your back''

he pulls back and looks at you for a second, his look completely unreadable. this time he complied. he stands up with a slow, deliberate motion and turns around. he lifts his shirt as far up as he could, pain clearly holding him back. gently taking hold of the shirt from his hand, you ease the fabric upward, careful to avoid causing him any more pain as you lift it higher

his back is painted with all sorts of colours - some bruises worse than others. you flinch at the sight, although you’re a little relieved to see no cuts

seeing there is nothing you can do you let his shirt fall back down, very carefully smoothing it on his back - hoping to provide some comfort with the soft touch

as you move next to him to rest a hand on his bicep, you ask him with a hushed voice, ''can I get you a new shirt'', meeting his gaze, ''yours is full of blood''

fully aware that the line that was not to be crossed has now become blurred

rafe nodded

you leave his side, moving to his drawer - your fingers fumble slightly as you sift through the clothes, searching for a shirt. you pick out a loose one, one that would not press against his back too much or that would be a struggle to put on

he now sat on his bed, patiently waiting for you, watching you

you turn back to him, seeing his eyes, his expression. a storm of thoughts no longer visible, only exhaustion

''is this one okay?'' you questioned. he nodded before clearing his throat and lowering his gaze, ''can you help me put it on'', clearly exhausted

you pull hisshirt up slowly, carefully and for a moment you’re stunned, staring in silence. the sight that greets you is just as shocking as it is heartbreaking - his chest is as bruised as his back

rafe is clearly avoiding your eyes, looking to his left with a tense jaw

without saying another word you pull the other shirt over his head, standing before him, ''are you gonna go back down?''

he replies with a shake of his head, ''no''

you quietly stars at him for a few seconds more, debating how to continue then letting your legs carry you towards the bathroom to clean up. but just as you turn to leave, you feel his hand snap out, gripping your wrist with a force that sent a jolt through your body. the touch was immediate, urgent, as though he couldn’t let you go. but then, as quickly as it had come, his grip softened, the tension draining away as he loosened his hold

your eyes flicker back to him

“stay”

#chat is this cringe#rafe cameron#rafe cameron x reader#rafe obx#rafe x reader#rafe cameron obx#rafe cameron fanfiction#obx season 4#obx#obx x reader#obx fanfiction#outerbanks#outerbanks rafe#outerbanks x reader#outer banks#drew starkey#drew starkey x reader#outer banks fanfiction#outer banks x reader#fanfiction#x reader

1K notes

·

View notes