#coriolis gas flow meter

Explore tagged Tumblr posts

Text

Unveiling Precision: Nagman Flow's Coriolis Mass Flow Meter

Welcome to Nagman Flow, where precision instrumentation meets cutting-edge technology. In this blog post, we dive into the world of flow measurement with a focus on the Coriolis Mass Flow Meter. We will explore the intricacies of this innovative device, its applications, and how Nagman Flow's expertise ensures unparalleled accuracy in mass flow measurement.

Coriolis Mass Flow Meter: A Breakthrough in Flow Measurement

The Coriolis Mass Flow Meter represents a revolution in flow measurement technology. Operating on the principle of the Coriolis effect, this meter offers unparalleled accuracy in measuring mass flow rates. Nagman Flow's Coriolis Mass Flow Meter is engineered to deliver precise measurements across various fluid mediums, from liquids to gases.

Advantages of Nagman Flow's Coriolis Mass Flow Meter

Precision Measurement: Nagman Flow's Coriolis Mass Flow Meter provides precise measurement of mass flow rates, ensuring accuracy and reliability in critical processes.

Versatility: Whether measuring liquids or gases, Nagman Flow's Coriolis Mass Flow Meter offers unmatched versatility, making it suitable for a wide range of applications.

Low Maintenance: Built with robust construction and advanced technology, Nagman Flow's Coriolis Mass Flow Meter requires minimal maintenance, reducing downtime and operational costs.

Coriolis Gas Flow Measurement: With specialized configurations for gas flow measurement, Nagman Flow's Coriolis Mass Flow Meter excels in accurately measuring gas flow rates, providing valuable insights for various industries.

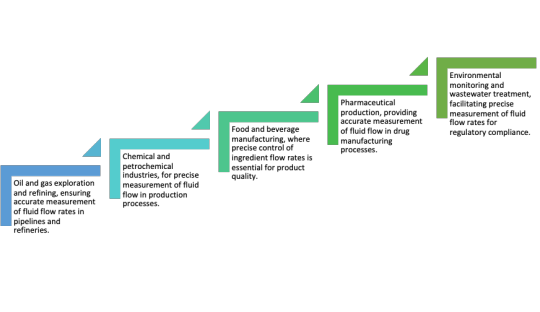

Applications of Coriolis Mass Flow Meter

Nagman Flow's Coriolis Mass Flow Meter finds applications across diverse industries, including:

In the realm of flow measurement, Nagman Flow's Coriolis Mass Flow Meter stands as a beacon of precision and reliability. With its advanced technology and unparalleled accuracy, Nagman Flow ensures that industries can rely on precise mass flow measurements for optimal performance and efficiency. Trust Nagman Flow to deliver exceptional solutions for all your flow measurement needs. Contact us today to learn more about Nagman Flow's Coriolis Mass Flow Meter and experience the difference in precision instrumentation.

0 notes

Text

The Future of Flow Meter Technology: Trends and Innovations in the UAE Market

Flow meters are handy instruments that quantify a fluid flow in a pipe or channel, either the volume or the velocity. Flow measurement is needed by most industries, such as oil and gas, water treatment, chemical processing, and food and beverage manufacturing.

In the UAE, where all these businesses thrive, there is growing demand for accurate and reliable flow measurement solutions. Ali Yaqoob offers a full range of flow meters to suit the varied requirements of businesses in this region.

Flow Meter Technology

There are several different types of flow meters using different technologies and providing different advantages for different purposes. Below is a description of some of the most used ones:

Differential Pressure (DP) Flow Meters: Here, the pressure difference that is generated as fluid passes through a surface narrowing in the process of fluid flow through a pipe is determined by the flow meter. Simple applications of the same are orifice plates, Venturi tubes, and flow nozzles. DP meters are common because they can be performed easily and at low expenses.

Positive Displacement (PD) Flow Meters: PD meters directly measure the liquid that passes through the meter. PD meters consist of oscillating or rotating members which suck in and expel an equal amount of liquid per cycle. PD meters are very accurate and can be used to measure viscous liquids.

Velocity Flow Meters: These record the velocity of the fluid and determine the flow rate from the cross-sectional area of the pipe. Turbine meters, paddlewheel meters, and electromagnetic meters are common examples.

Electromagnetic (Mag) Flow Meters: Mag meters function by developing a magnetic field, which detects velocity in conductive liquids. They create an extremely low level of flow obstruction and can be used with virtually all fluids, such as fluids with solids.

Ultrasonic Flow Meters: The geophysical application of ultrasonic flow meters is utilized in fluid velocity flow measurement using sound waves. Transit-time and Doppler are the two most widely used types, utilized more than others in other configurations. Ultrasonic flow meters are not invasive and will measure almost all liquids and gases.

Vortex flow meters: The vortex meters contain a bluff body, which causes vortices in the stream of flow. The vortex frequency is a function of the flow rate. The vortex meters provide precise measurement of steam flow, gas flow, and liquid flow.

Coriolis flow meter: The Coriolis meters directly measure mass flow rate by measuring the Coriolis forces caused by the fluid's movement. It's precise for mass flow measurement and can measure any fluid of any viscosity and density.

Factors to Be Considered While Choosing a Flow Meter

An appropriate flow meter must be chosen to allow an accurate and repeatable measurement of flow. Utilize the following number of factors:

Fluid Type: The physical attributes of a fluid (like viscosity, density, conductivity, and corrosiveness) are factors that will greatly influence how far toward the end of effective range a flow meter will function.

Fluid Properties: The mechanical characteristics of a fluid (e.g., viscosity, density, conductivity, and corrosiveness) will likely influence the operation of a flow meter to a great extent.

Range of Flow Rates: Choose a flow meter suitable for the application with the intended fluid flow rate range of the application.

Accuracy Requirement: It defines the accuracy requirement of the application.

Installation Needs: Available space, piping design, and installation and maintenance access must be considered.

Flow Meter Suppliers in UAE

There are some suppliers in UAE who are offering different flow meters of different manufacturers. While choosing a supplier, consider the following:

Range of Products: Choose a supplier which possesses a large variety of flow meter technologies in order to be in a place to serve many different applications. Ali Yaqoob possesses a wide variety of flow meters

Technical Expertise: Provide a supplier which possesses experienced engineers to hand for supplying technical advice and assistance in the range selection of flow meter, installation, and fault identification.

Service and Support: Select a supplier that provides quality after-sales service, i.e., calibration, servicing, and maintenance.

Experience and Reputation: Select a supplier with good reputation for quality supply of flow meters and technical service.

Price and Availability: Obtain lead times and quotations from several vendors and shop around to compare prices and achieve the best value.

Featured Flow Meter: Liquid Controls M7 & M15

Liquid Controls M7 & M15 flow meters are accurate, positive-displacement flow meters that are reliable. Liquid Controls M7 and M15 flow meters are used extensively, primarily to measure gasoline, chemical liquids, and other liquids for most businesses. Ali Yaqoob provides special offer prices for Liquid Controls M7 & M15 flow meters temporarily.

Conclusion

Flow meters are quite important for the measurement of fluids to high accuracy by most business companies in the UAE. Selection of flow meters needs to be carried out using proper analysis of fluid properties, flow rate range, accuracy requirement, operating conditions, and installation constraints. Through an effective supplier such as Ali Yaqoob and their expertise and wide product range, UAE businesses can have confidence that they have the best flow measurement solution for their own specific application.

0 notes

Text

Overview of Digital Flow Meters: Accurate Flow Measurement for Modern Industries

Flow meters are essential tools in many industries, used to measure the volume or mass of a fluid moving through a pipeline. With the growing demand for more precise, reliable, and real-time data, digital flow meters have become increasingly popular. These advanced instruments offer enhanced accuracy, easy integration with digital systems, and lower maintenance needs compared to traditional mechanical meters.

This blog will provide a clear overview of digital flow meters, how they work, their types, benefits, and where they are used.

What is a Digital Flow Meter?

A digital flow meter is a device that measures the flow of liquids or gases and displays the results in a digital format. It uses sensors and electronic components to monitor flow rates with high precision and often includes features such as:

Digital displays for real-time monitoring

Remote data transmission

Integration with SCADA, PLC, or IoT systems

Alarm settings and data logging

These meters are commonly used in water treatment plants, oil & gas industries, chemical processing, and HVAC systems, among others.

Types of Digital Flow Meters

There are several types of digital flow meters, each suited for different applications based on the type of fluid and required accuracy:

1. Electromagnetic Flow Meters

Ideal for conductive liquids like water, slurries, and chemicals. These meters use electromagnetic fields to measure flow without any moving parts.

2. Ultrasonic Flow Meters

Use high-frequency sound waves to measure the velocity of the fluid. They are perfect for both clean and dirty liquids and work well in large pipes.

3. Turbine Flow Meters

Contain a spinning rotor that turns with the flow. The rotational speed is proportional to the flow rate. These are used in clean, low-viscosity liquids.

4. Coriolis Flow Meters

Measure mass flow directly using the Coriolis effect. Known for their high accuracy and are used in chemical and pharmaceutical industries.

5. Thermal Mass Flow Meters

Used mainly for gases, these measure flow by detecting heat loss from a heated sensor placed in the flow path.

Benefits of Using Digital Flow Meters

✅ High Accuracy: Digital sensors reduce human error and provide exact measurements.

✅ Easy to Read: Digital displays are user-friendly and easy to interpret.

✅ Remote Monitoring: Many models support wireless or wired connectivity for remote data access.

✅ Low Maintenance: With fewer moving parts, these meters are durable and require minimal upkeep.

✅ Data Storage: Many meters come with memory functions for storing historical data for analysis.

Applications of Digital Flow Meters

Digital flow meters are used across various industries, including:

Water & Wastewater Management: For monitoring distribution and treatment systems.

Oil & Gas: For controlling the flow of fuels and gases.

Food & Beverage: Ensures precise ingredient mixing and quality control.

Pharmaceutical: For high-accuracy dosage and mixing applications.

HVAC Systems: For measuring water and air flows for better energy efficiency.

Conclusion

Digital flow meters have revolutionized how industries measure and manage fluids. Their combination of accuracy, reliability, and advanced features makes them an essential part of modern process control systems. Whether you are managing water resources, producing chemicals, or ensuring clean air flow, a digital flow meter can greatly improve your operational efficiency.

If you’re searching for reliable Digital flow meter manufacturers in India, it’s important to choose a company with proven expertise, quality products, and excellent service support to match your industry’s specific needs.

Looking for the right digital flow meter for your application? Connect with a trusted supplier today and discover how digital technology can enhance your flow measurement systems.

#flow meters#electromagnetic water meter#digital water flow meter#digital flow meters#digital water flow meter manufacturer in india#digital water flow meter india#electromagnetic flow meters#digital water meter#electromagnetic flow meter suppliers in india#electromagnetic flow meter manufacturers in india

0 notes

Text

The Complete Guide to Industrial Flow Measurement Technology

In today's complex industrial environments, accurate flow measurement isn't just helpful—it's essential. Whether you're monitoring water treatment processes, managing chemical manufacturing, or overseeing oil and gas operations, understanding the fundamentals of flow measurement technology can make the difference between optimal efficiency and costly mistakes.

Understanding Industrial Flow Measurement Basics

Industrial flow measurement involves quantifying the movement of fluids—whether liquid, gas, or steam—through pipes, channels, or other containment structures. The accuracy of these measurements directly impacts production quality, operational efficiency, and regulatory compliance.

Most industrial processes rely on precise flow data to:

Maintain product quality and consistency

Optimize energy consumption

Ensure regulatory compliance

Prevent system failures

Reduce waste and operating costs

Key Flow Measurement Technologies in Modern Industry

Electromagnetic Flow Measurement

Electromagnetic flowmeters operate on Faraday's Law of Electromagnetic Induction. When conductive fluid passes through a magnetic field generated by the meter, it produces a voltage proportional to the flow velocity. This voltage is then measured by electrodes and converted into flow rate readings.

Electromagnetic flow sensors excel in applications involving:

Wastewater treatment

Pulp and paper processing

Mining slurries

Chemical manufacturing

Food and beverage production

The technology offers exceptional accuracy for conductive fluids, with minimal pressure drop and maintenance requirements. However, they cannot measure non-conductive fluids like hydrocarbons or purified water.

Ultrasonic Flow Meter Technology

Ultrasonic flow meters use sound waves to measure fluid velocity. These devices come in two primary varieties:

Transit-time ultrasonic meters measure the difference in time it takes for ultrasonic pulses to travel with and against the flow direction. This technology works exceptionally well with clean, homogeneous liquids.

Doppler ultrasonic meters measure the frequency shift of an ultrasonic signal reflected off particles or bubbles in the fluid. This makes them ideal for slurries, sludge, and other particle-laden flows.

Ultrasonic flow meter installations offer several advantages:

Non-invasive measurement (clamp-on types)

No moving parts to wear out

No pressure drop

Suitable for large pipe diameters

Ability to measure bi-directional flow

These meters have transformed industries like water distribution, HVAC, and energy management by providing reliable measurements without disrupting the flow process.

Coriolis Flow Meter Precision

Coriolis flow meters represent the gold standard for mass flow measurement accuracy. These meters measure the twist in oscillating tubes caused by the Coriolis effect as fluid moves through them. This technology directly measures mass flow rather than volumetric flow, eliminating the need for temperature and pressure compensation.

Industries that benefit most from coriolis flow meter technology include:

Pharmaceutical manufacturing

Food processing

Oil and gas custody transfer

Chemical batching

High-purity applications

While these meters typically command higher upfront costs, their exceptional accuracy (often ±0.1% or better) and ability to simultaneously measure density and temperature make them invaluable for critical applications.

Traditional Rotameter Flowmeter Applications

Despite advances in digital technology, variable area meters—commonly known as rotameter flowmeters—remain widely used in certain applications. These simple devices consist of a tapered tube containing a float that rises proportionally to flow rate.

Rotameter flowmeters are particularly valuable in:

Local flow indication without power

Low-flow applications

Simple process monitoring

Laboratory settings

Economical installations

While lacking the advanced features of electronic meters, rotameters offer reliability, simplicity, and visual indication at a fraction of the cost.

Selecting the Right Flow Measurement Technology

Choosing the appropriate flow meter requires careful consideration of several factors:

Fluid Properties: Viscosity, conductivity, corrosiveness, and presence of particles all influence meter selection.

Process Conditions: Temperature, pressure, flow range, and required accuracy determine which technologies are viable.

Installation Requirements: Available straight pipe runs, space constraints, and maintenance access affect installation options.

Budget Considerations: Initial purchase cost must be balanced against maintenance requirements, expected lifespan, and accuracy needs.

Industry Standards: Certain applications may require specific meter types to meet regulatory or custody transfer requirements.

Flow Monitoring Integration with Industrial Systems

Modern flow measurement extends beyond standalone meters to integrated monitoring systems. Today's flow meters often include:

Digital communication protocols (HART, Modbus, Foundation Fieldbus)

Built-in diagnostics and verification capabilities

Remote monitoring functionality

Data logging and analysis features

Mobile connectivity options

These advanced features enable predictive maintenance, reduce downtime, and provide valuable insights into process efficiency.

Future Trends in Flow Measurement Technology

The industrial flow measurement landscape continues to evolve with several emerging trends:

Increased Intelligence: Self-calibrating meters with advanced diagnostics

Multi-parameter Measurement: Single devices measuring flow, temperature, pressure, and fluid quality

IIoT Integration: Flow meters as critical nodes in Industrial Internet of Things networks

Enhanced Visualization: Augmented reality interfaces for maintenance and troubleshooting

Machine Learning Applications: AI-driven flow pattern analysis for predictive insights

Conclusion

Effective industrial flow measurement requires understanding available technologies and selecting the right solution for each specific application. Whether implementing electromagnetic flowmeters for conductive fluids, ultrasonic flow meters for non-invasive monitoring, coriolis flow meters for mass flow precision, or traditional rotameter flowmeters for visual indication, proper selection ensures accurate data for process control and optimization.

As industrial processes grow increasingly complex, reliable flow measurement becomes ever more critical. By understanding the strengths and limitations of each technology, industrial operators can make informed decisions that improve efficiency, reduce costs, and ensure consistent product quality.

For specialized applications or challenging environments, consulting with flow measurement experts can help identify the optimal solution among the diverse range of flowmeter technologies available today.

0 notes

Text

The Science of Accuracy: Understanding Modern Flow Meters

In industries where precise measurement is crucial, flow meters play a significant role in ensuring accuracy and efficiency. From monitoring gas usage to optimizing industrial processes, flow meters provide essential data that helps businesses reduce waste, improve productivity, and enhance safety. With technological advancements, modern flow meters are now more accurate, reliable, and efficient than ever before.

Looking for high precision flow meters from leading flow meter manufacturers? Explore our wide range of advanced flow measurement solutions and find the perfect fit for your industry. Contact us today for expert guidance!

The Importance of Accurate Flow Measurement

Flow meters are essential tools for measuring the flow rate of liquids and gases in various industries such as oil and gas, chemical processing, and water treatment. Accurate flow measurement ensures optimal performance, regulatory compliance, and cost control. Whether it is a thermal mass flow meter for gas applications or an RPD gas meter for precise volumetric measurements, choosing the right flow meter is vital for operational success.

Types of Modern Flow Meters

With numerous types of flow meters available in the market, selecting the best one depends on the specific application. Some of the most commonly used flow meters include:

Thermal Mass Flow Meters: Ideal for measuring gas flow, these meters are highly accurate and do not require moving parts, reducing maintenance costs.

RPD (Rotary Positive Displacement) Gas Meters: Used in industrial and commercial applications, these meters provide precise volume measurement of gas.

Ultrasonic Flow Meters: These meters use sound waves to measure flow and are widely used in water and wastewater management.

Coriolis Flow Meters: Known for their high accuracy, they measure mass flow directly and are useful in chemical and food industries.

Each type of flow meter has unique benefits, and working with reliable flow meter manufacturers ensures that businesses get the best product suited for their needs.

Choosing the Right Flow Meter Supplier

Selecting the right flowmeter suppliers is just as important as choosing the right flow meter. A trusted supplier provides not only high-quality products but also technical support, calibration services, and guidance on installation. When looking for flow meter suppliers, consider factors such as industry experience, product range, accuracy standards, and after-sales support.

The Future of Flow Measurement

Partner with a trusted suppliers to stay ahead in the ever evolving world of flow measurement technology. Get in touch with us now to find the best solution for your needs!

In conclusion, modern flow meters are the backbone of accurate fluid measurement in various industries. Whether you need a thermal mass flow meter, RPD gas meter, or any other type of flow meter, working with the right flow meter manufacturers and suppliers ensures long-term efficiency, accuracy, and reliability. Choose wisely and stay ahead in the competitive industrial landscape!

0 notes

Text

Liquid Flow Meter Calibration

Ensuring Accuracy in Fluid Measurement: Nagman's Expertise in Liquid Flow Meter Calibration

In numerous industries, from oil and gas to pharmaceuticals and water treatment, the precise measurement of liquid flow is critical. Accurate flow measurement ensures efficient processes, quality control, and regulatory compliance. Liquid flow meters are essential instruments for this purpose, but their accuracy can drift over time due to wear and tear, environmental factors, or changes in the fluid being measured. This is where calibration becomes vital, and Nagman Calibration Services stands out as a leading expert in this field.

Nagman Calibration Services boasts a proven track record in designing, supplying, installing, and commissioning flow meter calibration systems, both within India and internationally. This extensive experience underscores their deep understanding of the intricacies of flow measurement and calibration. What sets Nagman apart is their comprehensive facility for calibrating a wide range of flow meter sizes, from DN 6 up to DN 400. This capability makes them one of the few companies in India equipped to handle such a diverse range of flow meter calibration needs.

Nagman employs various calibration methods, including gravimetric, volumetric, and comparison methods, ensuring the most appropriate technique is used for each specific flow meter and application. These methods are based on fundamental principles of physics and metrology, providing the highest level of accuracy and traceability.

The gravimetric method, considered the most accurate, involves measuring the mass of liquid that flows through the meter over a specific time interval. This method is particularly suitable for calibrating flow meters used in custody transfer applications, where the accurate measurement of mass is paramount.

The volumetric method, on the other hand, measures the volume of liquid that flows through the meter over a specific time interval. This method is commonly used for calibrating flow meters used in applications where volume flow rate is the primary measurement parameter.

The comparison method involves comparing the flow meter under test against a calibrated reference flow meter. This method is often used for calibrating large-size flow meters, where gravimetric or volumetric methods may be impractical.

Nagman's commitment to quality and accuracy is further demonstrated by their NABL accreditation as per ISO/IEC 17025:2017. This accreditation, established in both Chennai and Mumbai, signifies that their calibration laboratories meet stringent international standards for technical competence and quality management. It provides customers with the assurance that Nagman's calibration services are reliable, traceable, and performed by highly skilled personnel using calibrated equipment.

Nagman calibrates a wide variety of liquid flow meter types, including:

Turbine Flow Meters: These meters use a rotor that spins at a rate proportional to the flow velocity.

Vortex Flow Meters: These meters generate vortices that are proportional to the flow velocity.

Coriolis Mass Flow Meters: These meters directly measure the mass flow rate of the liquid.

Electromagnetic Flow Meters: These meters use a magnetic field to measure the flow velocity of conductive liquids.

Positive Displacement Flow Meters: These meters measure the flow by trapping and counting discrete volumes of the liquid.

Variable Area Flow Meters: These meters use a float that rises in a tapered tube to indicate the flow rate.

Ultrasonic Flow Meters: These meters use sound waves to measure the flow velocity.

By offering calibration services for such a diverse range of flow meter types, Nagman ensures that they can meet the needs of virtually any industry that relies on accurate liquid flow measurement.

The benefits of using Nagman's liquid flow meter calibration services are numerous:

Improved Accuracy: Regular calibration ensures that flow meters provide accurate readings, leading to more efficient processes and better quality control.

Traceability: NABL accreditation guarantees that calibration results are traceable to national and international standards, ensuring the integrity of measurement systems.

Regulatory Compliance: Accurate flow measurement is often required for regulatory compliance, and calibrated flow meters help companies meet these requirements.

Cost Savings: Accurate flow measurement can help identify and prevent leaks or inefficiencies in fluid systems, leading to significant cost savings.

Enhanced Product Quality: In industries where liquid flow is a critical process parameter, accurate flow measurement ensures consistent product quality.

In conclusion, Nagman Calibration Services plays a vital role in ensuring the accuracy and reliability of liquid flow measurement across a wide range of industries. Their extensive experience, comprehensive facilities, diverse calibration methods, and NABL accreditation make them a trusted partner for companies seeking to maintain the highest standards of fluid measurement.

0 notes

Link

0 notes

Text

Understanding Gas Flow Meters: A Key to Accurate Measurement

In Industrial settings like oil & gas, pharmaceuticals, food processing industries and different manufacturing plants, efficient and accurate gas flow measurement is essential to maintain safety, optimize processes and reduce waste. Gas flow meters are thus essential and indispensable devices for measuring the volume or mass of gas moving through a system.

There are a variety of gas flow meters, including thermal, ultrasonic, electromagnetic, Coriolis flow meters, and many other types, each designed for specific applications. These advanced meters provide direct measurements of mass flow rate, volumetric flow rate, temperature, and density, making them invaluable in brewing, dairy, and petrochemicals.

For example, Using Faraday's law of electromagnetic induction, electromagnetic flow meters are ideal for applications in water treatment, chemical industries, food and beverage processing, and where conductive fluids are common.

Investing in a high-quality gas flow meter ensures long-term efficiency and safety. Choose a reliable manufacturer to get the best solution tailored to your operational needs.

0 notes

Text

Key Trends Shaping the Future of the Flow Meter Market

The global flow meter market was valued at USD 10.02 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.5% from 2024 to 2030. In 2020, the market shipment size was recorded at 53,78,749 units, reflecting the ongoing demand for flow rate measurement technology across various industries. Over the forecast period, the market is expected to experience significant growth, primarily driven by the increasing need for accurate flow rate measurements in industries such as oil and gas (O&G), chemical processing, and petroleum refining.

One of the main drivers of this market growth is the rising demand for flow rate measurement in O&G management applications globally. The oil and gas industry, in particular, relies heavily on flow meters to measure the flow of liquids, gases, and vapors in pipelines, refining processes, and distribution networks. The increasing exploration and production activities in the O&G sector, including the recent discovery of shale gas reserves in North America, Europe, and the Asia Pacific, are expected to create significant demand for flow meters. These regions are likely to see expanded investments in oil and gas infrastructure, which will, in turn, boost the market for flow measurement instruments.

Besides O&G, other industrial sectors such as water and wastewater, power generation, and pulp and paper are also expected to contribute to the market growth. These industries are increasingly adopting measurement technologies and instruments to monitor and control the flow of fluids in their operations, ensuring efficiency, safety, and regulatory compliance. The growing emphasis on environmental sustainability and resource management is pushing these industries to invest in advanced flow meters for monitoring water usage, energy generation, and waste management.

An important trend that will influence the market in the coming years is the increased demand for intelligent systems. The integration of the Internet of Things (IoT) has paved the way for smart measurement solutions, which offer real-time data collection, remote monitoring, and predictive analytics. This has made flow meters not just tools for measurement, but also integral components in smart manufacturing and automation systems. With this integration, companies can optimize their operations, reduce energy consumption, and improve system reliability.

Gather more insights about the market drivers, restrains and growth of the Flow Meter Market

Regional Insights

The North American flow meter market is driven by the presence of key players such as General Electric, Emerson Electric Corporation, and Honeywell International Inc., who significantly contribute to the region's market share in terms of revenue. These industry giants play a vital role in the development and distribution of advanced flow measurement technologies, driving growth in the U.S. and Canada.

U.S. Flow Meter Market

In the U.S., the flow meter market is expected to account for a significant share of the North American market. The ongoing digitalization and the integration of IoT-enabled flow meters are expected to boost market growth. These advanced systems offer remote monitoring, predictive maintenance, and real-time data analytics, making them increasingly popular across industries. The adoption of these technologies is enhancing operational efficiency, reducing downtime, and improving overall system performance, which is anticipated to accelerate market expansion in the U.S. over the forecast period.

Europe Flow Meter Market Trends

Europe dominated the global flow meter market, holding over 35.37% of the global revenue share in 2023. The region has a high adoption rate of flow measurement systems, particularly in the power generation sector, which contributes significantly to the regional market's growth. In addition, the demand for advanced flow meters such as magnetic, ultrasonic, and Coriolis flow meters is expected to increase in the oil and gas (O&G) industry as the region focuses on more efficient and sustainable energy solutions.

Europe is home to several major manufacturers and providers of flow measurement technologies, including Endress+Hauser AG, Krohne Messtechnik GmbH, and ABB Ltd. These companies play a pivotal role in driving the market in Europe, and the region's strong industrial base, particularly in manufacturing, chemical, and O&G industries, ensures continued growth. As a result, Europe accounted for the largest market share in 2020, and this dominance is expected to persist throughout the forecast period.

• U.K. Flow Meter Market: The U.K. is expected to hold a significant share of the European flow meter market. Demand for flow meters is being driven by growing emphasis on water conservation and environmental protection, particularly in industries such as water and wastewater management. Accurate flow measurement is crucial in these sectors to optimize resource use, improve efficiency, and ensure regulatory compliance.

• Germany Flow Meter Market: The German flow meter market is expected to capture a substantial revenue share in Europe. Germany's strong manufacturing sector, particularly in industries like oil and gas, chemicals, and pharmaceuticals, has driven high demand for flow meters in process monitoring and control applications. Germany's focus on advanced industrial automation and technological innovation further boosts the demand for precision measurement instruments like flow meters.

• France Flow Meter Market: The French market for flow meters is expected to grow significantly, driven by technological advancements such as the integration of digital and wireless technologies. These advancements enable enhanced accuracy, reliability, and remote monitoring capabilities, making flow meters even more vital in sectors like water management and industrial process control.

APAC Flow Meter Market Trends

The Asia-Pacific (APAC) region is anticipated to witness a substantial CAGR of over 7.1% from 2024 to 2030. Growth in this region is largely driven by ongoing developments in the water and wastewater management sector in countries like India and China.

• China Flow Meter Market: China is expected to capture a significant revenue share in the APAC flow meter market. The country’s rapid industrialization and urbanization are driving a rising demand for flow meters across a variety of industries, including oil and gas, water and wastewater management, chemicals, and pharmaceuticals. As China continues to develop its infrastructure and industrial base, the need for accurate and efficient flow measurement solutions will continue to increase.

• India Flow Meter Market: The Indian market is expected to experience significant growth, fueled by the country's focus on infrastructure development, particularly in sectors such as energy, utilities, and construction. The increasing demand for flow meters in these industries to monitor and control fluid flow in pipelines, plants, and facilities is expected to drive the market.

• Japan Flow Meter Market: Japan is also projected to hold a significant revenue share in the APAC flow meter market. Stringent environmental regulations in Japan, aimed at curbing pollution and ensuring efficient resource management, have driven the widespread adoption of flow meters to measure and manage water, air, and other fluids. The demand for accurate measurement solutions in both industrial and environmental sectors is expected to continue growing.

Brazil Flow Meter Market Trends

The Brazil flow meter market is expected to capture a significant revenue share within the Latin American flow meter market. Technological advancements, including the rise of smart meters and the digitalization of flow measurement systems, have played a crucial role in the market's growth. These innovations offer improved accuracy, efficiency, and enhanced data management capabilities, all of which are contributing to the increasing demand for flow meters in Brazil.

Saudi Arabia Flow Meter Market Trends

The flow meter market in Saudi Arabia (KSA) is anticipated to grow significantly in the coming years, driven by an expanding industrial base, rising infrastructure needs, and increasing focus on environmental sustainability. As the country invests in infrastructure projects and adopts cleaner energy solutions, the demand for advanced flow meters to monitor fluid flows in industrial processes, utilities, and environmental applications will continue to rise.

Browse through Grand View Research's Sensors & Controls Industry Research Reports.

• The global industrial automation and control systems market size was estimated at USD 206.33 billion in 2024 and is anticipated to witness a CAGR of 10.8% from 2025 to 2030.

• The global biometric sensor market size was valued at USD 2.09 billion in 2024 and is projected to grow at a CAGR of 19.8% from 2025 to 2030.

Key Flow Meter Company Insights

The flow meter market is highly competitive, with companies employing various strategies such as partnerships, business expansions, new product developments, and contracts to increase their market share. Geographic expansion, through partnerships and collaborations, along with mergers and acquisitions, is a key strategy for market growth. Companies are also investing heavily in R&D to develop innovative and differentiated products that cater to specific industry needs.

Some of the prominent players in the flow meter market include:

• ABB Ltd.: A global leader in industrial automation and digitalization solutions.

• Emerson Electric Corporation: Specializing in a wide range of automation and measurement solutions.

• General Electric: A multinational conglomerate with strong operations in energy and industrial technologies.

• Krohne Messtechnik GmbH: A leading manufacturer of industrial process instrumentation, including flow meters, for various sectors.

• HÖNTZSCH GMBH & CO. KG: Known for its high-precision flow measurement equipment.

• Hitachi High-Tech Corporation: Specializing in advanced measurement solutions for industrial applications.

• Siemens: A global powerhouse in electrical engineering and industrial automation, offering comprehensive flow measurement solutions.

Key Flow Meter Companies:

The following are the leading companies in the flow meter market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these flow meter companies are analyzed to map the supply network.

• ABB Ltd.

• Emerson Electric Corporation

• em-tec GmbH

• Endress+Hausar AG

• General Electric

• Hitachi High-Tech Corporation

• Honeywell International Inc.

• HÖNTZSCH GMBH & CO. KG

• Krohne Messtechnik Gmbh

• Siemens

• Yokogawa Electric Corporation

Order a free sample PDF of the Flow Meter Market Intelligence Study, published by Grand View Research.

0 notes

Text

A Closer Look at Flow Meters: Enhancing Accuracy and Efficiency in Fluid Measurement

Introduction:

In industries where fluid flow plays a critical role, accurate measurement is essential for process optimization, quality control, and cost management. Flow meters are the unsung heroes in these operations, providing vital data and insights into fluid dynamics. In this blog post, we will delve into the world of flow meters, exploring their significance, working principles, types, and the benefits they offer in various applications. So, let's dive in and unravel the mysteries of flow meters!

1. The Importance of Flow Meters:

Fluid flow is a fundamental aspect of many industries, including oil and gas, chemical processing, water management, and manufacturing. In this section, we will discuss why flow meters are crucial for these sectors and how they contribute to enhanced productivity, safety, and resource utilization.

2. Understanding Flow Meter Principles:

To comprehend the intricacies of flow meters, we must grasp their underlying principles. In this section, we will explore the four main types of flow meters: differential pressure, positive displacement, velocity, and mass flow meters. We'll explain the working mechanisms of each type and highlight their strengths and limitations.

3. Differential Pressure Flow Meters:

One of the most common types of flow meters is the differential pressure flow meter. In this section, we will take a closer look at orifice plates, venturi tubes, and flow nozzles - three widely used differential pressure flow meter variants. We'll explain their construction, working principles, and discuss their applications and considerations for accurate measurements.

4. Positive Displacement Flow Meters:

Positive displacement flow meters are known for their precise measurements of low flow rates. In this section, we will examine the working principles of gear meters, nutating disc meters, and oval gear meters. We'll explore their advantages, limitations, and typical applications in industries such as food and beverage, pharmaceuticals, and fuel distribution.

5. Velocity Flow Meters:

Velocity flow meters, such as turbine and electromagnetic meters, rely on the fluid's velocity to measure flow rates. In this section, we will delve into their working principles, installation considerations, and applications. We'll also discuss the challenges associated with fluid properties, calibration, and maintenance.

6. Mass Flow Meters:

For applications where mass measurement is crucial, mass flow meters provide accurate results by directly measuring the mass of the flowing fluid. We will explore thermal mass flow meters, Coriolis flow meters, and their working principles, advantages, and limitations. This section will highlight their significance in industries like pharmaceuticals, chemical processing, and HVAC systems.

7. Selecting the Right Flow Meter:

Choosing the appropriate flow meter for your specific application is vital for accurate and reliable measurements. In this section, we will discuss the key factors to consider, such as fluid characteristics, flow range, accuracy requirements, installation constraints, maintenance needs, and cost considerations. By understanding these factors, you can make an informed decision when selecting a flow meter.

8. The Future of Flow Meter Technology:

As technology advances, so does the field of flow meters. In this section, we will explore emerging trends and innovations, including digitalization, Internet of Things (IoT) integration, and advancements in sensor technology. We'll discuss how these developments are shaping the future of flow meter technology and the potential benefits they offer.

9. Conclusion:

Flow meters are indispensable tools for accurate fluid measurement in various industries. By understanding their principles, types, and considerations for selection, you can optimize processes, reduce costs, and ensure safe operations. We hope this blog post has shed light on the world of flow meters and provided you with valuable insights into their significance and applications. Remember, precision in flow measurement leads to efficiency and success!

#flow meters#water meter test bench#gas meter calibration#flow meter#coriolis mass flow meters#flow meter calibration#liquid flow calibration system

0 notes

Text

Unlocking the Potential of Industrial Precision with Flow Meters

Flow meters have become indispensable tools in various industries, measuring the movement of liquids and gases with high accuracy. As industrial processes become more complex and demand greater efficiency, the flow meter market is seeing remarkable growth, driven by technological advancements and the need for optimized fluid management.

Overview of Market Growth

In 2024, the global flow meter market is on track to hit approximately USD 9.1 billion, with projections indicating it could grow to USD 12.6 billion by 2029, expanding at a 6.7% compound annual growth rate (CAGR). This growth is largely fueled by industries such as oil & gas, water treatment, chemical processing, and power generation, all of which require precise fluid monitoring for safety, efficiency, and compliance.

Importance Across Industries

Flow meters play a critical role across industries by ensuring accurate measurement of liquid and gas flow. In sectors like oil & gas, the reliability of these meters impacts production quality and safety, preventing costly mishaps such as leaks or inefficient energy use. In the water and wastewater management sectors, flow meters contribute to resource conservation, ensuring systems are running smoothly while complying with environmental regulations.

In industries that are highly regulated, such as pharmaceuticals and food & beverage, the precision provided by flow meters is paramount for maintaining quality control. Flow meters are also key in the renewable energy sector, where they help in monitoring biofuel production and improving energy efficiency.

Technological Advancements and IIoT Integration

The rapid adoption of advanced technologies is reshaping the flow meter market. The advent of digital flow meters, integrated with Industrial Internet of Things (IIoT) technology, has revolutionized how industries monitor and optimize their systems. These devices offer real-time data, predictive analytics, and enhanced diagnostic features. By harnessing IIoT, flow meters provide continuous insights, allowing operators to proactively address potential issues, reduce downtime, and increase operational efficiency.

Furthermore, the growing sophistication of flow meter technologies is reflected in the diversification of product types. Flow meters like Coriolis, ultrasonic, magnetic, and vortex meters are all tailored for specific industrial requirements. Coriolis meters, for example, are known for their accuracy in mass flow measurement, making them ideal for industries such as oil & gas. Meanwhile, ultrasonic and electromagnetic flow meters are extensively used in sectors that deal with conductive fluids, such as wastewater treatment.

Leading Players and Competitive Strategies

Top companies like Emerson Electric Co. and Siemens AG are pushing the boundaries of innovation in the flow meter space. Their products are designed to meet the evolving demands of multiple industries. Siemens AG, for instance, has developed ultrasonic and electromagnetic flow meters that are highly efficient in various industrial applications, while Emerson Electric is recognized for its state-of-the-art Coriolis and magnetic flow meters, which are widely used in hazardous environments.

These key players are not only focused on product innovation but are also strategically expanding their market presence through acquisitions and collaborations. Such strategies enable them to diversify their product offerings and expand into new markets, particularly in regions with growing industrial infrastructure, such as Asia-Pacific and the Middle East.

Future Trends in the Flow Meter Market

Looking ahead, the flow meter market is expected to continue evolving in response to both technological and regulatory pressures. Sustainability is becoming a crucial focus across industries, with governments worldwide implementing stricter regulations around energy efficiency and environmental conservation. Flow meters will play a vital role in helping industries meet these regulatory requirements by providing accurate measurements of water, air, and energy usage, thereby minimizing waste and emissions.

The push towards smart manufacturing and the implementation of Industry 4.0 will further accelerate the demand for advanced flow meters. As more industries transition to fully automated and interconnected production systems, the ability to remotely monitor and control processes via IIoT-enabled devices will be essential. This integration will lead to smarter, more sustainable operations, with flow meters at the heart of process optimization.

Download PDF Brochure :

Flow meters are becoming increasingly important in driving operational efficiency and ensuring industrial safety across multiple sectors. The market’s growth trajectory, supported by ongoing technological advancements and the increasing need for precision, positions it for continued expansion in the coming years. Companies like Emerson Electric and Siemens AG are at the forefront of this evolution, constantly innovating to meet the diverse needs of global industries. With trends like IIoT, sustainability, and smart manufacturing leading the way, flow meters are set to remain a cornerstone of industrial progress well into the future.

#flow meters#IIoT#smart manufacturing#sustainability#energy efficiency#industrial automation#Industry 4.0

0 notes

Text

How to Choose the Right Flow Meter for Your Industry

Selecting the right flow meter is essential for ensuring accurate measurement, process efficiency, and cost optimization across various industries. With different types of flow meters available, understanding their working principles and choosing the best one for your application can be challenging.

Whether you are in water treatment, oil & gas, pharmaceuticals, food processing, or chemical manufacturing, this guide will help you make an informed decision. Plus, we’ll highlight some of the top flow meter manufacturers in India to help you find the best supplier.

What is a Flow Meter?

Factors to Consider When Choosing a Flow Meter

1. Type of Fluid Being Measured

Before selecting a flow meter, consider whether you are measuring liquid, gas, or steam. The characteristics of the fluid, such as viscosity, conductivity, and cleanliness, will impact the type of flow meter needed.

Water & Wastewater — Electromagnetic or ultrasonic flow meters

Oil & Gas — Coriolis or thermal mass flow meters

Steam & Air — Vortex flow meters

2. Accuracy Requirements

Industries such as pharmaceuticals and chemical processing require high-precision flow meters, while applications like water distribution may allow for slight variations.

High Accuracy Needs — Coriolis or ultrasonic flow meters

General Industrial Use — Electromagnetic or turbine flow meters

3. Installation Environment

Consider the pipeline size, temperature, and pressure conditions where the flow meter will be installed. Some flow meters require direct contact with the fluid, while others work non-invasively.

High Temperature & Pressure — Vortex or differential pressure flow meters

Non-Contact Measurement — Ultrasonic flow meters

4. Maintenance and Durability

Some flow meters have moving parts that require regular maintenance, while others are designed for low-maintenance operation. If your application requires a long-lasting, durable solution, opt for a non-mechanical flow meter.

Low Maintenance — Ultrasonic or electromagnetic flow meters

Regular Calibration Required — Turbine or positive displacement flow meters

5. Cost and Budget Considerations

The cost of a flow meter varies depending on technology, accuracy, and durability. Investing in the right flow meter can save costs in the long run by reducing errors, minimizing waste, and improving operational efficiency.

Cost-Effective Solutions — Electromagnetic or turbine flow meters

Premium Accuracy & Performance — Coriolis or ultrasonic flow meters

Top Flow Meter Manufacturers in India

Choosing a reliable flow meter manufacturer in India is just as important as selecting the right type of flow meter. Atlantech is one of the leading manufacturers, offering high-quality electromagnetic, ultrasonic, Coriolis, and thermal mass flow meters designed for industrial applications.

Why Choose Atlantech?

Wide Range of Flow Meters — Suitable for various industries

High Accuracy & Durability — Ensures long-term performance

Advanced Technology — Designed for precise measurement

Strong After-Sales Support — Maintenance, calibration, and technical assistance

If you are looking for trusted flow meter manufacturers in India, Atlantech provides cutting-edge solutions to meet your industry’s specific needs.

Conclusion

Choosing the right flow meter depends on several factors, including fluid type, accuracy, installation environment, and maintenance needs. Investing in a high-quality flow meter ensures better efficiency, cost savings, and regulatory compliance for your industry.

For the most reliable and advanced flow meters, trust Atlantech, one of the leading flow meter manufacturers in India. Contact Atlantech today to find the best flow measurement solutions tailored to your business!

#flow meters#digital flow meters#Digital Water Flow Meter India#Magnetic flow meter#Electromagnetic Flow Meters#digital water flow meter#Electromagnetic water meter#Digital Water Flow Meter manufacturer in India#Flow meter manufacturer#Electromagnetic Flow meter manufacturers in India#flow meter suppliers in india#flow meter manufacturers in india#electromagnetic flow meter suppliers in india#digital water meter#water flow meter

0 notes

Text

The Complete Guide to Industrial Flow Measurement Technology

In today's precision-driven industrial landscape, accurate flow measurement isn't just a technical requirement—it's the backbone of efficient operations, quality control, and regulatory compliance. Whether you're managing water treatment facilities, chemical processing plants, or food and beverage production lines, understanding the intricacies of industrial flow measurement technology can significantly impact your bottom line.

Understanding the Fundamentals of Industrial Flow Measurement

At its core, industrial flow measurement involves quantifying the rate at which liquids or gases move through pipes, channels, or vessels. This seemingly simple concept becomes increasingly complex as we consider variables like fluid properties, environmental conditions, and specific application requirements.

The evolution of flow measurement technology has transformed from basic mechanical devices to sophisticated electronic systems capable of providing unprecedented accuracy. Modern solutions offer not just flow data, but intelligent analytics that drive process optimization and predictive maintenance.

Selecting the Right Flow Measurement Principle

Different industrial applications demand different measurement approaches. Let's explore the major technologies driving today's flow measurement landscape:

Velocity-Based Measurement

These technologies measure flow by detecting the speed at which fluid moves through a defined area:

Magnetic principles in flow measurement have revolutionized how we monitor conductive liquids. By generating a magnetic field across a pipe and measuring the voltage produced as the liquid flows through it, these devices offer exceptional accuracy with minimal pressure drop. This technology excels in applications involving water, chemicals, and slurries.

Ultrasonic technology utilizes sound waves to determine flow rates either through transit-time or Doppler methods. Transit-time systems measure how long it takes ultrasonic signals to travel upstream versus downstream, while Doppler systems analyze frequency shifts as sound waves bounce off particles in the fluid. These non-invasive solutions work well for clean liquids and natural gas applications.

Positive Displacement Measurement

These mechanical systems physically capture and count discrete volumes of fluid:

Rotary meters use rotating components that trap and release measured quantities of fluid. Their high accuracy makes them ideal for custody transfer applications, though they typically require more maintenance than electronic alternatives.

Mass Flow Measurement

Instead of volumetric calculations, these technologies directly measure the mass flow rate:

Coriolis technology represents the pinnacle of mass flow measurement precision. By vibrating tubes and measuring how fluid flow affects these vibrations through the Coriolis effect, these instruments deliver exceptional accuracy regardless of fluid properties. While initially expensive, their low maintenance requirements and multi-parameter measurement capabilities often justify the investment.

Differential Pressure Measurement

This classic approach relies on measuring pressure differences across a restriction:

Orifice plates and venturi tubes create predictable pressure drops that correlate with flow rates. Though simple in principle, these systems require careful engineering to account for various flow conditions.

Variable Area Measurement

Rotameter technology uses a tapered tube with a float that rises in proportion to flow rate. These visual indicators offer simplicity and reliability for less demanding applications.

Critical Factors Affecting Flow Measurement Accuracy

Several variables can impact measurement performance:

Installation considerations: Proper straight pipe runs before and after meters prevent turbulence that can compromise accuracy.

Fluid properties: Viscosity, density, temperature, and conductivity all influence measurement performance.

Environmental factors: Vibration, electromagnetic interference, and ambient temperature fluctuations can affect sensitive instruments.

Calibration requirements: Regular verification against known standards ensures continued accuracy throughout a meter's operational life.

Advanced Features in Modern Flow Measurement Systems

Today's flow measurement technology extends far beyond basic rate detection:

Digital communication protocols like HART, Profibus, and Foundation Fieldbus enable seamless integration with control systems.

Self-diagnostic capabilities alert operators to potential issues before they affect production.

Multi-parameter measurement combines flow data with temperature, pressure, and density readings for comprehensive process insight.

Battery-powered options enable remote installation where power infrastructure is limited.

Selecting the Optimal Flow Measurement Solution

When evaluating flow measurement technologies for your application, consider these factors:

Process fluid characteristics: Conductivity, viscosity, and cleanliness will eliminate certain technologies from consideration.

Required accuracy: Higher precision typically demands more sophisticated technology and proper installation.

Installation constraints: Available straight pipe runs, power availability, and environmental conditions matter.

Budget considerations: While initial purchase price matters, total cost of ownership—including maintenance, calibration, and operational impact—should guide decision-making.

Regulatory requirements: Certain industries face strict metrological standards that influence technology selection.

Industry-Specific Applications

Different sectors leverage flow measurement technology in unique ways:

Water/wastewater: Magnetic flow meters excel in treatment processes and distribution networks.

Oil and gas: Coriolis meters provide the high accuracy needed for custody transfer and process control.

Chemical processing: Corrosion-resistant flow meters with appropriate safety certifications ensure reliable measurement of aggressive media.

Food and beverage: Hygienic design flow meters meet stringent sanitation requirements while providing the accuracy needed for recipe control.

Future Trends in Flow Measurement

As we look ahead, several developments promise to reshape industrial flow measurement:

IoT integration enables real-time monitoring and analytics across distributed facilities.

Artificial intelligence applications will enhance predictive maintenance and flow pattern recognition.

Miniaturization continues to reduce the physical footprint of sophisticated measurement technologies.

Enhanced battery life expands the feasibility of wireless flow measurement in remote locations.

Conclusion

Choosing the right industrial flow measurement technology involves balancing technical requirements, operational constraints, and economic considerations. By understanding the principles, limitations, and advantages of different measurement approaches, you can make informed decisions that optimize process efficiency, product quality, and regulatory compliance.

The ideal flow measurement solution isn't necessarily the most expensive or technically advanced—it's the one that delivers reliable, accurate data for your specific application while minimizing total cost of ownership. As technology continues to evolve, staying informed about emerging capabilities will ensure your measurement infrastructure remains both effective and competitive.

For more information about specific flow measurement solutions for your application, consult with experienced measurement professionals who can evaluate your unique requirements and recommend appropriate technologies.

0 notes

Text

Precision Flow Meters Suppliers Deliver Every Time

In industries where accuracy is non negotiable, precision flow meters are the unsung heroes. From oil and gas to pharmaceuticals, these devices ensure that every drop, every liter, and every cubic meter is measured with absolute precision.

But the real game changer? The flow meter suppliers who deliver these high performance tools. Let’s explore why partnering with the right supplier ensures precision, reliability, and efficiency every single time.

Why Precision Matters in Flow Measurement

In industries like chemical processing, water treatment, and food production, even the slightest measurement error can lead to significant consequences. Inaccurate flow readings can result in product waste, regulatory non compliance, and operational inefficiencies. This is where precision flow meters come into play. Designed to deliver exact measurements, these devices are critical for maintaining process integrity and achieving optimal performance.

However, the precision of a flow meter is only as good as the supplier behind it. A trusted flow meter supplier doesn’t just provide a product they deliver a solution tailored to your specific needs, ensuring seamless integration into your operations.

Need precision you can rely on? Contact Us today to explore our range of high accuracy flow meters.

What Sets Precision Flow Meter Suppliers Apart

Not all suppliers are created equal. The best flow meter suppliers stand out by offering cutting edge technology, unmatched expertise, and unwavering reliability. Here’s how they deliver value every time:

Advanced Technology for Unmatched Accuracy Leading suppliers provide precision flow meters equipped with the latest advancements, such as ultrasonic, electromagnetic, and Coriolis technologies. These devices are designed to handle even the most challenging applications, from high-pressure systems to corrosive fluids, ensuring accurate measurements in any environment.

Custom Solutions for Unique Challenges Every industry has its own set of challenges. Whether it’s handling viscous liquids, operating in extreme temperatures, or meeting stringent regulatory standards, a reliable flow meter supplier will work with you to design a customized solution that fits your needs perfectly.

End to End Support for Seamless Operations The relationship with a top-tier supplier doesn’t end at the point of sale. They offer comprehensive support, including installation, calibration, and maintenance services, to ensure your flow meters perform at their best throughout their lifecycle. This reduces downtime and maximizes efficiency.

Commitment to Quality and Reliability Precision flow meters from trusted suppliers are built to last. Made from high-quality materials and rigorously tested, these devices deliver consistent performance, even in the most demanding industrial environments. Read More

The Impact of Precision on Industrial Efficiency

The benefits of partnering with a reliable flow meter supplier extend far beyond accurate measurements. Precision flow meters enable industries to:

Optimize resource usage by minimizing waste and reducing costs.

Enhance product quality by ensuring consistent and accurate processes.

Meet regulatory requirements with confidence, avoiding costly penalties.

Improve operational efficiency by reducing downtime and maintenance needs.

In short, precision flow meters are a cornerstone of industrial success, and the right supplier ensures you get the most out of your investment.

Choosing the Right Supplier

When selecting a flow meter supplier, look for a partner with a proven track record, a wide range of high quality products, and a commitment to customer satisfaction. The right supplier will not only provide precision flow meters but also act as a trusted advisor, helping you achieve your operational goals.

Upgrade to precision flow meters that deliver every time! Request a Quote now and experience the difference.

Final Thoughts

In a world where precision is power, flow meter suppliers play a critical role in delivering accuracy, reliability, and efficiency. By choosing a trusted partner, you can ensure that your operations run smoothly, your costs stay low, and your performance remains top notch every single time.

0 notes

Text

Flow Meters & Meter Calibration: Ensuring Accurate Measurements

Chemical and Petrochemical: Monitoring process flow rates for quality control and efficiency.

Water and Wastewater: Measuring water consumption and treatment processes.

Oil and Gas: Measuring crude oil, natural gas, and refined products.

Food and Beverage: Monitoring production processes and quality control.

Pharmaceutical: Ensuring accurate dosing and process control.

Types of Flow Meters We Offer:

Magnetic Flow Meters: Ideal for conductive liquids, offering high accuracy and low maintenance.

Ultrasonic Flow Meters: Suitable for a wide range of liquids and gases, providing non-invasive measurement.

Vortex Flow Meters: Accurate for gases and liquids, with a wide measurement range.

Turbine Flow Meters: Precise for liquids and gases, offering high repeatability and long service life.

Coriolis Mass Flow Meters: Ideal for accurate mass flow measurement of liquids and gases, regardless of fluid properties.

Calibration Services:

On-Site Calibration: Our experienced technicians can calibrate your flow meters directly at your facility, minimizing downtime and ensuring accuracy.

Laboratory Calibration: For high-precision measurements, we offer laboratory calibration services using state-of-the-art equipment.

Traceable Standards: Our calibration services are traceable to national standards, ensuring the reliability of your measurements.

Why Choose Smart Jet Engineering?

Quality Products: We offer a wide range of high-quality flow meters from trusted manufacturers.

Expert Calibration: Our experienced technicians provide accurate and reliable calibration services.

Customized Solutions: We can tailor our solutions to meet your specific needs and applications.

Excellent Customer Service: We are committed to providing exceptional customer service and support.

Contact Smart Jet Engineering today to discuss your flow measurement requirements and learn how we can help you achieve accurate and reliable results.

0 notes

Text

How To Choose The Right Flow Meter For Your Industry?

Selecting the right flow meter for your industry can be a game-changer, ensuring accurate measurements, efficient processes, and cost savings. With so many options available, how do you find the perfect fit? Let’s dive into the world of the best flow meters and explore the factors you need to consider to make the best choice.

Understanding Flow Meters

Flow meters are essential devices to measure the flow rate of liquids or gases in a pipeline. They come in various types, each with unique features suited to specific applications. The right flow meter can enhance operational efficiency, reduce wastage, and ensure compliance with industry standards.

Key Factors to Consider

Type of Fluid

The first step in selecting a flow meter is understanding the type of fluid you’ll be measuring. Different fluids have varying properties, such as viscosity, density, and conductivity, which can influence the performance of a flow meter. Here are some common fluid types and the best flow meters for each:

Liquids: Positive displacement, turbine, and electromagnetic flow meters are great choices.

Gases: Thermal mass, differential pressure, and vortex flow meters work well.

Slurries and Viscous Fluids: Coriolis and ultrasonic flow meters are ideal.

Flow Rate and Range

Consider the flow rate and range you need to measure. Some flow meters are better suited for low flow rates, while others can handle high volumes. Ensure the flow meter you choose can accurately measure within your required range without compromising accuracy.

Accuracy and Precision

Accuracy is critical in many industries, such as pharmaceuticals and chemical processing, where minor discrepancies can have significant consequences. Check the accuracy specifications of the flow meter and ensure it meets your industry standards.

Installation Environment

The environment where the flow meter will be installed plays a crucial role in its selection. Factors like temperature, pressure, and the presence of hazardous materials can affect the flow meter's performance. For example, electromagnetic flow meters are excellent for clean water applications but may not be suitable for highly corrosive environments.

Popular Types of Flow Meters

Electromagnetic Flow Meters

Electromagnetic flow meters are widely used in the water and wastewater industry. They work on Faraday’s Law of Electromagnetic Induction and are ideal for measuring the flow of conductive liquids. They are known for their accuracy, reliability, and minimal maintenance.

Coriolis Flow Meters

Coriolis flow meters are highly accurate and versatile. They are suitable for various fluids, including gases and slurries. They measure mass flow rate by detecting changes in fluid momentum. These flow meters are perfect for high-precision applications like chemical processing and oil and gas.

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to measure the flow rate of liquids. They are non-invasive and can be installed outside the pipe, making them ideal for applications where it’s challenging to interrupt the flow. These flow meters are commonly used in water treatment, HVAC systems, and energy management.

Turbine Flow Meters

Turbine flow meters measure the velocity of liquids and gases. They are known for their accuracy and reliability in clean, low-viscosity fluids. These flow meters are widely used in aerospace, pharmaceuticals, and food and beverage industries.

Making the Right Choice

Choosing the right flow meter involves understanding your application needs and matching them with the appropriate flow meter type. Here’s a quick checklist to help you make an informed decision:

Identify the type of fluid you need to measure.

Determine the required flow rate and range.

Consider the accuracy and precision needed for your application.

Assess the installation environment and any potential challenges.

By considering these factors, you can select the best flow meters for your industry, ensuring efficient and accurate flow measurement.

Conclusion

Investing in the right flow meter is crucial for optimising your processes and maintaining high standards in your industry. With a clear understanding of your needs and the various types of flow meters available, you can make an informed choice that will benefit your operations for years to come.

Remember, the key to selecting the perfect flow meter lies in understanding your application and the unique demands of your industry.

0 notes