#coriolis mass flow meters

Explore tagged Tumblr posts

Text

A Closer Look at Flow Meters: Enhancing Accuracy and Efficiency in Fluid Measurement

Introduction:

In industries where fluid flow plays a critical role, accurate measurement is essential for process optimization, quality control, and cost management. Flow meters are the unsung heroes in these operations, providing vital data and insights into fluid dynamics. In this blog post, we will delve into the world of flow meters, exploring their significance, working principles, types, and the benefits they offer in various applications. So, let's dive in and unravel the mysteries of flow meters!

1. The Importance of Flow Meters:

Fluid flow is a fundamental aspect of many industries, including oil and gas, chemical processing, water management, and manufacturing. In this section, we will discuss why flow meters are crucial for these sectors and how they contribute to enhanced productivity, safety, and resource utilization.

2. Understanding Flow Meter Principles:

To comprehend the intricacies of flow meters, we must grasp their underlying principles. In this section, we will explore the four main types of flow meters: differential pressure, positive displacement, velocity, and mass flow meters. We'll explain the working mechanisms of each type and highlight their strengths and limitations.

3. Differential Pressure Flow Meters:

One of the most common types of flow meters is the differential pressure flow meter. In this section, we will take a closer look at orifice plates, venturi tubes, and flow nozzles - three widely used differential pressure flow meter variants. We'll explain their construction, working principles, and discuss their applications and considerations for accurate measurements.

4. Positive Displacement Flow Meters:

Positive displacement flow meters are known for their precise measurements of low flow rates. In this section, we will examine the working principles of gear meters, nutating disc meters, and oval gear meters. We'll explore their advantages, limitations, and typical applications in industries such as food and beverage, pharmaceuticals, and fuel distribution.

5. Velocity Flow Meters:

Velocity flow meters, such as turbine and electromagnetic meters, rely on the fluid's velocity to measure flow rates. In this section, we will delve into their working principles, installation considerations, and applications. We'll also discuss the challenges associated with fluid properties, calibration, and maintenance.

6. Mass Flow Meters:

For applications where mass measurement is crucial, mass flow meters provide accurate results by directly measuring the mass of the flowing fluid. We will explore thermal mass flow meters, Coriolis flow meters, and their working principles, advantages, and limitations. This section will highlight their significance in industries like pharmaceuticals, chemical processing, and HVAC systems.

7. Selecting the Right Flow Meter:

Choosing the appropriate flow meter for your specific application is vital for accurate and reliable measurements. In this section, we will discuss the key factors to consider, such as fluid characteristics, flow range, accuracy requirements, installation constraints, maintenance needs, and cost considerations. By understanding these factors, you can make an informed decision when selecting a flow meter.

8. The Future of Flow Meter Technology:

As technology advances, so does the field of flow meters. In this section, we will explore emerging trends and innovations, including digitalization, Internet of Things (IoT) integration, and advancements in sensor technology. We'll discuss how these developments are shaping the future of flow meter technology and the potential benefits they offer.

9. Conclusion:

Flow meters are indispensable tools for accurate fluid measurement in various industries. By understanding their principles, types, and considerations for selection, you can optimize processes, reduce costs, and ensure safe operations. We hope this blog post has shed light on the world of flow meters and provided you with valuable insights into their significance and applications. Remember, precision in flow measurement leads to efficiency and success!

#flow meters#water meter test bench#gas meter calibration#flow meter#coriolis mass flow meters#flow meter calibration#liquid flow calibration system

0 notes

Text

Optimizing Filtration Efficiency with Desander Hydrocyclone Filter in the Oil and Gas Industry

Introduction:

The oil and gas industry is constantly evolving, with the demand for efficient and cost-effective filtration solutions becoming increasingly critical. One such solution that has gained prominence in recent years is the desander hydrocyclone filter. This compact and highly efficient filter has proven to be an effective tool in separating solids from liquids in various oil and gas processes. In this blog, we will delve deeper into the desander hydrocyclone filter and its applications in the oil and gas industry, highlighting its benefits and optimization techniques for enhanced filtration efficiency.

What is a Desander Hydrocyclone Filter?

A desander hydrocyclone filter is a type of centrifugal separator that uses the principle of cyclonic separation to remove solid particles from liquids. It typically consists of a conical-shaped chamber with an inlet at the top for the incoming fluid mixture and an outlet at the bottom for the separated solids. As the fluid mixture enters the desander hydrocyclone filter, it is subjected to centrifugal forces, causing the heavier solid particles to move towards the outer wall of the chamber and eventually be discharged through the bottom outlet, while the cleaner fluid is discharged through the top outlet. https://kapwell.co.uk/products/hydrocyclones/desander-hydrocyclone/

Applications in the Oil and Gas Industry:

Desander hydrocyclone filters find extensive applications in the oil and gas industry, where the removal of solid particles from drilling mud, produced water, and other process fluids is crucial for efficient operations. Some of the key applications of desander hydrocyclone filters in the oil and gas industry include:

Drilling Operations: During drilling operations, desander hydrocyclone filters are used to remove drill cuttings, sand, and other solid particles from the drilling mud, ensuring that the mud can be recirculated for optimal drilling performance and reducing wear and tear on drilling equipment.

Produced Water Treatment: In the production of oil and gas, large volumes of water are generated as a byproduct, which needs to be treated before disposal or reuse. Desander hydrocyclone filters are employed in produced water treatment systems to remove solids, such as sand, clay, and other contaminants, ensuring compliance with environmental regulations and protecting downstream equipment.

Refinery Operations: Kapwell Desander hydrocyclone filters are used in refineries to remove catalyst fines, sand, and other solid particles from process fluids, preventing fouling of downstream equipment, such as heat exchangers, pumps, and valves, and optimizing process efficiency.

Benefits of Desander Hydrocyclone Filters:

The use of Kapwell desander hydrocyclone filters in the oil and gas industry offers several benefits, including:

Enhanced Filtration Efficiency: Kapwell Desander hydrocyclone filters are highly efficient in removing solid particles from liquids due to the centrifugal forces generated, resulting in a cleaner fluid stream for downstream processes.

Compact Design: Kapwell Desander hydrocyclone filters are compact in size, making them suitable for installations in space-constrained areas, such as offshore platforms and mobile drilling rigs.

Cost-effective: Kapwell Desander hydrocyclone filters are generally more cost-effective compared to other types of solid-liquid separation equipment, as they do not require filter media replacements, and have low maintenance requirements.

Optimizing Filtration Efficiency: To optimize the filtration efficiency of Kapwell desander hydrocyclone filters in the oil and gas industry, the following techniques can be employed:

Proper Sizing: Selecting the appropriate size of the desander hydrocyclone filter based on the specific application is crucial to achieve optimal filtration efficiency. Factors such as the flow rate, particle size distribution, and desired separation efficiency should be considered during sizing.

Regular Maintenance: Regular inspection and maintenance of desander hydrocyclone filters are essential to ensure optimal performance. This includes cleaning.

Head Office

Provender House, 37 Waterloo Quay, Aberdeen, Scotland, United Kingdom AB11 5BS

[email protected] Phone: +44 01224 007288

0 notes

Text

Types Of Flow Measurement Devices

In the dynamic realm of industrial processes, the accurate measurement of fluid flow is crucial for efficiency and performance. In this article, we delve into the different types of flow measurement devices that play a pivotal role in optimizing processes across various sectors.

Electromagnetic Flow Meters: In applications where the fluid is conductive, electromagnetic flow meters shine. These devices utilize Faraday's law of electromagnetic induction to measure the velocity of the fluid. The resulting data, combined with the pipe's cross-sectional area, provides a precise measurement of the flow rate, making them ideal for industries dealing with water or other conductive liquids.

Ultrasonic Flow Meters: Employing ultrasonic waves to determine the velocity of fluid, these non-intrusive devices are gaining popularity. Transit-time and Doppler are two common types within this category. Transit-time ultrasonic meters measure the time it takes for ultrasonic signals to travel with and against the flow, while Doppler meters use the frequency shift of reflected waves to calculate flow velocity.

Coriolis Flow Meters: Renowned for their accuracy, Coriolis flow meters operate on the principle of the Coriolis effect. As fluid flows through a vibrating tube, the Coriolis effect induces a phase shift, which is proportional to the mass flow rate. This technology is particularly effective for measuring both liquids and gases with high precision.

Vortex Shedding Flow Meters: Capitalizing on the phenomenon of vortices forming downstream of a bluff body placed in the fluid stream, vortex Shedding flow meters are apt for measuring the flow of gases and liquids. The frequency of vortices shed is directly proportional to the flow rate, enabling accurate measurements.

In conclusion, the world of flow measurement devices is as diverse as the industries they serve. Each type has its strengths and applications, catering to specific needs and scenarios. As industries continue to evolve, the synergy of these devices with cutting-edge technologies ensures that accurate flow measurement remains a cornerstone for optimizing processes and enhancing overall efficiency.

2 notes

·

View notes

Text

Understanding Gas Flow Meters: A Key to Accurate Measurement

In Industrial settings like oil & gas, pharmaceuticals, food processing industries and different manufacturing plants, efficient and accurate gas flow measurement is essential to maintain safety, optimize processes and reduce waste. Gas flow meters are thus essential and indispensable devices for measuring the volume or mass of gas moving through a system.

There are a variety of gas flow meters, including thermal, ultrasonic, electromagnetic, Coriolis flow meters, and many other types, each designed for specific applications. These advanced meters provide direct measurements of mass flow rate, volumetric flow rate, temperature, and density, making them invaluable in brewing, dairy, and petrochemicals.

For example, Using Faraday's law of electromagnetic induction, electromagnetic flow meters are ideal for applications in water treatment, chemical industries, food and beverage processing, and where conductive fluids are common.

Investing in a high-quality gas flow meter ensures long-term efficiency and safety. Choose a reliable manufacturer to get the best solution tailored to your operational needs.

0 notes

Text

Unlocking the Potential of Industrial Precision with Flow Meters

Flow meters have become indispensable tools in various industries, measuring the movement of liquids and gases with high accuracy. As industrial processes become more complex and demand greater efficiency, the flow meter market is seeing remarkable growth, driven by technological advancements and the need for optimized fluid management.

Overview of Market Growth

In 2024, the global flow meter market is on track to hit approximately USD 9.1 billion, with projections indicating it could grow to USD 12.6 billion by 2029, expanding at a 6.7% compound annual growth rate (CAGR). This growth is largely fueled by industries such as oil & gas, water treatment, chemical processing, and power generation, all of which require precise fluid monitoring for safety, efficiency, and compliance.

Importance Across Industries

Flow meters play a critical role across industries by ensuring accurate measurement of liquid and gas flow. In sectors like oil & gas, the reliability of these meters impacts production quality and safety, preventing costly mishaps such as leaks or inefficient energy use. In the water and wastewater management sectors, flow meters contribute to resource conservation, ensuring systems are running smoothly while complying with environmental regulations.

In industries that are highly regulated, such as pharmaceuticals and food & beverage, the precision provided by flow meters is paramount for maintaining quality control. Flow meters are also key in the renewable energy sector, where they help in monitoring biofuel production and improving energy efficiency.

Technological Advancements and IIoT Integration

The rapid adoption of advanced technologies is reshaping the flow meter market. The advent of digital flow meters, integrated with Industrial Internet of Things (IIoT) technology, has revolutionized how industries monitor and optimize their systems. These devices offer real-time data, predictive analytics, and enhanced diagnostic features. By harnessing IIoT, flow meters provide continuous insights, allowing operators to proactively address potential issues, reduce downtime, and increase operational efficiency.

Furthermore, the growing sophistication of flow meter technologies is reflected in the diversification of product types. Flow meters like Coriolis, ultrasonic, magnetic, and vortex meters are all tailored for specific industrial requirements. Coriolis meters, for example, are known for their accuracy in mass flow measurement, making them ideal for industries such as oil & gas. Meanwhile, ultrasonic and electromagnetic flow meters are extensively used in sectors that deal with conductive fluids, such as wastewater treatment.

Leading Players and Competitive Strategies

Top companies like Emerson Electric Co. and Siemens AG are pushing the boundaries of innovation in the flow meter space. Their products are designed to meet the evolving demands of multiple industries. Siemens AG, for instance, has developed ultrasonic and electromagnetic flow meters that are highly efficient in various industrial applications, while Emerson Electric is recognized for its state-of-the-art Coriolis and magnetic flow meters, which are widely used in hazardous environments.

These key players are not only focused on product innovation but are also strategically expanding their market presence through acquisitions and collaborations. Such strategies enable them to diversify their product offerings and expand into new markets, particularly in regions with growing industrial infrastructure, such as Asia-Pacific and the Middle East.

Future Trends in the Flow Meter Market

Looking ahead, the flow meter market is expected to continue evolving in response to both technological and regulatory pressures. Sustainability is becoming a crucial focus across industries, with governments worldwide implementing stricter regulations around energy efficiency and environmental conservation. Flow meters will play a vital role in helping industries meet these regulatory requirements by providing accurate measurements of water, air, and energy usage, thereby minimizing waste and emissions.

The push towards smart manufacturing and the implementation of Industry 4.0 will further accelerate the demand for advanced flow meters. As more industries transition to fully automated and interconnected production systems, the ability to remotely monitor and control processes via IIoT-enabled devices will be essential. This integration will lead to smarter, more sustainable operations, with flow meters at the heart of process optimization.

Download PDF Brochure :

Flow meters are becoming increasingly important in driving operational efficiency and ensuring industrial safety across multiple sectors. The market’s growth trajectory, supported by ongoing technological advancements and the increasing need for precision, positions it for continued expansion in the coming years. Companies like Emerson Electric and Siemens AG are at the forefront of this evolution, constantly innovating to meet the diverse needs of global industries. With trends like IIoT, sustainability, and smart manufacturing leading the way, flow meters are set to remain a cornerstone of industrial progress well into the future.

#flow meters#IIoT#smart manufacturing#sustainability#energy efficiency#industrial automation#Industry 4.0

0 notes

Text

Flow Meters & Meter Calibration: Ensuring Accurate Measurements

Chemical and Petrochemical: Monitoring process flow rates for quality control and efficiency.

Water and Wastewater: Measuring water consumption and treatment processes.

Oil and Gas: Measuring crude oil, natural gas, and refined products.

Food and Beverage: Monitoring production processes and quality control.

Pharmaceutical: Ensuring accurate dosing and process control.

Types of Flow Meters We Offer:

Magnetic Flow Meters: Ideal for conductive liquids, offering high accuracy and low maintenance.

Ultrasonic Flow Meters: Suitable for a wide range of liquids and gases, providing non-invasive measurement.

Vortex Flow Meters: Accurate for gases and liquids, with a wide measurement range.

Turbine Flow Meters: Precise for liquids and gases, offering high repeatability and long service life.

Coriolis Mass Flow Meters: Ideal for accurate mass flow measurement of liquids and gases, regardless of fluid properties.

Calibration Services:

On-Site Calibration: Our experienced technicians can calibrate your flow meters directly at your facility, minimizing downtime and ensuring accuracy.

Laboratory Calibration: For high-precision measurements, we offer laboratory calibration services using state-of-the-art equipment.

Traceable Standards: Our calibration services are traceable to national standards, ensuring the reliability of your measurements.

Why Choose Smart Jet Engineering?

Quality Products: We offer a wide range of high-quality flow meters from trusted manufacturers.

Expert Calibration: Our experienced technicians provide accurate and reliable calibration services.

Customized Solutions: We can tailor our solutions to meet your specific needs and applications.

Excellent Customer Service: We are committed to providing exceptional customer service and support.

Contact Smart Jet Engineering today to discuss your flow measurement requirements and learn how we can help you achieve accurate and reliable results.

0 notes

Text

Coriolis Flow Meter Principles - How Coriolis Flow Meters Work

Introduction to Coriolis Flow Meters and Coriolis Flow Meter Principles. Brief Description of What a Coriolis Flow Meter Is: A Coriolis flow meter is a sophisticated instrument that measures the mass flow rate of a fluid directly by utilizing the Coriolis effect. Unlike traditional flow meters that often measure volumetric flow and then calculate mass flow indirectly, Coriolis flow meters…

0 notes

Text

How To Choose The Right Flow Meter For Your Industry?

Selecting the right flow meter for your industry can be a game-changer, ensuring accurate measurements, efficient processes, and cost savings. With so many options available, how do you find the perfect fit? Let’s dive into the world of the best flow meters and explore the factors you need to consider to make the best choice.

Understanding Flow Meters

Flow meters are essential devices to measure the flow rate of liquids or gases in a pipeline. They come in various types, each with unique features suited to specific applications. The right flow meter can enhance operational efficiency, reduce wastage, and ensure compliance with industry standards.

Key Factors to Consider

Type of Fluid

The first step in selecting a flow meter is understanding the type of fluid you’ll be measuring. Different fluids have varying properties, such as viscosity, density, and conductivity, which can influence the performance of a flow meter. Here are some common fluid types and the best flow meters for each:

Liquids: Positive displacement, turbine, and electromagnetic flow meters are great choices.

Gases: Thermal mass, differential pressure, and vortex flow meters work well.

Slurries and Viscous Fluids: Coriolis and ultrasonic flow meters are ideal.

Flow Rate and Range

Consider the flow rate and range you need to measure. Some flow meters are better suited for low flow rates, while others can handle high volumes. Ensure the flow meter you choose can accurately measure within your required range without compromising accuracy.

Accuracy and Precision

Accuracy is critical in many industries, such as pharmaceuticals and chemical processing, where minor discrepancies can have significant consequences. Check the accuracy specifications of the flow meter and ensure it meets your industry standards.

Installation Environment

The environment where the flow meter will be installed plays a crucial role in its selection. Factors like temperature, pressure, and the presence of hazardous materials can affect the flow meter's performance. For example, electromagnetic flow meters are excellent for clean water applications but may not be suitable for highly corrosive environments.

Popular Types of Flow Meters

Electromagnetic Flow Meters

Electromagnetic flow meters are widely used in the water and wastewater industry. They work on Faraday’s Law of Electromagnetic Induction and are ideal for measuring the flow of conductive liquids. They are known for their accuracy, reliability, and minimal maintenance.

Coriolis Flow Meters

Coriolis flow meters are highly accurate and versatile. They are suitable for various fluids, including gases and slurries. They measure mass flow rate by detecting changes in fluid momentum. These flow meters are perfect for high-precision applications like chemical processing and oil and gas.

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to measure the flow rate of liquids. They are non-invasive and can be installed outside the pipe, making them ideal for applications where it’s challenging to interrupt the flow. These flow meters are commonly used in water treatment, HVAC systems, and energy management.

Turbine Flow Meters

Turbine flow meters measure the velocity of liquids and gases. They are known for their accuracy and reliability in clean, low-viscosity fluids. These flow meters are widely used in aerospace, pharmaceuticals, and food and beverage industries.

Making the Right Choice

Choosing the right flow meter involves understanding your application needs and matching them with the appropriate flow meter type. Here’s a quick checklist to help you make an informed decision:

Identify the type of fluid you need to measure.

Determine the required flow rate and range.

Consider the accuracy and precision needed for your application.

Assess the installation environment and any potential challenges.

By considering these factors, you can select the best flow meters for your industry, ensuring efficient and accurate flow measurement.

Conclusion

Investing in the right flow meter is crucial for optimising your processes and maintaining high standards in your industry. With a clear understanding of your needs and the various types of flow meters available, you can make an informed choice that will benefit your operations for years to come.

Remember, the key to selecting the perfect flow meter lies in understanding your application and the unique demands of your industry.

0 notes

Text

Diesel Flow Meter Suppliers: Measure Efficiency with Confidence

In today's fast-paced industrial world, efficiency is key. Whether you're managing a large-scale fuel distribution network or a smaller operation, having precise and reliable measurements is crucial. This is where diesel flow meter suppliers come into play. Let's dive into how these essential tools can boost your operation's efficiency and why partnering with the right suppliers is vital.

Understanding Diesel Flow Meters

What is a Diesel Flow Meter?

A diesel flow meter is an instrument designed to measure the flow rate of diesel fuel through a pipeline. It ensures that the fuel being distributed is accurately measured, preventing discrepancies that can lead to significant financial losses or operational inefficiencies.

Types of Diesel Flow Meters

Positive Displacement Meters: These meters capture a specific volume of diesel and measure the flow based on the number of times the volume is filled.

Turbine Meters: Utilizing a turbine wheel, these meters measure flow based on the speed of the fuel passing through the turbine.

Coriolis Meters: These provide highly accurate measurements by calculating the mass flow rate of the diesel fuel.

Ultrasonic Meters: Using sound waves, these meters measure the flow rate based on the time it takes for the waves to travel through the fuel.

The Importance of Reliable Diesel Flow Meter Suppliers

Ensuring Accuracy and Reliability

Reliable diesel flow meter suppliers offer high-quality products that ensure precise measurements. Accuracy is critical in maintaining operational efficiency, managing costs, and ensuring compliance with industry standards.

Advanced Technology

Top-tier suppliers provide meters equipped with the latest technology, enhancing the accuracy and functionality of the devices. This includes features like digital displays, remote monitoring capabilities, and automatic data logging.

Custom Solutions

Every operation has unique needs. Reputable diesel flow meter suppliers understand this and offer custom solutions tailored to specific requirements. Whether it's a particular type of meter or a specialized installation, these suppliers can provide what you need.

Benefits of Using Diesel Flow Meters

Cost Efficiency

Accurate measurement of diesel flow helps in reducing wastage and ensuring that every drop of fuel is accounted for, leading to significant cost savings over time.

Enhanced Operational Control

With precise data on fuel usage, operators can make informed decisions, optimize processes, and ensure smooth operation. This leads to better resource management and improved overall efficiency.

Compliance and Reporting

In many industries, there are stringent regulations regarding fuel usage and reporting. Diesel flow meters help in maintaining compliance by providing accurate and reliable data, simplifying the reporting process.

Choosing the Right Diesel Flow Meter Supplier

Reputation and Experience

When selecting a diesel flow meter supplier, consider their reputation and experience in the industry. Long-standing suppliers are often more reliable and knowledgeable about the latest trends and technologies.

Customer Support

Excellent customer support is essential. Ensure the supplier offers comprehensive support, including installation, maintenance, and troubleshooting services.

Product Range

A good supplier should have a wide range of products to choose from, catering to various needs and applications. This ensures you can find the perfect meter for your specific requirements.

Conclusion

Partnering with reliable diesel flow meter suppliers is crucial for any operation that relies on precise fuel measurement. By ensuring accuracy, adopting advanced technology, and offering custom solutions, these suppliers help businesses measure efficiency with confidence. Investing in quality diesel flow meters not only enhances operational control and cost efficiency but also ensures compliance with industry standards. Choose wisely, and watch your operational efficiency soar.

Contact Now

Location: 476 Boundary Road Derrimut Victoria 3026

Call: (03) 9311 7822

Mail: [email protected]

0 notes

Text

Portable Water Meter Calibration System

A portable water meter calibration system is a compact and mobile solution designed for on-site calibration of water meters. It allows for accurate testing and calibration of water meters without the need to remove them from their installation location. This system typically includes portable test equipment, such as a compact test bench, weighing scales, and other necessary instruments for calibration. It provides convenience and flexibility by enabling technicians to perform calibration directly at the meter's location, saving time and resources. The portable water meter calibration system is commonly used by water utilities, field service technicians, and maintenance teams who need to verify the accuracy of water meters in various locations. With its portability and ease of use, it ensures that water meters are properly calibrated to ensure precise measurement and billing accuracy.

#flow meter calibration#water meter test bench#flow meters#level transmitter#gas meter calibration#water meter calibration system#liquid flow calibration system#coriolis mass flow meters#flow meter#electrical

0 notes

Text

Why Is The Actual Mass Flow Rate Important In Gas Flow Measurement?

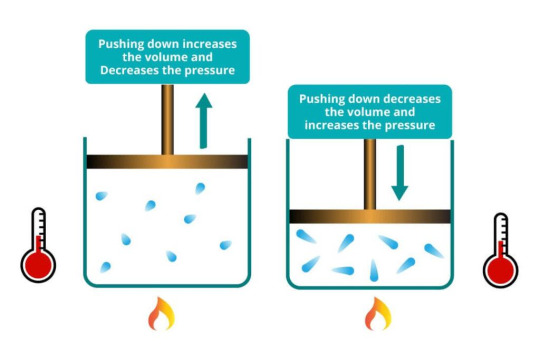

Measurement of gas mass flow under process circumstances is never easy. To do it, there aren't many flow methods available, such thermal mass calorimetry and coriolis flow.Gas mass stays constant but gas volume changes in response to changes in temperature and pressure, according to Charles & Boyle's law. This is the primary justification for why it's crucial to determine actual mass flow rate during procedures.

First, let's examine the distinction between Standard and Actual Flow Rates.

STANDARD FLOW RATES:

Standard flow rate is a flow rate of gas at specific pressure and temperature conditions. It is dependent on pressure and temperature conditions. It is termed as Standard volumetric (Sm3/hr or SCFM) or Standard Mass flow rate (Kg/hr at specific standard conditions).

There are different standards conditions used internationally such as :

ISO2533 (1.01325bara @ 15°C );

DIN 1343 ( 1.01325bar @ 0°C);

Standard (1.01325bar @ 20°C) etc. (above with 0% relative humidity conditions generally or sometime varying conditions )

ACTUAL FLOW RATES

Actual Flow rate is a flow rate of gas at different pressure and temperature conditions, It is independent of pressure and temperature conditions. It is termed as Actual Volumetric ( Am3/hr or ACFM ) or Actual Mass Flow Rate (Kg/hr at actual process conditions)

IMPORTANCE OF ACTUAL MASS FLOW RATE MEASUREMENT

As per Charles Law states that at constant pressure ideal gas volume increases with increase in temperature or gasses expands when heated.

And Bolye’s Law asserts that at a fixed temperature ideal gas volume is inversely proportional to pressure imposed on the gas. It suggests at constant temperature volume increases when pressure falls and gas volume decreases when pressure increases.

According to the aforementioned laws, measuring the volumetric gas flow rate results in a significant measurement inaccuracy because the volume of the gas changes as temperature and pressure do.

In order to accurately monitor and regulate the process conditions, we must ascertain the real mass flow rate of gas.

The Leomi 587 Insertion Thermal Mass Flow Meter for Actual Mass / Volume Flow Rate measurement was created with the process industry's actual need for precise and genuine measurement when improving process conditions in mind.

#thermal mass flow meter#compressed air#gas flow meter in india#compressed air flow meter#gas flow meter

0 notes

Text

Are You Looking For Flow Meter Manufacturer in India?

If you are Looking for Flow Meter. Creative Engineers are the leading Flow Meter manufacturer and supplier in Ahmedabad, India.

We suppy Flow Meter in Ahmedabad, Vadodara, Vapi, Gandhinagar, Surat, Rajkot, Halol, Nagpur, Mumbai, Bangalore, Hyderabad, Pune, Pimpri Chinchwad. South Africa, Dubai, Nepal, Sri Lanka.

What is Flow Meter?

A Flow Meter is a device used for measuring the flow rate passing from pump or pipes. It can measure the flow rate or quantity of a gas or liquid moving through a pipes. Flow meter can measure all types of fluids which flows linear, non-linear, mass, or volumetric flow rates and indicates in digital or analog form on meter.

Flow Meter is used in many industries, including water treatment, chemical processing plant, oil and gas industries, and food and beverage.

Application of Flow Meter

Flow meters are used in a wide range of industries and applications

Water and wastewater treatment

Oil and gas production and refining

Chemical processing

Food and beverage manufacturing

Pharmaceutical production

Environmental monitoring and compliance

Types of Flow Meter

Differential Pressure Flow Meters:

We are manufacturer and supplier of Differential Pressure Flow Meters.

Magnetic Flow Meters:

We are manufacturer and supplier of Magnetic Flow Meters.

Ultrasonic Flow Meters:

We are manufacturer and supplier of Ultrasonic Flow Meters.

Coriolis Flow Meters:

We are manufacturer and supplier of Coriolis Flow Meters.

For more Details Click here : https://www.sspumpsindia.com

0 notes

Text

Are You Looking For Flow Meter Manufacturer in India?

If you are Looking for Flow Meter for you industries. Creative Engineers are the leading Flow Meter manufacturer from Ahmedabad, India. Our Flow Meter are available in Ahmedabad, Vadodara, Vapi, Gandhinagar, Surat, Rajkot, Halol, Nagpur, Mumbai, Bangalore, Hyderabad, Pune, Pimpri Chinchwad. South Africa, Dubai, Nepal, Sri Lanka.

A Flow Meter is a device used for measuring the flow rate passing from pump or pipes. It can measure the flow rate or quantity of a gas or liquid moving through a pipes. Flow meter can mostly measure all types of flows linear, non-linear, mass, or volumetric flow rates and indicates in digital or analog form on meter.

Flow meters are used in many industries, including water treatment, chemical processing plant, oil and gas industries, and food and beverage. We manufacture 4 types of Flow Meter.

Differential Pressure Flow Meters:

We are manufacturer and supplier of Differential Pressure Flow Meters.

Magnetic Flow Meters:

We are manufacturer and supplier of Magnetic Flow Meters.

Ultrasonic Flow Meters:

We are manufacturer and supplier of Ultrasonic Flow Meters.

Coriolis Flow Meters:

We are manufacturer and supplier of Coriolis Flow Meters.

For ore Details Click here : https://www.sspumpsindia.com

0 notes

Text

A Guide to Natural Gas Flow Meters

As you reviewed the selection guide, you have likely narrowed your search to a few meters that might be suitable for your project. Now you should weigh the advantages and disadvantages of each so that you can make an educated decision.

Thermo mass flow meters rely on the principle that heat transfer is proportional to the mass flow of gas. They contain a heated element and one or more temperature sensors. In order to determine the flow rate, the temperature difference between the heated element and the gas is measured. For large natural gas pipelines, the flow meter price can be very low for insertion type natural gas flow meters and inline type natural gas flow meters. It has SCFM, kg/h, grams per second, grams per minute, mmscfd, Sm3/h, Nm3/h.

These meters utilize the Coriolis effect, which is the deflection of fluid due to the rotation of the Earth. The gas flows through a vibrating tube in a Coriolis flow meter. The gas motion causes the tube to twist, and the degree of twisting is proportional to the mass flow rate. The Coriolis flow meter is the best natural gas flow meter. It can measure natural gas mass flow directly, and it is the most accurate meter for measuring natural gas flow. Additionally, it can measure natural gas flow rates at high pressures.

A turbine rotor is placed in the gas stream to measure the flow rate. The rate of rotation is proportional to the flow rate as the gas flows through the meter. In order to calculate the flow rate, this rotational motion is converted into an electrical signal.

The Vortex Shedding Flow Meter is based on the principle that vortices or swirling patterns are shed alternately on each side of an obstacle when gas flows past it (such as a bluff body). Flow rate is determined by the frequency of vortex shedding. These vortices are detected and counted.

An orifice plate is a thin plate with a hole (or orifice) in the center. With each flow of gas through the orifice, there is a pressure drop that correlates to the flow rate. Pressure sensors are used to measure this pressure drop before and after the orifice plate.

Technical specifications for natural gas flow meters

A wide range of natural gas flow sensors is available: 3/4", 1/2", 1", 2", 3", 4", NB 100mm, 6", 8", 10", 12" and max 6000mm.

Process connections include wafers or flanges, threads, inline natural gas turbine flow meters, and insertion natural gas flow meters.

A low pressure rating, such as 10 PSI, can be used to detect natural gas leaks and measure low flow rates. It also comes in high pressure ratings, such as 150LB, 300LB, 600LB ,900 class high pressure natural gas flow meters.

Natural gas turbine flow meter with 4-20mA, pulse or relay outputs, real-time data transmission, RS485 or HART interface

Price of natural gas flow meters in the industry

Industrial natural gas flow meters are priced based on a number of factors. Our natural gas flow meter price starts at $500. Customers can choose the right meter for their field application and budget. Contact us at [email protected] to get your price cost for an industrial natural gas flow meter.

Generally, the larger the gas sensor size, the higher the price. For example, a 4" natural gas flowmeter costs more than a 1" flowmeter.

The different measurement principle for natural gas flowmeters results in different prices. In addition to DP flow meters (differential pressure flow meters), we can also provide orifice flow meters for natural gas, Coriolis mass flow meters, thermal gas flow meters for measuring natural gas, and turbine flow meters for measuring natural gas volumetric flow. Unfortunately, SILVER does not offer portable natural gas flow meters or ultrasonic natural gas flow meters.

Our natural gas flowmeters are rated at 232 PSI (normal condition), but if customers require 600LB or 300 Class flowmeters, ANSI or ASME pressure, the price will be higher. To detect leaks from NG pipes, you can purchase our low flow natural gas flow meter for NG gas with typical low flow.

There are several functions of a natural gas flowmeter: electronic natural gas flow meter, totalizer calculation, HART communication, RS 485, lithium battery power supply, and EVC (temperature and pressure correction). These functions affect the price of a natural gas flowmeter. Get more info about compressed air insertion flow meter.

Natural gas flowmeter brand: The natural gas flowmeter of well-known brands is not cheap, such as EMERSON, ROSEMOUNT, ENDRESS, FOXTHERMAL, SIERRA. In contrast, SILVER offers many cheap alternatives, you can buy economical natural gas flow meters from China factories.

What is the best natural gas flow meter?

In order to save money on natural gas flow meters, we all hope to buy the best models. The best natural gas lies in the working conditions and applications that the industrial natural gas flowmeter you choose to meet, the budget to be met, the prompt delivery date, and the timely after-sales service. Choosing the right manufacturer is the best solution for your industrial natural gas flow meter needs.

0 notes

Text

Sanitary and hygienic Coriolis flow meter

Sanitary and hygienic Coriolis flowmeter is with tri-clamp end fitting and 316L SS wet parts material for food, dairy, biotechnology and pharmaceutical applications. The SH-CMF Coriolis meter is designed based on the Coriolis force and is currently one of the most powerful flow measurement devices today, and is now widely used for batch control, custody transfer and accurate process measurement.

Read more : https://pt.silverinstruments.com/coriolis-mass-flow-meter/

0 notes

Text

Understanding Thermal Mass Flow Meters and Coriolis Mass Flow Meters: A Comparative Overview

In the field of flow measurement, two commonly used devices are thermal and Coriolis mass flow meters. Both these instruments play a crucial role in various industries by providing accurate and reliable measurements of fluid flow rates.

This discussion aims to provide an informative overview of these two types of flow meters, highlighting their principles of operation, key features, and applications.

Thermal Mass Flow Meters

Thermal mass flow meters operate based on the principle of heat transfer. They measure the convective heat transfer from a heated sensing element to the flowing fluid. The heat transfer is directly proportional to the mass flow rate of the fluid, allowing for accurate measurements.

Discover the essential characteristics that make this flow meter an ideal choice for flow measurement.

Temperature Sensors: Thermal mass flow meters typically incorporate temperature sensors to accurately measure the temperature difference between the heated element and the fluid.

No Moving Parts: One of the significant advantages of these meters is their lack of moving parts, resulting in minimal maintenance requirements and increased reliability.

Wide Range of Fluids: These flow meters can measure a wide range of fluids, including gases and liquids, making them versatile for various applications.

Applications of Thermal Mass Flow Meters

These flow meters find their application in the following two areas.

Gas Flow Monitoring: They are commonly used in industries such as chemical, oil, gas, and power generation to monitor and control gas flow rates accurately.

Environmental Monitoring: They are also employed in environmental monitoring systems to measure air and gas flow rates, enabling accurate emissions monitoring and compliance.

Coriolis Mass Flow Meters

Coriolis mass flow meters utilize the Coriolis effect, which occurs when a fluid flowing through a vibrating tube experiences a force perpendicular to both the flow direction and the vibration. The deflection caused by this force is directly proportional to the fluid's mass flow rate.

The following are some key features of these flow meters.

High Accuracy: They are known for their exceptional accuracy, making them ideal for applications requiring precise measurements.

Density Measurement: These flow meters can also provide accurate density measurements, which can be useful for determining the composition and quality of fluids.

Wide Turndown Ratio: Coriolis flow meters offer a wide turndown ratio, allowing them to measure both low and high flow rates with the same level of accuracy.

Applications of Coriolis Mass Flow Meters

Two main applications of these flow meters are as follows.

Chemical Processing: Coriolis meters find extensive use in the chemical industry, where accurate measurement and control of fluid flow rates are crucial for process optimization.

Food and Beverage Industry: These flow meters are utilized in the food and beverage industry to measure flow rates of liquids, including dairy products, beverages, and viscous fluids like syrups and oils.

The End Note

Both the mass flow meters we have discussed are valuable tools for flow measurement, each with unique features and applications. Thermal mass flow meters excel in measuring gas flow rates with their simplicity and lack of moving parts.

On the other hand, Coriolis meters offer exceptional accuracy and density measurements, making them suitable for a wide range of applications in industries such as chemical processing and food and beverage.

By understanding the principles of operation and applications of these flow meters, industries can make informed decisions when selecting the most appropriate instrument for their specific needs.

0 notes