#machine vision in automotive industry

Explore tagged Tumblr posts

Text

Machine vision inspection system of Intsoft Tech, medicine defect detection case study.

#medicine inspection#machine vision system#intsoft tec#surface inspection#machine vision in automotive industry#surface inspection systems

1 note

·

View note

Text

Vision Inspection Machine in pune | India

The goal of the cutting-edge Machine Vision Camera Inspection System is to find flaws, impurities, and other anomalies in manufactured goods. Using digital cameras and image processing software, our specialist vision systems for quality inspection are able to detect problems. This allows us to improve quality control systems across a wide range of industrial industries.

#Vision Inspection in Automotive Industry Pune#Best Offers India#One Touch Vision Measuring Machine Pune#Vision India#O Ring Inspection Machine Pune#Machine Benefit India#Optical Sorting Machine Pune#Nano Glass Disc Machine India#Metal Disk Based

0 notes

Text

How Vision Inspection Enhances Auto Industry in Smart Manufacturing

The automotive industry is undergoing a major transformation. India has witnessed a massive change and growth in this segment. The Indian auto parts industry is witnessing a massive growth, it marked a 23% growth in 2023 and is contributing 2.3% to India’s GDP.

Everything from smart manufacturing to sustainable practices will strongly impact how the automotive industry will function in the future. One of the key technologies that is pivotal in redefining the auto industry’s efficiency is the vision inspection system.

Stringent quality practices are a must for automotive part manufacturers. The visual inspection system has become integral for smart manufacturing processes. It enables the manufacturer to achieve unparalleled reliability, efficiency and productivity. This blog will unfold the details of how a vision inspection system can enhance the automotive industry.

What is a Vision Inspection System?

Before delving deeper into how vision inspection systems can enhance smart manufacturing processes, let’s examine what makes this technology crucial for the automotive sector. Vision Inspection System, or Machine Vision, is a technology that uses cameras and image processing software to inspect and measure objects in real-time.

It works on similar principles as the human visual system but with better efficiency and precision. It helps identify defects, inconsistencies, or deviations from the desired specifications. One of the unique propositions of this technology is that it is highly versatile and is not just limited to the automotive industry. There are several other applications of the same.

Implementing Vision Inspection System Ensures:

Quality products

Increased production efficiency

It helps in reducing the cost

Compliance with the safety standards

Types Of Vision Inspection Systems Used In the Auto Industry

1. Laser Marking Inspection

This helps mark identification codes, logos, and labels on automotive components. It ensures accuracy by verifying its position and quality.

2. Barcode Scanning

Another type includes the scanning of barcodes. It is used for tracking and tracing of the automotive parts. Also, it ensures effective inventory management and reduces the probability of errors.

3. Pattern Matching Inspection

As the name indicates, this method identifies specific patterns and shapes of the automotive components. It is integral for the quality control and ensures that each component fits perfectly. This ensures seamless functioning of the manufacturing process.

4. Bearing Inspection

Bearings are critical components in vehicles; their integrity is essential for safety and performance. Vision Inspection Systems can detect even minor defects in bearings, such as cracks or irregularities, ensuring that only high-quality components make it into the assembly line.

How Vision Inspection Enhances Auto Industry in Smart Manufacturing

1. Improved Quality Control and Defect Detection

One of the key reasons companies rely on vision inspection system is because it ensures precise quality control. The vision inspection system canteen even the minutest of errors or flaws otherwise invisible to the human eye. Identifying the defence early in manufacturing can help overcome the issues and reduce the probability of faulty products. This also helps in maintaining the brand quality and ensures better customer satisfaction.

2. Enhanced Efficiency and Production Speed

With the growing demand in the automotive sector, automotive companies are always on their toes to address these demands. With modern technologies like vision inspection systems, companies can ensure real-time inspection. With effective quality control, they can overcome the delay of manual quality checks and also reduce the labour cost. This overall increases productivity and helps in maintaining consistency. This further increases the product efficiency.

3. Real-time Monitoring and Data Analysis

In the case of smart manufacturing, the company heavily relies on the data. This data will give them an analysis of the production process, allowing the manufacturers to gain valuable insight. By analysing the data generated during the inspection process, the companies can identify trends, pinpoint areas of improvement and make data-driven decisions, which can help gain a competitive edge.

4. Cost Reduction and Resource Optimization

By reducing the occurrence of defects and minimizing rework, Vision Inspection Systems contribute to cost reduction. Additionally, the efficiency gains achieved through automation and real-time monitoring lead to resource optimization. Manufacturers can allocate their workforce and resources more effectively, making their operations leaner and more cost-efficient. This, in turn, allows for competitive pricing while maintaining profit margins.

5. Compliance with Industry Regulations

For an automotive company to gain a competitive edge, it must adhere to the quality and comply with the safety regulations. The vision inspection system makes it easier to ensure complete consistency and accuracy while inspecting the components and products. Thus, the manufacturers can demonstrate their commitment to quality standards, reducing the risk of regulatory penalties.

Trends in Vision Inspection Technology

Technological implementation is pivotal for any organisation to stay ahead of the curve. The vision inspection system can further be improvised with the integration of modern technologies like:

Artificial Intelligence and Machine Learning

We cannot separate AI and machine learning when discussing technological revolution. Technologies like artificial intelligence and machine learning drive the modern-day revolution. With these technologies, it becomes easier to analyse the trends in the past and adapt new methods that can help improve the vision inspection process. AI-powered vision systems are becoming more sophisticated and capable of handling complex inspection tasks.

Enhanced Connectivity and Industry 4.0

The vision inspection system has become crucial for automotive companies. It is an integral part of Industry 4.0 initiatives. The data exchange is playing a pivotal role in this. These systems are increasingly integrated into the broader manufacturing ecosystem, allowing seamless communication between machines, robots, and other equipment. This interconnectedness enables real-time decision-making and the optimization of the entire production process.

Miniaturization and Portability

Advancements in camera technology and miniaturization have made it possible to deploy Vision Inspection Systems in smaller, more challenging spaces. Portable vision systems can be used for on-site inspections and maintenance, enhancing efficiency and flexibility.

Conclusion

As the technology continues to evolve, its applications will transform the industry and the process. Vision inspection system has become an indispensable tool for the automotive industry. Its ability to deliver consistent quality control, enhance production efficiency and real-time insights helps the automotive company comply with the quality standards, keeping them ahead of the curve.

SOURCE: https://optopixel.com/how-vision-inspection-enhances-auto-industry-in-smart-manufacturing/

0 notes

Text

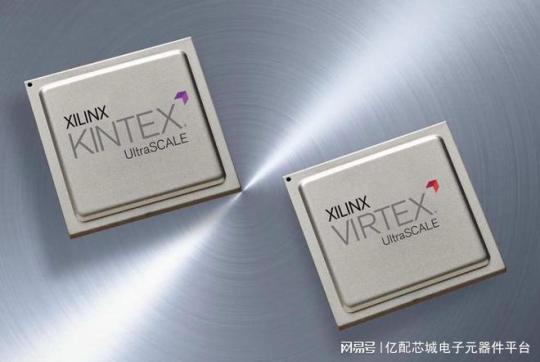

Beginner's learning to understand Xilinx product series including Zynq-7000, Artix, Virtex, etc.

Xilinx (Xilinx) as the world's leading supplier of programmable logic devices has always been highly regarded for its excellent technology and innovative products. Xilinx has launched many excellent product series, providing a rich variety of choices for different application needs.

I. FPGA Product Series

Xilinx's FPGA products cover multiple series, each with its own characteristics and advantages.

The Spartan series is an entry-level product with low price, power consumption, and small size. It uses a small package and provides an excellent performance-power ratio. It also contains the MicroBlaze™ soft processor and supports DDR3 memory. It is very suitable for industrial, consumer applications, and automotive applications, such as small controllers in industrial automation, simple logic control in consumer electronics, and auxiliary control modules in automotive electronics.

The Artix series, compared to the Spartan series, adds serial transceivers and DSP functions and has a larger logic capacity. It achieves a good balance between cost and performance and is suitable for mid-to-low-end applications with slightly more complex logic, such as software-defined radios, machine vision, low-end wireless backhaul, and embedded systems that are cost-sensitive but require certain performance.

The Kintex series is a mid-range series that performs excellently in terms of the number of hard cores and logic capacity. It achieves an excellent cost/performance/power consumption balance for designs at the 28nm node, provides a high DSP rate, cost-effective packaging, and supports mainstream standards such as PCIe® Gen3 and 10 Gigabit Ethernet. It is suitable for application scenarios such as data centers, network communications, 3G/4G wireless communications, flat panel displays, and video transmission.

The Virtex series, as a high-end series, has the highest performance and reliability. It has a large number of logic units, high-bandwidth serial transceivers, strong DSP processing capabilities, and rich storage resources, and can handle complex calculations and data streams. It is often used in application fields with extremely high performance requirements such as 10G to 100G networking, portable radars, ASIC prototyping, high-end military communications, and high-speed signal processing.

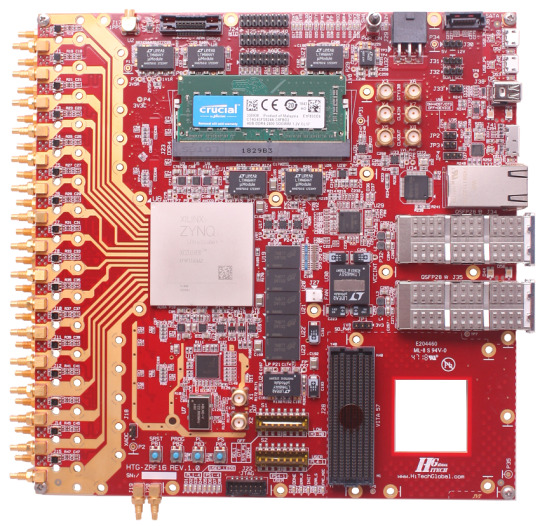

II. Zynq Product Series

The Zynq - 7000 series integrates ARM and FPGA programmable logic to achieve software and hardware co-design. It provides different models with different logic resources, storage capacities, and interface numbers to meet different application needs. The low-power consumption characteristic is suitable for embedded application scenarios such as industrial automation, communication equipment, medical equipment, and automotive electronics.

The Zynq UltraScale + MPSoC series has higher performance and more abundant functions, including more processor cores, larger storage capacities, and higher communication bandwidths. It supports multiple security functions and is suitable for applications with high security requirements. It can be used in fields such as artificial intelligence and machine learning, data center acceleration, aerospace and defense, and high-end video processing.

The Zynq UltraScale + RFSoC series is similar in architecture to the MPSoC and also has ARM and FPGA parts. However, it has been optimized and enhanced in radio frequency signal processing and integrates a large number of radio frequency-related modules and functions such as ADC and DAC, which can directly collect and process radio frequency signals, greatly simplifying the design complexity of radio frequency systems. It is mainly applied in radio frequency-related fields such as 5G communication base stations, software-defined radios, and phased array radars.

III. Versal Series

The Versal series is Xilinx's adaptive computing acceleration platform (ACAP) product series.

The Versal Prime series is aimed at a wide range of application fields and provides high-performance computing and flexible programmability. It has high application value in fields such as artificial intelligence, machine learning, data centers, and communications, and can meet application scenarios with high requirements for computing performance and flexibility.

The Versal AI Core series focuses on artificial intelligence and machine learning applications and has powerful AI processing capabilities. It integrates a large number of AI engines and hardware accelerators and can efficiently process various AI algorithms and models, providing powerful computing support for artificial intelligence applications.

The Versal AI Edge series is designed for edge computing and terminal device applications and has the characteristics of low power consumption, small size, and high computing density. It is suitable for edge computing scenarios such as autonomous driving, intelligent security, and industrial automation, and can achieve efficient AI inference and real-time data processing on edge devices.

In short, Xilinx's product series are rich and diverse, covering various application needs from entry-level to high-end. Whether in the FPGA, Zynq, or Versal series, you can find solutions suitable for different application scenarios, making important contributions to promoting the development and innovation of technology.

In terms of electronic component procurement, Yibeiic and ICgoodFind are your reliable choices. Yibeiic provides a rich variety of Xilinx products and other types of electronic components. Yibeiic has a professional service team and efficient logistics and distribution to ensure that you can obtain the required products in a timely manner. ICgoodFind is also committed to providing customers with high-quality electronic component procurement services. ICgoodFind has won the trust of many customers with its extensive product inventory and good customer reputation. Whether you are looking for Xilinx's FPGA, Zynq, or Versal series products, or electronic components of other brands, Yibeiic and ICgoodFind can meet your needs.

Summary by Yibeiic and ICgoodFind: Xilinx (Xilinx) as an important enterprise in the field of programmable logic devices, its products have wide applications in the electronics industry. As an electronic component supplier, Yibeiic (ICgoodFind) will continue to pay attention to industry trends and provide customers with high-quality Xilinx products and other electronic components. At the same time, we also expect Xilinx to continuously innovate and bring more surprises to the development of the electronics industry. In the process of electronic component procurement, Yibeiic and ICgoodFind will continue to provide customers with professional and efficient services as always.

3 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

Global AI Accelerator Chip Market Expected to Grow Substantially Owing to Healthcare Industry

Global AI Accelerator Chip Market Expected to Grow Substantially Owing to Increased Use of AI Accelerator Chips in Healthcare Industry. The global AI accelerator chip market is expected to grow primarily due to its growing use in the healthcare industry. The cloud sub-segment is expected to flourish immensely. The market in the North American region is predicted to grow with a high CAGR by 2031. NEW YORK, March 17, 2023 - As per the report published by Research Dive, the global AI accelerator chip market is expected to register a revenue of $332,142.7 million by 2031 with a CAGR of 39.3% during the 2022-2031 period.

Dynamics of the Global AI Accelerator Chip Market

Growing use of AI accelerator chips across the global healthcare industry is expected to become the primary growth driver of the AI accelerator chip market in the forecast period. Additionally, the rise of the cyber safety business is predicted to propel the market forward. However, according to market analysts, lack of skilled AI accelerator chip workforce might become a restraint in the growth of the market. The growing use of AI accelerator chip semiconductors is predicted to offer numerous growth opportunities to the market in the forecast period. Moreover, the increased use of AI accelerator chips to execute AI workloads such as neural networks is expected to propel the AI accelerator chip market forward in the coming period.

COVID-19 Impact on the Global AI Accelerator Chip Market

The Covid-19 pandemic disrupted the routine lifestyle of people across the globe and the subsequent lockdowns adversely impacted the industrial processes across all sectors. The AI accelerator chip market, too, was negatively impacted due to the pandemic. The disruptions in global supply chains due to the pandemic resulted in a decline in the semiconductor manufacturing industry. Also, the travel restrictions put in place by various governments reduced the availability of skilled workforce. These factors brought down the growth rate of the market.

Key Players of the Global AI Accelerator Chip Market

The major players in the market include: - NVIDIA Corporation - Micron Technology Inc. - NXP Semiconductors N.V. - Intel Corporation - Microsoft Corporation - Advanced Micro Devices Inc. (AMD) - Qualcomm Technologies Inc. - Alphabet Inc. (Google Inc.) - Graphcore Limited. - International Business Machines Corporation These players are working on developing strategies such as product development, merger and acquisition, partnerships, and collaborations to sustain market growth. For instance, in May 2022, Intel Habana, a subsidiary of Intel, announced the launch of 2nd generation AI chips which according to the company, will provide a 2X performance advantage over the previous generation NVIDIA A100. This product launch will help Intel Habana to capitalize on this rather nascent market and will consolidate its lead over the competitors further.

What the Report Covers:

Apart from the information summarized in this press release, the final report covers crucial aspects of the market including SWOT analysis, market overview, Porter's five forces analysis, market dynamics, segmentation (key market trends, forecast analysis, and regional analysis), and company profiles (company overview, operating business segments, product portfolio, financial performance, and latest strategic moves and developments.)

Segments of the AI Accelerator Chip Market

The report has divided the AI accelerator chip market into the following segments: Chip Type: Graphics Processing Unit (GPU), Application-Specific Integrated Circuit (ASIC), Field Programmable Gate Arrays (FPGA), Central Processing Unit (CPU), and others Processing Type: edge and cloud Application: Natural Language Processing (NLP), computer vision, robotics, and network security Industry Vertical: financial services, automotive and transportation, healthcare, retail, telecom, and others Region: North America, Europe, Asia-Pacific, and LAMEA SegmentSub-SegmentChip TypeCentral Processing Unit (CPU) – Most dominant market share in 2021 - The use of CPU for improving the performance of a computer while running graphics and video editors are expected to push the growth of this sub-segment further.Processing TypeCloud – Significant revenue growth in 2021 Cloud acceleration chip helps content creators, publishers, and other entities to offer material to end users promptly which is predicted to propel the growth rate of the market higher.ApplicationNatural Language Processing (NLP) – Highest market share in 2021 Increased use of Natural Language Processing (NLP) due to its ability to make computer-human interactions more natural is expected to propel the sub-segment forward.Industry VerticalHealthcare– Huge market revenue in 2021 The growing use of AI by major healthcare companies to complement medical imaging is anticipated to offer numerous growth opportunities to the sub-segment in the forecast period.RegionNorth America – Most profitable by 2031 The development of new technologies in artificial intelligence (AI) accelerators in this region is predicted to propel the market in the forecast period. Read the full article

3 notes

·

View notes

Text

The Importance of CNC Turned Components in Manufacturing

Manufacturing has been around for hundreds of years, but the advancements made by CNC machine manufacturers today are changing the world as we know it. As a manufacturer, you can benefit from these advancements in many ways. In this article, we'll explore some of them:

Precisions CNC machining is used to manufacture components that require high precision. The most common types of components are those used in aerospace, medical and automotive industries such as aircraft engines and gears. CNC machined parts undergo rigorous testing at the factory before they're shipped out to customers. The importance of precisions can also be seen in consumer products such as beer taps or wine glasses where a small deviation from the desired dimensions would result in unacceptable product quality.

Less Waste CNC machines are more precise and they can produce parts with less waste. This is because they use a machine vision system that guides the cutting process, ensuring that only the desired material is cut. The computer also calculates how many times each part should be machined before it gets out of tolerance, so you don't have to worry about running into problems because of over-machining or under-machining your parts. These benefits come at an expense though — CNC machines require more space than manual operations do, which means your manufacturing environment will need to accommodate them as well. In addition, there's always some risk involved when using computers in manufacturing processes: if something goes wrong during operation (e.g., power failure), your entire production line could shut down for hours at a time until repairs are made!

Higher Volume

A CNC machine is a tool that can be used to make many parts at once, which means that it can save time and money. In addition, CNC machines can produce parts with the same dimensions. This means that you won’t have to waste time or money on making parts again if they aren't the same as the other ones already in production.

Manufacturers rely on CNC turning for many reasons

CNC turning is a highly precise process that cuts the material directly into the desired shape and size. The machine can be programmed to perform any number of operations, such as cutting holes and slots or engraving text or images onto the finished product. CNC turning allows manufacturers to produce complex shapes quickly and cost-effectively because it uses computer-aided design (CAD), which makes it possible for workers who don't have advanced training in engineering technology but possess basic knowledge of computer programming languages like SolidWorks or AutoCad to create intricate designs using specialized software programs running on their computers.

About CNC Manufacturing

Computer numerical control (CNC) machines are used in the manufacturing industry to make components. They are also used by aerospace and defense industries, as well as automotive manufacturers.

Benefits of CNC Turned Components in Manufacturing

CNC turning is a process that uses a computer to control the movement of a cutting tool. It's used in a wide range of industries, including aerospace, automotive, and medical. This type of manufacturing can produce components with complex shapes and dimensions as well as complex geometries. For CNC turntables to run efficiently, they need high-quality components made from materials such as steel or aluminum. These materials are often used because they have high hardness levels which allow them to withstand repeated operations without bending or warping under pressure while remaining strong enough not only withstands vibrations but also to resist wear over time due to their resistance against corrosion caused by water moisture ingress due to air humidity levels change during operation cycle etc.

CNC machines are changing the way we manufacture, and more importantly, they're changing the way we work. They have become so powerful that they can now be used for almost any type of manufacturing process. This opens up many opportunities for small businesses that want to expand their operations with cutting-edge technologies.

The first thing you should know about CNC machines is that they aren't just for manufacturing anymore—they're also being used in other industries such as aerospace and automotive manufacturing. The reason why this happens is that these companies know how much faster it takes to use CNC technology versus traditional methods like manual machining or lathe turning. Another benefit of using a CNC machine instead? You'll save money! Not only does it cost less money upfront than traditional methods like manual machining but also once things get going – since there's no learning curve involved – your time spent producing parts will decrease significantly over time due to fewer errors caused by human error during production stages compared with those done manually by someone else. CNC Turned Components Manufacturers today are changing the world as we know it. The evolution of the industry has led to a new era in manufacturing, where precision is at the forefront and turn times have been cut down substantially. With this technology becoming more accessible, many people can now experience what it's like to work in this kind of environment which offers so many benefits over traditional manufacturing methods such as cutting steel by hand or using hand tools on an assembly line with no automation involved at all. Ganeshprecision.com manufactures and supplies CNC Turned Components in India with high Accuracy & Good quality.

4 notes

·

View notes

Text

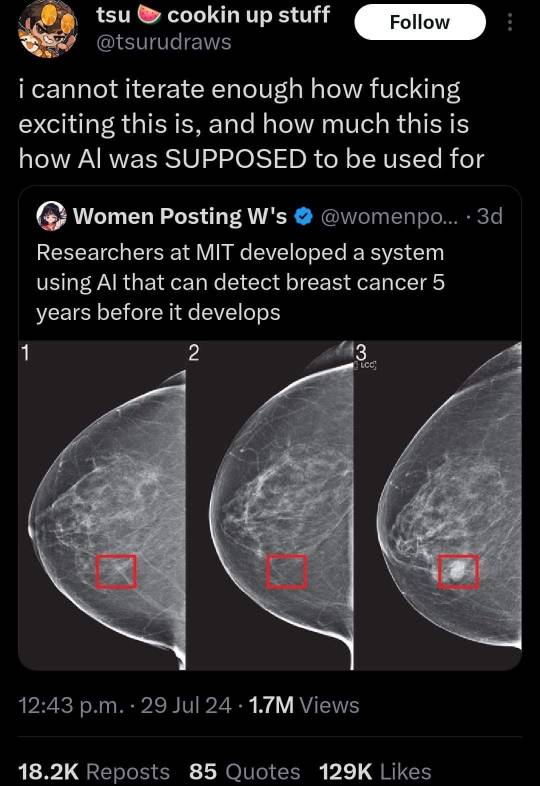

Saying that vision systems were invented to “recognize different bread types” vastly underrepresents an entire field of software/machine learning. Academics have been ID’ing cancer and tumors with vision systems for decades, wayyyy before that bread algorithm made the news.

My first job was in designing robotic systems that go in big (mostly automotive) manufacturing plants, and vision systems have been used there for years to help automate tasks that are dangerous, physically strenuous, or super repetitive. In a more basic form, it was already standard tech in the industry when I started in 2018.

Also basically every client we had had unions, so they weren’t firing any workers. They bought the machines because it let them make 5X as many cars in an hour, and making higher quality goods cheaper is good for everyone.

Also, the unions made it economically advantageous for them to automate away the most dangerous jobs to avoid workers comp. And the most repetitive, soul sucking jobs also got automated out, because they were the easiest to do that to. So the result was that workers by and large upskilled into machine maintenance or more interesting and complicating and rewarding production jobs.

We’ve eliminated most of the “grab and twist something hard” or “put a part into machine and press a button” jobs that were the most soul sucking. As someone who works closely with people in manufacturing, that’s been as helpful for them as anything. Doing the same thing for 8 hours a day is wayyy better when that thing isn’t one of the two types of jobs I described above.

126K notes

·

View notes

Text

Robotics Training

In today's technologically advanced society, robotics has become a transforming force. From AI-powered healthcare robots to automated manufacturing systems, the need for qualified robotics workers is growing rapidly. Robotics training is an essential subject for anyone hoping to contribute to the technology revolution since it gives people the knowledge and abilities they need to design, construct, program, and operate robotic devices.

Core Components of Robotics Training

Programming Skills

Hardware Understanding

AI and Machine Learning

Simulation and Modeling

Problem-Solving and Team Collaboration

Types of Robotics Training

Basic Courses

These classes, which are intended for beginners in robotics, cover fundamental programming, hardware parts, and basic robot construction.

Advanced Classes

Advanced courses for professionals focus on autonomous systems, robotic vision, and AI integration.

Training Particular to the Industry

Robotics applications in industries like healthcare, automotive, and space exploration are the main emphasis of customized projects.

Online Accreditations

Online platforms provide flexible and easily available certificates in IoT integration, AI, and robotics development.

Benefits of Robotics Training

Improved Ability to Solve Problems

Learning robotics pushes students to think critically and come up with creative solutions.

Enhanced Employability

Candidates with certified robotics abilities are in high demand in the job market.

Future-Proof Employment

Robotics knowledge guarantees job stability and advancement as industries embrace automation more and more.

Worldwide Possibilities

Professionals in robotics are in high demand globally and have the chance to work in a variety of creative settings.

Learning technical skills is only one aspect of robotics instruction; another is encouraging creativity, critical thinking, and adaptability. Investing in robotics training can lead to a fulfilling path in one of the most active and influential sectors today, regardless of whether you are a professional looking to upskill or a student considering career choices.

Begin your robotics adventure now to contribute to the technological advancements influencing our future!

To know more, click here.

0 notes

Text

Best AI & ML Courses

The work you do can lead to significant improvements in various fields, making a difference in people’s lives. You can work as a Data Scientist, AI Engineer, Machine Learning Researcher, or specialize in areas like Natural Language Processing or Computer Vision. These roles are prevalent in many industries, from tech and automotive to healthcare and entertainment. The highest-paying careers in AI-related fields include computer scientists, information research scientists, and computer network architects. As the revolution in artificial intelligence (AI) continues to explode, many people are looking into studying AI. Harness the power of artificial intelligence to quickly and reliably process your data with our machine learning courses and certifications - data science and data analytics course.

The instructor-led training was rigorous but concise, comprehensive, insightful, and a practical introduction to deep learning. I am looking forward to new research areas and applications that will emerge from this training. Our students can choose a Bachelor's degree in Computing with a specialisation in Artificial Intelligence at undergraduate level. The module provides for coverage of a variety of statistical methods, including descriptive statistics and validating formulated hypotheses, as well as predictive analytics. The computational foundations and methods of importance to data science are also covered, along with consideration for relevant supporting software and tools, and the need for data science governance - data science machine learning course.

With state-of-the-art labs and experienced faculty, the institute provides a conducive environment for research and innovation. The Generative AI and Machine Learning course enriches your career with comprehensive coverage of machine learning, deep learning, NLP, generative AI, reinforcement learning, computer vision, and more. Combining theory with hands-on practice. Our curriculum empowers you with the expertise needed to thrive in your career. Through systematic learning and practical industry projects, you'll adeptly address intricate challenges and remain at the forefront of the AI & ML field. The program covers diverse subjects including Python programming, exploratory data analysis, supervised and unsupervised learning, deep learning, generative AI, prompt engineering, LLMs, NLP, and much more. For more information, please visit our site https://eagletflysolutions.com/

0 notes

Text

Robotic Sensors Market Report: Unlocking Efficiency and Innovation in Automation

Robotic Sensors Market Report: Unlocking Efficiency and Innovation in Automation

Market Definition and Latest Trends

The robotic sensors market refers to the industry that designs, manufactures, and supplies sensors for use in robotics and automation systems. These sensors enable robots to perceive their environment, detect changes, and make informed decisions. The latest trends in the robotic sensors market include:

Advancements in sensor technologies, such as vision, force, and torque sensing

Increased adoption of Industry 4.0 and smart manufacturing

Growing demand for collaborative robots (cobots) and autonomous mobile robots (AMRs)

Integration of artificial intelligence (AI) and machine learning (ML) in robotic systems

The robotic sensors market refers to the industry focused on the development, manufacturing, and application of sensors used in robotic systems. These sensors are crucial for enabling robots to perceive and interact with their environment, providing essential feedback for various operations. Robotic sensors can be used for a wide range of applications, including navigation, obstacle detection, manipulation, environmental monitoring, and human-robot interaction.

The types of sensors commonly used in robotics include proximity sensors, vision sensors, force sensors, temperature sensors, and tactile sensors, among others. These sensors play an integral role in various robotic applications, such as industrial automation, healthcare, agriculture, and autonomous vehicles.

Market Size and Forecast

According to the latest report by Straits Research, the global robotic sensors market size was valued at USD 570.06 million in 2022 and is projected to reach from USD XX million in 2023 to USD 1166.41 million by 2031, growing at a CAGR of 8.28% during the forecast period (2023–2031).

Report Request Sample Link:https://straitsresearch.com/report/robotic-sensors-market/request-sample

Market Segmentation

The robotic sensors market is segmented into two main categories:

By Type

Force and Torque Sensor: Measures the force and torque applied to a robot's joints or end-effector.

Temperature Sensor: Monitors the temperature of a robot's components or environment.

Pressure Sensor: Detects changes in pressure, often used in robotic grippers or end-effectors.

Position Sensor: Tracks the position and orientation of a robot's joints or end-effector.

Proximity Sensor: Detects the presence or absence of objects within a certain range.

Vision Sensor: Uses cameras or other imaging technologies to detect and interpret visual data.

Other Type of Sensors: Includes sensors for detecting sound, vibration, or other environmental factors.

By End-User

Manufacturing: Uses robotic sensors in assembly, welding, and material handling applications.

Automotive: Employs robotic sensors in assembly, painting, and inspection applications.

Process and Packaging: Utilizes robotic sensors in food processing, packaging, and pharmaceutical applications.

Logistics: Deploys robotic sensors in warehousing, inventory management, and transportation applications.

Other End-Users: Includes industries such as healthcare, aerospace, and education.

Growth Factors and Opportunities

The robotic sensors market is driven by several growth factors, including:

Increasing demand for automation and robotics in various industries

Advancements in sensor technologies and artificial intelligence

Growing need for precision and accuracy in manufacturing and logistics

Rising adoption of Industry 4.0 and smart manufacturing

The market also presents several opportunities, including:

Development of new sensor technologies and applications

Integration of robotic sensors with other technologies, such as AI and IoT

Expansion into new industries and markets

Increasing demand for collaborative robots and autonomous mobile robots

Key Players in the Robotic Sensors Market

Some of the key players in the robotic sensors market include:

ATI Industrial Automation Inc. (Novanta Inc.): Offers a range of robotic sensors, including force and torque sensors.

Baumer Group: Provides sensors for robotic applications, including vision, pressure, and temperature sensors.

FUTEK Advanced Sensor Technology Inc.: Specializes in force and torque sensors for robotic applications.

FANUC Corporation: Offers a range of robotic sensors, including vision, force, and torque sensors.

Honeywell International Inc.: Provides sensors for robotic applications, including pressure, temperature, and vision sensors.

Infineon Technologies AG: Offers a range of sensors for robotic applications, including pressure, temperature, and position sensors.

Sensata Technologies: Provides sensors for robotic applications, including pressure, temperature, and position sensors.

OMRON Corporation: Offers a range of robotic sensors, including vision, force, and torque sensors.

TE Connectivity Ltd: Provides sensors for robotic applications, including pressure, temperature, and position sensors.

Tekscan Inc.: Specializes in force and pressure sensors for robotic applications.

Report Buy Now Link:https://straitsresearch.com/buy-now/robotic-sensors-market

About Straits Research

Straits Research is a leading market research firm that provides actionable insights and accurate analysis of various industries. Our team of experienced researchers and analysts use cutting-edge research techniques to provide comprehensive reports that help businesses make informed decisions.

#Robotic Sensors Market#Robotic Sensors Market Share#Robotic Sensors Market Size#Robotic Sensors Industry

0 notes

Text

How AI Development Solutions Are Driving Digital Transformation

In today’s fast-evolving digital landscape, Artificial Intelligence (AI) is more than a buzzword it is a critical driver of innovation and transformation. Businesses across industries are embracing AI development solutions to reimagine their operations, optimize processes, and deliver exceptional value to their customers. This blog explores how AI is catalyzing digital transformation and why investing in AI development solutions is essential for staying competitive in 2024 and beyond.

The Role of AI in Digital Transformation

Digital transformation involves integrating digital technologies into all aspects of a business, fundamentally changing how it operates and delivers value to its stakeholders. AI is a cornerstone of this transformation, enabling organizations to:

Enhance Decision-Making: By analyzing large datasets, AI provides actionable insights that support strategic decisions.

Streamline Operations: AI automates repetitive tasks, reducing errors and freeing up resources for more critical activities.

Improve Customer Experience: AI-driven personalization ensures customers receive tailored experiences, fostering loyalty and satisfaction.

Drive Innovation: From predictive analytics to intelligent automation, AI fuels the development of new products, services, and business models.

Key AI Development Solutions Powering Digital Transformation

AI development solutions encompass a broad range of tools and technologies that empower businesses to harness the potential of artificial intelligence. Here are some of the key solutions driving change:

1. Custom AI Models

Off-the-shelf solutions often lack the flexibility to address specific business challenges. Custom AI models bridge this gap by:

Addressing Unique Needs: Tailored algorithms cater to industry-specific requirements.

Enhancing Efficiency: Focused solutions streamline workflows and improve productivity.

Providing Competitive Edge: Businesses can gain insights and capabilities that set them apart from competitors.

For instance, in retail, custom AI models can optimize inventory management by predicting demand patterns, while in healthcare, they can assist in diagnostics by analyzing patient data.

2. Machine Learning Algorithms

Machine Learning (ML) is a critical component of AI development. ML algorithms enable systems to learn and improve from data over time without explicit programming. Applications include:

Predictive Analytics: Forecasting market trends and consumer behavior.

Anomaly Detection: Identifying fraud or irregularities in financial transactions.

Optimization: Enhancing supply chain management and operational efficiency.

ML solutions are instrumental in helping businesses anticipate and adapt to changes, ensuring resilience in a dynamic market.

3. Natural Language Processing (NLP)

NLP allows machines to understand, interpret, and respond to human language. This capability is transforming communication and customer interaction through:

Chatbots and Virtual Assistants: Providing real-time, 24/7 support.

Sentiment Analysis: Gaining insights into customer feedback and emotions.

Document Processing: Extracting and analyzing data from unstructured text.

NLP solutions are particularly valuable in industries like customer service, finance, and marketing, where clear and efficient communication is vital.

4. Computer Vision

Computer vision solutions empower machines to process and analyze visual data, enabling:

Quality Control: Detecting defects in manufacturing processes.

Facial Recognition: Enhancing security and authentication systems.

Image Analysis: Automating tasks in fields like healthcare and real estate.

These solutions are revolutionizing industries such as retail, where visual AI can enhance inventory management, and automotive, where it enables advancements in autonomous vehicles.

5. AI-Powered Automation

Automation is at the heart of digital transformation. AI-powered tools like Robotic Process Automation (RPA) and intelligent workflow systems streamline operations by:

Reducing Manual Workload: Automating repetitive, time-consuming tasks.

Improving Accuracy: Minimizing human errors in processes like data entry and compliance checks.

Enhancing Scalability: Allowing businesses to grow without proportional increases in resources.

From finance to logistics, AI-driven automation is enabling companies to operate more efficiently and cost-effectively.

6. AI Integration Services

Implementing AI technologies requires seamless integration with existing systems. AI integration services include:

Data Migration: Ensuring data is accurately transitioned to AI platforms.

API Development: Connecting AI tools with existing applications for real-time functionality.

Cloud Integration: Leveraging the scalability and flexibility of cloud-based AI solutions.

Effective integration ensures that businesses can adopt AI without disrupting their operations, maximizing the value of their investment.

Industries Transforming with AI Development Solutions

AI development solutions are not limited to specific sectors; they are driving transformation across industries:

Healthcare: AI is revolutionizing diagnostics, personalized medicine, and administrative efficiency.

Retail: From dynamic pricing to personalized shopping experiences, AI is enhancing customer engagement.

Finance: AI-driven risk assessment, fraud detection, and robo-advisors are reshaping financial services.

Manufacturing: Predictive maintenance, quality control, and supply chain optimization are key benefits of AI.

Education: AI-powered learning platforms offer personalized learning paths and improve student outcomes.

Benefits of Investing in AI Development Solutions

Investing in AI development solutions offers numerous benefits, including:

Increased Efficiency: Automating tasks and optimizing processes save time and resources.

Better Insights: Advanced analytics provide a deeper understanding of business operations and customer behavior.

Improved Agility: AI enables businesses to adapt quickly to changing market conditions.

Enhanced Competitiveness: Companies leveraging AI can innovate faster and more effectively.

Final Thoughts

AI development solutions are not just tools but strategic assets that drive digital transformation. By automating processes, enhancing decision-making, and delivering personalized experiences, AI empowers businesses to thrive in an increasingly competitive environment.

To unlock the full potential of AI, it is crucial to partner with experienced providers who understand your industry and can deliver tailored solutions. The journey to digital transformation starts with the right AI strategy. Embrace AI development solutions today and lead your business into a smarter, more innovative future.

0 notes

Text

Glass Disk Based Optical Sorting Machine For Nuts and Washers

With its base of a glass disk, Visimaster's Glass Disk Based Optical Sorting Machine For Nuts and Washers ensures that the manufacturing sector uses the least amount of defective fasteners, nuts,and washers. For that reason, any owner of a manufacturing company who is serious about growing their production line, increasing organizational efficiency, and significantly reducing errors has to have this equipment from Visimaster.

#Vision Inspection in Automotive Industry Pune#Best Offers India#One Touch Vision Measuring Machine Pune#Vision India#O Ring Inspection Machine Pune#Machine Benefit India#Optical Sorting Machine Pune#Nano Glass Disc Machine India#Metal Disk Based

0 notes

Text

Machine Vision System and Components Market

Machine Vision System and Component Market Size, Share, Trends: Cognex Corporation Leads

Rapid adoption of automation and Industry 4.0 technologies drives market growth

Market Overview:

The global machine vision system and component market is expected to develop at a 9.2% CAGR between 2024 and 2031. Starting with a base value in 2024, the market is predicted to grow significantly by 2031. North America currently dominates the market, owing to the presence of significant technological companies and the extensive adoption of automation across many industries. The market has significant development potential due to rising demand for quality control, process optimization, and advanced industrial automation across a wide range of end-user categories.

DOWNLOAD FREE SAMPLE

The rising emphasis on improving industrial efficiency and product quality has resulted in a considerable growth in the use of machine vision systems. More than 60% of manufacturers have integrated machine vision systems into their production processes, especially in regions with high labor costs and demanding quality standards such as North America and Europe. Industry 4.0 ambitions and the growing use of smart manufacturing technologies have fueled the demand for improved machine vision systems.

Market Trends:

Technological advancements in 3D vision technologies, such as stereo vision, structured light, and time-of-flight sensors, have created new opportunities for machine vision systems. These advanced technologies can enhance depth perception, object detection, and measurement capabilities, allowing for more precise quality control and process monitoring. Additionally, the incorporation of machine vision capabilities into embedded systems has resulted in the creation of tiny, cost-effective, and highly adaptable vision solutions catering to a broader range of end users.

Market Segmentation:

In the machine vision system and components market, the cameras segment dominates with nearly 35% of the overall revenue. Cameras play a crucial role as the principal sensing element in machine vision systems. Technological advancements, such as the development of high-resolution, high-speed, and specialized cameras, have led to widespread adoption across various applications. Over the last two years, the demand for industrial-grade cameras has surged by 25%, particularly in sectors like manufacturing, automotive, and healthcare.

The camera segment's continued growth is driven by economies of scale and improved manufacturing techniques, resulting in a 15% reduction in camera pricing. Analysts predict that the cameras segment will maintain its dominance due to ongoing integration of advanced imaging technologies and the growing demand for high-performance vision solutions.

Market Key Players:

Leading the machine vision system and component market are key players such as:

Cognex Corporation

Basler AG

Teledyne Technologies Incorporated

Omron Corporation

National Instruments

FLIR Systems, Inc.

These industry leaders are driving innovation and setting standards for quality and performance, ensuring the market's dynamic growth.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: Aurora Wave Intellects

0 notes

Text

CMOS Camera Market to Surge with 11% CAGR, Projected to Reach $15.6 Billion by 2033

The CMOS camera market is poised for substantial growth, with a projected Compound Annual Growth Rate (CAGR) of 11% between 2023 and 2033. This remarkable surge is anticipated to propel the market to a valuation of US$ 15.6 billion by 2033, more than doubling its current size of US$ 5.5 billion.

Start Exploring Wisdom: Download Your Insights Sample.

Key Takeaways of CMOS Camera Market Study

North America is expected to hold a significant share in the global CMOS camera market during the forecast period.

Low-light CMOS cameras are likely to capture a leading share in the global CMOS camera market among all camera types, as these cameras are widely used for video detection and monitoring systems.

By pixel density (megapixels), less than 5MP is anticipated to retain its significant share in the global CMOS camera market over the coming decade, as this pixel density has high growth opportunities in the automotive industry.

The consumer electronics industry is witnessing top-line growth all over the world. However, security & surveillance is estimated to continue to hold significant market share in the global CMOS camera market during the forecast period.

Competitive Landscape-Regional Trends

As the CMOS camera market experiences exponential growth, competition among industry players intensifies. Regional trends in the competitive landscape are shaping the market dynamics, with various regions vying for dominance. Key players are focusing on strategic partnerships, mergers, and acquisitions to consolidate their positions and gain a competitive edge.

Increasing Demand for Machine Vision to Propel Sales

Growth in machine vision adoption, with the convergence of advanced imaging analysis, robotics, and machine learning, is leading to new creative and never-before-seen solutions for industrial vision applications. Machine vision cameras will remain critical to the development of next-level solutions in a variety of growing global markets. Moreover, HD CMOS Cameras have taken over a majority of the machine vision market. CMOS chips yield higher quantum efficiency, and are expected to drive the growth of the global CMOS camera market, as they are used for near infrared (NIR), scientific, and life science applications.

More Valuable Insights on CMOS Camera Market

Future Market Insights offers an unbiased analysis of the global CMOS camera market, providing historical data of 2014-2021 and forecast statistics for 2022-2029. To understand the opportunities in the CMOS camera market, the market is segmented on the basis of camera type, professional services, pixel density (megapixels), and application, across seven major regions.

CMOS CAMERA MARKET TAXONOMY

The global CMOS camera market is segmented in detail to cover every aspect of the market, and present a complete market intelligence approach to the readers.

CMOS Camera Market

Camera Type

Firstly, Stereo Vision CMOS Cameras

Next, Low-light CMOS Cameras

Additionally, Low-noise CMOS Cameras

Furthermore, HD CMOS Cameras

Moreover, Ultra-HD CMOS Cameras

Professional Services

In addition, Imaging Consultancy Services

Additionally, Camera Integration Services

Furthermore, Support & Maintenance Services

Pixel Density (Megapixels)

Subsequently, Less Than 5MP

Moreover, 5-10MP

Likewise, 10-20MP

Additionally, More Than 20MP

Application

In particular, Aerospace & Defense

Similarly, Land-based Applications

Additionally, Naval-based Applications

Furthermore, Airborne Applications

Moreover, Automotive & Transportation

Likewise, Roadways

Moreover, Railways

Additionally, Seaways

Furthermore, Medical Devices

Similarly, Consumer Electronics

Likewise, Industrial

Moreover, Security & Surveillance

Finally, Others

0 notes

Text

Unlock a Future in AI with the Best Artificial Intelligence Course in Pune

Artificial Intelligence (AI) has emerged as a transformative technology reshaping industries worldwide, from healthcare to finance, retail, and beyond. The demand for AI professionals has never been higher, making it a lucrative career path for tech enthusiasts and professionals alike. If you’re searching for an AI course near me, Ethan’s Tech in Pune offers a top-notch artificial intelligence course in Pune that equips you with the skills and knowledge needed to thrive in this cutting-edge domain.

Why Choose Ethan’s Tech for AI Training?

1. Industry-Centric CurriculumThe artificial intelligence course in Pune at Ethan’s Tech is designed to meet the dynamic needs of today’s AI-driven world. The curriculum includes:

Fundamentals of AI and machine learning

Neural networks and deep learning

Natural Language Processing (NLP)

Computer vision and AI deployment

Working with popular AI tools like Python, TensorFlow, Keras, and OpenCV

This comprehensive curriculum ensures that students are well-versed in both theoretical concepts and practical applications, making them job-ready upon course completion.

2. Hands-On TrainingEthan’s Tech focuses on practical learning by incorporating real-world projects and case studies. Students in the AI classes in Pune will work on tasks like building chatbots, developing image recognition models, and creating recommendation systems. This hands-on approach bridges the gap between academic knowledge and industry requirements.

3. Experienced FacultyLearn from industry experts with years of experience in artificial intelligence and machine learning. The instructors at Ethan’s Tech provide in-depth guidance, real-world insights, and personalized mentorship to ensure every student maximizes their potential.

4. Placement AssistanceOne of the highlights of Ethan’s Tech is its strong focus on career support. The AI courses in Pune come with placement assistance, including resume-building workshops, mock interviews, and connections with top companies in the field. With their support, students can confidently transition into high-paying AI roles.

5. Flexible Learning OptionsEthan’s Tech offers both classroom and online learning options for its AI classes in Pune, making it easier for students and working professionals to balance their education with their schedules.

Career Opportunities in Artificial Intelligence

Artificial intelligence is a booming field with immense career potential. Upon completing the artificial intelligence course in Pune, you can pursue roles like:

AI Engineer

Machine Learning Specialist

Data Scientist

NLP Engineer

Computer Vision Specialist

These roles are in high demand across industries such as technology, healthcare, automotive, e-commerce, and finance, offering lucrative salaries and long-term career growth.

Who Should Enroll?

The AI courses in Pune are ideal for:

Fresh graduates aiming to build a career in AI

Working professionals looking to upskill and transition into AI roles

Entrepreneurs interested in leveraging AI for business innovation

For More Information: https://ethans.co.in/course/artificial-intelligence-training-in-pune/

Conclusion

Ethan’s Tech’s artificial intelligence course in Pune is your gateway to a successful career in one of the most sought-after fields today. With an industry-relevant curriculum, hands-on projects, expert mentorship, and robust placement support, this AI course near me offers everything you need to thrive in the world of AI. Don’t miss the opportunity to shape your future—enroll at Ethan’s Tech today!

0 notes