#low cost slide mould maker in china

Explore tagged Tumblr posts

Photo

New Post has been published on https://www.injectionmouldchina.com/hot-runner-mold/

Hot Runner Mold

Hot runner molds from China mould produce services factory ought to be considered at whatever point gating adaptability, cycle productivity, and material effectiveness are significant. In a hot runner system, the feed system is encased in a warmed channel with the goal that the plastic stays liquid during the trim cycle. Since the plastic doesn’t cool in a hot runner system, there is no compelling reason for oem/odm industrial mold design factory to plasticize the liquefy that would be needed to fill the feed system,

■inject the material that would fill the feed system, hang tight for the material in the feed system to cool, open the shape a generous add up to eliminate the feed system as in a three-plate form,

■de door the feed system from the shaped items, or

■re-granulate or dispose of the runner system,

For every one of these reasons, it isn’t phenomenal for hot runner molds to work with 20% quicker process durations and 20% less piece material than a traditional two-plate or three-plate cold runner shape. Nonetheless, hot runner molds do require a higher beginning venture than either two-plate or three plate molds and furthermore require hot runner regulators to keep up the soften temperature. While hot runners may appear to build vitality usage [2], the related increases in improved material use and trim profitability give net decreases to add up to vitality costs.

China industrial injection moulding manufacturers give a part through an isometric perspective on a hot runner system. This hot runner configuration incorporates a hot sprue bushing, complex, two drops or “spouts,” four warmer control zones, and different parts. During activity, the material from the embellishment machine’s spout will go down the hot sprue bushing to the essential runner situated in the complex. The dissolve at that point crosses down the length of at least one runners to downstream hot runner spouts. The length of the spout is controlled by the good ways from the centerline of the complex to the gating area of each shape depression.

Contrasted with cold runner plans, the distances across of the runners and drops in a hot runner system might be very enormous, since all the material in the hot runner will in the end be constrained into the shape pits. Since the polymer dissolve isn’t squandered, hot runner system can have enormous runner breadths to accommodate low stream opposition and amazing transmission of the infusion strain to the shape pits. Notwithstanding, excessively huge breadths can allow the material to corrupt in the hot runner and forbid quick change overs between various plastic pitches and hues.

A segment through a hot runner form gathering is appeared. This form configuration accommodates the infusion of the plastic soften into the left and right sides of the PC bezel through a normally offset hot runner system with two drops. As can be watched, an air hole encompasses most of the hot runner system to limit heat move from the warmed complex and spouts to the colder form steel.

During trim, the dissolve pressure applied on the essences of the shape depression and hot runner system will bring about powers that would will in general reason the hole embed and the hot runner system to divert. Push cushions, in some cases machined from titanium, are utilized to move these powers from the hot runner system to the top clip plate while moving a negligible measure of warmth. With hot runner molds, cooling lines or potentially protecting sheets ought to be utilized with the top brace plate to forestall the exchange of noteworthy warmth to the platens of the embellishment machine.

The hot runner system configuration gave is a moderately straightforward plan, which uses warm entryways that will be determined in the following section. In this plan, the hot runner spouts are concentric with the door removed gave in the depression embed. Since the complex will extend with changes in the complex temperature, the complex is permitted to grow and slide over the top surface of the spouts. The complex and spouts are kept up in pressure in the stature bearing to forestall any noteworthy measure of liquid polymer from getting away.

There are a wide range of hot runner system arrangements, including drops that are strung and in any case fit to the complex. Various designs of hot runner manifolds are additionally normal. The straight-bar complex is among the easiest. Two other normal plans incorporate the “H” and”X” complex plans. The”H” complex gives different branches to take care of the polymer dissolve through essential, optional, and even tertiary runners situated on the centerline of the complex as like the plan. The”X” complex uses a more straightforward plan wherein all essential runners exude legitimately from the focal point of the complex at the hot sprue bushing. This plan ordinarily accommodates more productive material usage. On the off chance that various drops are being taken care of, numerous manifolds may likewise be stacked.

Hot runner plans have expanded in multifaceted nature and capacity with designs undeniably more unpredictable that those appeared. Later presents stack molds in which at least two hot runner system are stacked in the shape stature heading to consider augmentation of the form depressions without an expansion in brace weight. Hot runner providers can likewise plan “seven-leg specials” in which the lengths and stretching of a hot runner are hand crafted to accomplish unique application prerequisites, commonly for multigated parts, for example, car body boards. The form originator ought to talk with various hot runner providers to comprehend the advantages and issues related with accessible hot runner system.

This article is from https://www.injectionmouldchina.com

#artistic teapots#china gas assisted mould#china industrial injection mold suppliers#china industrial injection moulding manufacturers#china industrial injection moulding suppliers#china molds produce services suppliers#china mould produce services factory#china precision plastic injection die manufacturers#china tooling-building services manufacturers#double coler mold parts suppliers china#High precision plastic injection mould manufacturers#high-precision molds factory#high-precision mould manufactory#injection manufacturing factory#low cost slide mould maker in china#mould produce maker#oem/odm industrial injection overmolding factory#oem/odm industrial mold design factory#oem/odm short shot injection molding#pipe fitting mold made in china#plastic injection moulding services china#Plastic precision injection mould manufacturers china#upvc pipe fitting mould maker#Plastic Mold

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/mold-cost-overview/

Mold Cost Overview

High precision plastic injection mould manufacturers know it clearly that there are three principle cost drivers for mold items:

the expense of the mold and its upkeep,

the materials cost, and

the preparing cost.

Beneath gives a breakdown of these essential cost drivers and their hidden parts. Note that these expenses do exclude roundabout costs of high-precision molds factory, for example, offices, managerial overhead, incidental advantages, or benefits. In any case, such aberrant expenses might be represented through the modification of hourly rates or use of backhanded cost rates.

Despite the fact that most shaped molds have a similar cost drivers, the extent of expenses differs generally by application for different china industrial injection mold suppliers. It shows the cost breakdown for a ware application, (for example, a link attach with a creation volume of 10 million pieces) and a uniquely application, (for example, a custom electrical connector with a creation volume of 100,000 pieces). While these two items are around a similar weight, it is seen that the greatness and extent of expenses are immeasurably extraordinary. The item part will in general have lower costs because of economies of scale that permit (1) amortization of the shape cost across immense creation amounts, (2) advancement of the embellishment cycle for lower forming expenses, and (3) lower material expenses related with mass acquisition of sap. As Fig. 3.3 proposes, the material expenses speak to most of the complete shaped part cost in ware applications though the form/tooling expenses can rule for custom moldings with low creation amounts.

where Cnol/part is the amortized cost of the form and upkeep per part, Cmateria/part is the material expense per part, Cprocess/part is the handling coSt per part, and yield is the division of shaped parts that are satisfactory. Every one of these terms will be therefore assessed. To exhibit the cost assessment technique, every one of these cost drivers is examined for the PC bezel. The model examination accept that 1,000,000 sections are to be shaped of ABS from a solitary pit hot sprinter form.

The expense of the shape for a given application is assessed later. Given the gauge or a statement for the form cost, Crotal shape, the expense of the form per part can be surveyed as where ntotal is the absolute creation amount of parts to be formed, and fmaintenance is a factor related with keeping up the form. Most disintegrates play out a few degrees of upkeep, including:

■preventive upkeep after each embellishment run, .

■inspections and minor fixes on an irregular premise,

■scheduled general shape support on a quarterly or semiannual premise, and

■mold revamping as important.

The requirement for shape support and fix is identified with the quantity of embellishment cycles played out, the properties of the plastic and form materials, the preparing conditions, and the nature of the shape. When in doubt, yearly support expenses can be assessed as 10% of the form buy cost, yet will change with the plan, materials, and preparing conditions in application. As the sap turns out to be more grating comparative with the hardness of the form, the wear of the shape quickens and more upkeep is required. Then again, a very much structured, solidified form should show lower support costs when utilized with an unfilled low-consistency plastic.

where Vpart is the volume of the formed part, Ppolymer is the thickness of the shaped polymer at room temperature, Rpolymer is the expense of the formed polymer per unit weight, and I scrap is the absolute extent of material expended including startup, deformities, and scrap related with the feed framework. This article is from https://www.injectionmouldchina.com

#automobile mould china#china industrial injection mold suppliers#china industrial injection moulding manufacturers#china industrial injection moulding suppliers#china precision plastic injection die manufacturers#china tooling-building services manufacturers#High precision plastic injection mould manufacturers#high-precision molds factory#injection mold service china#low cost slide mould maker in china#medical devices mould made in china#mould produce maker#oem/odm industrial injection overmolding factory#plastic injection moulding services china#Plastic precision injection mould manufacturers china#Plastic Mold

0 notes

Text

mold manufacturers in China | Topworks-China Mold maker | 30% COST LOWER,10 DAYS LESS

Mold manufacturers in China

Many people assume that mold manufacturers in China are going to be of poor quality. However, a huge number of companies- including multinational corporations- still choose to buy such plastic molds. Does that mean these companies are naive or making a mistake? Of course not. In fact, Topworks plastic mold company, as one of the Top mold manufacturers in China, is capable of making some of the best molds on the market- for a much lower price( 35% COST LOWER,15 BUILDING DAYS LESS) than European and American companies can possibly offer. China has seen a steady increase in the number of manufacturers of plastic injection molds as the industry has grown to be globally competitive. Not only do Mold manufacturers in China have the skills required to make superior injection molds, but we also possess excellent English skills for technology and business. That extends into the Topworks marketing departments, too- most of our sales staff have a strong grasp of CAD drawing, and the technical capability to choose the right mold building project for you. This allows them to speed up the communication process between Topworks and the customer. When making a new plastic injection mold, not only in China but all over the world, the process usually starts with a rendering of the final product drawing. After reading the drawing, engineers can then adjust how to build the mold based on things like the size and structure of the intended parts, the choice of material and how to keep the cost as low as possible – all while considering everything the customer asks for. China mold maker Our factory has worked with multiple European and American companies for many years now, so all you need to do is send us your drawings- we’ll be happy to carry out a test to show you what we have to offer. https://res.cloudinary.com/dl8a9jvpa/video/upload/v1572574321/plastic%20mold.mp4 Mold manufacturing has been around in China for over 30 years, meaning there are plenty of high-quality manufacturers operating today. Many China mold makers possess the same skills and experience as their western counterparts. While those injection mold manufacturers in China may only be paid around 65% of what they could make doing the same job in the US, they will still produce top-quality molds that you can really rely on. " order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]

How should I go about choosing mold manufacturers in China?

To clarify, the reason why a lot of US and European clients are declining to get their plastic injection mold from China is mainly that they are often more affordable (up to 35% cheaper than in their country). It should not, however, be the only factor you evaluate when weighing your options- you should also consider the following as a second factor to make sure that the mold manufacturers in China you choose are likely to provide you with a comprehensive task when it comes to developing the mold. - Can they afford to serve customers worldwide? - Consumers who used the service earlier and gave us their recommendations - Tool steel quality - The China mold factory manufacturing plant and their gear are of an industry standard. - Measures for quality control and validation - If you opted for a service provider who doesn't understand what they are dealing with, you may not have to waste your time. - Ability– will the China mold maker be able to carry out the entire task themselves, or will they have to employ a third party to help them with it?

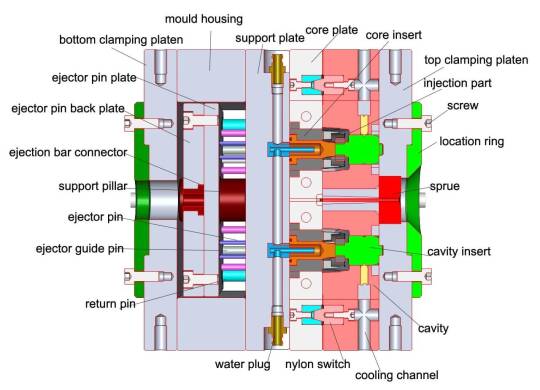

plastic mold structure

The process of China mould making

A design engineer is generally responsible for drawing a component pattern of the new part before the china mold factory can start the actual production of the mold. This blueprint gives the toolmaker an idea of what the new component will look like, so he can start designing the mold before proceeding with the work. In order to design a mold in a way to replicate the finished part very precisely, the specifications of the final part must be carefully reviewed. By performing the initial design on the computer, the mold designer who worked at mold manufacturers in China can get accurate results. The designer of a mold has to consider not only the gate on the part, but also the flow of water in the mold, to decide where the parting line will be on the part, and also to determine how the parts will be pushed out of the mold. Once these decisions have been made, the actual machining steps then begin. There are a variety of operations that need to be carried out in order to make a mold, the raw metal blocks need to be cut into rough dimensions. To obtain exact dimensions, precision machining is required, with this precision machining, this machining generally entails milling operations, grinding, drilling, and the use of electrical discharge machining or EDM. The process of using the lathe to polish the surface of the mold once it has been completed. There have been several trials done to determine how well the mold is able to produce good parts in an appropriate cycle time.

China mould making tips

It is a prevalent understanding that injection molds are as varied in profile, complexity, and size as are the parts they are used to produce. The most simple form of injection molding involves two pieces of steel plates (core and cavity plate) that can be easily installed in a small injection machine and which can also be molded using directly cutting the impression of the article to be molded into the steel. More complex injection molds made by China mold companies will have more cooling channels for controlling the temperature and means for ejecting the moldings. A sliding block may be provided for undercut sections of the part, unscrewing devices for moldings that have a screw thread, and plastic in the runner of the mold may be kept hot to provide a good fluid path. For the purpose of ejecting the moldings after injection molding, there are sometimes hydraulic devices installed, and sometimes compressed air is applied. The process of the production of an injection mold generally begins with the design and construction of the mold. Care must be taken to optimize the design of the components so that they can be molded by China mold makers, and then it must be ejected in the construction of the mold itself. Then, if necessary, it will be tested in the China mold factory and, if necessary, modified before the mold production department is entrusted with producing the mold. Steel is traditionally used to manufacture molds, and it is still the most common material that is used. Cavities and core inserts are crafted from high-quality tool steel that can be hardened as needed. Ejector pins and other ejectors are made with hard tool steel when it comes to the ejection systems, so the same goes for the guide pins and bushes as well. The molding housing, or bolster, is made of mild steel that is softer than the hard steel. In fact, in the production of the mold, it is best to use this grade of steel for all the parts that do not have to endure frictional wear and tear, as it results in minimizing the mold builder’s costs. Also, the steel grade must be selected carefully so that the surface finish required matches the demand is. In the past, like some other molders, injection mold manufacturers in China have been unwilling to accept other materials, such as POM, PVC, on the basis of the assumption that the abrasive action of the plastic passing through the mold will gradually wear away the surface polish. Thermosetting materials and compression are what happen in this process, and the process of making transfer molds is nearly always hardened and chromium plated.

mold manufacturers in China In retrospect, thermoplastics have little abrasive action, and therefore most of the time, even when runs have run as high as one million or more, soft materials have been used after hardening, especially for household ware plastic mold. These materials include aluminum, brass, zinc, aluminum-zinc alloys (Kirksite). The two last materials are ideal for prototype work since they can be cast easily from them using machines. You need to always look for the best possible mold when it comes to long-run products. Such molds are very costly. However, their cost per unit item is calculated out of ten and one hundred thousand items per mold, which is very small. Over a long period of time, the value of a well-made mold will grow, and in its turn, the cost of the mold will rise. This is because a well-made mold will not require frequent repairs, while the value per unit of the finished product will be very high.

EDM shop Nowadays, more and more customers want injection mold manufacturers in China to make prototypes so they can evaluate the market and then ask them to make several thousand pieces of the mold design with hardened steel. A prototype mold is exactly what its title suggests, a mold that is being created to serve as a prototype for a product. In rare instances, from a product mold from China, one could find a way to make a long production run, but this is never a matter of course in a business world. The good thing about a prototype mold is that it teaches us a lot about how molds should be manufactured and makes us a lot more confident that we will produce a good mold, but that is probably the extent to which a prototype mold can be helpful.

China Mould Classification

China Mould Classification is generally classified into three general categories: - prototype molding (25 to 1,000 pieces) - Production molding (from 1,000 to 10,000 pieces) - High volume molding (from 10,000 to 2,000,000 pieces) - China Prototype Moulds Creating a prototype thermoplastic injection mold is one of the preliminary steps in building a new product. To evaluate the properties of the resin for injection molding and the set-up requirements for the mold, original prototypes have to be produced from the resin to monitor the dimensional control, the set-up process, and the setting of the mold. In certain products, prototype moldings are designed to meet specifications for product Quality Control testing. Therefore, they are generally used for product quality control testing and (occasionally) as the basis for the initial market testing requirement. As China prototype molds are intended to mimic the production part before launching a production run, they can be used as a relatively inexpensive learning device to point out and correct potential design issues or material selection issues before moving forward on a production run. An existing prototype mold may be fabricated utilizing an existing mold frame, interchangeable soft cavity inserts, manual loading and unloading systems, and a simple cooling system. - China Production Moulds The construction of china production molds utilizes a low-cost mold base and hardened tool steel cavities; the cavities should be machined into predefined shapes and sizes on demand according to specifications at established production rates. The mold must allow for the ease of repair as well as facilitate the escape of trapped air and volatile materials during the molding cycle employing facilitating the venting of the cavities. In this context, a production mold must also incorporate an automatic ejection system and thermoplastic melting temperature control for continuous cooling, ensuring shorter cycle times, lower costs, and consistently high quality. - China High Volume Production Moulds For the China moulds to fully meet the requirements of production tools, the molds must have multiple cavities and be composed of interchangeable mold components. In addition, an efficient high-volume production mould made in China should be easy to maintain and be designed to be resistant to adverse outside forces. For instance, - How often do you begin dismantling a mold only to discover too many inserts that are not numbered or labeled with positions? - What about slots for pry bars? - Could jack screw holes be useful in the removal of cavities? A well-configured mold can help minimize the risks of its design and construction and prevent corrosion and erosion. In addition, a customized preventative maintenance program can be incorporated, as well as surface coatings. Read the full article

0 notes