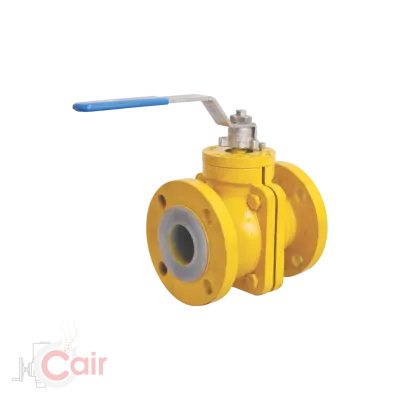

#lined ball valves manufacturer

Explore tagged Tumblr posts

Text

Butterfly Valves Understanding the Role of Manufacturers in Quality Control

Butterfly valves play a role in numerous industries by regulating the flow of liquids and gases through pipelines. Their uncomplicated design and user-friendly operation have made them a popular choice for a range of applications. To navigate the world of butterfly valves effectively, it is essential to grasp both the product itself and the crucial involvement of manufacturers in maintaining quality standards. Let’s take a closer look.

#Richter#Butterfly Valve#Ball Valves Manufacturer#Ball Valves#Pfa Lined Valve#pump and valves#IDEX India

0 notes

Text

What are old cars like to drive now?

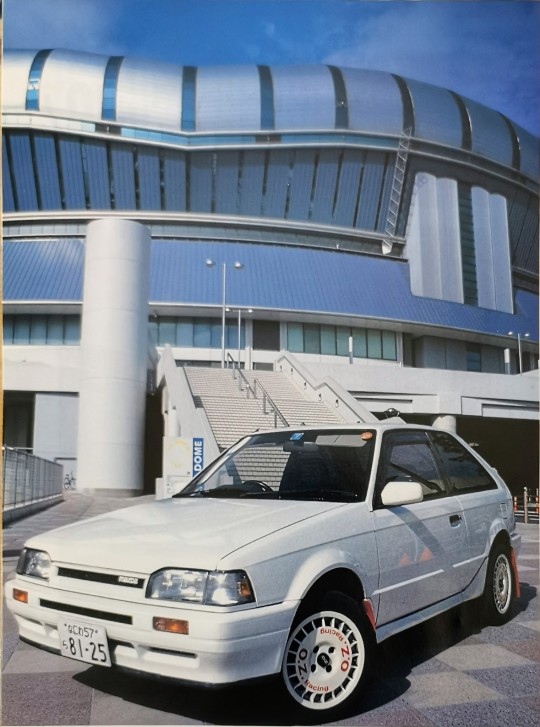

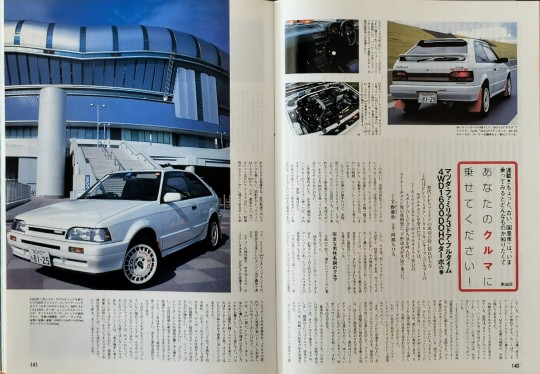

Mazda Familia 3 door full time 4WD1600DOHC turbo review.

The second generation FF Familia tends to be overshadowed by the success of the first FF Familia. The Familia underwent a Key Concept model change in 1985, and the sports version of the 1.6 (twin cam turbo + full-time 4WD) became popular. Yasushi Shimono drove to Osaka for the later model after minor changes.

Text | Yasushi Shimono Photos Chihiro Abe

The other day, I rented a Familia car in Takamatsu, Shikoku. If you see Nippon Rent-a-Car, Toyota Rent-a-Car, and Nissan Rent-A-Car lined up at the counter in the airport lobby, if you're a car fan, you should probably rent a Mazda Rent-A-Car at this time of year.

It's a personal choice, but the Familia 1500AT I rented was actually very nice. The engine and suspension have the solid feel of a German car, and it feels great. Even though I've already driven over 20,000km, I can barely see any wear and tear.

During my summer vacation two years ago, I took a Familia rental car at the station in Tsuruoka, Yamagata Prefecture, and it was a great ride, and my family was happy with it.

For test drives, members of the media always ride in the manufacturer's so-called PR vehicles.

However, when they later try the same car in a rental car, they are often disappointed to varying degrees. I don't have the space to write about the reasons in detail here, but Familia is an extremely rare example of people rediscovering their charm through rental cars. It feels like a very seriously made car.

I am holding this.

FULLY MASCULINE NOUN CAR

In downtown Osaka, I was given a ride on a nostalgic Familia. 1988 model 3 door twin cam turbo 4W.D. It is a full-time 4WD high-performance model that was part of the second-generation FF Familia series that debuted in 1985.

I splurged on expensive 200,000 yen 0Z racing aluminum wheels for the car I bought this spring. There is a bright red mudflap in the wheel arches.

The guard hangs down. The hobby of the owner, Mr. M (35 years old), who really wants to drive a Lancia Delta Integrale, seems to be depicted on the outside.

The inside can also be customized.

It is. The front seats are BRIDE bucket seats. The handle is MOMO's Prototipo. At the tip of the shift lever is a plastic shift knob that looks like a white ball.

The main body of the 1.6LDOHC turbo engine has not been modified, but the muffler and air cleaner have been replaced with "HKS''. The suspension also uses Mazda genuine sports springs combined with GAB dampers. I'm not Kiyoshi Nishikawa, but I get the strong impression that he was trying to do things one by one, starting with what he could do. Mr. M, who works as a tire wholesaler, is a pleasant young man. It is the year of the year. When I pushed in the tape whose head was peeking out from the set, it played Mr. Children, which doesn't really suit Osaka (?).

However, once it started running, the Familia Integrale was a much more radical car than the standard.

First of all, the suspension is much harder than you might imagine from the specs. The ride quality is almost that of a competition vehicle, reacting honestly to the bumps and undulations of the road surface and transmitting short, jerky vibrations.

I didn't think it was power steering at first either. I slowly turned the steering wheel to turn off the engine and realized for the first time that it had power assist. That's how responsive it is. Basically, the normal engine is so energetic that it's hard to believe. Power is already 140 yen on NET display. However, it is more powerful than the face value, and at the signal Grand Prix the acceleration of all four wheels is like that of a rabbit.

I'll show you.

Even though it is a turbo, it starts to crash immediately after idling.

Delivers comfortable torque. The response in the low rotation range is also not bad. Tachometer red zone from 7000rpm. However, the latest 4-valve It's not as smooth and light as the unit.

It has been replaced with an air cleaner for competition. So, at the top end of 6500 or higher, the engine noise, mainly the intake noise, becomes louder.

Air conditioner control panels, air vents, and

-Dark areas where stereo units, ashtrays, etc. are crowded.

There was a designer who once described the center part of the dash as ``the most expensive part of the car's interior,'' but this car has a panel that says ``FULLTIME 4WD'' embedded in part of it. There is. It was kind of noisy. There is also a shiny silver switch inside the spring, and this is for locking the center differential. The owner once benefited from being muddy.

Apparently there is.

The turbo is effective without any noticeable bumps.

It starts to work, and what's more, it works like a turbo. I miss the way the green snail lights up in the instrument panel every time the turbo kick explodes. What's more, every time I shift up and release the accelerator, I hear the resonant whine of the turbine, which is nostalgic. I wasn't able to do it this time due to time constraints, but I was able to drive on mountain passes and some dirt roads, and it still looked really interesting. Manly and sweaty, a perfect masculine noun.

It's Luma.

Of course, the current Familia, which no longer has a sports model in its lineup, is not such a macho car. However, the Familia has always been a car that has not had a fancy feel to it for generations. Fancy is something like ``a womanly thing that a man has come up with.'' I like the character, which is unusual for domestically produced vehicles, but I'm sure there are people who say that's why it doesn't sell well.

PIC CAPTIONS

The second generation FF Familia underwent a full model change in January 1985. It has a 3/5-door hatch and a 4-door sedan body. Initially, it started with 1.3ℓ and 1.5ℓ NA and turbo units, but a 1.6��� turbo unit was soon added. The photo is of the later model. The body size is: total length x width x height = 3990 x 1645 x 1405mm. Wheelbase 2400mm.

The steering wheel has been replaced with "MOMO" and the seat has been replaced with "BRIDE". When the New Familia was announced, the company emphasized the improved quality of the interior, saying, ``If the packaging is the same, the quality of the interior is important.''

With minor changes in 8 years, NA unit

The remaining old E-type units were wiped out and replaced by B-type units. Photo of 1597cc 16V DOHC turbo with 140ps @ 6000rpm and 19.0kgm torque @ 5000rpm

Mr. M's Delta Familia has a majestic red mudguard. The ``GAB'' and ``HKS'' stickers and white OZ wheels clearly reflect the owner's taste.

42 notes

·

View notes

Text

Steam Trap Supplier in Algeria

African Valve is the leading Steam Trap Supplier in Algeria. It is a critical device that is used in steam systems to remove condensate and non-condensable gasses, such as air, from the steam lines while preventing the escape of steam. Its primary function is to prevent the loss of steam while efficiently draining condensate from the system; they are essential for maintaining the efficiency and performance of steam equipment and ensuring the safe operation of steam systems.

Types of Steam Trap we supply:

Ball Float Steam Trap: These valves are used to remove condensate from steam systems, the ball lifts to open the valve, allowing condensate to drain while preventing steam loss.

Inverted Bucket Steam Trap: They uses a bucket that floats on condensate to control valve operation, when they are filled it tilts and opens the valve to discharge the condensation, and close when the bucket get empty

Bimetallic Steam Trap: When the condensate cools, the metals bend and open the valve to discharge condensate, while steam heat causes the metals to return to their original shape and close the valve

Thermodynamic Steam Trap: Use a disc and a temperature-sensitive mechanism to open and close the valve, allow concentrated gas to escape and prevent steam

Thermostatic Steam Trap: They work on temperature change, as the temperature of the condensate changes, the element expands or contracts, allowing the valve to release condensate and prevent steam.

Advantages:

Industries in Nigeria maintain their steaming system and manufacturing units with the assurance of the trusted Steam Trap Supplier in Algeria , thus ensuring smooth operation and high energy efficiency in their processes.

Efficient Condensate Removal, ensure that steam systems operate efficiently and maintain optimal heat transfer.

Energy Savings:By preventing steam leakage and reducing energy losses, they help save fuel and energy costs.

Equipment Protection: By removing condensate they protect equipment water hammer and corrosion.

Process Efficiency: Improve consistent temperature and pressure in the system, enhancing process stability and performance.

Safety Enhancement: Provide safety to the equipment and manage effective flow control

Industries:

Heating Systems

Industrial Processes

Power Generation

Steam Distribution Networks

Process Sterilization

Description:

Available materials: Cast Iron, Ductile Iron, Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9) Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316], A105

Size: 1/2" to 4"

Nominal Pressure: PN10 to PN250

Class: 150 to 1500

Ends: Flanged, Buttweld, Socket weld, Threaded

Visit today: https://www.africanvalve.com/product-category/steam-trap/

2 notes

·

View notes

Text

Top valve manufacturer and supplier near me

Explore a comprehensive range of high-quality industrial manufacturing valves at Dinesh Industries. Our product line up includes precision-engineered valves such as needle valves, non-return valves, ball valves, 2-way manifolds, 3-way manifolds and 5-way manifold . Designed for efficiency and reliability, our valves are ideal for a variety of applications. Find the perfect solution for your fluid control needs with our durable and performance-driven valve products. Trust Dinesh Industry for top-notch engineering and unmatched quality in every valve we offer.

3 notes

·

View notes

Text

What Is a Ball Valve? A Complete Guide to Its Function and Uses

Ball valves are one of the most commonly used types of valves in industries worldwide. Their design and versatility make them ideal for controlling the flow of various fluids and gases. This comprehensive guide will explore what a ball valve is, how it functions, and its various applications, along with insights into the ball valve manufacturing industry in India.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical ball to control the flow of media (liquids, gases, or slurries) through a pipe or system. The ball has a hole or port through the center, which aligns with the flow path when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow path and preventing the passage of the media.

The simplicity of this design allows for quick and efficient operation. Ball valves are known for their durability, reliability, and ability to maintain a tight seal even after long periods of use.

How Does a Ball Valve Work?

A ball valve consists of several key components, including the body, the ball, the stem, and the handle or actuator. The ball is mounted inside the valve body, with the hole or port aligned with the flow path when the valve is open. When the valve handle is turned, the stem rotates the ball, either opening or closing the valve.

The flow direction and the valve's status (open or closed) are determined by the orientation of the ball. In the open position, the flow passes through the hole in the ball, allowing the fluid or gas to move through the valve. In the closed position, the ball rotates 90 degrees, blocking the flow entirely.

One of the key features of ball valves is their ability to create a tight seal. The design ensures minimal leakage, even in high-pressure applications, making them highly reliable in various industries.

Types of Ball Valves

There are different types of ball valves, each suited for specific applications. The most common types include:

Standard Ball Valve: This is the most basic type of ball valve, ideal for simple on/off applications.

V-Port Ball Valve: This valve has a V-shaped ball, which allows for precise flow control, making it suitable for throttling applications.

Multi-Port Ball Valve: These valves have multiple ports, allowing for directional flow control and bypassing multiple channels. They are used when more complex flow control is needed.

Trunnion Ball Valve: A trunnion ball valve has a ball that is supported by bearings, allowing for larger sizes and higher-pressure applications.

Uses of Ball Valves

Ball valves are widely used across different industries due to their efficiency and reliability. Some of the key applications include:

Oil and Gas: Ball valves are essential in oil and gas systems for controlling the flow of crude oil, natural gas, and other fluids. Their ability to withstand high pressures and temperatures makes them ideal for this industry.

Water Treatment: In water treatment plants, ball valves are used to control the flow of water and chemicals. They are often found in filtration systems, distribution lines, and pumping stations.

Chemical Processing: Chemical plants use ball valves to manage the flow of various chemicals, ensuring safe and controlled operations. The tight seal offered by ball valves minimizes leaks and contamination.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, ball valves regulate the flow of fluids used for heating and cooling purposes.

Food and Beverage: In the food and beverage industry, ball valves ensure the smooth flow of ingredients, liquids, and gases, as well as maintain hygienic conditions.

Pharmaceuticals: Ball valves are also critical in the pharmaceutical industry, where cleanliness and precise flow control are required for producing medicines and vaccines.

Why Choose Ball Valves?

There are several reasons why ball valves are favored in various industries:

Durability: Ball valves are highly durable and can withstand harsh operating conditions, such as extreme temperatures and high pressures.

Leak-Proof Performance: Ball valves are designed to provide a tight seal, preventing leaks even in demanding applications.

Ease of Operation: With a simple 90-degree turn, ball valves are easy to operate and provide quick response times.

Versatility: They can be used for a wide range of applications, from small-scale systems to large industrial plants.

Low Maintenance: Due to their robust design and minimal moving parts, ball valves require little maintenance compared to other types of valves.

India has become a significant player in the global valve manufacturing industry, with many reputable ball valve manufacturers producing high-quality valves. A ball valve manufacturer in India is equipped with advanced technology and expertise to meet the growing demand for industrial valves in various sectors.

These manufacturers use state-of-the-art materials and rigorous quality control processes to ensure that their products meet international standards. As a result, India's ball valve manufacturers are well-positioned to cater to both domestic and international markets, offering products that are durable, reliable, and cost-effective.

Conclusion

Ball valves are essential components in many industries, offering excellent control and reliability in fluid and gas handling systems. Their simple design, combined with a tight seal, makes them an ideal choice for various applications. Whether in oil and gas, water treatment, or pharmaceuticals, ball valves continue to play a crucial role in ensuring smooth and safe operations. As the demand for high-quality valves grows, ball valve manufacturers in India are playing a crucial role in supplying the global market with reliable and durable valves to meet diverse industry needs.

0 notes

Text

Megatop – Your One-Stop Shop for Premium Plumbing Hardware and Supplies

When it comes to plumbing projects, the quality of your materials can make or break the success of your installation or repair. Whether you are a professional plumber, contractor, or DIY enthusiast, finding a reliable supplier for high-quality plumbing hardware and supplies is crucial.

At Megatop, we pride ourselves on being a trusted, one-stop shop for all your plumbing needs. From pipes and fittings to valves, faucets, and accessories, we provide a comprehensive selection of plumbing products to ensure efficient and durable solutions for any project.

If you're looking for premium plumbing hardware at competitive prices, Megatop has got you covered. Let’s explore what makes us the go-to choice for plumbing professionals and homeowners alike.

1. Why Choosing the Right Plumbing Supplier Matters

Plumbing is the backbone of any residential, commercial, or industrial building. Using low-quality materials can result in:

✅ Leaks and water damage✅ Frequent repairs and high maintenance costs✅ Reduced efficiency and performance✅ Non-compliance with safety standards

By choosing Megatop, you ensure that your plumbing system is built with reliable, high-performance components that offer long-lasting durability and optimum functionality.

2. Extensive Range of Plumbing Products at Megatop

At Megatop, we stock a wide variety of plumbing supplies, ensuring you find everything you need in one place. Here’s what we offer:

a) Pipes and Fittings

Pipes and fittings are the foundation of any plumbing system. We offer:

PVC Pipes & Fittings – Lightweight, corrosion-resistant, and perfect for water supply lines.

Copper Pipes & Fittings – Durable, antimicrobial, and ideal for high-pressure applications.

PEX Pipes & Fittings – Flexible, easy to install, and suitable for both hot and cold water supply.

Stainless Steel & Brass Fittings – Strong, corrosion-resistant, and excellent for commercial plumbing.

b) Valves and Faucets

For efficient water flow control, we provide:

Ball Valves – Reliable and long-lasting shut-off valves.

Gate Valves – Best for on/off water control in large plumbing systems.

Mixing Valves – Perfect for regulating hot and cold water in heating systems.

High-Efficiency Faucets – Water-saving and stylish designs for residential and commercial use.

c) Plumbing Accessories and Tools

Every plumbing project requires the right accessories and installation tools, including:

Sealants & Teflon Tape – To ensure leak-proof joints.

Plumbing Wrenches & Cutters – For quick and precise installations.

Water Pumps & Filtration Systems – For clean and efficient water distribution.

Drain Cleaners & Unclogging Tools – To maintain a smooth-flowing system.

Whatever your plumbing needs, Megatop provides top-quality products to get the job done right.

3. Benefits of Buying Plumbing Supplies from Megatop

There are plenty of plumbing hardware suppliers, but why choose Megatop? Here’s what sets us apart:

a) High-Quality Materials for Lasting Performance

We source our plumbing supplies from reputable manufacturers, ensuring that every item meets industry standards for durability and efficiency.

b) Competitive Prices and Bulk Discounts

Whether you're buying a single valve or bulk materials for a large-scale project, we offer fair pricing and discounts on large orders.

c) A One-Stop Shop for All Plumbing Needs

Forget the hassle of searching multiple stores for different parts. Megatop stocks everything from pipes to tools, making it easy to order everything in one place.

d) Expert Customer Support and Advice

Not sure what you need? Our knowledgeable team is ready to assist you with product recommendations, technical support, and installation tips.

e) Fast and Reliable Shipping

We understand the importance of timely delivery. With quick order processing and shipping, we ensure you get your plumbing hardware exactly when you need it.

4. How to Choose the Right Plumbing Supplies for Your Project

When purchasing plumbing hardware, consider the following:

✅ Material Compatibility – Choose materials that suit your plumbing system (e.g., copper for high-pressure, PVC for low-cost installations). ✅ Water Pressure Requirements – Ensure your pipes and fittings can handle the water flow. ✅ Leak Prevention – Invest in quality valves, seals, and adhesives to avoid costly water damage. ✅ Ease of Installation – If you're doing a DIY project, look for user-friendly fittings and tools. ✅ Environmental Impact – Opt for water-saving faucets and energy-efficient components.

If you need help selecting the right supplies, Megatop’s team is here to guide you.

5. Who Can Benefit from Megatop’s Plumbing Hardware?

Megatop caters to a wide range of customers, including:

🏠 Homeowners & DIY Enthusiasts – Whether fixing a leaky faucet or upgrading your home plumbing, we have the right tools and parts.

🔧 Professional Plumbers & Contractors – Need bulk supplies for construction projects? We offer wholesale pricing and top-tier materials.

🏢 Businesses & Property Managers – Keep your commercial buildings running smoothly with high-quality maintenance and repair supplies.

🏭 Industrial Facilities – Get heavy-duty plumbing hardware for factories, warehouses, and large infrastructure projects.

6. Shop Plumbing Supplies Online with Megatop

Shopping for plumbing hardware online has never been easier. At Megatop, you can:

✔ Browse a wide selection of plumbing products✔ Compare specifications and pricing easily✔ Place secure online orders anytime, anywhere✔ Enjoy fast delivery and responsive customer service

With a user-friendly website and trusted payment options, we ensure a seamless shopping experience for all our customers.

7. Conclusion: Megatop – The Best Choice for Plumbing Hardware

When it comes to quality, affordability, and convenience, Megatop stands out as the best plumbing hardware supplier for professionals and DIYers alike.

✔ High-quality plumbing materials✔ Competitive pricing and bulk discounts✔ Wide range of products for every need✔ Expert customer support and advice✔ Fast and secure online shopping experience

If you’re looking for reliable plumbing hardware, visit Megatop’s Plumbing Section today and get the best supplies for your next project! 🚰🔧 visit ; https://megatop.com/

0 notes

Text

Functions and applications of non return valves

Non-return valves, commonly referred to as check valves, are essential components in various industrial systems and equipment. These valves are specifically designed to prevent the backflow of fluids and gases, ensuring the safety, efficiency, and reliability of the system they are integrated into.

Types of Non-Return Valves

Non-return valves come in different types, each with unique features and capabilities tailored to specific applications. Some of the most common types include:

Swing Check Valves: Utilize a hinged disc mechanism to prevent backflow. Ideal for low-pressure systems.

Lift Check Valves: Employ a spring and poppet design, making them suitable for high-pressure applications.

Ball Check Valves: Use a ball to block backflow, often found in applications requiring compact and simple valve designs.

Non-Return Valves

Applications of Non-Return Valves

Non-return valves are widely used across various industries, including:

Oil and Gas: Ensuring unidirectional flow in pipelines and storage systems.

Water and Wastewater: Preventing contamination and maintaining flow direction in treatment plants and sewage systems.

Pharmaceuticals: Maintaining sterility and preventing contamination in drug production processes.

Food Industry: Ensuring hygiene and preventing backflow in food processing lines.

Non-Return Valves in the Food Industry

In the food industry, maintaining hygiene and process integrity is paramount. Non-return valves play a critical role in preventing the backflow of fluids, ensuring that production processes meet strict health and safety standards. These valves are often employed in applications such as:

Dairy Processing: Preventing cross-contamination between raw and pasteurized milk.

Beverage Production: Maintaining the purity of ingredients during blending and bottling.

Food Packaging: Ensuring unidirectional flow in filling lines to uphold product quality.

The robust construction and easy maintenance of these valves make them indispensable in food production environments.

Non-Return Valves in Pharmaceuticals

In the pharmaceutical sector, the prevention of backflow is crucial for ensuring the safe handling of sensitive and potentially hazardous materials. Non-return valves provide the following benefits:

Drug Manufacturing: Preventing liquid backflow to ensure precise ingredient proportions and maintain process consistency.

Hazardous Material Management: Avoiding gas backflow, which helps preserve material integrity and system safety.

Non-return valves are integral to maintaining compliance with stringent regulatory standards in pharmaceutical production.

Why Choose Parth Valve and Hoses LLP?

Parth Valve and Hoses LLP stands out as a leading manufacturer and supplier of high-quality non-return valves in India. Their products are known for their durability, efficiency, and ease of maintenance. Catering to both industrial and commercial needs, the company offers:

A wide variety of non-return valves suitable for diverse applications.

Timely delivery and exceptional customer service.

Solutions tailored to industry-specific requirements, ensuring optimal performance.

Conclusion

Non-return valves are vital for preventing fluid and gas backflow in various industrial applications. Their role in ensuring the safe and efficient operation of systems cannot be overstated. Industries such as food, pharmaceuticals, oil and gas, and water treatment rely heavily on these valves for maintaining process integrity.

Parth Valve and Hoses LLP, with its commitment to quality and reliability, has established itself as India’s top supplier of non-return valves. Whether for the food industry, pharmaceuticals, or other sectors, their products deliver unmatched performance and longevity, making them the preferred choice for businesses nationwide.

Visit Us- https://parthvalve.com/pressure-valve/

Email Us- [email protected]

Call At- (+91)8600034431

0 notes

Text

Hydraulic 2-Way Ball Valve Manufacturer in Delhi – Pedlock Valves

When it comes to managing the flow of liquids or gases in hydraulic systems, precision and reliability are key. Hydraulic 2-way ball valves are a crucial component in ensuring efficient control and regulation. At Pedlock Valves, we are proud to be one of Delhi’s leading manufacturers and exporters of high-quality hydraulic ball valves, tailored to meet the rigorous demands of various industries.

Why Choose Pedlock Valves for Your Hydraulic 2-Way Ball Valve Needs?

At Pedlock Valves, we specialize in designing and manufacturing top-of-the-line hydraulic 2-way ball valves that offer robust performance, longevity, and superior flow control. As a leading hydraulic ball valve manufacturer in Delhi, we use cutting-edge technology and strict quality controls to ensure that our products meet both national and international standards.

Key Features of Our Hydraulic 2-Way Ball Valves:

Precision Engineering: Our valves are engineered to the highest precision, ensuring optimal performance and durability in even the most demanding applications.

Leak-Free Design: We offer ball valves with a leak-proof design, guaranteeing complete control over the hydraulic system and preventing costly downtime or fluid loss.

Corrosion Resistance: With advanced materials and coatings, our hydraulic 2-way ball valves resist corrosion and wear, making them ideal for industries like oil and gas, chemical processing, and manufacturing.

Variety of Sizes and Configurations: We provide a wide range of sizes and valve configurations to suit the specific needs of your hydraulic system.

Applications of Hydraulic 2-Way Ball Valves

Our hydraulic 2-way ball valves are widely used in several industries, including:

Oil and Gas: For controlling flow in critical pipelines and machinery.

Chemical Processing: To manage the safe transport of chemicals and other fluids.

Water Treatment: Essential for controlling water flow in various treatment processes.

Industrial Manufacturing: Used in machinery and automated systems for flow regulation.

Why Hydraulic 2-Way Ball Valves are Essential in Hydraulic Systems

Hydraulic systems require valves that can handle high pressure and provide precise control over the flow of liquids or gases. Hydraulic 2-way ball valves are ideal for these applications, as they offer:

Quick and Accurate Operation: With just a 90-degree turn of the handle, the valve’s ball mechanism shifts to regulate flow efficiently.

Minimal Pressure Drop: The spherical ball inside the valve allows for smooth flow, minimizing pressure loss in the system.

Durability: Our valves are built to withstand high pressures and harsh environmental conditions, ensuring long-term functionality.

Pedlock Valves – Your Trusted Hydraulic Ball Valve Exporter

As an exporter, we not only serve customers across Delhi but also cater to global markets. We prioritize customer satisfaction, offering timely delivery and competitive pricing on all our hydraulic 2-way ball valves.

Conclusion

Whether you're looking to upgrade your existing hydraulic system or install new valves, Pedlock Valves is your go-to manufacturer and exporter of high-quality hydraulic 2-way ball valves in Delhi. Contact us today to learn more about our products and how we can help you optimize your hydraulic systems for maximum efficiency and reliability.

0 notes

Text

Flow Regulating Valve Manufacturer – Ensuring Precision and Efficiency in Fluid Control

Flow regulating valves play a crucial role in various industries by controlling the rate of fluid or gas flow within a system. These valves are widely used in applications such as water distribution, HVAC systems, industrial processing, oil and gas pipelines, and more. A flow regulating valve manufacturer specializes in designing and producing high-quality valves that ensure smooth and efficient operations across different industries.

What is a Flow Regulating Valve?

A flow regulating valve, also known as a flow control valve, is designed to maintain a steady flow rate regardless of pressure variations within the system. These valves help prevent system inefficiencies, reduce energy consumption, and enhance overall operational performance.

Types of Flow Regulating Valves

Leading flow regulating valve manufacturers offer a wide range of valves, including:

Pressure-Compensated Flow Control Valves – These valves maintain a constant flow rate despite pressure fluctuations.

Needle Valves – Allow precise adjustment of fluid flow using a tapered needle mechanism.

Ball Valves with Flow Regulation – Equipped with modulating features for flow adjustment.

Butterfly Valves – Used for regulating flow in large-diameter pipes.

Proportional Flow Control Valves – Provide electronic control for precise flow adjustments.

Industries Using Flow Regulating Valves

Flow regulating valves are integral to various industries due to their ability to ensure consistent and efficient fluid control. Some key sectors that rely on these valves include:

Water Treatment and Distribution: Used in water supply systems to maintain optimal flow rates.

Oil & Gas Industry: Essential for regulating flow in pipelines, refineries, and processing plants.

HVAC Systems: Help in maintaining efficient heating and cooling processes.

Chemical & Pharmaceutical Industry: Required for precise dosing and mixing of fluids.

Food & Beverage Processing: Ensures accurate flow of liquids in production lines.

Why Choose a Trusted Flow Regulating Valve Manufacturer?

1. High-Quality Standards

A reputed flow regulating valve manufacturer adheres to international quality standards like ISO, API, ASME, and CE certifications. These standards ensure that the valves meet rigorous safety and performance criteria.

2. Advanced Technology and Innovation

Manufacturers invest in research and development (R&D) to create innovative valve solutions with enhanced durability, corrosion resistance, and energy efficiency. Modern manufacturing facilities utilize computer-aided design (CAD) and CNC machining to produce high-precision valves.

3. Customization Options

Top manufacturers offer customized flow control solutions tailored to specific industrial needs. They design and engineer valves based on flow rate, pressure, material requirements, and operational conditions.

4. Cost-Effective and Durable Products

Indian manufacturers provide cost-effective solutions without compromising on quality. They use premium materials like stainless steel, brass, cast iron, and special alloys to enhance valve longevity and performance.

5. Excellent After-Sales Support

Reliable manufacturers offer technical support, maintenance services, and spare parts availability, ensuring long-term operational efficiency for customers.

Top Flow Regulating Valve Manufacturers

Some of the leading global and Indian manufacturers of flow regulating valves include:

L&T Valves – A reputed name in the valve industry, offering high-performance flow control solutions.

Forbes Marshall – Specializes in precision-engineered valves for industrial and utility applications.

Kirloskar Valves – Known for manufacturing durable and efficient regulating valves.

Emerson Valves – Offers advanced flow control technologies for critical applications.

Flowserve – A globally recognized brand providing innovative valve solutions.

How to Choose the Right Flow Regulating Valve Manufacturer?

When selecting a flow regulating valve manufacturer, consider the following factors:

✅ Industry Experience – Choose a manufacturer with a strong track record and industry expertise. ✅ Certifications & Compliance – Ensure they meet international quality and safety standards. ✅ Product Range & Customization – Check if they offer diverse valve types and custom solutions. ✅ Material Quality & Durability – High-quality materials ensure long-lasting performance. ✅ Technical Support & Service – Reliable after-sales support is essential for maintaining efficiency.

Conclusion

A flow regulating valve manufacturer plays a crucial role in ensuring efficient fluid control across various industries. With advancements in technology and a commitment to quality, leading manufacturers deliver high-performance, durable, and cost-effective valve solutions. Whether for water management, oil and gas, chemical processing, or HVAC systems, investing in premium flow control valves can significantly enhance system efficiency and reliability.

For industries looking for a trusted flow regulating valve manufacturer, partnering with an experienced and certified company guarantees long-term operational success and cost savings.

For more information, visit us: -

Stainless Steel TC Blind Manufacturer

Stainless Steel TC Hose Nipple Manufacturer

Stainless Steel Cross Manufacturer

0 notes

Text

Comprehensive Guide to Industrial Valves: Applications and Benefits

Introduction to Industrial Valves

Industrial valves are pivotal components in fluid control systems, ensuring the smooth and efficient operation of various industries. As a leading manufacturer of industrial valves, we specialize in providing high-quality solutions tailored to diverse applications. Our product portfolio includes a wide array of valves designed to meet the demanding requirements of industries such as oil and gas, water treatment, chemical processing, HVAC systems, and more. Let’s explore the types of valves manufacture and their specific applications.

Gate Valves: Reliable Flow Control

Gate valves are designed for on-off control, ensuring minimal pressure loss and uninterrupted flow. As a trusted manufacturer of gate valves, we cater to industries like water and sewage systems, oil and gas, and industrial processes. These valves are highly efficient for isolating flow and are commonly used in pipelines where full flow or no flow conditions are required.

Globe Valves: Precision in Flow Regulation

Globe valves are ideal for regulating fluid flow and are widely used in water and wastewater systems, chemical processing, oil and gas, and power plants. Our range of globe valves is engineered to provide exceptional control and durability, making them a preferred choice for applications where precision is paramount.

Non-Return Valves: Preventing Backflow

Non-return valves, also known as check valves, are essential for preventing the reverse flow of fluids. We manufacture various types, including swing check valves, non-slam check valves, dual plate check valves, wafer check valves, and lift-type non-return valves. These valves find applications in water distribution systems, pumping stations, wastewater treatment plants, fire protection systems, and HVAC systems, ensuring operational efficiency and safety.

Strainers: Protecting Equipment

Strainers play a critical role in removing debris from pipelines, safeguarding downstream equipment. We offer basket/pot-type strainers and Y-type strainers, commonly used in water systems, HVAC systems, industrial processes, marine applications, and petrochemical industries. These strainers are designed for high efficiency and longevity, minimizing maintenance costs.

Ball Valves: Versatile and Durable

Ball valves are known for their durability and versatile applications. Our product line includes single-piece, two-piece, three-piece, and three-way (L-port and T-port) ball valves. These valves are utilized in residential plumbing, oil and gas, chemical processing, water and wastewater treatment, HVAC systems, and the food and beverage industry. Their reliable sealing and ease of operation make them indispensable across multiple sectors.

Butterfly Valves: Efficient Flow Regulation

Butterfly valves are lightweight, compact, and highly efficient for flow regulation. As a leading butterfly valves manufacturer, we cater to industries such as water and wastewater treatment, HVAC systems, industrial processes, and pipelines. These valves are engineered to provide optimal performance in demanding conditions.

Pressure Reducing Valves: Enhancing System Safety

Pressure-reducing valves are crucial for maintaining safe and consistent pressure levels. Our range is widely used in water systems, gas systems, steam systems, hydraulic systems, and industrial water systems. These valves ensure the safety and efficiency of processes, making them a vital component in various industries.

Sight Glass: Visual Flow Monitoring

Sight glasses are indispensable tools for monitoring fluid flow in pipelines. They are extensively used in chemical processing, water treatment, oil and gas, power generation, and the food and beverage industry. Our sight glasses are designed to withstand high pressure and temperature conditions, ensuring durability and reliability.

Knife Edge Gate Valves: Handling Tough Media

Knife edge gate valves are specially designed to handle slurry and viscous media. These valves are highly effective in water treatment plants, mining operations, pulp and paper industries, and chemical processing facilities. Their robust construction ensures efficient operation even in challenging environments.

Specialty Valves for Unique Applications

Angle Type/Spring-Loaded Safety Relief Valves: Designed for boilers, pressure vessels, pipelines, and HVAC systems, these valves provide safety by releasing excess pressure.

Moisture Separators: Essential for steam and compressed air systems, moisture separators improve process efficiency by removing moisture.

Flush Bottom Valves: Flush bottom valves facilitate efficient cleaning and maintenance in industrial processes, making them an essential tool in reactors and storage tanks.

Blow Down Valves: Specifically designed for removing impurities from boilers and pressure vessels, blow down valves ensure optimal performance and safety.

Precision Control with Needle and Piston Valves

Needle valves and piston valves offer precise control over fluid flow in critical applications. Needle valves are commonly used in laboratories, hydraulic systems, fuel systems, and aerospace industries, while piston valves are preferred in hydraulic and pneumatic systems, chemical processing, and water treatment. Our advanced manufacturing techniques ensure these valves meet the highest performance standards.

Steam Traps and Advanced Control Valves

Steam traps thermodynamic variants, are integral to heating systems, steam boilers, sterilizers, and autoclaves. We also manufacture 2-3 way motorized, cylinder, and pneumatic control valves, offering precision and automation for modern industrial needs. These valves enhance process efficiency while reducing energy consumption.

Advanced Check Valves for Reliable Performance

Swing Check Valves: Widely used in preventing backflow in water distribution and industrial processes.

Non-Slam Check Valves: Ideal for pumping stations and HVAC systems, ensuring quiet and reliable operation.

Dual Plate Check Valves: Designed for compact spaces, these valves are used in water treatment plants and power generation.

Wafer Check Valves: Lightweight and easy to install, these valves are suitable for chemical, pharmaceutical, and HVAC applications.

Lift Type Non-Return Valves: Commonly used in preventing backflow in high-pressure systems, ensuring system integrity.

Diverse Ball Valve Solutions

Single Piece Ball Valves: Suitable for residential plumbing and industrial processes.

Two Piece Ball Valves: Offering easy maintenance, these valves are ideal for water and wastewater treatment.

Three Piece Ball Valves: Used in demanding applications such as oil and gas and chemical processing.

Three Way Ball Valves: Providing multiple flow configurations, these valves are essential in complex fluid control systems.

Conclusion: Excellence in Valve Manufacturing

As a premier industrial valves manufacturer, we pride ourselves on delivering products that combine quality, innovation, and performance. Our comprehensive range of valves, from gate and globe valves to specialty solutions, is designed to meet the diverse needs of industries worldwide. By choosing our valves, you are investing in reliability, efficiency, and superior craftsmanship.

0 notes

Text

Why is Ball Valve Essential for Automobiles? Check Reasons!

A ball valve is durable, easy to operate, and requires minimal maintenance for precise control over fluid flow and is ideal for critical automobile functions. These valves come with a robust design to handle high-pressure and temperature variations, ensuring optimal performance of some systems including fuel lines, cooling systems, and hydraulics of a car.

Similarly, a check valve, often used alongside ball valves, ensures unidirectional fluid flow to prevent backflow and save sensitive systems from the risks of operational and structural damage.

In challenging and high-pressure applications, they are essential for maintaining system integrity, regulating fluid flow, and guaranteeing safety. Purchasing valves from reputable suppliers ensures long-term value and maximum system performance.

Advantages of Essential Ball and Check Valves from Renowned Manufacturers

Businesses should buy essential valves from renowned manufacturers to ensure reliability and efficiency, precise fluid control, prevent backflow, motion control, fluid power applications, and withstand high-pressure conditions.

These valves are essential to many industries, including water treatment, chemical processing, oil and gas, and pharmaceuticals to improve safety and customer experience with cutting-edge technologies like remote factory acceptance tests and mixed reality training.

Renowned manufacturers adhere to strict quality standards, ensuring durability and consistent performance to maintain global quality. Locally engineered and tested valves meet the specific demands of industries like defence, mining, construction, and power generation.

These experts have expertise in fluid technology, combined with bespoke design and predictive maintenance solutions, to ensure that their valves deliver superior functionality. Additionally, they support industries with services like on-site audits, engineering advice, and technical training.

Find a Trusted Manufacturer of Essential Machinery Parts

Finding a trusted manufacturer of essential machinery parts requires thorough research and consideration.

Evaluate the manufacturer’s experience and reputation in the industry. Check whether they are certified and authorised by authorised bodies which indicates adherence to high-quality standards.

Check if the manufacturer offers customized solutions to meet specific needs and provides services like engineering support, on-site audits, and technical training.

Ensure they have expertise in the required industry and a proven track record of delivering reliable products and after-sales support.

Consider manufacturers that integrate advanced technologies like predictive maintenance or remote testing, as these innovations enhance efficiency and safety.

Finally, select a manufacturer known for precision, durability, and comprehensive support.

Source

0 notes

Text

FRP Blower Supplier in Chandigarh

Sunfiber is a Manufacturer and Supplier of FRP Blower in Chandigarh, India. Our Manufacturing Unit is in Ahmedabad, Gujarat, India An FRP blower is an air-moving device made from fiberglass reinforced plastic. The blower’s fiberglass construction gives it superior corrosion resistance, making it an ideal solution for industries that deal with aggressive chemicals, high temperatures, or corrosive environments. Industries widely use FRP blowers in applications such as ventilation, exhaust, and cooling systems due to their durability and long-lasting performance. Features of Our PTFE Lined Ball Valves: High-quality PTFE lining for superior corrosion resistance Durable ball design for reliable performance Precision-engineered components for optimal functionality Variety of sizes and configurations to meet specific needs Compliance with industry standards and regulations Applications of FRP Blowers: Ventilation in chemical processing plants Exhaust and air supply in textile mills Cooling systems in industrial plants Air handling in power plants Exhaust and ventilation in pharmaceutical plants What is an FRP blower? An FRP blower is made of fiberglass reinforced plastic, offering superior corrosion resistance and durability for industrial applications. Why should I choose FRP blowers? FRP blowers are corrosion-resistant, energy-efficient, and lightweight, making them ideal for industries dealing with harsh chemicals or high-temperature environments. Can FRP blowers be customized? Yes, we can customize FRP blowers based on your airflow requirements, pressure ratings, and specific industrial needs. Sunfiber is a FRP Blower Supplier in Chandigarh, India Including Raipur, Bilaspur, Kanker, Raigarh, Rajnandgaon, Bemetara, Baikunthpur, Ambikapur, Jagdalpur, Chirimiri, Kondagaon, Manendragarh, Bhatapara, Baloda Bazar, Sakti, Takhatpur, Ambagarh Chowki, Sarangarh, Khairagarh, Dharamjaigarh, Bilha, Arang, Simga, Katghora, Saraipali, Bijapur, Kharsia, Pandariya, Pithora, Kurud, Pathalgaon, Akaltara, Ramanujganj, Bagbahara, Gharghoda, Jashpur Nagar, Bishrampur, Mahasamund, Mungeli, Korba, Dhamtari. For detailed information or inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Akaltara#AmbagarhChowki#Ambikapur#Arang#Bagbahara#Baikunthpur#BalodaBazar#Bemetara#Bhatapara#Bijapur#Bilaspur#Bilha#Bishrampur#Chirimiri#Dhamtari#Dharamjaigarh#FRPBlowerSupplierinChandigarh#FRPBlowerSupplierinGujarat#FRPBlowerSupplierinIndia#Gharghoda#Jagdalpur#JashpurNagar#Kanker#Katghora#Khairagarh#Kharsia#Kondagaon#Korba#Kurud#Mahasamund

0 notes

Text

CREATING A STRONG MEDICAL GAS SPECIFICATION

WHAT IS A MEDICAL GAS SPECIFICATION?

A Medical Gas Specification is a document issued by Plumbing Designers that serves to define the parameters of the materials and equipment to be installed in a facility during a construction project. This document ensures compliance with local codes and must be updated and revised for each project, including technology and code changes depending on the location.

There are many benefits of having a strong specification, including making reviewing submittals easier and reducing change orders. Another advantage is that they ensure the owner/end-user have the products that meet their expectations and align with their comfortability. Having a strong specification also results in less RFIs from the contractor, by ensuring drawings and specification complement one another. They aid in understanding the equipment options to allow the owner strong value engineering options.

PRODUCT SECTION: ACCEPTED MANUFACTURERS When thinking about accepted manufacturers, there are some common mistakes that are made. Many of these errors come from the way that they are listed, including listing manufacturer representatives and not the manufacturer themselves. Another is listing industrial manufacturers when they have the potential to provide systems that are not compliant with NFPA 99. Including manufacturers of raw materials instead of complete systems is another common mistake.

PRODUCT SECTION: MATERIALS

Outlets

Pattons Medical gas outlets are designed for gas distribution in centralized areas of several industries and are available in four styles. This information can also be found on the Pattons Medical website.

Pin Index – This means you have two pins that your secondary equipment lines up with to plug. The bottom pin moves to make it gas specific. Ohmeda Diamond Series – Diamond 1, 2, 3 and DiamondCare (proprietary of BeaconMedaes) Latch Valve Style – This is where you have two latches that you push down on which opens the teeth that are gas specific. Chemetron – Series 400, 500

DISS – The threads in this category will be different depending on the gas specific. Threaded Geometric – You will have a different shape depending on the gas. Puritan Bennett

Zone Valve Boxes

There are several standards to follow when implementing zone valve boxes. This includes material, pressure rating, and ball valve type. In addition to this, gauges are required and you must have cover requirements listed. Information about medical zone valve box specifications can be found on the Pattons Medical website.

Zone Valve Box with Sensor Provisions Some benefits of this option are that there is ease of certification because the sensor location can be confirmed without needed ceiling access. Also, each gas has a DISS demand check that the sensor is installed on to ensure the gas in correctly identified. Another advantage is that this particular one does not need to be project specific; it can be standard. Zone Valve/Area Alarm Combination A benefit of this is specifically for very small facilities, where the zone valve is close to the nursing station so the area alarm can be monitored.

Manifolds Standards for manifolds include following location and installation requirements as well as header requirements. It is important to follow automatic changeovers. You can find more information on the Pattons Medical website by viewing our “Overview of Medical Gas Manifolds” webinar or by navigating to our manifold specifications.

Bulk – usually provided by owner or a contract with the owner Liquid by Liquid This particular option is equipped with electronic controls to reduce venting and is also equipped with a “look-back” control to ensure the liquid container is fully utilized. High Pressure by High Pressure This option utilizes dome biased regulators. It reduces the need for all gases. Another thing to note is that it does not allow shuttle valves which are a single point of failure.

Alarm Panels

For alarm panels, the standards are found within the wiring and programming requirements. Pattons Medical has many resources regarding alarm panels, including specification information and a webinar entitled "Overview of Medical Gas Alarms and Zone Valve Box Placement."

Ethernet for Master and/or Area Alarm Panels A benefit of this is connecting to a building management system. However, it’s important to consider: does the owner want every alarm panel connected or only the master? Ethernet capability adds cost to every panel and most value engineering practices remove Ethernet from the area. If the facility wants to keep an eye on their source equipment, then the master alarm panel should be ethernet capable. On the area alarms, the facility will not need this, which will reduce unnecessary costs.

OVERVIEW

Overall, it is important to update your specification as it aligns with your project. Remember to clean up your approved manufacturers list, delete sections that are not relevant to the project that the specification applies to, and make choices that are needed for technologies. Pattons Medical specification makes that easy by putting choices in red or blue.

You can find the Pattons Medical specification guide on our website.

0 notes

Text

Valve components forging

Valve Components Forging, Size From 1/2" To 48",Including Valve Body, Adaptor, Stem, Seat, Ball Etc.

ACE Valve located in Yancheng, Jiangsu Province is a customer-centric manufacturer of professional valve components used in oil and gas, chemical power generation, and mining. water treatment and general industrial systems. our main products are valve bodies. closures, seat rings bonnets, trunnion plates, stems, top flanges, and other accessories. our facilities allow us to manufacture valve assemblies from 1/2-56"it has a group of dedicated and professional staff with ten years of experience in the production line, factory management, and quality control marketing. etc. We are equipped with more than 50 sets of advanced processing equipment including CNC machine tools, and CNC machining centers. lathes, etc., and testing equipment.

E-mail [email protected]

Mobile / Whatsapp / Wechat: +86 - 15722580267

Address No. 1 Shenfeng Rd. Dafeng Economic Zone, Jiangsu, P.R.China.

0 notes

Text

Top Ball Valves Manufacturers in Pune

Pune, Maharashtra’s industrial hub, is home to top manufacturers in many industries. One of the most trusted names in the industry is Parth Valves and Hoses LLP. Parth Valves, known for their quality and innovation, manufactures and services a comprehensive range of Ball Valves for various industrial needs.

What Are Ball Valves?

Industries that need precise liquid and gas control use ball valves. Quarter-turn valves control material flow via a hollow, perforated, revolving ball. Oil and gas, medicines, water treatment, and manufacturing employ ball valves for their effective sealing.

Ball valves are indispensable for many applications due to their great pressure and temperature tolerance.

Ball Valves

Why Ball Valves Manufacturing Is Popular in Pune

Pune’s industrial ecosystem, facilities, and qualified people make it suitable for ball valve manufacture. The city’s manufacturers value innovation, quality, and durability.

Parth Valves and Hoses LLP, a Pune-based ball valve manufacturer, sets standards with their cutting-edge facilities and customer service. They have years of experience making durable, high-performance ball valves for many sectors.

Ball Valves Trusted Name Parth Valves and Hoses LLP

1. Wide Selection of Ball Valves Parth Valves offers a wide range of ball valves for various industrial applications. There are standard ball valves and sophisticated high-performance models:

Two- and three-piece ball valves are modular and easy to maintain. Flanged Ball Valves: High-pressure friendly. Full-Port and Reduced-Port Ball Valves: Flexible flow control for various applications.

Uncompromising Quality Parth Valves manufactures with quality in mind. Each valve is rigorously tested to meet ISO, ASTM, and ASME standards. Their ball valves work reliably in the harshest situations due to their thorough approach.3. Unique Needs Customization Since every sector has unique needs, Parth Valves excels in tailored solutions. Their professionals work with clients to design and build ball valves to exact specifications for optimal efficiency and lifetime.4. Innovation Focus Innovation also distinguishes Parth Valves. Their valve development team uses cutting-edge technology to improve performance and durability.Applications of Ball Valves Parth Valves ball valves are versatile and appropriate for many applications:Oil and Gas: Pipeline high-pressure fluid and gas management. Pharmaceutical Industry: Hygienic flow regulation in delicate situations. Purification plant water flow regulation. Manufacturing Units: Supporting production line efficiency.

Why Choose Parth Valves and Hoses LLP for Ball Valves?

Ball valve manufacturers should be chosen based on quality, reliability, and customer service. Parth Valves and Hoses LLP excels in these areas:

Their engineers and technicians have decades of experience and provide unmatched expertise. Timely Delivery: They deliver on time to keep projects on track. They offer high-quality valves at competitive prices.

Improvement in Ball Valves Manufacturing

Parth Valves and Hoses LLP provides precision, dependability, and durability in ball valves for industries. Their dedication to quality has made them Pune’s top ball valve producers.

Contact Parth Valves Now

Contact Parth Valves and Hoses LLP for durable ball valves. Industries in Pune and beyond choose them for their experience and customer-first approach.

With Parth Valves, you’re buying a heritage of quality that guarantees your industrial operations run smoothly. Enjoy the greatest ball valves with Parth Valves and Hoses LLP.

Website- https://parthvalve.com/

Email id – [email protected]

Call On- (+91)8600034431

0 notes

Text

Starmax Pipes: Leading UPVC Ball Valves Manufacturers in India

When it comes to choosing the right valves for industrial, commercial, or residential applications, the quality, durability, and functionality of the product are paramount. Among the wide range of options available, UPVC ball valves stand out for their exceptional performance, ease of use, and cost-effectiveness. As one of the leading UPVC ball valves manufacturers in India, Starmax Pipes offers top-of-the-line solutions for various fluid control needs, ensuring reliability and efficiency across different industries.

What Are UPVC Ball Valves?

UPVC (Unplasticized Polyvinyl Chloride) ball valves are a critical component in many fluid systems, designed to control the flow of liquids or gases. These valves are highly durable, resistant to corrosion, and ideal for systems that require high resistance to pressure and temperature. UPVC ball valves consist of a spherical mechanism that rotates to either block or allow fluid flow, making them highly versatile in applications such as plumbing, irrigation, chemicals, and other industrial systems.

Why Choose Starmax Pipes for UPVC Ball Valves?

As one of the best UPVC ball valves manufacturers in India, Starmax Pipes has built a reputation for delivering products that meet the highest standards of quality and performance. With a strong emphasis on precision engineering and quality control, Starmax Pipes ensures that each valve is manufactured with the utmost care, using high-grade materials and the latest technology. Here's why Starmax Pipes should be your first choice when looking for UPVC ball valves:

1. Exceptional Quality

At Starmax Pipes, quality is a top priority. The best UPVC ball valves manufactured by the company are built to last, offering long-term performance even in the most demanding environments. The valves are made from premium-quality UPVC material that is resistant to corrosion, rust, and chemicals, ensuring that they can withstand harsh conditions. This durability translates to fewer maintenance requirements and longer service life, providing excellent value for money.

2. Wide Range of Sizes and Specifications

Every fluid control system is unique, which is why Starmax Pipes offers a wide range of UPVC ball valves in various sizes and specifications. Whether you need a valve for small-scale residential applications or a robust solution for large industrial systems, you can trust Starmax Pipes to have the perfect fit. The company provides a diverse selection, including different pressure ratings and sizes, making it easy to find a valve that meets your specific requirements.

3. Innovative Technology and Manufacturing Process

With a focus on innovation, Starmax Pipes employs the latest manufacturing technologies to create superior UPVC ball valves. The state-of-the-art production process ensures that each valve meets international standards of quality and reliability. From design to final production, the company uses advanced machinery and techniques to guarantee precision, durability, and optimal performance. This commitment to innovation allows Starmax Pipes to remain at the forefront of the UPVC ball valve manufacturing industry in India.

4. Affordable Pricing

Despite offering some of the best UPVC ball valves in the market, Starmax Pipes remains committed to providing cost-effective solutions. The company understands the importance of budget-conscious purchasing decisions, particularly for large-scale projects. By maintaining efficient manufacturing practices and sourcing high-quality materials at competitive prices, Starmax Pipes ensures that their UPVC ball valves provide excellent value for money.

5. Customization Options

Not all applications are the same, which is why Starmax Pipes offers customizable UPVC ball valves to suit specific needs. Whether it's adjusting the valve size, design, or pressure rating, Starmax Pipes works closely with clients to deliver tailored solutions. This flexibility ensures that you get the best possible valve for your unique requirements.

6. Reliable Customer Support

When you purchase UPVC ball valves from Starmax Pipes, you’re not just buying a product; you’re gaining a reliable partner. The company is known for its exceptional customer service, offering technical support, product guidance, and after-sales assistance. Whether you need help selecting the right valve or require assistance with installation, the experienced team at Starmax Pipes is always ready to help.

Applications of UPVC Ball Valves

UPVC ball valves are used across a wide range of industries due to their versatility and reliable performance. Here are some common applications:

1. Plumbing Systems

In residential and commercial plumbing, UPVC ball valves are used to regulate water flow and prevent backflow. Their resistance to corrosion and ease of operation make them ideal for this purpose. The ball valve design allows for quick on/off control, ensuring efficient water flow management.

2. Irrigation Systems

For agricultural applications, Starmax Pipes' UPVC ball valves are frequently used in irrigation systems. These valves help control the flow of water to ensure that crops receive the appropriate amount of moisture. The durability of the valves ensures long-term use in harsh environmental conditions.

3. Chemical and Pharmaceutical Industries

The chemical and pharmaceutical industries require reliable, corrosion-resistant valves to handle various fluids, including acids, solvents, and other chemicals. UPVC ball valves from Starmax Pipes provide excellent resistance to a wide range of chemicals, making them an ideal choice for these industries.

4. Water Treatment Plants

Water treatment facilities often rely on UPVC ball valves for regulating the flow of water through various treatment stages. These valves are durable enough to handle high-pressure conditions and are resistant to the chemicals used in the treatment process.

5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, UPVC ball valves help manage the flow of water or air throughout the system. Their reliable operation ensures that the HVAC systems work efficiently, maintaining optimal performance and temperature control.

Key Features of Starmax Pipes' UPVC Ball Valves

The UPVC ball valves manufactured by Starmax Pipes come with a range of features designed to enhance performance, longevity, and ease of use. Here are some of the standout features:

1. Corrosion and Chemical Resistance

UPVC is naturally resistant to corrosion, which makes Starmax Pipes' valves ideal for use in corrosive environments. These valves can withstand a wide range of chemicals, ensuring longevity and consistent performance even in harsh conditions.

2. Leak-Proof Design

The valves are designed to be leak-proof, ensuring that they provide a secure seal and prevent any unwanted fluid leakage. This makes them highly reliable for both low and high-pressure applications.

3. Easy Installation and Operation

The design of UPVC ball valves ensures quick installation and simple operation. Whether it's for a plumbing system or an industrial application, the valves are user-friendly, reducing the time and cost associated with installation.

4. Temperature and Pressure Resistance

Starmax Pipes’ UPVC ball valves are engineered to handle a wide range of temperatures and pressures. They provide consistent performance under high-pressure conditions, making them suitable for use in both residential and industrial systems.

Conclusion: Why Starmax Pipes is Your Go-To UPVC Ball Valve Manufacturer

When you need reliable, durable, and high-performance UPVC ball valves, Starmax Pipes stands out as the leading choice among UPVC ball valve manufacturers in India. With their exceptional quality, diverse product range, and commitment to customer satisfaction, Starmax Pipes continues to deliver the best UPVC ball valves for various applications. Whether you’re looking for valves for a residential plumbing system, an irrigation project, or an industrial setup, you can trust Starmax Pipes to meet your needs with top-quality solutions.

0 notes