#linearguideways

Explore tagged Tumblr posts

Text

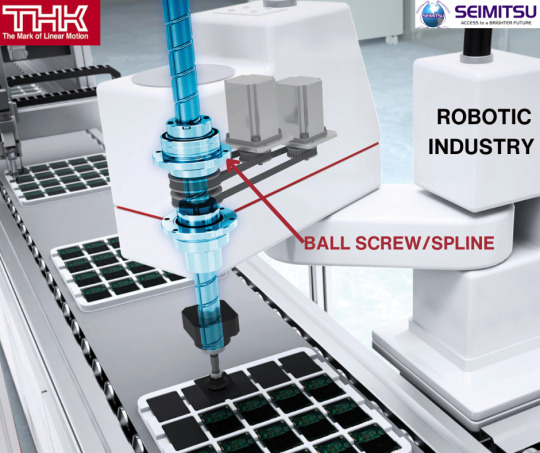

THK Ball Screw | Seimitsu Factory Automation

#MachineTools#PrecisionEngineering#BallScrews#linearguideways#SEIMITSU#linearmotion#thkdistributor#THK

0 notes

Text

#avoidplastics #FollowTrafficRules #ourbestqualityproduct #ontimematerialdispatch #bestproducts #goodwillenginnering #DrugFreeSociety #LinearGuideways

A linear guide is a machine element that utilizes bearings, which were developed for rotary motion, in order to move heavy objects easily in a straight line. It is referred to as a “recirculating linear ball bearing” by ISO and JIS, and “linear guideway” by the Japan Machine Tool Builders' Association.

#avoidplastics#FollowTrafficRules#ourbestqualityproduct#ontimematerialdispatch#bestproducts#goodwillenginnering#DrugFreeSociety#LinearGuideways#A linear guide is a machine element that utilizes bearings#which were developed for rotary motion#in order to move heavy objects easily in a straight line. It is referred to as a “recirculating linear ball bearing” by ISO and JIS#and “linear guideway” by the Japan Machine Tool Builders' Association.

0 notes

Text

Linear Motion Blocks

Linear Motion Blocks from Tallman Robotics Limited SNTC/SNW Linear Motion Blocks. 1. The slider and guide rail are made of stainless steel and carbon steel respectively. Including sliders, rails, and other metal accessories such as steel balls, retainers, etc., all made of stainless steel material with anti rust properties. 2. Adopting a Gothic four point contact design. Capable of withstanding loads in all directions, with strong rigidity and high accuracy. 3. Rolling cycle system. Sliders, rails, steel balls, retainers 4. Reserve oil injection holes on the cover side to inject oil or grease into the interior of the slider for lubrication. 5. Product specifications, models, and characteristics of interchangeability and non interchangeability Two types of linear slide rails, non interchangeable and interchangeable, have the same specifications and dimensions. The difference is that interchangeable slide rails can be used interchangeably for single shipments, which is more convenient. However, their combination accuracy cannot meet the customized accuracy requirements of non interchangeable slide rails However, SNT has good size control and strict quality requirements in manufacturing, and interchangeability can also meet the needs.

Linear motion blocks are a type of mechanical component used in engineering and construction projects. They are commonly used in systems that require straight and precise movement, such as conveyor belts, robotic arms, and sliding doors. Linear motion blocks consist of a stationary base and a moving carriage. The carriage is mounted on ball bearings or rollers, allowing it to slide smoothly along the base. The motion can be controlled manually or automated using motors and control systems. These blocks are typically made from durable materials such as steel or aluminum to withstand heavy loads and ensure long-lasting performance. They are designed with precision to minimize friction and increase efficiency. Linear motion blocks are available in various sizes and load capacities, allowing engineers to select the appropriate block for their specific application. They can be easily integrated into existing systems or used as a standalone component. their use in industrial settings, linear motion are also common in DIY projects, such as building CNC machines or 3D printers. Their versatility and ease of use make them a popular choice for both professional engineers and hobbyists. Overall, linear motion blocks play a crucial role in creating smooth and controlled linear movement in a wide range applications. They provide a reliable and efficient solution for achieving precise motion in diverse engineering projects. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearBearingLinearBearingBlocks#Linearguiderailsandlinearblocks#LinearGuides#LinearGuideways#LinearMotionBlocks#LinearMotionGuideBlocks#LinearMotionGuides&Blocks#LinearMotionSlideBlocks#StandardLinearMotionBlock

0 notes

Text

THK LM Guide Supplier in India | Seimitsu

The THK Linear Guideway (Linear Motion) is a highly advanced system that enables linear motion through the integration of rolling components between a rail and a block. This system is capable of creating high-precision, energy-efficient, high-rigidity, and high-speed machines with extended lifespans, and is used in a variety of industries, used in Machine Tools, Semiconductor and LCD Manufacturing equipment, Industrial Robots, Automobile Industry, Aerospace, Medical, and Assistive industries, among many others.

# # # # #slideguide #cagedballllmguide #cagedrollerlmguide #fullrollerlmguide #lmguidefullballtype #rail #block # # #industrialautomation #factoryautomation #distributor #supplier # # #india #linearmotionguideways #linearmotionguide #linearmotionguiderail #typesoflinearmotionguideways #maintenance

#linearguideways#linearguides#lmguides#linearmotion#seimitsufactoryautomation#seimitsu#channelpartner#pune

0 notes

Text

THK is known for its commitment to innovation and continuous improvement in motion control technology. THK Ball Screw/Spline are components used for motion in a rotational system. Applied in automotive systems, such as steering columns, to achieve controlled linear movement.

To Know More Visit: https://www.seimitsu.in/THK-Linear-Motion-Ball-Screw-Precision-Ball-Screw-Spline.html

Drop us an email at [email protected]

Contact: +91 9028121211

#thk#LinearGuideways#ballscrew#ballspline#camfollower#rollerfollower#crossrollerring#Linearbushing#rotationalsystems#seimitsu

0 notes

Text

THK is known for manufacturing Linear Guideways, Ball screws, LM Guide Actuators, Cross Roller Ring, Cam Followers, Linear Bushing, and other industrial products. THK Cross Roller Ring is a rotary roller with high rotation accuracy. They are known for their integration in robotic joints with difficult motion and load requirements. THK Cross Roller Rings are available in various models such as:

-Model RU: It consists of inner and outer rings, with mounting holes on both rings which enables stable and accurate rotation.

-Model RB: The outer ring is separable while the inner ring is integrated with the main body.

-Model RE: It is used where the outer ring requires high rotation accuracy.

-Model RA: It is a compact model with thin outer and inner rings with a lightweight design structure.

To Know More Visit: https://www.seimitsu.in/THK-rotation-Cross-Roller-Ring-Cross-Roller-Ring-Inner-Ring-Rotation-Outer-Ring-Rotation-Model-RU.html

Email us at [email protected]

Contact us:+91 9028121211

#Thk#LinearGuideways#ballscrew#lmguideactuator#crossrollerrings#camfollowers#Linearbushing#accuracy#Rotationalmotion#suppliers#seimitsufactoryautomation

0 notes

Text

THK LM Guide SRS uses in Semiconductor Industry | SEIMITSU Factory Automation Pvt. Ltd.

The semiconductor and LCD panel manufacturing equipment is essential for the production of all kinds of electric and electronic appliances, including PCs, cell phones and flat-panel televisions. THK’s products can meet the high technology need for fine movement control.

Applications: LCD Panel Prober Table Units, Glass Substrate Conveyor Equipment, IC dicing saws

Following Linear Guideways are using for above applications:

1. SRS LM Guide: The SRS LM Guide is a miniature type with a compact structure. Part of the LM Block is made of resin to reduce weight. Also, the ball cages eliminate the friction between ball cages and retains lubricants, thus achieving low dust generation.

2. RSX/RSX-M1: The RSX LM Guide is a two-row gothic arch groove structure, compact, can take loads in any direction and can be used in a single axis where space is required or where moments act.

Here in India SEIMITSU Factory Automation Pvt. Ltd. is an authorized distributor of THK Linear Motion System and we have 12 branch offices as well across India such as Mumbai, Surat, Ahmedabad, Vadodara, Delhi, Faridabad, Ghaziabad, Hyderabad, Chennai, Coimbatore, Bangalore, Pune (Head Office).

Thank you for your valuable attention and please write us at Contact Person Email Id: [email protected]

Click here to download catalogue: https://www.seimitsu.in/pdf/E_01_LMGuide.pdf

#seimitsu#seimitsufactoryautomationpvtltd#lmguidesrs#lmguide#linearguideways#lmblock#semiconductorindustry#distributor#thklinearmotionsystem

0 notes

Text

THK LM Guide Models HCR, HSR-M1 & HSR-M1VV use in Satellite for Planetary Observation | SEIMITSU Factory Automation Pvt. Ltd.

THK LM Guide Model HCR, HSR-M1 and HSR-M1VV uses in Satellite for the application of Planetary Observation.

This is observatory’s telescope that moves very slowly to observe the stars of the night sky. Vibration-Free, smoothly moving linear guidance systems move quietly as they support the telescope and observatories dome.

LM Guide Mode HCR: The HCR LM Guide allows clearance-free, highly accurate circular motion as opposed to sliding guides or cam followers. You can easily assemble this model by simply mounting the LM Rail and LM block with rail. It allows circular motion of 5 m or greater. Which is impossible for swivel bearings.

LM Guide Model HSR-M1: The HSR-M1 high temperature type LM Guide is capable of being used at the service temperature of up to 150° C thanks to THK’s unique technologies in material, heat treatment and lubrication. The use of stainless steel in end plates and high temperature rubber in end seals achieves the maximum service temperature.

LM Guide Model HSR-M1VV: The HSR-M1VV LM Guide for medium to low vacuum is highly effective in a broad range of environments ranging from atmospheric pressure to vacuum (10-3 pa). A newly developed dedicated labyrinth end seal and special grease help to ensure stable rolling resistance.

Here in India, SEIMITSU Factory Automation Pvt. Ltd. is an authorized distributor of THK and for getting detailed technical information or selection parameters about THK Linear Guideways please do contact us.

Reference link: https://www.seimitsu.in/THK-Linear-Motion-LM-Guide-Full-Ball-Type-LM-Guide.html

Click here to download technical catalogues: https://www.seimitsu.in/pdf/E_01_LMGuide.pdf

For more details contact us: +91 9975185459

Concern Person Email Id: [email protected]

#seimitsu#seimitsufactoryautomationpvtltd#distributor#lmguide#linearguideways#lmrail#lmblock#rail#block#satellite#planetary#telescope

0 notes

Link

Today we have come up with how to navigate yourself for finding THK Products information and its readily available enclosed PDF on our Website.

This Video make your work more ease to find each product category along with its various types and technical specification sheet.

The Purpose of uploading this video is to reaching us and resolve their queries related to products enquiries, sales support and visit if possible.

In this Video THK Linear Motion products are our main focus, various products come under linear motion including Linear Guideways, Ball Screw, Ball Spline, LM Actuator, Cam Follower, Roller Follower, Linear Guide and Cross Roller Bearings and many more.

SEIMITSU Factory Automation Pvt. Ltd. is an authorized distributor of THK Linear Motion, we have 12 branch offices across India including Pune (Head), Mumbai, Surat, Hyderabad, Chennai, Coimbatore, Vadodara, Ahmedabad, Bangalore, Faridabad and Gurgaon.

For more update, please visit us: we have social media channels as well like LinkedIn, Facebook, Twitter and YouTube.

Our Web Address: https://www.seimitsu.in/index.html

LinkedIn Address: https://www.linkedin.com/company/14418636

Facebook Address: https://www.facebook.com/SEIMITSUFACTORYAUTOMATION/

Twitter: https://twitter.com/sfapvtltd

YouTube: https://www.youtube.com/channel/UCesujalxCEJ4_Kh10L4rWfw

We will come with more video to make your work very easy.

For meanwhile Subscribe our Channels for more updates.

#seimitsu#seimitsufactory#thkproducts#distributor#lmguide#linearguideways#ballscrew#ballspline#lmguideactuator#actuator#crossrollerbearing#supplier#linkedin#youtube#facebook#twitter

1 note

·

View note

Link

We have explained in the attached PDF how THK Products provide high performance in unusual operating environments and fulfil the industrial application demand.

Please visit us: https://www.seimitsu.in/thk-linear-motion-system-distributor-india.html

SEIMITSU Factory Automation Pvt. Ltd. is an authorized distributor of THK Linear Motion System.

Email Us for more information: [email protected]

Contact us: +91 9975185459

Web Address: https://www.seimitsu.in/index.html

#seimitsu#seimitsufactoryautomationpvtltd#distributor#lmguide#linearmotion#linearmotionguidewaymanufacturer#linearguideways#ballscrew#ballspline#crossrollerring#crossrollerbearing#thklinearmotion#thklinearmotionguide#thklinearbearings#thkditributorinindia#linearrail#linearblock#medical#aerospace

0 notes

Link

THK Full Roller LM Guide Model HRX meets the demand of heavy industrial application like Machine Tool, evenly in very harsh situation because Roller linear guide rail has interchangeable property which uses rollers as rolling element which is placed at 45 degrees and the rated load applied to the LM block are uniform in four directions which enable LM Guide to be used in all orientation for achieving high rigidity.

Apart from Model HRX Roller LM Guide THK Linear Motion system designed and manufactured various products such as Ball Screw, Ball Spline, Linear Guide Actuator, Cross Roller Bearing, Cam Follower, Roller Follower, Link Ball, Linear Bushing, Spline Nut, Rod End Cross Roller Guide, and Lead Nut.

SEIMITSU Factory Automation Pvt. Ltd. is an authorized distributor of THK Linear Motion System.

Please click here to download catalogue: https://www.seimitsu.in/pdf/426e_HRX%20catalogue.pdf

Reference link: https://www.seimitsu.in/THK-HRX-FULL-ROLLER-LM-GUIDE.html

#fullrollerlmguidehrx#rollertypelmguidehrx#lmguidemodelhrx#4wayequalloadrollertype#thkrollerlmguideformachinetool#rollerlinearguiderail#ultrahighrigidity#ultrahighloads#lmguideforultrahighrigidity#globalstandardrollerguidehrx#thkhrx#thkfullrollerlmguide#linearmotion#rollerlmguideways#linearguideways#rollerbearing#lmblock#lmrail#linearblock#linearrail#rollertypelinearmotion#rollingguides#linearmotionguide#slideguide#cagedrollerlmguide#rollerrailguides#seimitsu#seimitsufactoryautomation#distributor#supplier

0 notes

Link

Public passenger transport and freight transport by rail are two important components in achieving the ecological goals of society. Applications in rail traffic for which linear technology products from THK provide solutions for - from train manufacturing over railway interiors to maintenance including Automatic opening and closing gate, Boggi, Seat handle, and many more. Here we have shown you a small glimpse of Railway interior wherein all Products are using.

Our Team always believes to work into preciseness, by giving sales support 24/7, main objective to fulfill customer needs by providing a solution within clock around.

Please download catalogue from here: https://www.seimitsu.in/pdf/E_01_LMGuide.pdf

SEIMITSU Factory Automation Pvt. Ltd. is an authorized distributor of THK India.

#lmguide#linearmotion#linearguide#linearguides#linearguidewayrail#linearguideways#linearguiderailsystem#linearguidewaybearing#linearmotionguideways#linearguideroller#linearnearme#linearguidesrail#linearguideway#linearguidewayblock#linearguidesystem#linearguideraildealers#typesoflinearguideways#linearguidewaysthk#linearguiderailprice#linearguidesandrail#linearguideballscrew#linearguiderailindia#linearguiderailtypes#guidelinear#linearguiderailheavyduty#linearguidetypes#linearGuideindia#linearguiderailsdealersinIndia#LinearGuidewayssupplierinChennai#linearguiderailgrease

0 notes

Text

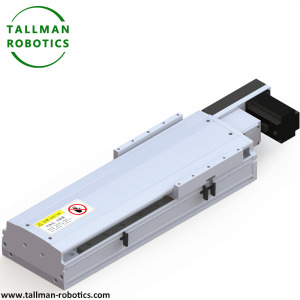

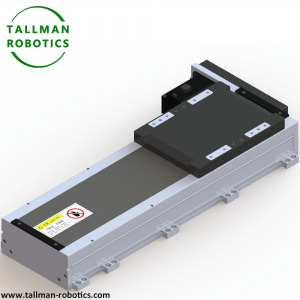

Modular Electric Slides

Modular Electric Slides You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Modular Electric Slides, also can be named as High Precision Linear Modules, Linear Motion Module, Industrial Linear Motion, Linear Actuator Bundle, etc in this industrial automation. Tallman Robotics’s Modular Electric Slides type TM220 with body with by 220mm have 4 series. These Linear slides have 0 mm to 3500 mm stroke, and 8kgs up to 150kgs input payload. TM Modular Electric Slides can be integrated with many brand motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in extruded super quality AL frame system to ensure requirement of precision and common projects. Precision, Stroke, lead, Brake and no Brake can be selected depending on your specific details. TM by Tallman Robotics, which is located in Shenzhen, has strong ability in design and engineering experience. We have exported all kinds of Modular Electric Slides such as screw driven modules, belt driven modules, and also ,also there are semi sealed type and fully sealed type for common and dust free applications. Our Modular Electric Slides perform all kinds of application such as: Winding Machine by eliminating the clearance of the traverse axis Circuit Board Mounting with linear modules used in high-precision and compact circuit board mounted. Driller with high rigidity linear module used in the drilling machine Positioning Device with linear module used for the moving parts of the work piece and the welding moving parts. Dispenser with linear module used in the dispenser, the movement is smooth and the coating is even., Laser Marking with linear module used in the laser marking machine in a clean room, etc.

Basic Specification of TM220 Modular Electric Slides series Model No TMS220-CM TMS220CR Drive solution Ball screw Sealed or not Semi closed Fully closed Motor power AC (W) 400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 25 lead (mm) 5 10 25 50 Fastest speed Motor speed 3000 (rpm) 250 500 1250 2500 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 150 150 120 50 Vertical 0.3G 55 45 20 8 Rate Thrust (N) 2100 1050 420 210 Linear guide (mm) 23*18.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMB220-CM TMB220-CR Drive solution Timing Belt Timing Belt Sealed or not Semi closed Fully closed Motor power AC (W) 750w Repeatability (mm) ±0.04 Reduction Ratio 1:1 1:2 lead (mm) 90 45 Fastest speed Motor speed 3000 (rpm) 4500 2250 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 35 75 Vertical 0.3G - Rate Thrust (N) 163 326 Linear guide (mm) 23*18.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Related knowledge: Common problems and countermeasures for installation and use of single-axis and multi-axis robotic arms a. The flatness of the bottom surface of the single-axis manipulator installation does not meet the standard. If the flatness of the bottom surface of the single-axis manipulator is too large, the bottom surface of the electric slide table will be forcibly locked, resulting in strong bending deformation of the bottom surface of the slide table, linear guide rails and ball screws. If it is light, it will increase the running resistance of the single-axis manipulator. If it is heavy, the electric slide may not be able to run, and the life of the electric slide will be shortened sharply. According to the accuracy level of the single-axis manipulator, the flatness of the general installation level should be less than 0.05mm/m. For the precision grade, the flatness of the bottom surface of the installation should be less than 0.02mm/mm. b. The locking order of the fixing screws at the bottom of the single-axis manipulator is wrong. The fixing screw at the bottom of the single-axis manipulator should follow the principle of first middle, then both ends, and then locked in sequence. If the two ends are locked first, the arch deformation caused by the deformation cannot be eliminated, resulting in the linear guide rail not running smoothly, reducing the walking parallelism and straightness accuracy. c. The motor shaft of the single-axis manipulator and the end of the screw shaft are not concentric. Although the coupling can eliminate a certain degree of eccentricity, if the value of the concentricity runout of the shaft end of the single-axis manipulator screw and the motor shaft exceeds the allowable range of the coupling, the damage of the coupling will be accelerated, causing the coupling to be different. Sound, or shrapnel breaks. It should be avoided as much as possible. d. The installation height of both sides of the multi-axis gantry combined mechanical arm is uneven. When the mechanical arm is installed in a gantry type, if the height of the guide rails on both sides is uneven, or the two slides are not parallel, the electric slide will be held back and the damage of the electric slide will be accelerated. f. The single-shaft electric slide timing belt tension is too loose or too tight. The tension of the timing belt of the electric sliding table should be kept moderate. If the belt tension is too tight, the tension of the timing wheel and the timing belt will be too large, and there will be abnormal noise. If the belt tension is too loose, it will cause gaps in the transmission process and reduce accuracy. In severe cases, it will produce tooth skipping. The tension of the synchronous belt is generally determined by the tension and deflection. The measurement method is: use a thrust meter to press the vertical direction of the belt midpoint and apply a certain amount of installation force to measure the resulting deflection value. Reference values corresponding to different center distances and belt specifications. g. The installation of the timing belt of the single-axis electric slide is not aligned. The synchronous belt-driven electric slide table, or the motor-mounted electric slide table on the side of the motor, should keep the synchronous wheel flush, otherwise, it will cause the belt to deviate, and then the belt edge and the synchronous belt rib friction will occur, the synchronous belt within a short time Will be damaged and broken. h. The single axis electric slide induction switch collides with the sensor due to deformation. The induction slide of the electric slide induction switch is damaged due to deformation and collision with the photoelectric switch. Countermeasure: Before energizing and sliding the slider, first check the photoelectric switch. You can pass the photoelectric switch normally. i. The stroke of the cantilever shaft of the mechanical arm (electric slide) is too long, and the overhang length is too large. If the cantilever length of the robot arm is too large, the allowable torque of the guide rail will be overloaded. Under different accelerations and decelerations, the closing time will change. The vibration generated at the end of the beam is finally absorbed by the electric slide table. Long-term vibration will shorten the life of the guide rail. j. The load of the robot arm/electric slide exceeds the range of use. When selecting the robotic arm, in addition to referring to the loadable load data in the selection manual, the effects of the dynamic allowable torque, acceleration and deceleration changes, and cantilever length should also be checked, and sufficient safety factors should be reserved. k. The wiring of the robot arm sensor switch is wrong or burned due to overvoltage. The electric slide induction switch generally uses a photoelectric switch. The reverse connection of the positive and negative poles of the photoelectric switch will cause damage to the photoelectric switch. The photoelectric switch cannot share the power supply with the motor driver or other inductive loads. Otherwise, the back electromotive force generated by the motor or the inductive load will cause a large voltage fluctuation, which will burn the photoelectric switch. Read the full article

#BeltdriveLinearMotionGuideActuators#BeltDrivenLinearModules#Gearballscrewdrivenactuators#Leadscrewlinearactuators#Leadscrewlinearmodules#LinearGuideWays#LinearMotionSystems#LinearStages#ModularElectricSlides#ModularStages#Motionbeltdrivelinearactuators#Precisionlinearactuators#StainlessBearingActuators

0 notes

Link

Steel tapes (Plate cover Roller) are available for the LM Guide as an essential means of contamination protection for machine tools. The plate cover SV drastically increases saleability by covering the LM rail mounting holes with an ultra-thin stainless steel (SUS304) plate, preventing coolant or cutting chips from penetrating the top face of the LM rail, which was previously impossible.

Detailed product information please visit our website: https://www.seimitsu.in/index.html

Please reach on below contact details for further clarifications:

Email Id: [email protected]

Phone no.: +91 (20) - 46212700

Mobile No.: +91 9028121211

#seimitsu#seimitsufactoryautomation#distributor#lmrail#platecoverforlmrail#linearguideways#lmguideways

1 note

·

View note

Link

How Linear Guideways does use in Aerospace Industry?

Now a day’s aerospace industry is also demanding for high performance products and systems in Aircraft which is able to survive in unfamiliar environment. THK’s Product Linear Guideways developed for use in special kind of operating environments and equipments are being manufactured from spacecraft bodies to its seat mechanism.

Seat Sliding working Mechanism:

LM Guide Radial Model SR is used often in the aircraft seat sliding mechanism of small size aircraft because the floors are using in Aircraft which are made of steel metal. It is very difficult to place equipment in aircraft and oftenly mounting and measuring related errors arise and become lengthy process therefore despite being all those scenario Linear Motion Guideway Radial Type Model SR is having a unique and excellent capabilities to be absorbed error and optimal capability to be mounted directly on the aircraft floor as result of assembly work is reduced.

Unique Features of LM Guide Radial Type Model SR:

1. Compact, Heavy Load: Linear Guideways Radial Type Model SR is designed in way that to be used in space constraint place. It has low sectional height and placed ball contact structure robustly in radial direction as a result of optimal for horizontal guide units.

2. Mounting accuracy can easily be achieved: LM Guide Radial Type model SR is self –adjusting type which is capable of absorbing an accuracy error correspondence and maintain level between two rail, due to its preciseness property it is highly accurate and able to achieve smooth motion easily.

3. Low Noise Features: The endplate is mounted at the bottom end of LM Block and ensure to be received a smooth motion easily and low noise due to circulation of Balls at moving area/turning area.

4. High Durability: Though under excessive load differential slip of balls are minimal as result of get high wear resistance and long term maintenance accuracy is achieved.

5. Stainless Steel Material available: LM Block, LM Rail and Balls are made of stainless steel.

SEIMITSU is an authorized distributor of THK Linear Motion in Pune. We have 8 branch offices across India include Mumbai, Chennai, Surat, Bangalore, Coimbatore, Hyderabad, Ahmedabad and Delhi.

Detailed product information please visit our website: www.seimitsu.in

Please reach on below contact details for further clarifications: Email Id: [email protected]

Phone no.: +91 (20) - 46212700

Mobile No.: +91 9028121211

#lmguideways#lmguide#advantagesoflmguideways#linearguideways#radialtypemodelSR#typesoflmguideways#typesofguideways#lmguidewaysmanufacturers#lmguidewaysworking#lmguidespecifications#linearmotion#linearmotionguidewaymanufacturer#linearmotionguidewaysupplier#lmguidewayssupplierinpune#typesoflinearmotion#lmrail#lmblock#linearrail#linearblock#linearbearingblock#linearmotionguide#linearmotionguideways#lmguidemanufacturer

0 notes

Link

Why does Caged Ball LM Guide Miniature Model SRS use in Pharmaceutical Industry?

Caged Ball LM Guide Miniature Model SRS is designed in way that wherein 2 raceways are placed into compact Body to be allowed to receive external loads in all direction. Importantly in SRS Miniature Model uses ball cages to remove friction between the balls therefore it achieves high speed, low noise, long service life, long-term free maintenance operation and acceptable running sound while operation.

SEIMITSU is distributor of THK Linear Motion Guide and SRS Series Miniature Caged Ball Supplier in Pune.

Needless to say, LM Guide Miniature Model SRS is using in Pharmaceutical Industry for getting High Precision and accuracy.

Few Glimpse of Features to Show Why does use in?

1. Low Dust generation: by using Ball Cages in compact body to eliminate friction between the balls as result of retains lubricant and achieve low dust generation. By using material of Stainless steel in LM Rail & LM Block which is highly resistant to corrosion.

2. Compact Body: SRS Miniature Guide has compact designed wherein rail cross section area is designed to be low and only two row of balls contain which can be installed in space saving locations

3. Light Weight: Miniature Model SRS is lightweight and get low inertia of linear Guideways.

Referral link: https://www.seimitsu.in/THK-Linear-Motion-LM%20Guide-Caged-Type-LM-Guide.html

#seimitsu#seimitsufactoryautomation#cagedballlmguideminiaturemodelSRS#lmguideminiaturemodelSRS#SRSminiatureguide#SRSseriesminiaturecagedball#lmguideways#lmGuide#linearguideways#advantagesoflmguideways#typesofLMguideways#typesofguideways#lmguidewaysmanufacturers#lmguidewaysworking#lmguidespecifications#linearmotion#linearmotionguidewaymanufacturer#linearmotionguidewaysupplier#lmguidewayssupplierinpune#typesoflinearmotion#rail#block#cagedball#linearrail#linearblock#linearbearingblock#linearmotionguide#linearmotionguideways#lmguidemanufacturer

0 notes