#linear weighers

Explore tagged Tumblr posts

Text

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is devoted to the R&D and manufacturing of multihead weighers, linear weighers, check weighers,combination weigher, metal detectors with high speed and high accuracy. With the continuous exploration, research, and application of advanced technology, we developed more than 30 different models made of different materials including the mini weigher, counting weigher, noodle weigher, frozen food weigher, feeding control weigher, salad weigher, hardware weigher, anchovy fish weigher, screw feeding weigher, mixing weigher, linear weigher, check weigher, metal detector, printer, electronic counting machine, manipulator, conveyor, etc., which are widely used in food, pharmaceutical, chemical, hardware, household, and other fields to meet various requirements of our customers. Kenwei makes unremitting efforts to help global customers and partners save costs and improve their production efficiency. Visit now on: https://www.kenweigh.com/

#Guangdong Kenwei Intellectualized Machinery Co.#Ltd. is devoted to the R&D and manufacturing of multihead weighers#linear weighers#check weighers#combination weigher#metal detectors with high speed and high accuracy. With the continuous exploration#research#and application of advanced technology#we developed more than 30 different models made of different materials including the mini weigher#counting weigher#noodle weigher#frozen food weigher#feeding control weigher#salad weigher#hardware weigher#anchovy fish weigher#screw feeding weigher#mixing weigher#linear weigher#check weigher#metal detector#printer#electronic counting machine#manipulator#conveyor#etc.#which are widely used in food#pharmaceutical#chemical#hardware

0 notes

Text

A continuation/part two to my favorite/lesser known Hermes epithets because I am a fool and forgot some or found more.

Hermes Psykhostasia - Weigher of souls (lives) or One who weighs souls (lives). In a mix of fulfilling his duty as a guide to all souls and being present before and after death while also being the messenger of Zeus, this aspect shines through. He carries out the will of both the Moirai and Zeus at times and in others he alone holds sway over the decision. Whichever ker (keres) was heavier (to the point of tipping the scales) was the one to die between the two individuals.

Hermes Panepóptēs - All-Observing. It's an epithet I can run with mainly found in the PGM

Hermes Kêryx - Herald of the Gods or Crier for a more rudimentary translation. It's a fairly interesting epithet in regards to naming Hermes as the son of Demeter (identified with Maia). In this specific incarnation, he has special control over the winged Keres in-flight into and out of Demeter Pandora, personified wine-storage jars blamed for all of the ills of humans, where only Hope lingered at the rim.

Hermes Hippios - Of the Horses. Hermes Hippokourios - Horse Tender. Though a rare aspect of his, he does connections with horses in a manner similar to Athene and Artemis. One of his famous sons was known for his skill when it came to handling horses, especially for races. He is also known for gifting the Dioskouroi with their horses and driving the chariot of Hades whenever Persephone enters or departs the underworld. Anyone that owned horses would pray to Hermes so they would thrive and for their increase.

Hermes Araoia / Hermes Araios - The Ram. One of the oldest attestations of the god is found in the Linear B inscriptions at Pylos and Mycenaean Knossos. With this epithet in mind, depictions of Hermes with sheep/ram horns would be fairly appropriate and a part of his appearance I see from time to time.

Hermes Kranaios - Of the Fountain? Of Springs. I know this one was on the last one but I really spaced on getting into why I love and appreciate it. It's a spring/nature sanctuary, one that ties him to water/rivers and what is heavily associated with deities that heal/can heal??? springs and pools of water!!!

Sources:

Weighing iconography of love in classical and early hellenistic art: considering allusions and metaphor in images of Aphrodite balancing Eros by Hannah Lisbeth Jones

L. D. Caskey, J. D. Beazley, Attic Vase Paintings in the Museum of Fine Arts, Boston

πανεπόψιος

Aischylos and the Trojan cycle: The lost tragedies by Ioanna Hadjicosti

Porphyry: On Abstinence from Killing Animals translated by Gillian Clark

Kerykes wikipedia entry

A Replica of the Hermes Propylaios by Alkamenes Found at Qasr Al-Hallabat by Ignacio Arce

Mycenaean Divinities

Where I pulled Hermes of the Fountain from as well as Hermes of the Springs

Kretan cult and customs, especially in the Classical and Hellenistic periods: a religious, social, and political study by Carolyn Schofield

Burning bulls, broken bones: sacrificial ritual in the context of palace period Minoan religion by Robert James Cromarty

Hermes Favor: Dioskouroi

“Dearest to be Man's Companion”: Hermes, Divine Aid, and Agency by David Chou

The link is down for now but has more information on Hermes and his connection to horses

223 notes

·

View notes

Text

0 notes

Text

Snacks Packing Machine: Elevating Packaging Efficiency with Munky Packaging Machines

In today’s fast-paced world, the demand for ready-to-eat snacks is continuously rising. Whether it’s potato chips, popcorn, or namkeen, snack manufacturers are under constant pressure to meet the increasing consumer demand while ensuring the quality and freshness of their products. To address these challenges, Munky Packaging Machines offers state-of-the-art snacks packing machines that are designed to streamline and optimize the packaging process.

Why Choose Munky Packaging Machines for Snack Packaging?

At Munky Packaging Machines, we understand the critical role packaging plays in product quality, shelf life, and brand reputation. Our snack packing machines are engineered to provide precision, speed, and reliability, making them the ideal solution for businesses of all sizes in the snack industry.

Here are some key features and benefits of using our snacks packing machines:

1. Automated Solutions for Consistent Performance

Our snacks packing machines are fully automated, allowing for efficient and precise packaging. The automation reduces human errors and minimizes product waste, ensuring that each pack contains the exact amount of product. With Munky’s machines, you can guarantee uniform packaging across all batches, which is essential for maintaining quality standards.

2. High-Speed Weighing and Filling

Accuracy is crucial in the snack industry, especially when dealing with high-volume production. Our machines come equipped with our Made in India linear weighers that ensure each pack contains the precise weight of the snack, whether it's light and airy popcorn or denser snacks like namkeen. Once weighed, the products are transferred seamlessly to the filling station for swift and accurate filling into pouches or containers.

3. Reliable Sealing Technology

The sealing process is critical to preserving the freshness of snacks. Our machines use cutting-edge sealing technology to ensure that the packages are airtight, keeping the product crispy and fresh. From pillow pouches to stand-up pouches, the machine can handle a variety of packaging styles. Additionally, the inclusion of nitrogen flushing is an optional feature that further prolongs shelf life by replacing oxygen inside the package with nitrogen, which prevents oxidation and spoilage.

4. Versatility Across Snack Types

One of the standout features of our snacks packing machines is their versatility. They can efficiently handle a wide range of snack types, including:

Potato Chips

Popcorn

Namkeen

Roasted Dry fruits

Extruded snacks This versatility makes our machines a perfect fit for manufacturers producing multiple snack varieties under one roof.

5. Easy to Operate and Maintain

Our machines are user-friendly and come with intuitive interfaces that require minimal training for operators. This ensures smooth day-to-day operations with minimal downtime. Additionally, the machines are designed for easy maintenance, with readily accessible parts and a robust build that ensures longevity.

The Three-Step Packaging Process of Munky Snack Packing Machines

Our snacks packing machines follow a three-step process to deliver perfectly packed products every time:

Weighing The machine accurately measures the desired weight of the product before it’s packaged. This ensures consistency in every pouch, reducing wastage and maintaining cost efficiency.

Filling After weighing, the product is transferred to the filling station, where it is filled into the selected pouch or container. The filling process is smooth and precise, handling even fragile products like chips without damage.

Sealing The filled pouches are then sealed to protect the product from air and moisture. Our machines use advanced sealing technology that ensures a secure and airtight closure, maintaining the product's crunch and flavor for an extended period.

Customizable Solutions for Your Business

At Munky Packaging Machines, we know that no two businesses are alike. That’s why we offer customizable solutions to meet your specific production needs. Whether you need a machine that can handle high-volume production or one that’s capable of handling different types of snacks, we’ve got you covered. Our team works closely with clients to deliver tailor-made solutions that align with their goals.

0 notes

Text

Smart Weigh Pack

Smart Weigh Pack specializes in providing innovative weighing and packaging solutions. They offer a wide range of equipment including multihead weighers, linear weighers, and various packaging machines designed for efficiency and accuracy in the food and non-food industries.

pouch packaging machine manufacturer

1 note

·

View note

Text

Revolutionizing Food Packaging With Flow Wrappers

The emergence of food flow wrappers has left its mark on the packaged food industry. The driving force behind the innovation and efficiency in a food factory has led to engineering marvels like the food flow wrap machine. From their humble beginnings to today's sophisticated designs, flow wrappers have become indispensable in the world of food packaging. Almost all bakery items like chocolate, muffins, nutbars, muesli bars etc, use flow wrappers for maximizing speed and efficiency. Apart from the food industry, non-food products like hardware use flow wrappers to ensure optimal efficiency.

The Introduction Of The Flow Wrappers

The roots of food flow wrappers can be traced back to the mid-20th century when the demand for efficient packaging solutions surged alongside the growth of the food manufacturing sector. As the technology evolved, so did the regulatory landscape. In the modern world, the use of food flow wrappers is suggested by regulatory bodies and widely adopted by factories for their incredible efficiency. These machines not only ensure fast packaging but also the safety of the consumers.

The benefits of flow wrappers are not limited to the food industry. Let us explore how flow wrappers have influenced the modern landscape:

Marketing And Brand Value Improvement: The implementation of food flow wrappers goes beyond the functional aspects of packaging. These machines work as a powerful marketing tool. Brands that invest in high-quality and well-designed packaging, signal to consumers a commitment to quality and innovation. The convenience and freshness ensured by flow wrappers contribute to a positive customer experience, enhancing brand loyalty. The aesthetic appeal of professionally packaged products also elevates a brand's visual identity on store shelves, contributing to greater visibility and recognition. In a competitive market, the use of advanced packaging technology can set a brand apart, making a lasting impression on consumers.

Use Cases In The Food Industry: The use cases of food flow wrappers in the food industry are diverse and expansive. Whether packaging individual snacks, baked goods, or fresh produce, flow wrappers offer a level of efficiency and consistency that traditional packaging methods often struggle to achieve. Their ability to handle a variety of product sizes and shapes makes them ideal for both small and large-scale production. Additionally, flow wrappers are integral in creating eye-catching and informative packaging. The transparent films commonly used with these machines allow consumers to see the product, fostering a connection between the item and the potential buyer. This visual appeal is crucial in a market where packaging often influences impulse buying decisions.

How To Find The Best Flow Wrap Machines?

For Australian food manufacturers seeking the best food flow wrapper solutions, it is crucial to partner with companies specializing in this technology. Contacting industry leaders who understand the unique requirements of the Australian market ensures you get access to tailored solutions for your factory. Having the best flow wrap machines enhances packaging efficiency and contributes to the overall success of your brand in the dynamic food industry landscape.

Some of the other “Packaging Machines”:

Linear Weighers

Multi Head Weighers

Vertical Form Fill Seal Packaging Machines

Pre-Made Bag Packaging Machines

Finishing thoughts on advanced packaging machines

Food flow wrappers represent a pivotal advancement in food packaging technology, driven by a desire for efficiency, safety, and sustainability. The importance of these wrappers extends beyond mere functionality. They serve as catalysts for marketing and brand value improvement. As the food industry continues to evolve, embracing cutting-edge packaging solutions is not just a choice but a necessity for brands aiming to stay competitive and resonate with consumers.

Source: https://optimaweightech.com.au/news/revolutionizing-food-packaging-with-flow-wrappers/

0 notes

Text

The Revolution of Packaging: Multihead Packing Machines

The Revolution of Packaging: Multihead Packing Machines In the fast-paced world of manufacturing and packaging, efficiency and accuracy are paramount. One innovation that has significantly improved these aspects is the multihead packing machine.To get more news about multihead packing machine, you can visit ft-pack.com official website.

A multihead packing machine, also known as a multihead weigher, is a sophisticated device designed for high-speed weighing and packaging of products1. It comprises a hopper, multiple weigh heads, and a discharge chute1. Each head weighs a predetermined portion of the product and discharges it into a bucket. This process ensures precise measurement and quick packaging, making it an indispensable tool in both food and non-food industries. Multihead weigher packing equipment usually consists of a multihead weigher and collar-type packing machines. The multihead weigher weighs the filling materials and puts them into a lapel packing machine used for forming bags, filling, sealing, and cutting3. Common combination weighers include ten head weighers and fourteen head weighers.

Companies like Kenwei and Ishida are leading manufacturers of multihead weighers. Kenwei offers a variety of weigher machines, including meat weighers, hardware weighers, and mini weighers. They also provide a two-year warranty for all customers who purchase their multi-head weighers4. On the other hand, Ishida, with over 120 years of experience, offers the RV Series Multi Head Weigher, known for its speed, toughness, and intelligence.

These machines are not only efficient but also customizable to meet the individual needs of different customers4. By accurately calculating and controlling the time of the hopper motor, the delay time of the linear vibrator, and the running time of the vibrator, various interference factors on the weight reading are avoided as much as possible4. This results in high accuracy and strong stability.

In conclusion, the multihead packing machine has revolutionized the packaging industry. Its ability to weigh and package products at high speeds with remarkable accuracy has made it an essential tool in various sectors. As technology continues to advance, we can expect even more improvements and innovations in this field, further enhancing efficiency and accuracy in the packaging process.

0 notes

Text

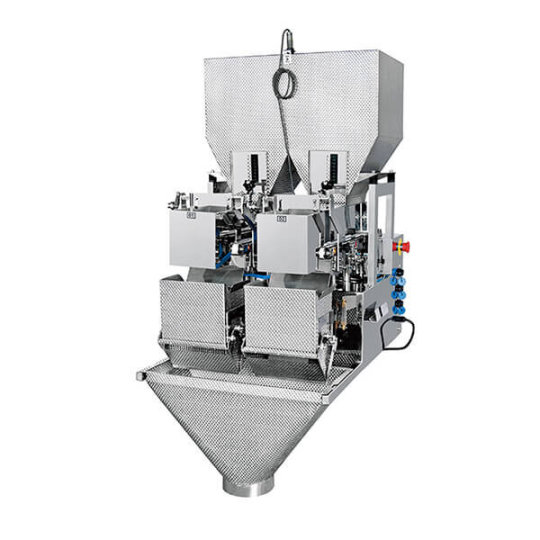

Linear Weigher

Linear multihead weigher is used for weighing different kinds of dry granules, such as rice and beans, there are different modes for option, such as independent mode linear weigher, mixing mode linear weighing machine or combination mode linear weigher packing machine. Linear weigh filler can be 1-8 heads for option, it can work manually or automatically working with packing machine, speed is around 10-40bag/min.

Types of Linear weigher for Sale

2 Heads Linear Weigher

2 Heads Linear Weigher

Apply advanced digital signal processing and high speed and stable weighing.

4 Head Linear Weigher

4 Head Linear Weigher

10.4" touch screen with different kinds of languages for option.

6 Head Linear Weigher On Meat Project (Screw Feeder Design)

6 Head Linear Weigher On Meat Project (Screw Feeder Design)

Both 6 head & 8 head linear weigher with widely used on sticky & fresh products, fragile and difficult moving products, like fresh meat, cooked rice, vegetable, saucing product, sea foods etc....

8 Head Linear Weigher On Meat Project (Screw Feeder Design)

8 Head Linear Weigher On Meat Project (Screw Feeder Design)

Both 6 head & 8 head linear weigher with widely used on sticky & fresh products, fragile and difficult moving products, like fresh meat, cooked rice, vegetabe,saucing product, sea foods etc.Ma...

ACZ-B Small Linear Weigher

ACZ-B Small Linear Weigher

Apply advanced digital signal processing and high speed and stable weighing.

https://www.highdream-en.net/products/linear-weigher/

0 notes

Text

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is devoted to the R&D and manufacturing of multihead weighers, linear weighers, check weighers,combination weigher, metal detectors with high speed and high accuracy. With the continuous exploration, research, and application of advanced technology, we developed more than 30 different models made of different materials including the mini weigher, counting weigher, noodle weigher, frozen food weigher, feeding control weigher, salad weigher, hardware weigher, anchovy fish weigher, screw feeding weigher, mixing weigher, linear weigher, check weigher, metal detector, printer, electronic counting machine, manipulator, conveyor, etc., which are widely used in food, pharmaceutical, chemical, hardware, household, and other fields to meet various requirements of our customers. Kenwei makes unremitting efforts to help global customers and partners save costs and improve their production efficiency. Visit now on: https://www.kenweigh.com/multihead-weighers

#multihead weigher packing machine#packing machine manufacturers#combination weigher#multihead weighers

0 notes

Photo

multihead Linear digital weigher/weight checker for turmeric powder

0 notes

Video

youtube

Weigher For Stick-shaped Products

Application: It is suitable for weighing stick shaped products, such as sausage, salty sticks, chopsticks, pencil, etc. max 200mm length. Mechanical character 1. Special rotary top cone dispense products evenly to each linear feeder pan. 2. Special linear feeder pan to make sure of feeding process. 3. Special hopper design to keep the material in a vertical state. 4. Independent discharge chute can make sure that material discharge into packaging machine vertically. 5. The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time. 6. Optional weighing type material detection, accurate control of feeding time, material thickness, to ensure the accuracy of the weighing. Guangdong Kenwei Intellectualized Machinery Co.,LTD. ADD: No.34, Zhenlian Road, Shangnan District, Fusha Town, Zhongshan City, Guangdong, China. Name: York Chen Tel: +86 22510253-253 Cell/WhatsApp/Wechat: +86 18938704765 Website: https://www.kenweigh.com https://en.multiweigh.com.cn Mail: [email protected] Skype: [email protected]

#multiheadweigher#linearweigher#fillingmachine#combinationweigher#KNEWEI#VFFS#checkweigher#metaldetector#packagingmachine#packingmachine#verticalpackaging#formfillseal#sealingmachine#foodpackagingmachine

1 note

·

View note

Text

Hipermak Packaging Machine

Cumhuriyet Mah. 9081 Sk No:57/1, Ulucak, Kemalpasa/Izmir/TURKEY

+90 (232) 461 4202 https://www.hipermak.com.tr/en/

HIPERMAK was established with over 30 years of industrial experience and the knowledge as family company in 2004. Hipermak produce Fully Automatic Vertical Packaging Machines, Z Elevators, Multihead linear weighers, helezones and conveyors since established. Hipermak believes that sustainable success can provide with high customer satisfaction and loyalty. Hipermak serves best after sale service with storage and broad service network.Our packaging machines, Linear weighers, Feeder elevators, Helezones and other supporting equipment suitable for packing all kind of powder & granular food/non food products. Ourcompany combines research and development as well as promotion, sale, and service of packaging equipment. Hipermakspecializes in the production and sales of packagingequipment and packaging materials and has more than 20 series and more than100 models of packaging equipment, which today, thanks to more than 30 years of experience-is known all over the world. The main activityof the company Hipermak is thesupply of modern packaging machines. It is manufactured using high-quality materials, taking into account world quality standards, so the machines meet the requirements of modern production.

1 note

·

View note

Photo

Linear Weigher

http://www.accufillc.com/products/weighing-solutions/

Our weighing solutions include linear weigher. To know about it’s features and cost, give us a call right away.

1 note

·

View note

Text

For Net linear Scales and Flow wrapper Contact us

Plan IT Packaging specializes in delivering high-quality end-to-end packaging system solutions to businesses ranging from small to Fortune 500. Our goal is to be known as THE automated packaging solution supplier in North America. As your partner, our mission is to assist you in being more productive and lucrative by packaging your items swiftly and effectively while staying within your budget. Plan IT Packaging provides cutting-edge packaging equipment from start to finish, including flow wrappers (Flow wrapper , flow pack, flow wrap machine), pre-made pouch machines (stand-up machine / doy pack machine), vertical form fill & seal (VFFS), horizontal form fill & seal (HFFS), stick pack machine, sachet machine, thermoforming, tray sealers, multi-head weigher (Net linear Scales ), shrink wrapping, bundling machine, and end of line solution.

Every aspect of your packaging solution is crucial. We make the packaging process easier for you by providing full-service automated packaging solutions. Find out what it's like to collaborate with us. We will come to your company for an on-site consultation anywhere in North America after your free 30-minute automated packaging planning call. Our automated packaging specialists will observe your production procedures, current equipment, and physical work environment during an on-site consultation. The outcomes of this visit are crucial in choosing which packaging options are ideal for your business. This on-site meeting is free of charge, however it will provide basic information on how a turnkey automated packaging system might help your company. Every company that is contemplating automated packaging systems has different requirements.

We will examine the unique demands of your company in order to adopt the best packaging solution for you. We at Plan It Packaging fully anticipate your company to face its own set of problems in order to get the greatest benefits from automated packaging. These challenges excite us, and we are ready to meet them. We begin developing the plan for your ideal automated packaging system only after a comprehensive consultation and in-depth examination of your company's demands. Before any equipment arrives, we present all of our results, conclusions, designs, and plans for your approval. We value our cooperation with your company, therefore we make sure your bespoke automated packaging plan is complete and mutually acceptable before moving further. Visit us online at http://www.planitpackaging.com/

0 notes

Text

Linear Weigher Packing Machine

Smart Weigh Packaging Machinery Co., Ltd is a reputable manufacturer in the design, manufacture and installation of multihead weigher, linear weigher, check weigher, metal detector with high speed and high accuracy and also provides complete weighing and packing line solutions to meet the various customized requirements. Established since 2012, Smart Weigh Pack appreciates and comprehends the challenges faced by food manufacturers. Working closely with all partners, Smart Weigh Pack uses its unique expertise and experience to develop advanced automated systems for weighing, packing, labeling and handling of food and non-food products.

Linear Weigher Packing Machine

1 note

·

View note