#ioT control

Explore tagged Tumblr posts

Text

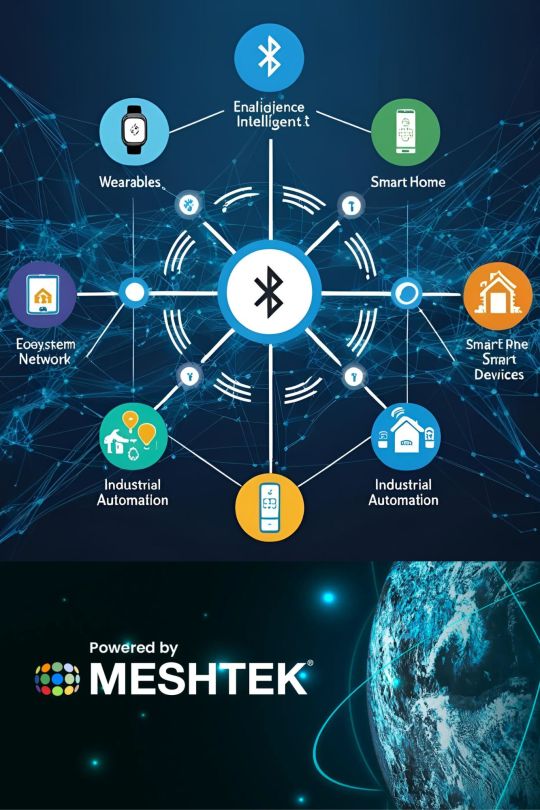

MeshTek’s Vision: Empowering IoT with Bluetooth Mesh Networking

MeshTek’s robust Bluetooth Mesh Networking ecosystem—seamlessly linking smart homes, wearables, industrial automation, and connected devices into one intelligent grid. It illustrates how MeshTek empowers secure, low-energy, and scalable communication across complex environments, enabling real-time control, optimized performance, and unmatched flexibility. Built to support everything from smart devices to enterprise-level automation, MeshTek’s platform is at the heart of next-gen IoT transformation.

#Bluetooth Mesh Networking#MeshTek#smart automation#connected devices#industrial IoT#IoT ecosystem#smart home network#IoT infrastructure#wearable integration#scalable IoT platform#low-energy communication#real-time control#IoT app development#MeshTek technology#intelligent automation

2 notes

·

View notes

Text

Unveiling the Power of Position Velocity Feedback Transmitter Systems in Modern Industries

Introduction: The Importance of Position and Velocity Feedback Systems in Precision Control

Position and velocity feedback transmitter systems are integral to industries that demand high-precision control and motion tracking. These systems are employed to monitor the position and velocity of moving objects in real-time, providing critical data for automated operations. The evolution of these systems has been significant, with advancements in technology enabling more compact, accurate, and reliable feedback mechanisms that drive automation, robotics, aerospace, automotive, and healthcare applications.

With the global shift towards increased automation, the demand for such systems is on the rise. Industries across the board require precise control of machinery, vehicles, and robots to enhance performance, improve safety, and optimize productivity. The growing need for smart manufacturing, autonomous vehicles, and medical robotics underscores the vital role these systems play in modern industries. Despite some challenges, such as high upfront costs and integration complexities, the long-term benefits of precision, efficiency, and reliability outweigh these hurdles.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40604-global-position-velocity-feedback-transmitter-systems-market

Position Velocity Feedback Transmitter Systems Market Dynamics: Drivers, Challenges, and Opportunities

Drivers of Growth

The Position Velocity Feedback Transmitter Systems market is experiencing robust growth driven by several key factors:

Advancements in Automation and Robotics: Industries across manufacturing, automotive, and aerospace are increasingly adopting automation technologies. These systems allow for faster, more accurate control, driving the need for precise position and velocity feedback.

Technological Advancements in Sensors: Innovations in sensor technology, particularly in digital systems, are facilitating the development of more accurate and miniaturized position velocity feedback systems. The integration of Internet of Things (IoT) technologies is making these systems smarter and more adaptable, driving their adoption in industries such as healthcare, smart manufacturing, and autonomous vehicles.

The Rise of Industry 4.0: Industry 4.0 technologies are revolutionizing production lines, with automation and data-driven decisions at their core. Position velocity feedback systems play a critical role in enabling smarter, more efficient manufacturing processes.

Emerging Applications in Healthcare and Autonomous Vehicles: In healthcare, robotic surgeries and diagnostics systems demand highly accurate motion control, while autonomous vehicles require precise feedback systems for safe operation. Both sectors are driving significant demand for position and velocity feedback systems.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40604-global-position-velocity-feedback-transmitter-systems-market

Challenges to Position Velocity Feedback Transmitter Systems Market Adoption

Despite the promising growth, several barriers could slow the widespread adoption of position velocity feedback transmitter systems:

High Initial Investment Costs: The cost of acquiring and integrating high-precision position velocity feedback systems can be prohibitive, especially for small and medium-sized enterprises (SMEs). High upfront costs can deter organizations from upgrading or adopting these systems, limiting market expansion.

Complexity of System Integration: Integrating new feedback systems with existing infrastructure and machinery can be complex and time-consuming, especially in industries that have legacy systems. This complexity increases the time to market and may discourage immediate adoption.

Specialized Training Requirements: The operation, calibration, and maintenance of advanced position velocity feedback systems require highly specialized knowledge and skills. The shortage of skilled labor in these fields may hinder growth, particularly in developing regions.

Key Opportunities

Several emerging trends present substantial opportunities for the growth of the position velocity feedback transmitter systems market:

Smart Manufacturing: As manufacturing processes become increasingly automated, there is a growing demand for position velocity feedback systems to enhance productivity and reduce human error. These systems are integral to improving the efficiency of production lines and ensuring consistent product quality.

Healthcare Robotics: Surgical robots, diagnostic devices, and rehabilitation technologies require real-time motion control. The healthcare sector’s increasing reliance on these technologies provides a substantial opportunity for the growth of high-precision position feedback systems.

Autonomous Vehicles: The rapid development of autonomous vehicles (AVs) hinges on accurate motion tracking and feedback systems for safe navigation. As the demand for AVs increases, so too will the demand for position and velocity feedback transmitters that ensure precise vehicle control.

Position Velocity Feedback Transmitter Systems Market Segmentation and Analysis

By Type

The position velocity feedback transmitter systems market can be divided into two key types:

Position Feedback Transmitter: This sub-segment is expected to dominate the market, driven by the increasing demand for precision in industrial automation applications. Position feedback transmitters provide accurate location tracking, ensuring the correct placement of components in automated systems.

Velocity Feedback Transmitter: While this segment is smaller, it is growing rapidly due to the need for precise speed control in applications such as robotics, aerospace, and automotive industries.

By Technology

Analog Systems: While still in use, analog systems are being increasingly replaced by more sophisticated digital feedback systems that offer greater accuracy and scalability.

Digital Systems: Dominating the market, digital systems provide real-time, highly accurate feedback for a range of applications, particularly in industries like automotive, aerospace, and healthcare. The continued innovation in sensor technology and integration with IoT is expected to fuel further growth in this segment.

By Application

The demand for position and velocity feedback systems spans a variety of industries:

Industrial Automation: Expected to maintain the largest market share, industrial automation continues to be the leading driver of demand for precise motion control systems. These systems are integral to ensuring the accuracy and speed of machinery in sectors such as manufacturing and material handling.

Aerospace and Defense: Aerospace applications require high-precision feedback systems for tasks such as flight control, navigation, and satellite positioning.

Automotive: As automotive systems become more automated, the demand for position and velocity feedback systems grows. These systems ensure precise vehicle control in autonomous and semi-autonomous driving technologies.

Energy: The energy sector, particularly in renewable energy systems, requires high-performance motion control to optimize energy production and distribution.

By Region

The market is geographically diverse, with distinct growth patterns across various regions:

North America: Dominating the market, North America is poised to continue leading the position velocity feedback transmitter systems market due to its advanced industrial sectors, including aerospace and automotive.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and the increasing adoption of automation technologies in countries like China and India.

Europe: Europe’s strong automotive and industrial automation sectors will continue to contribute to the growth of this market.

Latin America and Middle East & Africa: While smaller markets, the demand for these systems is expected to rise as industries in these regions embrace automation and robotics.

Position Velocity Feedback Transmitter Systems Market Competitive Landscape

Key Players

The market for position velocity feedback transmitters is highly competitive, with several industry leaders at the forefront:

Pepperl+Fuchs: Known for its next-generation sensors, Pepperl+Fuchs continues to innovate with solutions tailored to the needs of the automotive and industrial automation sectors. The company launched new high-performance sensors aimed at enhancing precision in harsh industrial environments in 2024.

Temposonics: Specializing in digital feedback systems, Temposonics has made significant strides in the robotics and aerospace sectors. Their advanced systems offer real-time position and velocity tracking, catering to industries that demand high-speed and high-accuracy solutions.

Other Key Players: Other companies in this market include Balluff, Siemens, and Honeywell, each offering various solutions across different applications, from industrial automation to healthcare.

Emerging Trends in Competition

Integration of IoT: Manufacturers are increasingly integrating IoT technologies into their position velocity feedback systems to enhance data collection, improve connectivity, and enable predictive maintenance.

Customization and Tailored Solutions: Companies are focusing on providing customized solutions for specific industries to cater to the unique needs of sectors such as automotive, aerospace, and healthcare.

Sustainability Initiatives: With growing environmental concerns, companies are developing energy-efficient systems that not only meet performance requirements but also adhere to sustainable production practices.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40604-global-position-velocity-feedback-transmitter-systems-market

Conclusion:

The Position Velocity Feedback Transmitter Systems Market is on a rapid growth trajectory, driven by advancements in automation, robotics, and sensor technologies. The demand for high-precision motion control systems is intensifying as industries seek to improve efficiency, safety, and productivity. Despite challenges such as high initial costs and integration complexities, the opportunities presented by emerging applications in healthcare, autonomous vehicles, and smart manufacturing are substantial.

With continued innovation and a focus on integration with IoT and digital technologies, the market is well-positioned for long-term expansion. As the industrial landscape continues to evolve, the role of position and velocity feedback systems will be pivotal in shaping the future of automation and precision control across various sectors.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Position Velocity Feedback Transmitter Systems Market#Position Feedback Systems#Velocity Feedback Transmitters#Automation#Industrial Automation#Motion Control Systems#Precision Motion Tracking#Position and Velocity Sensors#Digital Feedback Systems#Robotics#Aerospace Industry#Autonomous Vehicles#Healthcare Robotics#Smart Manufacturing#Industrial Robotics#Sensor Technology#Motion Control#Market Growth#Industry 4.0#Digital Position Sensors#Automotive Automation#IoT-enabled Feedback Systems#High-Precision Transmitters#Real-time Position Feedback#Aerospace Sensors#Automation Trends#Smart Manufacturing Systems#Position Velocity Sensors#Market Analysis#Precision Control Systems

1 note

·

View note

Note

Weaving and Finger Painting for the ask meme!

(Weaving: are your works typically similar to one another? Pick two works, and share one similarity and one difference between them.)

I don't know if I'd say my works are similar per se, but there's most definitely themes I gravitate towards, and as such most of my works have said themes in common.

As to what said themes are... I'm honestly not entirely sure, to be honest. I definitely like writing character interactions, so I guess most of my works have strong inter-character relationships? I also really like exploring platonic love (and in general find exploring various types of love/relationships fun) so there's that as well.

As to the two works, I'll pick The Golden City and Mercy City (placeholder title) since they're the two I've been recently working on. Similarity- the main protagonist of TGC's name is Felix and the main protagonist of MC's name is Felice Aside from their names, Felix and Felice are pretty similar in some aspects. Also each of these stories currently has City in the title. Difference- Well, the first thing that comes to mind is that MC has a magic system and TGC does not, just average humans. There's also a lot more groups of people up to their own agendas in MC than TGC.

(Finger Painting: share a small snippet from your earliest work (or the earliest that you can get back to). How would you rewrite it today? Either share the rewrite itself or just describe how you'd do it.)

Oh wow, my earliest work... Actually, hang on, I might be able to get that. One moment... Yeah, couldn't find my actual earliest work. It's hypothetically somewhere in my email, but I emailed it to someone when I was like 11 or something, so yeah.

My actual earliest work was a fantasy book where the main characters were horses, believe it or not. I called it Isles of the Endless Sea (which is honestly a very cool name) and it had like 3 or 4 books before I got bored halfway through the ending of one and just. stopped writing them haha.

IotES was honestly quite a good series despite the rather clunky writing (not blaming my past self, she did her best), I reread it recently and there's quite a few moments where I was like 'huh that's actually a really cool concept/line'. The first book's title was 'Night of Shadows' and I honestly can't figure out if that's a bit too dramatic or if it's actually a very cool title.

I'd like to try rewriting it someday, to be honest. If I did, the biggest change I'd make would be changing the characters to humans. I'd also adjust the plot a bit so it's less convoluted, and definitely change how ALL THE CHARACTERS are somehow related. (I'd just discovered the concept of 'secret evil sibling' and was very enamoured with it).

There's a snippet (the first book's prologue) under the cut! Notes specifically on the snippet... not that bad honestly. Formatting could definitely use some work. If I were to edit it now, I'd probably rewrite some of the lines, but overall quite good, especially for what was basically my first time writing.

“She will see you now.”

The white attendant stepped out of the way, and Reikan strode past him, into the throne room. The mare who waited there was beautiful, a deadly kind of beauty, however.

She was the color of polished black ebony, and had striped hooves. Her face was neatly structured, suggesting a hint of Arabian. The only flaw was a long scar,running down her jawline. It was not a ugly thing, merely a line where there was no hair. However, it served as a reminder of who she was to her legions. That and the sabre, that deadly curved sword, that hung in a sheath at her side. It had emeralds studded down the handle, and a blade many suspected was dipped in poison.

It was, in fact. A narrow tube ran down the blade, feeding from the tip, to a reservoir set in the handle, that was filled with adders venom! It had a plug at the tip, so that when it stabbed something , that plug would give leeway for a thin trickle of venom. If you felt the tip, you could feel a slight bump, the plug. However, no-horse felt the tip, as Ziara made most of her kills without using the poison at all.

But perhaps her most recognizable feature was her eyes. They were black, which was not a strange thing. But the kind of black..ah, that was strange. They were a deep black that if you stared into, you felt almost as if you were being sucked into a vacuum. When she was angry, the black gained a strange gleam to it. She was also a master of stares, and could make almost any horse feel the way she wanted them to.

Ziara was studying a map when Reikan entered. However, she greeted him before the door had even closed

“Reikan.”

Somewhat astonished at how she had know it was him, he bowed, and replied. “Milady”

Eyes spitting fire, she turned around.

“Reikan! How many times must I remind you? Do. Not. Call. Me. Milady!” “Apologies General. It was a slip of the tongue.”

The lethal mare returned to her previous state, one so charming it was impossible not to be awed by her beauty.

“Your report?”

#wrose writes#ask and ye shall be answered#the golden city#isles of the endless sea#mercy city#thank you very much for the ask!#wow that was a long post lol#man. iotes. what a memory#personally a big fan of how some of the characters just started outright performing magic in the later books#but i'd somehow managed to gaslight myself into believeing it. wasn't magic??#like girl. they are mind controlling people with their eyeballs. how is that a Normal Horse thing

2 notes

·

View notes

Text

Devlopment board

#controller#esp32#esp32project#pcb#pcbdesign#pcbassembly#engineer#engineering#electricalengineering#circuits#iot#smarthome#diyelectronics#trending#viral#reels#instagram#instragramreels#followers#boost#explore#explorepage#likeforlikes#electricalengineer#electricalwork#electricalcontractor#electricalhacks#electricallife#electricalsky

4 notes

·

View notes

Text

0 notes

Text

Elio Prime Fan, Smart Ceiling Fan, BLDC+ Fan, Havells Smart Fan, Energy Saving Fan, Voice Control Fan, IoT Ceiling Fan, Remote Controlled Fan

For more information- https://havells.com/fans/ceiling-fans/fhce25sslm48-c.html

#Elio Prime Fan#Smart Ceiling Fan#BLDC+ Fan#Havells Smart Fan#Energy Saving Fan#Voice Control Fan#IoT Ceiling Fan#Remote Controlled Fan

0 notes

Text

Ideeaz Automation – Smart Lighting & Motorized Shade Solutions for Modern Spaces

Ideeaz Automation offers advanced smart lighting control systems and motorized shading solutions tailored for homes, offices, hotels, and commercial spaces. With over a decade of innovation, we help transform ordinary spaces into intelligent environments—elevating aesthetics, energy efficiency, and user comfort. Discover our range of lighting automation products and services designed to redefine modern living.

@ideaazautomation

#lighting automation#lighting control systems#smart home#smart house lighting#energy-efficient lighting#ideeaz automation#efficiency#iot lighting solutions#smart lighting#smart lighting control#motorized shades#home automation lighting#commercial lighting solutions#office lighting control#IoT lighting systems#intelligent lighting solutions#motorized window treatments#lighting control systems India#luxury lighting automation#smart lighting for buildings#automated lighting solutions#lighting and shading automation#Ideeaz Automation#smart building technology

0 notes

Text

AI-Powered Ventilation for Industrial Kitchens in Food Processing Units

Explore how Theta Technolabs leverages AI-powered ventilation systems to enhance air quality, energy efficiency, and safety in industrial kitchens and food processing units. Discover smart solutions transforming the food industry.

#AI-powered ventilation systems#industrial kitchen ventilation solutions#intelligent ventilation control systems#IoT ventilation solutions for kitchens#automated airflow management systems#industrial kitchen safety solutions

0 notes

Text

Rail Logistics and IoT: We are on the right Track

0 notes

Text

Redes Industriales en México

Exellios®: Potenciando las Redes Industriales en México para la Industria 4.0 La transformación digital ha llegado para quedarse, y con ella, la necesidad imperante de redes industriales robustas y eficientes. En México, donde la manufactura y la automatización avanzan a pasos agigantados, contar con una infraestructura de comunicación industrial confiable no es un lujo, sino una necesidad. Es…

#Automatización de plantas#Automatización de procesos México#Automatización industrial CDMX#Automatización Industrial México#Ciberseguridad industrial México Exellios#Ciberseguridad OT/IT#Comprar Exellios México#Conectividad de máquinas#Conectividad industrial México#Consultoría redes industriales México#Contacto Exellios México#Control industrial#Diagnóstico de redes industriales Exellios#Digitalización industrial#Eficiencia operativa industrial México#Exellios#Exellios distribuidores México#Exellios Monterrey#Exellios para sector automotriz México#Gestión de redes industriales Exellios#Implementación Exellios en México#Industria 4.0 México#Integración sistemas industriales México#IoT industrial (IIoT)#Mantenimiento predictivo industrial México#Monitoreo redes industriales México#Optimización de redes de comunicación industrial#PLC y redes industriales México#Precios Exellios soluciones#Proveedor redes industriales México

0 notes

Video

youtube

Real Time Smart Sensor Monitoring and Remote Load Control Using IoT and ...

#youtube#Real-Time Smart Sensor Monitoring and Remote Load Control Using IoT and Blynk | 🧠 Full Project Kit Available – With Code Circuit & Support

0 notes

Text

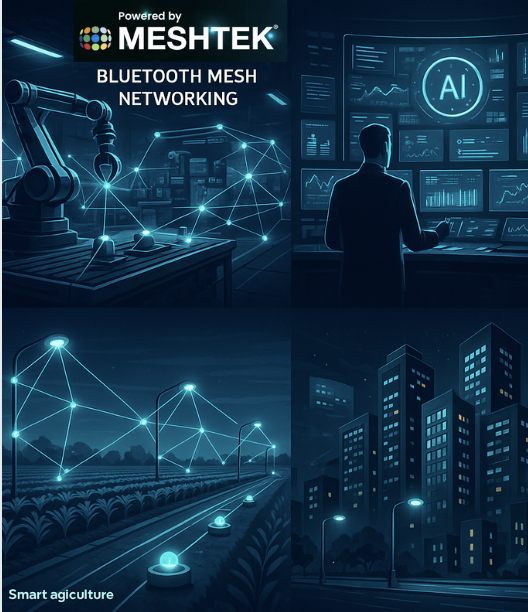

Connected Intelligence: Powering Tomorrow with Bluetooth Mesh

MeshTek’s advanced Bluetooth Mesh Networking seamlessly integrates across diverse sectors — from industrial automation and AI-driven operations to smart agriculture and urban lighting. Real-time data flow, secure communication, and synchronized control across a decentralized, energy-efficient IoT network. Designed for scalability and precision, MeshTek’s platform enables smarter environments through robust, low-latency connectivity.

#Bluetooth Mesh Networking#Smart Lighting#Industrial Automation#AI Connectivity#Smart Agriculture#MeshTek IoT#Edge Devices#Real-Time IoT Control#Scalable Mesh Network#IoT Infrastructure

1 note

·

View note

Text

Monitoring with Fire Annunciators and Temperature Transmitters

In today’s industrial landscape, where precision and safety are paramount, integrating advanced monitoring and alert systems is no longer optional—it’s a necessity. ESD, a leader in process instrumentation, offers cutting-edge solutions designed to meet the evolving demands of manufacturing, chemical processing, and automation sectors. Among its most vital innovations are Alarm Annunciators and Temperature Transmitters, both of which play a pivotal role in maintaining welfare, reliability, and preferred process control.

The Role of Alarm Annunciators in Industrial Welfare

An Alarm Annunciator is an essential component in any control panel, tasked with alerting operators to abnormal conditions in real-time. These devices are engineered to display faults and activate audible or optical alarms whenever a process variable exceeds its safe operating limits.

At ESD, our alarm annunciator systems are built with configurable logic, LED indicators, and relay outputs to ensure prompt attention to critical situations. From power plants to water treatment facilities, our annunciators ensure that every alert is visible, distinguishable, and immediate, helping mitigate possibilities and prevent downtime.

Precision Monitoring with Temperature Transmitters

A Temperature Transmitter is another cornerstone of industrial process control. It converts temperature sensor signals into standardized output signals, enabling seamless communication with control systems. These devices are crucial for maintaining consistent product quality, optimizing energy utilization, and ensuring safety in temperature-sensitive processes.

ESD temperature transmitters are known for their high accuracy, fast response time, and resistance to industrial environmental conditions. With robust housing and digital communication protocols, our transmitters are ideal for both legacy structures and Industry integration.

Why Select ESD?

With experience in automation and instrumentation, ESD stands out as a trusted manufacturer and supplier of reliable process monitoring devices. Our solutions, including alarm annunciators and temperature transmitters, are tailored to meet the stringent demands of modern industries, ensuring continuous show and performance.

Whether you're upgrading an existing system or designing a new one from scratch, ESD offers discussion, customization, and post-sales support to help you every step of the way.

Ready to enhance your industrial monitoring and welfare systems?

Explore our range of high-performance products at www.esd-india.com or contact us to discuss how we can help you achieve your automation goals.

#Alarm Annunciator#Modbus Display#Flameproof Indicator#Flow Indicator Totalizer#Jumbo Display#Temperature Controller#Loop Powered Indicator#IOT data logger#IOT Energy Monitoring#Open Channel Flowmeter#Temperature Transmitter#Signal Isolator

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

#plc#plc system#AHU controllers#Programmable Logic Controllers (PLC)#HVAC system.#Energy management systems#IoT enabled PLC#VFDs (Variable Frequency Drives)#PLC automation system#IEC 61131-3 standard

0 notes

Text

Discover Real-World IoT Device Examples for Industrial Use

Want to see real IoT devices examples in action? At Aknitech, we implement IoT device monitoring, PLC integration, and access control IoT devices across various industries. Empower your systems with the next generation of automation solutions. Tags: iot devices examples, iot device monitoring, plc integration, access control iot devices, iot examples

0 notes

Text

Athena Lighting Control System – Smarter Spaces by Ideeaz Automation

Upgrade your space with Athena by Ideeaz – a modern lighting control system for energy-efficient and intelligent environments. Perfect for residential, commercial, and hospitality applications.

#lighting automation#lighting control systems#smart home#smart house lighting#energy-efficient lighting#ideeaz automation#efficiency#iot lighting solutions#smart lighting#lighting automation India#Athena control system#smart home lighting#intelligent lighting solution#energy-saving automation

0 notes