#inventory management Software

Explore tagged Tumblr posts

Text

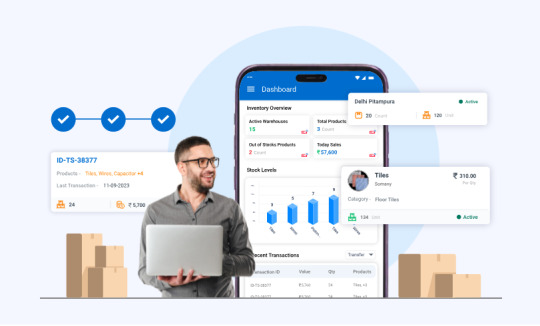

Run your store smartly, not manually. Automate billing, reports & invoices with Shoppeez!

#billing software#POS#Inventory management software#gst billing software#AI powered inventory software#retail billing software

1 note

·

View note

Text

How a Unified Commerce Platform Helps Brands Sell Seamlessly Across Online & Offline Channels

In today's fragmented retail landscape, consistency is everything. A Unified Commerce Platform allows brands to centralize their inventory, customer data, and sales processes across in-store and digital channels. This not only streamlines operations but also enhances customer satisfaction by offering real-time availability, personalized experiences, and faster service. Whether you're selling through an app, website, or physical outlet, the unified approach ensures data sync and brand consistency. As consumers demand more flexibility, businesses leveraging unified commerce are better positioned to scale, adapt, and outperform. Explore how this transformative shift is setting new standards in omnichannel retailing.

#Unified Commerce Platform#supply chain management#inventory management software#ecommerce platform#order management software

0 notes

Text

When selecting a Third Party Logistics (3PL) software, it’s crucial to understand the features that truly make a difference. Choosing the right solution can streamline your logistics, boost efficiency, and reduce errors. Here are the top features of Third Party Logistics software you should look for:

#Logistics software#Third Party Logistics#Warehouse Management System#3pl#Inventory management software

0 notes

Text

Revolutionize Your Warehouse with Smart Inventory Management Software by Datascan

Boost your warehouse game with powerful Inventory management software by Datascan. Whether you're in retail, logistics, or manufacturing, this WMS solution streamlines everything—order picking, stock tracking, real-time visibility, and workflow automation. Designed for businesses of all sizes, it supports both cloud and on-premise setups with seamless ERP integration.

Say goodbye to manual errors and hello to efficiency with mobile apps, barcode scanning, and automated alerts. From smarter decision-making to reduced labor costs, Datascan helps you manage inventory like a pro. Ready to level up your warehouse? This is the future of inventory, now.

1 note

·

View note

Text

The Strategic Importance of Switchgear Price Lists in Control Panel Manufacturing and Quotation Software Integration

In the competitive world of electronics control panel manufacturing, pricing accuracy can make or break a deal. One of the most critical cost drivers in control panel production is switchgear—components like circuit breakers, contactors, relays, and disconnectors that form the backbone of electrical distribution and protection systems.

Maintaining an updated switchgear price list and integrating it into quotation software is no longer just a best practice—it’s a business necessity. This blog explores why a well-managed switchgear price list is crucial, how it impacts profitability, and the advantages of integrating it with modern quotation systems.

Why a Switchgear Price List is Critical for Control Panel Manufacturers

1. Accurate and Competitive Quotations

Switchgear components account for 30-50% of total control panel costs, depending on the complexity of the system. Without an updated price list:

Underpricing leads to shrinking profit margins or even losses.

Overpricing makes bids uncompetitive, losing potential contracts.

Manual price checks slow down quotation turnaround time.

Solution: A centralized, digital switchgear price list ensures real-time pricing accuracy, allowing sales teams to generate competitive and profitable quotes quickly.

2. Faster and More Efficient Quotation Processing

In a fast-moving industry, delays in quoting can mean losing a project to competitors.

Challenges Without a Digital Price List:

Sales teams waste time cross-referencing supplier catalogs or calling vendors.

Human errors in manual data entry lead to incorrect pricing.

Frequent price fluctuations (due to supply chain issues or currency changes) make static Excel sheets obsolete.

Solution: Integrating the switchgear price list into automated quotation software allows:

Instant price fetching from the database.

Dynamic adjustments based on quantity discounts or supplier changes.

One-click quote generation, reducing response time from hours to minutes.

3. Dynamic Cost Management and Supplier Negotiations

Switchgear prices fluctuate due to:

Raw material cost changes (copper, steel, plastics).

Supply chain disruptions (global shortages, logistics delays).

Currency exchange rate variations (for imported components).

Without a Managed Price List:

Procurement teams miss out on bulk discounts due to fragmented data.

Manufacturers fail to adjust quotes in time, leading to cost overruns.

Solution:

Track historical pricing trends to negotiate better supplier deals.

Set up automated alerts when prices exceed budget thresholds.

Compare multiple vendors within the quotation system to select the best-cost option.

4. Consistency Across Sales and Procurement Teams

Disorganized pricing leads to:

Different sales reps quoting different prices for the same components.

Procurement ordering parts at higher costs than what was quoted.

Solution:

A unified switchgear price list ensures all departments work with the same data.

Role-based access in quotation software prevents unauthorized price overrides.

5. Improved Profit Margins Through Cost Optimization

A well-maintained price list helps:

Identify cheaper alternatives (e.g., using a different brand of circuit breaker with similar specs).

Avoid last-minute expensive purchases by planning procurement in advance.

Apply markups strategically based on real-time component costs.

Integrating Switchgear Price Lists with Quotation Software

To maximize efficiency, manufacturers should integrate their switchgear price lists with modern quotation software. Key benefits include:

1. Automated Price Updates

Sync with supplier databases to reflect real-time price changes.

Apply bulk price adjustments when market conditions shift.

2. Smart Discounting and Tiered Pricing

Automatically apply volume discounts based on order quantity.

Custom pricing for loyal customers without manual intervention.

3. Seamless ERP and Inventory Integration

Check component availability before quoting.

Prevent overselling by linking quotes to stock levels.

4. Digital Quotation Approval Workflows

Route quotes for manager approval if discounts exceed thresholds.

Track quote status (pending, approved, rejected) in real time.

5. Data-Driven Decision Making

Analyze win/loss rates to adjust pricing strategies.

Forecast costs based on supplier trends.

Best Practices for Managing Switchgear Price Lists

Regularly Update Prices

Assign a team member to review and update prices monthly (or more frequently for volatile markets).

Standardize Part Numbering

Use consistent naming conventions (e.g., Schneider LC1D09 vs. Siemens 3RT2017-1AP00) to avoid confusion.

Leverage Cloud-Based Solutions

Ensure remote teams access the same updated prices in real time.

Train Teams on Quotation Software

Avoid errors by ensuring sales and procurement teams use the system correctly.

Monitor Supplier Performance

Track delivery times, quality issues, and pricing trends to choose the best vendors.

Conclusion

For electronics control panel manufacturers, an accurate and well-managed switchgear price list is not just about cost control—it’s about staying competitive, winning more deals, and maximizing profits.

By integrating the price list with quotation software, manufacturers can: ✅ Generate accurate quotes in minutes (not hours). ✅ Avoid pricing errors that lead to losses. ✅ Negotiate better supplier deals with historical data. ✅ Improve profit margins through smart cost optimization.

In an industry where every percentage point in cost savings matters, leveraging technology to manage switchgear pricing is a game-changer.

Is your company still relying on manual price lists? Consider upgrading to an automated quotation system today to streamline operations, reduce errors, and boost profitability.

#project management software#stock management software#inventory management software#quotation management software#product management system

0 notes

Text

Inventory Management Software | System - Payraty

Streamline your inventory processes with Payraty’s advanced inventory management software. Optimize tracking, control, and reporting for better business efficiency.

0 notes

Text

Home Insurance Claims and Asset Management with Leevaapp

When it comes to home insurance claims, having a comprehensive and organized home inventory is essential. Whether you’re dealing with a minor loss or a major disaster, being able to quickly and accurately document your belongings can make the process easier and faster. But managing a home inventory without the right tools can be challenging. This is where Leevaapp comes in as the best home inventory app designed to simplify the process for you.

The Importance of Home Inventory for Insurance

A thorough home inventory for insurance purposes is crucial in case you ever need to file a claim. Insurance companies often require detailed lists of the items in your home, including descriptions, purchase dates, values, and any serial numbers. It can be difficult to remember everything, especially if you're under stress after a loss. By having an up-to-date home inventory management software like Leevaapp, you can easily create a digital record of all your assets, which is invaluable when submitting claims.

Features of Leevaapp: The Ultimate Home Inventory Software

Leevaapp is an inventory management software that offers multiple features to help you manage your home inventory efficiently. It allows you to track your belongings and store important details like descriptions, images, and even receipts. The app is designed to be user-friendly and accessible, ensuring that you can update your inventory whenever needed.

Organize Your Inventory Easily: With Leevaapp, you can categorize your assets based on rooms, types, or any other criteria you prefer. Whether you're tracking your inventory home or organizing your entire household, the app helps keep everything in order.

Track and Manage Your Assets: The best inventory tracking software provides real-time updates, ensuring that your records are always up-to-date. Whether you’re at home or on the go, you can track new purchases or changes to your assets instantly.

Prepare for Insurance Claims: Having all your belongings organized in one place not only makes it easy to retrieve information when needed but also speeds up the home insurance claims process. When filing a claim, you'll have all the necessary documentation in the app, reducing the risk of delays.

Digital Asset Management Software: Beyond basic home inventory, Leevaapp also serves as a digital asset management software. You can keep a detailed digital record of each item in your home, making it easier to prove the value of your assets if needed.

Easy to Use: With Leevaapp, you don’t need to be tech-savvy to create a professional home inventory. The intuitive design ensures that anyone can use the app to manage their assets without feeling overwhelmed.

Why Choose Leevaapp for Your Home Inventory?

The home insurance claims process can be frustrating if you don't have your inventory properly documented. Leevaapp eliminates the guesswork, helping you easily compile and maintain a detailed home inventory. It ensures you're always ready for the unexpected, with your belongings tracked and protected in the app.

Additionally, with Leevaapp, you don’t just get inventory home management for insurance; you get an all-in-one asset management software that’s perfect for any homeowner. Whether you're interested in a simple home depot inventory checker or a more robust inventory management software to track everything in your house, Leevaapp meets all your needs.

Start Organizing Your Home Inventory Today

Get ahead of any potential insurance claims or asset management needs by downloading Leevaapp today. This powerful inventory tracking software is available on both iOS and Android devices, so you can manage your home inventory from anywhere.

Leeva Secure Home Inventory on the App Store

Leevaapp on Google Play

With Leevaapp, you can ensure that your home inventory is always up-to-date, organized, and ready for anything life throws at you. Take control of your home insurance claims and asset management today!

#Insurnace claim home#home insurance claims#home insurance claims process#home inventory#inventory home#home depot inventory checker#home depot inventory#home inventory software#best home inventory app#home inventory for insurance#home inventory management software#asset management software#best inventory management software#digital asset management software#inventory management software#best inventory tracking software

0 notes

Text

Odoo ERP for Inventory Management Software

The Inventory Management Software provided by Odoo offers an integrated solution for handling stock, warehouses and logistics of any business in the best possible manner. Features like real time tracking, multi location management and automated reordering make businesses work more efficiently and make better decisions. Here are the key features and benefits of using Odoo for inventory-management.

#odoo#odooerp#erp system#businesssolutions#inventory management#inventory management software#erpsoftware#erp#odoo erp

0 notes

Text

Unlock Efficient Supply Chains: Why Inwizards is Your Go-To for Inventory Management

In today's fast-paced business landscape, efficient supply chain and inventory management are more critical than ever. Companies face the constant challenge of balancing stock levels, avoiding overstocking or understocking, and ensuring timely deliveries—all while minimizing costs. This is where Inwizards, a leading IT company, steps in with innovative inventory management solutions tailored to your business needs.

Why Inventory Management Matters

Effective inventory management isn't just about keeping track of stock—it's about optimizing resources, enhancing productivity, and delivering exceptional customer experiences. Businesses that fail to streamline their inventory systems often face disruptions, increased costs, and dissatisfied customers.

How Inwizards Makes a Difference

At Inwizards, we understand the unique challenges faced by businesses across industries. Our inventory management solutions are designed to:

Automate Processes: Eliminate manual errors and streamline stock management with advanced automation tools.

Real-Time Data Insights: Make informed decisions with real-time analytics and reporting.

Scalability: Whether you're a small startup or a large enterprise, our systems grow with your business.

Custom Solutions: Every business is unique, and so are our inventory management solutions.

Cutting-Edge Technology at Your Fingertips

Inwizards leverages the latest technologies, including AI, IoT, and cloud computing, to ensure your inventory management system is not only efficient but also future-ready. Our user-friendly platforms integrate seamlessly with existing ERP and supply chain tools, offering a smooth operational experience.

Real Business Impact

Partnering with Inwizards has helped businesses achieve:

Up to 40% reduction in inventory carrying costs.

Improved order accuracy by up to 99%.

Enhanced customer satisfaction through faster deliveries.

Why Choose Inwizards?

With years of experience in delivering IT solutions, Inwizards is not just a service provider—it's your strategic partner. Our team of experts works closely with you to identify pain points, implement tailored solutions, and drive measurable results.

Ready to transform your supply chain and inventory management systems? Partner with Inwizards and unlock new levels of efficiency and growth.

🚀 Let's redefine inventory management together!

#inwizards software technology#Inventory Management Software#Software#web development#Custom Software

0 notes

Text

Effective inventory control is the key to seamless operations! With ServitiumCRM's Inventory Management, empower your service teams with the insights they need to plan more efficiently, provide better service, and enhance customer satisfaction. Everything is easily accessible, from monitoring product specifications and purchase history to overseeing stock movements. Whether in the warehouse or on-site with the client, every detail remains perfectly synchronized for optimal performance. Maintain precise and real-time stock levels. Experience the intelligent way to handle your inventory today: Read More...

#inventory management services#inventory management crm#inventory management software#simple inventory management software#servitiumcrm

0 notes

Text

0 notes

Text

#technews#Enterprise Resource Planning (ERP)#ERP Solutions#Business Management Software#Integrated Business Applications#Supply Chain Management#Customer Relationship Management (CRM)#Financial Management Systems#Human Resources Management#Inventory Management Software#Manufacturing Resource Planning#Cloud ERP Solutions#On-Premise ERP Systems#ERP Implementation Services#ERP Consulting#ERP Software for Small Business#ERP Software for Manufacturing#ERP System Integration#ERP Software Development#ERP Customization Services#ERP Training and Support

0 notes

Text

The Critical Role of Engineering Data Management in Electronics Control Panel Manufacturing

The electronics control panel manufacturing industry is a highly specialized sector where precision, efficiency, and compliance are non-negotiable. Control panels are the nerve centers of industrial automation, power distribution, and machinery operations, meaning any error in design, procurement, or assembly can lead to costly failures, safety hazards, and project delays.

To mitigate these risks, manufacturers must adopt Engineering Data Management (EDM)—a systematic approach to organizing, storing, and controlling engineering data throughout the product lifecycle. EDM ensures that all stakeholders—from design engineers to procurement teams and production managers—work with accurate, up-to-date information.

In this blog, we will explore why EDM is indispensable for control panel manufacturers, the challenges it addresses, and best practices for implementation.

Why Engineering Data Management is Essential in Control Panel Manufacturing

1. Ensuring Design Accuracy & Version Control

Control panel designs involve complex schematics, wiring diagrams, and component specifications. Without a structured EDM system:

Engineers may work on outdated drawings, leading to mismatched components.

Multiple file versions can cause confusion, resulting in incorrect assemblies.

Manual updates increase the risk of human error.

How EDM Helps:

Maintains a single source of truth for all design documents.

Tracks revisions with audit trails, ensuring only the latest versions are used.

Supports CAD/EDA (Computer-Aided Design/Electronic Design Automation) integrations for seamless updates.

2. Facilitating Cross-Department Collaboration

A control panel’s journey from concept to delivery involves multiple teams:

Design Engineers create schematics and layouts.

Procurement sources components based on the Bill of Materials (BOM).

Production assembles the panels according to approved designs.

Quality Assurance verifies compliance with industry standards.

Without EDM:

Emailing files back and forth leads to version mismatches.

Delays occur when teams wait for manual approvals.

Miscommunication results in incorrect part orders or assembly errors.

With EDM:

Cloud-based platforms enable real-time collaboration.

Role-based access ensures stakeholders see only relevant data.

Automated workflows speed up approvals and reduce bottlenecks.

3. Compliance with Industry Standards & Regulations

Control panels must comply with stringent standards such as:

IEC 61439 (Low-voltage switchgear and controlgear assemblies)

UL 508A (Industrial control panels)

NEC (NFPA 70) (National Electrical Code)

Challenges Without EDM:

Manual tracking of certifications is time-consuming.

Missing documentation can lead to failed inspections.

Non-compliance risks legal penalties and reputational damage.

How EDM Ensures Compliance:

Centralizes certification documents, test reports, and compliance records.

Automates alerts for expiring certifications.

Links design files to regulatory requirements, ensuring adherence at every stage.

4. Accelerating Time-to-Market

In a competitive industry, faster project delivery is a key differentiator. Delays in design finalization, procurement, or production can cost customers time and money.

How EDM Speeds Up Processes:

Automated BOM Generation: Reduces manual entry errors and speeds up procurement.

Digital Twin Simulations: Allows virtual testing before physical production.

Integration with ERP/MRP Systems: Ensures seamless data flow from design to manufacturing.

5. Reducing Costs & Minimizing Waste

Mistakes in control panel manufacturing can be expensive—wrong components, rework, and scrap materials eat into profits.

EDM’s Cost-Saving Benefits:

Eliminates Rework: Accurate data prevents assembly errors.

Optimizes Inventory: Syncs BOMs with procurement to avoid overstocking or shortages.

Identifies Cost-Effective Alternatives: Tracks component performance and supplier pricing for better sourcing decisions.

Implementing Engineering Data Management in Control Panel Manufacturing

1. Choose the Right EDM/PLM Software

Not all data management systems are suited for electrical engineering. Look for solutions that:

Support electrical CAD (eCAD) integrations (e.g., EPLAN, AutoCAD Electrical).

Offer version control, change management, and approval workflows.

Provide cloud-based access for remote teams.

2. Integrate with ERP & Quotation Systems

To maximize efficiency:

Link EDM with Enterprise Resource Planning (ERP) for real-time inventory updates.

Connect to quotation software to ensure accurate cost estimations based on the latest BOMs.

3. Standardize Documentation Processes

Use templates for schematics, wiring diagrams, and test reports.

Automate compliance documentation to reduce manual effort.

4. Train Teams on EDM Best Practices

Conduct workshops on data entry protocols, revision control, and system navigation.

Assign data stewards to oversee accuracy and updates.

5. Leverage Analytics for Continuous Improvement

Track design changes, production errors, and component failures to identify trends.

Use insights to refine processes and reduce recurring issues.

Conclusion

Engineering Data Management is no longer optional for electronics control panel manufacturers—it’s a strategic necessity. By implementing a robust EDM system, manufacturers can: ✔ Eliminate costly errors caused by outdated or incorrect data. ✔ Speed up project timelines with seamless collaboration. ✔ Ensure compliance with industry regulations. ✔ Reduce waste and optimize costs through accurate BOM management. ✔ Gain a competitive edge by delivering high-quality panels faster.

In an industry where precision and efficiency define success, investing in EDM is a game-changer. Manufacturers that embrace digital transformation today will lead the market tomorrow.

Is your control panel manufacturing process optimized with EDM? If not, now is the time to take the first step toward smarter, more efficient operations.

#project management software#stock management software#inventory management software#product management system#quotation management software#product management software

0 notes

Text

Easily Track Your Inventory in Real Time with TRIRID Accounting

It is not easy to manage your inventory, especially if the levels change quickly. With the help of TRIRID Accounting & Billing Software, you can easily monitor your inventory in real-time and be ahead of the game.

Why Real-Time Inventory Tracking Is Important

Accurate stock levels: Never be short of stock or overorder again! Monitor the level of your inventory at various locations in real time.

Better Cash Flow: Buy at the right time to ensure you have products.

Seamless Integration: Connect your accounting, sales, and billing processes with TRIRID for reduced manual errors and savings in time.

Faster Decisions: Real-time data ensures you are making better data-driven decisions that grow your business.

Key Features of TRIRID's Live Stock Updates

Live Inventory Monitoring: Accurate tracking of available stock.

Multi-Location Management: See and manage inventory across multiple warehouses or branches.

Low Stock Alerts: Get notified when stock levels are running low.

Automated Reordering: Set up automatic purchase orders to restock inventory.

Detailed Reports: Generate comprehensive reports on stock movement, sales, and trends.

With TRIRID Accounting & Billing Software you get more than inventory control. You get an entire account, billing, and financials solution all in one.

Ready to take hold of your inventory?

Call @ +91 8980010210 / +91 9023134246

Visit @ https://tririd.com/tririd-biz-gst-billing-accounting-software

#Best accounting software in Ahmedabad Gujarat#real-time inventory tracking#inventory management software#TRIRID-Billing software in Bopal in Ahmedabad#TRIRID-Billing software in ISCON-Ambli road-ahmedabad

0 notes

Text

Home Insurance Claims with Leevaapp: The Ultimate Home Inventory and Asset Management Tool

When it comes to home insurance claims, having a comprehensive and organized home inventory is essential. Whether you’re dealing with a minor loss or a major disaster, being able to quickly and accurately document your belongings can make the process easier and faster. But managing a home inventory without the right tools can be challenging. This is where Leevaapp comes in as the best home inventory app designed to simplify the process for you.

The Importance of Home Inventory for Insurance

A thorough home inventory for insurance purposes is crucial in case you ever need to file a claim. Insurance companies often require detailed lists of the items in your home, including descriptions, purchase dates, values, and any serial numbers. It can be difficult to remember everything, especially if you're under stress after a loss. By having an up-to-date home inventory management software like Leevaapp, you can easily create a digital record of all your assets, which is invaluable when submitting claims.

Features of Leevaapp: The Ultimate Home Inventory Software

Leevaapp is an inventory management software that offers multiple features to help you manage your home inventory efficiently. It allows you to track your belongings and store important details like descriptions, images, and even receipts. The app is designed to be user-friendly and accessible, ensuring that you can update your inventory whenever needed.

Organize Your Inventory Easily: With Leevaapp, you can categorize your assets based on rooms, types, or any other criteria you prefer. Whether you're tracking your inventory home or organizing your entire household, the app helps keep everything in order.

Track and Manage Your Assets: The best inventory tracking software provides real-time updates, ensuring that your records are always up-to-date. Whether you’re at home or on the go, you can track new purchases or changes to your assets instantly.

Prepare for Insurance Claims: Having all your belongings organized in one place not only makes it easy to retrieve information when needed but also speeds up the home insurance claims process. When filing a claim, you'll have all the necessary documentation in the app, reducing the risk of delays.

Digital Asset Management Software: Beyond basic home inventory, Leevaapp also serves as a digital asset management software. You can keep a detailed digital record of each item in your home, making it easier to prove the value of your assets if needed.

Easy to Use: With Leevaapp, you don’t need to be tech-savvy to create a professional home inventory. The intuitive design ensures that anyone can use the app to manage their assets without feeling overwhelmed.

Why Choose Leevaapp for Your Home Inventory?

The home insurance claims process can be frustrating if you don't have your inventory properly documented. Leevaapp eliminates the guesswork, helping you easily compile and maintain a detailed home inventory. It ensures you're always ready for the unexpected, with your belongings tracked and protected in the app.

Additionally, with Leevaapp, you don’t just get inventory home management for insurance; you get an all-in-one asset management software that’s perfect for any homeowner. Whether you're interested in a simple home depot inventory checker or a more robust inventory management software to track everything in your house, Leevaapp meets all your needs.

Start Organizing Your Home Inventory Today

Get ahead of any potential insurance claims or asset management needs by downloading Leevaapp today. This powerful inventory tracking software is available on both iOS and Android devices, so you can manage your home inventory from anywhere.

Leeva Secure Home Inventory on the App Store

Leevaapp on Google Play

With Leevaapp, you can ensure that your home inventory is always up-to-date, organized, and ready for anything life throws at you. Take control of your home insurance claims and asset management today!

#Insurnace claim home#home insurance claims#home insurance claims process#home inventory#inventory home#home depot inventory checker#home depot inventory#home inventory software#best home inventory app#home inventory for insurance#home inventory management software#asset management software#best inventory management software#digital asset management software#inventory management software#best inventory tracking software

0 notes