#industrial lubricant

Explore tagged Tumblr posts

Text

High-temperature grease, or high-temperature lubricating grease, is a special mix. It stands up to hot conditions and still works like a charm. Standard grease might get weak or vanish at high heat. But this high-temperature stuff stays strong, keeping its texture and ability to slide smoothly.

0 notes

Text

Oracle on 57th Street. Shell Oil Company ad - 1950.

#vintage illustration#vintage advertising#oil companies#shell oil#petroleum products#shell#american industry#the 50s#the 1950s#shell oil company#lubricants#petroleum#fossil fuels

15 notes

·

View notes

Text

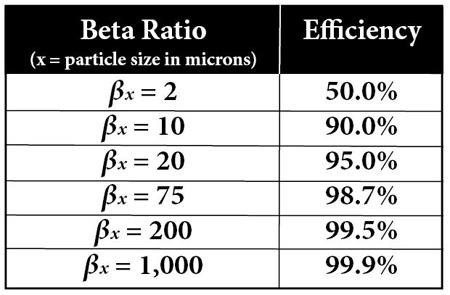

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

Motor Oil In UAE

Are you looking for high-quality motor oil products for your automotive business or industrial needs in UAE? TradersFind is your ultimate platform to connect with top-notch motor oil suppliers and manufacturers in UAE.

Trusted by buyers and sellers alike, TradersFind offers a wide range of motor oil products that meet the highest standards of quality and performance. Whether you need engine oils, lubricants, or hydraulic fluids, you can find them all on our platform.

Connect with us on WhatsApp at +971 56 977 3623 to discuss your motor oil requirements and find the perfect supplier for your business.

Visit TradersFind today and explore our comprehensive directory of motor oil suppliers in UAE. Experience the convenience of sourcing premium motor oils from trusted manufacturers and distributors, all in one platform.

Visit - https://www.tradersfind.com/category/motor-oil

#MotorOil#Automotive#Industrial#Lubricants#EngineOils#HydraulicFluids#TradersFind#B2B#UAE#Dubai#AbuDhabi#Sharjah#Ajman#RasAlKhaimah

5 notes

·

View notes

Text

May Lord Krishna brings an abundance of health and wealth at this Govardhan

Alienskart Web wishes you and your family a very happy and auspicious Govardhan Pooja. May this festival brings a lot of happiness and joy in your life. Alienskart hope this festival of Govardhan brings good fortune, wealth and prosperity to your life. May lord krishna always be in your heart and help you remain happy and healthy. Wishing you all the good things in life. Praying that the festival fills your life with unlimited happiness, peace and success.

#alienskart Web#industrial hub#industrial gadgets#commercial site#motors#gearboxes#machinery lubricants#Aliens world#online business#metal working#mechanical engineer#steel#factory gadgets

2 notes

·

View notes

Text

2 notes

·

View notes

Text

Www.nozhanpolymer.com [email protected] [email protected]

+989053007300

#engineering#oilandgas#oil#baseoil#motoroil#engineoil#locomotiveoil#petroleum#marine oil#automotive lubricants#industrial lubricants#RPO

3 notes

·

View notes

Text

just saw the funniest fucking gay sex scene since brokeback mountain. new rule: illegal to write about anal sex if you haven't had something up your own ass at least once

#it's industry on hbo btw#the shows actually really good this scene just made me roll my eyes all the way into the back off my head#someone PLEASE explain to straight men that an asshole is not just alternative pussy#it ain't gonna lubricate itself babes

5 notes

·

View notes

Text

Understanding Lubrication Tools & Accessories: The Key to Efficient Heavy-Duty Machinery Maintenance

When it comes to maintaining heavy-duty machinery, one of the most critical components is proper lubrication. Without the right lubricants and accessories, machinery can quickly wear out, resulting in downtime and costly repairs. This blog will delve into lubrication tools and accessories, highlighting their importance and guiding you to the best lubricants for heavy-duty machines.

What Are Lubrication Tools & Accessories?

Lubrication tools and accessories are devices and products used to apply lubricants to machines and equipment to reduce friction, wear, and heat buildup. These tools are essential in a variety of industries, including manufacturing, construction, and agriculture, where heavy machinery plays a significant role in daily operations.

The range of lubrication tools includes manual grease guns, automatic lubrication systems, oil dispensers, lubrication hoses, and fittings. Each tool has a unique function to ensure the proper distribution of lubricants, ensuring that moving parts are protected and can operate smoothly under heavy workloads.

Why Lubrication is Crucial for Heavy-Duty Machines

Heavy-duty machines, such as excavators, bulldozers, and industrial trucks, face extreme operating conditions. They work in harsh environments, including high-pressure, high-temperature, and high-load scenarios. The components of these machines require adequate lubrication to:

Reduce Friction: Friction is a significant contributor to wear and tear. Proper lubrication helps reduce the friction between moving parts, extending the life of components.

Dissipate Heat: Lubricants act as a heat sink, drawing heat away from the moving parts and preventing overheating.

Prevent Corrosion: Moisture and contaminants can cause corrosion. High-quality lubricants form a protective barrier that helps prevent rust and other forms of corrosion.

Improve Performance: Consistent lubrication enhances the overall performance of machinery by ensuring that parts move freely without unnecessary resistance.

Best Lubricants for Heavy-Duty Machines

Choosing the best lubricants for heavy-duty machinery is crucial for achieving optimal performance and extending the lifespan of the equipment. Here are a few key factors to consider when selecting the best lubricants:

Viscosity: The viscosity of a lubricant is one of the most important characteristics. For heavy-duty machinery, you'll need a lubricant with a high viscosity to withstand the high temperatures and pressures typical in these machines.

Additives: The best lubricants for heavy-duty machines often contain various additives to enhance their performance. These include anti-wear additives, detergents, dispersants, and corrosion inhibitors, all of which provide additional protection.

Temperature Range: Heavy-duty machines often operate in extreme temperatures. Choosing lubricants that perform well under both high and low temperatures is essential to keep the machinery running smoothly.

Synthetic vs. Mineral Oils: Synthetic oils are usually the best choice for heavy-duty machinery. They provide better stability, enhanced performance in extreme conditions, and a longer service life compared to mineral oils.

Popular options for lubricants in heavy-duty applications include:

Multi-purpose Greases: These are ideal for lubricating bearings, gears, and other components in heavy-duty machines. They often contain both synthetic oils and thickening agents to maintain performance over long periods.

High-Performance Engine Oils: Heavy-duty engines require specialized oils that can handle high-stress environments. High-performance engine oils typically contain additives to improve wear protection, oxidation stability, and corrosion resistance.

Hydraulic Oils: Hydraulic systems in heavy-duty machinery need lubricants designed to resist oxidation and foaming. High-quality hydraulic oils also protect against rust and corrosion, ensuring the system remains efficient.

Essential Lubrication Tools for Heavy-Duty Equipment

To apply lubricants effectively, you need the right tools. Below are some of the most essential lubrication tools for maintaining heavy-duty machinery:

Grease Guns: Manual and powered grease guns allow for the precise application of grease to components that require regular lubrication, such as bearings and joints. Automatic grease guns are also available for continuous, hands-free operation.

Oil Pumps and Dispensers: For machinery that requires oil-based lubricants, oil pumps and dispensers can ensure that oil is applied accurately to the right parts without spills or mess.

Automatic Lubrication Systems: These systems are ideal for large machinery fleets or high-maintenance applications. Automatic lubrication systems continuously supply lubricants to various parts of the machine, ensuring consistent lubrication and minimizing downtime.

Lubrication Hoses and Fittings: These components help deliver the lubricant from the source to the parts that need it. Durable hoses and well-sealed fittings are essential to prevent leaks and ensure efficient application.

Regular Maintenance: The Role of Lubrication Accessories

Lubrication tools and accessories are not only useful for applying lubricants but also for ensuring their consistent performance. Regular maintenance checks are crucial for heavy-duty machinery, and lubrication accessories, such as filters, reservoirs, and level gauges, play a vital role in monitoring and managing lubrication levels.

Filters: Filters are used to remove contaminants from lubricants, ensuring that only clean lubricant is applied to sensitive machinery parts.

Reservoirs: Proper storage and containment of lubricants are necessary for ensuring that the right quantity is available when needed. Using well-maintained reservoirs ensures that lubrication is always ready for use.

Level Gauges: These accessories help operators monitor the lubricant levels in various parts of the machinery, ensuring that maintenance can be performed at the right intervals.

Conclusion

Lubrication tools and accessories are essential for maintaining the health and efficiency of heavy-duty machinery. Using the best lubricants for heavy-duty machines, combined with the right tools and accessories, can help extend the life of your equipment, improve performance, and reduce costly repairs.

Regular lubrication and maintenance should be part of every operator's routine to ensure that machinery continues to run smoothly under demanding conditions. By investing in high-quality lubricants and accessories, you're not only protecting your equipment but also ensuring that it performs at its best, day after day.

#industrial equipment#groz usa#heavyduty#lubrication#woodworking#hammer#frl combination sets#handtools#tools#grozusa#Lubrication Tools & Accessories#Lubrication Tools#Lubrication Accessories#woodworking hand tools#automotive hand tools#ai tools#automotive tools#writing tool#beauty tools and accessories#electric#howto#record#phone#electronics#bussiness#busservices#tool store#online store#store

0 notes

Text

Time to Use Grease

Grease is crucial for mechanical operations requiring lubrication. It's especially handy when oil isn't enough due to its tendency to flow or be displaced. Grease, a semi-solid lubricant with thickening agents, acts as a sealant, ensuring continuous lubrication for vehicles and machinery. Visit here: https://www.quora.com/When-should-grease-be-used/answer/Rahul-Bhutt

0 notes

Text

Specs for 20-20 eyes. Shell Oil Company ad - 1945.

#vintage illustration#vintage advertising#oil companies#shell oil#petroleum products#shell#american industry#life during wartime#ww2#wwii#wwii era#ww2 era#the 40s#the 1940s#shell oil company#lubricants#petroleum#fossil fuels#war production#military industrial complex#war supplies#world war ii#world war two#world war 2

4 notes

·

View notes

Text

Success Story: A small change can bring a Big Difference

Do you agree that the little things, if done consistently, add to the big things? The same applies to every field of life, whether it is personal or professional. The very recent example recites it very true. The whole story begins with an opportunity to supply and commission 8 numbers of Oil Quality Testing Equipment for a sector that is crucial regarding the nation's safety. It was a great experience to work with the best brains and brave hearts.

We started our journey from Pune to a remote location in Odisha, Koraput. When we landed at the nearest airport, we knew it was more than a 5-hour journey by road, crossing many hills, valleys, forests, and ghats. During our travel, we encountered many wild animals and, surprisingly, snakes like pythons crossing the road. Probably, high wind and rain were making it more scary and adventurous. We arrived at our stay very late at night. After such a long day, we were excited to hit the bull’s eye the next day.

We couldn’t resist the enthusiasm and reached the plant before the time the next morning. We were very happy to see the grand welcome following intense security protocols. The industry can be classified as Defense & Space. A division regularly conducted workshops for the customers to better understand and utilize the products.

We showed our advanced Oil Testing Equipment, LPA3, but a few officers were not confident enough about the deliverables. The technology they used then was outdated and failed to meet the latest standard. We had to install, commission, and demonstrate 8 particle counters at different locations and in different machines. We did it within 10 working hours, which was an achievement in every sense. Along with the demonstration, we made them understand the minimum human intervention and the impossibility of tampering with our oil quality testing equipment results. As they were following traditional practices, this technological advancement was much needed in their plant, and it was about to bring a big difference. We did our best in the least time. The company officials were really happy & fulfilled and so were we. It was a great experience, and a perfect example of a small change can bring a big difference.

Subscribe to our YouTube Channel and be a part of our Journey - Cick Here

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil#lube oil flushing#oil testing#oil filters#oil industry#oil and gas#oil#gas turbine market trends#gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power generation#metal#heavy metal#mining#oil dehyration#oil dehydration systems#oil purification system#hydraulic oil flushing#oil flushing systems

0 notes

Text

Synthetic Lubricants Market Industry Outlook: Forecasting Market Trends and Growth for the Coming Years

Synthetic Lubricants Market Strategies: Taking Advantage of Trends to Drive Growth in 2032

The Synthetic Lubricants Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Synthetic Lubricants Market market size was valued at USD 17.2 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 22.9 Billion by 2031, growing at a CAGR of 3.28% during the forecast period (2023–2031).

Get Free Request Sample Report @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

TOP Key Industry Players of the Synthetic Lubricants Market

Royal Dutch Shell

ExxonMobil

Sasol

Valvoline

British Petroleum

Chevron

Morris Lubricants

Dow

Indian Oil

Petronas

Lukoil

Idemitsu Kosan

Fuchs

Total Energies

Sinopec

Global Synthetic Lubricants Market: Segmentation

As a result of the Synthetic Lubricants market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Applications

Engine Oil

Transmission Fluids and Hydraulic Fluids

Metalworking Fluids

Greases

Others

By End-User

Power Generation

Automotive and Transportation

Heavy Equipment

Food and Beverage

Others

By Type

Polyalphaolefin

Esters

Polyalkylene Glycol

Browse Full Report and TOC @ https://straitsresearch.com/report/synthetic-lubricants-market/request-sample

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Synthetic Lubricants Market#Synthetic Lubricants Market Share#Synthetic Lubricants Market Size#Synthetic Lubricants Market Research#Synthetic Lubricants Industry#What is Synthetic Lubricants?

0 notes

Text

ELGi's Oil lubricated compressors ensures smooth operation

ELGi's Oil lubricated compressors ensures smooth operation, reduced friction, and extended equipment life. They are typically more powerful and efficient than oil-free models, making them suitable for demanding industrial applications.

0 notes

Text

Industrial Lubricants Market Size, Share, Research, Report 2030

0 notes