#industrial gases glass industry market report

Explore tagged Tumblr posts

Text

The global industrial gases-glass industry market size grew from $3.5 billion in 2022 to $3.81 billion in 2023 at a compound annual growth rate (CAGR) of 8.8%.

#industrial gases glass industry market report#industrial gases glass industry market segment#industrial gases glass industry market size#industrial gases glass industry market research#industrial gases glass industry market forecast#industrial gases glass industry market trends#global industrial gases glass industry market#industrial gases glass industry market growth#industrial gases glass industry market analysis#industrial gases glass industry market share#industrial gases glass industry market

0 notes

Text

Flue Gas Desulfurization Systems Market - Forecast(2024 - 2030)

FGD systems is utilizing in the industry to extract to remove Sulphur dioxide (SO2) from the flue gases, it assist in lowering the amount of SO2 in flue gas and assist greenhouse gas emission. Dry, wet and semi dry FGD systems is the key technology to the market. wet FGD is mostly use in the market that is high priced as compare to the dry FGD system and it have low maintenance and operating cost feature also. Dry FGD system perform efficiently in power plant with the capacity of 300MW while wet FGD system efficiency is more than 300MW. Some of the country is growing the flue gas desulfurization market for thermal power generation, the control of SO2 emission from thermal power plant is examined in developing commercial process.

Request Sample

The worldwide Flue Gas Desulfurization Systems Market has been analyzed on the basis its types and the process and different absorbers of flue gas desulfurization and their applications. FGD process are segmented as throwaway product, saleable product process. It has many applications in different industry such as to produce the power, to provide energy to metal smelters, and for cement kilns.

What is Flue Gas Desulfurization Systems Market?

Term flue gas desulfurization referred to wet scrubbers which remove Sulphur dioxide (SO2) from emissions of coal combustion. Flue gas desulfurization is commonly named as FGD, this technology is generally used in power plants to extract the Sulphur dioxide (SO2) from the exhaust combustion gases, this combust gases comes when they burn coal or oil to produce steam for turbines that drive electricity generators. In FGD we use acid rain or acid control system interchangeably to segment a wide range of control system design. FGD system can be categorized as dry FGD, semi-dry FGD, and wet FGD system.

Inquiry Before Buying

What are the applications of Flue Gas Desulfurization Systems Market?

Flue gas desulfurization system has various role to the environment, their sub process such as lime plays a key role to air pollution control. It has many typical industrial application such as pollution control in utility combustion in industry like stationary coal and oil fired, other combustion unit such as medical and municipal waste incinerators, petroleum refineries, glass furnaces, metal smelters, and cement and lime kilns manufacturing facilities.

Market Research and Market Trends of Flue Gas Desulfurization Systems Market:

Many of the country with high pollution rate are working for new advanced feature of FGD system, which is one of the outcomes to their continuous innovation over years. This new AFGD system is more efficient as compare to FGD system efficiency.

FGD scrubbers system creates a wastewater stream which contains high suspended solids, metals and chloride content that is very difficult to handle and recycling for reuse in power plant. So without disposing that waste water they take it into the Zero-liquid discharge (ZLD) water treatment process which completely recycle water under certain limitations.

Schedule a Call

Who are the Major Players of Flue Gas Desulfurization Systems Market?

The major players in this market are Siemens, Chinaboqi, Babcock & Wilcox Company and XX other companies.

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Buy Now

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#flue gas desulfurization systems market#flue gas desulfurization systems market price#flue gas desulfurization systems market size#flue gas desulfurization systems market shape#flue gas desulfurization systems market report#flue gas desulfurization systems market research#flue gas desulfurization systems market forecast#Sulphur dioxide (SO2)#flue gases#exhaust combustion gases

0 notes

Text

Pharmaceutical Glass Packaging Market: Trends, Challenges, and Growth Opportunities Driving Innovation in Sterility and Sustainability Solutions

According to a new report by UnivDatos Market Insights, the Pharmaceutical Glass Packaging Market, is expected to reach USD 26 billion in 2030 by growing at a CAGR of 8%. Pharmaceutical glass packaging refers to a type of packaging made from a variety of glass components and designed to ensure the secure carriage of various medical products. By nature, glass is so resistant to temperature changes, using it for pharmaceutical packaging presents many advantages. Glass is extensively used to package a variety of pharmaceutical drugs and medicines. Ultra-resistant borosilicate glass, soda-lime glass with a surface treatment, normal soda-lime glass, and soda-lime glass for general use are some of the widely used pharmaceutical glass packaging materials. Based on product, the market is segmented into bottles, vials, ampoules, cartridges and syringes and others. Based on drug type, the market is divided into generic, branded and biologic. Based on application, the market is segmented into oral, injectable, nasal and others. North America Pharmaceutical glass packaging market is expected to continue to grow in the coming years.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=51543&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

The report suggests that the Increasing Pharmaceutical industry is the major factors driving the growth of the pharmaceutical glass packaging market during the forthcoming years. The pharmaceutical industry has been experiencing significant growth in recent years, and this expansion has a direct and profound impact on the packaging sector, particularly the pharmaceutical glass packaging market. This growth can be attributed to various factors, each playing a crucial role in shaping the landscape of the pharmaceutical industry and, consequently, the demand for reliable and efficient packaging solutions.

One of the primary drivers behind the increasing demand for pharmaceutical glass packaging is the rapid expansion of the pharmaceutical sector worldwide. The pharmaceutical industry encompasses the research, development, manufacturing, and distribution of drugs and medications, catering to a diverse range of healthcare needs. As global populations continue to grow and age, there is a parallel increase in the prevalence of various health conditions, driving the demand for pharmaceutical products.

Pharmaceutical companies are continually innovating and introducing new drugs to address emerging health challenges, including chronic diseases, infectious diseases, and rare disorders. This proliferation of drug development has led to a surge in the production of pharmaceuticals, consequently fueling the demand for appropriate packaging solutions. Pharmaceutical glass packaging is favored in this context due to its unique properties that ensure the safety, stability, and efficacy of the enclosed medications.

The inert nature of glass makes it an ideal material for pharmaceutical packaging. Glass is non-reactive and does not interact with the drugs it contains, ensuring that the integrity of the medication is maintained throughout its shelf life. This is particularly crucial for sensitive drugs and biopharmaceuticals, which are becoming increasingly prevalent in the pharmaceutical market. Biologics, vaccines, and specialty pharmaceuticals often require specialized packaging that can provide the necessary protection against external factors, and glass is well-suited for this purpose.

In addition to its inert qualities, glass offers excellent barrier properties. It is impermeable to gases and moisture, providing an effective barrier against external contaminants. This is essential for preserving the stability of medications, especially those that are susceptible to degradation in the presence of oxygen or moisture. The ability of glass to act as a barrier contributes to the extension of the shelf life of pharmaceutical products, meeting the stringent quality standards imposed by regulatory authorities.

Stringent regulations and quality standards in the pharmaceutical industry also play a pivotal role in driving the adoption of glass packaging. Regulatory authorities, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have established strict guidelines to ensure the safety and efficacy of pharmaceutical products. Glass packaging is often preferred as it complies with these regulations, providing a reliable and compliant solution for pharmaceutical companies.

The rising healthcare expenditure globally is another key driver contributing to the growth of the pharmaceutical industry and, consequently, the demand for pharmaceutical glass packaging. As countries invest more in their healthcare systems, there is an increased capacity for research and development, healthcare infrastructure, and the accessibility of pharmaceutical products. This investment supports the pharmaceutical industry by facilitating advancements in drug discovery and development, leading to a greater need for suitable packaging materials.

Moreover, the growing focus on personalized medicine and advancements in therapeutic areas such as oncology and rare diseases contribute to the expansion of the pharmaceutical industry. These specialized medications often require packaging solutions that can ensure precise dosing, protection from external elements, and long-term stability—all of which are attributes associated with pharmaceutical glass packaging.

The global nature of the pharmaceutical supply chain further emphasizes the importance of reliable packaging materials. Pharmaceutical products are manufactured in one location and distributed globally, requiring packaging solutions that can withstand international transportation and storage conditions. Glass packaging's durability and protective qualities make it a preferred choice for pharmaceutical companies aiming to maintain the integrity of their products across diverse geographic regions.

Advancements in glass packaging technology also contribute to the growing popularity of pharmaceutical glass packaging. Innovations such as improvements in glass strength, weight reduction, and enhanced barrier properties are enhancing the performance of glass as a packaging material. These advancements address concerns related to the weight and fragility of traditional glass packaging, making it more feasible and cost-effective for pharmaceutical manufacturers.

The environmental considerations associated with glass packaging further support its role in the pharmaceutical industry. Glass is a highly recyclable material, aligning with the increasing emphasis on sustainability and eco-friendly packaging solutions. Pharmaceutical companies are under growing pressure to adopt environmentally responsible practices, and the recyclability of glass positions it as a favorable choice for those seeking to reduce their environmental footprint.

Additionally, the consumer's heightened awareness of safety and the importance of secure pharmaceutical packaging contributes to the preference for glass. Consumers often associate glass with purity and safety, trusting it as a material that will not leach harmful substances into their medications. This perception aligns with the pharmaceutical industry's commitment to patient safety and contributes to the positive image of glass packaging in the eyes of consumers.

Click here to view the Report Description & TOC : https://univdatos.com/get-a-free-sample-form-php/?product_id=51543&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Conclusion

the increasing growth of the pharmaceutical industry serves as a driving force behind the rising demand for pharmaceutical glass packaging. This growth is fueled by a combination of factors, including the expansion of the pharmaceutical sector, advancements in drug development, regulatory requirements, and the unique properties of glass as a packaging material. As the pharmaceutical industry continues to evolve to meet the healthcare needs of a growing and aging population, the demand for reliable, safe, and efficient packaging solutions like glass is expected to persist and even escalate in the coming years.

In a rapidly changing and dynamic pharmaceutical landscape, the role of glass packaging remains integral in ensuring the integrity and efficacy of pharmaceutical products. Its inert nature, barrier properties, compliance with regulations, and sustainability make it a preferred choice for pharmaceutical companies aiming to deliver high-quality and safe medications to patients globally. As the pharmaceutical industry continues to innovate and expand, the pharmaceutical glass packaging market is poised for sustained growth, driven by the essential role it plays in preserving the safety and efficacy of pharmaceutical products.

0 notes

Text

0 notes

Text

Specialty Gases for FPD Market Analysis, Demand, Trends and Forecast 2030

On 2024-8-8 Global Info Research released【Global Specialty Gases for FPD Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030】. This report includes an overview of the development of the Specialty Gases for FPD industry chain, the market status of Consumer Electronics (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), Household Appliances (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Specialty Gases for FPD. According to our (Global Info Research) latest study, the global Specialty Gases for FPD market size was valued at US$ 984 million in 2023 and is forecast to a readjusted size of USD 1527 million by 2030 with a CAGR of 7.1% during review period. This report is a detailed and comprehensive analysis for global Specialty Gases for FPD market. Both quantitative and qualitative analyses are presented by company, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided. Market segment by Type: CVD Gas、Deposition Gas、Ion Implantation Gas、Etching Gas、Laser Gas Market segment by Application:LCD、OLED、LED Major players covered: SK specialty、Merck (Versum Materials)、Taiyo Nippon Sanso、Linde plc、Kanto Denka Kogyo、Hyosung、PERIC、Resonac、Solvay、Nippon Sanso、Air Liquide、Air Products、Foosung Co Ltd、Jiangsu Yoke Technology、Jinhong Gas、Linggas、Mitsui Chemical、ChemChina、Shandong FeiYuan、Guangdong Huate Gas、Central Glass、Jiangsu Nata Opto-electronic Material、Hunan Kaimeite Gases

Market segment by region, regional analysis covers: North America (United States, Canada and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe), Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa). The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Specialty Gases for FPD product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Specialty Gases for FPD, with price, sales, revenue and global market share of Specialty Gases for FPD from 2019 to 2024. Chapter 3, the Specialty Gases for FPD competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Specialty Gases for FPD breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Specialty Gases for FPD market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Specialty Gases for FPD. Chapter 14 and 15, to describe Specialty Gases for FPD sales channel, distributors, customers, research findings and conclusion.

Data Sources:

Via authorized organizations:customs statistics, industrial associations, relevant international societies, and academic publications etc.

Via trusted Internet sources.Such as industry news, publications on this industry, annual reports of public companies, Bloomberg Business, Wind Info, Hoovers, Factiva (Dow Jones & Company), Trading Economics, News Network, Statista, Federal Reserve Economic Data, BIS Statistics, ICIS, Companies House Documentsm, investor presentations, SEC filings of companies, etc.

Via interviews. Our interviewees includes manufacturers, related companies, industry experts, distributors, business (sales) staff, directors, CEO, marketing executives, executives from related industries/organizations, customers and raw material suppliers to obtain the latest information on the primary market;

Via data exchange. We have been consulting in this industry for 16 years and have collaborations with the players in this field. Thus, we get access to (part of) their unpublished data, by exchanging with them the data we have.

From our partners.We have information agencies as partners and they are located worldwide, thus we get (or purchase) the latest data from them.

Via our long-term tracking and gathering of data from this industry.We have a database that contains history data regarding the market.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

How Custom Reed Switch Sensors Improve Industrial Automation

In the realm of industrial automation reed switch based sensors ,are paramount because it has precision, reliability, and efficiency . As technology continues to evolve, custom reed switch sensors are playing an increasingly critical role in enhancing these aspects. This article delves into how custom reed switch sensors are revolutionising industrial automation, highlighting their benefits, applications, and impact on the industry.

Understanding Reed Switch Sensors

Reed switch sensors are electromagnetically devices that consist of two ferromagnetic blades sealed within a glass envelope. When exposed to a magnetic field, these blades either come together or separate, thereby opening or closing an electrical circuit. This fundamental yet robust mechanism is ideal for a wide range of industrial applications.

Benefits of Custom Reed Switch Sensors in Industrial Automation

1. Enhanced Precision and Control

Custom reed switch sensors can be tailored to meet specific operational requirements, ensuring precise control and measurement. This customisation allows for fine-tuning of sensor sensitivity and activation points, resulting in more accurate and reliable data collection and system responses. According to a study by Grand View Research, the global industrial automation market is expected to reach $296.7 billion by 2026, driven by the demand for precision and efficiency.

2. Increased Reliability and Durability

Industrial environments often expose equipment to harsh conditions, including extreme temperatures, vibrations, and corrosive substances. Custom reed switch sensors are designed to withstand these challenges, offering high durability and reliability. The Reed Switch Development Company reports that reed switch sensors can last up to 50 years, making them a cost-effective solution for long-term industrial applications.

3. Energy Efficiency

Reed switch sensors consume very little power, making them ideal for energy-efficient industrial automation systems. They only use power when switching states, which contributes to overall energy savings and reduced operational costs. This is particularly beneficial in large-scale industrial operations where energy consumption is a critical concern.

4. Compact and Versatile Design

The compact size of reed switch sensors allows for easy integration into various industrial equipment and systems. Their versatility makes them suitable for a wide range of applications, from simple position detection to complex control systems. This adaptability helps streamline the design and implementation of automated processes.

Key Applications of Custom Reed Switch Sensors in Industrial Automation

1. Position Sensing and Control

Custom reed switch sensors are extensively used for position sensing in industrial automation. They detect the presence, absence, or position of an object, providing critical data for process control and monitoring. For example, in manufacturing lines, reed switch sensors can detect the position of conveyor belts and robotic arms, ensuring precise and efficient operation.

2. Flow Measurement and Control

In fluid handling systems, custom reed switch sensors are used to monitor and control the flow of liquids and gases. These sensors can detect the flow rate and trigger valves or pumps to maintain optimal levels. The global flow sensor market, according to MarketsandMarkets, is projected to reach $8.5 billion by 2025, indicating the growing importance of accurate flow measurement in industrial processes.

3. Safety and Security Systems

Reed switch sensors play a crucial role in industrial safety and security systems. They are used to monitor the status of doors, gates, and machinery guards, ensuring they are securely closed or in the correct position. In case of unauthorized access or unsafe conditions, these sensors can trigger alarms or shutdown procedures, preventing accidents and enhancing workplace safety.

4. Environmental Monitoring

Custom reed switch sensors are also employed in environmental monitoring systems within industrial settings. They can detect changes in conditions such as temperature, humidity, and pressure, enabling real-time adjustments to maintain optimal operating environments. This capability is essential for industries like pharmaceuticals and food processing, where environmental conditions are tightly regulated.

Real-World Examples of Custom Reed Switch Sensor Applications

Automotive Manufacturing

In automotive manufacturing, custom reed switch sensors are used in assembly lines to monitor the position of parts and components. They ensure that each part is correctly positioned before proceeding to the next stage of assembly, reducing errors and improving overall production efficiency.

Chemical Processing Plants

Chemical processing plants utilize custom reed switch sensors to monitor the flow and levels of various chemicals. These sensors help maintain the correct mixture and concentration of chemicals, ensuring product quality and safety.

Packaging Industry

In the packaging industry, reed switch sensors are integrated into machinery to detect the presence of packages and containers. They ensure that each package is correctly sealed and labeled, enhancing productivity and reducing waste.

Future Trends in Custom Reed Switch Sensors for Industrial Automation

The future of custom reed switch sensors in industrial automation looks promising, with several trends poised to drive further advancements:

Integration with IoT and Industry 4.0

The integration of reed switch sensors with the Internet of Things (IoT) and Industry 4.0 technologies is set to revolutionize industrial automation. These integrations allow for real-time data collection, remote monitoring, and predictive maintenance, significantly improving efficiency and reducing downtime. A McKinsey report estimates that IoT applications could generate up to $11.1 trillion per year in economic value by 2025.

Advancements in Sensor Materials and Technology

Ongoing research and development in sensor materials and technology are leading to more sensitive, durable, and efficient reed switch sensors. These advancements will expand their application range and enhance their performance in challenging industrial environments.

Miniaturisation and Customisation

The trend towards miniaturisation and increased customisation will continue, enabling the development of even smaller and more specialised reed switch sensors. This will allow for greater flexibility in sensor placement and integration, further streamlining industrial automation processes.

Conclusion

Custom reed switch sensors offer numerous benefits for industrial automation, including enhanced precision, reliability, energy efficiency, and versatility. Their applications span a wide range of industries, from automotive manufacturing to chemical processing and environmental monitoring. As technology continues to evolve, these sensors will play an increasingly important role in driving innovation and efficiency in industrial automation.

Investing in custom reed switch sensors is not just about improving current operations; it's about preparing for the future of industrial automation. By leveraging the advantages of these sensors, industries can enhance their productivity, safety, and overall performance, staying ahead in an increasingly competitive landscape.

0 notes

Text

Industrial Gases Market: Navigating the Impact of Geopolitical Tension

Overview

Industrial Gases Market size was valued to be worth USD 100.5 Billion in 2022. From 2023 to 2032, it is estimated to reach USD 192.6 billion growing at a CAGR of 6.9%.

The industrial gases market refers to the industry involved in the production and distribution of gases like nitrogen, oxygen, carbon dioxide, and hydrogen, which are crucial for various industrial applications. These gases are typically supplied to end-use industries, such as food and beverage, electronics, healthcare, and steel manufacturing, in both liquefied and gaseous forms.

They are produced using cryogenic air filtration techniques in air separation units, and their applications range from refrigeration and fuel to specialty and medical uses. The market's growth is driven by the increasing demand for these gases across diverse sectors, particularly as industries continue to globalize and expand their manufacturing and processing capabilities.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/industrial-gases-market/request-sample/

This expansion is further supported by the rapid development of sectors such as steel, glass, oil, and fiber optics in developing countries, which require substantial amounts of industrial gases. As these industries continue to grow, the demand for industrial gases is expected to rise, creating new growth opportunities for market players and contributing to the overall expansion of the industrial gases market.

Key Market Segments

Product

Oxygen

Nitrogen

Carbon dioxide

Hydrogen

Argon

Acetylene

Other Products

Application

Packaging

Coolant

Carbonation

Cryogenic

Cutting & Welding

Laboratory

Air Separation

Other Applications

Distribution

Onsite

Bulk (Liquid Gas Transport)

Cylinder (Merchant)

End-User

Metallurgy

Healthcare

Chemical

Food & beverage

Oil & Gas

Power

Pulp & Paper

Electronics

Water Treatment

Mining

Other End-Users

The industrial gases market is significantly influenced by the dominance of the oxygen segment, which held a 27.5% share in 2022. Oxygen is crucial for steel melting, fabrication, and medical applications, enhancing fuel efficiency and aiding in environmental cleanup. Nitrogen's primary role is in creating ammonia for fertilizers and explosives, Carbon dioxide, utilized as refrigerants and coolants, also plays a vital role in the chemical and food industries due to its inert properties.

Market Key Players:

Yingde Gases Group Company Limited

Air Liquide S.A

Linde Group

Airgas Inc.

Messer Group

Buzwair Industrial Gases Factories

Air Products and Chemicals Inc.

Taiyo Nippon Sanso Corporation

Air Water Incorporation

BASF SE

INOX-Air Products Inc.

Iwatani Corporation

Other Key Players

Driving Factors:

The global industrial gases market is being driven by the increasing consumption of oil and gases, fueled by public and private investments in sectors such as metallurgy, food and beverage, mining, and metals. Rising demand for crude oil and the need for refining processes have also boosted the use of industrial gases in the oil and natural gas industries, with applications in drilling, well raising, and maintenance.

Restraining Factors:

Market growth is being hampered by stringent regulations and high costs associated with gas storage, transportation, and manufacturing. Regulations such as the EU Regulation 231/2012 and ADR 13, along with environmental inspections and increased transit costs, have raised industrial gas prices.

Growth Opportunity:

The growing demand for industrial gases in emergency situations, as well as in the food and beverage, electronics, and healthcare sectors, presents significant growth opportunities. Rapid development in steel, glass, oil, and fiber optics industries, especially in developing countries, is also contributing to market expansion.

Challenges:

A major challenge for the industrial gases market is the production of low-cost gases. High costs associated with industrial gas production and distribution, along with stringent regulatory requirements, make it difficult to achieve cost-effective solutions. The need for long-term gas purchase contracts due to the high capital costs of air separation units (ASUs) adds to the financial burden on major industrial customers.

0 notes

Text

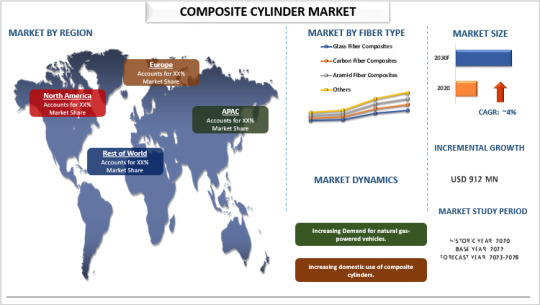

The Growth and Dynamics of the Composite Cylinder Market

The composite cylinder market has witnessed significant growth in recent years, driven by advancements in materials technology, increasing safety regulations, and a growing demand for lightweight, durable, and efficient gas storage solutions. Composite cylinders, made from high-strength fibers such as glass, aramid, or carbon embedded in a matrix of polymer resin, are becoming the preferred choice across various industries due to their superior properties compared to traditional metal cylinders.

Market Drivers

1. Technological Advancements: The development of advanced composite materials has been a key driver for the composite cylinder market. These materials offer high strength-to-weight ratios, corrosion resistance, and improved safety features. The integration of nanotechnology and improved manufacturing processes has further enhanced the performance and reliability of composite cylinders.

2. Regulatory Compliance and Safety: Stringent safety regulations and standards imposed by governments and international bodies have fueled the adoption of composite cylinders. These cylinders are designed to withstand high pressures and harsh environments, reducing the risk of leaks and explosions. Compliance with standards such as ISO 11119 and DOT specifications ensures their acceptance in various regions and applications.

3. Environmental Concerns: The growing emphasis on reducing carbon footprints and promoting sustainability has led to increased demand for eco-friendly solutions. Composite cylinders are lightweight, which reduces transportation fuel consumption and greenhouse gas emissions. Additionally, their longer lifespan compared to metal cylinders means fewer replacements and less environmental waste.

4. Rising Demand in Various Applications: Composite cylinders are used in a wide range of applications, including industrial gases, medical oxygen, automotive, aerospace, and recreational activities. The automotive industry, in particular, is witnessing a surge in demand for composite cylinders due to the increasing adoption of alternative fuel vehicles such as hydrogen and compressed natural gas (CNG) vehicles.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/composite-cylinder-market/

Market Segmentation

The composite cylinder market can be segmented based on material type, end-user, and region.

1. Material Type:

- Glass Fiber Composites: These cylinders are economical and offer moderate performance, making them suitable for applications with lower pressure requirements.

- Carbon Fiber Composites: Known for their high strength and lightweight properties, carbon fiber composite cylinders are ideal for high-pressure applications and are extensively used in aerospace and automotive industries.

- Aramid Fiber Composites: These provide a balance between performance and cost, offering good resistance to impacts and chemicals, thus finding use in various industrial applications.

2. End-User:

- Industrial: The industrial sector uses composite cylinders for storing and transporting gases such as oxygen, nitrogen, and argon.

- Healthcare: In the healthcare sector, composite cylinders are crucial for medical oxygen delivery systems due to their lightweight and portable nature.

- Automotive: The rise of hydrogen fuel cell vehicles and CNG vehicles has boosted the demand for composite cylinders in the automotive industry.

- Aerospace and Defense: Composite cylinders are used in aircraft for oxygen supply and in defense applications for breathing apparatuses and other critical systems.

3. Region:

- North America: The region has a well-established market for composite cylinders, driven by the presence of major manufacturers and stringent safety regulations.

- Europe: Europe is witnessing growth in the composite cylinder market due to increased adoption of alternative fuel vehicles and a strong focus on sustainability.

- Asia-Pacific: Rapid industrialization, urbanization, and the push for cleaner energy solutions are driving the market in the Asia-Pacific region.

- Rest of the World: Other regions are also contributing to market growth, particularly in niche applications and emerging markets.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=46359

Challenges and Future Outlook

Despite the positive growth trajectory, the composite cylinder market faces challenges such as high initial costs, complex manufacturing processes, and the need for specialized equipment and handling. However, ongoing research and development activities aimed at reducing costs and improving manufacturing efficiency are expected to mitigate these challenges over time.

The future of the composite cylinder market looks promising, with increasing investments in hydrogen infrastructure, advancements in material science, and expanding applications across various industries. As the world continues to transition towards cleaner energy solutions and sustainable practices, the demand for composite cylinders is set to rise, making them a vital component in the global push for a greener and safer future.

In conclusion, the composite cylinder market is poised for significant growth, driven by technological advancements, regulatory support, environmental concerns, and expanding applications. As industries continue to seek efficient and sustainable solutions, composite cylinders will play a crucial role in meeting these demands, ensuring safety, reliability, and performance in a wide range of applications.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Composite Cylinder Market#Composite Cylinder Market Growth#Composite Cylinder Market Share#Composite Cylinder Market Trends

0 notes

Text

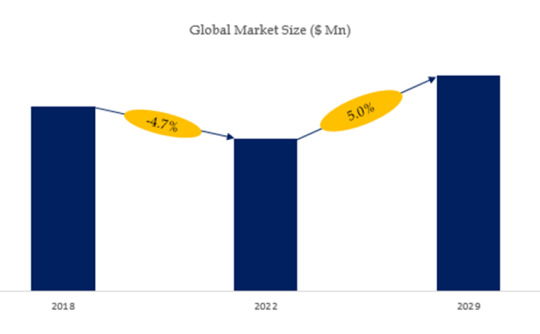

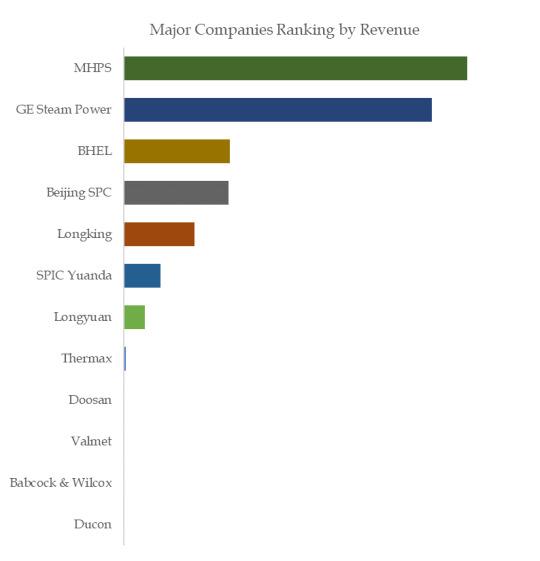

Global Top 5 Companies Accounted for 77% of total Flue Gas Desulfurizer (FGD) market (QYResearch, 2021)

Flue gas desulfurizer (FGD) is equipment which can remove sulfur dioxide (SO2) from flue gas emissions, often chemically. Sulfur dioxide in gases is produced by the combustion of fossil fuels and many industrial processes such as gasoline refining as well as cement, paper, glass, steel, iron and copper production. Sulfur dioxide emissions are a primary contributor to acid rain and have been regulated by every industrialized nation in the world.

FGD processes vary depending on the amount of SO2 involved, the solution being used to absorb the SO2, and the particular equipment used in the absorption tower.

According to the new market research report “Global Flue Gas Desulfurizer (FGD) Market Report 2023-2029”, published by QYResearch, the global Flue Gas Desulfurizer (FGD) market size is projected to reach USD 6.29 billion by 2029, at a CAGR of 5.0% during the forecast period.

Figure. Global Flue Gas Desulfurizer (FGD) Market Size (US$ Million), 2018-2029

Figure. Global Flue Gas Desulfurizer (FGD) Top 12 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Flue Gas Desulfurizer (FGD) include MHPS, GE Steam Power, BHEL, Beijing SPC, Longking, SPIC Yuanda, Longyuan, Thermax, Ducon, Babcock & Wilcox, etc. In 2020, the global top five players had a share approximately 77.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

The global industrial gases-glass industry market size grew from $3.5 billion in 2022 to $3.81 billion in 2023 at a compound annual growth rate (CAGR) of 8.8%.

#industrial gases glass industry market report#industrial gases glass industry market segment#industrial gases glass industry market size#industrial gases glass industry market research#industrial gases glass industry market forecast#industrial gases glass industry market trends#global industrial gases glass industry market#industrial gases glass industry market growth#industrial gases glass industry market analysis#industrial gases glass industry market share#industrial gases glass industry market

0 notes

Text

Water-Based Barrier Coatings Market Outlook and Forecast 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Water-Based Barrier Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Water-Based Barrier Coatings Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Water-Based Barrier Coatings?

The global water-based barrier coatings market size reached US$ 3.9 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 6.5 billion in 2032, exhibiting a growth rate (CAGR) of 5.9% during 2024-2032.

What are Water-Based Barrier Coatings Market?

Water-based barrier coatings refer to aqueous formulations applied to surfaces to establish a protective layer that repels liquids, gases, or other substances. These coatings are environmentally friendly, predominantly utilizing water as a solvent to reduce the presence of volatile organic compounds (VOCs). Widely employed in industries like packaging, water-based barrier coatings act as a safeguard against moisture, oil, and contaminants, thereby augmenting the durability and preservation of products. Applied to materials such as paper and cardboard, these coatings provide a sustainable and less hazardous alternative to solvent-based counterparts. Their adaptability and eco-friendly characteristics contribute to their increasing popularity across various applications, driving the demand in the market.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1902

What are the growth prospects and trends in the Water-Based Barrier Coatings Market industry?

The water-based barrier coatings market growth is driven by various factors. The market for water-based barrier coatings is experiencing notable growth as industries increasingly opt for environmentally sustainable solutions in surface protection. These coatings, formulated with water as a primary solvent, provide a green alternative to traditional solvent-based options. Predominantly utilized in packaging, water-based barrier coatings establish protective layers that effectively repel liquids and gases, thereby improving the durability and overall quality of products. The market's expansion is driven by the rising demand for eco-conscious solutions, with these coatings finding applications across various industries where resistance to moisture and contaminants is essential. The adaptable and environmentally friendly characteristics of water-based barrier coatings position them as significant players in the evolving landscape of surface protection technologies. Hence, all the factors contribute to water-based barrier coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Market Segmentation By Type:

Acrylic

Polyurethane

Epoxy

Others

Market Segmentation By Substrate:

Metal

Paper & Paperboard

Plastic

Glass

Others

Market Segmentation By End-Use Industry:

Packaging

Building & Construction

Automotive

Electronics

Textile

Others

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Akzo Nobel N.V.

PPG Industries Inc.

Axalta Coating Systems Ltd.

BASF SE

The Sherwin-Williams Company

RPM International Inc.

Arkema Group

Dow Inc.

Valspar Corporation

Asian Paints Limited

Nippon Paint Holdings Co., Ltd.

Hempel A/S

Jotun Group

Sika AG

Kansai Paint Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Water-Based Barrier Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Water-Based Barrier Coatings Market Size#Water-Based Barrier Coatings Market Share#Water-Based Barrier Coatings Market Demand#Water-Based Barrier Coatings Market Analysis

0 notes

Text

Biomass Gasification Market: Unlocking Market Potential

Renewable Energy Mandates and Policies and Technological Advancements are the factors propelling the market growth.

According to TechSci Research report, “Global Biomass Gasification Market - Industry Size, Share, Trends, Competition Forecast & Opportunities, 2028”. Global Biomass Gasification is anticipated to project robust growth in the forecast period with a CAGR of 8.58% through 2028. Biomass is organic matter that is obtained from plants and animals. It is a renewable source that can be used for generating energy. It is capable of providing energy in form of heat as well as electricity upon burning and later turning the heat into electricity. Biomass Gasification is a process in which organic and fossil fuels are converted into gases. It is carried out through a controlled amount of oxygen and steam without any combustion. This process is carried out at high temperatures without allowing the matter to burn or combust.

Biomass Biomass Gasification is a process where biomass obtained from organic matter is converted into gases such as carbon dioxide, hydrogen, and carbon monoxide in a controlled environment. This process is carried out through different gasifiers. Carbon monoxide hence produced reacts with water in a water-gas shift reaction and produces more hydrogen and carbon dioxide from which hydrogen is further used as fuel.

Biomass Biomass Gasification is gaining momentum owing to several factors, one of them being a municipal solid waste. MSW consists of biomass such as paper, cardboard, wood chippings, leaves, and leather products, and non-biomass products such as plastic, glasses, and metal. There are several concerns linked to municipal solid waste (MSW). Handling and managing MSW has raised so many questions as disposing of such huge amounts of waste, directly and indirectly, impacts the earth’s environment.

According to the U.S. Energy Information Association (EIA), in 2018, a total of 12% of total MSW was burnt in waste-to-energy biomass Biomass Gasification plants. MSW is used for producing energy which has led to increased contribution from the source in the biomass Biomass Gasification market. It acts as a driving factor for the biomass Biomass Gasification market growth.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on " Global Biomass Gasification Market.” https://www.techsciresearch.com/report/biomass-gasification-market/14961.html

Based on Application, Power segment is expected to hold the largest share of Biomass Gasification market during the forecast period, The power application dominated the market share and is expected to grow at a higher CAGR during the projection period. This can be attributed to the fact that the power sector is actively working on an energy transition from coal-based to economical and environmentally friendly options, biomass is expected to grow its contribution with increased advancements in Biomass Gasification technology.

The electric power sector uses wood and biomass-derived wastes to generate electricity for sale to the other sectors. Biomass energy provided about 4.8 quadrillion Btu and is equal to about 5% of total U.S. primary energy consumption. The U.S. had a total of 9% consumption of biomass energy in the power sector for the year 2021.

Based on Region, Europe will dominate the market, Europe region has the presence of major industry players which contributed towards its dominance in the market share for 2021. It is expected to continue as it is actively working on its energy shift towards renewable sources for primary energy production which will act as a strong driving factor for the market growth. Europe is 90% dependent on imported fossil gas and offers no significant support to ensure the fast deployment of renewable gases.

Key market players in the Global Biomass Gasification Market are following: -

Vaskiluoto Voima Oy

Beltran Technologies, Inc.

Valmet Corporation

KASAG Swiss AG

Goteborg Energi AB

Ankur Scientific Energy Technologies Pvt. Ltd.

Thyssenkrupp AG

Infinite Energy Pvt. Ltd.

Download Free Sample Report https://www.techsciresearch.com/sample-report.aspx?cid=14961

Customers can also request for 10% free customization on this report.

“The global biomass gasification market is influenced by multiple key drivers that underscore its significance in the sustainable energy landscape. Increasing renewable energy mandates and government policies aimed at curbing carbon emissions have fueled the adoption of biomass gasification. Growing environmental concerns and a commitment to mitigating climate change contribute to its appeal as a clean energy solution. Technological advancements play a crucial role, enhancing efficiency and reducing costs, thereby bolstering the commercial viability of biomass gasification technologies. This progress includes improved gas cleaning and purification techniques, ensuring compliance with stringent environmental standards.

The diversification of biomass sources, coupled with the utilization of waste materials, broadens the scope of biomass gasification. Its role in rural development and job creation, particularly by utilizing locally available biomass resources, adds an economic dimension to its attractiveness. Additionally, biomass gasification serves as a dual-purpose solution, addressing waste management challenges while producing renewable energy.

Corporate sustainability initiatives and a global shift towards greener practices further stimulate market growth, as businesses increasingly integrate biomass gasification into their strategies to meet environmental targets. Collectively, these factors position biomass gasification as a pivotal player in the global transition to sustainable and environmentally friendly energy solutions.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based global management consulting firm.

Biomass Gasification Market – Global Industry Size, Share, Trends, Opportunity, and Forecast Segmented by Source (Solid Biomass, Liquid Biomass, Biogas, Municipal Waste, Others), By Application (Chemical, Liquid Fuel, Gaseous Fuel, and Power), By Region, By Competition 2018-2028has evaluated the future growth potential of Global Biomass Gasification Market and provides statistics and information on market structure, size, share, and future growth. The report is intended to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities present in the Global Biomass Gasification Market.

Browse Related Research Reports:

Smart Meters Market https://www.techsciresearch.com/report/global-smart-meters-market/3909.html Diesel Power Engine Market https://www.techsciresearch.com/report/global-diesel-power-engine-market/2184.html High Voltage Capacitors Market https://www.techsciresearch.com/report/high-voltage-capacitors-market/16557.html

Contact Us-

TechSci Research LLC

420 Lexington Avenue, Suite 300,

New York, United States- 10170

M: +13322586602

Email: [email protected]

Website: www.techsciresearch.com

#Biomass Gasification Market#Biomass Gasification Market Size#Biomass Gasification Market Share#Biomass Gasification Market Trends#Biomass Gasification Market Growth

0 notes

Text

Heatwave Hegemony: Forecasting North America’s Prolonged Leadership in Industrial Furnaces The market for industrial frnaceurnaces will likely reach US$ 17,112 million by 2033, with sales increasing at a moderate CAGR of 4.3% between 2023 and 2033. The market for industrial furnaces will likely reach an estimated US$ 11,230 Million in 2023, driven by a rapidly increasing preference for automation technologies and electrical industrial equipment. Thermal enclosures which process both liquid and solid raw materials at high temperatures are categorized as industrial furnaces. These furnaces can attain higher temperatures in comparison to open-air systems. Available in various forms, industrial furnaces are applied in different industries like food processing, glass, metal, refractories, cement, plastic, fiber, ceramic, and many others. The enduring usage of industrial furnaces in these industries will continue to bolster the demand for industrial furnaces in the upcoming years. Request Sample Report: Empower Your Industry Understanding with Invaluable Insights https://www.futuremarketinsights.com/reports/sample/rep-gb-5744 The major driver for the target market is the constant demand for steel, iron, and other essential metals and materials. Industries like automobiles, buildings & construction, metallurgy, and others contribute to the escalating demand for these metals. This growing demand results in the establishment and expansion of enterprises that supply industrial furnaces. Again, the introduction of IIoT and Industry 4.0 has enabled industrial furnaces to optimize efficiency and automation. All of this culminates in the steady growth if the industrial furnaces market over the forecast period. Furthermore, since industrial furnaces are a vital part of major industries for the processing of various materials like oil, gases and food products, many newer and different versions of the furnaces are being introduced in the market. In addition to this, expansion strategies of older market players as well as entry of new market players are stimulating the competitive environment which in turn boosts the scope of the industrial furnaces market over the projected period. “Advancing the manufacturing industry is expected to facilitate growth opportunities for the global industrial furnaces market over the forecast period,” says an FMI analyst.

0 notes

Text

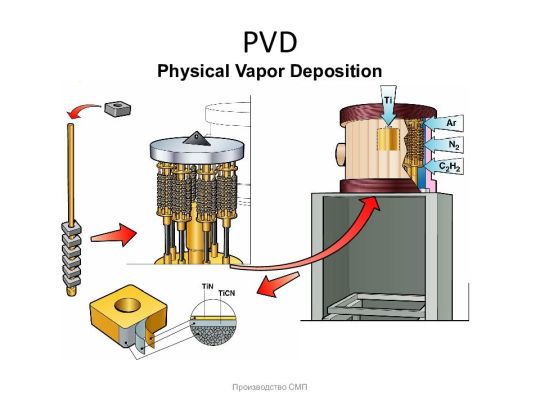

In-depth Analysis of Key Players Shaping the Physical Vapor Deposition Market

The Physical Vapor Deposition Market is estimated for 2023 for the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Physical vapor deposition (PVD) is a process used to deposit thin films on substrates by condensation of a vaporized form of the desired material. It finds applications in microelectronics, data storage, cutting tools, and decorative coatings.

Market Dynamics:

The growth of the physical vapor deposition market is driven by increased adoption in microelectronics and data storage industries. Physical vapor deposition processes such as sputtering and evaporation are widely used in the manufacturing of semiconductors and data storage devices. As the demand for electronic components grow, the need for PVD techniques for thin film applications also increases. Further, the increasing demand for wear and corrosion resistant coatings from automotive and industrial machinery sectors is expected to fuel the market growth during the forecast period.

Increasing Demand for Low-Friction and Wear-Resistant Coatings is Driving the Physical Vapor Deposition Market

The demand for low-friction and wear-resistant coatings has been growing significantly across various industries such as automotive, aerospace, cutting tools, and medical devices. Physical vapor deposition is an effective and commonly used technique for depositing hard coatings like titanium nitride and chromium nitride that improve surface properties and durability. The increasing usage of PVD coatings on components subjected to severe friction, wear and corrosion is propelling the physical vapor deposition market growth. For instance, PVD coatings are widely used on engine components, brake pads and rotors in automobiles to enhance fuel efficiency and performance. They are also used on drill bits, cutting tools and inserts in manufacturing industries to increase tool life. With technological advancements and requirement for high-quality surface finishes, the need for functional PVD coatings is expected to continue rising thereby driving market expansion over the coming years.

Growing Requirement for Decorative Coatings Stimulates Demand

The demand for decorative and aesthetic coatings has increased substantially across various sectors including consumer electronics, architectural and solar glass. Physical vapor deposition enables depositing thin films, with excellent uniformity and adhesion, that impart color, luster and anti-reflective properties to surfaces. Metals like gold, silver, platinum and alloys are commonly deposited using PVD techniques for visually appealing finishes. The growing production of smartphones with decorative bezels and televisions and laptops with anti-glare and scratch-resistant coatings has fueled the market growth. Moreover, the thriving solar and architectural glass industry is utilizing PVD coatings for achieving tinting, low-emissivity and self-cleaning effects. The rising consumer inclination towards aesthetics and appearance is driving increasing preference for decorative PVD coatings hence boosting the market.

Fluctuating Raw Material Prices Pose a Challenge

The physical vapor deposition market experiences price fluctuations due to shifting costs of raw materials used including metals and gases. The prices of precious metals like gold, silver and platinum that are commonly used for decorative and electrical coatings are highly unstable and vary as per global market conditions and supply-demand variations. Similarly, reactive gases used in PVD processes including argon, nitrogen and oxygen exhibit price volatility depending upon availability and supplier contracts. Major market players have limited control over raw material costs due to supplier dependence. Therefore, frequent changes in prices of these crucial inputs pose major challenges related to budgeting, profit margins and project costs for equipment manufacturers, service providers as well as end-use industries. Unpredictable raw material prices can restrain market growth to some extent until better inventory management and long-term supplier contracts are implemented.

Opportunity for High-Volume Production of Smart Wearables

The emerging concept of smart wearables presents significant opportunities for the physical vapor deposition market. Technologies like smart watches, fitness bands and AR/VR headsets are gaining widespread popularity and demand. For optimal performance and durability, these devices require PVD coatings on components contacting human skin. Coatings such as silver, indium tin oxide and fluorinated diamond-like carbon are functional as well as provide corrosion resistance under harsh conditions of perspiration, skin oils and cleaning agents. As new smart wearable products are rapidly introduced and consumer electronics giants expand production, high-volume PVD coating of components offers valuable opportunities for equipment manufacturers and service providers. Moreover, the integration of decorative and anti-reflective coatings will further stimulate market growth by improving product design aesthetics, visual experience and marketability of wearable devices. This presents lucrative scope for PVD market players in collaborating with major consumer electronics OEMs.

Technology Innovations Catalyze Market Evolution

The physical vapor deposition market is continuously evolving due to ongoing technology innovations that enhance coating quality and throughput. Advancements like multi-target cathodic arc deposition enable depositing multifunctional and nanostructured coatings. Meanwhile, industrial-scale pulsed laser deposition systems facilitate mass production of complex thin films. Vendors are also developing modular PVD deposition heads capable of multi-wafer handling for improving productivity. Technologies such as electron beam PVD offer cost-effectiveness for nano-engineered coatings even on temperature-sensitive substrates.

#Physical Vapor Deposition Market#Physical Vapor Deposition Market Trends#Physical Vapor Deposition Market Growth

0 notes

Text

Rigid Food Packaging Market CAGR, Trends, Top Players, Analysis, Industry Size - Forecast 2033

The rigid food packaging market is a crucial segment of the global packaging industry, providing sturdy and protective packaging solutions for a wide range of food products. Rigid packaging materials include materials like glass, metal, plastic, and paperboard, which are chosen based on the specific requirements of the food product being packaged. Here's an overview of the scenario in the rigid food packaging market:

Key Features and Characteristics:

Protection: Rigid food packaging offers superior protection against external factors such as moisture, light, air, and physical damage, helping to maintain the freshness and quality of food products.

Versatility: Rigid packaging materials come in various forms, including bottles, jars, cans, cartons, and trays, making them suitable for packaging a wide range of food items, from beverages and condiments to dairy products and dry goods.

Barrier Properties: Many rigid packaging materials have excellent barrier properties, which are essential for products that require protection from oxygen or other gases to extend shelf life.

Tamper-Evident: Rigid packaging can incorporate tamper-evident features, enhancing product safety and consumer confidence.

Brand Presentation: Rigid packaging allows for attractive branding and labeling, helping products stand out on store shelves.

Request Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-16447

Market Scenario:

The rigid food packaging market is influenced by several factors:

Consumer Demand: Changing consumer lifestyles, including a preference for on-the-go and convenience foods, drive the demand for rigid packaging formats.

Product Innovation: Manufacturers are continually developing innovative packaging solutions that offer convenience, sustainability, and longer shelf life.

Sustainability: Increasing awareness of environmental concerns has led to a shift towards sustainable packaging materials and practices, including recyclable and biodegradable options.

E-commerce: The rise of e-commerce has created opportunities for customized and protective rigid packaging solutions to ensure products reach consumers intact.

Regulations: Stringent food safety and labeling regulations play a crucial role in shaping packaging requirements, especially in the food and beverage industry.

For more info: https://www.futuremarketinsights.com/reports/rigid-food-packaging-market

Applications:

Beverages: Rigid packaging is commonly used for beverages such as bottled water, soft drinks, and alcoholic beverages.

Dairy: Dairy products like milk, yogurt, and cheese are often packaged in rigid containers.

Processed Foods: Ready-to-eat and convenience foods rely on rigid packaging for protection and ease of handling.

Canned Goods: Canned vegetables, fruits, and meats are classic examples of rigid food packaging.

Snack Foods: Many snacks, including chips and nuts, come in rigid packaging for freshness.

Condiments: Bottles and jars are used for packaging sauces, ketchup, and condiments.

Market Trends:

Eco-Friendly Materials: The use of eco-friendly materials like recyclable plastics and biodegradable options is a significant trend in rigid food packaging.

Portion Control: Single-serve and portion-controlled packaging formats cater to consumers' convenience and health-conscious preferences.

Innovative Designs: Packaging with unique shapes, closures, and dispensing systems enhances consumer experience and convenience.

Smart Packaging: Integration of smart packaging technologies, such as QR codes and NFC tags, for product information and traceability.

Reduced Packaging: Manufacturers are working on reducing the amount of packaging material while maintaining product protection.

0 notes

Text

Cryogenic Insulation Market Size, Type, segmentation, growth and forecast 2023-2030

The Cryogenic Insulation Market is expected to grow from USD 1.20 Billion in 2022 to USD 4.54 Billion by 2030, at a CAGR of 18.00% during the forecast period.

Get the Sample Report: https://www.reportprime.com/enquiry/sample-report/11814

Cryogenic Insulation Market Size

Cryogenic insulation is a type of insulation that is specifically designed to maintain low temperatures, typically below -150°C, such as those found in cryogenic applications. It is used in various industries, including energy and power, chemicals, metallurgical, electronics, shipping, healthcare, and others. The cryogenic insulation market can be segmented based on type, including PU & PIR, cellular glass, polystyrene, fiberglass, perlite, and others. It can also be segmented by region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Key market players in the cryogenic insulation market include Saint Gobain, Owens Corning, Armacell International, Lydall, BASF, Cabot Corporation, Rochling Group, Johns Manville, Dunmore Corporation, Imerys Minerals, Aspen Aerogels, G+H Group, Hertel, and Amol Dicalite. Regulatory and legal factors specific to the market conditions may include safety regulations for handling cryogenic materials, environmental regulations regarding insulation materials, and licensing or certification requirements for manufacturers and installers. These factors play a significant role in the development, production, and distribution of cryogenic insulation products and services.

Cryogenic Insulation Market Key players

Saint Gobain

Owens Corning

Armacell International

Lydall

BASF

Buy Now & Get Exclusive Discount on this

Cryogenic Insulation Market Segment Analysis The Cryogenic Insulation market is witnessing significant growth owing to the increasing demand for LNG (liquefied natural gas) and other cryogenic gases across various industries. Cryogenic insulation helps in maintaining low temperatures and preventing heat transfer in applications involving storage and transportation of such gases. The market is characterized by the growing need for energy efficiency and the rising adoption of LNG as a cleaner fuel source.One of the major factors driving revenue growth in the Cryogenic Insulation market is the expanding LNG industry. The increasing global energy demand and the shift towards cleaner fuel sources have led to a surge in LNG production and consumption. This, in turn, is driving the demand for efficient cryogenic insulation solutions to ensure safe storage and transportation of LNG. The growth of the LNG industry is particularly evident in regions like Asia-Pacific, where countries like China and India are investing heavily in LNG infrastructure.Another key driver of the Cryogenic Insulation market is the growing demand for cryogenic insulation in the medical and healthcare sector. Cryogenic gases are extensively used in medical applications such as cryosurgery, cryopreservation, and cryotherapy. The need for reliable and efficient insulation materials for medical cryogenic equipment is increasing, thereby boosting the demand for cryogenic insulation products.In terms of trends, the Cryogenic Insulation market is witnessing a shift towards the adoption of advanced insulation materials. Traditional insulation materials like perlite and expanded polystyrene (EPS) are being replaced by more efficient options such as polyurethane foam and vacuum insulation panels. These advanced materials offer superior thermal performance and durability, making them increasingly preferred in cryogenic applications.However, the Cryogenic Insulation market also faces certain challenges. The high cost of advanced insulation materials and the complexity of installation are some of the key challenges faced by industry players. Moreover, the volatile prices of raw materials used in cryogenic insulation production can hinder market growth. Additionally, stringent regulations and safety standards pertaining to the handling and transportation of cryogenic gases pose challenges for market players.The main findings of the report indicate that the Cryogenic Insulation market is expected to witness significant growth in the coming years, driven by the expansion of the LNG industry and the increasing demand for cryogenic gases in various sectors. The adoption of advanced insulation materials is expected to witness a substantial rise, owing to their superior thermal performance. However, the market faces challenges due to the high cost of materials and the complexity of installation.To overcome these challenges, the report recommends industry players focus on research and development to develop cost-effective insulation materials and innovative installation techniques. Collaboration with stakeholders across the value chain, including raw material suppliers and end-users, can help in addressing market challenges and enhancing product offerings. Additionally, market players should stay updated with the evolving regulations and safety standards in the industry to ensure compliance and maintain customer satisfaction.This report covers impact on COVID-19 and Russia-Ukraine wars in detail.Purchase This Report: https://www.reportprime.com/checkout?id=11814&price=3590

Market Segmentation (by Application):

Saint Gobain

Owens Corning

Armacell International

Lydall

BASF

Information is sourced from www.reportprime.com

0 notes