#Water-Based Barrier Coatings Market Share

Explore tagged Tumblr posts

Text

Water-Based Barrier Coatings Market Future Trends, Growth, Trends, Revenue Analysis 2024-32

The Reports and Insights, a leading market research company, has recently releases report titled “Water-Based Barrier Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Water-Based Barrier Coatings Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Water-Based Barrier Coatings?

The global water-based barrier coatings market size reached US$ 3.9 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 6.5 billion in 2032, exhibiting a growth rate (CAGR) of 5.9% during 2024-2032.

What are Water-Based Barrier Coatings Market?

Water-based barrier coatings refer to aqueous formulations applied to surfaces to establish a protective layer that repels liquids, gases, or other substances. These coatings are environmentally friendly, predominantly utilizing water as a solvent to reduce the presence of volatile organic compounds (VOCs). Widely employed in industries like packaging, water-based barrier coatings act as a safeguard against moisture, oil, and contaminants, thereby augmenting the durability and preservation of products. Applied to materials such as paper and cardboard, these coatings provide a sustainable and less hazardous alternative to solvent-based counterparts. Their adaptability and eco-friendly characteristics contribute to their increasing popularity across various applications, driving the demand in the market.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1902

What are the growth prospects and trends in the Water-Based Barrier Coatings Market industry?

The water-based barrier coatings market growth is driven by various factors. The market for water-based barrier coatings is experiencing notable growth as industries increasingly opt for environmentally sustainable solutions in surface protection. These coatings, formulated with water as a primary solvent, provide a green alternative to traditional solvent-based options. Predominantly utilized in packaging, water-based barrier coatings establish protective layers that effectively repel liquids and gases, thereby improving the durability and overall quality of products. The market's expansion is driven by the rising demand for eco-conscious solutions, with these coatings finding applications across various industries where resistance to moisture and contaminants is essential. The adaptable and environmentally friendly characteristics of water-based barrier coatings position them as significant players in the evolving landscape of surface protection technologies. Hence, all the factors contribute to water-based barrier coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Market Segmentation By Type:

Acrylic

Polyurethane

Epoxy

Others

Market Segmentation By Substrate:

Metal

Paper & Paperboard

Plastic

Glass

Others

Market Segmentation By End-Use Industry:

Packaging

Building & Construction

Automotive

Electronics

Textile

Others

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Akzo Nobel N.V.

PPG Industries Inc.

Axalta Coating Systems Ltd.

BASF SE

The Sherwin-Williams Company

RPM International Inc.

Arkema Group

Dow Inc.

Valspar Corporation

Asian Paints Limited

Nippon Paint Holdings Co., Ltd.

Hempel A/S

Jotun Group

Sika AG

Kansai Paint Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Water-Based Barrier Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Water-Based Barrier Coatings Market Size#Water-Based Barrier Coatings Market Share#Water-Based Barrier Coatings Market Demand#Water-Based Barrier Coatings Market Analysis

0 notes

Text

0 notes

Text

Biodegradable Packaging Market Trends Role of Consumer Demand in Market Growth

The biodegradable packaging industry is witnessing continuous innovation in materials such as plant-based bioplastics, mushroom packaging, and seaweed-based films. Companies are developing durable, lightweight, and moisture-resistant alternatives to traditional plastics. Innovations in water-soluble packaging, paper-based coatings, and nanotechnology-based biodegradable materials are shaping the future of the packaging industry.

Biodegradable Packaging Market Trends: Growth Drivers and Market Expansion

Rising environmental concerns, government mandates, and increasing consumer preference for sustainable packaging are key market growth drivers. The food and beverage industry, e-commerce, and personal care sectors are rapidly adopting biodegradable packaging. Companies are expanding their market presence by investing in production facilities, supply chains, and new product lines.

Biodegradable Packaging Market Trends: Impact of Government Regulations

Stringent regulations on single-use plastics and extended producer responsibility (EPR) programs are accelerating the adoption of biodegradable packaging. Governments worldwide are imposing bans on non-recyclable packaging and offering tax incentives for sustainable alternatives. Compliance with these regulations is essential for businesses to maintain market access and drive eco-friendly innovation.

Biodegradable Packaging Market Trends: Advancements in Compostable Packaging

The demand for compostable packaging is increasing as consumers and businesses seek packaging solutions that break down naturally. Advances in bio-based polymer formulations, home-compostable materials, and improved decomposition rates are making compostable packaging a viable alternative to conventional plastic. Companies are focusing on certification and proper disposal infrastructure to enhance adoption.

Biodegradable Packaging Market Trends: Challenges in Adoption and Scalability

Despite market growth, several challenges hinder large-scale adoption. High production costs, raw material availability, and lack of composting facilities pose significant barriers. Additionally, inconsistencies in biodegradability standards and consumer misinformation about disposal methods slow market penetration. Overcoming these obstacles requires continued investment in technology, education, and infrastructure.

Biodegradable Packaging Market Trends: Role of Consumer Demand in Market Growth

Consumer awareness and preference for sustainable packaging play a vital role in market expansion. Brands are leveraging eco-conscious marketing strategies to appeal to environmentally responsible consumers. Companies investing in biodegradable packaging solutions are gaining customer loyalty and competitive advantage as sustainability becomes a key purchasing factor in various industries.

Biodegradable Packaging Market Trends: Investment and R&D for New Solutions

Investments in research and development are driving the development of high-performance biodegradable packaging materials. Companies are exploring biodegradable polymers with improved flexibility, strength, and shelf-life properties. Funding for innovative startups, collaborations with universities, and government grants are fueling breakthroughs in biodegradable packaging technologies and production scalability.

Biodegradable Packaging Market Trends: Industry Collaborations and Partnerships

Strategic collaborations between packaging manufacturers, recycling companies, and consumer goods brands are crucial for market growth. Partnerships are focused on improving material sourcing, optimizing production processes, and expanding composting infrastructure. These collaborations ensure a seamless transition to biodegradable packaging and facilitate knowledge sharing within the industry.

Biodegradable Packaging Market Trends: Cost-Effectiveness and Competitive Pricing

One of the biggest challenges for biodegradable packaging is cost. Companies are implementing strategies to reduce production expenses, such as improving manufacturing efficiencies, using recycled content, and optimizing logistics. As demand increases and production scales up, the cost gap between conventional and biodegradable packaging is expected to decrease, making it more accessible.

Biodegradable Packaging Market Trends: Future Prospects and Sustainability Goals

The future of biodegradable packaging is promising, with ongoing advancements in materials, production methods, and regulatory support. Companies are aligning their business models with circular economy principles and sustainability targets. Emerging trends such as reusable biodegradable packaging and smart packaging technologies will shape the next phase of the biodegradable packaging industry.

Conclusion

The biodegradable packaging market is evolving rapidly, driven by technological advancements, consumer demand, and regulatory pressures. Companies are focusing on material innovations, expanding production, and forming strategic partnerships to ensure sustainable growth. While challenges remain, the industry's future is bright, with increasing investment and commitment toward a greener and more sustainable packaging landscape.

#Biodegradable Packaging Market#Biodegradable Packaging Market trends#Biodegradable Packaging#Biodegradable#eco friendly packaging

0 notes

Text

Future of Intumescent Coatings Market: Demand and Growth Forecast to 2031

Global sales of intumescent coatings are projected to grow at a compound annual growth rate (CAGR) of approximately 3%, reaching over US$ 1 billion by 2031, as reported by Fact.MR. This growth is largely driven by the increasing emphasis on passive fire protection. The oil and gas sector is anticipated to account for more than 40% of the global demand for intumescent coatings, propelled by significant exploration and extraction initiatives in key regions.

Various end-use industries, including building and construction, industrial applications, and aerospace, utilize intumescent coatings to enhance passive fire protection. These coatings serve as a fire-resistant barrier for substrates during a fire, facilitating quicker rescue and evacuation efforts.

Request a Sample Report:

According to the World Health Organization (W.H.O), fires alone are responsible for an estimated 180,000 fatalities annually, with additional deaths resulting from scalds, electrical burns, and other burn-related incidents. More than 90% of these fatalities occur in low- and middle-income countries. While many burns stem from accidents in residential environments, industrial settings also present significant fire hazards, contributing to a majority of burn injuries and incidents. Consequently, key end users are increasingly adopting intumescent coatings to help prevent such tragedies.

Intumescent Coatings Market - Competitive Landscape: Prominent manufacturers are leveraging such strategic initiatives as geographical expansion, partnerships, mergers & acquisitions, and new product launches to cement their market presence. Some notable developments are as follows:

In March 2021, Akzo Nobel collaborated with QLayers to acquire a stake in the company’s industrial coatings portfolio, part of the former’s Paint the Future collaborative innovation ecosystem.

Also, that same month, Hempel A/S inaugurated its new campus in Copenhagen, Denmark, which is an R&D facility expected to provide a hub for international scientists and contribute to accelerating and strengthening development of innovative solutions.

In January 2021, Albi Protective Coatings obtained the GREENGUARD Gold Certification for four of its products: Albi Clad TF+, Albi Clad TF, Albi Clad FP and Albi Cote FRL-X.

The Oil & Gas Industry: A Key Consumer of Intumescent Coatings

The oil and gas sector is projected to account for more than 40% of the global revenue share by 2031, making it a significant end-user of intumescent coatings. This anticipated growth is driven by increased investments in exploration initiatives, deep-water projects, and enhancements in refining capacity. The demand for these coatings is particularly pronounced due to the frequent occurrence of fire hazards on-site. Intumescent coatings provide essential passive protection for steel structures, including oil rigs and drilling equipment, by expanding in response to rising temperatures.

How Are Growing Energy Demands Driving the Adoption of Intumescent Coatings?

The expansion of the global population, coupled with rapid urbanization and infrastructure development, has led to a surge in energy consumption. This trend has resulted in heightened demand for traditional energy sources such as oil, gas, and shale across various regions. According to the International Energy Agency (IEA), oil constituted over 35% of the total energy supply in 2019, primarily sourced from OECD countries, while natural gas accounted for nearly 30%. Consequently, there has been a significant increase in exploration activities, further elevating the need for intumescent coatings to maintain operational safety.

Source: https://www.globenewswire.com/news-release/2022/02/16/2386518/0/en/Demand-for-Epoxy-based-Intumescent-Coatings-to-Surge-at-a-CAGR-of-4-and-Reach-a-Valuation-of-over-US-175-Million-by-2031-Fact-MR-Analysis.html

0 notes

Text

Emulsion Polymer Market: Driving Sustainability and Innovation Across Industries

The emulsion polymer market has emerged as a cornerstone in the global drive toward eco-friendly industrial practices. With applications spanning construction, packaging, automotive, and textiles, emulsion polymers have cemented their position as a versatile, cost-effective, and sustainable solution.

What are Emulsion Polymers?Emulsion polymers are created through a water-based polymerization process, making them an environmentally friendly alternative to solvent-based polymers. Their low VOC (volatile organic compounds) emissions and high-performance capabilities have made them indispensable across industries.

Why is the Emulsion Polymer Market Growing?

Eco-Friendly AdvantagesThe shift toward sustainable materials has boosted the adoption of emulsion polymers. Their water-based composition aligns with stringent environmental regulations while delivering superior performance.

Applications in High-Growth IndustriesFrom paints and coatings to adhesives and paper, emulsion polymers are essential in industries prioritizing efficiency and innovation.

Technological AdvancementsInnovations like nanotechnology and bio-based formulations are pushing the boundaries of what emulsion polymers can achieve.

Key Market Trends

Bio-Based Polymers: Growing consumer awareness is driving the demand for renewable, bio-based alternatives.

Smart Polymers: Self-healing and adaptive emulsion polymers are gaining traction in high-tech applications.

Sustainability Efforts: Companies are integrating eco-friendly practices, such as biodegradable packaging and green chemistry.

Global Market Overview

The emulsion polymer market is projected to grow at a CAGR of 6% from 2023 to 2030, with Asia-Pacific leading in market share. This growth is driven by urbanization, increased construction projects, and demand for sustainable materials.

Challenges in the Market

While the future is bright, challenges like raw material price volatility, stringent regulations, and technological barriers in developing economies need to be addressed for sustainable growth.

Conclusion

The emulsion polymer market is driving innovation and sustainability across industries, meeting the demands of an eco-conscious world. Businesses investing in this market are well-positioned to benefit from its growing applications and technological advancements.

Looking for high-quality emulsion polymers or insights into the market? Connect with us to learn more about solutions tailored to your industry needs.

0 notes

Text

"Edible Food Packaging: Changing the Game for Sustainable Consumption 🍴🌿"

Edible Food Packaging Solutions Market is redefining packaging by introducing materials that can be safely consumed along with food products. This market addresses sustainability challenges, offering biodegradable alternatives to reduce plastic waste. It includes edible films, coatings, and wraps made from natural ingredients like seaweed, starch, and proteins, appealing to eco-conscious consumers and industries aiming for greener packaging solutions.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10948 &utm_source=SnehaPatil&utm_medium=Article

This market is experiencing significant growth, fueled by sustainability concerns and shifting consumer preferences. Starch-based packaging leads the segments due to its biodegradability and versatility. Seaweed-based packaging is also gaining traction for its renewable nature and minimal environmental impact. North America dominates the regional market, driven by stringent environmental regulations and a strong focus on sustainable practices. Europe follows closely, supported by a robust eco-friendly packaging infrastructure and high consumer awareness. The United States and Germany are standout performers in these regions, benefiting from advanced technological capabilities and substantial investments in research and development.

Market Segmentation:

Type: Films, Coatings, Sprays, Sheets, Capsules

Material Type: Proteins, Polysaccharides, Lipids, Composites, Algae

Technology: Antimicrobial, Nanotechnology, Biodegradable, Active, Intelligent Packaging

Application: Food and Beverage, Pharmaceuticals, Nutraceuticals, Personal Care, Agriculture

End Users: Food Manufacturers, Beverage Manufacturers, Retailers, Food Service Providers, Pharmaceutical Companies

Form: Solid, Liquid, Gel, Powder

Functionality: Barrier Properties, Mechanical Properties, Biodegradability, Edibility

Process: Extrusion, Coating, Molding, Casting

Solutions: Customized, Standard Packaging Solutions

In 2023, the market volume was estimated at 320 million metric tons, expected to reach 500 million metric tons by 2033. The film segment holds the largest market share at 45%, followed by coatings at 30%, and bags at 25%. The dominance of films is driven by their versatility and rising demand for sustainable solutions. Key players such as WikiCell Designs Inc., Lactips, and Notpla are pioneering in biodegradable packaging. The competitive landscape is shaped by these companies’ innovative strategies, with WikiCell Designs Inc. leading in biodegradable packaging and Lactips expanding its water-soluble films range.

Regulatory frameworks, such as the European Green Deal, play a significant role in market dynamics, influencing compliance costs and eco-friendly initiatives. The market is poised for further growth, with a projected 15% increase in capital expenditure by 2033. This optimistic outlook is driven by opportunities in biodegradable films and coatings, despite challenges like stringent regulations and competition from conventional packaging alternatives. The integration of nanotechnology and smart packaging is expected to unveil new growth prospects.

#EdiblePackaging #SustainablePackaging #EcoFriendly #Biodegradable #ZeroWaste #FoodInnovation #GreenPackaging #EcoConscious #PlasticFree #CleanLabel #SustainableLiving #NaturalIngredients #FuturePackaging #EdibleInnovation #EcoTech #SustainableSolutions #SmartPackaging #FoodSustainability #GreenFuture #InnovativePackaging

0 notes

Text

Corrosion Inhibitors Market 2027 Outlook, Regions, Size Estimation and Upcoming Trend

The global corrosion inhibitors market was valued at USD 7.4 billion in 2019 and is projected to grow at a compound annual growth rate (CAGR) of 3.8% from 2020 to 2027. This anticipated growth is primarily driven by advancements in biobased and eco-friendly corrosion inhibitors, which align with the market's shift toward sustainability. Such a shift is expected to foster increased acceptance of corrosion inhibitors among eco-conscious industries. Corrosion inhibitors work by forming a protective barrier on surfaces, preventing moisture a key factor in corrosion from reaching the underlying material.

The mechanisms through which organic corrosion inhibitors operate include interfacial activity, anodic and cathodic activity, barrier activity, and adsorption activity. In contrast, inorganic corrosion inhibitors function via mechanisms such as anodic and cathodic passivation, anion exchange, and saponification. Research and development have been crucial in advancing corrosion mitigation technologies, and innovation in this area has led to numerous product improvements, as manufacturers have heavily invested in R&D to enhance product performance.

However, in the U.S., the corrosion inhibitors market has been influenced by regulatory standards regarding product toxicity. While phosphate-based corrosion inhibitors are widely used in water systems, their application is regulated due to concerns regarding environmental and wastewater treatment impacts, as well as reactions with aluminum.

Gather more insights about the market drivers, restrains and growth of the Corrosion Inhibitors Market

Regional Insights:

Asia Pacific Corrosion Inhibitors Market Trends

In 2019, the Asia Pacific region dominated the global market with a 36.3% share and is expected to be one of the fastest-growing regions in the coming years. This growth is attributed to rapid industrialization, which has increased demand from power generation and various other industries. Developing economies in Asia, such as India and China, are also seeing rising demand in the chemical and metalworking sectors, which further supports market growth.

Europe Corrosion Inhibitors Market Trends

In Europe, the market for corrosion inhibitors is strong due to significant water consumption in industries like sugar, ethanol, and petrochemical production. Effective water treatment is essential to support corrosion control in Europe, helping to preserve the operational integrity of heat transfer systems and improve the energy efficiency of process units.

Browse through Grand View Research's Category Organic Chemicals Industry Research Reports.

The global mixed mode chromatography resin market size was estimated at USD 117.5 million in 2024 and is expected to grow at a CAGR of 12.3% from 2025 to 2030.

The global 2-ethylhexanol market was estimated at USD 6.50 billion in 2024 and is expected to grow at a CAGR of 2.8% from 2025 to 2030.

Key Companies & Market Share Insights

The market for corrosion inhibitors is highly fragmented, with a large number of companies competing to meet the high demand from end-users. Key industry players focus on customized production, leveraging advanced technologies and implementing strategic measures, such as long-term agreements and mergers, to expand their market presence and increase revenue. Many manufacturers have integrated their operations across the value chain to enhance efficiency. For example, Arkema has achieved backward integration by using renewable raw materials in its production processes, while The Lubrizol Corporation is forward integrated, using its corrosion inhibitors in the formulation of its fuel additives, such as PowerZol 9548A. Cortec Corporation produces a range of high-strength release components and coating products, utilizing its proprietary Migratory Corrosion Inhibitors (MCIs). Additionally, SUEZ supplies corrosion inhibitors for various water treatment projects, showcasing the diverse applications and market reach of these companies.

This competitive landscape is characterized by companies strategically positioning themselves through innovation, integration, and collaboration to meet the evolving needs of a growing market.

Key Corrosion Inhibitors Companies

Nouryon

Cortec Corporation

Ashland

Ecolab

Henkel Ibérica, S.A.

The Lubrizol Company

BASF SE

Dow

DuPont de Nemours, Inc.

Baker Hughes, a GE company LLC

Order a free sample PDF of the Corrosion Inhibitors Market Intelligence Study, published by Grand View Research.

0 notes

Text

Corrosion Inhibitors Industry Development Trends Report By 2027

The global corrosion inhibitors market was valued at USD 7.4 billion in 2019 and is projected to grow at a compound annual growth rate (CAGR) of 3.8% from 2020 to 2027. This anticipated growth is primarily driven by advancements in biobased and eco-friendly corrosion inhibitors, which align with the market's shift toward sustainability. Such a shift is expected to foster increased acceptance of corrosion inhibitors among eco-conscious industries. Corrosion inhibitors work by forming a protective barrier on surfaces, preventing moisture a key factor in corrosion from reaching the underlying material.

The mechanisms through which organic corrosion inhibitors operate include interfacial activity, anodic and cathodic activity, barrier activity, and adsorption activity. In contrast, inorganic corrosion inhibitors function via mechanisms such as anodic and cathodic passivation, anion exchange, and saponification. Research and development have been crucial in advancing corrosion mitigation technologies, and innovation in this area has led to numerous product improvements, as manufacturers have heavily invested in R&D to enhance product performance.

However, in the U.S., the corrosion inhibitors market has been influenced by regulatory standards regarding product toxicity. While phosphate-based corrosion inhibitors are widely used in water systems, their application is regulated due to concerns regarding environmental and wastewater treatment impacts, as well as reactions with aluminum.

Gather more insights about the market drivers, restrains and growth of the Corrosion Inhibitors Market

Regional Insights:

Asia Pacific Corrosion Inhibitors Market Trends

In 2019, the Asia Pacific region dominated the global market with a 36.3% share and is expected to be one of the fastest-growing regions in the coming years. This growth is attributed to rapid industrialization, which has increased demand from power generation and various other industries. Developing economies in Asia, such as India and China, are also seeing rising demand in the chemical and metalworking sectors, which further supports market growth.

Europe Corrosion Inhibitors Market Trends

In Europe, the market for corrosion inhibitors is strong due to significant water consumption in industries like sugar, ethanol, and petrochemical production. Effective water treatment is essential to support corrosion control in Europe, helping to preserve the operational integrity of heat transfer systems and improve the energy efficiency of process units.

Browse through Grand View Research's Category Organic Chemicals Industry Research Reports.

The global mixed mode chromatography resin market size was estimated at USD 117.5 million in 2024 and is expected to grow at a CAGR of 12.3% from 2025 to 2030.

The global 2-ethylhexanol market was estimated at USD 6.50 billion in 2024 and is expected to grow at a CAGR of 2.8% from 2025 to 2030.

Key Companies & Market Share Insights

The market for corrosion inhibitors is highly fragmented, with a large number of companies competing to meet the high demand from end-users. Key industry players focus on customized production, leveraging advanced technologies and implementing strategic measures, such as long-term agreements and mergers, to expand their market presence and increase revenue. Many manufacturers have integrated their operations across the value chain to enhance efficiency. For example, Arkema has achieved backward integration by using renewable raw materials in its production processes, while The Lubrizol Corporation is forward integrated, using its corrosion inhibitors in the formulation of its fuel additives, such as PowerZol 9548A. Cortec Corporation produces a range of high-strength release components and coating products, utilizing its proprietary Migratory Corrosion Inhibitors (MCIs). Additionally, SUEZ supplies corrosion inhibitors for various water treatment projects, showcasing the diverse applications and market reach of these companies.

This competitive landscape is characterized by companies strategically positioning themselves through innovation, integration, and collaboration to meet the evolving needs of a growing market.

Key Corrosion Inhibitors Companies

Nouryon

Cortec Corporation

Ashland

Ecolab

Henkel Ibérica, S.A.

The Lubrizol Company

BASF SE

Dow

DuPont de Nemours, Inc.

Baker Hughes, a GE company LLC

Order a free sample PDF of the Corrosion Inhibitors Market Intelligence Study, published by Grand View Research.

0 notes

Text

Corrosion Inhibitors Market Key Companies and Emerging Trends, 2027

The global corrosion inhibitors market size was valued at USD 7.4 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) 3.8% from 2020 to 2027.

The growth in the market can be attributed to the development of biobased and more eco-friendly corrosion inhibitors. A gradual shift toward the development of environment-friendly corrosion inhibitors may potentially lead the market toward sustainable development and increase the acceptance of corrosion inhibitors among sustainable end users. A corrosion inhibitor functions by creating a barrier over the coated surface and preventing it from moisture, which is primarily the primary cause of erosion. The mechanisms of organic products include interfacial activity, anodic activity, cathodic activity, barrier activity, and adsorption activity.

Gather more insights about the market drivers, restrains and growth of the Corrosion Inhibitors Market

Detailed Segmentation:

Product Insights

The organic segment held largest market share of 73.8% in 2019. In recent years, there has been significant development concerning bio-based corrosion inhibitors. These are low in cost, have low toxicity, and are readily available organic compounds, which are obtained from plant extracts such as aromatic herbs, spices, and medicinal plants. Generally, bio-based corrosion inhibitors have aromatic structures with long aliphatic chains and free electron pairs. For instance, Delonix regia and rosemary leaves prevent the deterioration of aluminum metal, while natural honey inhibits corrosion of copper. The factors mentioned above are estimated to drive segment growth over the forecast period.

Type Insights

The water-based segment held the largest market share of 56.2% in 2019. Water-based corrosion inhibitors are readily soluble in water and are usually sold in solid form. They form a protective layer on the metal surface by altering the physical characteristics of the surface to resist oxidation of the metallic surface, thereby offering rust protection. Moreover, they are cost-effective, form transparent coating after drying, and can be easily applied by using spray, immersion, or brush before subsequent operations.

End-use Insights

The oil and gas segment held the largest market share of 33.1% in 2019. This is attributed to the rising number of internal corrosion problems in pipelines, refineries, and petrochemical plants. The corrosion inhibitors market is gaining popularity in the power generation sector in the developing economies of the Asia Pacific region due to rapid urbanization and industrialization. In power plants, erosion has been one of the significant factors that lead to critical downtime. The steam circuits in nuclear, thermal, and hydropower plants are susceptible to deterioration as the metal components are always in contact with water. To ensure effective power generation, most power plants monitor parameters such as pH value, conductivity, and the presence of corroding anions and cations, which indicate the corrosion rate. Also, they ensure the adequate presence of corrosion inhibitors such as phosphonates, phosphate, and zinc (for steel) and triazoles (for copper).

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2019 and is projected to be one of the fastest-growing markets in the near future. The growth in the market can be attributed to rapid industrialization in the region, which has triggered the demand from the power generation and several other end-use industries as well. The growing chemical and metalworking sectors in developing economies of the region, including India and China, are also projected to contribute significantly to the market in the near future.

Browse through Grand View Research's Organic Chemicals Industry Research Reports.

• The global caprolactam market was valued at USD 15.3 billion in 2023 and is projected to grow at a CAGR of 5.1% from 2024 to 2030.

• The global potting compounds market size was estimated at USD 33,275.20 million in 2023 and is projected to grow at a CAGR of 3.2% in terms of revenue from 2024 to 2030.

Key Companies & Market Share Insights

The competitive landscape of the market is highly fragmented in nature, with the presence of a large number of key players coupled with high demand from end-users. Key players are concentrating on customized production by using advanced technology and adopting new strategic initiatives such as long-term agreements and mergers to strengthen their base and generate more revenue in the near future. Manufacturers involved in the market are integrated across the value chain. For instance, Arkema is integrated backward by using renewable raw materials for production. On the contrary, The Lubrizol Corporation is forward integrated. The company manufactures fuel additives by using its corrosion inhibitors in the formulation of the product (PowerZol 9548A). Cortec Corporation manufactures several strength-release components and coating products by using their Migratory Corrosion Inhibitors (MCIs). In addition, SUEZ supplies its corrosion inhibitors for several water treatment projects. Some of the prominent players operating in the corrosion inhibitors market include:

• Nouryon

• Cortec Corporation

• Ashland

• Ecolab

• Henkel Ibérica, S.A.

• The Lubrizol Company

• BASF SE

• Dow

• DuPont de Nemours, Inc.

• Baker Hughes, a GE company LLC

Corrosion Inhibitors Market Segmentation

Grand View Research has segmented the global corrosion inhibitors market on the basis of product, type, end use, and region:

• Product Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Organic

• Inorganic

• Type Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Water Based

• Oil Based

• End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• Power Generation

• Oil & Gas

• Paper & Pulp

• Metal Processing

• Chemical Processing

• Water Treatment

• Others

• Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

• North America

o The U.S

o Canada

o Mexico

• Europe

o Germany

o The U.K.

o France

o Italy

• Asia Pacific

o China

o India

o Japan

o South Korea

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o South Africa

o Saudi Arabia

o UAE

o Iran

o Iraq

o Kuwait

o Oman

o Bahrain

Order a free sample PDF of the Corrosion Inhibitors Market Intelligence Study, published by Grand View Research.

#Corrosion Inhibitors Market#Corrosion Inhibitors Market size#Corrosion Inhibitors Market share#Corrosion Inhibitors Market analysis#Corrosion Inhibitors Industry

0 notes

Text

Water-Based Barrier Coatings Market Outlook and Forecast 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Water-Based Barrier Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Water-Based Barrier Coatings Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Water-Based Barrier Coatings?

The global water-based barrier coatings market size reached US$ 3.9 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 6.5 billion in 2032, exhibiting a growth rate (CAGR) of 5.9% during 2024-2032.

What are Water-Based Barrier Coatings Market?

Water-based barrier coatings refer to aqueous formulations applied to surfaces to establish a protective layer that repels liquids, gases, or other substances. These coatings are environmentally friendly, predominantly utilizing water as a solvent to reduce the presence of volatile organic compounds (VOCs). Widely employed in industries like packaging, water-based barrier coatings act as a safeguard against moisture, oil, and contaminants, thereby augmenting the durability and preservation of products. Applied to materials such as paper and cardboard, these coatings provide a sustainable and less hazardous alternative to solvent-based counterparts. Their adaptability and eco-friendly characteristics contribute to their increasing popularity across various applications, driving the demand in the market.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1902

What are the growth prospects and trends in the Water-Based Barrier Coatings Market industry?

The water-based barrier coatings market growth is driven by various factors. The market for water-based barrier coatings is experiencing notable growth as industries increasingly opt for environmentally sustainable solutions in surface protection. These coatings, formulated with water as a primary solvent, provide a green alternative to traditional solvent-based options. Predominantly utilized in packaging, water-based barrier coatings establish protective layers that effectively repel liquids and gases, thereby improving the durability and overall quality of products. The market's expansion is driven by the rising demand for eco-conscious solutions, with these coatings finding applications across various industries where resistance to moisture and contaminants is essential. The adaptable and environmentally friendly characteristics of water-based barrier coatings position them as significant players in the evolving landscape of surface protection technologies. Hence, all the factors contribute to water-based barrier coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Market Segmentation By Type:

Acrylic

Polyurethane

Epoxy

Others

Market Segmentation By Substrate:

Metal

Paper & Paperboard

Plastic

Glass

Others

Market Segmentation By End-Use Industry:

Packaging

Building & Construction

Automotive

Electronics

Textile

Others

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Akzo Nobel N.V.

PPG Industries Inc.

Axalta Coating Systems Ltd.

BASF SE

The Sherwin-Williams Company

RPM International Inc.

Arkema Group

Dow Inc.

Valspar Corporation

Asian Paints Limited

Nippon Paint Holdings Co., Ltd.

Hempel A/S

Jotun Group

Sika AG

Kansai Paint Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Water-Based Barrier Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Water-Based Barrier Coatings Market Size#Water-Based Barrier Coatings Market Share#Water-Based Barrier Coatings Market Demand#Water-Based Barrier Coatings Market Analysis

0 notes

Text

Hydrophobic Coatings Market is Growing Due to Rising Applications in Electronics

The hydrophobic coatings market has witnessed significant growth in the recent years owing to increasings demand from the electronics industry. Hydrophobic coatings have the ability to repel water and are ideal for use in devices sensitive to moisture damage like smartphones, tablets, laptops etc. These coatings form a barrier against water and other liquids when applied to surfaces. They find widespread applications in protecting electronic device screens and components from water damage which could occur from accidental liquid splashes or spills. The global hydrophobic coatings market is estimated to be valued at US$ 1.39 billion in 2024 and is expected to exhibit a CAGR of 11% over the forecast period 2024 to 2031.

Key players operating in the hydrophobic coatings market are Sharp Corporation, Apple Inc., Sony Corporation, ASUSTEK Computer Inc., LG Electronics, AU Optronics, Samsung Group, and Fujitsu Limited. Key Takeaways Key players: Sharp Corporation, Apple Inc., Sony Corporation, ASUSTEK Computer Inc., LG Electronics, AU Optronics, Samsung Group, and Fujitsu Limited are some of the prominent players in the hydrophobic coatings market. These companies are focusing on developing innovative hydrophobic coating solutions to strengthen their market position. Growing demand: There has been a surge in the demand for various electronic devices like smartphones, laptops, tablets, etc. in the recent years. hydrophobic coatings find wide application in protecting sensitive components and surfaces in these devices from liquid damage, driving the demand. Global expansion: Leading electronics manufacturers are expanding their business globally to cater to the Hydrophobic Coatings Market Demand. The players in hydrophobic coatings market are accordingly increasing their production capacities and geographical reach to leverage the widespread market opportunities. Market Key Trends One of the key trends gaining traction in the hydrophobic coatings market is the development of non-fluorinated or fluorine-free coatings. Strict environmental regulations regarding use of fluorinated chemicals is propelling research towards eco-friendly coating alternatives. Players are investing in R&D to develop bio-based or silicon-based hydrophobic coatings without fluorine content.

Porter’s Analysis Threat of new entrants: The hydrophobic coatings market requires high R&D investments creating high entry barriers for new players.

Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitutes. However, differentiated properties of hydrophobic coatings reduce impact.

Bargaining power of suppliers: Presence of many suppliers reduces their bargaining power. Suppliers depend on OEMs for business.

Threat of new substitutes: Limited substitutes are available. Hydrophobic coatings have unique properties that are difficult to replicate.

Competitive rivalry: Market fragmentation leads to high competition between numerous global and regional players. Geographical Regions Asia Pacific accounts for the largest share of the global hydrophobic coatings market in terms of value. This is due to the vast electronics industry and growing aerospace sector in countries such as China, South Korea, Japan and India. North America is another major region for hydrophobic coatings led by the aerospace industry and technological advancements. Fastest Growing Region Europe is projected to be the fastest growing regional market for hydrophobic coatings during the forecast period. This is attributed to increasing research into nano- and bio-coatings along with the expanding automotive production base in Germany, UK, France and Italy. The demand is further supported by stringent environmental regulations regarding emission control.

Get more insights on Hydrophobic Coatings Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Coherent Market Insights#Hydrophobic Coatings Market#Hydrophobic Coatings#Surface Protection#Nano Coatings#Superhydrophobic Coatings#Waterproofing Solutions#Hydrophobic Technology#Moisture Protection

0 notes

Text

Vietnam Specialty Chemicals Market Demand, Trends, Forecast 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated Vietnam Specialty Chemicals Market size at USD 17.3 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects Vietnam Specialty Chemicals Market size to expand at a CAGR of 6.30% reaching a value of USD 26.3 million by 2030. Increasing investments in R&D, stricter environmental laws, growing manufacturing and agriculture sectors, and rapid urbanization and industrialization are major growth factors for Vietnam Specialty Chemicals Market. By volume, BlueWeave estimated Vietnam Specialty Chemicals Market size at 3.9 million tons in 2023. During the forecast period between 2024 and 2030, BlueWeave expects Vietnam Specialty Chemicals Market size to expand at a CAGR of 3.80% reaching the volume of 5.1 million tons by 2030.

Opportunity - Expanding Middle Class Population in Vietnam

The expanding middle class population is fueling the demand for various consumer goods, such as cosmetic products, home care products, and cleaners. These products contain specialty chemicals. The chemicals sector is growing as a result of this demographic trend since manufacturers are meeting the varied demands and preferences of their customers.

Growth Drivers

Rising Adoption of Sustainable Practices

The increasing shift towards sustainability is emerging as one of the major driving factors for the growth of Vietnam specialty chemicals market. Growing environmental consciousness and regulatory requirements are driving the demand for sustainable and eco-friendly specialty chemicals. Vietnamese companies are investing in green chemistry and sustainable manufacturing practices to meet changing customer demands and regulatory requirements, which is propelling the country's specialty chemicals market growth.

Challenges

Fluctuations in Availability of Raw Materials and Supply Chain

Vietnam Specialty Chemicals Market faces significant challenges due to fluctuations in raw material pricing and supply chain inefficiencies, which act as a barrier to its market growth. The fluctuations in raw material pricing result in inflation in the price of products and supply chain inefficiencies lead to delays in the production of the goods as it hinders the procurement of materials.

Vietnam Specialty Chemicals Market

Segmental Coverage

Vietnam Specialty Chemicals Market – By Product Type

Based on product type, Vietnam Specialty Chemicals Market is segmented into agrochemicals, rubber processing chemicals, construction chemicals, food & feed additives, cosmetic chemicals, oilfield chemicals, specialty pulp & paper chemicals, specialty textile chemicals, water treatment chemicals, pharmaceutical & nutraceutical additives, CASE (coatings, adhesives, and sealants & elastomers), and others (institutional & industrial cleaners, electronic chemicals, and mining chemicals). The institutional & industrial cleaners segment holds the largest share of Vietnam Specialty Chemicals Market. The stringent regulations around maintaining cleanliness and hygiene of products and surroundings act as a major driving factor for institutional & industrial cleaners.

Vietnam Specialty Chemicals Market – By End User Industry

On the basis of end user industry, Vietnam Specialty Chemicals Market is divided into automotive, construction, consumer goods, food & beverages, healthcare, industrial manufacturing, oil & gas, and other (packaging, personal care, water treatment) segments. The construction sector dominates Vietnam Specialty Chemicals Market. Specialty chemicals play a vital role in the construction sector by protecting concrete from air deterioration and improving its strength and quality. The rapid industrialization and urbanization for infrastructural development and economic growth act as a major catalyst for the rising demand for specialty chemicals in the sector.

Sample Request @ https://www.blueweaveconsulting.com/report/vietnam-specialty-chemicals-market/report-sample

Agrochemicals Largest Specialty Chemical Product Type

Vietnam Specialty Chemicals Market consists of various product types including agrochemicals, rubber processing chemicals, construction chemicals, food & feed additives, cosmetic chemicals, oilfield chemicals, specialty pulp & paper chemicals, specialty textile chemicals, water treatment chemicals, pharmaceutical & nutraceutical additives, CASE (coatings, adhesives, sealants, and elastomers), and other products (institutional & industrial cleaners, electronic chemicals, and mining chemicals). The agrochemical segment holds a substantial market share, primarily due a rising demand for biocides and synthetic fertilizers.

Competitive Landscape

Vietnam Specialty Chemicals Market is intensely competitive, as a number of companies are competing to gain a significant market share. Key players in the market include K.D. Feddersen Vietnam Co., Ltd., Oxy Chemicals Co., Ltd, AVCO, Trung Nguyen, MICHEM VIETNAM, Duc Giang Chemical Group Joint Stock Company (DGC), Wacker Chemie AG, VIET A CHEMICAL COMPANY LIMITED, and Adchem Joint Stock Company.

To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Green Coatings Market: Sustainable Solutions for a Greener World

The global green coatings market is estimated to be valued at US$ 70.06 billion in 2024 and is expected to exhibit a CAGR of 4.1% over the forecast period 2023 to 2030. Green or eco-friendly coatings are composed of environment-friendly and sustainable raw materials that produce lower or zero volatile organic compound emissions. These coatings are derived from plant or other natural sources and offer similar or better performance than conventional coatings. Many industries are using green coatings for their benefits such as low odor, minimal hazards, and eco-friendly process. They protect infrastructure from corrosion and deterioration while reducing environmental footprint. Key Takeaways

Key players operating in the green coatings market are The Sherwin Williams Company, PPG industries, Akzonobel N.V., Axalta Coating System, BASF, Valspar Corporation, Kansai PaintCompany Limited, Tikkurila OYJ, and Masco Corporation among others. These players are focusing on developing new sustainable technologies to cater to growing demand for eco-friendly coatings. The rising environmental concerns paired with stringent regulations regarding VOC emissions are fueling the demand for green coatings globally. Various industries are opting for sustainable coating solutions to achieve their sustainability targets. Moreover, increasing consumer awareness about eco-friendly products is compelling manufacturers to shift towards green alternatives. The green coatings market is also expanding rapidly across regions due to growing environmental standards and construction activities worldwide. Manufacturers are investing heavily in R&D to commercialize new biomass-based and bio-sourced coating ranges. Various field trials are conducted to test performance of green coatings in different conditions. Market Key Trends

Waterborne coatings emerged as one of the major green coating technologies in recent years owing to ease of manufacturing and high performance. These coatings are composed of water instead of VOCs and offer similar aesthetic and protective advantages. Their demand is anticipated to rise substantially during the forecast period owing to stringent environmental norms. Besides, bio-based coating varieties derived from plant or algal sources are gaining prominence due to renewable and sustainable properties. Further innovations are expected to boost the adoption of eco-friendly coatings across end-use industries.

Porter’s Analysis

Threat of new entrants: High capital requirement and stringent environmental regulations pose barrier for new players to enter the market Bargaining power of buyers: Large buyers can negotiate better pricing while demanding high quality and technical expertise Bargaining power of suppliers: Suppliers have higher bargaining power due to lesser number of raw material producers and need for technological advancement Threat of new substitutes: Continuous R&D can lead to new substitute products with improved properties posing threat Competitive rivalry: Intense competition exists between existing players prompting higher marketing spends and new product innovation Geographically, North America holds the major share of the green coatings market in terms of value due to stringent environmental regulations and higher consumer awareness. The US alone contributes more than 50% of the regional market. Asia Pacific is the fastest growing market for green coatings driven by rapid infrastructure growth and rising environmental consciousness in major countries like China and India. Supportive government initiatives towards green buildings further supplement the regional market expansion.

0 notes

Text

Wood Coatings Market: Trends & Opportunities 2024-2032

According to Triton Market Research, the Global Wood Coatings Market report is sectioned by Resin Type (Polyurethane, Nitrocellulose, Acrylic, Other Resin Types), Technology (Water-Borne, Powder Coatings, UV-cured, Solvent-Borne), Application (Furniture and Fixture, Cabinet, Doors and Window, Flooring, Deck), and Regional Outlook (Middle East and Africa, Europe, Asia-Pacific, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Porter’s Five Forces Analysis, Market Maturity Analysis, Supply Chain Analysis, Regulatory Framework, Key Buying Impact Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Based on Triton’s research report, the global market for wood coatings is set to advance in value at a CAGR of 4.02% during the forecast period 2024-2032.

Wood coating serves a dual purpose: safeguarding and enhancing wood or wood-based structures. By shielding wooden surfaces, it bolsters their durability and utility. Simultaneously, it elevates their aesthetic appeal, contributing to effective product promotion.

Factors such as personalized solutions for flooring and furniture, the emergence of smart coating technology, and improved coating performance via nanotechnology, creates lucrative opportunities for the wood coatings market globally. Smart coatings offer an array of functionalities, such as self-healing, anti-fouling, and antimicrobial properties, enhancing the durability and performance of wood surfaces. This extends the lifespan of wood products and reduces maintenance costs. Moreover, smart coatings contribute to sustainability efforts by minimizing the need for frequent reapplications and replacements, thus reducing waste. With increasing environmental concerns and a growing emphasis on eco-friendly solutions, the adoption of smart coatings is set to escalate, driving market growth and innovation.

However, fluctuating raw material costs and competition from composite materials limit the overall development of the wood coatings market worldwide.

The Asia-Pacific region is set for the fastest growth in the coming years. One key driver is the region’s growing construction and furniture industries, particularly in countries like China, India, and Vietnam, where urbanization and rising disposable incomes have fueled demand for high-quality wood products. Additionally, there is a growing awareness and emphasis on environmental sustainability, leading to an increasing preference for eco-friendly coatings with low volatile organic compound (VOC) content. Moreover, technological advancements in coatings formulations, such as the development of water-based and UV-curable coatings, are gaining traction due to their superior performance and reduced environmental impact.

The renowned companies in the wood coatings market are Nippon Paint Holdings Co Ltd, Diamond Paints, PPG Industries Inc, Asian Paints, RPM International Inc, The Sherwin-Williams Company, BASF SE, Akzo Nobel NV, Axalta Coating Systems LLC, and Kansai Helios.

With evolving consumer preferences and stringent environmental regulations, barriers to entry remain significant, deterring potential newcomers. Established players continually innovate to maintain market share, investing in research and development to offer eco-friendly and high-performance coatings. Intense rivalry among existing competitors fuels pricing pressures and product differentiation strategies, compelling companies to enhance quality and expand distribution networks. Amidst these challenges, strategic alliances and mergers are common, reshaping the competitive landscape and fostering consolidation.

0 notes

Text

Barrier Coatings for Paper Packaging, Global Key Players Rank and Market Share, Top Ten Companies Hold 33.2% (2022)

Barrier Coatings for Paper Packaging Market Summary

Barrier coatings for paper and cardboard substrates are ideal for products that protect against water leakage and vapors, solvents, oils, fatty acids and other substances. It improves the performance and functionality of paper packaging, better protects the product inside, and is used to meet specific performance requirements in applications such as food, dry goods, medical or consumer packaging.

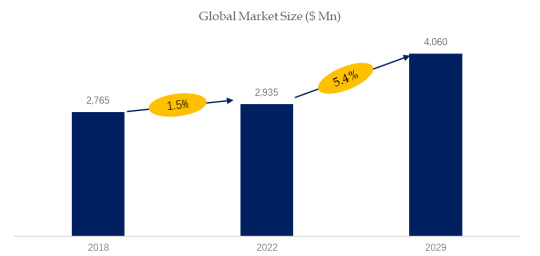

According to the new market research report “Global Barrier Coatings for Paper Packaging Market Report 2023-2029”, published by QYResearch, the global Barrier Coatings for Paper Packaging market size is projected to reach USD 4.06 billion by 2029, at a CAGR of 5.4% during the forecast period.

Figure. Global Barrier Coatings for Paper Packaging Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Barrier Coatings for Paper Packaging Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

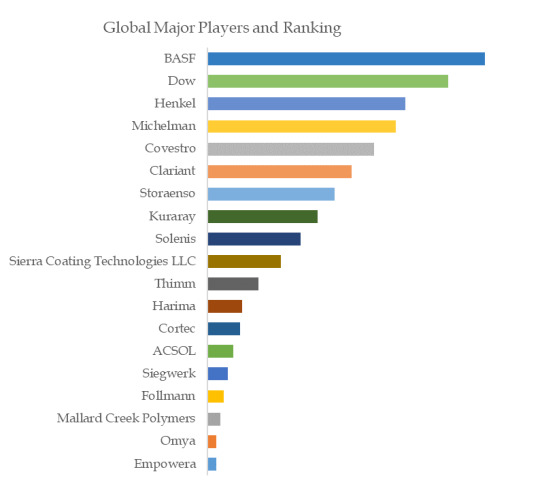

Figure. Global Barrier Coatings for Paper Packaging Top Ten Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Barrier Coatings for Paper Packaging Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Barrier Coatings for Paper Packaging include BASF, Dow, Henkel, Michelman, Covestro, Clariant, Storaenso, Kuraray, Solenis, Sierra Coating Technologies LLC, etc.

In 2022, the global top 10 players had a share approximately 33.2% in terms of revenue.

In recent years, consumers have become increasingly concerned about the environmental impact of products, resulting in increasing demand for sustainable paper and paperboard packaging. This trend has had an impact on paper and paperboard packaging manufacturers, who have been forced to stop using barrier coatings containing polyethylene, paraffin-based waxes, silicones and fluorinated chemicals in favor of more environmentally friendly barrier coatings layer, this phenomenon is even more prominent in the food and beverage packaging industry.

The extensive range of barrier coatings for paper and board provides protection against water, vapors, hot and cold liquids and grease. The current trend in the market for barrier coatings for paper is towards the use of recyclable coatings, i.e., paper and paperboard coated with these barrier coatings are repulpable, recyclable, compostable and biodegradable, facilitating paper and paperboard packaging production Build a sustainable brand image that is recognized by brand owners, retailers and consumers.

Industry development opportunities: Growing demand from the fast food and beverage container industry is driving the growth of the barrier coating market for paper.

About The Authors

Analyst: Ran xinrong

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Plastic Films Market Growth, Size, Trends, Revenue & Report 2024-2032

IMARC Group's report titled "Plastic Films Market by Product Type (Polyethylene Terephthalate (PET), Polyvinyl Chloride (PVC), Polypropylene (PP), Polyethylene (PE), and Others), Application (Packaging, Decoration, Industrial), and Region 2024-2032", offers a comprehensive analysis of the industry, which comprises insights on the global plastic films market share. The global plastic films market size reached US$ 159.7 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 241.1 Billion by 2032, exhibiting a growth rate (CAGR) of 4.54% during 2024-2032.

For an in-depth analysis, you can refer sample copy of the report: https://www.imarcgroup.com/plastic-films-market/requestsample

Factors Affecting the Growth of the Plastic Films Industry:

Increasing Demand Across Diverse Industries:

The rising demand for plastic films across a wide spectrum of industries is impelling the growth of the market. In packaging, plastic films are becoming indispensable due to their lightweight nature, cost-effectiveness, and versatility. They offer a reliable solution for safeguarding goods during transportation and storage, reducing the risk of damage, and ensuring product integrity. Furthermore, the use of plastic films in agriculture serves multiple purposes, including greenhouse coverings, mulching, and crop protection, leading to enhanced yields, improved crop quality, and reduced water consumption. In the construction sector, plastic films find extensive applications, such as moisture barriers, insulation materials, and roofing membranes. They contribute to enhancing energy efficiency, preventing moisture ingress, and ensuring the longevity of structures.

Advancements in Material Technology:

Continuous advancements in material science and manufacturing systems are supporting the market growth. These innovations are resulting in the development of next-generation plastic films with superior properties, such as enhanced barrier performance, thermal stability, and recyclability. Manufacturers are leveraging cutting-edge technologies to engineer films that meet the evolving needs of end-users while addressing sustainability concerns. One notable trend is the emergence of bio-based and biodegradable plastic films, which offer a sustainable alternative to traditional petroleum-based counterparts. These eco-friendly films are derived from renewable sources, such as plant-based polymers or agricultural residues, reducing the dependence on fossil fuels and mitigating environmental impact.

Expanding End-Use Applications:

The versatility of plastic films is driving their adoption across a wide array of end-use applications. In the food and beverage (F&B) industry, plastic films play a crucial role in preserving freshness, extending shelf life, and enhancing visual appeal. The demand for flexible packaging formats, such as pouches, wraps, and bags, is rising due to user preferences for convenience and portability. Additionally, advancements in printing and labeling technologies enable manufacturers to create eye-catching packaging designs that stand out on retail shelves, driving engagement and brand loyalty. Furthermore, plastic films find extensive use in the automotive sector for interior trim, upholstery, and protective coatings. They offer lightweight, durable, and cost-effective solutions for enhancing vehicle aesthetics and functionality.

Leading Companies Operating in the Global Plastic Films Industry:

Amcor plc

Berry Global Inc.

Cosmo Films Limited

Dow Inc.

DuPont de Nemours Inc.

Exxon Mobil Corporation

Inteplast Group Corporation

Jindal Poly Films

Mitsubishi Chemical Holdings Corporation

Polyplex Corporation Limited

RKW Group

Saudi Basic Industries Corporation (Saudi Arabian Oil Co.)

Toray Industries Inc.

UFlex Limited

Plastic Films Market Report Segmentation:

By Product Type:

Polyethylene Terephthalate (PET)

Polyvinyl Chloride (PVC)

Polypropylene (PP)

Polyethylene (PE)

Others

Polyethylene terephthalate (PET) represents the largest segment due to its durability.

By Application:

Packaging

Food Containers

Blister Packs

Electric & Electronic Purposes

Others

Decoration

Solid Color

Others

Industrial

Construction Materials

Safety Materials

Advertisement Lighting

Others

Packaging exhibits a clear dominance in the market due to the rising utilization of plastic films for packaging a wide variety of products, including food and beverages, electronics, and cosmetics.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Europe's dominance in the plastic films market is attributed to the rising production of bio-based plastic films.

Global Plastic Films Market Trends:

The proliferation of e-commerce platforms is revolutionizing the retail landscape, with a growing number of people opting for online shopping. Plastic films play a critical role in the packaging of products for e-commerce, offering protection during shipping and handling while also providing tamper-evident features. The rise in online retail activities is catalyzing the demand for plastic films, particularly in the form of air pillows, bubble wraps, and polybags used for parcel packaging. Stringent regulations governing packaging materials and growing environmental concerns are prompting manufacturers to focus on sustainability and eco-friendly solutions. Governments worldwide are also imposing restrictions on single-use plastics and promoting the use of recyclable and biodegradable alternatives.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the companys expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes